Preparation method of polymer nanocomposite with shape memory

A nanocomposite material and composite material technology are applied in the field of preparation of polymer nanocomposite materials, which can solve the problems of difficulty in preparing shape memory composite materials, poor compatibility, etc., and achieve fast excitation response speed, good shape recovery rate, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a polymer nanocomposite with shape memory, specifically comprising the steps of:

[0028] (1) First mix SEBS and extender oil evenly according to the mass ratio of 1:1, and leave it for 24 hours to obtain oil-extended SEBS.

[0029] (2) Weigh 37.2g oil-extended SEBS, 18.6g PCL, 3g SEBS-g-MA and 0.6g OMMT respectively, and mix well.

[0030] (3) Put the blended material in step (2) into the banbury chamber of the torque rheometer for melt blending. The blending conditions are set as: 195° C., 120 r / min rotating speed, and 15 min for time.

[0031] (4) The sample prepared in step (3) was hot-pressed in a hot press. The hot-pressing process conditions were 150 ° C, 5 MPa pre-pressed for 1 min, and then pressurized to 12 MPa for 5 min, and then cooled and held for 2 min. Shape memory nanocomposite samples with a thickness of 2 mm.

[0032] Die-cutting the obtained polymer shape memory nanocomposite into a long strip sample (denoted as l 0 ), and th...

Embodiment 2

[0037] Using the preparation method described in Example 1, weigh 37.8g oil-extended SEBS, 18.8g PCL, 3g SEBS-g-MA and 1.2g OMMT in step (2), and the prepared polymer nano Composite material as Example 2.

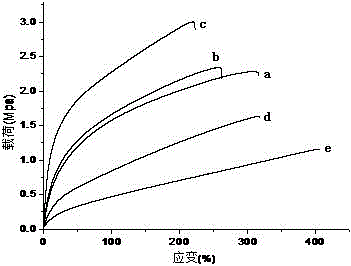

[0038] The primary shape recovery rate of Example 2 is 96.7%, and the secondary shape recovery rate is 95%, as shown in Table 1. The crystallization peak temperature of Example 2 is 29.54° C., and the crystallization peak temperature is 13.53 J / g. The tensile strength of embodiment 2 is 2.34MPa, and elongation at break is 261%, and its tensile stress curve is as figure 1 shown.

Embodiment 3

[0040] The operation steps are as follows:

[0041] Using the preparation method described in Example 1, weigh 36g of oil-extended SEBS, 18.0g of PCL, 3g of SEBS-g-MA and 3.0g of OMMT in step (2), and the prepared polymer nanometer with shape memory Composite material as Example 3.

[0042] The primary shape recovery rate of Example 3 is 88.9%, and the secondary shape recovery rate is 81.0%, as shown in Table 1. The crystallization peak temperature of Example 3 is 28.43° C., and the crystallization peak temperature is 14.40 J / g. The tensile strength of embodiment 3 is 3.0MPa, and elongation at break is 222%, and its tensile stress curve is as figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com