Patents

Literature

326results about How to "No effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lepidopteran-active Bacillus thuringiensis delta-endotoxin compositions and methods of use

InactiveUS6593293B1Low steady state levelGreat and less stabilityBiocideBacteriaDelta endotoxinAureobasidium sp.

Disclosed are Bacillus thuringiensis strains comprising novel crystal proteins which exhibit insecticidal activity against lepidopteran insects. Also disclosed are novel B. thuringiensis genes and their encoded crystal proteins, as well as methods of making and using transgenic cells comprising the novel nucleic acid sequences of the invention.

Owner:MONSANTO TECH LLC

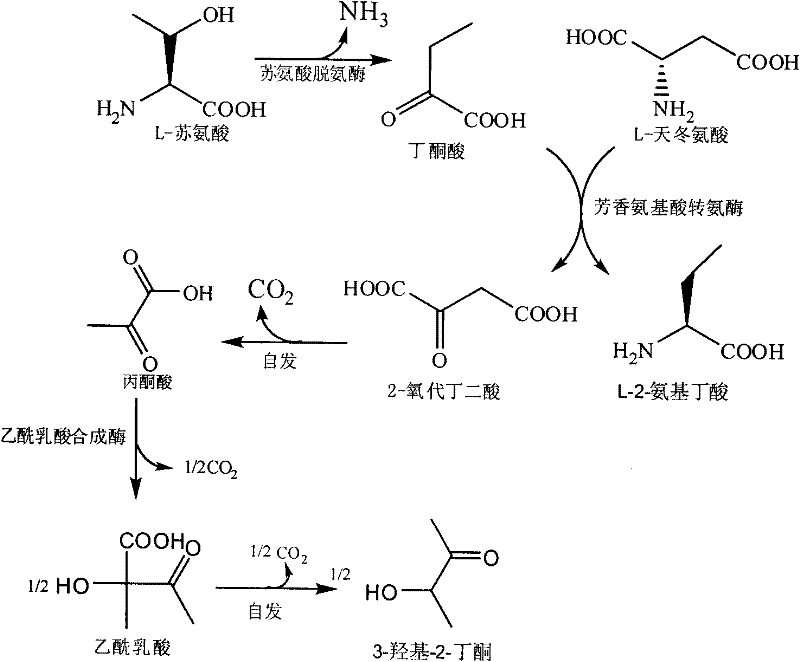

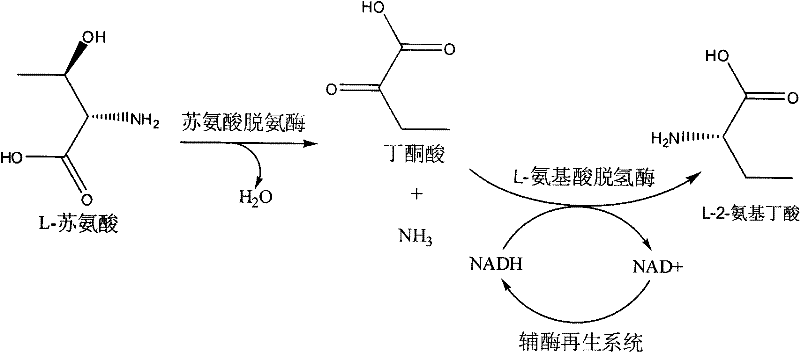

Method for producing L-2-aminobutyric acid

The invention discloses a method for producing L-2-aminobutyric acid, and the method comprises the following step: catalyzing L-threonine utilized as a raw material through an enzyme catalysis system consisting of threonine deaminase, L-amino acid dehydrogenase and coenzyme regeneration systems, thus producing the L-2-aminobutyric acid. The method for producing theL-2-aminobutyric acid has the advantages that the raw material is low in price, the property is stable, and the production cost of the L-2-aminobutyric acid can be greatly lowered, the conversion rate and product concentricity are high, no influence caused by byproducts exists, and the method is suitable for industrialization application.

Owner:湖州颐盛生物科技有限公司

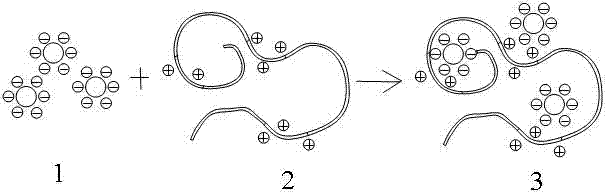

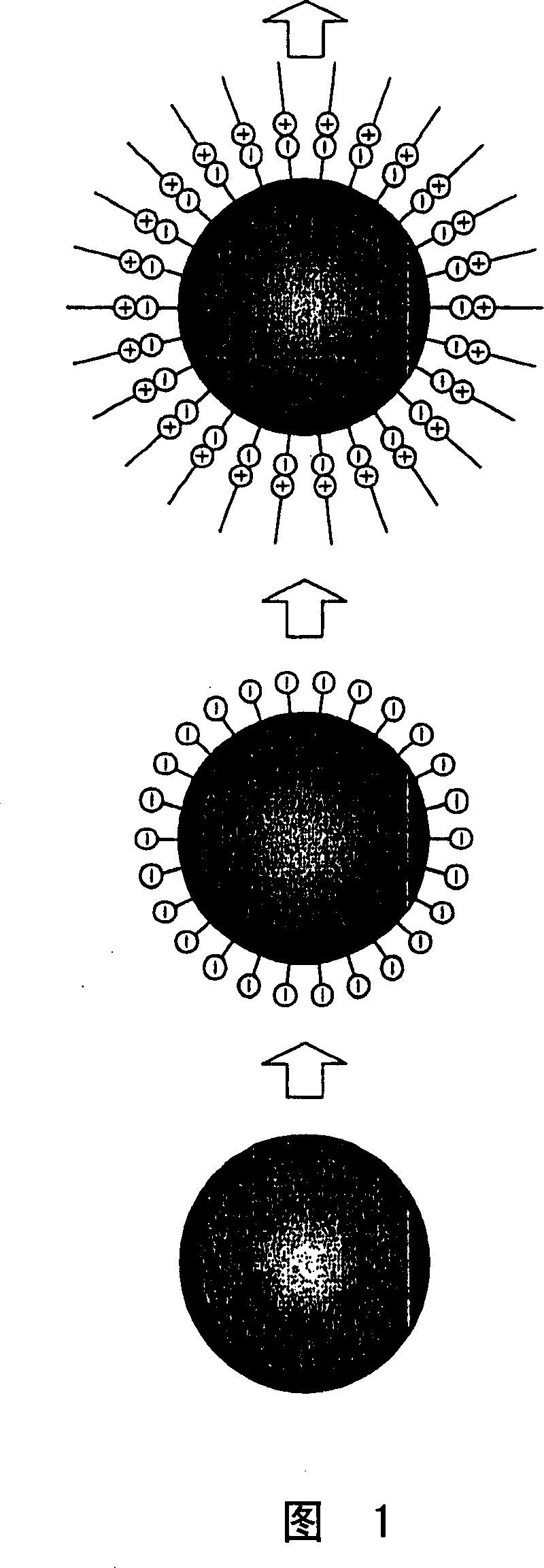

Quantum dot/acrylate polymer nanocrystal complex, preparation method of quantum dot/acrylate polymer nanocrystal complex, and colored conversion coating

ActiveCN103772872AGood dispersionEvenly dispersedPhotomechanical coating apparatusPhotosensitive materials for photomechanical apparatusPhotoluminescenceResin matrix

The invention discloses a quantum dot / acrylate polymer nanocrystal complex, a preparation method of the quantum dot / acrylate polymer nanocrystal complex, and a colored conversion coating, wherein the quantum dot / acrylate polymer nanocrystal complex is prepared by virtue of electrostatic interaction between an annion acrylate polymer and quantum dots with opposite charges. According to the invention, the quantum dots are pre-dispersed into the acrylate polymer, so as to prepare quantum dot / acrylate polymer nanocrystal complex. By virtue of similar composition of an acrylate polymer protection layer and acrylics as well as an acrylics modified photoresist resin matrix, the quantum dots can be easily dispersed into photoresist, are not easy to separate and are uniformly dispersed without aggregation, and thus the photoluminescent characteristic of the quantum dots is ensured. After the colored conversion coating prepared from the quantum dot / acrylate polymer nanocrystal complex is applied to a display, the colors of sub-pixel units of R / G / B colors corresponding to the colored conversion coating are relatively pure and have the relatively high saturability, energy of a backlight is sufficiently utilized, and the luminous efficiency is relatively high.

Owner:TCL CORPORATION

Quick roasting method of fresh grosvenor momordica

ActiveCN102100394AGuaranteed circulationExtend the baking timeFood preservationPharmaceutical product form changeTime rangeMicrowave oven

The invention discloses a quick roasting method of a fresh grosvenor momordica, which comprises the following steps: (1) classifying the ripe grosvenor momordica according to large, middle and small specifications and respectively placing into a special roasting tray used for a microwave oven; (2) placing the roasting tray filled with the grosvenor momordica into an intelligent microwave vacuum drying oven; and (3) determining the roasting time according to the weight of the grosvenor momordica and the power of the microwave oven and roasting, wherein the roasting temperature range is 20-40 DEG C, and the roasting time range is 30-150 minutes under the condition of vacuum degree less than -0.08MPa. In the method, the microwave technology for roasting is utilized, the roasting process is carried out at low temperature and constant temperature, the time consumption is short, the cost is low, and the fresh grosvenor momordica well keeps the bright yellow color and nutrition constituents and has good taste.

Owner:桂林普兰德生物科技有限公司

Method for producing high magnetic induction grain-oriented silicon steel

The invention relates to a method for producing high magnetic induction grain-oriented silicon steel, and belongs to the technical field of silicon steel production. The process comprises the following steps of: smelting, refining, and performing continuous casting to obtain a casting blank; performing hot rolling; normalizing, namely performing normalizing annealing and cooling; performing cold rolling at one time, wherein the cold rolling reduction ratio is 85 to 90 percent; nitriding by using a nitriding medium, namely dry NH3 at the temperature of between 600 and 740 DEG C for 5 to 40 seconds; decarburizing at the temperature of between 750 and 850 DEG C for 60 to 360 seconds, wherein the dew-point temperature is 25 DEG C; and annealing at a high temperature, and coating a stress coating. The method has the advantages that: a plate blank low-temperature heating process of nitriding at the temperature of between 600 and 740 DEG C and decarburizing annealing is adopted, the nitriding of a steel plate is not influenced by an oxidation film, the steel plate is uniformly nitrided, and efficiency is high; by controlling the nitriding and decarburizing processes, an appropriate amount of effective (Al, Si) N inhibitor is formed, and high magnetic property is achieved; and nitriding is performed at a low temperature, so energy consumption is low, and production cost is reduced.

Owner:SHOUGANG CORPORATION

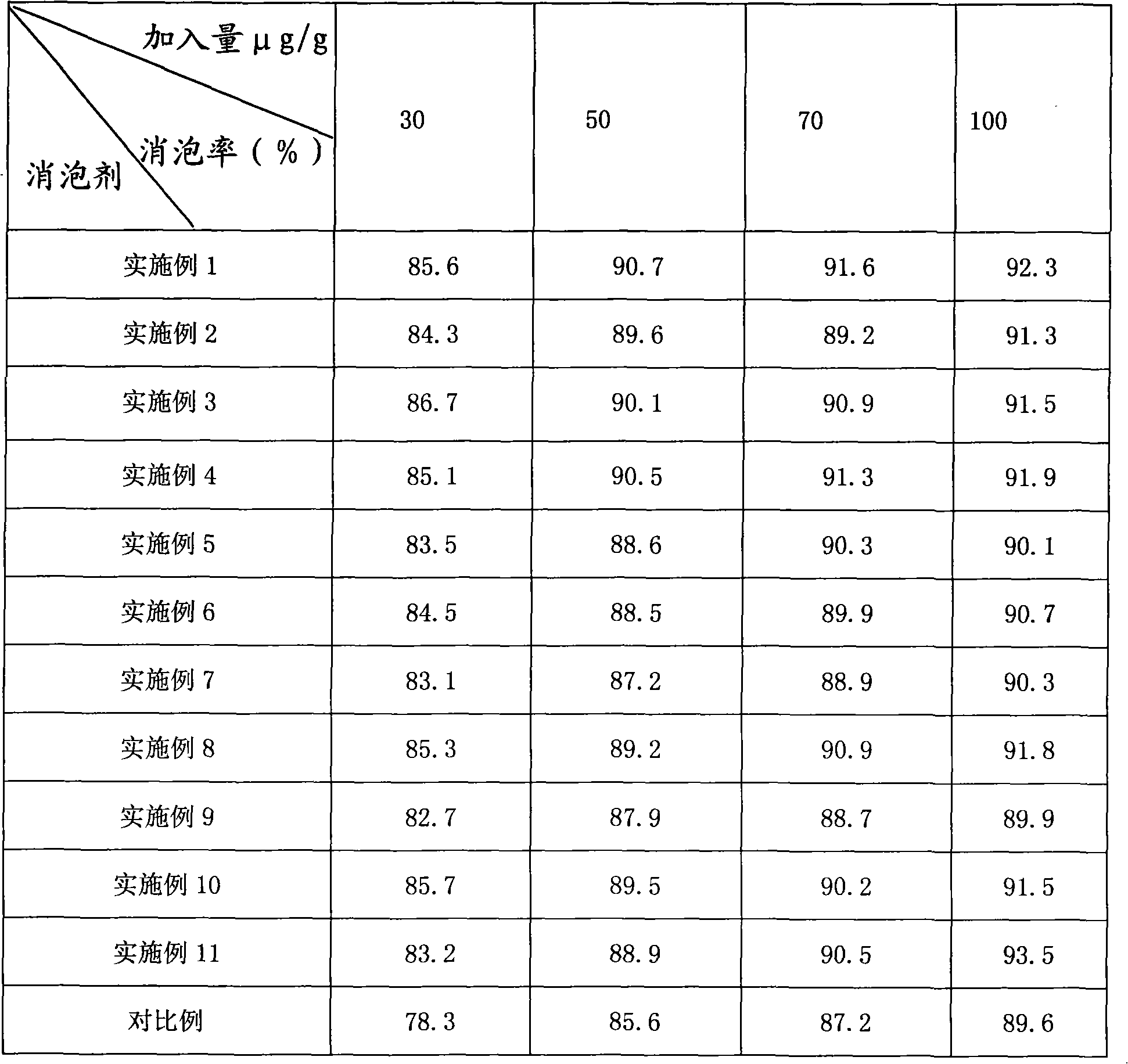

Delaying coking non-silicon defoaming agent with multiple active components and preparation method thereof

ActiveCN101780382ANo effectGood defoaming at high temperatureTransportation and packagingMixingAlcoholHigh carbon

The invention discloses a delaying coking non-silicon defoaming agent with multiple active components and a preparation method thereof, and the defoaming agent is formed by compounding 30-50 parts by weight of polyether or modified polyether polymer, 25-35 parts by weight of high-carbon alcohol mixture, 10-15 parts by weight of high-carbon alcohol fatty acid ester or fatty acyl amide and 15-20 parts by weight of alkymer. The preparation method of the defoaming agent comprises the following steps: adding the polyether or the modified polyether polymer, the high-carbon alcohol mixture, the high-carbon alcohol fatty acid ester or the fatty acyl amide and the alkymer into a reaction kettle according to the proportion, stirring, slowly increasing the temperature to 50-100 DEG C, carrying out reaction for 1-2h, finally stopping stirring, cooling, filtering for removing solid impurities and finally preparing the delaying coking non-silicon defoaming agent. The defoaming agent can effectively suppress and eliminate the formation of bubbles in a delayed coking reaction tower, improve the treatment capacity of the reaction tower, prolong the coking time of coke and prevent clogging phenomenon.

Owner:JIANGSU SAIOUXINYUE DEFOAMER

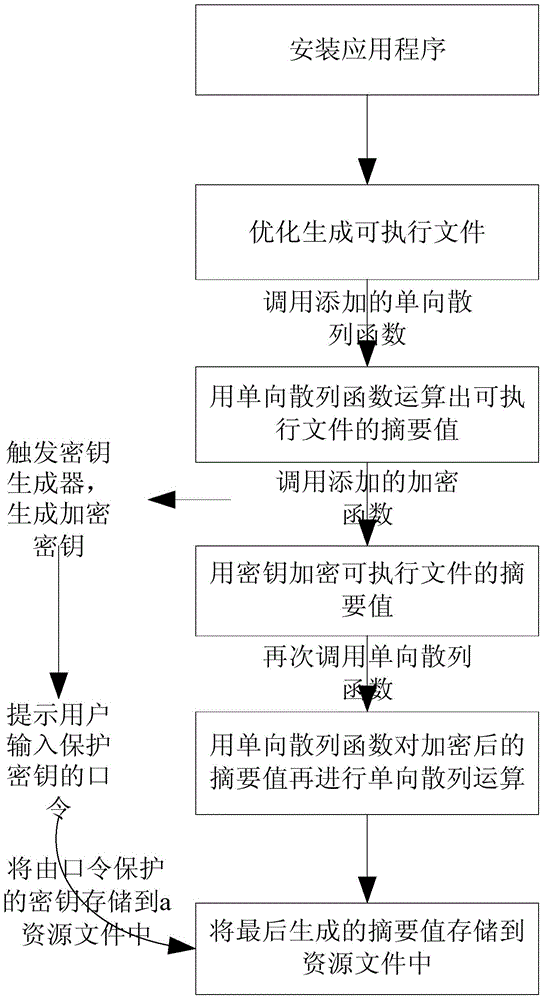

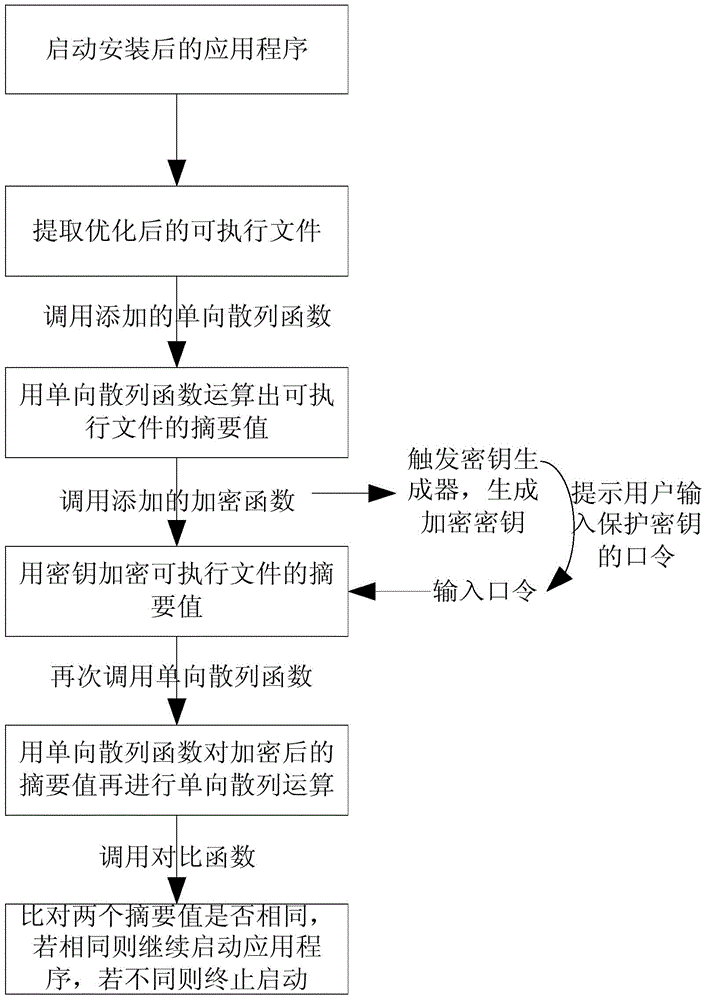

Method for protecting installed software on Android platform

InactiveCN104573490ANo effectAchieve protectionComputer security arrangementsSystem structureAuthentication

The invention discloses a method for protecting installed software on an Android platform. The method comprises the following steps: when an application program is installed, first, encrypting a digest value of an optimized executable code file by utilizing a private key, and finally, storing the encrypted digest value of the file; when the application program is installed, first, performing one-way hash operation on the optimized executable file to generate the digest value of the file, then, encrypting the generated digest value by utilizing a key, and finally, performing the one-way hash operation on the encrypted digest value again to obtain the digest value which serves as a root file for authentication. According to the method, the deficiency of an existing protecting scheme can be overcome, and the potential security hazard of an Android authentication mechanism can be eliminated; the Android system structure is not modified; any module is not required to be added; a developer of the application program is not affected.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Microbial preparation for purifying breeding wastewater

InactiveCN104152374AGood effectEasy to prepareBacteriaMicroorganism based processesWater contentMicrobiologic agent

The invention belongs to the technical field of environmental protection and discloses a microbial preparation for purifying breeding wastewater. A preparation method of the microbial preparation comprises the following steps: uniformly mixing mixed bacteria liquid, sawdust and diatomite according to a weight ratio of 1 to 1 to 1, drying at the low temperature of 4 DEG C, and controlling the water content to be 8%-10% after drying. The invention further discloses a use method of the microbial preparation. According to the microbial preparation, strains are reasonably mixed, are symbiotic and coordinative, and are not mutually antagonistic; the preparation method is simple and feasible, the operation is simple and convenient, and the industrialized production is facilitated.

Owner:河南恒野农牧股份有限公司

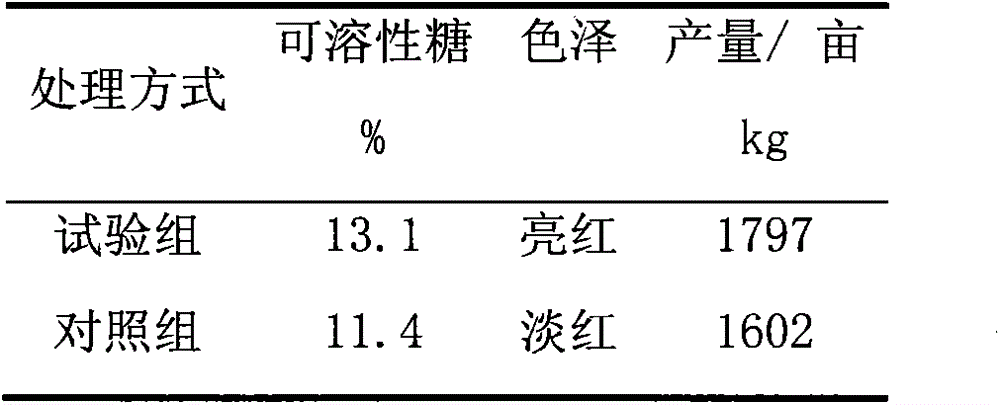

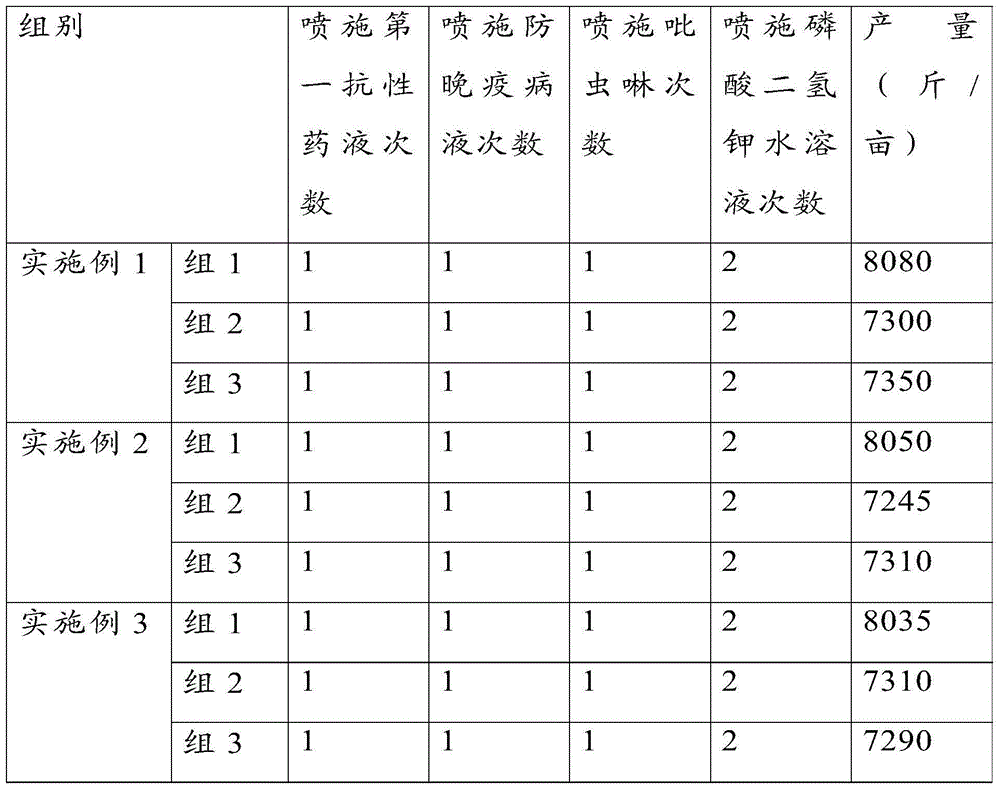

Method for planting potatoes

InactiveCN104472165AWarming up fastNo effectSeed and root treatmentPlant cultivationGround temperaturePlastic mulch

The invention relates to the field of crop planting, and particularly to a method for planting potatoes, which comprises the following steps: preparing land, fertilizing, and ditching; putting the potato seedlings into ditches, ridging, covering soil, covering parts on ridges, where the potato seedlings are planted, with colorless and transparent film, and covering two sides of the colorless and transparent film with black film; conducting field management, and harvesting potatoes. The method adopts the colorless and transparent film and the black film, which are in a matched manner, to plant the potatoes, the colorless and transparent film has good light transmittance and increases temperature quickly at the early stage, so the potatoes can root early; the black film has low visible light transmittance and can restrain weeds from growing, and the weeding rate can reach about 90 percent; during the middle and later periods of growth, the root systems enter below the black film, high temperature below the film, caused by strong sunlight, is prevented, and the premature senility of the root systems is avoided; the method can create a good environment for potato tuber growth in the period of tuberization, and has a ground temperature adjusting function that other film does not have; not only is the labor intensity of weeding reduced, but also the yield is increased by a large margin.

Owner:孔祥宜 +2

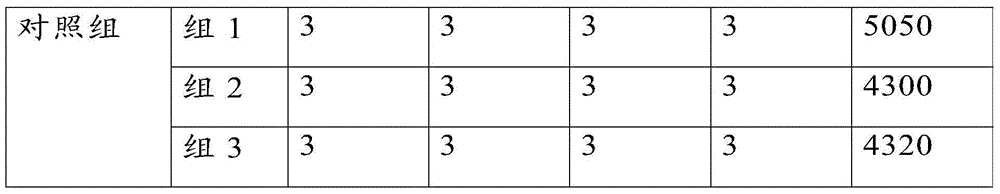

Bullet shooting counter

InactiveCN101126615AImprove reliabilityAccurate countFiring/trigger mechanismsContinuous useLiquid-crystal display

The utility model relates to a bullet shooting counting device, belonging to a bullet shooting counter, which comprises a single-chip microcomputer, a testing circuit of a magnetic field sensor, a power supply circuit, a keyboard circuit, a liquid crystal display circuit, a clock circuit, a communication circuit, a reset circuit, and a storage circuit. Compared with the prior art, the utility model has advantages of high reliability, precise countering, no affection on the normal shooting, and strong anti-interference performance. The utility model can be used to calculate the bullet speed in the bore of a gun, analyze the dynamical property of the bullet in the bore of a gun, and judge the technical feature of the guns, enabling the maintenance and the updating of multi counter system information with long time for continuous use.

Owner:ENG COLLEGE OF ENG CORPS PLA UNIV OF SCI & TECH

Novel sea-island fiber synthetic leather base cloth and production technology thereof

ActiveCN108589028ASolve pollutionNo emissionsConjugated synthetic polymer artificial filamentsNon-woven fabricsPolyethylene terephthalate glycolDecomposition

The invention discloses novel sea-island fiber synthetic leather base cloth. The novel sea-island fiber synthetic leather base cloth is a net which is prepared from water-soluble sea-island fibers byneedle punching and is of a three-dimensional network structure; a sea-island fiber needle-punched fabric layer is prepared from the sea-island fibers with water-soluble PVA (polyvinyl acetate) as a marine component and a PA (polyamide) or PET (polyethylene terephthalate) material as an island phase component by lapping and needle punching, wherein the island phase component accounts for 60%-85% of a fiber section area, the marine component accounts for 40%-15% of the fiber section area, denier of the sea-island fibers is 1.6-14 dtex, breaking strength is 3-6 cN / dtex, elongation at break is 7%-10%, single fiber denier of the island phase component is 0.8 dtex or lower, PVA is water-soluble PVA mater batch, and the melting point is 180-190 DEG C; the melting range is 175-195 DEG C, and thethermal decomposition temperature is 210-220 DEG C. The invention further discloses a production technology of the base cloth. The problem of pollution caused by the fact that complex fibers are treated and prepared from traditional PVA chips by adopting an organic solvent is solved, and the purpose of composite melt spinning with island phase resin is achieved.

Owner:浙江泓泰德建新纤维有限公司

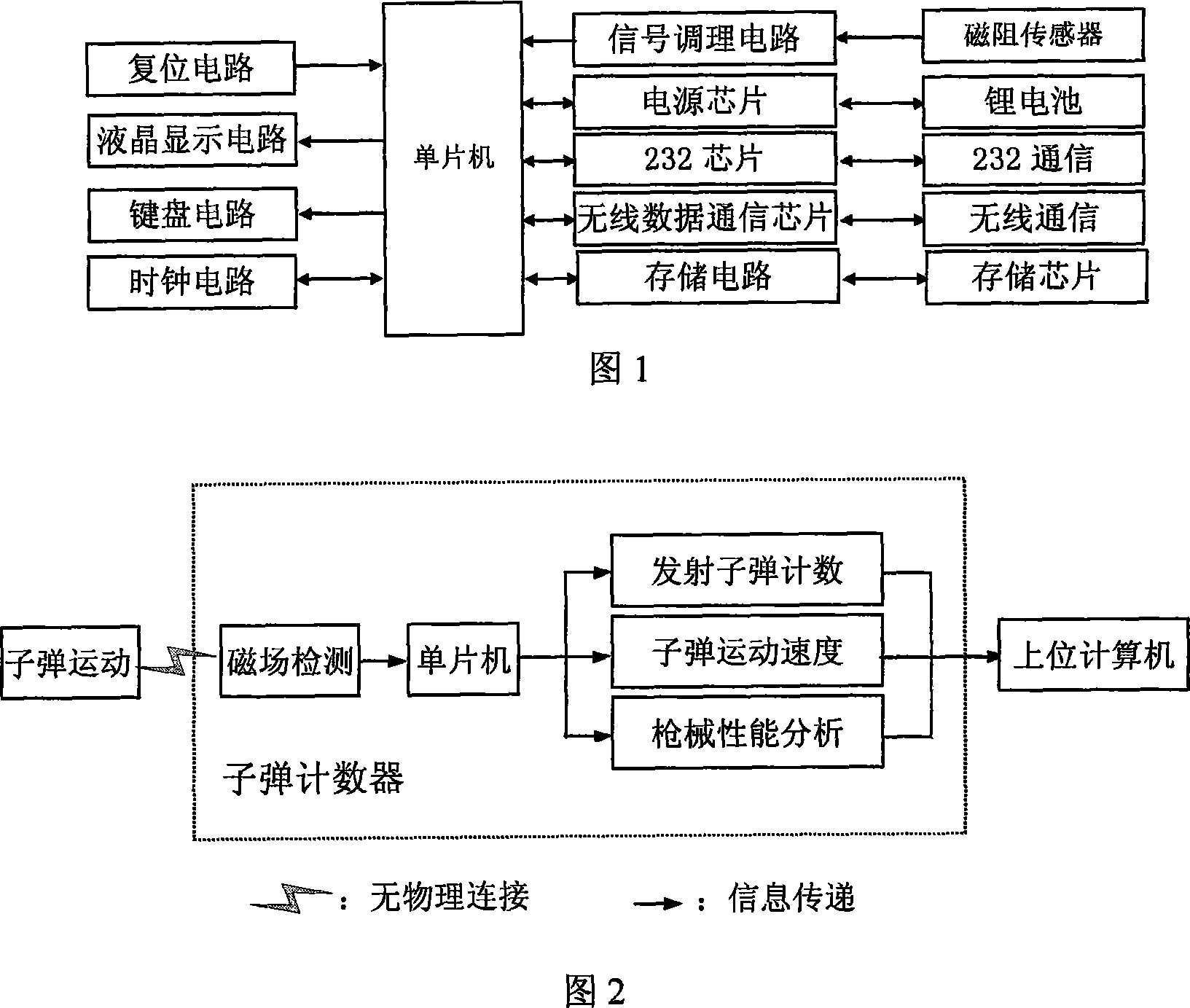

Aperture measuring method based on non-contacting type sensor combination

InactiveCN103278100AQuick and accurate measurementImprove detection accuracyUsing optical meansOptical axisDual sensor

The invention discloses an aperture measuring method based on non-contacting type sensor combination, is suitable for measuring the size of the inner diameter of a workpiece, and relates to the geometric sense measuring field. The method comprises the following steps: first, installing a main shaft of a double-sensor measuring head on a mechanism with the horizontal moving function so as to form a complete set of measuring system which is arranged in a workpiece to be measured; at measuring time, measuring optical axes of two sensors on the double-sensor measuring head being enabled to be on the same straight line; the double-sensor measuring head first rotating on a ZOY face, and then horizontally moving on an XOY face, finally the diameter of an inner hole of the workpiece to be measured is obtained; or, the double-sensor measuring head sequentially rotates on the ZOY face and the XOY face to obtain the diameter of the inner hole of the workpiece to be measured. When the method is used for measuring the diameter of the inner hole of the workpiece to be measured, only two procedures need operating theoretically, so that measuring efficiency is greatly improved, and a large number of measuring labor hours are saved. Moreover, the non-contacting measuring head is arranged on a lathe, a motion execution mechanism of the lathe is used for enabling the measuring head to rotate or move horizontally, so that on-machine accurate measuring can be achieved.

Owner:TIANJIN UNIV

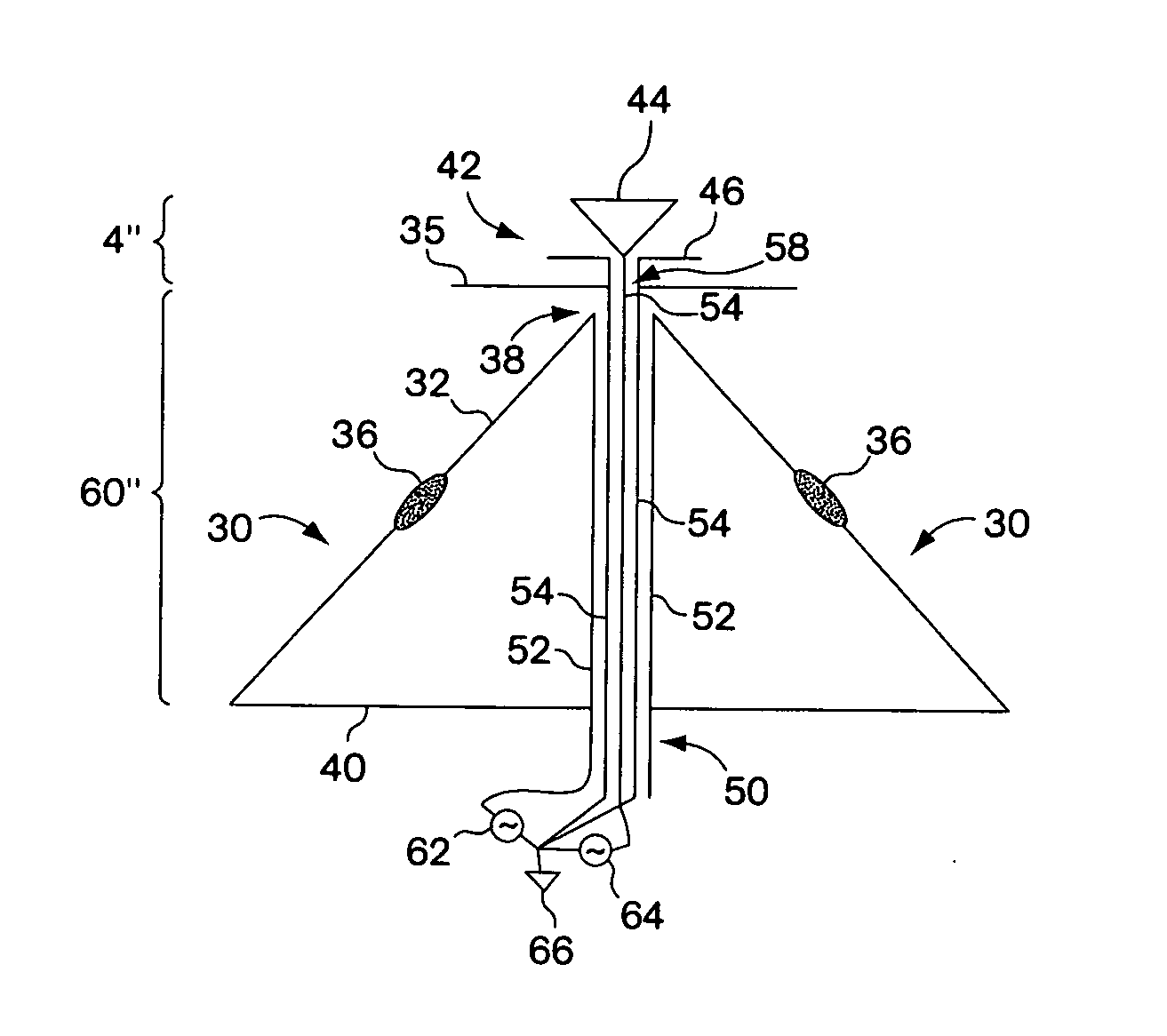

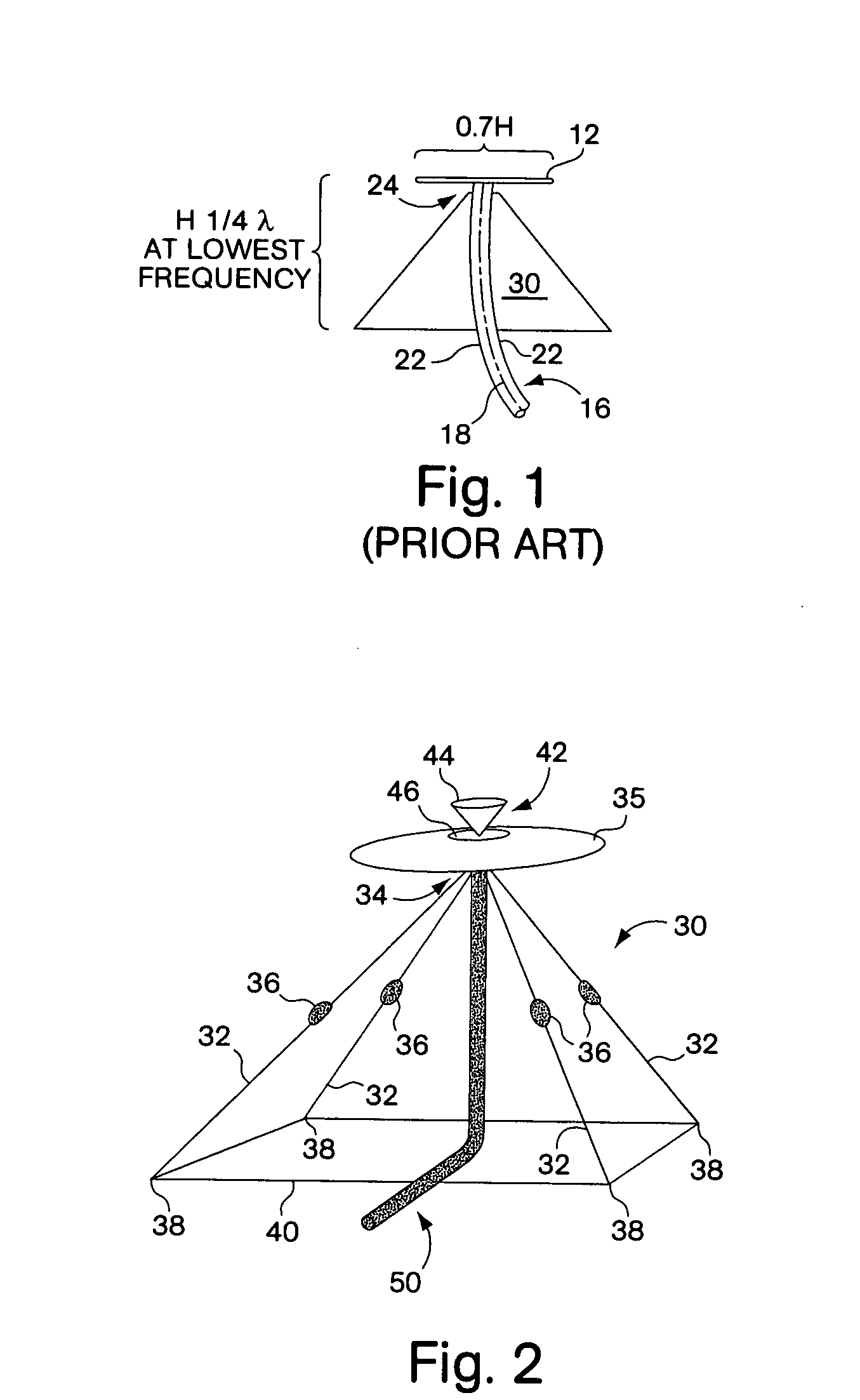

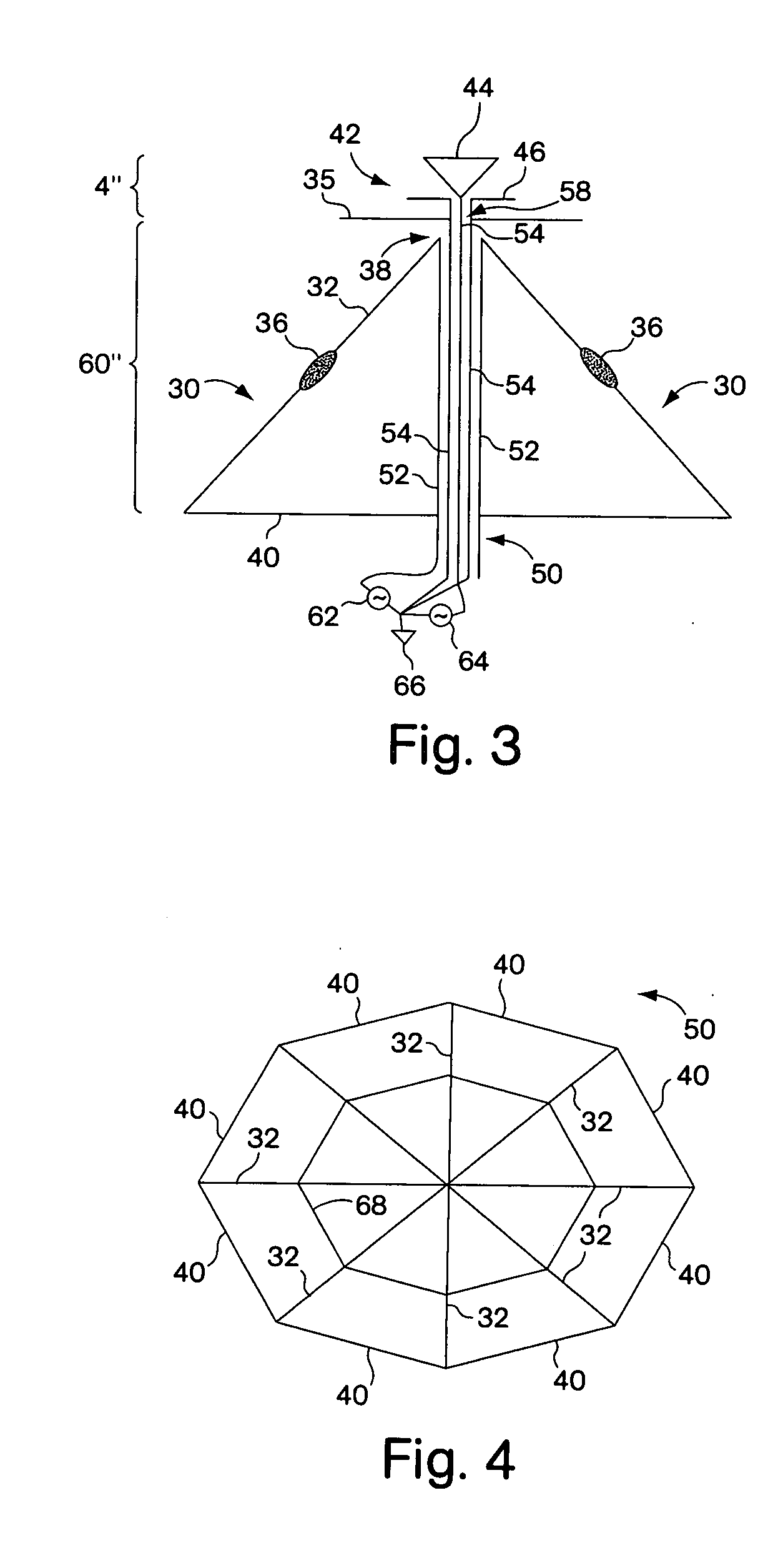

Collapsible wide band width discone antenna

InactiveUS20050168393A1Eliminate the effects ofReduce frequencyResonant long antennasCollapsable antennas meansCircular discCoaxial line

A collapsible discone antenna is provided with an ultra wide band width by providing a collapsible conical skeleton cone, with the rods of the skeleton being provided with meander lines so as to effectively reduce the overall dimensions of the antenna by a factor of 2, with the antenna rods being electrically interconnected at their distal ends so as to eliminate performance degradation due to varying ground conductivities. A specialized feed configuration is used in one embodiment to feed multiple antennas stacked above a low band disc through the utilization of one or more coaxial lines which are wrapped around a ferrite toroid so that they may be passed up through the low-band disc without detuning the low band discone antenna. The use of the toroid inductor between the low-band cone and the low-band disc further reduces the low frequency cutoff of the antenna by markedly decreasing the VSWR at frequencies as low as 20 megahertz.

Owner:SCHILMASS

Method for quantitatively detecting content of each component in mixture of polyester fiber and polypropylene fiber

The invention relates to a method for quantitatively detecting the content of each component in a mixture of polyester fiber and polypropylene fiber. The detection method comprises the following steps of: (1) putting a test sample with known dry weight which is pretreated by using a standard method into concentrated sulfuric acid in the mass volume ratio of 1g:(100-110ml), and stirring; (2) dissolving the polyester fiber in the mixture, performing sulfuric acid solution treatment, distilled water washing, diluted ammonia water neutralization and distilled water washing and treatment on the residual polypropylene fiber, filtering polypropylene into a glass sand core crucible, drying, weighing, and combining with a modified coefficient to obtain the percentage content of the polypropylene fiber; and (3) subtracting to obtain the content of the polyester fiber. The method has the advantages of accurate test data, nontoxicity of a used reagent to human bodies, no pollution on environment, safety and reliability.

Owner:INST OF WOOL & HEMP TEXTILE SCI SHANGHAI

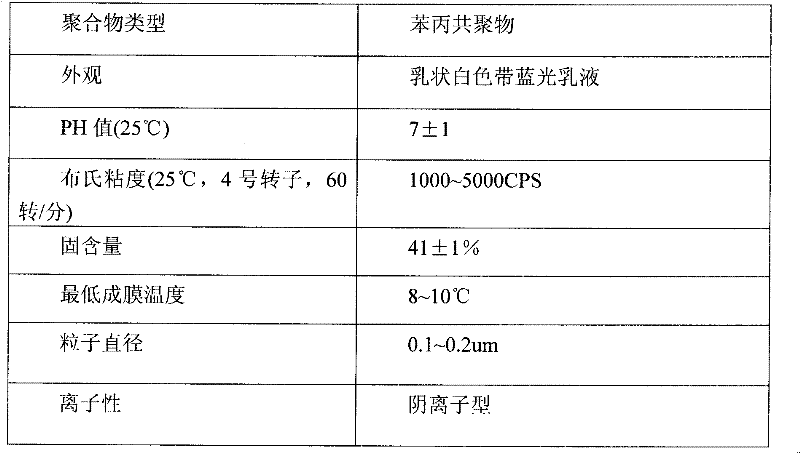

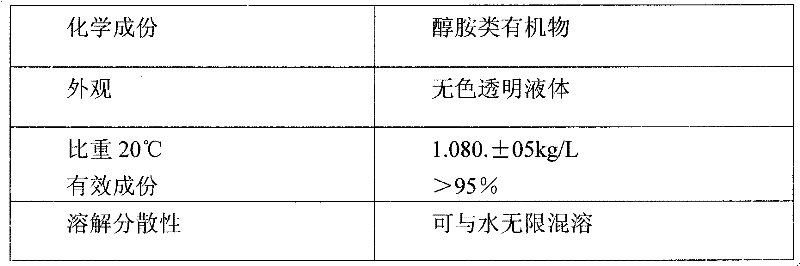

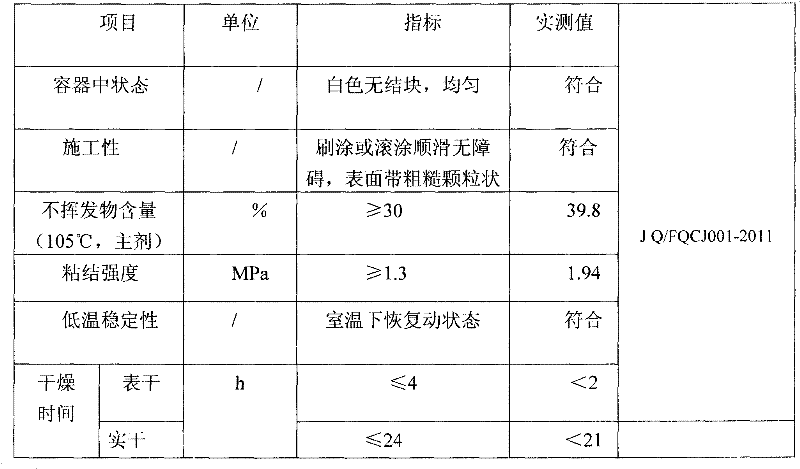

Polymer emulsion interface agent for base layer coating treatment and preparation method thereof

The invention discloses a polymer emulsion interface agent for base layer coating treatment and a preparation method thereof. The polymer emulsion interface agent for base layer coating treatment comprises a component A and a component B. In use, the component A and the component B are mixed according to a weight ratio of 1: 1. The mixture of the component A and the component B is white paint. The component A comprises 0.1 to 0.5% of hydroxyethylcellulose, 0.2 to 0.9% of a dispersing wetting agent, 12 to 19% of quartz powder, 48 to 65% of styrene-acrylic acid ester polymer emulsion, 0.05 to 0.35% of an antiseptic, 0.01 to 0.2% of a mildew inhibitor, 0.05 to 0.25% of a multifunctional auxiliary agent, 0.05 to 0.55% of a thickening agent, 0.1 to 0.5% of an antifoaming agent, 0.2 to 0.7% of a film forming auxiliary agent and 18 to 35% of water. The component B comprises 20 to 38% of wollastonite powder, 15 to 35% of quartz powder and 38 to 55% of quartz sand. Through combining the component A and the component B according to a ratio, the polymer emulsion interface agent for base layer coating treatment has the characteristics of good cohesion and adhesion, high bonding intensity, good closeness, rough surface layer and good adhesiveness with putty.

Owner:FUZHOU QICAIJU BUILDING MATERIAL

Method for synthesizing p-acetamido benzene sulfonyl chloride by phosphorus pentachloride

InactiveCN101613308AHigh yieldReduce dosageSulfonic acid preparationSulfonyl chlorideChlorosulfuric acid

The invention relates to a method for synthesizing p-acetamido benzene sulfonyl chloride by phosphorus pentachloride, relating to the preparation method for sterilization and mould inhibition midbody of sulfonamides. The invention takes acetanilide and chlorosulfonic acid as raw materials, uses phosphorus pentachloride as chlorinating agent; under the action of organic dissolvent, the raw materials are sulfonated, chloridized, separated, and washed to obtain the product. The invention has the effects of little chlorosulfonic acid usage, high product yield, few generated waste acid,, completely cycling dissolvent, recycled by-products, low manufacturing cost, being convenient to popularize and apply, and the like. The products prepared by the method can be widely applied to the preparation of the sterilization and mould inhibition of sulfonamides and industries such as coating, plastics, pesticides, etc.

Owner:CHONGQING UNIV

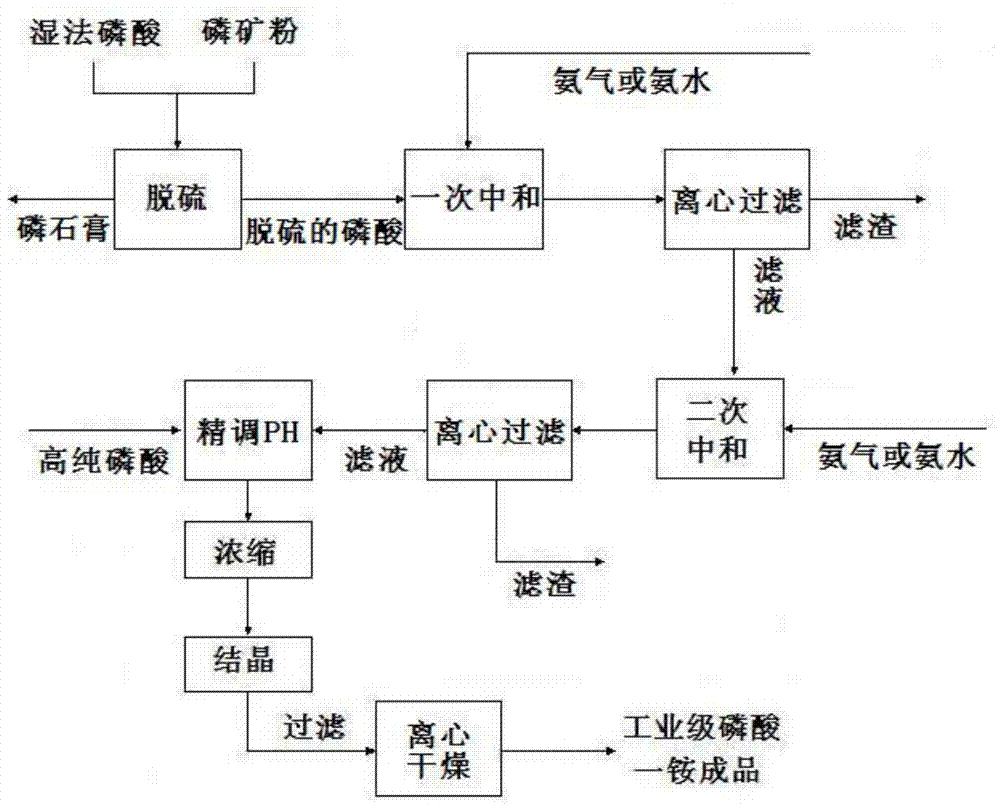

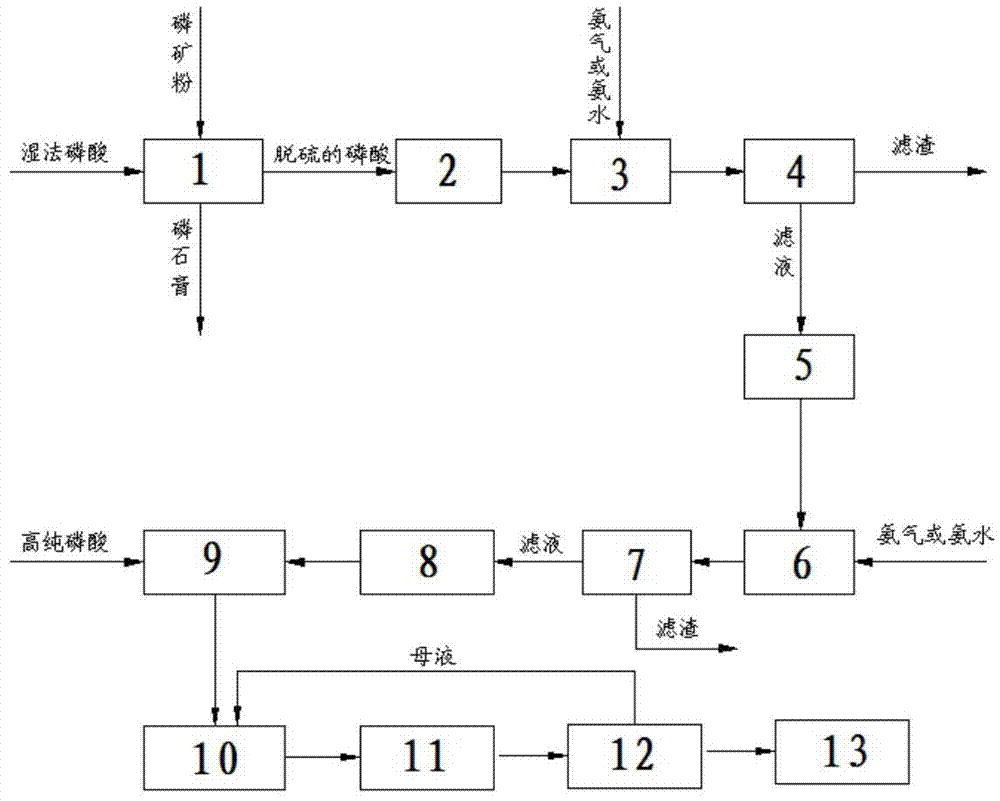

Method for producing industrial grade monoammonium phosphate through combination of wet process phosphoric acid and high-purity phosphoric acid

The invention discloses a method for producing industrial grade monoammonium phosphate through combination of wet process phosphoric acid and high-purity phosphoric acid. The method comprises the steps of performing neutralization reaction for two times on filtrate and ammonia gas or ammonia water to obtain ammonium phosphate slurry, wherein the filtrate is obtained by performing desulfurization reaction on phosphate rock powder and wet process phosphoric acid; performing concentration, crystallization and drying by using filtrate which is obtained by adjusting the pH value with high-purity phosphoric acid to obtain an industrial grade monoammonium phosphate product; removing most of impurity ions when the pH value is neutralized to 4.0-5.0 by the first neutralization reaction, then performing the second neutralization reaction to remove impurities in the wet process phosphoric acid, finely adjusting the pH value to 3.9-4.4 by using the high-purity phosphoric acid, and performing concentration and crystallization to obtain the industrial grade monoammonium phosphate. The method disclosed by the invention reduces the production cost and energy consumption and is environment-friendly and pollution-free; the obtained product is stable in quality, the process flow is short, the device construction investment is saved, the needed operators are less, the energy consumption is reduced, the pollution is reduced, and the quality of monoammonium phosphate is ensured through effective impurity removal, so that the method has a very good economic benefit.

Owner:GUIZHOU KAILIN GRP CO LTD

PET/PVA sea-island fiber with water-soluble sea facies, and production process of PET/PVA sea-island fiber

ActiveCN108486683AEnables thermoplastic processingNo emissionsFilament/thread formingConjugated synthetic polymer artificial filamentsPolyolSpinning

The invention discloses a PET / PVA sea-island fiber with water-soluble sea facies. The PET / PVA sea-island fiber with the water-soluble sea facies is obtained through stretching and heat setting a nascent fiber formed by adopting PET as an island face component and PVA as a sea face component, wherein the island face component of the nascent fiber accounts for 60 percent to 85 percent of the cross section area of the fiber; the sea component accounts for 40 percent to 15 percent of the cross section area of the fiber; water-soluble PVA master batch is prepared by blending the following raw materials in parts by weight: 50 to 70 parts of polyvinyl alcohol, 15 to 25 parts of polyhydric alcohol or salt compound modifier, 3 to 7 parts of an antioxidant, 3 to 7 parts of a lubricating agent, and 25 to 35 parts of deionized water. The invention also provides a production process of the sea-island fiber. Compared with traditional PVA, according to the PET / PVA sea-island fiber with the water-soluble sea facies, provided by the invention, the melting point is reduced, so that the PVA sea component can be melt and compositely spun with the PET with a high melting point, the problem of PVA decomposition cannot happen while the melting point is reached, and the problem that the traditional PVA is decomposed when encountering the high-temperature PET so that melting and composite spinning cannot be achieved is solved.

Owner:浙江泓泰德建新纤维有限公司

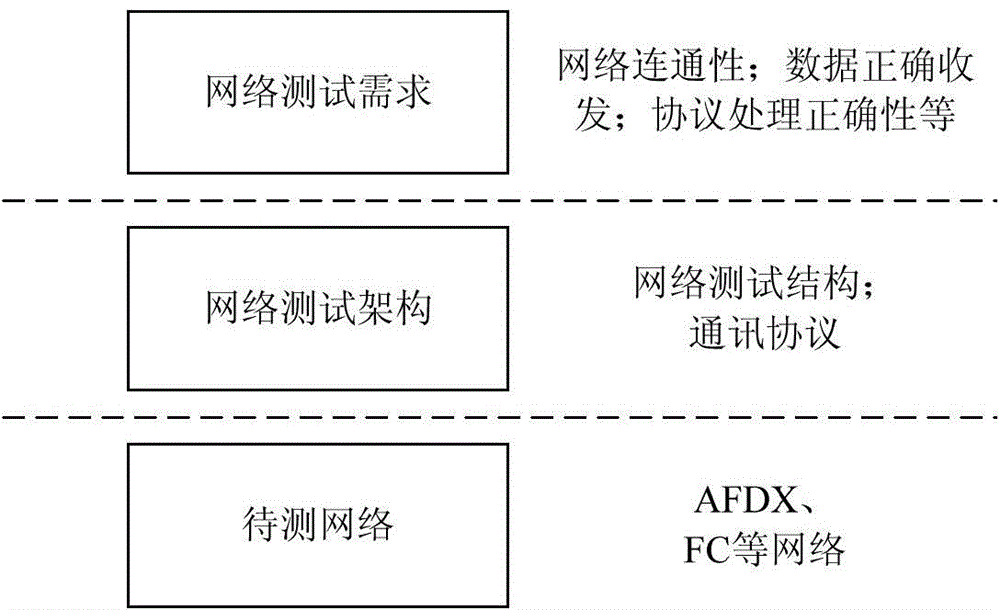

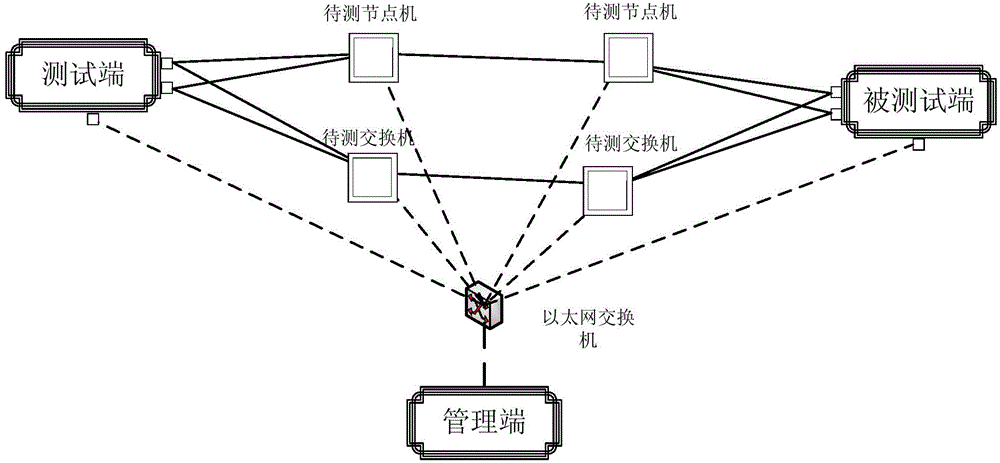

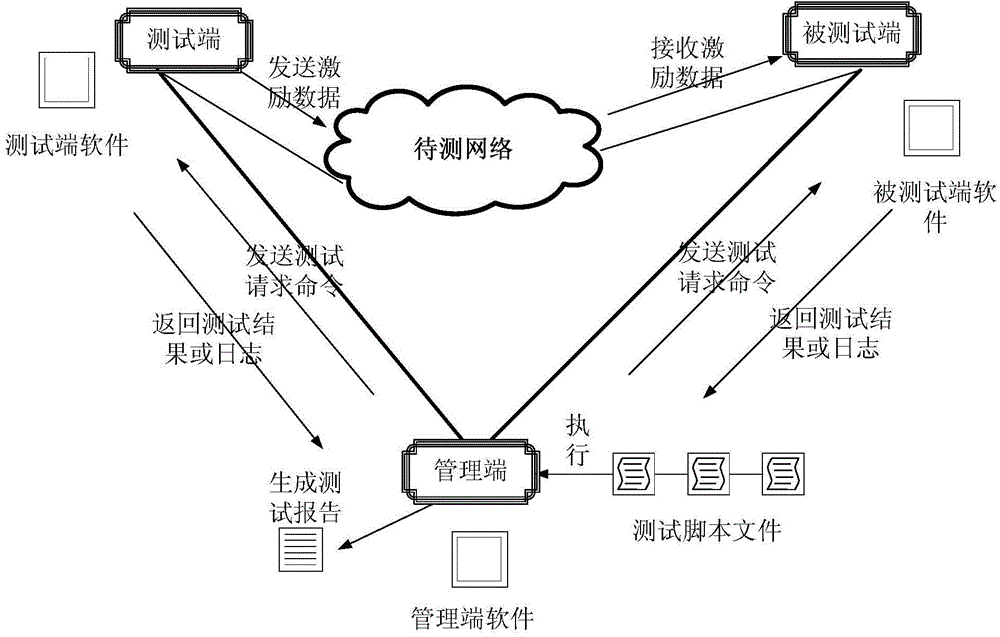

Communication method for testing console and testing equipment

The invention discloses a communication method for a testing console and testing equipment. According to all operations required by the communication method, control data and testing data are transmitted in a network division manner so as to ensure that no affect of the control data on the testing data is caused and the automation degree of network testing is improved; a management end is respectively in communication connection with a testing end and a tested end through Ethernet; the testing end is in communication connection with the tested end through a network to be tested to further ensure that no affect of the control data on the testing data is caused and the automation degree of network testing is improved. According to the communication method disclosed by the invention, command and data communication interaction between a testing server and a testing target end can be effectively realized, the functions of initialization, configuration loading, testing data control and the like of the network to be tested are finished and the automation degree of the network testing reliability is greatly improved.

Owner:AVIC NO 631 RES INST

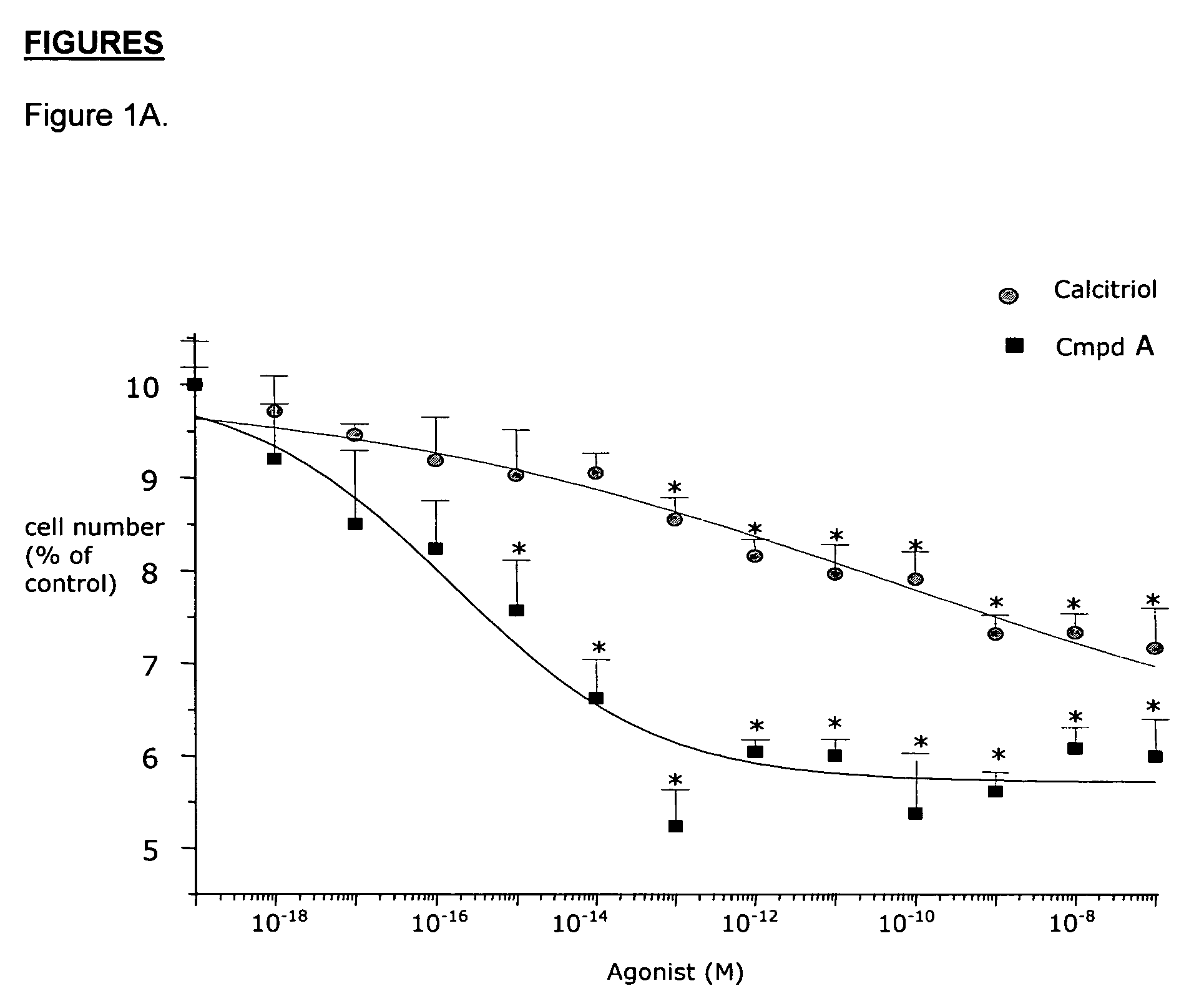

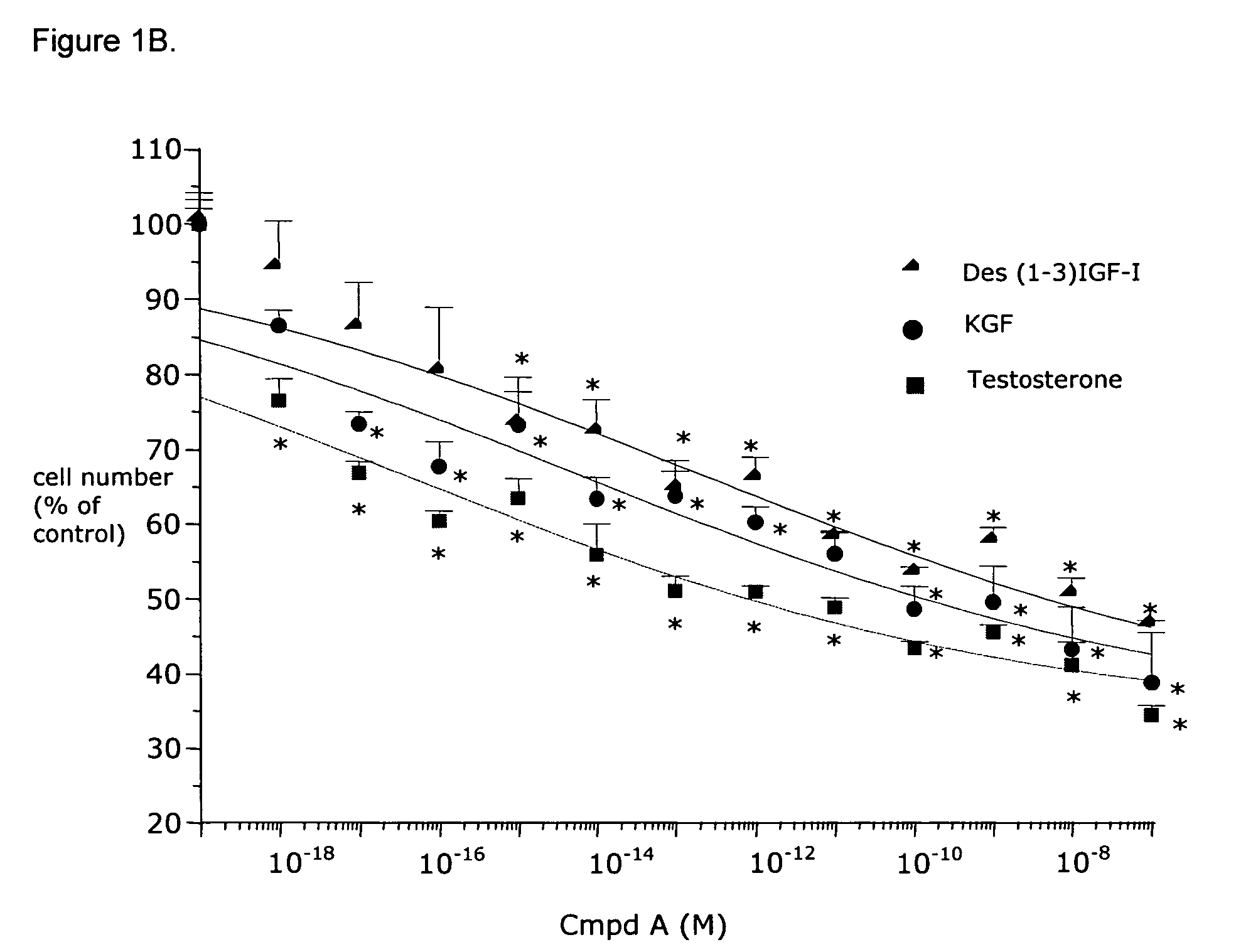

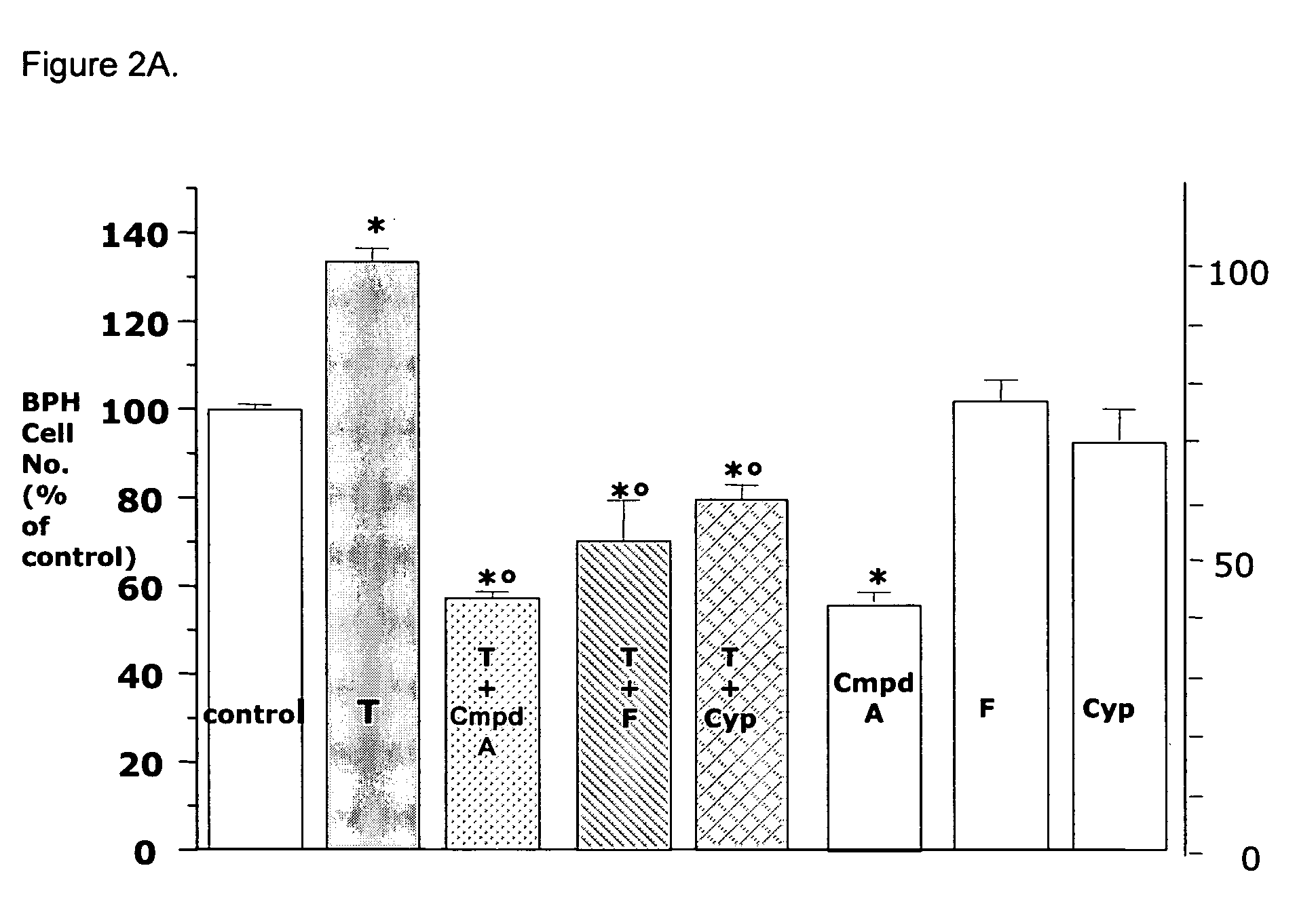

Method for treating benign prostatic hyperplasia

InactiveUS7332482B2Effective pharmacologic agentReduce the overall heightBiocideOrganic chemistryProstate hyperplasiaBenign prostatic hyperplasia (BPH)

Owner:BIOXELL

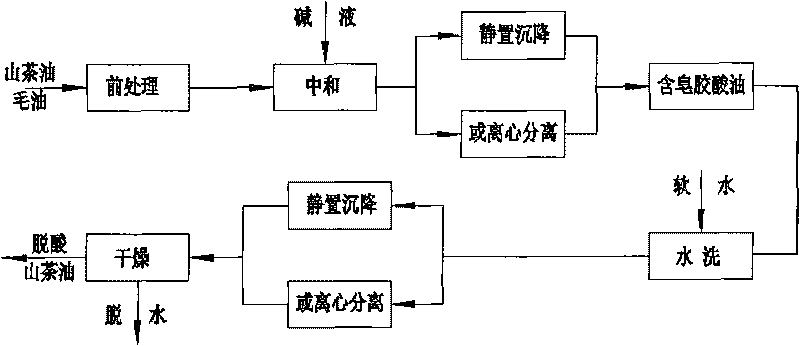

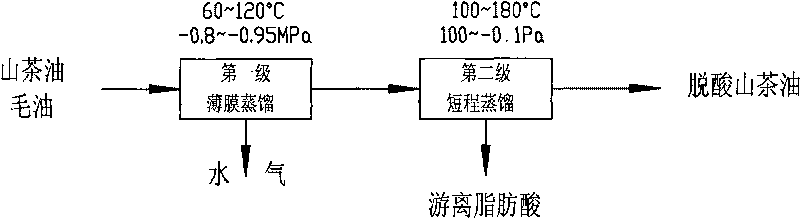

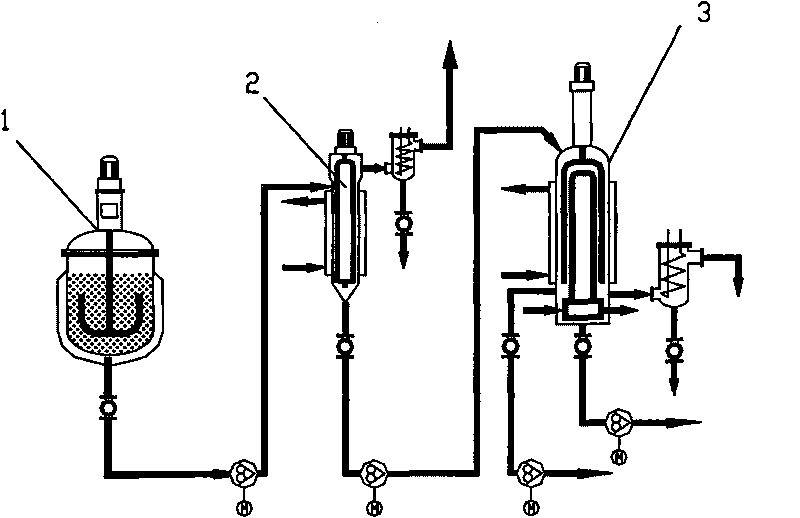

Method for refining camellia oil by adopting short-path distillation

InactiveCN101717690ANo effectNo pollution in the processFatty-oils/fats refiningOleic Acid TriglycerideChemical process

The invention discloses a method for refining camellia oil by adopting short-path distillation, comprising two-stage distillation. During first-stage distillation, firstly the crude camellia oil is directly poured into a buffer tank, then the crude camellia oil is introduced into a first-stage film evaporator through a pump to undergo primary dehydration and degasification under the conditions of temperature between 60 DEG C and 120 DEG C and pressure between minus 0.8MPa and minus 0.95MPa. During second-stage distillation, the camellia oil after undergoing dehydration and degasification is introduced into a second-stage short-path distillator through a pump to undergo deacidification under the conditions of temperature controlled between 100 DEG C and 180 DEG C and pressure between 100Pa and 0.1Pa, thus obtaining oleic acid with high acid value and camellia oil with low acid value. The process with high pollution of wastewater drained after soda soap washing and water washing in the chemical processes of alkali refining and neutralizing does not exist during processing the camellia oil. The flow is simple, the oleic acid with high value and the camellia oil with low acid value are separated by distillation, the separation process is a physical process, and the camellia oil is free of loss, thus having very high yield.

Owner:SOUTH CHINA UNIV OF TECH

Compound Chinese herbal medicine formulation for treating causative pathogen skin ulcerative syndrome of Apostichopus japonicus

InactiveCN101322760ANo toxicityWill not affect normal lifeAntibacterial agentsAnthropod material medical ingredientsDiseaseHerbal preparations

The invention discloses a compound Chinese herbal preparation for treating bacterial ulcerate disease of apostichopus japonicus selenka; the components of the Chinese herbal preparation comprise the following weight ratios: 80-90% of dark plum and 10-20% of Chinese gall. After the decocting of the components by water, the preparation obtained is used for medicated bath of apostichopus japonicus selenka or sprinkled in a whole pool and has reasonable composition formula. The compound Chinese herbal preparation has the following advantages that the raw materials are prepared based on the formula for Chinese medicinal herbs, which strengthens the efficacy of components; the preparation has no toxicity for the apostichopus japonicus selenka and no influence on the normal life of the apostichopus japonicus selenka, has quite obvious effect on killing pathogens in apostichopus japonicusand selenka and can repair ulcerate tissues thoroughly; the compound Chinese herbal preparation is degradable under the natural conditions, which has no toxic and side effect and no residue in the apostichopus japonicus selenka; the compound Chinese herbal preparation has less recruitment, convenient use, simple composition, stable raw material source, cheap price and simple production process.

Owner:DALIAN FISHERIES UNIVERSITY

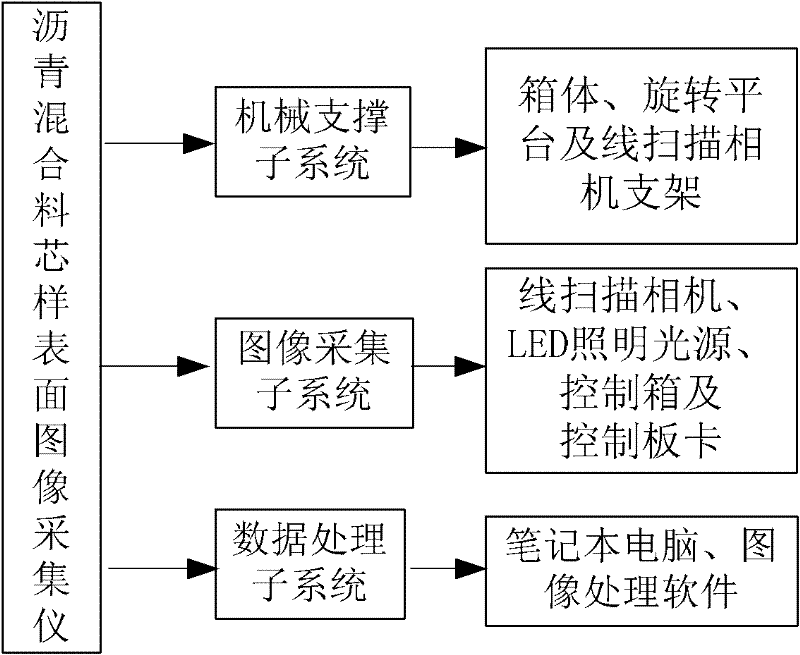

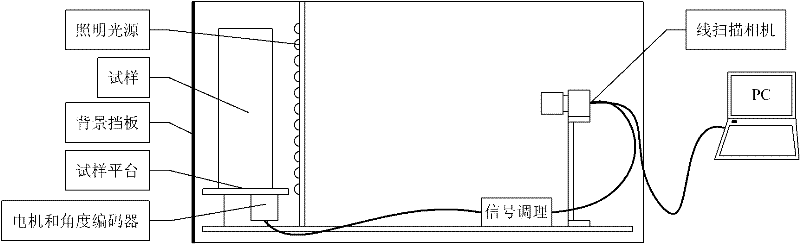

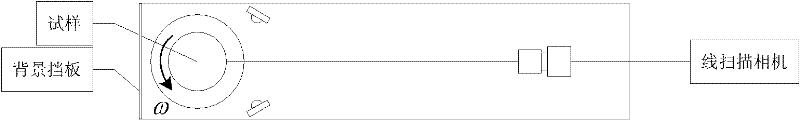

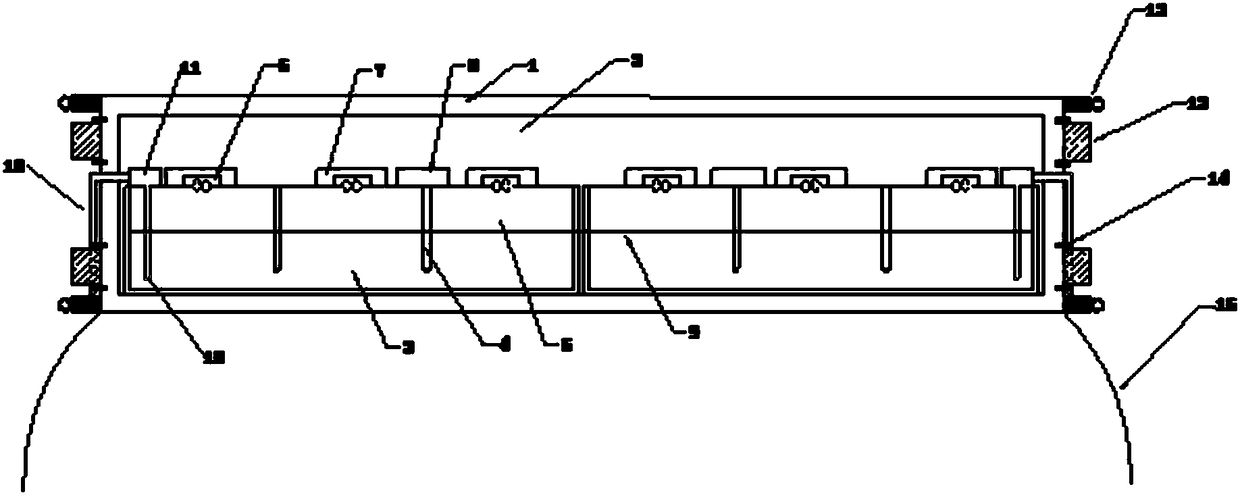

Asphalt mixture core sample surface image acquirer

InactiveCN102243184AIntegrity guaranteedAvoid surface distortionOptically investigating flaws/contaminationRoad surfaceCcd camera

The invention discloses an asphalt mixture core sample surface image acquirer which comprises a mechanical supporting subsystem, an image acquisition subsystem and an image processing subsystem that are connected as follows: all hardware of the image acquirer are arranged inside a box body of the mechanical supporting subsystem. The image acquirer is characterized in that a mechanical technology,an electric technology and a software technology are comprehensively utilized, a vertical rotating platform and a linear array CCD (Charge Coupled Device) are adopted, a core sample continuously rotates for 360 DEG and a CCD camera continuously acquire images, thus curved surface deformation and splicing difficulty of the traditional core sample surface image acquisition are overcome, and the images are shot by adopting a coder trigger linear array camera, so that integrity of image acquisition is ensured and the core sample is not damaged. According to the analysis result of digital image processing software, the asphalt mixture core sample surface image acquirer is used for guiding asphalt road surface construction, and has remarkable economic benefit and better application prospect.

Owner:BEIHANG UNIV

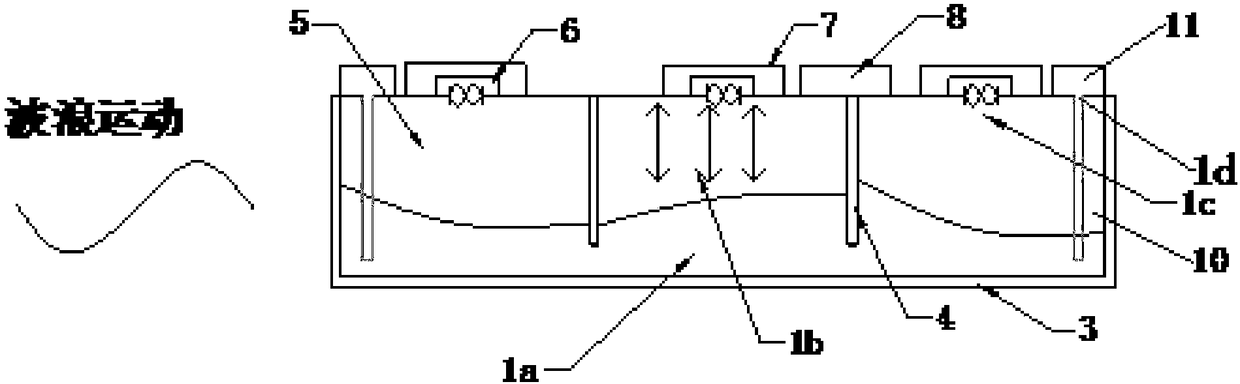

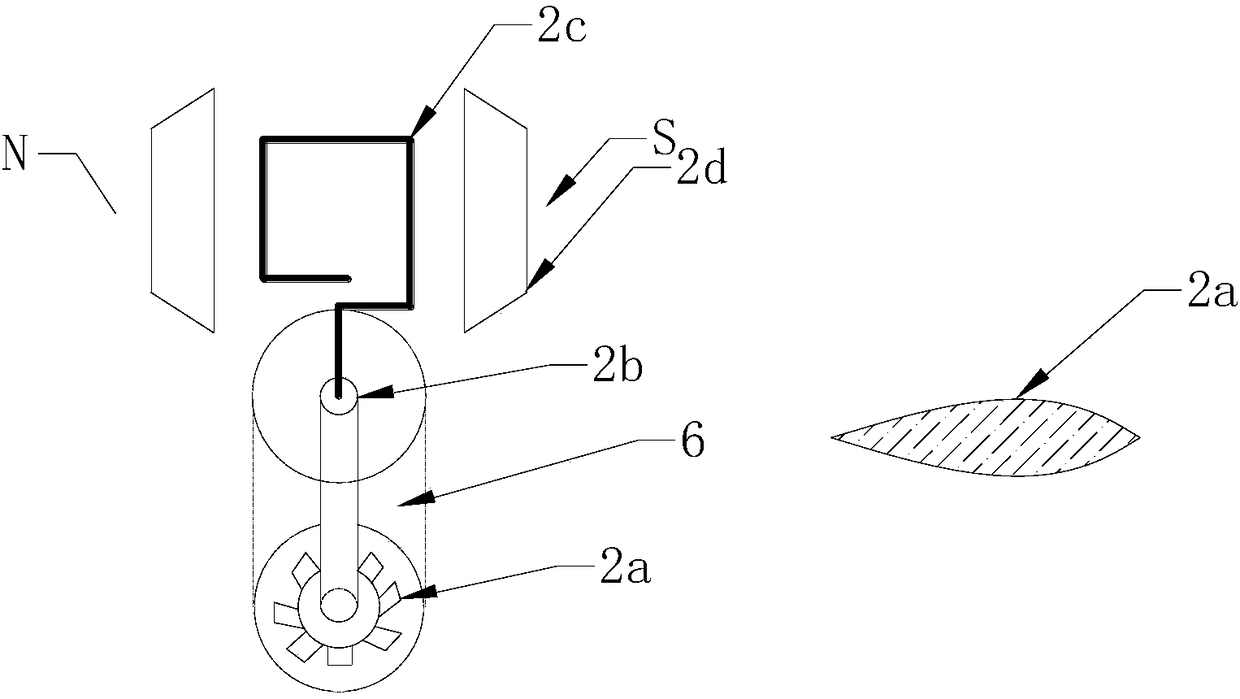

Movable floating breakwater with oscillation water column type wave energy conversion device

The invention discloses a movable floating breakwater with an oscillation water column type wave energy conversion device, and belongs to the field of ocean energy utilization. The movable floating breakwater consists of multiple floating breakwater modules; and the modules are elastically connected to realize independent movement and of each module and power generation, and can form a floating breakwater power generation pasture. Single floating breakwater module comprises a square box, a power generation device, a connecting device and a mooring system. The multiple modules are elastically connected through connecting devices. The movement of a floating body is caused by a wave motion to cause movement of a fluid in a power generation cabin, so that the air pressure at the upper part ofthe cabin is continuously changed; the air pressures on the two sides of a turbine are different to form reciprocating air currents; kinetic energy of gas is converted to mechanical energy through anair turbine; and the mechanical energy is converted to electric energy through a generator. The floating breakwater and a wave energy power generation device are fused to realize covering of offshoreocean structures and to generate the electric energy to achieve the advantages of capability of moving and repeating, no limitation from the water depth and the geology and the like; and the movable floating breakwater is simple in structure, easy to produce and maintain, free of pollution to the marine environment and broad in application prospect.

Owner:DALIAN UNIV OF TECH

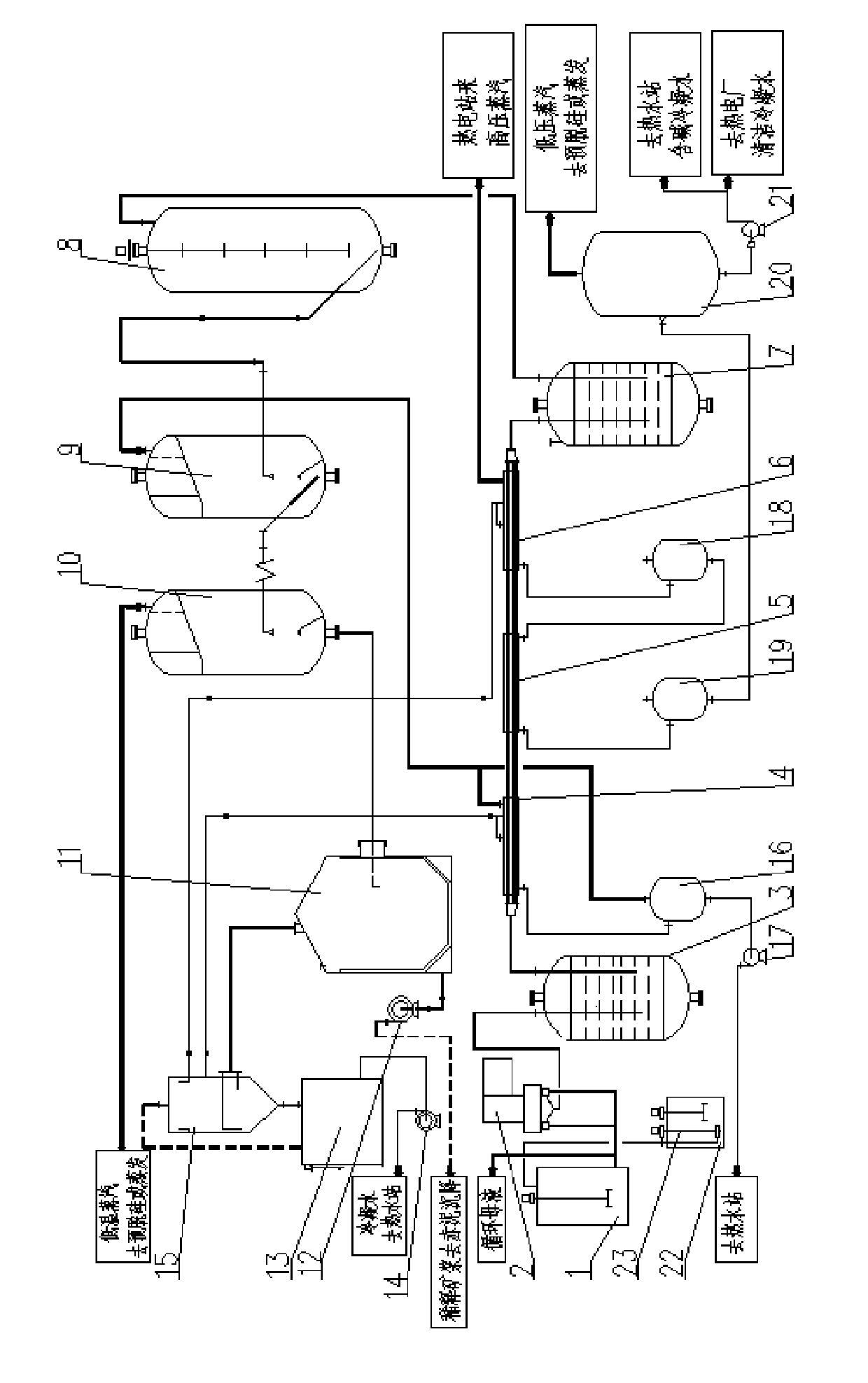

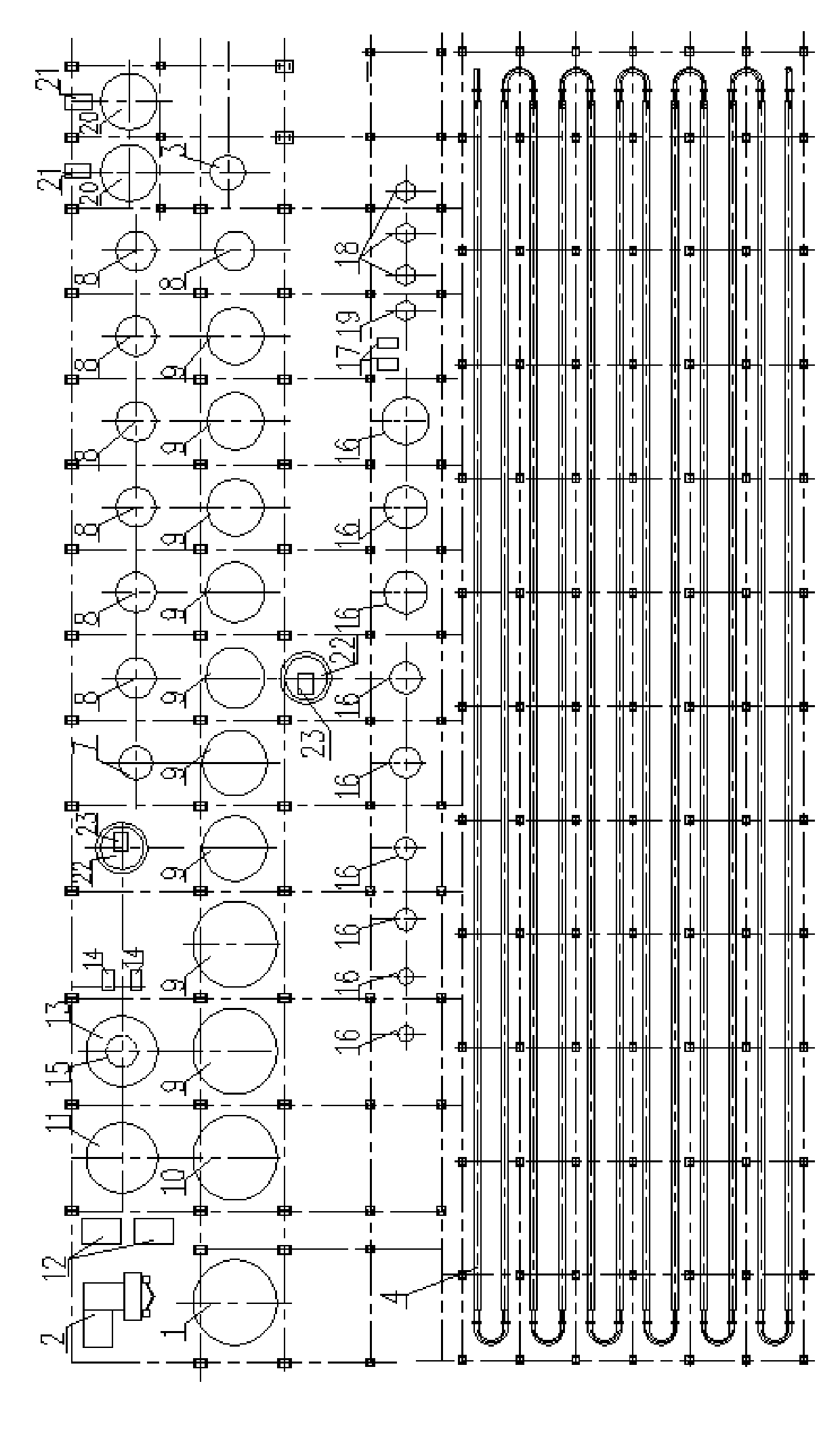

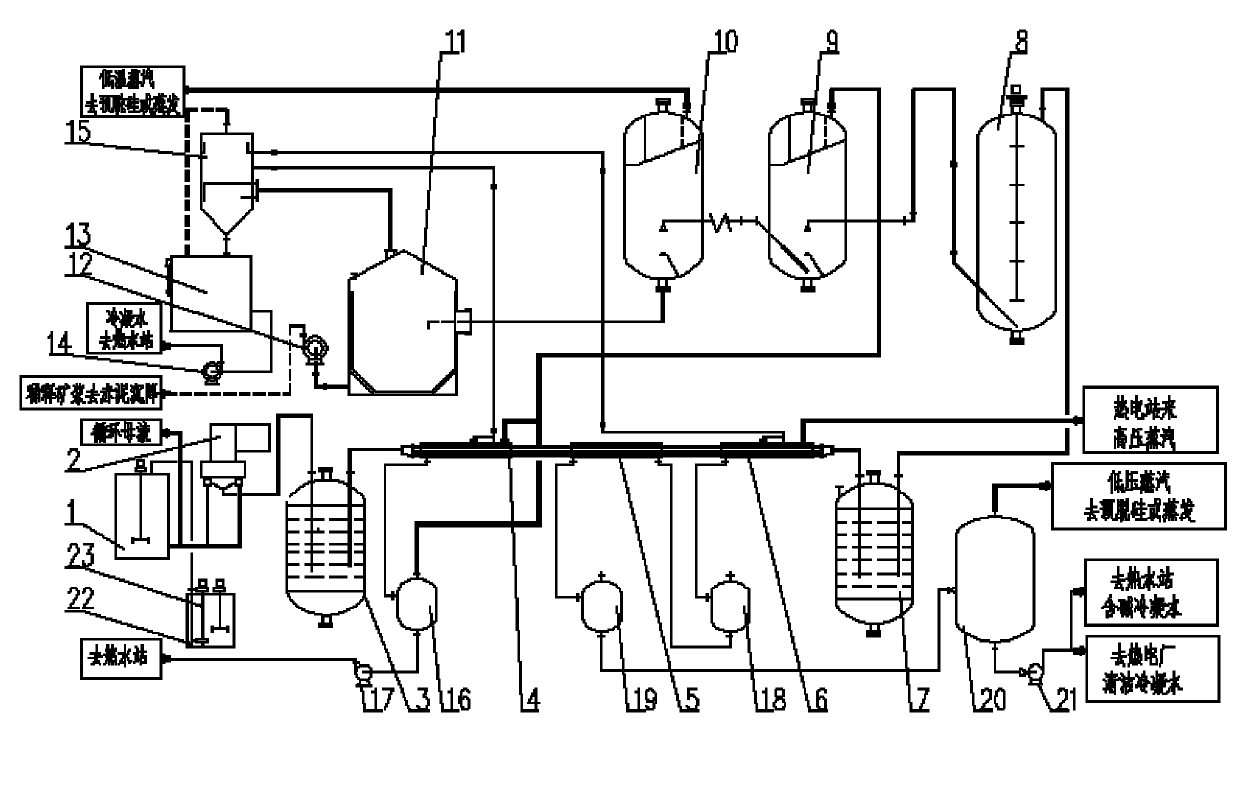

Dissolving-out process for large-sized pipeline remaining tank of diasporite bauxite ore

InactiveCN101767806ALarge pulp capacityImprove heat utilizationAluminium oxides/hydroxidesBoehmiteMother liquor

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

Leaking stoppage reinforcing agent

The invention discloses a leaking stoppage reinforcing agent which comprises the following components in parts by weight: 2-8 parts of urea resin, 1-5 parts of phenolic resin, 8-15 parts of slag, 1-5 parts of calcium sulfate, 5-8 parts of aluminum oxide, 3-6 parts of calcium chloride, 10-20 parts of calcium carbonate, 10-20 parts of silicon oxide, 0.1-0.4 part of polyanionic cellulose PAC-LV and 0.1-0.4 part of sodium carboxymethylcellulose CMC-LV. The leaking stoppage reinforcing agent is prepared by the steps of sequentially adding the components in parts by weight into a reaction kettle according to a conventional preparation method at 30-50 DEG C under normal pressure, stirring and mixing for 6-8 hours, subsequently adding the components into a kneading machine, uniformly mixing and stirring, drying, and crushing into a powder product with the particle size of 0.01-0.5mm. The leaking stoppage reinforcing agent has a remarkable leaking stoppage and reinforcing effect, is temperature resisting, good in stability and coagulability, high in structural stoppage capability and good in compatibility, can be thickened without solidification, is controllable in reinforcing time, wide in application range, safe in construction and free of toxicity or pollution, can be widely applied to petroleum and geological drilling process, and is particularly applicable to leaking stoppage construction in large cracks, large karst caves, underground rivers, severe deficit earth layers and crushed earth layers.

Owner:DONGYING TAIER GASOLINE TECH

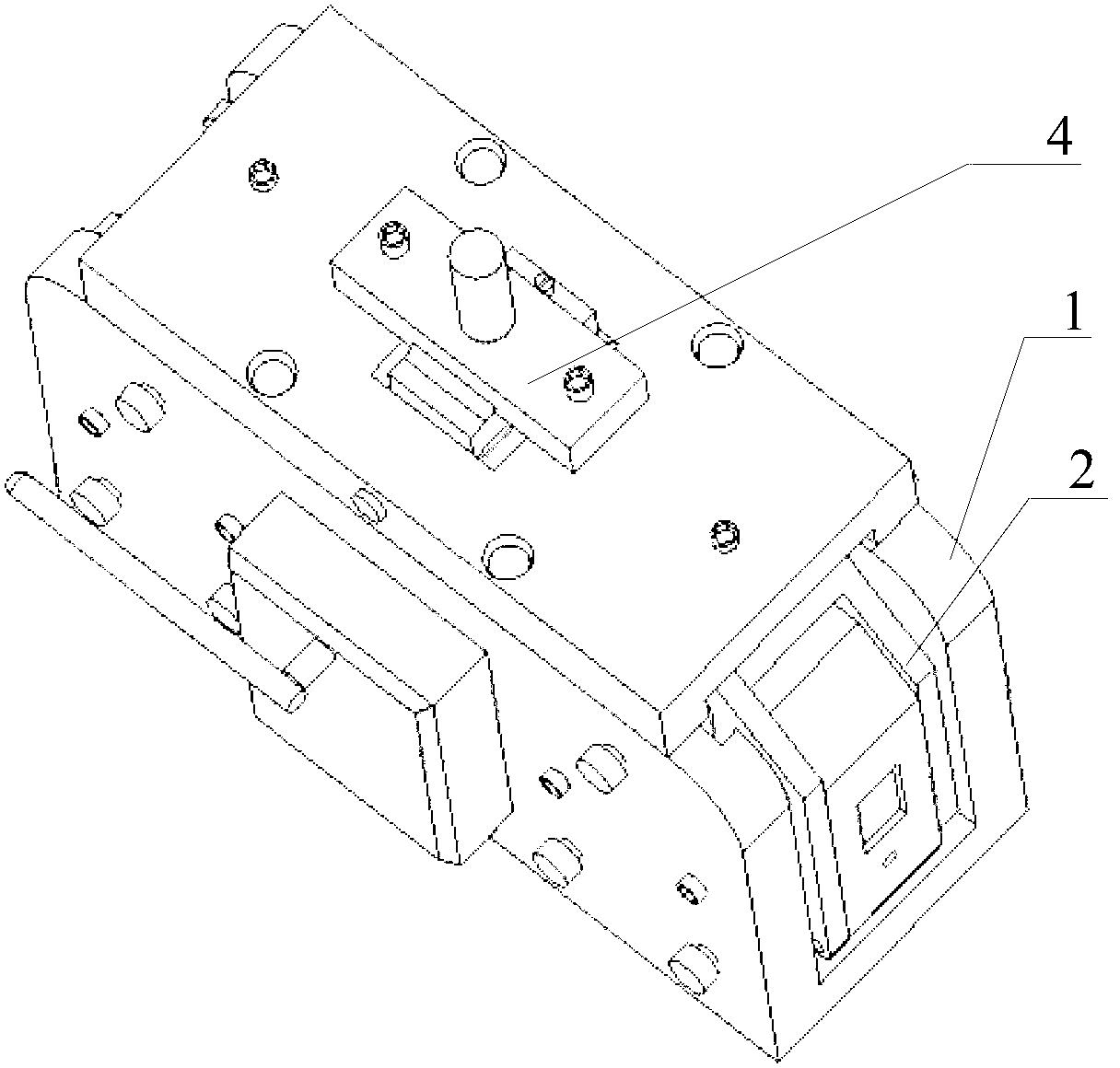

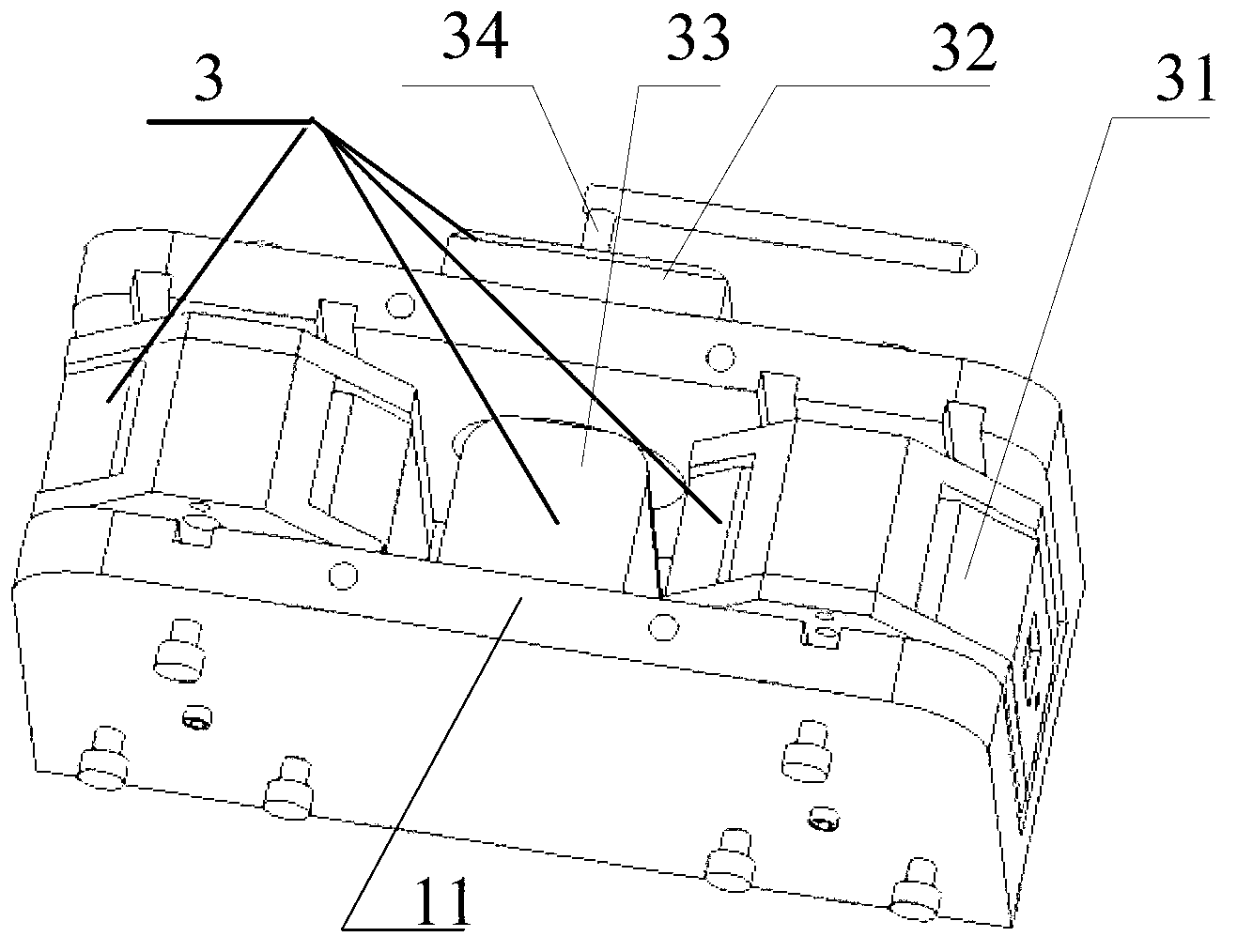

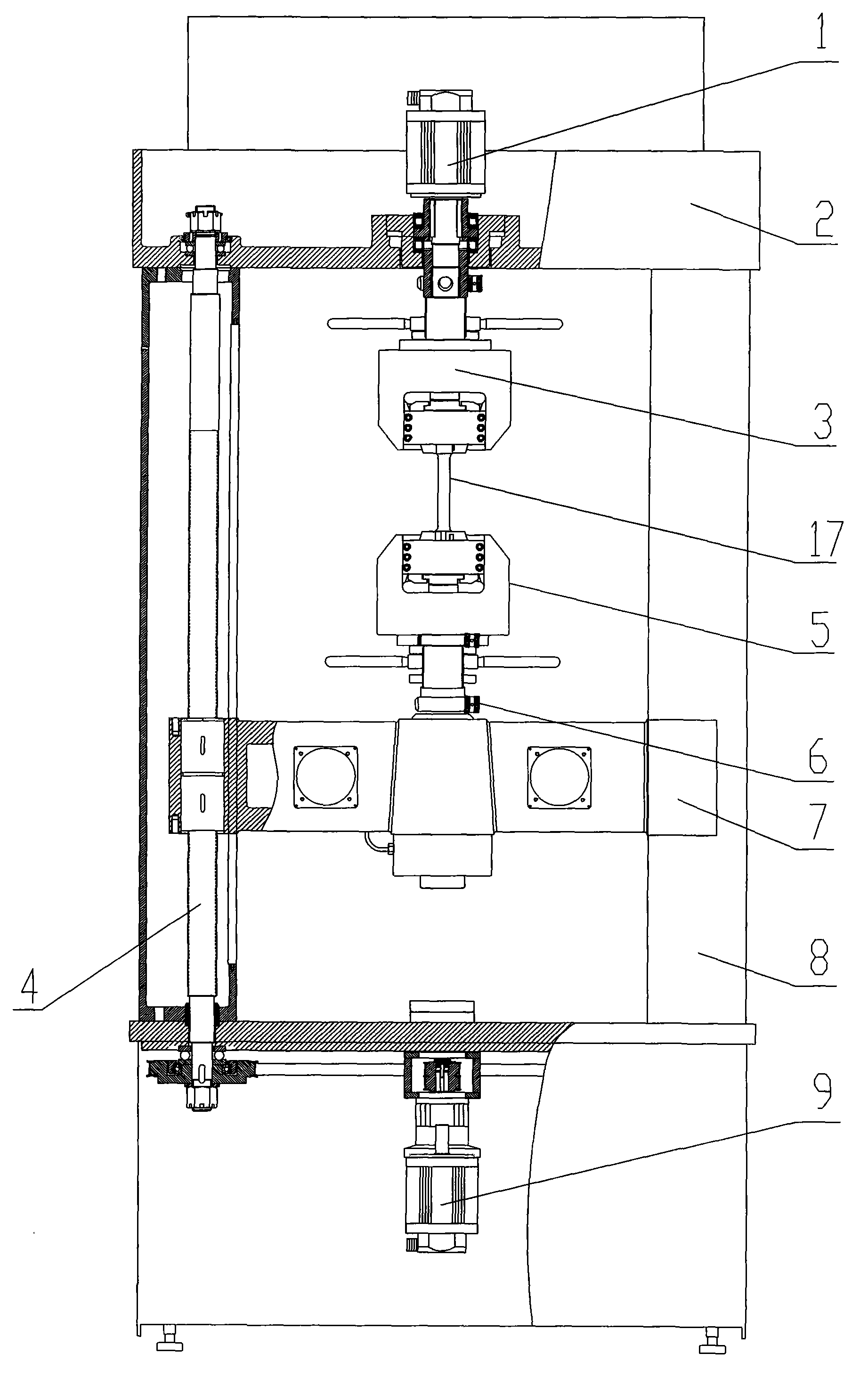

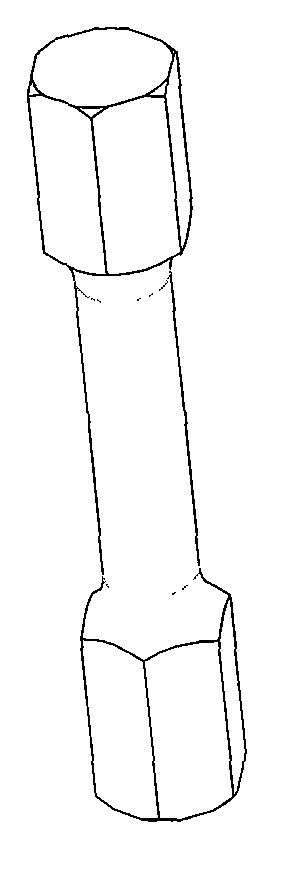

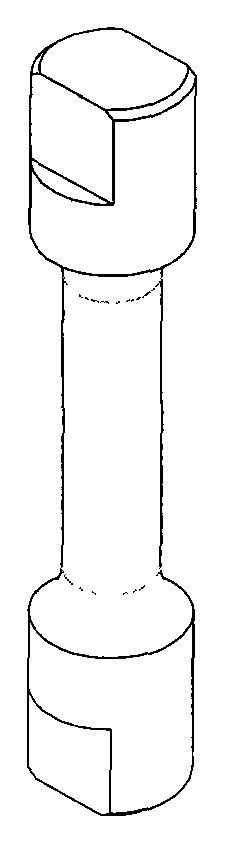

Tension-torsion test specimen fixture

The invention discloses a tension-torsion test specimen fixture, which comprises an upper chuck, a lower chuck and a tension-torsion test specimen, the upper chuck and the lower chuck are respectively provided with upper jaws and lower jaws, an upper clamped section of the tension-torsion test specimen is fixed by the upper jaws of the upper chuck, a lower clamped section of the tension-torsion test specimen is fixed by the lower jaws of the lower chuck, the upper clamped section of the tension-torsion test specimen is provided with upper test specimen key slots, the lower clamped section of the tension-torsion test specimen is provided with lower test specimen key slots, the upper jaws of the upper chuck are provided with upper jaw key slots corresponding to the upper test specimen key slots, the lower jaws of the lower chuck are provided with lower jaw key slots corresponding to the lower test specimen key slots, keys are mounted between the upper test specimen key slots and the upper jaw key slots, and keys are mounted between the lower test specimen key slots and the corresponding lower jaw key slots. The tension-torsion test specimen-clamping effect of the jaws of the tension-torsion test specimen fixture is good, the shapes of the clamped sections of the test specimen are not limited, the structure is simple, clamping does not need mechanical power, mechanical operation noise does not exist, the environment cannot be affected, and both the purchase cost and the use cost are low.

Owner:烟台力尔自动化设备有限公司

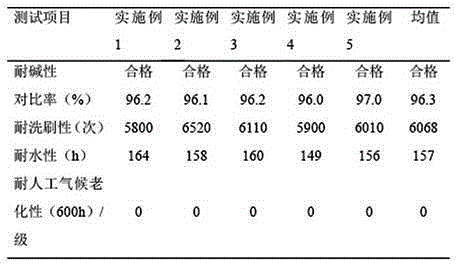

Inorganic waterproof anti-aging external wall coating and preparation method thereof

The invention discloses an inorganic waterproof anti-aging external wall coating and a preparation method thereof. The inorganic waterproof anti-aging external wall coating is prepared from, by weight, 55-60 parts of silica solution, 8-12 parts of sepiolite, 6-10 parts of aluminium hydroxide, 6-10 parts of pigment, 8-18 parts of filler and 0.5-1 part of thickening agent. The preparation method includes the steps of adding sepiolite, aluminium hydroxide and calcium powder to a silica solution to be soaked for 2 h and then dispersed for 10 min at the rotating speed of 6000 r / min, adding other filler to be soaked for 1h and dispersed for 20 min at the rotating speed of 3000 r / min till the fineness is smaller than 50 microns, reducing the rotating speed to 800 r / min, adding thickening agent to be evenly dispersed, and obtaining the target product. The coating has excellent waterproof performance and aging resistance, does not contain any organic components, and is free of toxin and environmentally friendly; the preparation method is easy to operate, low in device requirement and suitable for industrial large-scale production.

Owner:深圳力效新材料科技有限公司

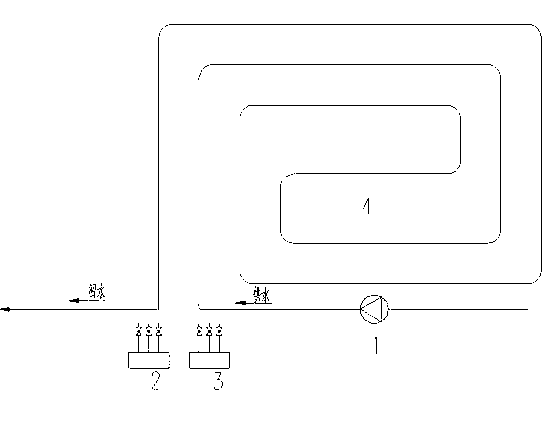

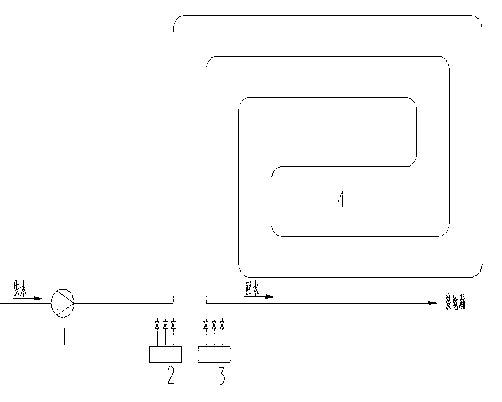

Method for cleaning floor heating pipes

The invention provides a method for cleaning floor heating pipes. The method is characterized by comprising the following steps of: firstly flushing, removing loams in the pipes, then soaking the pipes by cleaning fluid, dissolving rust and scale in the pipe, and finally Secondarily flushing the pipe. Through the method, the cleaning is safe and convenient, the cleaning time is short, the cleaning effect is excellent, the cleaning cost is low, the excellent radiation function of the pipe after cleaning can be kept, the service life of the floor heating pipe can be prolonged, no harm to human body is generated in the cleaning process, the equipment is not corroded, and the environment is not affected.

Owner:山西省第二建筑工程公司

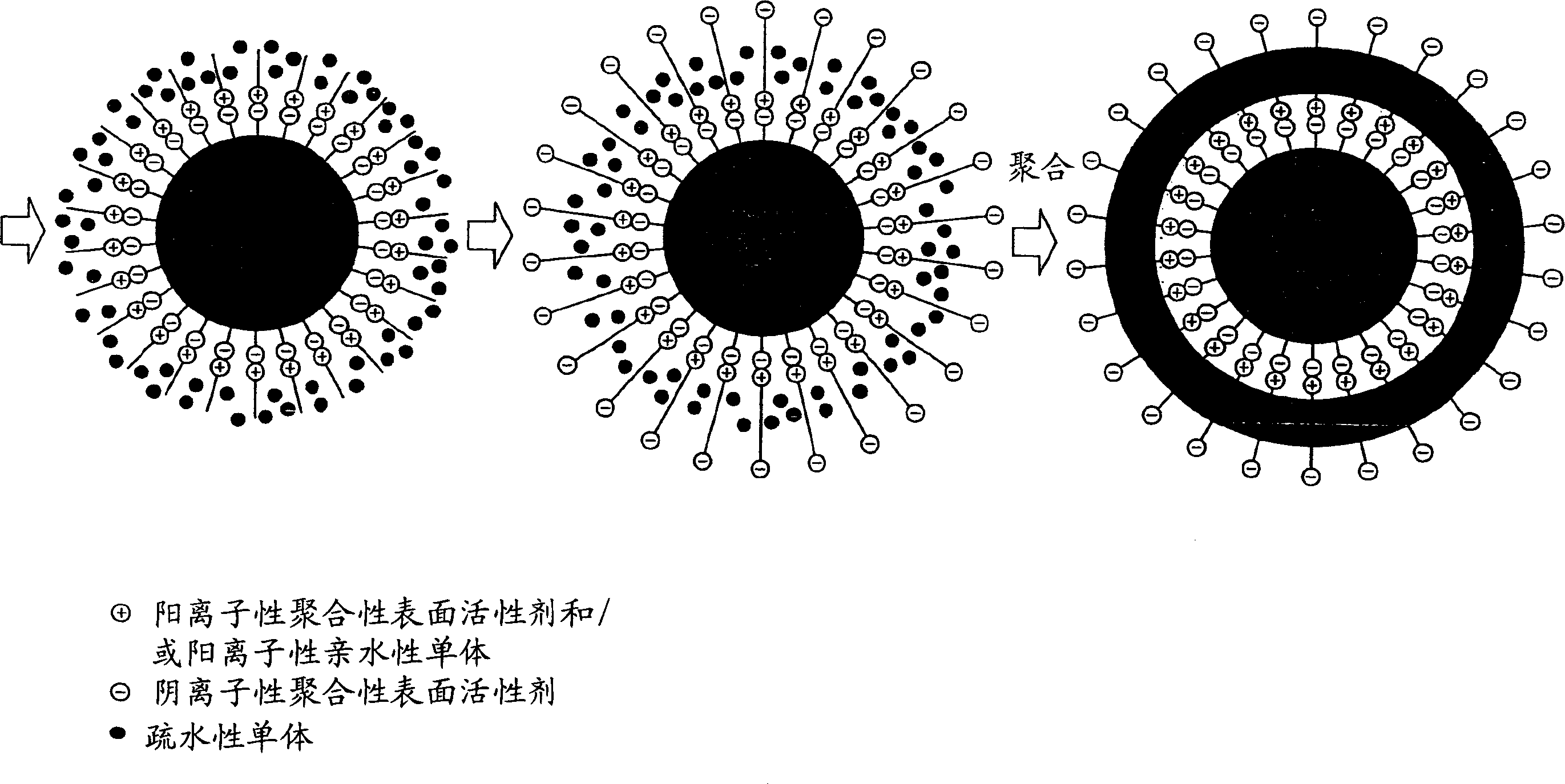

Encapsulation product, process for producing the same, and ink composition

InactiveCN101076395AUniform surface stateEasy to EncapsulateInksMicroballoon preparationSURFACTANT BLENDPolymer chemistry

An encapsulation product having excellent properties, e.g., no limitation on core substances. The encapsulation product comprises a wall material comprising a polymer as a major component and a core substance encapsulated therein, wherein the polymer is in contact with the core substance through an ionic surfactant (a) and comprises (1) structural repeating units derived from an ionic polymerizable surfactant (B) and / or an ionic monomer and (2) structural repeating units derived from an ionic polymerizable surfactant (C) having a charge which is the same as or opposite to that of the ionic surfactant (a). Alternatively, the encapsulation product comprises a wall material comprising a polymer as a major component and a core substance encapsulated therein, wherein the polymer comprises structural repeating units of a hydrophobic monomer and is present between (1) an ionic surfactant (b) and (2) an ionic surfactant (c).

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com