Pretreatment method for preparing medium-high pressure corrosion foil and application of pretreatment method

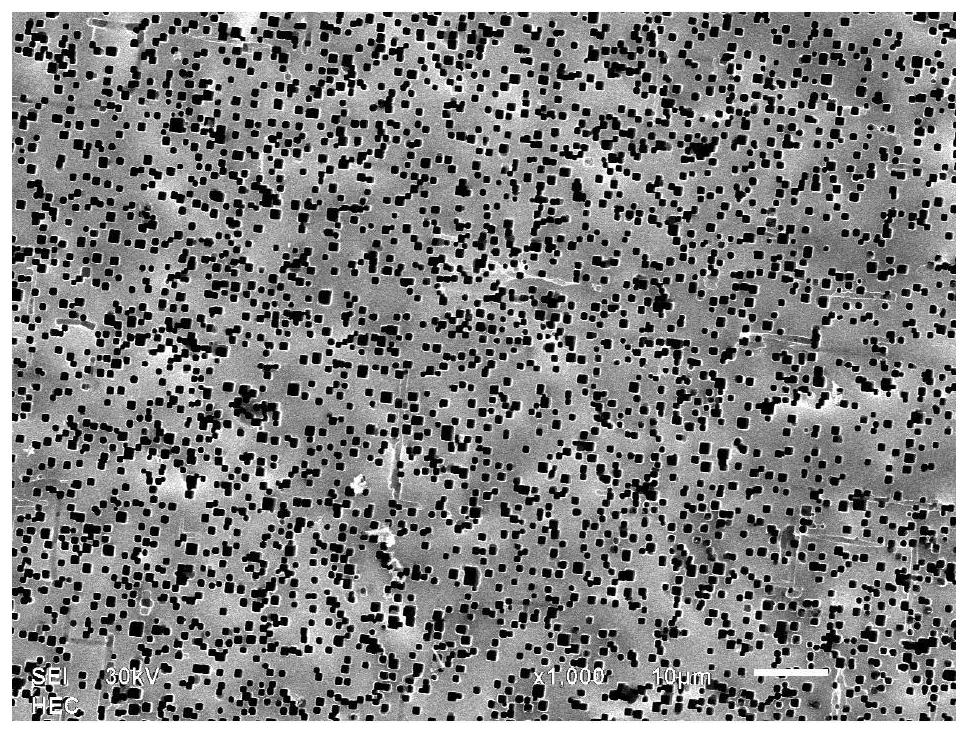

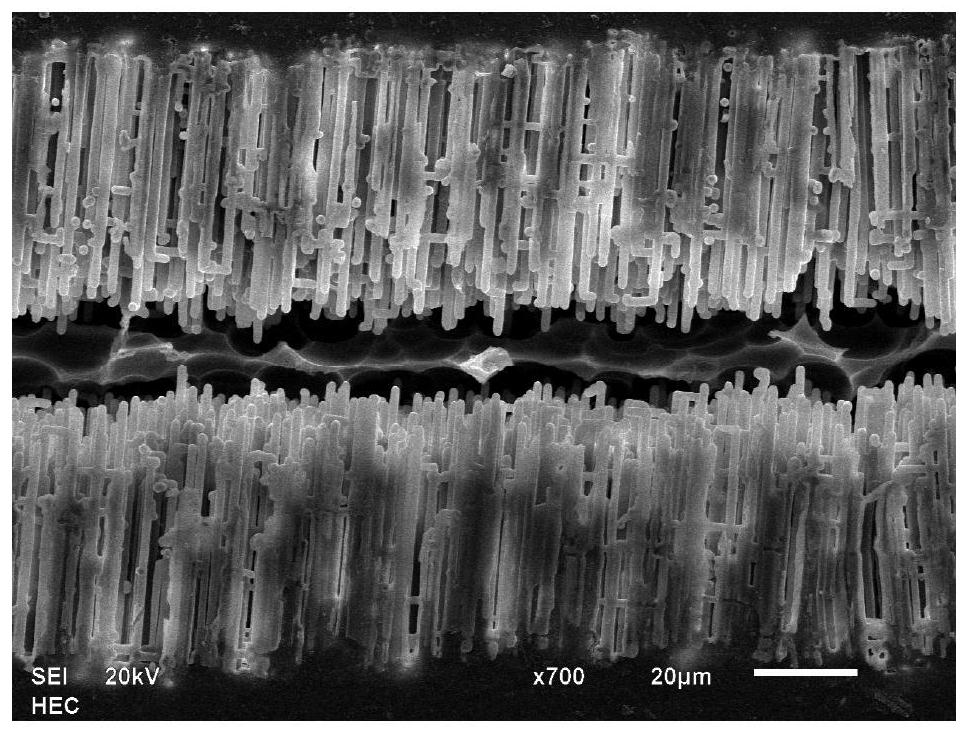

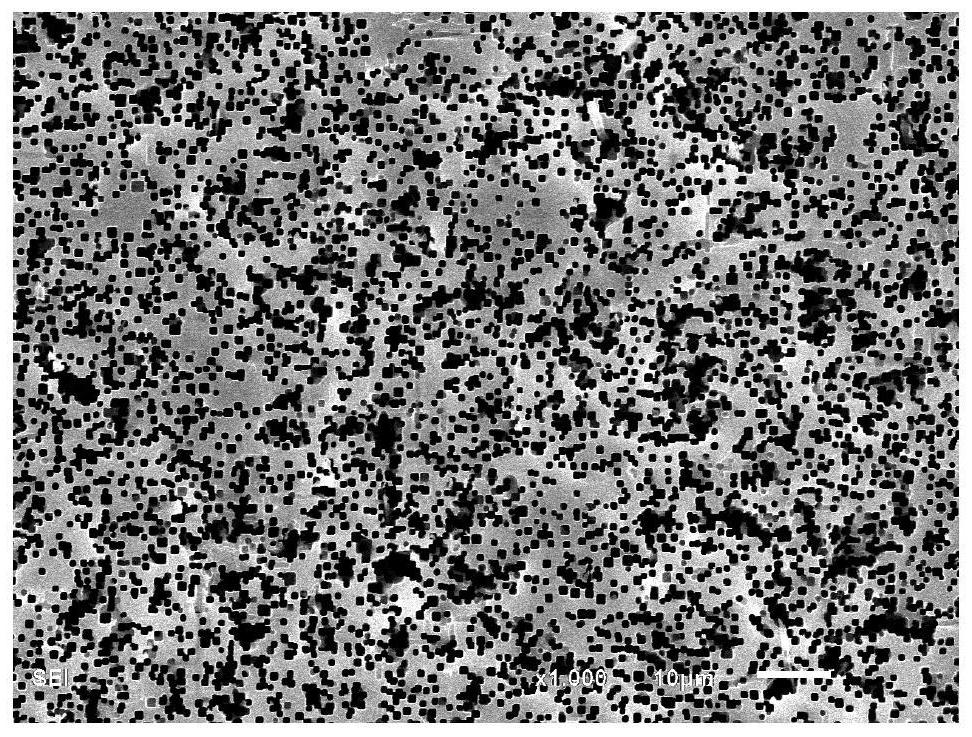

A medium and high voltage corrosion foil and pretreatment technology, which is applied to capacitors, circuits, electrical components, etc., can solve the problems of uneven distribution of surface corrosion pits and inconsistent lengths of tunnel holes, etc., to improve specific volume and bending performance, and improve Comprehensive performance, the effect of uniform pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A pretreatment method for preparing medium and high pressure etched foil, comprising the following steps:

[0053] S11. Pretreatment: put the aluminum foil into a pretreatment solution containing 50% phosphoric acid, 30% nitric acid, and 10% tartaric acid, and treat at 50°C for 180s;

[0054] S12. Pre-distribution of holes: put the aluminum foil pretreated in step S11. in a mixture of 10% hydrochloric acid and 0.3% sulfuric acid solution at 45°C for electrification treatment, and the current density is 0.35A / cm 2 , the power-on time is 50s, the frequency is 50Hz, the waveform is a sine wave, and then the water is washed at room temperature.

Embodiment 2

[0056] A pretreatment method for preparing medium and high pressure etched foil, comprising the following steps:

[0057] S11. Pretreatment: put the aluminum foil into a pretreatment solution with a mass fraction of phosphoric acid 60%, nitric acid 20%, and tartaric acid 5%, and treat at 30°C for 300s;

[0058] S12. Pre-distribution of holes: put the aluminum foil pretreated in step S11. in a mixture of 5% hydrochloric acid and 0.1% sulfuric acid solution at 25°C for electrification treatment, and the current density is 0.2A / cm 2 , the power-on time is 30s, the frequency is 30Hz, the waveform is a triangular wave, and then the water is washed at room temperature.

Embodiment 3

[0060] A pretreatment method for preparing medium and high pressure etched foil, comprising the following steps:

[0061] S11. Pretreatment: put the aluminum foil into a pretreatment solution containing 40% phosphoric acid, 35% nitric acid, and 20% tartaric acid, and treat at 50°C for 180s;

[0062] S12. Pre-arrangement of holes: put the aluminum foil pretreated in step S11. in a mixture of 15% hydrochloric acid and 0.5% sulfuric acid solution at 50°C for electrification treatment, and the current density is 0.5A / cm 2 , the power-on time is 60s, the frequency is 60Hz, the waveform is a rectangular wave, and then the water is washed at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com