Microbial preparation for purifying breeding wastewater

A technology of microbial preparations and aquaculture wastewater, applied in the direction of microbial-based methods, microorganisms, biological water/sewage treatment, etc., can solve the problems of poor treatment effect, difficult to meet the standard of effluent water quality, high cost of sewage purification and treatment, etc., and achieve improvement The quality of agricultural products, the benefits of industrial production, and the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A microbial preparation for the purification and treatment of aquaculture wastewater, which is prepared according to the following method:

[0027] Mix the mixed bacterial solution, sawdust and diatomaceous earth according to the weight ratio of 1:1:1, stir evenly, and then dry it at 4°C at a low temperature, and control the water content at 8% after drying; the mixed bacterial solution is obtained by Mix the following raw materials by volume: 8 parts of Bacillus subtilis, 8 parts of Paracoccus denitrificans, 6 parts of Alcaligenes faecalis, 6 parts of Acidophilus ferrooxidans, 3 parts of Bacillus megaterium, Pseudomonas aeruginosa 2 parts of bacteria, 2 parts of Bacillus cereus and 1 part of Sphingomonas; the concentration of the above-mentioned raw material bacteria was controlled at 1×10 8 pieces / ml. The particle diameters of the above-mentioned sawdust or diatomaceous earth are all controlled above 100 mesh.

[0028] The methods of using the above-mentioned microb...

Embodiment 2

[0033] A microbial preparation for the purification and treatment of aquaculture wastewater, which is prepared according to the following method:

[0034] Mix the mixed bacterial solution, sawdust and diatomaceous earth according to the weight ratio of 1:1:1, stir evenly, and then dry it at 4°C at a low temperature, and control the water content at 10% after drying; the mixed bacterial solution is obtained by Mix the following raw materials by volume: 8 parts of Bacillus subtilis, 8 parts of Paracoccus denitrificans, 6 parts of Alcaligenes faecalis, 6 parts of Acidophilus ferrooxidans, 3 parts of Bacillus megaterium, Pseudomonas aeruginosa 2 parts of bacteria, 2 parts of Bacillus cereus and 1 part of Sphingomonas; the concentration of the above-mentioned raw material bacteria was controlled at 2×10 8 pieces / ml; the particle size of the above-mentioned sawdust or diatomaceous earth is controlled above 100 mesh.

[0035]The Bacillus subtilis is Bacillus subtilis CGMCC No: 0954;...

Embodiment 3

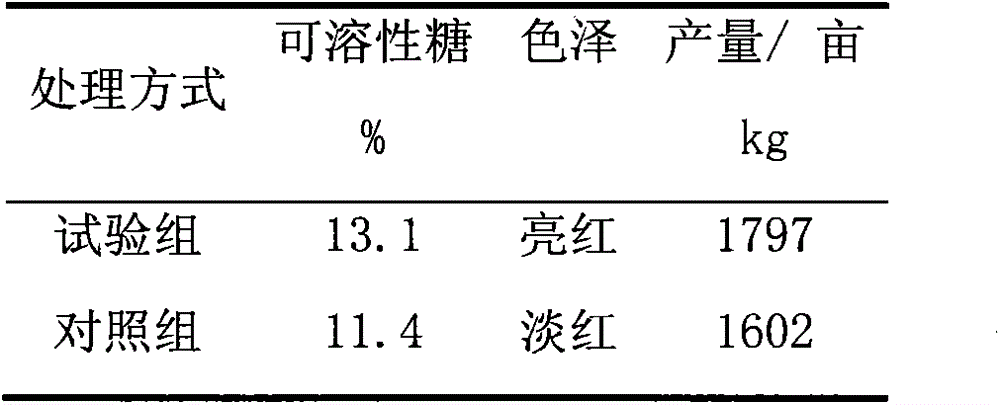

[0048] Taking the pig breeding wastewater of our company as an example, the treatment effect of the microbial preparation of Example 2 was tested, and the indicators such as ammonia nitrogen, nitronitrogen and phosphorus all reached the ideal discharge standard. The specific detection indicators are shown in Table 1:

[0049] Table 1 Parameter indicators before and after sewage treatment

[0050] project name

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com