Encapsulation product, process for producing the same, and ink composition

A manufacturing method and encapsulation technology, which is applied in the direction of microcapsule preparations, inks, dyeing polymer organic compounds, etc., can solve the problems of difficult encapsulation of core materials, difficult compounds, and mixing into products, and achieve excellent dispersion stability. Excellent image quality and excellent stability results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

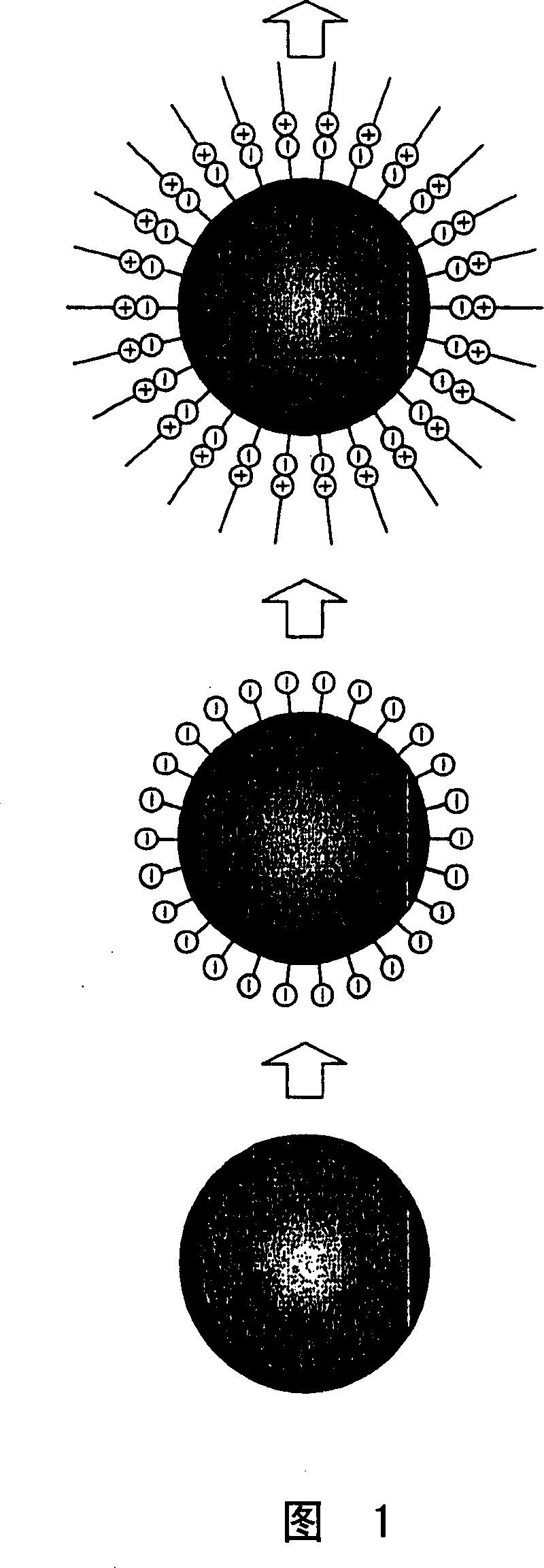

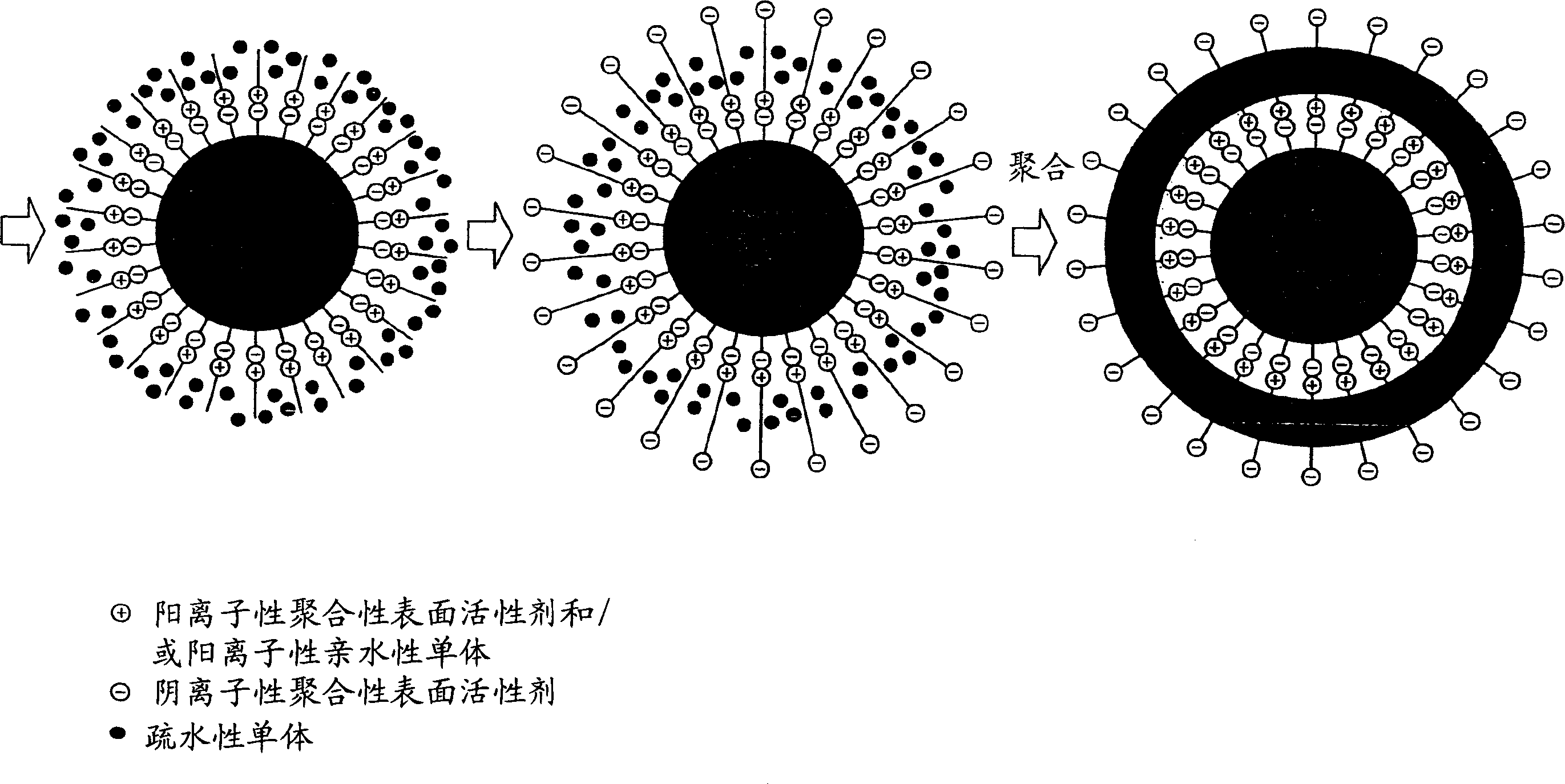

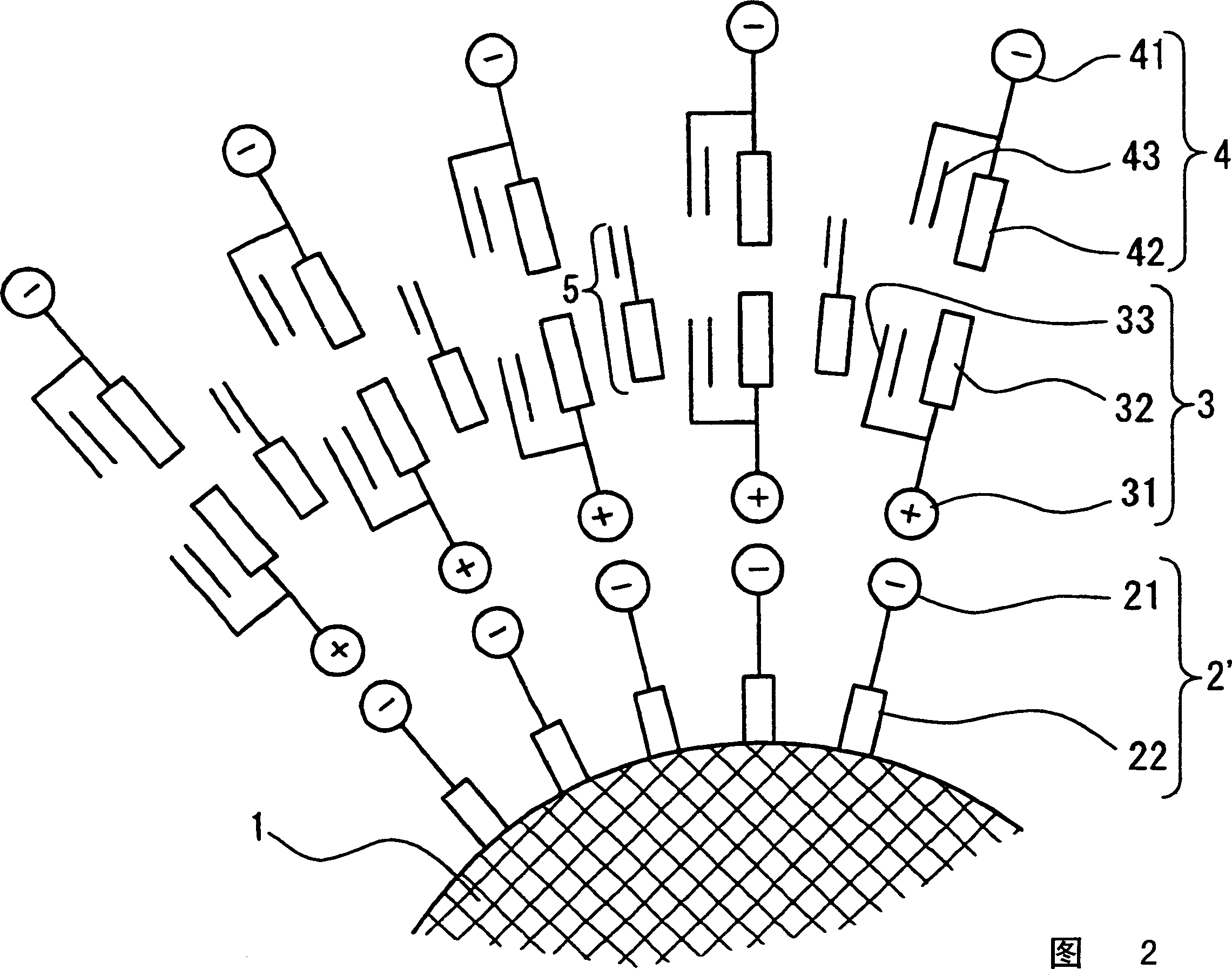

Method used

Image

Examples

Embodiment

[0451] Hereinafter, the present invention will be described more specifically based on examples, but the present invention is not limited by the examples. In addition, in the following examples, "part" means a mass part.

[0452] In addition, the anionic polymerizable surfactant Acron KH-10 (manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd.) used in Examples is a compound represented by the following formula.

[0453] [chem 37]

[0454]

[0455] n=9, 11

[0456] "Preparation of Encapsulated Pigment "MCP1""

[0457] 50 g of anionic polymerizable surface-active Acron KH-10 (manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd.) was dissolved in 850 g of ion-exchanged water, and 100 g of an isoindolinone pigment (C.I. Pigment Red 122) was added thereto and mixed. Using a disperser Aiga Motor Mill M250 (trade name, manufactured by Aiga Japan Co., Ltd.), the mixed solution was dispersed for 5 hours under the conditions of a bead filling rate of 70% and a rotation speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com