Patents

Literature

31results about How to "Has shape memory properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

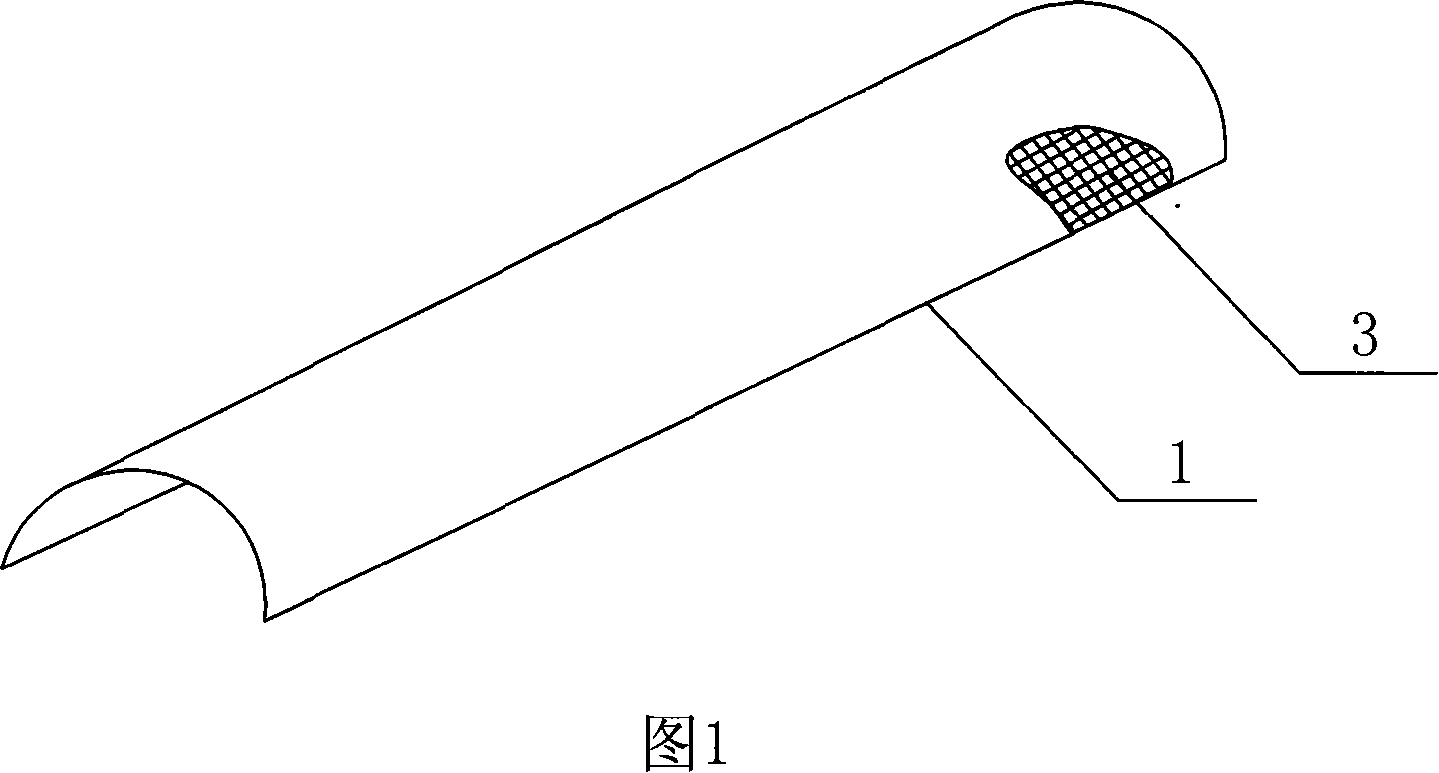

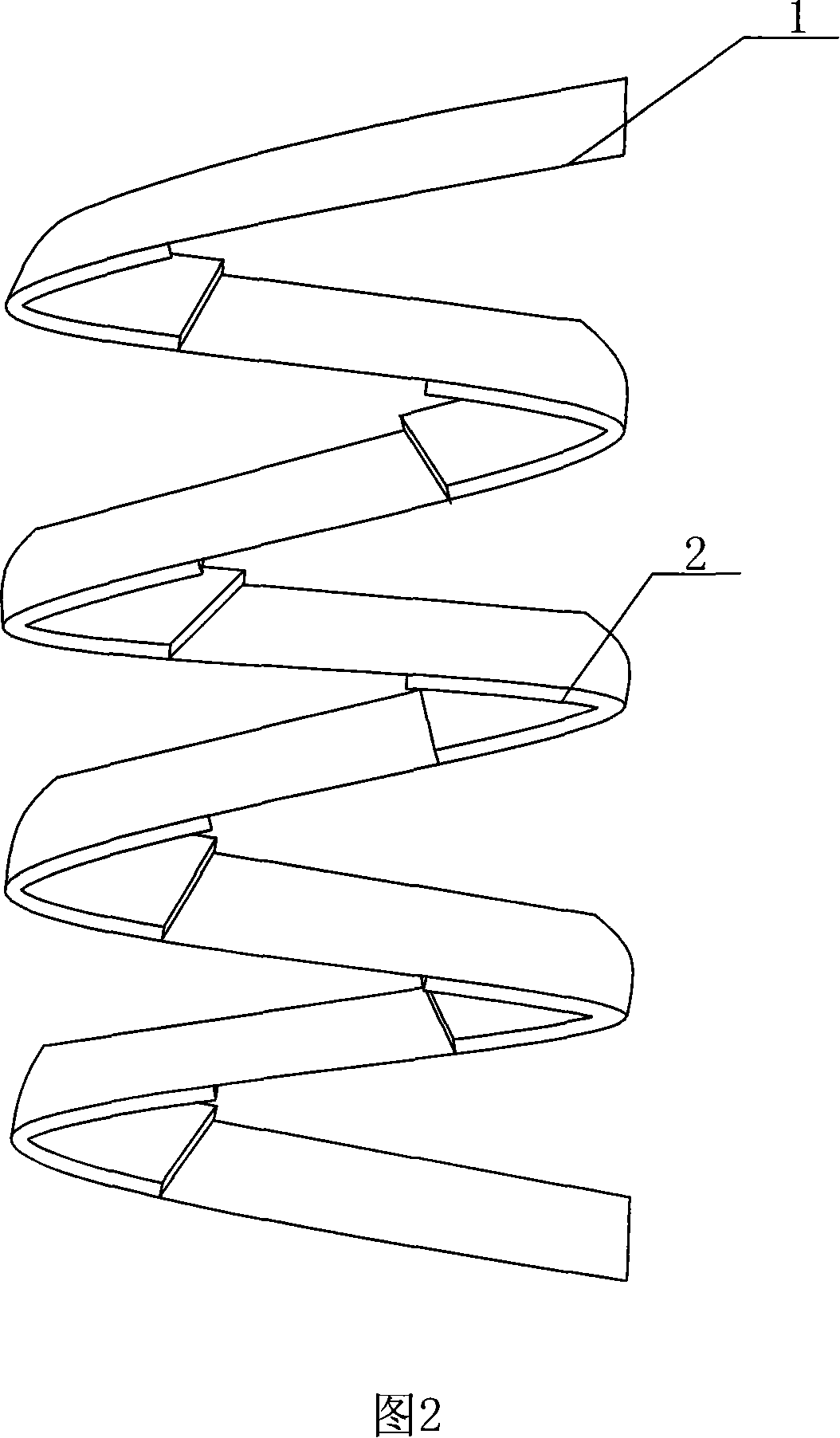

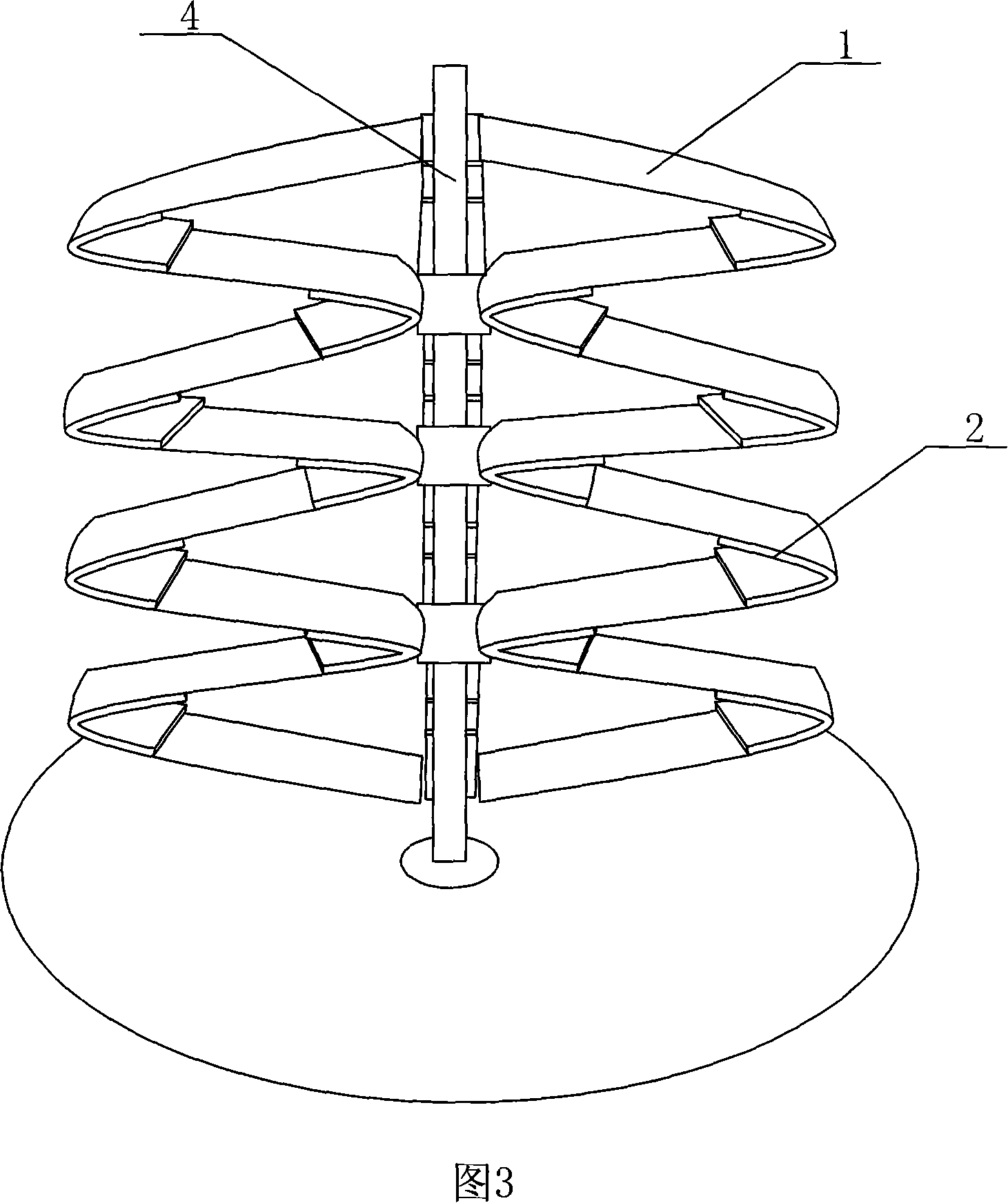

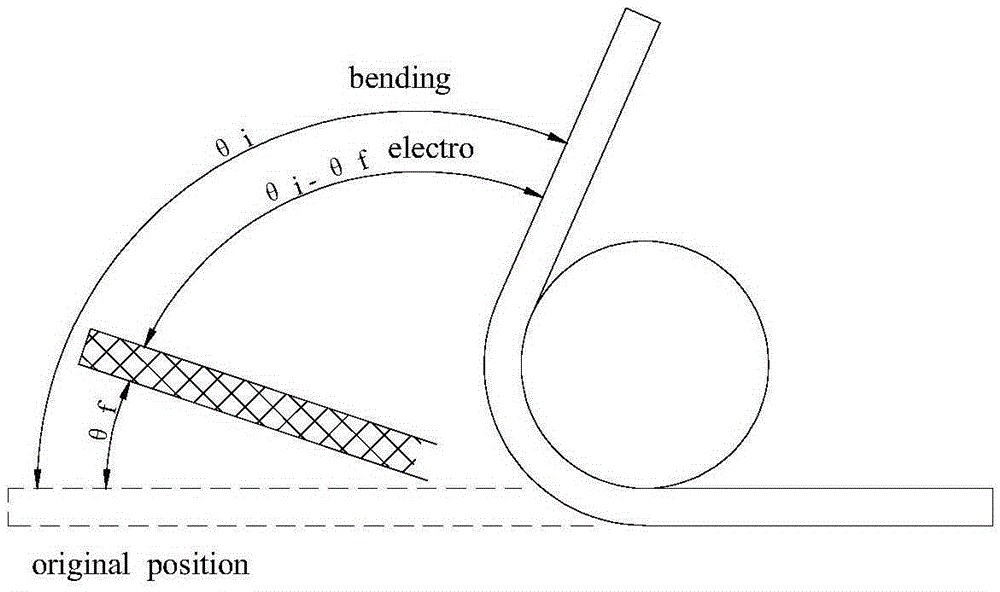

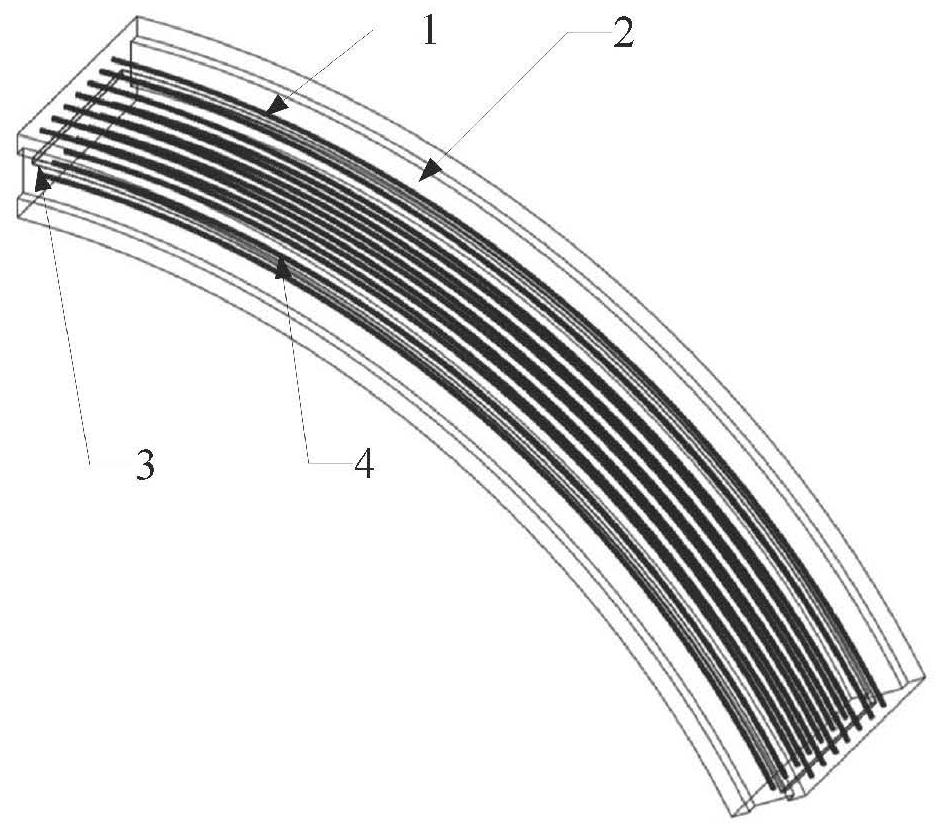

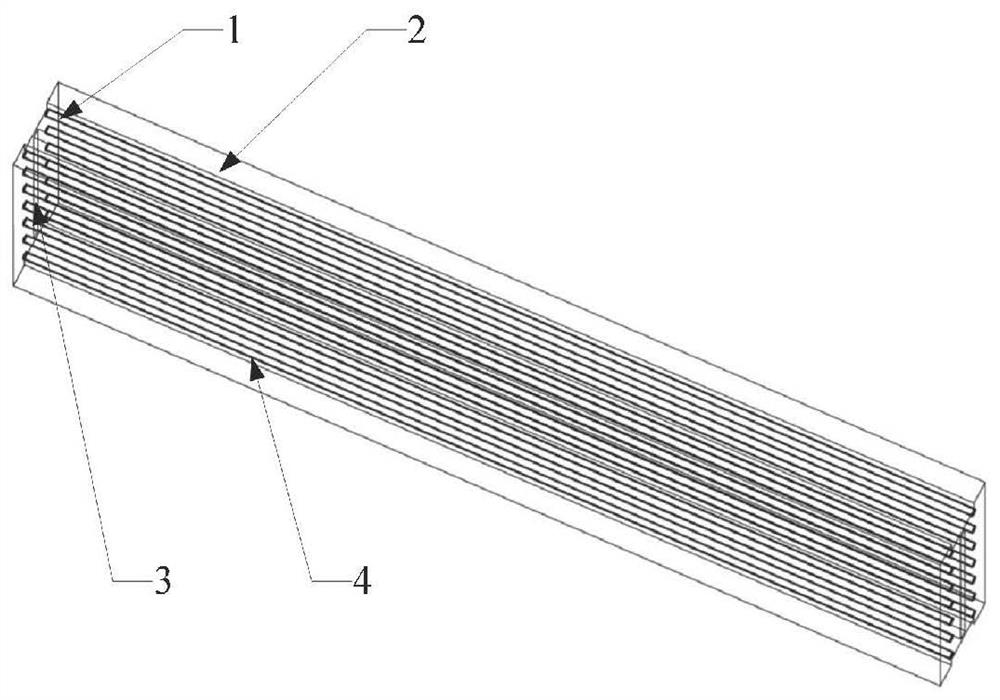

Shape memory polymer composite body with spatially-expanded three-wing beam and its preparation method

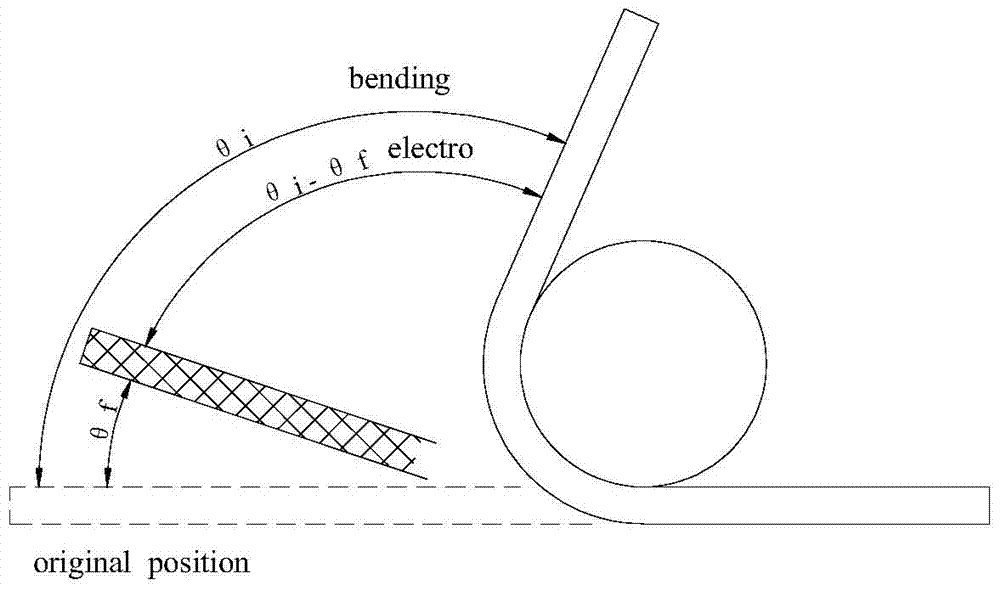

InactiveCN101055344AHigh specific strengthHigh specific modulusLamination ancillary operationsSynthetic resin layered productsElectrical resistance and conductancePolymer science

A space expanded three-wing-beam shaped remember polymer compound and the preparation thereof relates to a space expanded three-wing-beam shaped remember polymer and the preparation thereof, and to solve the problems of large material weight, complicated expanded mechanical performance, unsteady controlling of the expanding-telescoping procedure, and complicated fabrication technology in the existing space expanded beam structure design procedure. The compound material layer of the shaped remember polymer compound is shaped as superposition and the electric resistance silk screen is located therein. The inner of the compound material layer bending part of the shaped remember polymer compound is connected with a yalloy material layer, the preparation of which comprises the steps of: sorting, confect material, curing. The invention has the advantages of: high specific strength, small material weight, strong controlling ability for beam expanding, simple mechanical performance of the space beam expanding. Moreover, the invention has the characteristic of shaped remember and simple technological operation of the preparation.

Owner:HARBIN INST OF TECH

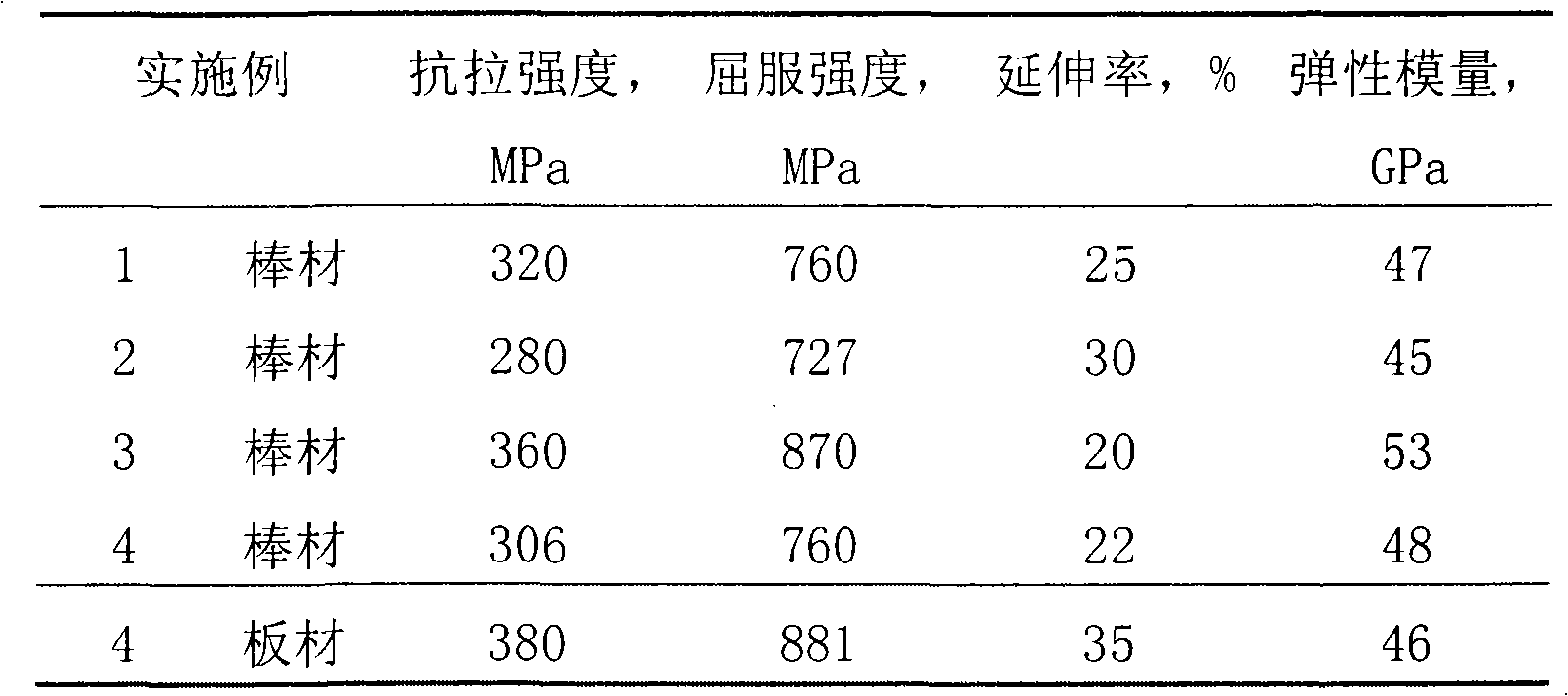

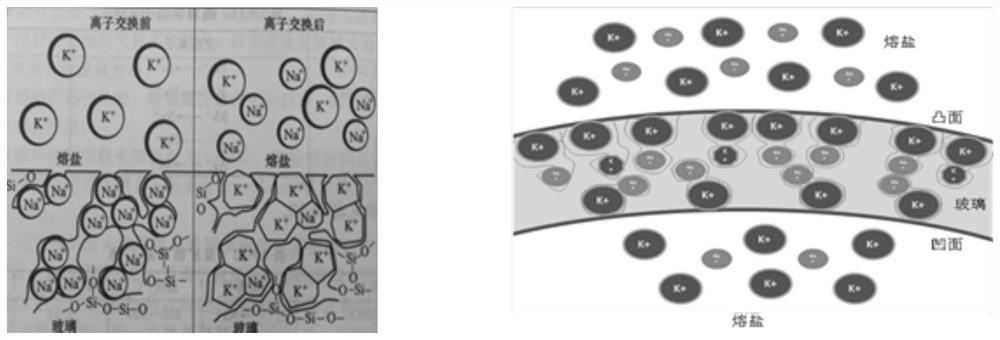

Biomedical titanium-niobium-based shape memory alloy as well as preparation method, processing method and application method thereof

The invention relates to a biomedical titanium-niobium-based shape memory alloy as well as a preparation method, a processing method and an application method thereof. The alloy comprises the following chemical compositions by weight percent: 28-39% of niobium, 0.35-5.5% of tin, 0.3-5.5% of aluminum, 0.5-5.5% of silicon, 0.2-5.5% of zirconium and the allowance of titanium. The alloy has the advantages of low elasticity modulus, good biocompatibility and mechanics compatibility, no toxic nickel element, good mechanical property and corrosion resisting property, excellent cold working property and low cold-working hardening ratio; the alloy can be used for cold working with large deformation such as cold rolling, cold wire drawing and the like, and the working cost is low. The titanium-niobium-based shape memory alloy is of the ideal and novel biological shape memory alloy material that replaces the TiNi shape memory alloy and can be widely used for an ultra-flexible bracket, an orthodontics dental arch wire and an orthopedics implantation instrument and the like in the fields of the medical treatment, the sports goods and the like.

Owner:GRINM MEDICAL INSTR BEIJING CO LTD

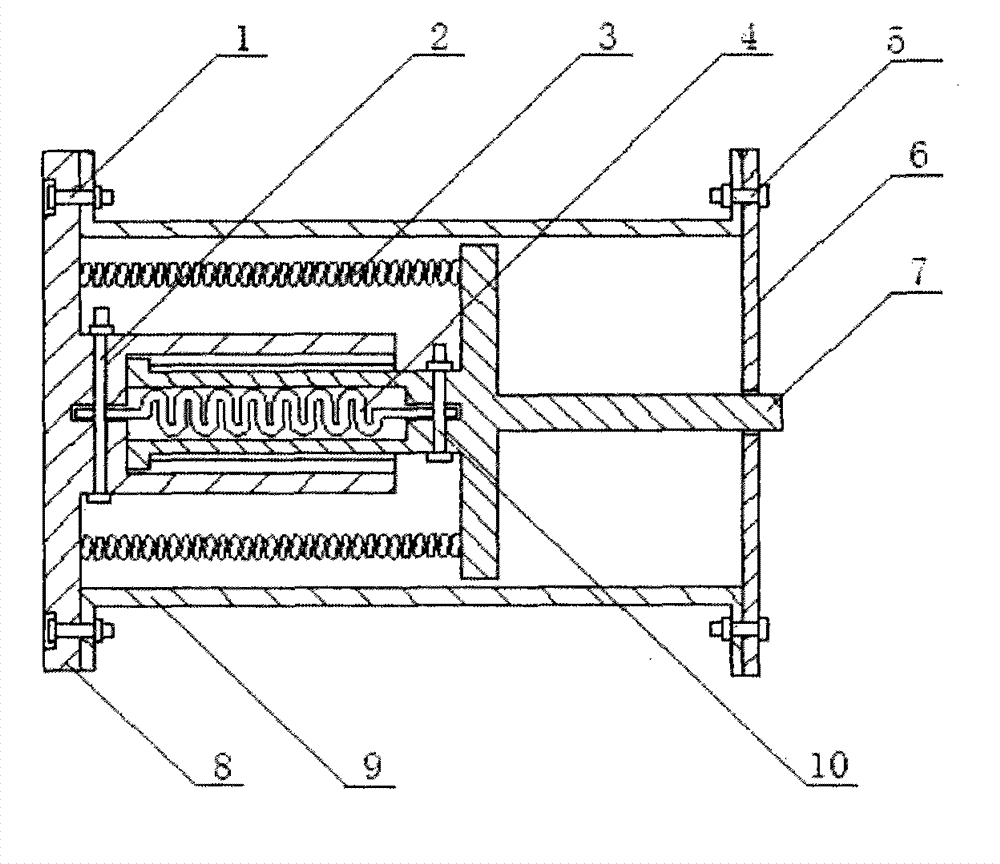

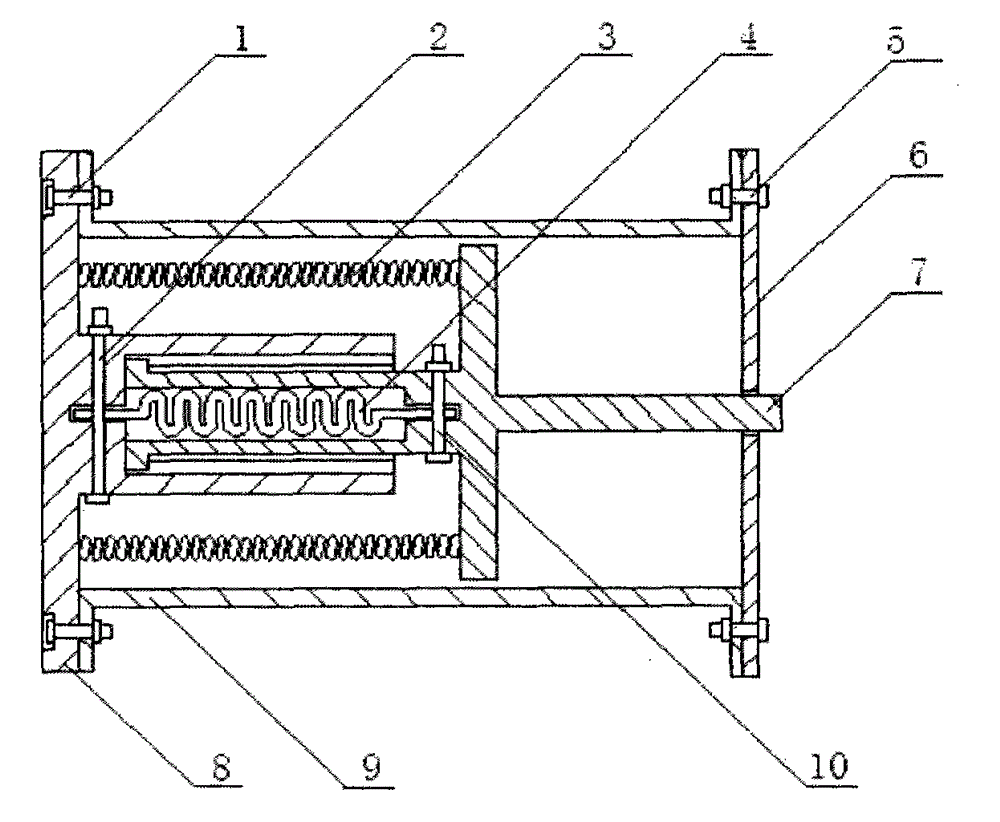

Two-way linear driver based on shape memory material actuator

InactiveCN102889188AHas shape memory propertiesLarge drive output displacementMachines/enginesMechanical power devicesPull forceAlloy

The invention discloses a two-way linear driver based on a shape memory material actuator and belongs to a linear driver technique. A stator and an end cover are respectively and fixedly arranged at the two end parts of a shell through a stator installation bolt and an end-cover installation bolt, a rotor is configured in the shell, the two side parts of the rotor are respectively inserted in the central holes of the stator and the end cover, an S-shaped shape memory polymer composite material actuator is configured in a central inner hole on one side of the rotor, the two ends of the S-shaped shape memory polymer composite material actuator are respectively fixedly connected with the stator and the rotor through a stator bolt and a power bolt, and the two ends of a shape memory alloy tension spring are respectively connected with the stator and the rotor. The driver disclosed by the invention is simple and compact in structure, large in drive output displacement, reliable in use, easy to operate and controllable in displacement, and can be used for achieving an effect of two-way linear drive.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

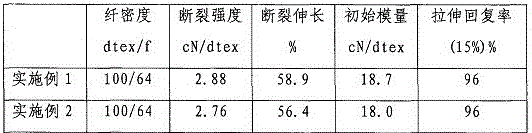

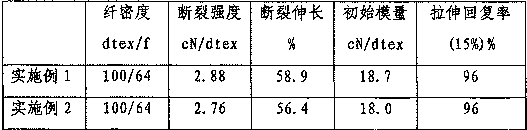

Method for preparing poly(trimethylene terephthalate) fibre having shape memory characteristic

InactiveCN101200821ANo residual stressStable unwindingMelt spinning methodsMonocomponent polyesters artificial filamentPolymer sciencePolyethylene terephthalate

The invention discloses a preparation method of polytrimethylene terephthalate fiber with shape memory characteristics, including: firstly, selected polyester polymer is provided with at least 0.8dL / g of intrinsic viscosity and contains at least 85mol percent of polytrimethylene terephthalate, wherein, at least 85mol percent of the repeating unit is composed of three-methylene; secondly, the polyester polymer is melted and transported through a screw melting extruder, the melting body is metered through a metering pump and is extruded out through a spinneret, and as-spun fibers are drafted successively through a pair of drafting hot rollers after being cooled through lateral blowing; thirdly, the drafted fibers are introduced into a group of grouping roller stereotype boxes with steam; fourthly, tow is introduced into a winding head to be winded into mold. The fiber made through the invention has the advantages of good packaging appearance forming, good structural stability and soft handle. And with lower modulus, the fiber is still provided with good elasticity and tensile recoverability. The textiles made of the fiber which are produced through the process are provided with good shape memory characteristics.

Owner:方圆化纤有限公司

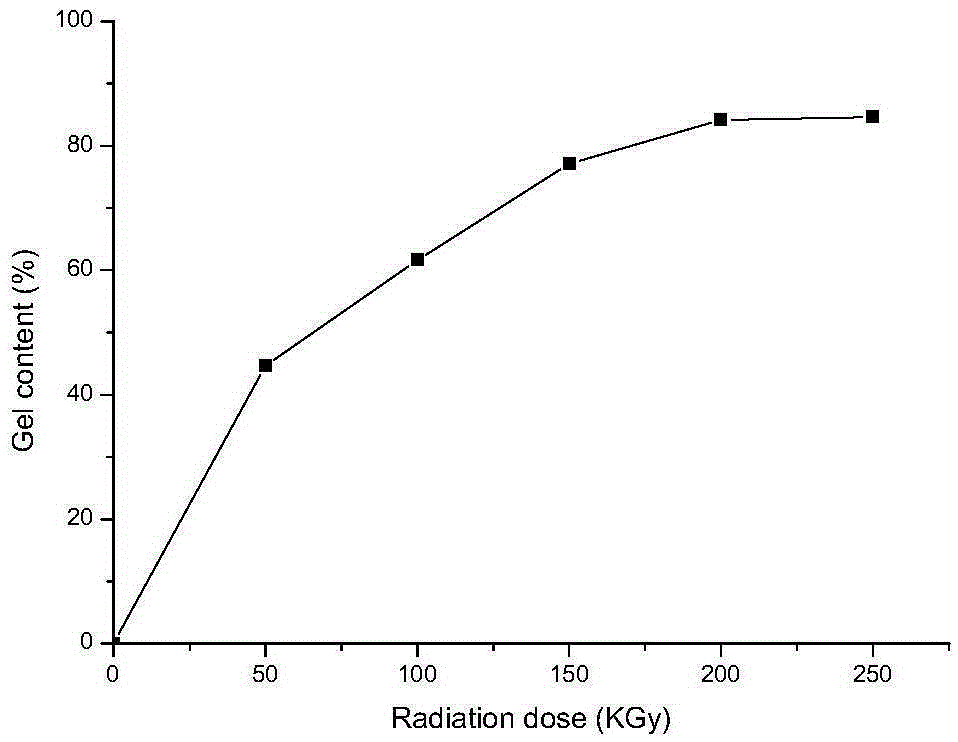

Electroshape memory composite material, preparation method and applications

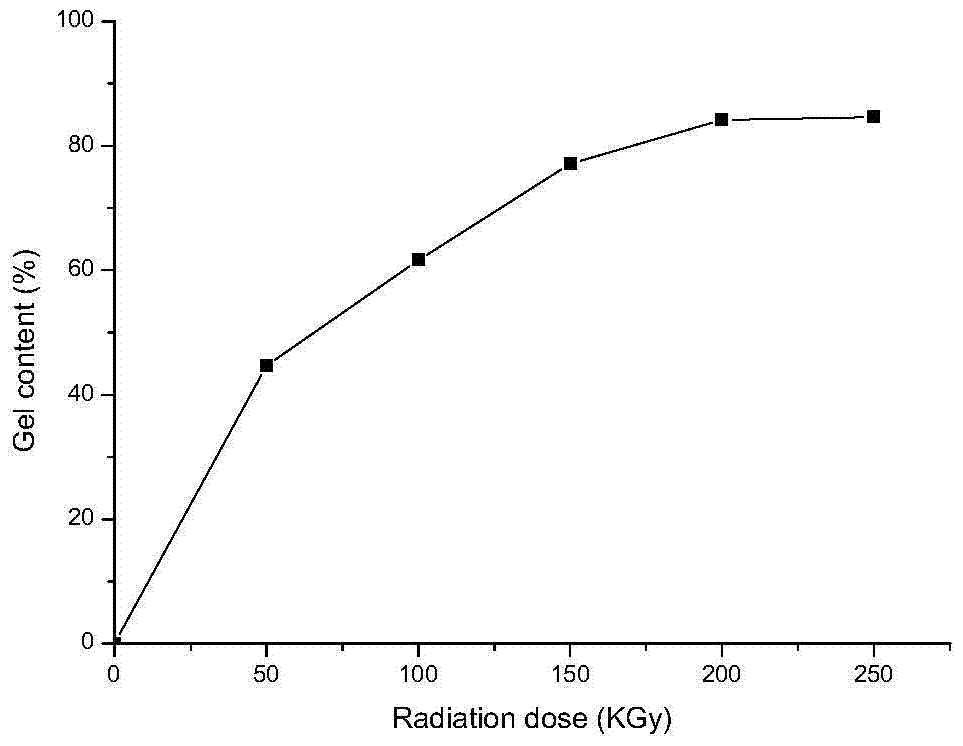

InactiveCN105400119AHas shape memory propertiesGood shape memory propertiesFlexible member pumpsPositive-displacement liquid enginesLow-density polyethyleneElectricity

Provided are an electroshape memory composite material, a preparation method and applications. Styrene-isoprene-styrene segmented copolymers and low-density polyethylene (SIS / LDPE) with a weight ratio of 60:40-80:20 are subjected to radiation crosslinking, a polymer matrix is prepared, then graphite with a mass fraction of 6%-30% of the polymer matrix is added, and the mixture is blended. The invention also comprises a preparation method for an electrographite / SIS / LDPE composite material and applications. The electrographite / SIS / LDPE composite material has an electroshape memory characteristic. Experiments prove that when the graphite content is higher than 6%, the graphite / SIS / LDPE composite material has a good electroshape memory characteristic. In addition, under action of a certain voltage, the deformation reversion rate can reach 100%, the response time decreases along with increase of the graphite content, and the response time of a sample is shortened along with increase of the voltage. In addition, electrocirculation shape memory tests for many times show that the deformation reversion rates are all higher than 95%.

Owner:XIDIAN UNIV

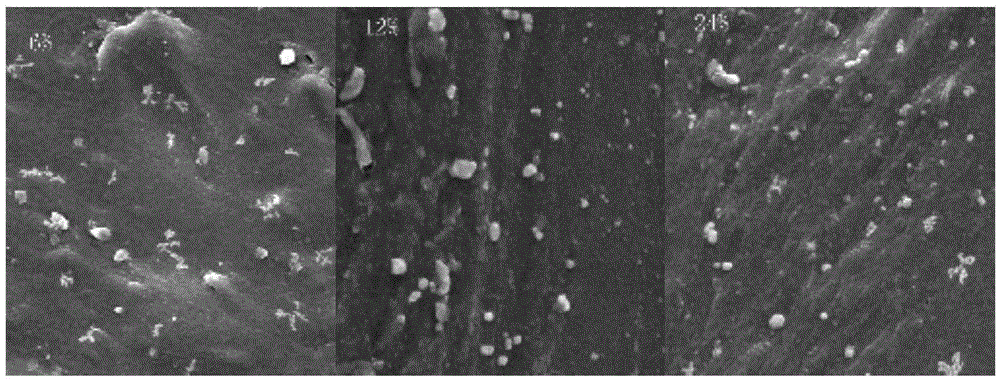

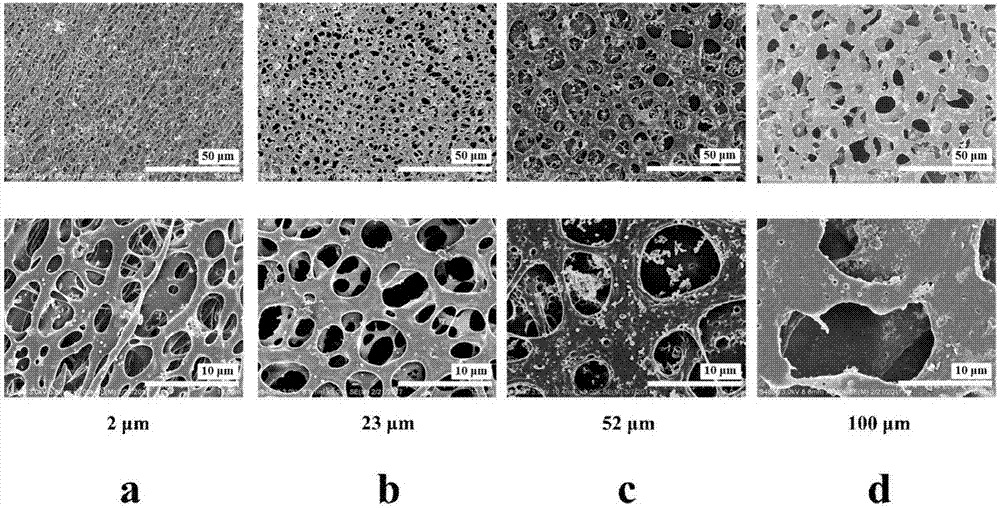

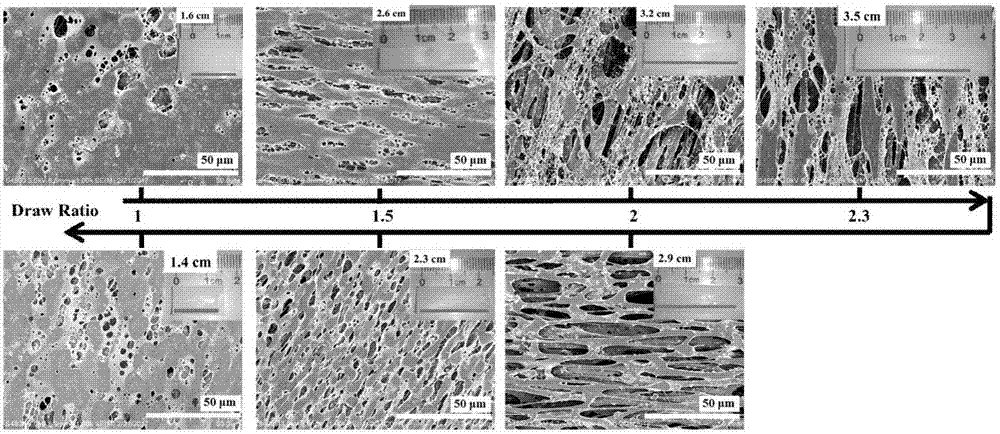

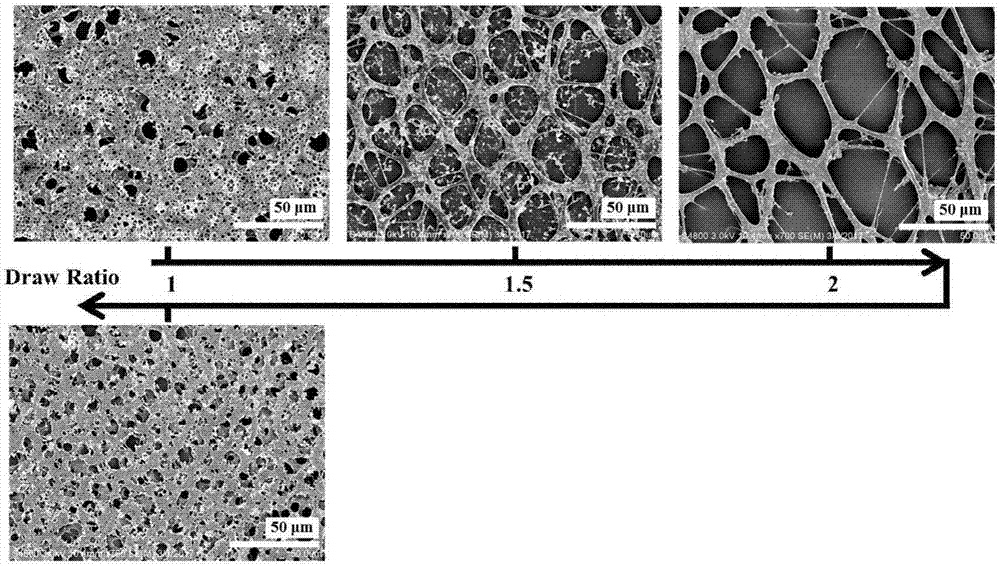

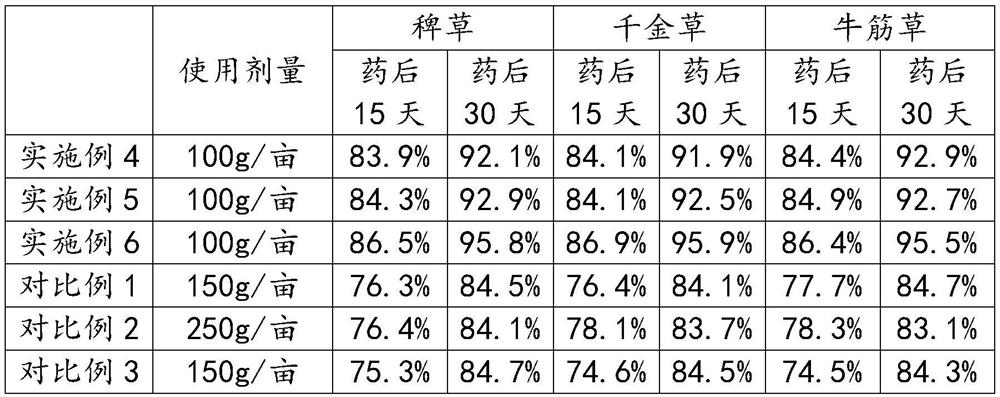

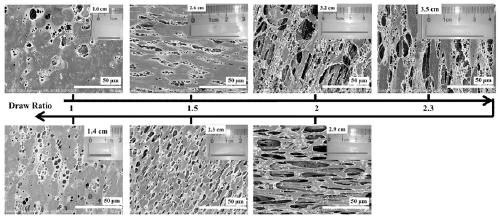

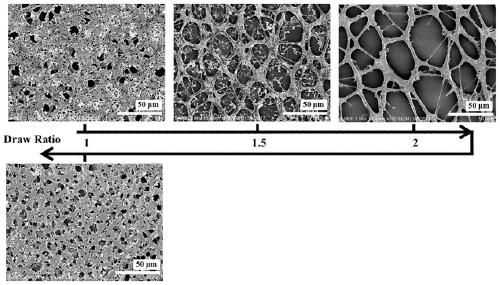

Preparation method for polylactic acid porous shape memory film

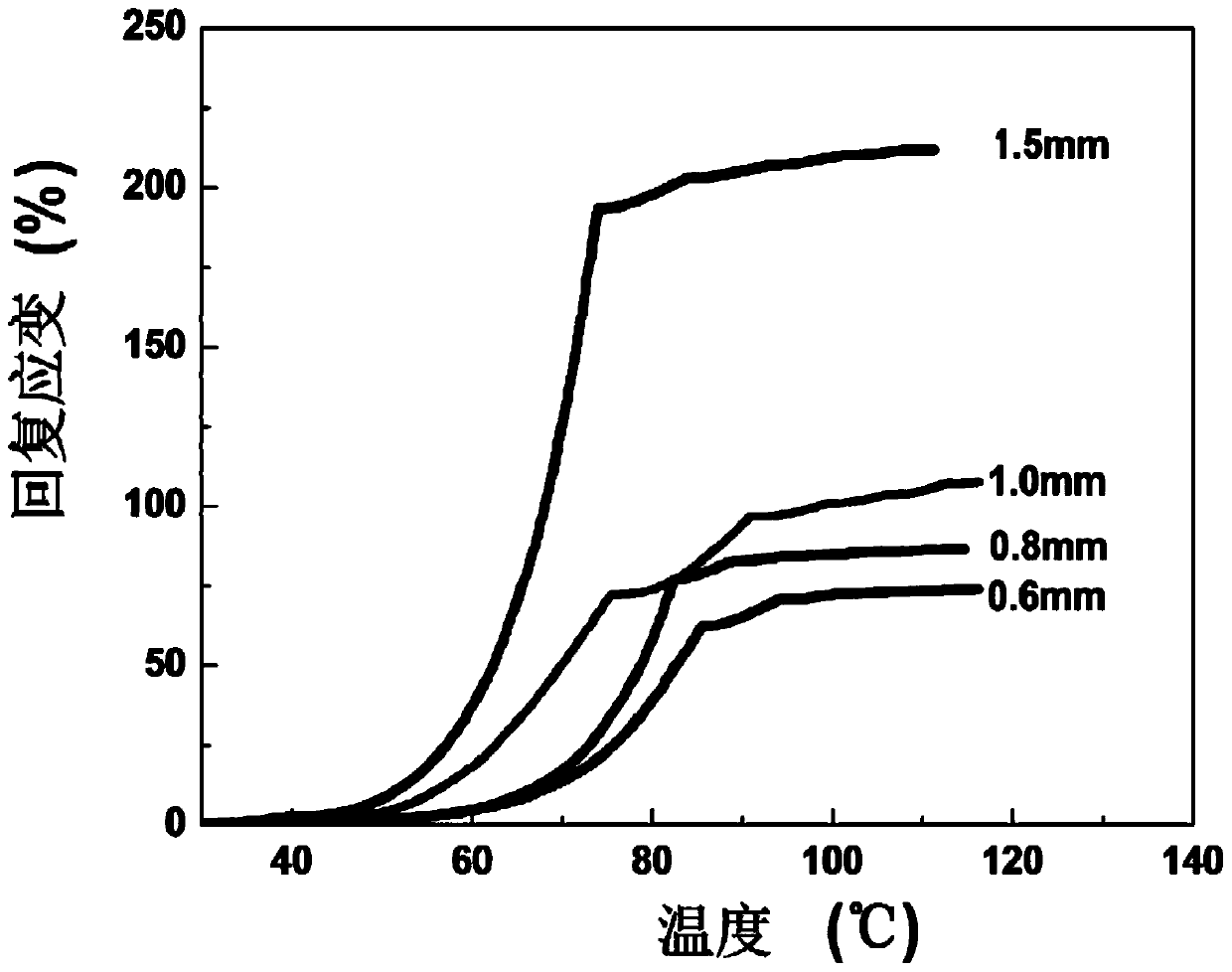

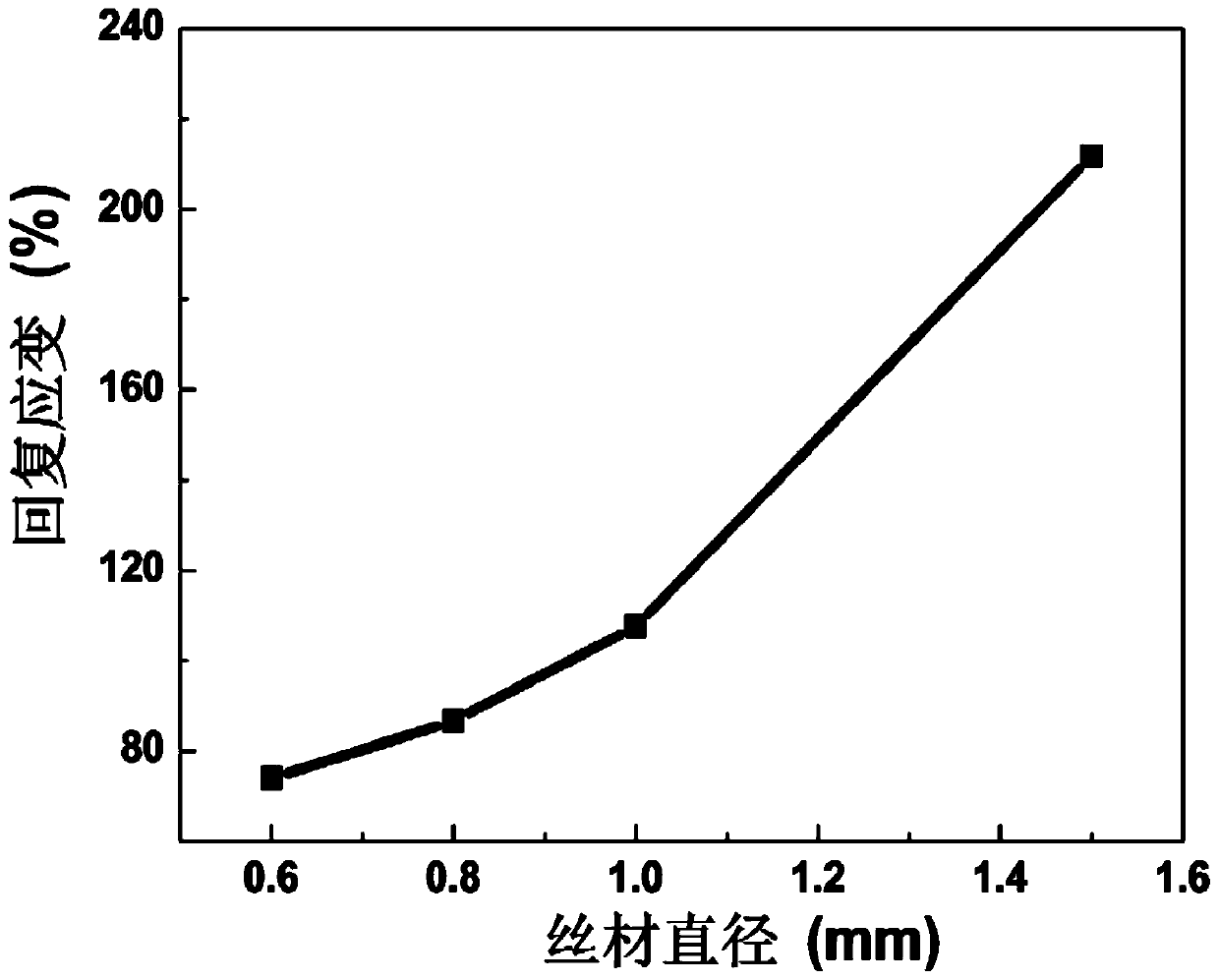

ActiveCN107090097ANot dischargedThe preparation method is fast and efficientMicron scalePolyethylene oxide

The invention discloses a preparation method for a polylactic acid porous shape memory film. The polylactic acid porous shape memory film in the invention is formed under the synergic effect of crystallization and phase separation. The method specifically comprises the following steps: dissolving polylactic acid and polyethylene oxide at a certain weight ratio in a co-solvent, and stirring under room temperature, thereby forming a homogeneous polymer solution; scraping the polymer solution into a film by using film scrapers of different thickness; etching a polyethylene oxide phase in the film; after etching, placing the film into a vacuum oven and drying, thereby acquiring the biodegradable polylactic acid porous shape memory film. The polylactic acid porous shape memory film has a micron-scale penetrated porous structure and a shape memory property. The sizes of formed holes are correspondingly changed according to different film thickness, and meanwhile, the polylactic acid porous shape memory film macroscopically and microscopically has better shape memory effect and is expected to be applied to the fields of separation filtering, medical materials, and the like.

Owner:HANGZHOU NORMAL UNIVERSITY

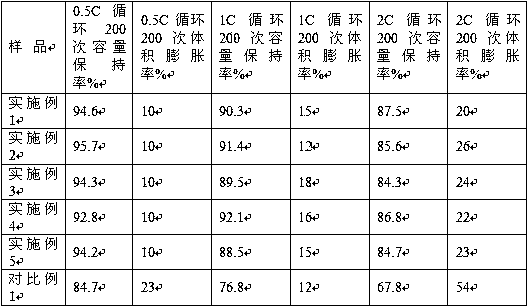

Low-cost and stable lithium battery silicon negative electrode and preparation method thereof

InactiveCN109671913AVolume stabilityImprove cycle performanceCell electrodesSecondary cellsPorosityFiber

The invention provides a low-cost and stable lithium battery silicon negative electrode and a preparation method thereof. Silicon-based nanoparticles, liquid silicone rubber and ethylene-vinyl acetatecopolymer are uniformly mixed up according to a mass ratio of 10: 3: 1, and then are heated, melted and dispersed. In this way, silicon-based nanoparticles are uniformly dispersed in the melt. Afterthat, a curing agent, graphene powders and carbon fibers are added into the melt prefabricated in the step (1), and the mixture is ultrasonically dispersed to obtain a slurry. The slurry is coated onthe surface of a negative current collector, and then is cured at 80 DEG C for 2 hours. After that, the material is dried, slit and tabletted to obtain the lithium battery silicon negative electrode.According to the invention, nano silicon is directly dispersed in the deformation memory silicone rubber to prepare the silicon negative electrode. The system has self-repairing performance and shapememory performance at a certain temperature. The problem of silicon expansion fragmentation is well solved. The preparation process is greatly simplified, and the preparation cost is reduced. The defects that an existing technology for solving the problem that a silicon negative electrode is prone to expansion is complex and high in cost, and the size is increased after porosity is achieved are overcome.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Preparation technology for tin-based shape memory alloy powder used for 3D printing

InactiveCN108746646AHigh strengthImprove heat resistanceAdditive manufacturing apparatusShielding gasShape-memory alloy

The invention provides a preparation technology for tin-based shape memory alloy powder used for 3D printing. The preparation technology comprises the following steps that Sb and Cu are added into a smelting furnace to be completely melted, Sn is added to be continuously stirred, then a graphene hydrochloric acid solution is added, after temperature rise and even stirring are carried out, Pb, Zn and Al are added to be stirred at high speed, and tin-based alloy liquid is obtained; the tin-based alloy liquid is added into shape memory alloy particles, repeated fusion treatment is carried out, and the tin-based shape memory alloy liquid is obtained; under the atmosphere of protective gas, the tin-based shape memory alloy liquid downwards flows out through a flow guide nozzle, an ultrahigh pressure spraying nozzle atomizes and crushes metal liquid into a large quantity of wee liquid drops under the effects of high pressure air flow and supersonic waves, the liquid drops are cooled and solidified during rotary flying, and the tin-based shape memory alloy particles are obtained; and the tin-based shape memory alloy particles are screened and processed to obtain the tin-based shape memoryalloy powder used for 3D printing.

Owner:DONGGUAN JIAQIAN NEW MATERIAL TECH CO LTD

Preparation method and application of eucommia ulmoide gum shape memory material

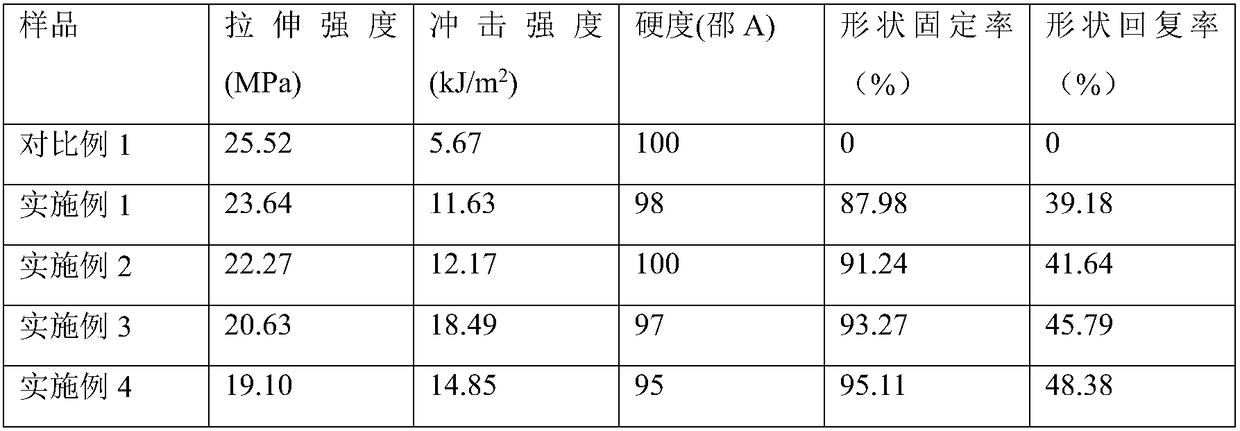

InactiveCN108357004AImprove impact resistanceHigh impact strengthVulcanizationUltimate tensile strength

The invention relates to a preparation method and application of a eucommia ulmoide gum shape memory material. The process of firstly, banburying and secondly, tabletting is adopted. The composite isprepared through the dynamic vulcanization technology. The material has the two beneficial effects that firstly, the impact resistance is excellent, and the impact strength of the material is improvedby more than three times compared with that of common PP materials; and secondly, shape memory performance is achieved.

Owner:QINGDAO UNIV OF SCI & TECH

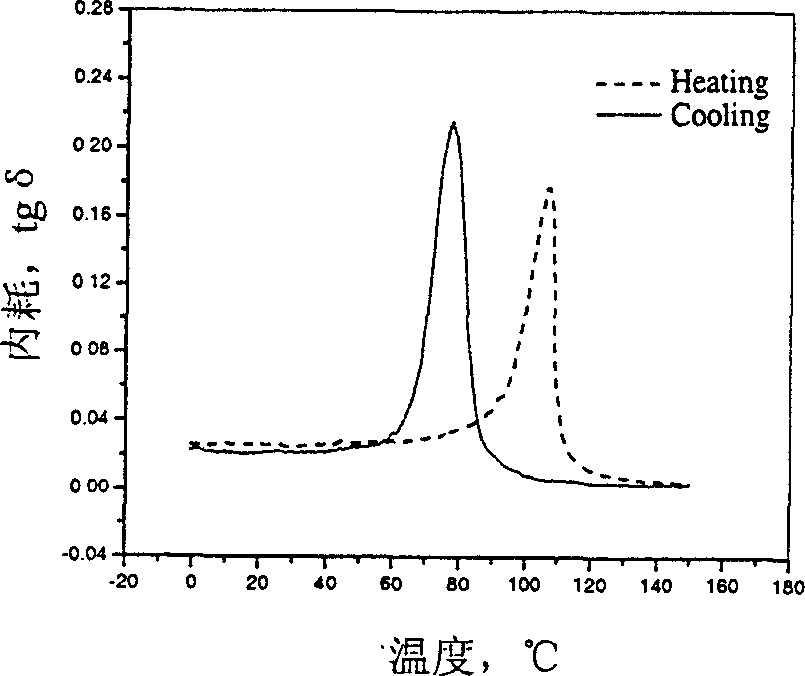

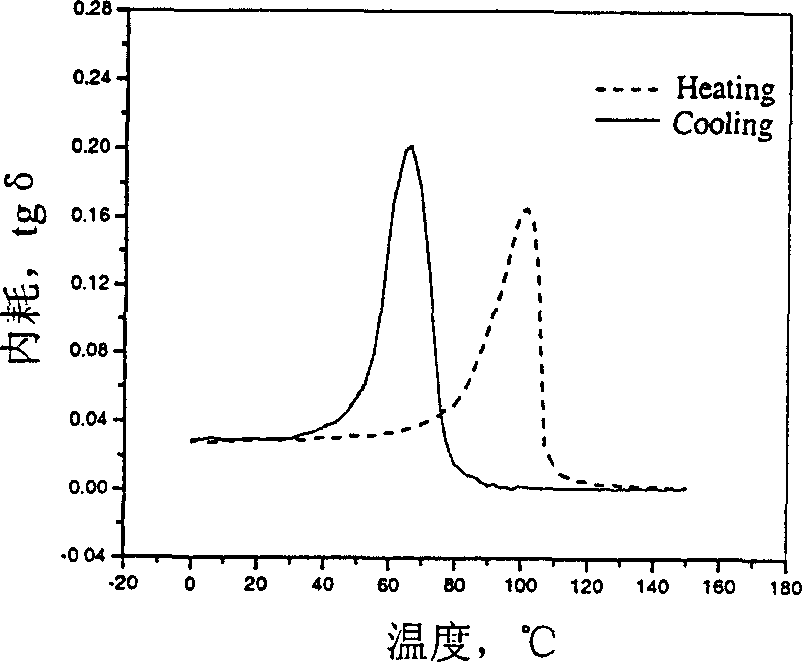

High-damping shape memory alloy

The present invention relates to a high-damping marmem. In the original marmem Ti-Ni-Cu the trace rare earth element Y is contained, the content of Y is 0.01-5 at%. Said invented high-damping alloy utilizes the regulation of content of constituent element Cu and Y can raise and control martensific phase transformation temperature of the alloy so as to obtain high-damping alloy with wider working temperature range. Said invented high-damping alloy can be smelted by adopting vacuum induction smelting process or electric arc process, can be directly prepared into the antivibration component product. Said invented high-damping marmem has excellent damping performance, wider application range, lower cost and excellent antifriction, wear-resisting and corrosion-proofing properties.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

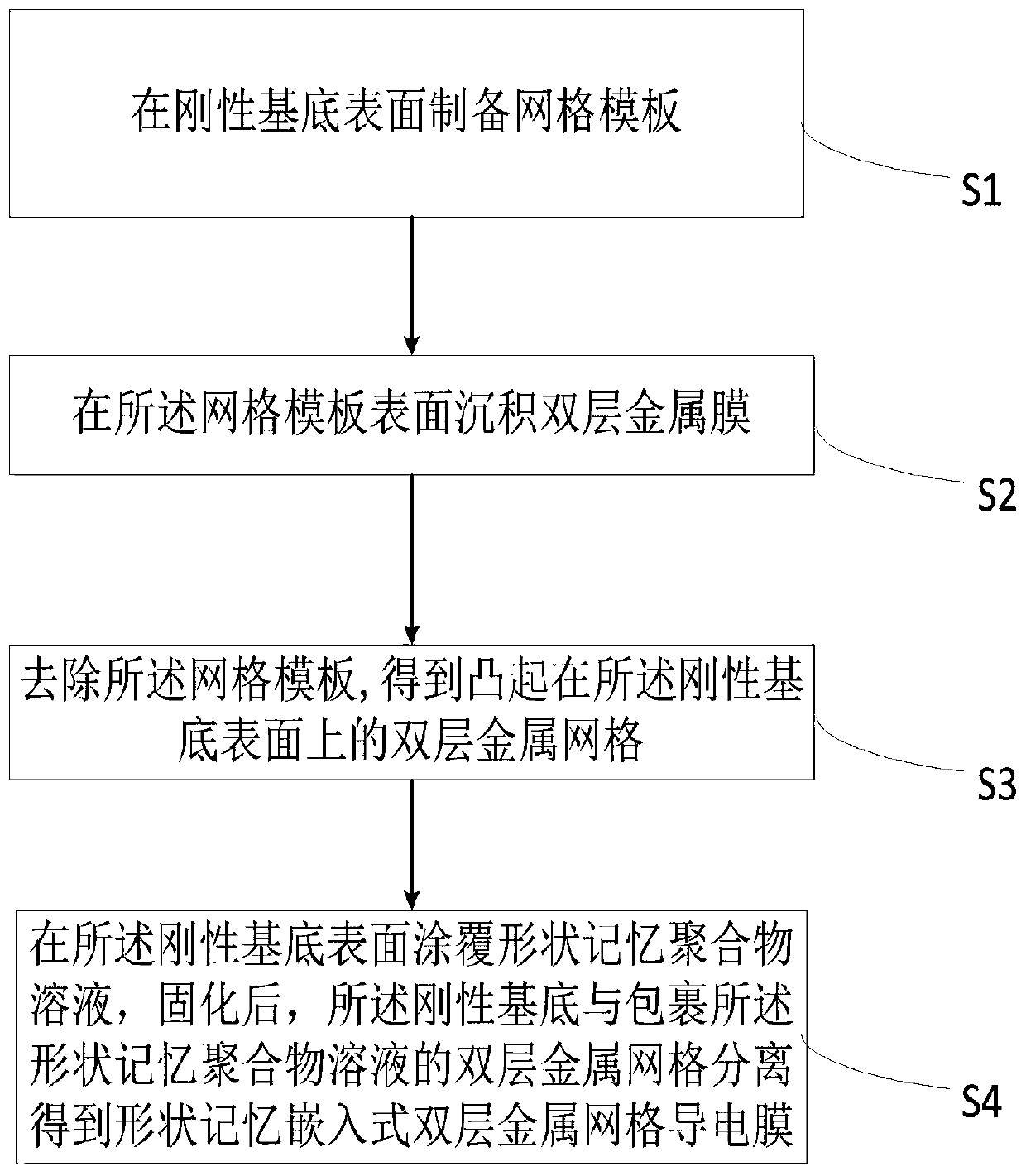

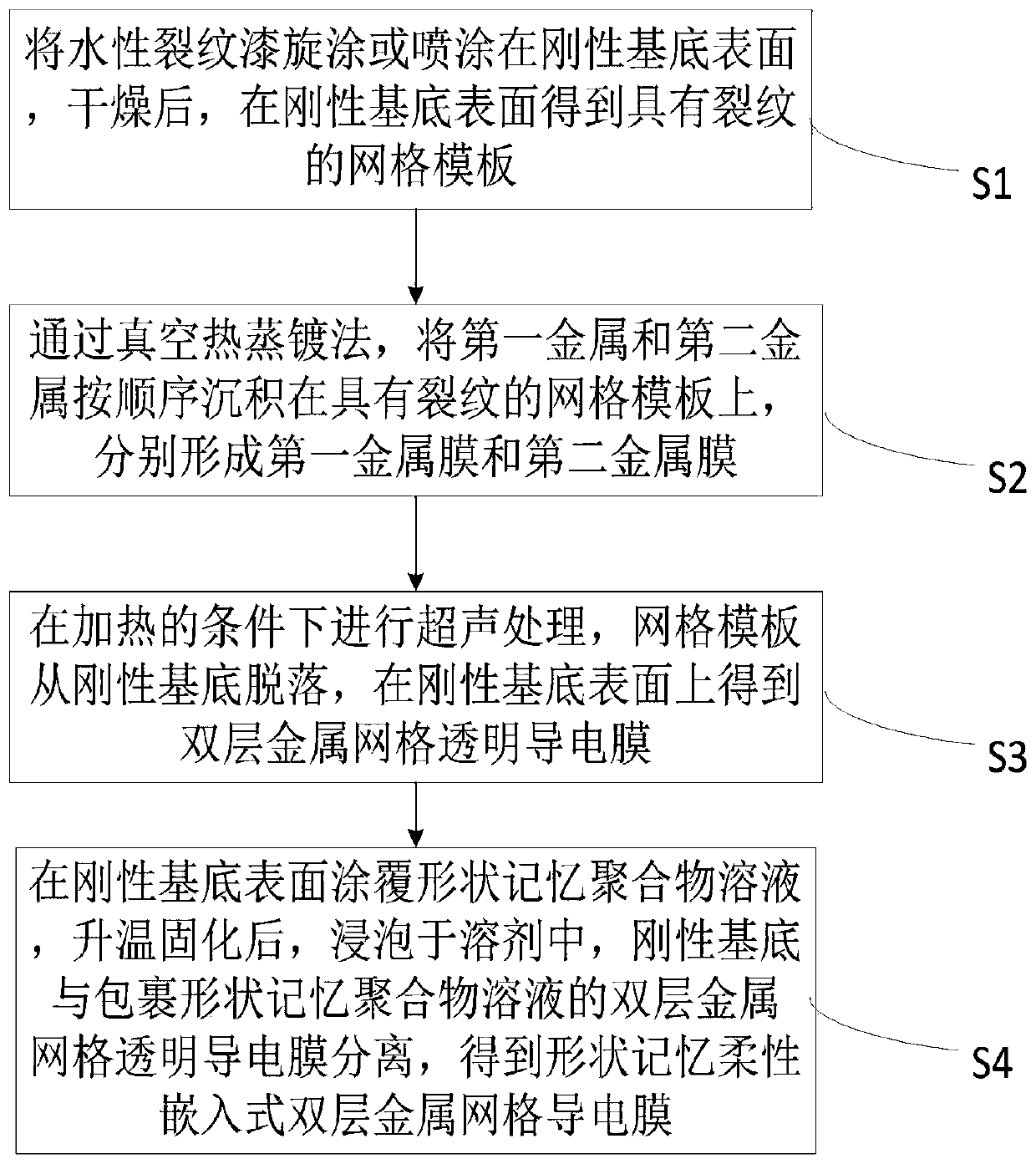

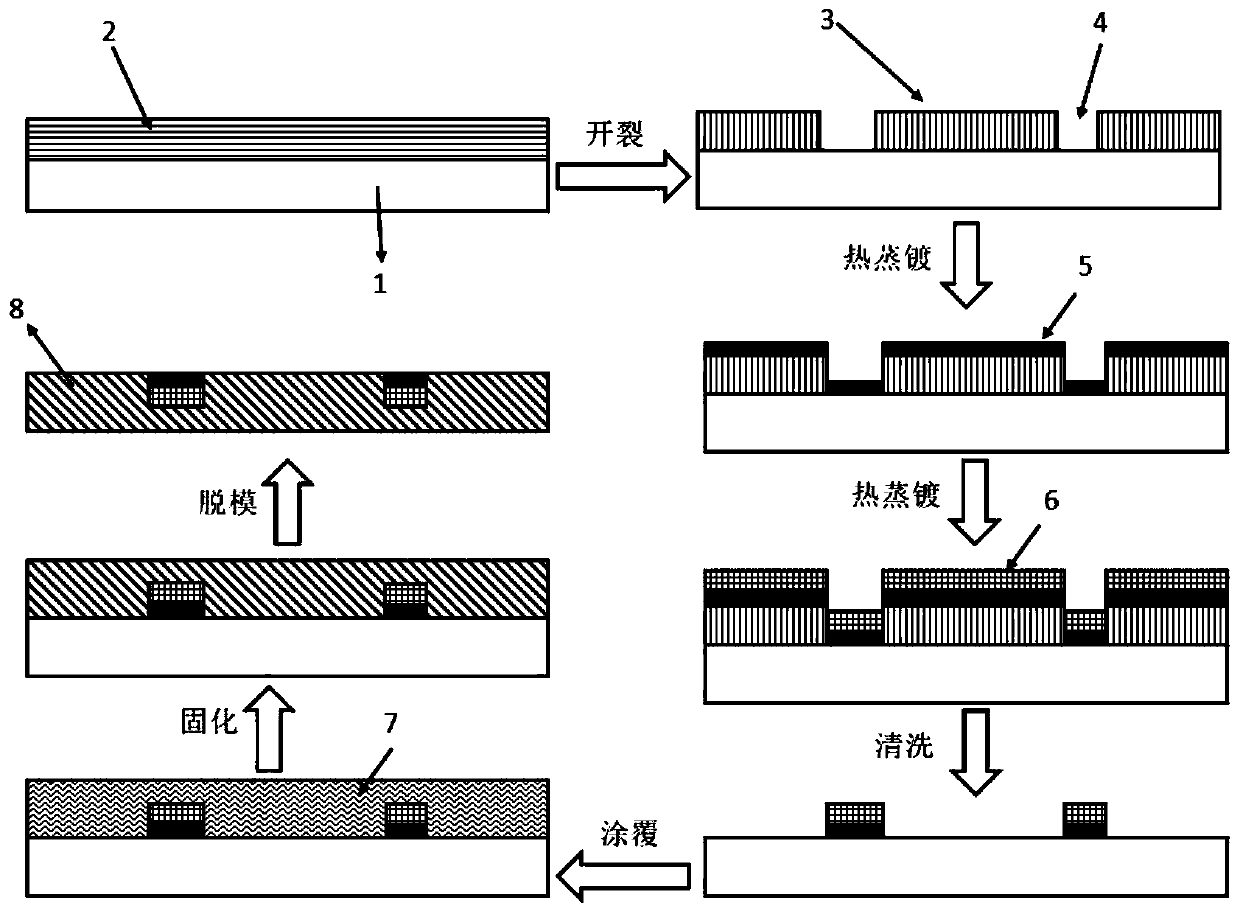

Shape memory embedded double-layer metal grid conducting film and preparation method thereof

InactiveCN110838386AGood scratch resistanceReduce surface roughnessConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersMetal gridElectrically conductive

The invention provides a shape memory embedded double-layer metal grid conducting film and a preparation method thereof, which belong to the technical field of flexible photoelectrons. The preparationmethod for the shape memory embedded double-layer metal grid conducting film comprises the following steps of: preparing a grid template on the surface of a rigid substrate, depositing a double-layermetal film on the surface of the grid template, removing the grid template to obtain a double-layer metal grid protruding on the surface of the rigid substrate, and coating the surface of the rigid substrate with a shape memory polymer, and after curing, separating the rigid substrate from the double-layer metal grid wrapping the shape memory polymer to obtain the shape memory embedded double-layer metal grid conducting film. Compared with the prior art, the shape memory embedded double-layer metal grid conducting film prepared by the invention has good scratch resistance, bending stability,corrosion resistance, oxidation resistance and shape memory performance.

Owner:HARBIN INST OF TECH

Shape memory alloy soft body driver

PendingCN113459077AGood biocompatibilityImprove environmental adaptabilityProgramme-controlled manipulatorSurgical ManipulationShape-memory alloy

The invention relates to a shape memory alloy soft body driver. The shape memory alloy soft body driver comprises a shape memory alloy wire, a flexible substrate, a reinforcing layer and a heat dissipation coating; the shape memory alloy wire is arranged in the flexible substrate; the reinforcing layer is arranged on the neutral surface of the flexible substrate; and the heat dissipation coating is sprayed on the surface of the shape memory alloy wire. The shape memory alloy soft body driver disclosed by the invention has the advantages of being high in response speed, convenient to manufacture, capable of driving a traditional structure to be integrated and the like. The shape memory alloy soft body driver is suitable for the fields of space operation, surgical operation robots, flexible manufacturing and the like.

Owner:SHANGHAI UNIV

Production method of spinning solution having memory function

InactiveCN105862170AStable unwindingStable structure and performanceFilament/thread formingConjugated synthetic polymer artificial filamentsFiberThermoforming

The invention relates to a production method of a spinning solution having a memory function. The production method comprises the steps of 1, preparing a fiber-forming polymer solution; 2, preparing slurry with the memory function; 3, uniformly dispersing the fiber-forming polymer solution prepared in step 1 and the slurry with the memory function prepared in step 2 in stirring equipment, and storing the materials for 24-36 hours till the materials are cured completely, so that a shell spinning solution is obtained, wherein the shell spinning solution can be used for spinning shells. According to production method, the modified spinning solution is prepared, it can be guaranteed that after silk flocks are subjected to drafting and thermoforming, basically no residual stress exists, and the silk flocks are unwound smoothly; what is more important, a fiber product which is stable in structural performance, good in mechanical performance and low in fiber modulus and has the shape memory characteristic is obtained.

Owner:NANTONG SUZHONG TEXTILE

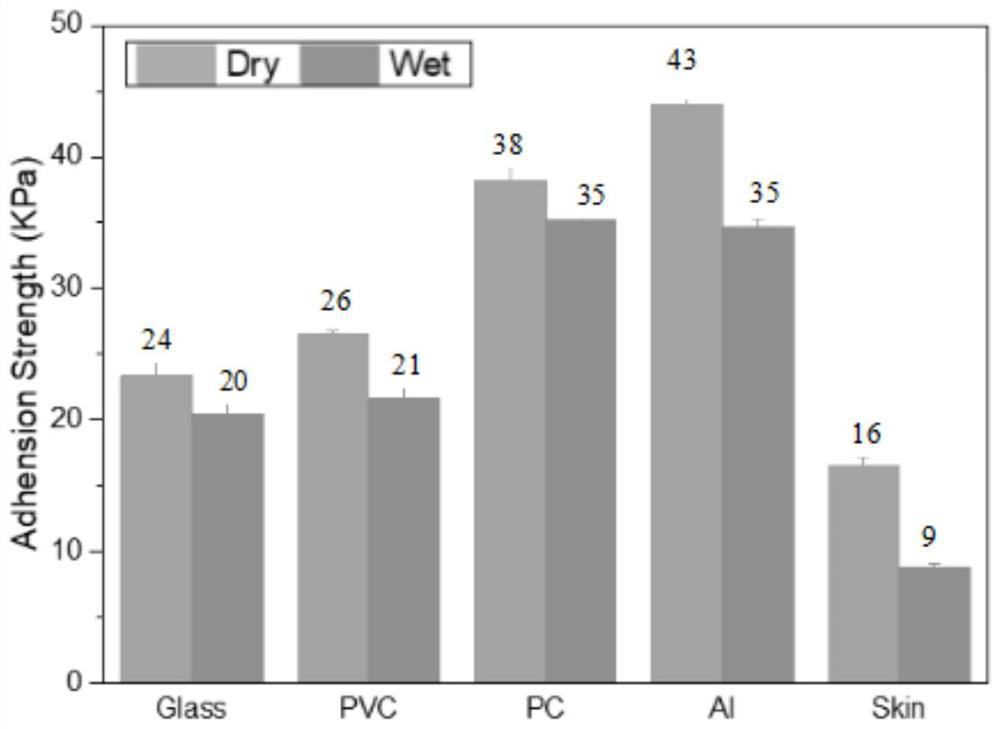

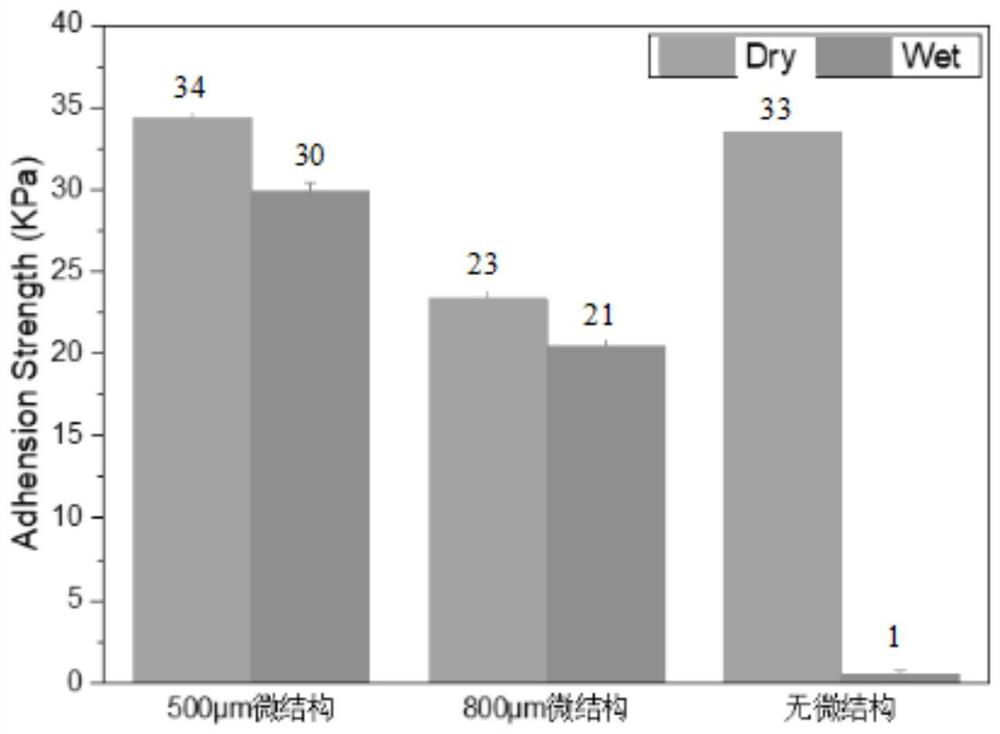

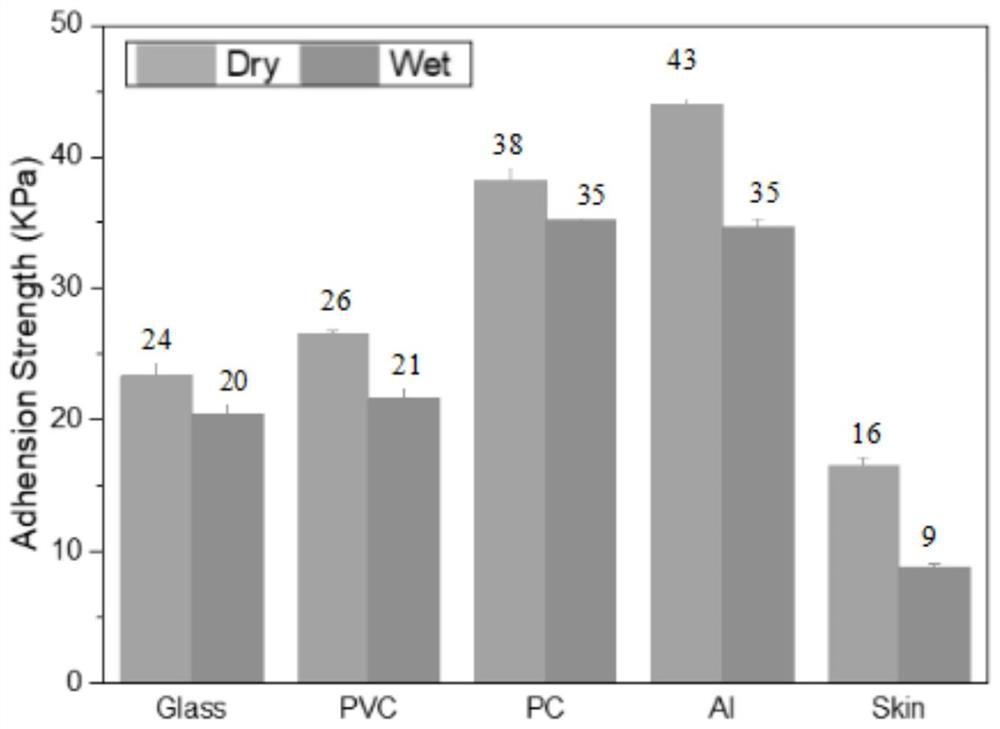

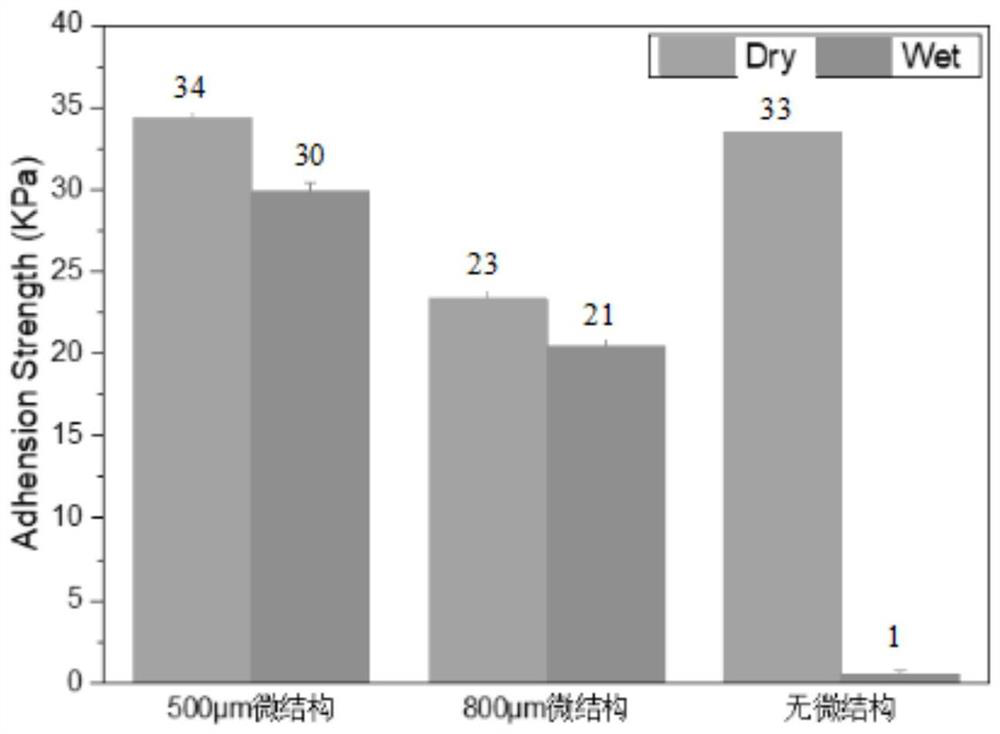

Hydrogel with adjustable adhesion in wet environment and preparation and use methods of hydrogel

The invention discloses hydrogel with adjustable adhesion in a wet environment and a preparation method and a use method of the hydrogel, and belongs to the technical field of hydrogel. Acrylonitrile, acrylic acid, methacrylic acid ureido ethyl ester, a cross-linking agent, an initiator and a solvent are added into a reaction mold to react for 6-9 hours at the temperature of 60-80 DEG C to prepare organic gel, and then the organic gel is put into water to obtain the hydrogel. The organic solvent is replaced with water to prepare the hydrogel. According to the invention, hydrogen bonds and dipole dipoles are introduced to interact to serve as temporary crosslinking points, so that the shape memory property of the hydrogel and the swelling resistance of the hydrogel in water are realized; then micro-patterns are constructed on the surface of the hydrogel, the surface drainage performance of the material is enhanced, wet adhesion of the hydrogel is achieved, finally, the surface microstructure is restored through the shape memory function, the hydrogel becomes a plane structure, the wet adhesion force of the hydrogel is reduced, and therefore regulation and control of the adhesion force of the hydrogel are achieved.

Owner:SOUTHWEST JIAOTONG UNIV

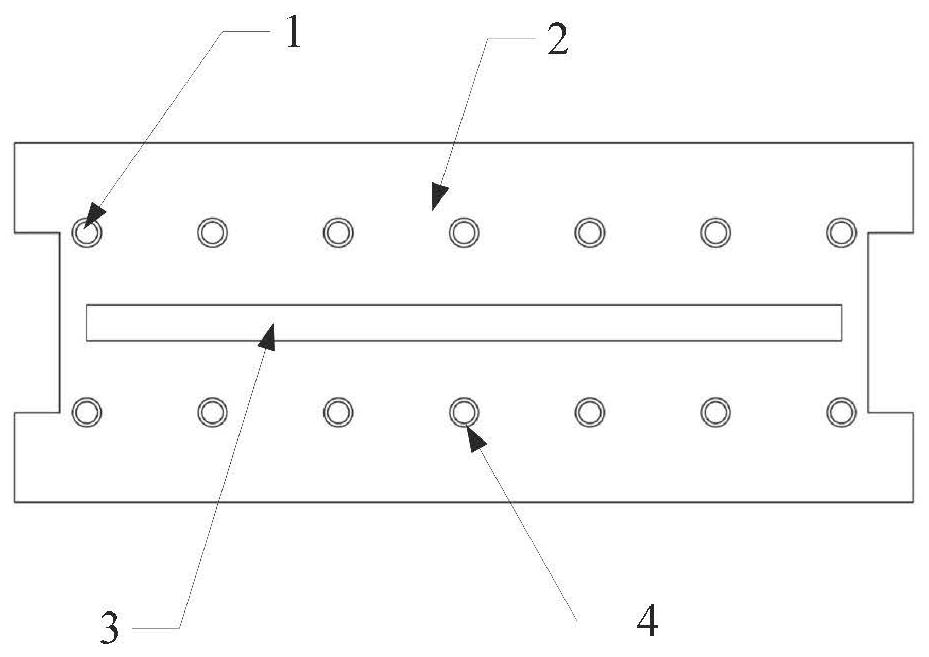

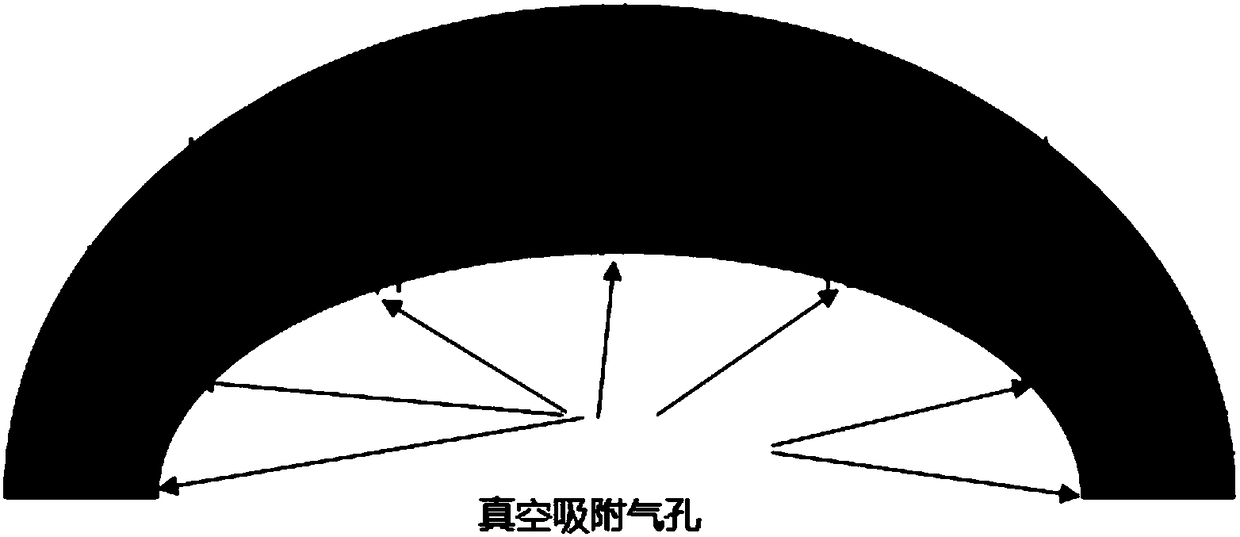

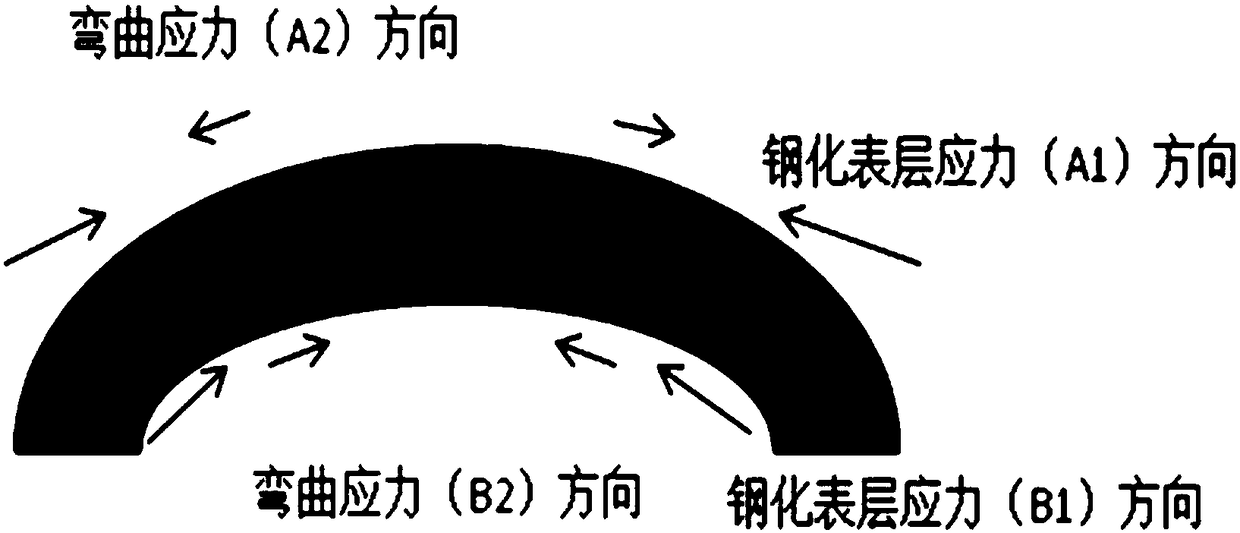

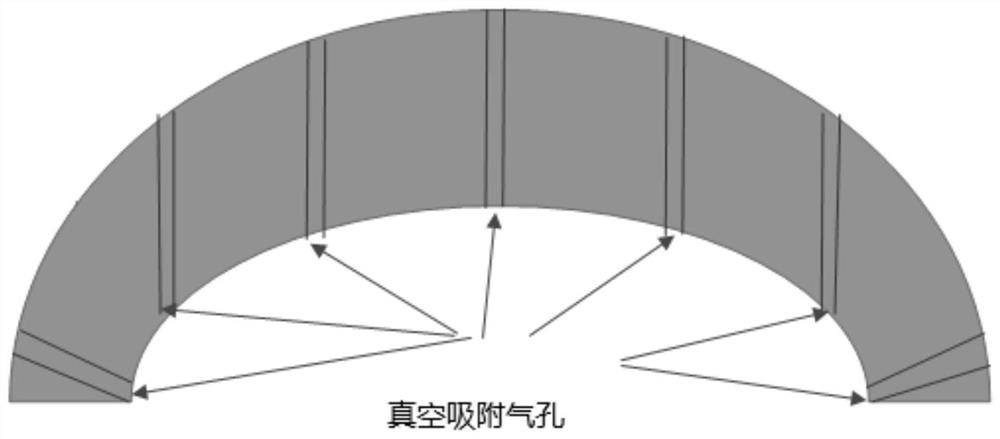

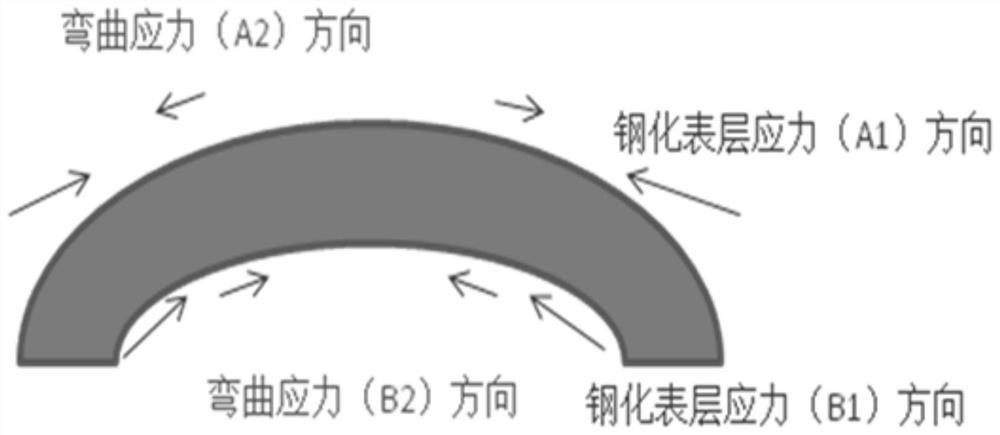

Curved surface composite cover plate and preparation method thereof

ActiveCN108515756AGood shape memory propertiesExcellent explosion-proof characteristicsSynthetic resin layered productsLaminationEngineeringToughened glass

The invention relates to a curved surface composite cover plate. The curved surface composite cover plate comprises curved surface glass and a plastic cover plate; a preparation method for the curvedsurface glass comprises the following steps: acquiring a curved surface clamp, fixing a glass sheet in the curved surface clamp, and enabling the glass sheet to keep a curved surface appearance; the first time of tempering: performing first tempering treatment on the glass sheet, cooling, preparing semi-tempered glass of which a tempering depth is 1 / 10-1 / 1.5 of a preset tempering depth of the glass sheet; the second time of tempering: performing second tempering treatment on the semi-tempered glass, cooling, preparing tempered glass of which the tempering depth is the preset tempering depth ofthe glass sheet, to obtain the curved surface glass. The above curved surface composite cover plate is capable of combining the above curved surface glass and the plastic cover plate. Compared with the single curved surface glass and the plastic cover plate, the curved surface composite cover plate has the better shape memory characteristics, the more excellent anti-explosion property and the better toughness.

Owner:VITALNK IND SHENZHEN +1

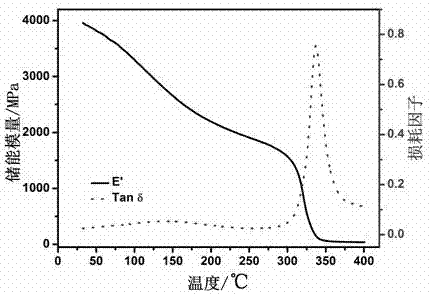

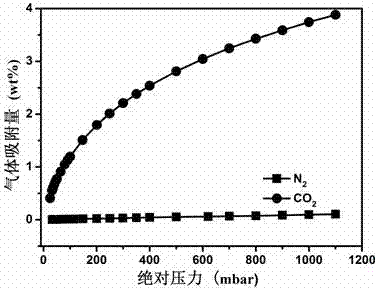

Gas separation membrane having shape memory property

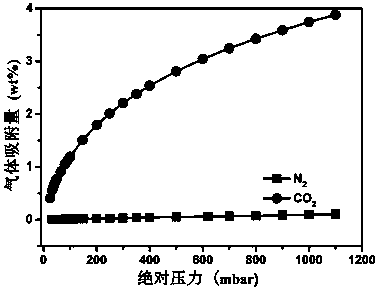

ActiveCN106902652AHas shape memory propertiesLarge specific surface areaSemi-permeable membranesMembranesStationary phaseDiaminodiphenyl ether

The invention discloses a gas separation membrane having a shape memory property; the gas separation membrane is prepared by the steps: firstly, forming a copolymerized linear oligomer from dianhydride 4,4'-(hexafluoroisopropylidene)diphthalic anhydride, diamine 4,4'-diaminodiphenyl ether and 2-(4-aminophenyl)-5-aminobenzoxazole, then carrying out a reaction of the copolymerized linear oligomer with 2,4,6-triaminopyrimidine gradually to form hyperbranched macromolecules, and finally, carrying out thermal imidization to obtain a hyperbranched polyimide membrane. The hyperbranched polyimide membrane has large specific surface area and can achieve gas adsorption; by adjusting the stiffness and flexibility of a structure of polyimide, the hyperbranched polyimide membrane has different adsorption characteristics on different gases, so as to achieve gas separation characteristics. In addition, the hyperbranched polyimide has obvious glass transition temperature, the transition can be used as a shape memory reversible phase, mutual entanglement of macromolecular chains and intermolecular strong interaction force in the polyimide structure can be used as a stationary phase, and thus the hyperbranched polyimide is endowed with the shape memory property.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

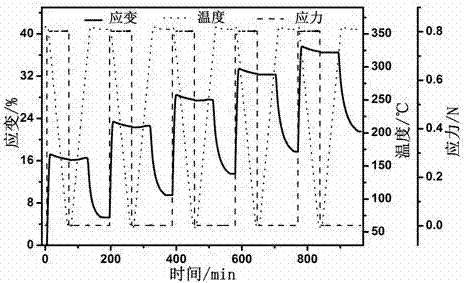

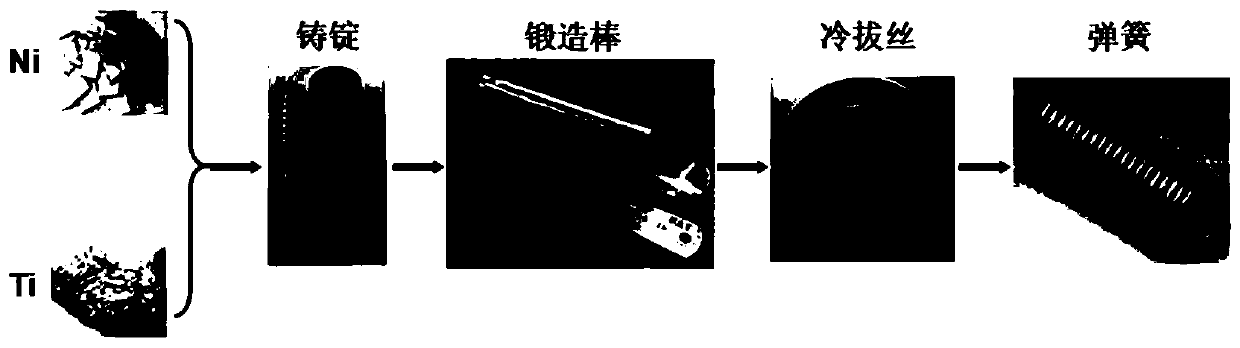

Method for preparing NiTi memory alloy springs by amorphous molds

ActiveCN110918840AGuaranteed dislocation densityHas shape memory propertiesFurnace typesWire springsShape-memory alloyHeat treated

The invention discloses a method for preparing NiTi memory alloy springs by amorphous molds. The method comprises the steps of 1) cold drawing treatment: NiTi memory alloy wires are cold drawn; 2) formation of springs by winding: the NiTi memory alloy wires cold drawn in the step 1) are wound as the springs; and 3) shaping and heating: the springs wound in the step 2) are shaped and heated in a non-constraint state to obtain the NiTi memory alloy springs. The method prepares the shape memory alloy springs without needing shaping molds, and can prepare the memory alloy springs with complex structures.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A kind of electric shape memory composite material and its preparation method and application

InactiveCN105400119BHas shape memory propertiesGood shape memory propertiesFlexible member pumpsPositive-displacement liquid enginesLow-density polyethyleneGraphite

Provided are an electroshape memory composite material, a preparation method and applications. Styrene-isoprene-styrene segmented copolymers and low-density polyethylene (SIS / LDPE) with a weight ratio of 60:40-80:20 are subjected to radiation crosslinking, a polymer matrix is prepared, then graphite with a mass fraction of 6%-30% of the polymer matrix is added, and the mixture is blended. The invention also comprises a preparation method for an electrographite / SIS / LDPE composite material and applications. The electrographite / SIS / LDPE composite material has an electroshape memory characteristic. Experiments prove that when the graphite content is higher than 6%, the graphite / SIS / LDPE composite material has a good electroshape memory characteristic. In addition, under action of a certain voltage, the deformation reversion rate can reach 100%, the response time decreases along with increase of the graphite content, and the response time of a sample is shortened along with increase of the voltage. In addition, electrocirculation shape memory tests for many times show that the deformation reversion rates are all higher than 95%.

Owner:XIDIAN UNIV

A kind of manufacturing method of spinning dope with memory function

InactiveCN105862170BStable unwindingStable structure and performanceFilament/thread formingConjugated synthetic polymer artificial filamentsFiberThermoforming

The invention relates to a production method of a spinning solution having a memory function. The production method comprises the steps of 1, preparing a fiber-forming polymer solution; 2, preparing slurry with the memory function; 3, uniformly dispersing the fiber-forming polymer solution prepared in step 1 and the slurry with the memory function prepared in step 2 in stirring equipment, and storing the materials for 24-36 hours till the materials are cured completely, so that a shell spinning solution is obtained, wherein the shell spinning solution can be used for spinning shells. According to production method, the modified spinning solution is prepared, it can be guaranteed that after silk flocks are subjected to drafting and thermoforming, basically no residual stress exists, and the silk flocks are unwound smoothly; what is more important, a fiber product which is stable in structural performance, good in mechanical performance and low in fiber modulus and has the shape memory characteristic is obtained.

Owner:NANTONG SUZHONG TEXTILE

A method of manufacturing fiber with memory function

ActiveCN105671684BNo residual stressStable unwindingConjugated synthetic polymer artificial filamentsArtifical filament manufactureHeat settingMaterials science

The invention relates to a method for manufacturing fibers with a memory function. The method includes the steps of core spinning solution manufacturing, shell spinning solution manufacturing and solution spinning. According to the method, by preparing spinning solutions modified by skin and cores respectively, it can be guaranteed that residual stress hardly exists in tows after drafting and heat setting, and the tows are unwound smoothly. More importantly, a fiber product which is stable in structural performance, good in fiber mechanical performance and lower in fiber modulus and has the shape memory characteristic is manufactured.

Owner:浙江万舟控股集团有限公司

A hydrogel with adjustable adhesion in wet environment and its preparation and use method

The invention discloses a hydrogel with adjustable adhesion in a wet environment and a preparation and use method thereof, belonging to the technical field of hydrogels. Add the initiator and solvent into the reaction mold, react at 60-80°C for 6-9 hours to obtain an organic gel, then place the organic gel in water, replace the organic solvent with water, and obtain a hydrogel . The present invention realizes the shape memory performance of the hydrogel and the anti-swelling performance of the hydrogel in water by introducing hydrogen bonds and dipole-dipole interactions as temporary cross-linking points; and then by constructing micropatterns on the surface of the hydrogel, Enhance the surface drainage performance of the material, realize the wet state adhesion of the hydrogel, and finally use the shape memory function to restore the surface microstructure, make the hydrogel into a planar structure, reduce the wet state adhesion of the hydrogel, and achieve Modulation of Adhesion of Hydrogels.

Owner:SOUTHWEST JIAOTONG UNIV

Curved composite cover plate and preparation method thereof

ActiveCN108515756BLarge amount of bending deformationHas shape memory propertiesSynthetic resin layered productsLaminationGlass chipToughened glass

The invention relates to a curved surface composite cover plate, which includes curved surface glass and a plastic cover plate; the preparation method of the curved surface glass comprises the following steps: obtaining a curved surface fixture, fixing a glass sheet in the curved surface fixture, so that the glass piece maintains a curved surface appearance; The first tempering: the glass sheet is tempered for the first time, cooled to prepare semi-tempered glass whose tempering depth is 1 / 10‑1 / 1.5 of the preset tempering depth of the glass sheet; the second tempering: semi-tempered The glass sheet is subjected to a second tempering treatment, cooled, and a tempered glass having a tempering depth equal to the predetermined tempering depth of the glass sheet is prepared. The above-mentioned curved composite cover plate combines the above-mentioned curved glass with a plastic cover plate, and has better shape memory properties, more excellent explosion-proof properties and better flexibility than a single piece of curved glass and plastic cover plates.

Owner:VITALNK IND SHENZHEN +1

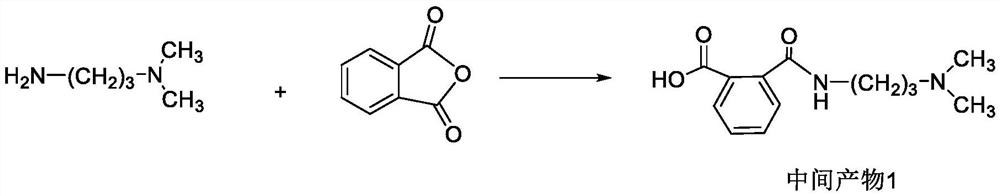

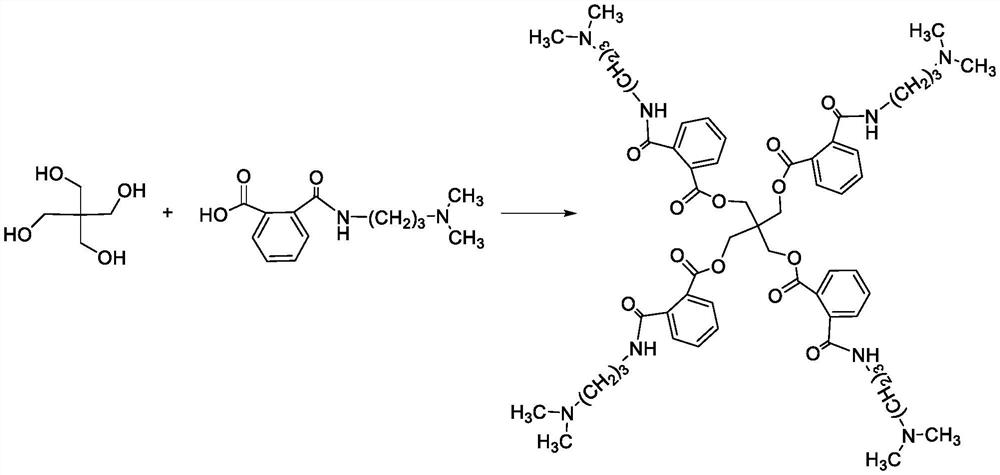

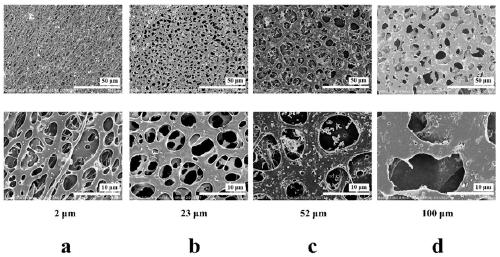

Metamifop and butachlor-based composite herbicide for rice

InactiveCN113068703AExpand the spectrum of weed controlReduce dosageBiocideAnimal repellantsWeedPhthalic acid anhydride

The invention discloses a metamifop and butachlor-based composite herbicide for rice, belongs to the technical field of pesticides, and aims to solve the problems that the dosage of an existing herbicide is increased year by year and the drug resistance of weeds is delayed. The composite herbicide is prepared from the following raw materials in parts by weight: 1 to 20 parts of metamifop, 20 to 60 parts of butachlor, 5 to 30 parts of supramolecular sol-gel, 1.5 to 16.5 parts of methyl oleate, 5.5 to 15 parts of an emulsifier and 0 to 3.5 parts of organic bentonite. According to the invention, phthalic anhydride, N, N'-dimethyl- 1, 3-propanediamine and pentaerythritol are utilized as raw materials to prepare tree-shaped amide; four amino groups in the tree-shaped amide are reacted with carboxyl groups in adipic acid to form a hyperbranched supramolecule; and loading and slow release on metamifop and butachlor in the supramolecule structure is performed due to existence of a special hydrophobic cavity in the supramolecule structure. The pesticide application amount is reduced and the generation of pesticide resistance of weeds is slowed down.

Owner:安徽海日农业发展有限公司

A kind of preparation method of polylactic acid porous shape memory film

ActiveCN107090097BNot dischargedThe preparation method is fast and efficientPolymer sciencePolyethylene oxide

The invention discloses a preparation method for a polylactic acid porous shape memory film. The polylactic acid porous shape memory film in the invention is formed under the synergic effect of crystallization and phase separation. The method specifically comprises the following steps: dissolving polylactic acid and polyethylene oxide at a certain weight ratio in a co-solvent, and stirring under room temperature, thereby forming a homogeneous polymer solution; scraping the polymer solution into a film by using film scrapers of different thickness; etching a polyethylene oxide phase in the film; after etching, placing the film into a vacuum oven and drying, thereby acquiring the biodegradable polylactic acid porous shape memory film. The polylactic acid porous shape memory film has a micron-scale penetrated porous structure and a shape memory property. The sizes of formed holes are correspondingly changed according to different film thickness, and meanwhile, the polylactic acid porous shape memory film macroscopically and microscopically has better shape memory effect and is expected to be applied to the fields of separation filtering, medical materials, and the like.

Owner:HANGZHOU NORMAL UNIVERSITY

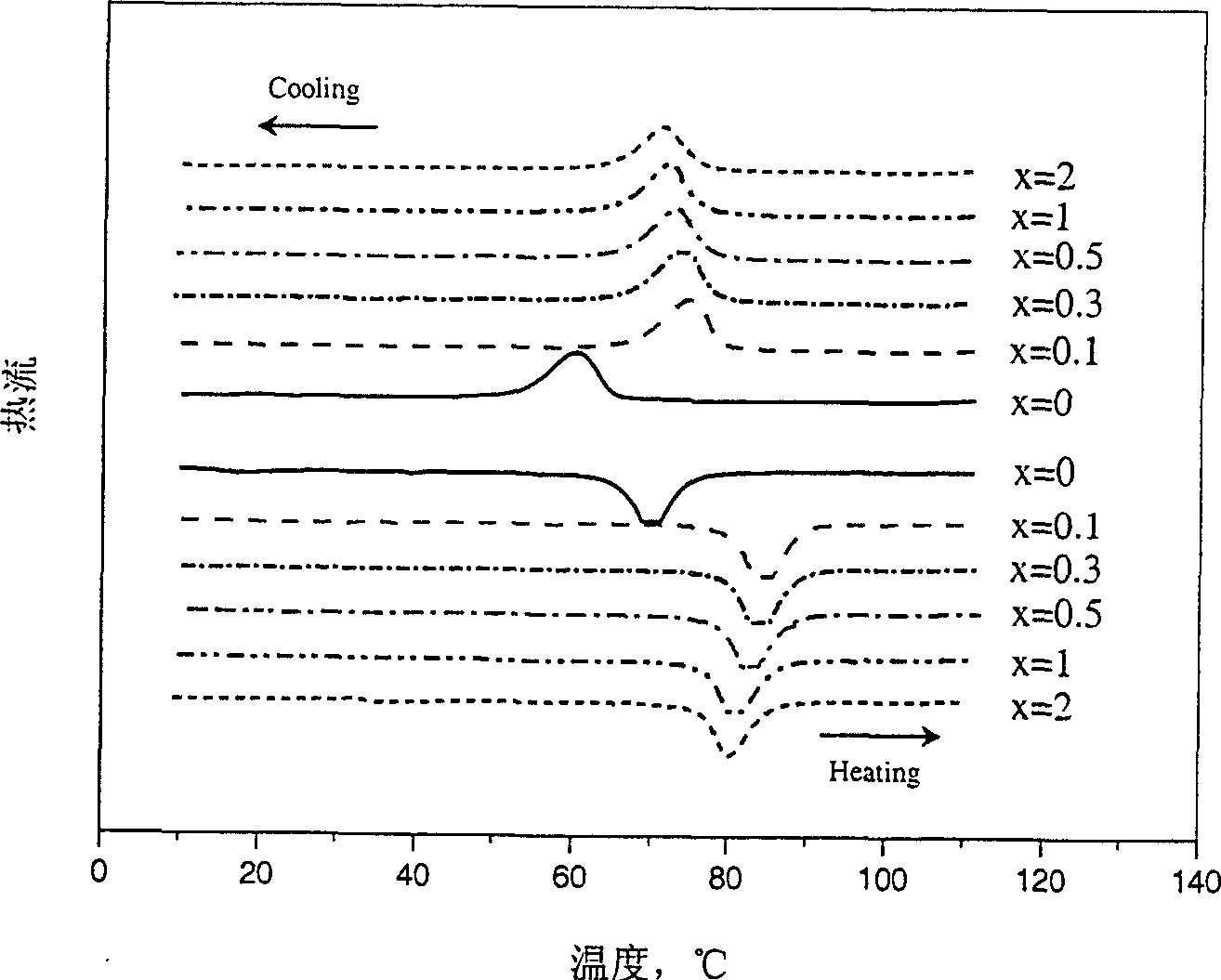

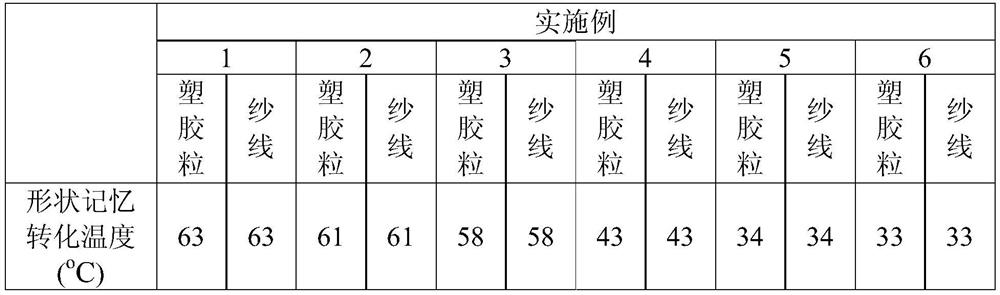

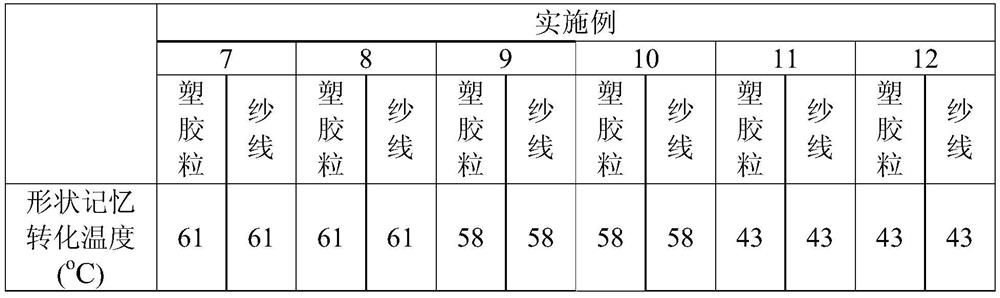

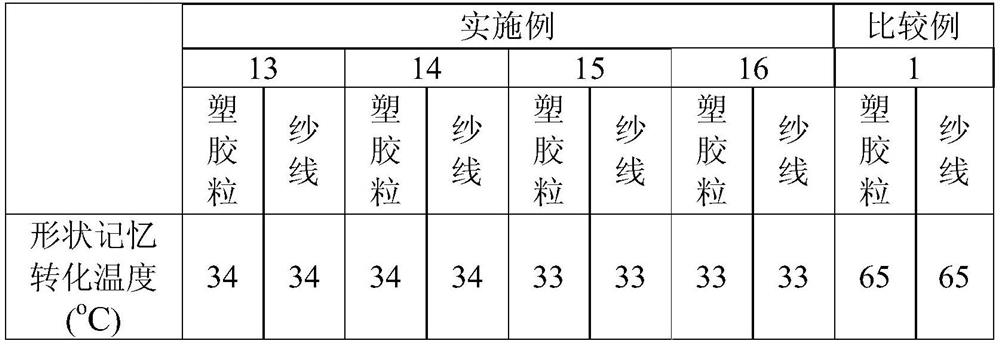

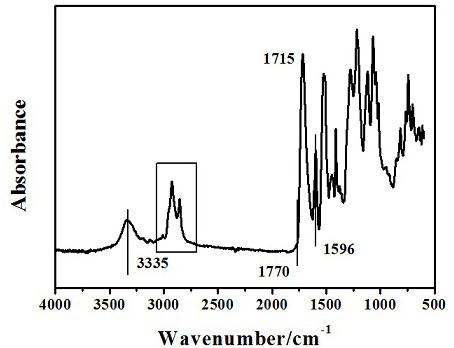

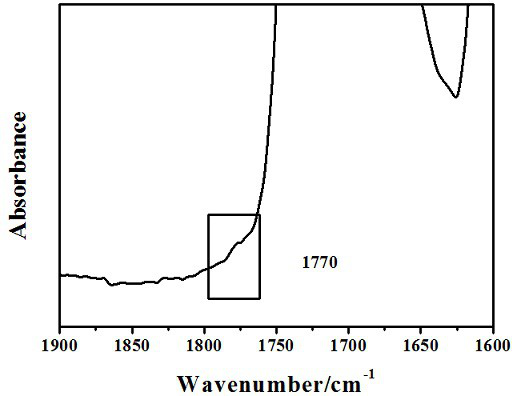

Plastic pellets and yarn

The invention provides a plastic particle and a yarn, the plastic particle includes shape-memory polyurethane, polyurethane and a polyurethane-type dispersant, wherein the shape-memory polyurethane is formed by the following steps: polymerizing a diisocyanate and a polyol to form a polymer, and The polymer is polymerized with a chain extender to form shape memory polyurethane. The yarn is made of the plastic pellets. The plastic particles and yarns have shape memory properties, and have good shape fixation rate, shape recovery rate, textile processability and textile applicability.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

Bidirectional Linear Actuator Based on Shape Memory Material Actuator

InactiveCN102889188BHas shape memory propertiesLarge drive output displacementMachines/enginesMechanical power devicesPull forceAlloy

The invention discloses a two-way linear driver based on a shape memory material actuator and belongs to a linear driver technique. A stator and an end cover are respectively and fixedly arranged at the two end parts of a shell through a stator installation bolt and an end-cover installation bolt, a rotor is configured in the shell, the two side parts of the rotor are respectively inserted in the central holes of the stator and the end cover, an S-shaped shape memory polymer composite material actuator is configured in a central inner hole on one side of the rotor, the two ends of the S-shaped shape memory polymer composite material actuator are respectively fixedly connected with the stator and the rotor through a stator bolt and a power bolt, and the two ends of a shape memory alloy tension spring are respectively connected with the stator and the rotor. The driver disclosed by the invention is simple and compact in structure, large in drive output displacement, reliable in use, easy to operate and controllable in displacement, and can be used for achieving an effect of two-way linear drive.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing poly(trimethylene terephthalate) fibre having shape memory characteristic

InactiveCN101200821BNo residual stressStable unwindingMelt spinning methodsMonocomponent polyesters artificial filamentPolymer sciencePolyethylene terephthalate

The invention discloses a preparation method of polytrimethylene terephthalate fiber with shape memory characteristics, including: firstly, selected polyester polymer is provided with at least 0.8dL / g of intrinsic viscosity and contains at least 85mol percent of polytrimethylene terephthalate, wherein, at least 85mol percent of the repeating unit is composed of three-methylene; secondly, the polyester polymer is melted and transported through a screw melting extruder, the melting body is metered through a metering pump and is extruded out through a spinneret, and as-spun fibers are drafted successively through a pair of drafting hot rollers after being cooled through lateral blowing; thirdly, the drafted fibers are introduced into a group of grouping roller stereotype boxes with steam; fourthly, tow is introduced into a winding head to be winded into mold. The fiber made through the invention has the advantages of good packaging appearance forming, good structural stability and soft handle. And with lower modulus, the fiber is still provided with good elasticity and tensile recoverability. The textiles made of the fiber which are produced through the process are provided with goodshape memory characteristics.

Owner:方圆化纤有限公司

Thermally reversible crosslinked polyurethane containing dicyclopentadiene crosslinked bridge, preparation method and application thereof

ActiveCN110128618BEnables repeated reprocessingEnables thermoplastic processingPolymer scienceCross linker

The invention provides thermally reversible crosslinked polyurethane containing dicyclopentadiene crosslinking bridged bonds, and a preparation method and applications thereof. Dicyclopentadiene dicarboxylic acid and polyisocyanate (I) carry out reactions to generate a terminal isocyanate component, which contains a dicyclopentadiene structure and is taken as a crosslinking agent, and the terminalisocyanate component and a terminal hydroxyl component carry out reactions to form a crosslinked polyurethane network. By introducing dicyclopentadiene bridged bonds into polyurethane, at a high temperature, bridged bonds are broken; at a low temperature, bridged bonds are formed again; and repeated processing of chemical crosslinking type polyurethane is realized. The primary reverse Diels-Alderreaction temperature of dicyclopentadiene bridged bonds is 170 DEG C; and dicyclopentadiene bridged bonds are introduced into polyurethane to realized thermoplastic processing of crosslinking type polyurethane in a temperature range of 170 to 210 DEG C. The prepared thermally reversible polyurethane has an excellent repeated processing property, and still has good mechanical properties after manytimes of processing and moulding.

Owner:BEIJING UNIV OF CHEM TECH +1

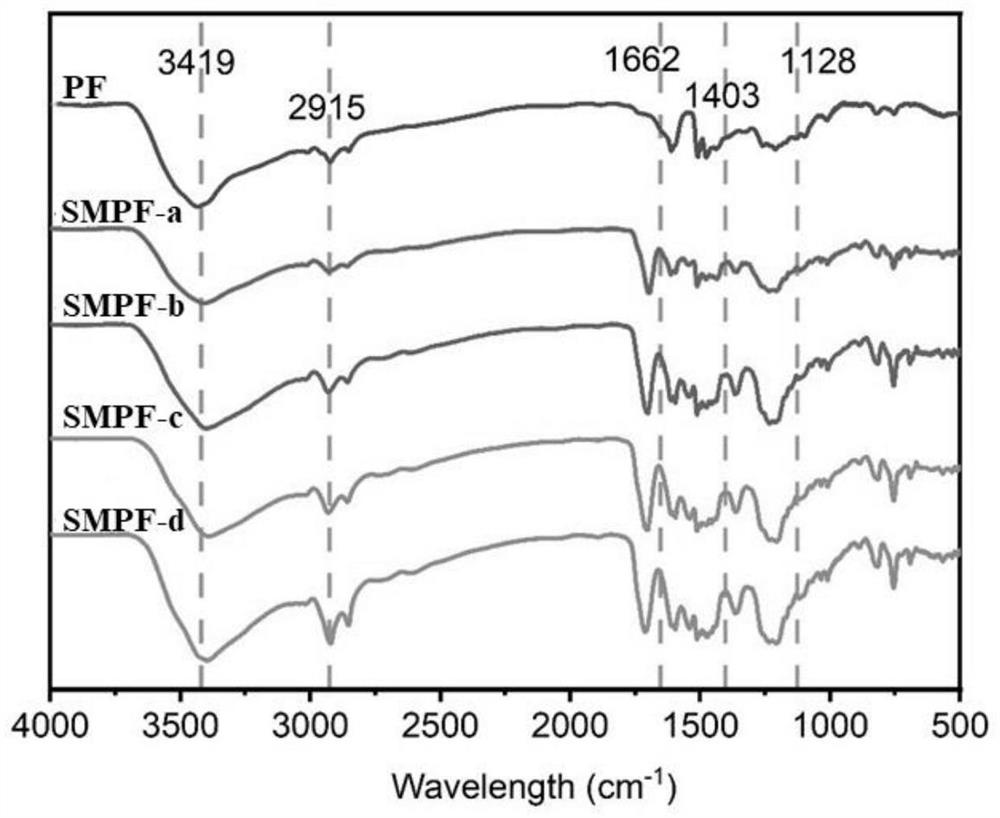

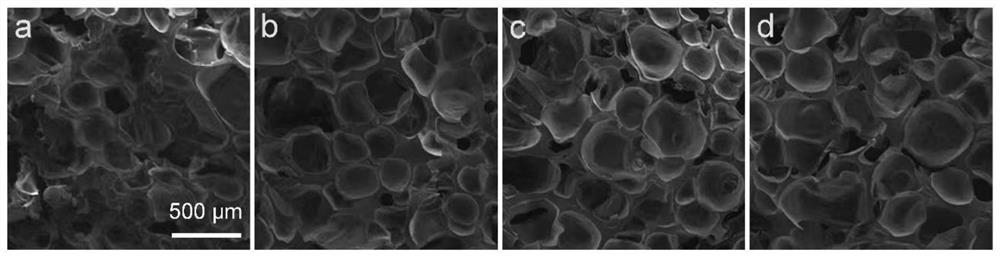

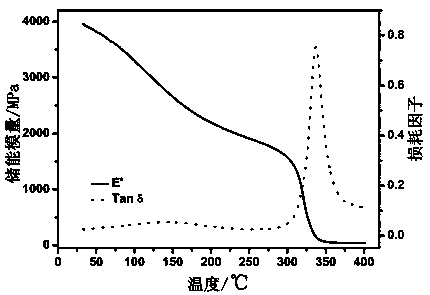

Shape memory phenolic foam and preparation method thereof

The invention provides shape memory phenolic foam and a preparation method thereof, and belongs to the technical field of shape memory polymer synthesis. The shape memory phenolic foam comprises the following components in parts by weight: 100 parts of A-stage phenolic resin, 10-30 parts of a toughening agent, 1-15 parts of a curing agent, 5-10 parts of a foaming agent and 5-10 parts of a surfactant, the toughening agent is prepared from diisocyanate. A long flexible chain is introduced to a benzene ring structure of resole phenolic aldehyde, so that the flexibility of a phenolic aldehyde structure is improved, the distance between cross-linking points in the shape memory phenolic foam is increased, and the molecular structure of the shape memory phenolic foam has two molecular chain segment structures, namely a hard segment and a soft segment; the soft section and the hard section (benzene ring) are matched, so that the phenolic foam has shape memory performance, the deformability is improved, the shape recovery rate is high, and the shape fixation rate and the shape recovery rate are high.

Owner:HARBIN INST OF TECH

A gas separation membrane with shape memory properties

ActiveCN106902652BHas shape memory propertiesLarge specific surface areaSemi-permeable membranesMembranesVitrificationStationary phase

The invention discloses a gas separation membrane having a shape memory property; the gas separation membrane is prepared by the steps: firstly, forming a copolymerized linear oligomer from dianhydride 4,4'-(hexafluoroisopropylidene)diphthalic anhydride, diamine 4,4'-diaminodiphenyl ether and 2-(4-aminophenyl)-5-aminobenzoxazole, then carrying out a reaction of the copolymerized linear oligomer with 2,4,6-triaminopyrimidine gradually to form hyperbranched macromolecules, and finally, carrying out thermal imidization to obtain a hyperbranched polyimide membrane. The hyperbranched polyimide membrane has large specific surface area and can achieve gas adsorption; by adjusting the stiffness and flexibility of a structure of polyimide, the hyperbranched polyimide membrane has different adsorption characteristics on different gases, so as to achieve gas separation characteristics. In addition, the hyperbranched polyimide has obvious glass transition temperature, the transition can be used as a shape memory reversible phase, mutual entanglement of macromolecular chains and intermolecular strong interaction force in the polyimide structure can be used as a stationary phase, and thus the hyperbranched polyimide is endowed with the shape memory property.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com