Thermally reversible crosslinked polyurethane containing dicyclopentadiene crosslinked bridge, preparation method and application thereof

A technology of crosslinking polyurethane and dicyclopentadiene, which is applied in the field of polymer materials, can solve the problems of inability to obtain heat resistance of thermoplastic processing temperature materials, poor heat resistance, high temperature thermal oxygen aging of polymers, etc., and achieve excellent repeated processing Sexuality and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

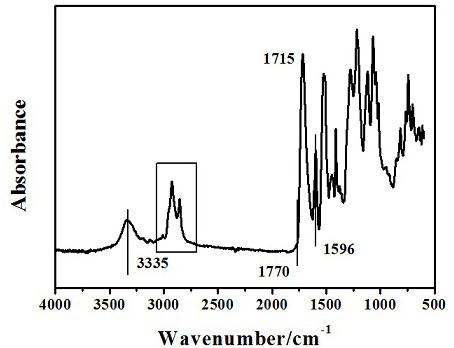

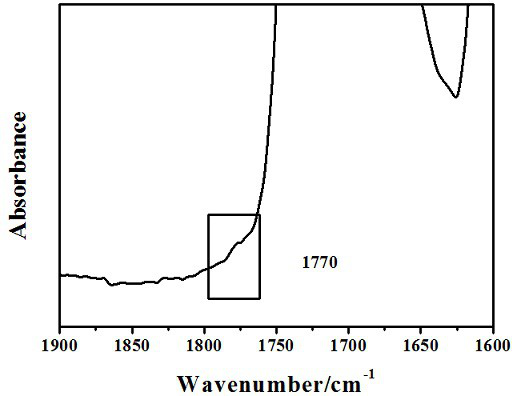

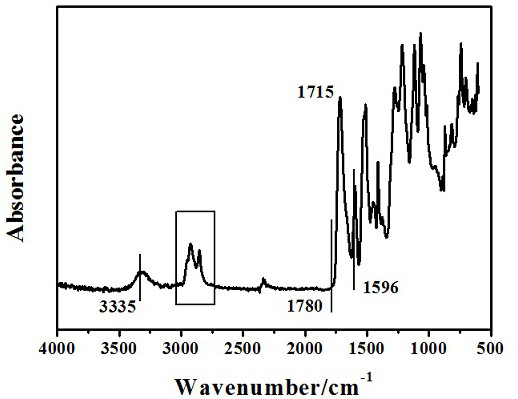

Image

Examples

Embodiment 1

[0055] A method for preparing a thermally reversible cross-linked polyurethane containing dicyclopentadiene cross-linked bridges, the steps are as follows:

[0056] (1) Preparation of hydroxyl-terminated polyurethane prepolymer

[0057] Take 117.89g (0.40mol) of polyester polyol PS1922 and place it in a 500ml three-neck flask, then weigh 28.97g (0.20mol) of liquefied diphenylmethane diisocyanate and pour it into the bottle. One port of the three-neck flask is connected to mechanical stirring, the other port is connected to the inlet of high-purity nitrogen gas, and the other port is connected to the gas outlet. Stirring and reacting for 3 hours at 60°C under high-purity nitrogen to obtain a hydroxyl-terminated polyurethane prepolymer;

[0058] (2) Preparation of isocyanate-terminated component (crosslinking agent)

[0059] Weigh 2.20g (0.02mol) of a crosslinking agent containing dicyclopentadiene dicarboxylic acid and place it in a 100ml three-necked flask, add 6.60g of diox...

Embodiment 2

[0065] A method for preparing a thermally reversible cross-linked polyurethane containing dicyclopentadiene cross-linked bridges, the steps are as follows:

[0066] (1) Preparation of hydroxyl-terminated polyurethane prepolymer

[0067] Take 117.89g (0.40mol) of polyester polyol PS1922 and place it in a 500ml three-neck flask, then weigh 28.97g (0.20mol) of liquefied diphenylmethane diisocyanate and pour it into the bottle. One port of the three-neck flask is connected to mechanical stirring, the other port is connected to the inlet of high-purity nitrogen gas, and the other port is connected to the gas outlet. Stirring and reacting for 3 hours at 60°C under high-purity nitrogen to obtain a hydroxyl-terminated polyurethane prepolymer;

[0068] (2) Preparation of terminal isocyanate group components

[0069] Weigh 3.30g (0.03mol) of cross-linking agent containing dicyclopentadiene structure into a 100ml three-necked flask, add 9.90g of dioxane, then add 14.23g (0.105mol) of P...

Embodiment 3

[0073] A method for preparing a thermally reversible cross-linked polyurethane containing dicyclopentadiene cross-linked bridges, the steps are as follows:

[0074] (1) Preparation of hydroxyl-terminated polyurethane prepolymer

[0075] Take 117.89g (0.40mol) of polyester polyol PS1922 and place it in a 500ml three-neck flask, then weigh 28.97g (0.20mol) of liquefied diphenylmethane diisocyanate and pour it into the bottle. One port of the three-neck flask is connected to mechanical stirring, the other port is connected to the inlet of high-purity nitrogen gas, and the other port is connected to the gas outlet. Stirring and reacting for 6 hours at 50°C under high-purity nitrogen to obtain a hydroxyl-terminated polyurethane prepolymer;

[0076] (2) Preparation of terminal isocyanate group components

[0077] Weigh 1.10g (0.01mol) of cross-linking agent containing dicyclopentadiene structure into a 100ml three-necked flask, add 1.10g of dioxane, then add 14.23g (0.105mol) of P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com