Thermoplastic polyvinyl alcohol-soapstone composite material and preparation method thereof

A kind of polyvinyl alcohol, composite material technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

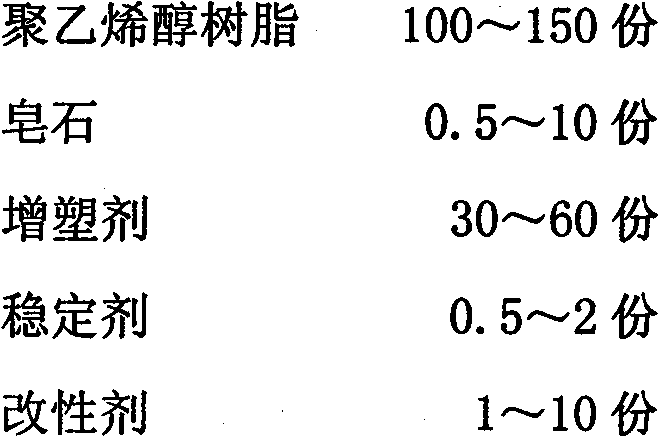

Method used

Image

Examples

Embodiment 1

[0036] Add 0.5 part of soapstone and 10 parts of water into a low-speed mixer, stir and mix at room temperature for 30 minutes, and then seal and place at room temperature for 1 hour; then add the above mixture, 100 parts of polyvinyl alcohol resin, and 30 parts of formamide , 0.5 part of fatty acid calcium, 1 part of citric acid. First, it is fully mixed by a high-speed stirring mixer at a stirring speed of 1000 rpm, sealed and placed for 48 hours, and then added to a screw extruder at 115° C. and a screw speed of 30 rpm for direct extrusion to obtain a thermoplastic polyvinyl alcohol-saponite composite material.

Embodiment 2

[0038] Add 10 parts of soapstone and 25 parts of water to a low-speed mixer, stir and mix at room temperature for 60 minutes, and then seal and place at room temperature for 1 hour; then add the above mixture, 150 parts of polyvinyl alcohol resin, and 60 parts of acetamide , 2 parts of fatty acid calcium, 10 parts of glutamic acid. First, it is fully mixed by a high-speed stirring mixer at a stirring speed of 2000 rpm, sealed and placed for 48 hours, and then added to a screw extruder at 140° C. and a screw speed of 80 rpm for direct extrusion to obtain a thermoplastic polyvinyl alcohol-saponite composite material.

Embodiment 3

[0040] Add 3 parts of soapstone and 10 parts of water to a low-speed mixer, stir and mix for 30 minutes at room temperature, and then seal and place at room temperature for 1 hour; then add the above mixture, 150 parts of polyvinyl alcohol resin, and 50 parts of formamide , 1 part of fatty acid calcium, 10 parts of urea. First, it is fully mixed by a high-speed stirring mixer at a stirring speed of 1500 rpm, sealed and placed for 48 hours, and then directly extruded into a screw extruder at 115°C and a screw speed of 60 rpm to obtain a polyvinyl alcohol-saponite composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com