A pretreatment method for homogenizing chromium-free conversion coating on magnesium alloy

A technology of homogenization treatment and chrome-free transformation, which is applied in the direction of superimposed layer plating, metal material coating process, coating, etc., can solve problems such as uneven film formation, achieve uniform film layer, uniform nucleation, and process stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In the present embodiment, the sample is a die-cast WE43 magnesium alloy, and its specific steps are as follows:

[0037] (1) Pretreatment: The pretreatment solution is an aqueous solution of sodium hydroxide 50g / l, sodium fluoride 20g / l, and sodium carbonate 20g / l, at a temperature of 60°C, soaking for 5 minutes;

[0038] (2) Homogenization treatment: the homogenization treatment solution is ammonium phosphate 20g / l, sodium silicate 10g / l, the aqueous solution of hydroxylamine sulfate 20mg / l, soaks 1min at normal temperature;

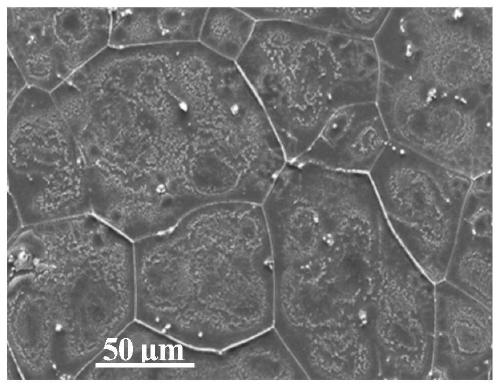

[0039] (3) Homogenization post-treatment: the homogenization post-treatment solution is 1wt% hydrochloric acid, 50mg / l sodium dodecylsulfonate aqueous solution, soaked at room temperature for 30s. After pretreatment according to this method, the second phase existing on the surface of the sample is completely dissolved, and its morphology can be seen in figure 2 ;

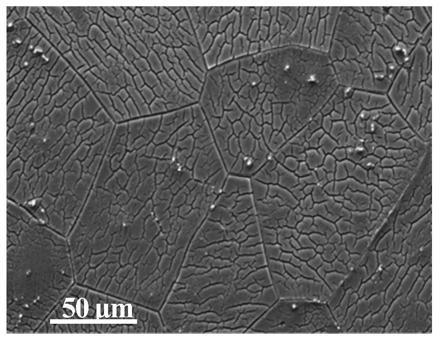

[0040] (4) Film formation: the sample after pretreatment is immersed in the p...

Embodiment 2

[0042] In the present embodiment, the sample is a die-casting GW93 magnesium alloy, and its specific steps are as follows:

[0043] (1) Pre-treatment: the pre-treatment solution is an aqueous solution of potassium hydroxide 40g / l, potassium fluoride 10g / l, and potassium carbonate 25g / l at a temperature of 50°C for 8 minutes;

[0044](2) Homogenization treatment: the homogenization treatment solution is ammonium dihydrogen phosphate 50g / l, sodium silicate 5g / l, the aqueous solution of hydroxylamine hydrochloride 40mg / l, soaks 2min at normal temperature;

[0045] (3) Homogenization post-treatment: the homogenization post-treatment solution is an aqueous solution of 3 wt % citric acid and 100 mg / l tetraethylamine perfluorooctane sulfonate, soaked at room temperature for 30 s.

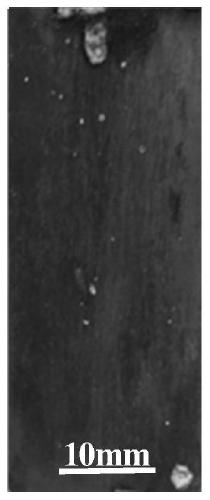

[0046] (4) Film formation: The sample after pretreatment is soaked in the phosphate solution described in patent ZL02132772.6 to prepare the film layer to form a phosphate conversion film with a thickness ...

Embodiment 3

[0048] In the present embodiment, the sample is a die-casting EW75 magnesium alloy, and its specific steps are as follows:

[0049] (1) Pretreatment: The pretreatment solution is an aqueous solution of sodium hydroxide 100g / l, sodium fluoride 40g / l, and sodium carbonate 20g / l at a temperature of 80°C for 5 minutes;

[0050] (2) homogenization treatment: the homogenization treatment solution is diammonium hydrogen phosphate 25g / l, sodium silicate 20g / l, the aqueous solution of ammonium metavanadate 100mg / l, soaks 2min at normal temperature;

[0051] (3) Homogenization post-treatment: the homogenization post-treatment solution is an aqueous solution of 5 wt % nitric acid and 150 mg / l disodium edetate, soaked at room temperature for 60 s.

[0052] (4) Film formation: the sample after pretreatment is soaked in the phosphate solution described in patent ZL201010125808.4 to prepare the film layer to form a phosphate conversion film with a thickness of 5 μm, and the film layer is uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com