A sea-island fiber synthetic leather base cloth and its production process

A sea-island fiber and production process technology, which is applied in the field of sea-island fiber synthetic leather base fabric and its production process, can solve problems such as composite fiber pollution, achieve high peeling strength, smoother appearance and texture on the cloth surface, and improve the effect of thermal decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

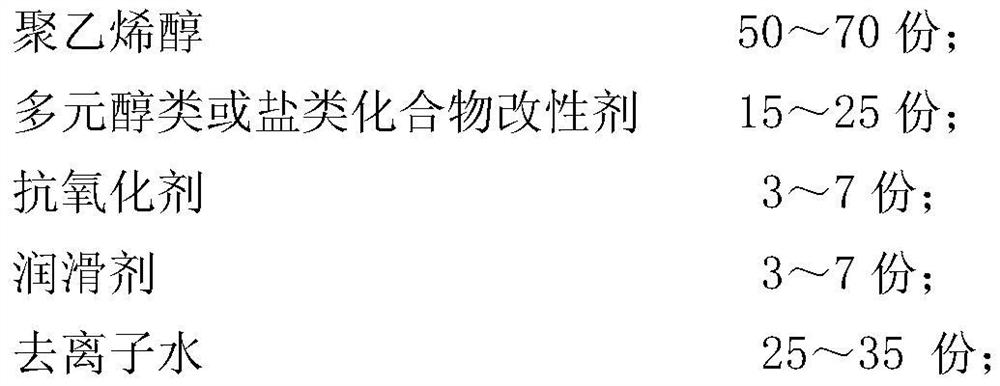

[0045] This embodiment is a kind of sea-island fiber synthetic leather base cloth, which is composed of water-soluble sea-island fiber and forms a network of three-dimensional network structure through needle punching. The sea-island fiber needle-punched cloth layer is composed of water-soluble PVA The PA material is made of sea-island fibers composed of island phase components by laying and needle punching. The island phase components of the sea-island fibers account for 60% of the fiber cross-sectional area, and the sea component accounts for 40% of the fiber cross-sectional area. The sea-island fiber The fineness of the fiber is 1.6-14dtex, the breaking strength is 3-6cN / dtex, the elongation at break is 7-10%, the single fiber fineness of the island component is below 0.8dtex, and the PVA is water-soluble PVA masterbatch. The water-soluble PVA The masterbatch is formed by fusing raw materials in the following proportions by weight: 50 parts of polyvinyl alcohol; 15 parts of ...

Embodiment 2

[0062] The same part of this embodiment and embodiment 1 will not be repeated, and its difference is:

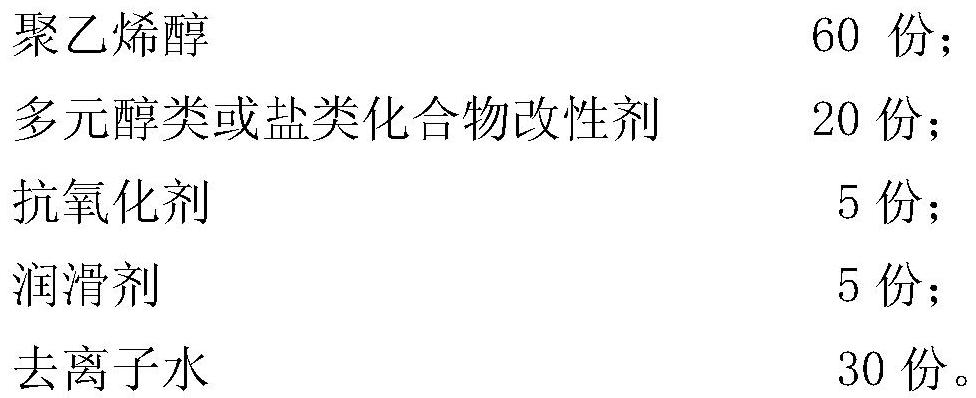

[0063] An island-in-the-sea fiber synthetic leather base cloth is composed of water-soluble island-in-the-sea fibers that are needled to form a three-dimensional network structure. The sea-island fiber needle-punched cloth layer consists of water-soluble PVA as the sea phase component, PA The material is made of sea-island fibers of island phase components. The sea-island fiber is made by laying nets and needle punching. The island phase component of the sea-island fiber accounts for 70% of the cross-sectional area of the fiber, and the sea component accounts for 30% of the cross-sectional area of the fiber. The fineness of the sea-island fiber is 1.6-14dtex, and the breaking strength is 3 ~6cN / dtex, the elongation at break is 7~10%, the single fiber fineness of the island component is below 0.8dtex, the PVA is a water-soluble PVA masterbatch, and the water-soluble PVA m...

Embodiment 3

[0080] The same part of this embodiment and embodiment 1, 2 will not be repeated, and its difference is:

[0081] An island-in-the-sea fiber synthetic leather base cloth, which is composed of water-soluble island-in-the-sea fibers and forms a three-dimensional network structure through needle punching. The sea-island fiber needle-punched cloth layer is composed of water-soluble PVA as the sea phase component, The PA material is made of sea-island fibers of the island phase component. The sea-island fiber is made by laying nets and needle punching. The island phase component of the sea-island fiber accounts for 85% of the cross-sectional area of the fiber, and the sea component accounts for 15% of the cross-sectional area of the fiber. The fineness of the sea-island fiber is 1.6-14dtex, and the breaking strength is 3-6cN / dtex, the elongation at break is 7-10%, the single fiber fineness of the island component is below 0.8dtex, and the PVA is a water-soluble PVA masterbatch,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com