Patents

Literature

39results about How to "Contributes to uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrathin high porosity film and preparation method thereof

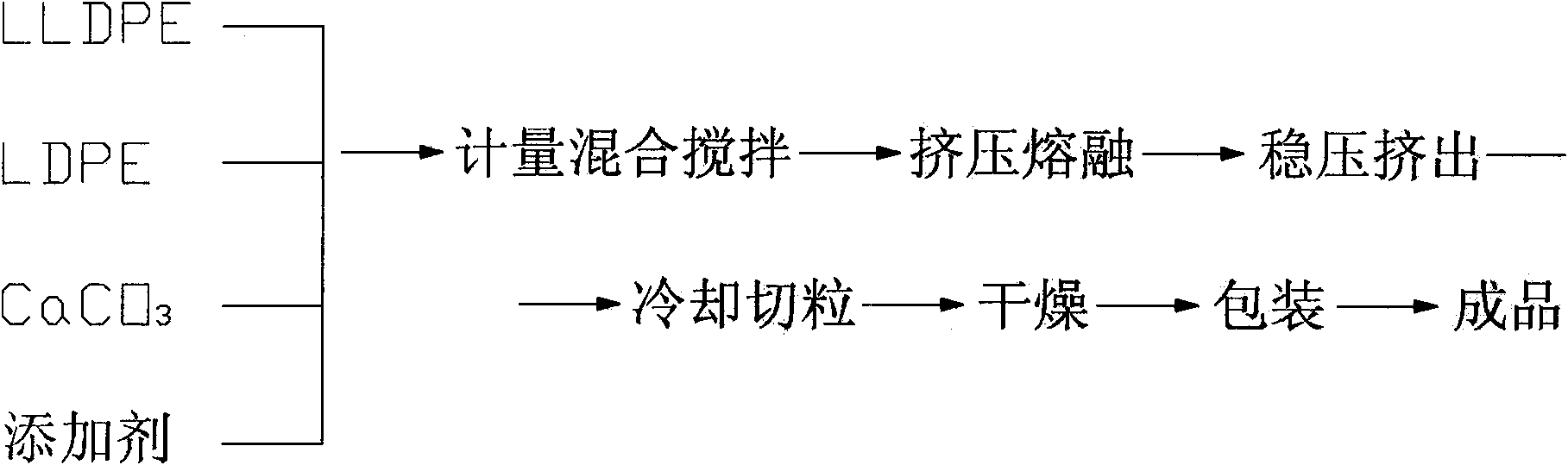

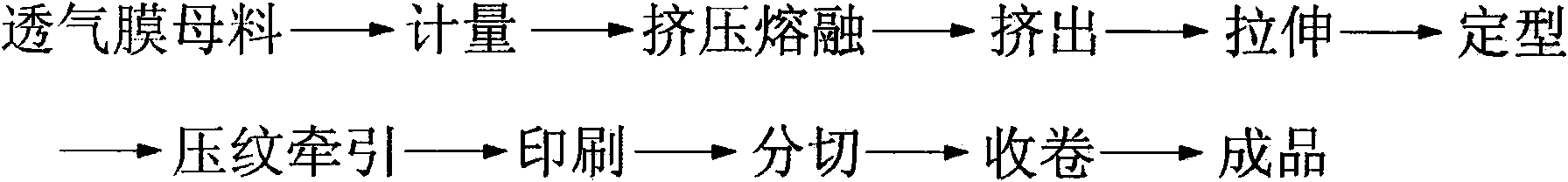

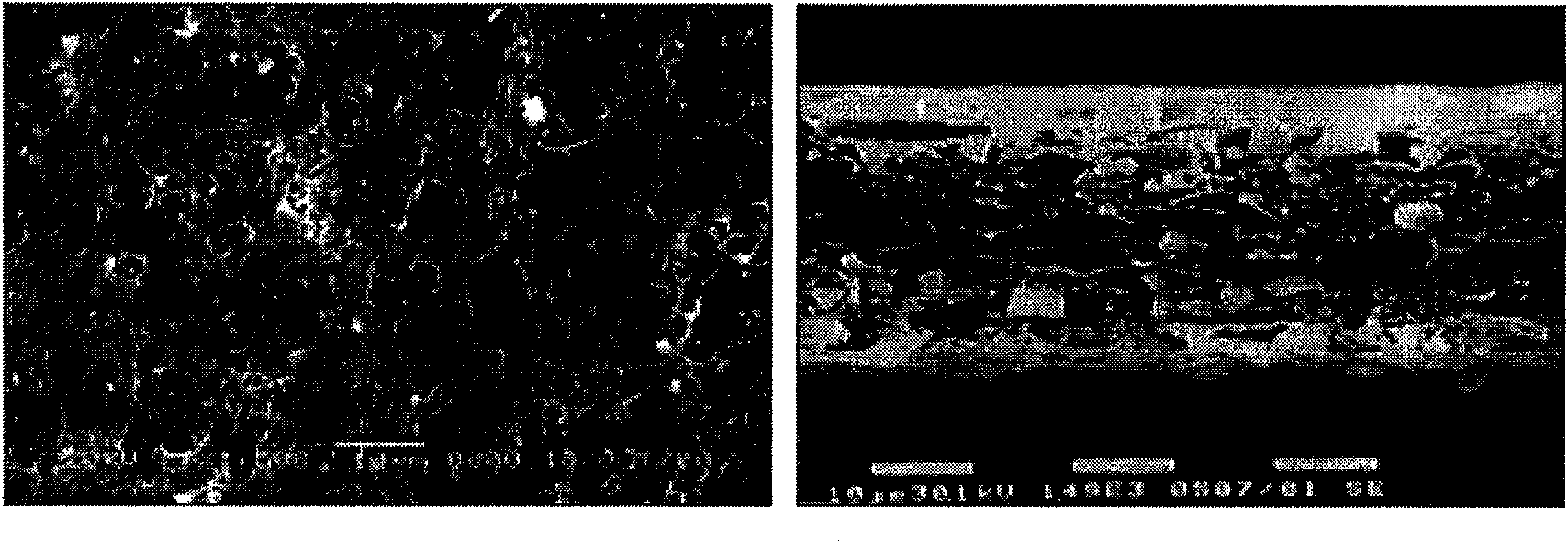

The invention discloses an ultrathin high porosity film and a preparation method thereof. The film comprises the following components by weight percent: 40-50% of : PE(LLDPE / LDPE), 45-55% of calcium carbonate and 3-5% of modified additives (plastic additive and film forming additive). The preparation method of the invention comprises the following steps: (1) breathable film master batch process flow and (2) breathable film process flow. The product of the invention can replace imported products, thus reducing the production cost of the breathable film, improving the current dilemma of foreignmonopoly, filling the domestic blank to develop and produce the breathable film material with independent intellectual property rights and having practical and great economic benefit and social benefit.

Owner:ZHEJIANG YUEHAN TECH BREATHABLE MATERIAL

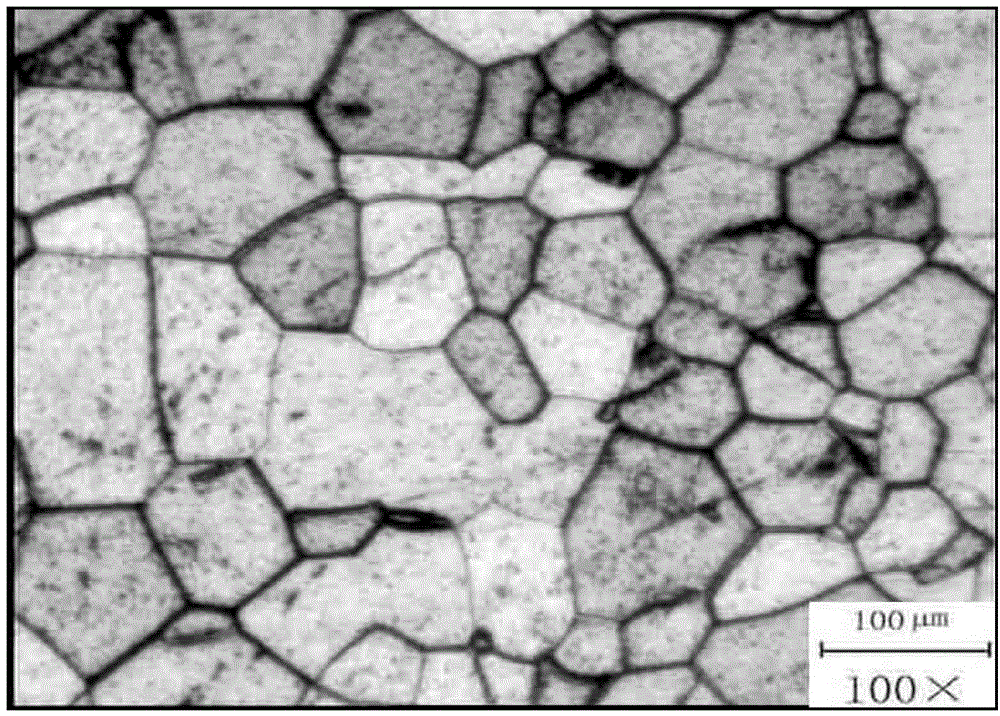

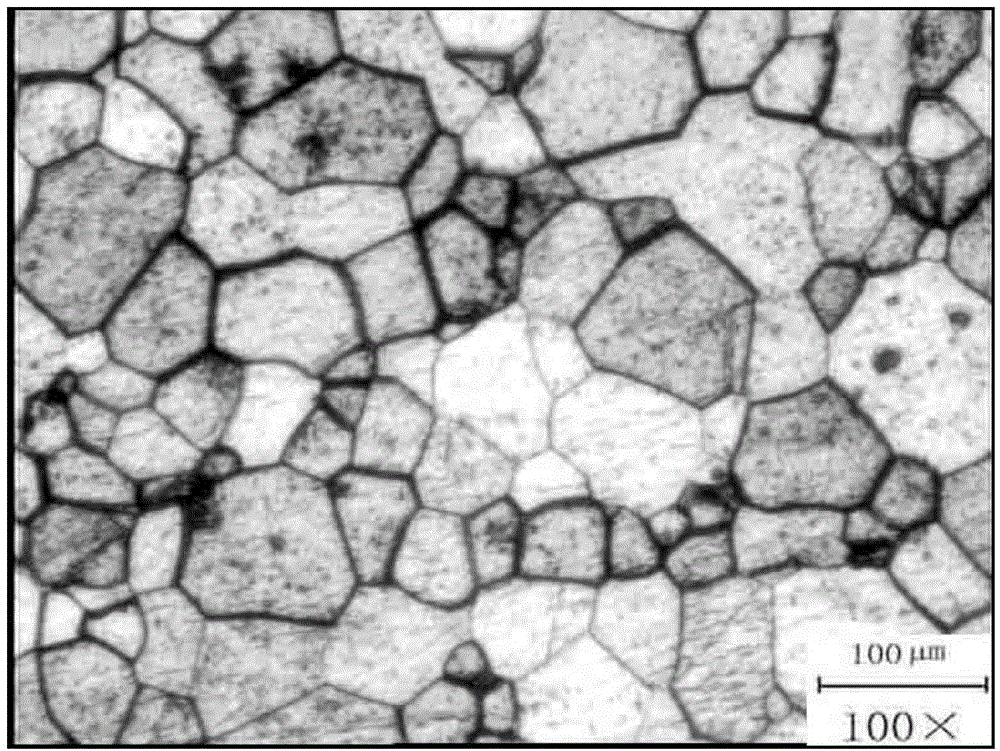

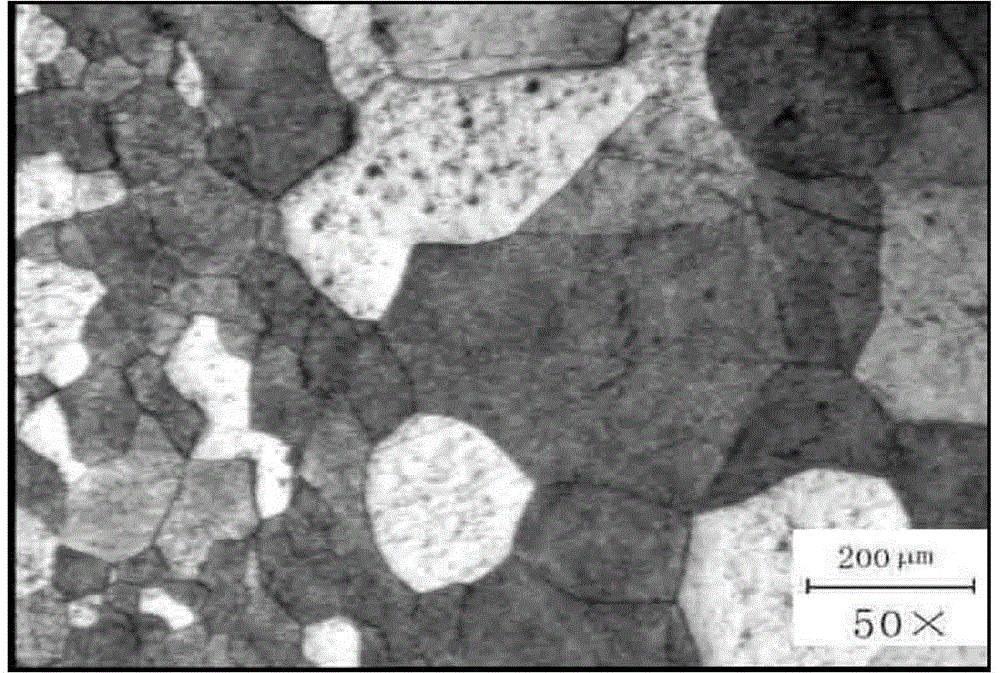

Niobium target and preparation method of niobium target

ActiveCN103009000AReduce surface roughness valueImprove surface qualityVacuum evaporation coatingSputtering coatingNiobiumSurface roughness

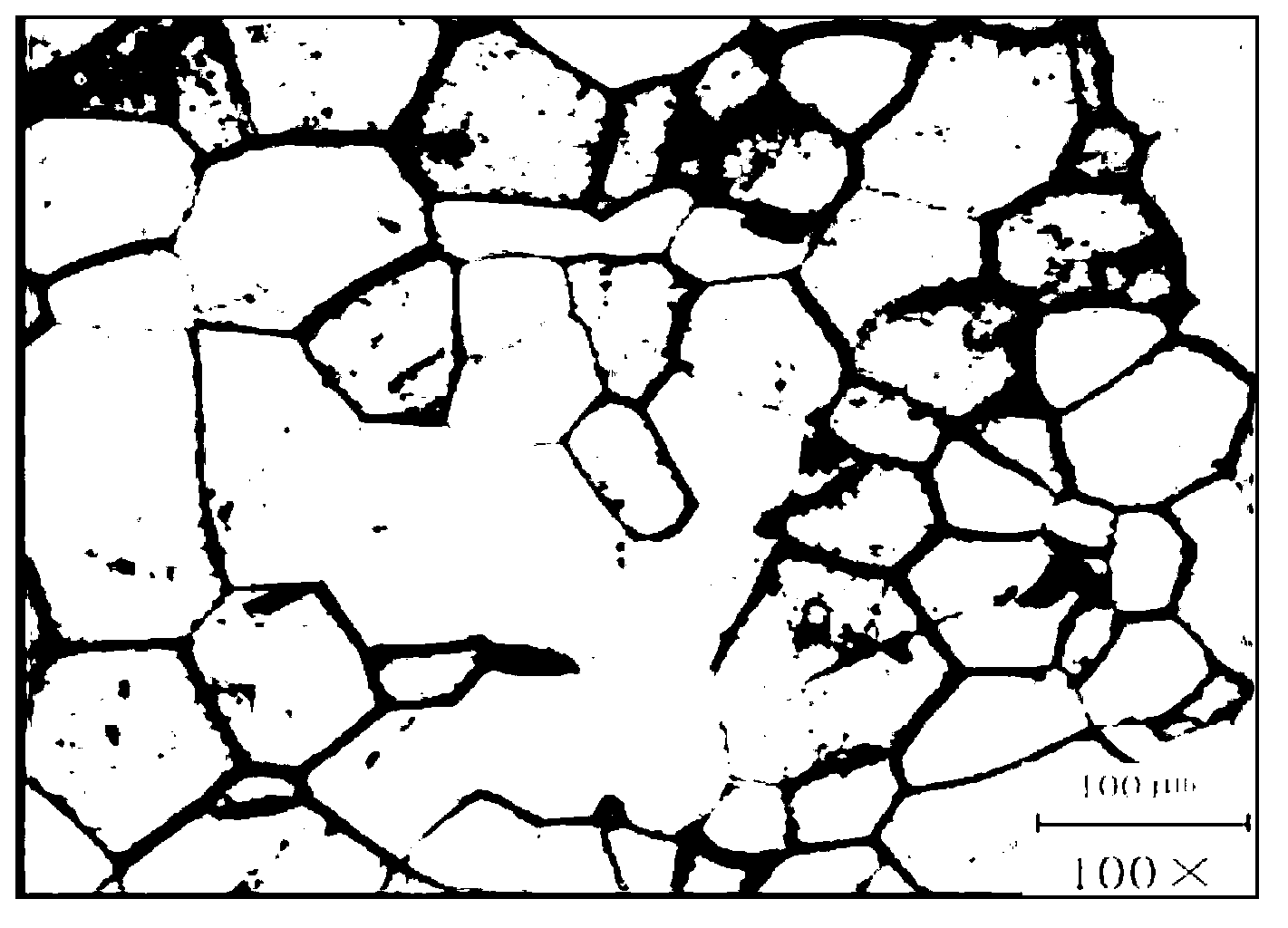

The invention provides a preparation method of a niobium target. According to the preparation method, firstly, a niobium pipe blank is subjected to hot extrusion, and then, the niobium pipe blank subjected to the hot extrusion is subjected to inner hole processing, so the niobium target is obtained. In the niobium target preparation process, firstly, glass powder is coated on the niobium pipe blank surface, because the niobium pipe blank surface is sprayed with the glass powder, a better lubricating effect is realized in the extrusion process, and the surface quality of the niobium pipe blank is better; the subsequent hot extrusion processing and the thermal treatment are favorable for the refining and homogenization of niobium pipe blank crystalline grains; and finally, the extruded niobium pipe blank is subjected to machining, a special tool is selected for carrying out boring and milling inner holes of the niobium pipe blank, broken chips can be continuously discharged out from the inner holes, and the problem of inner hole surface processing influence caused by the accumulation of the broken chips in the inner holes is avoided, so the niobium target with uniform inner crystalline grains and lower surface roughness value is obtained. The invention also provides the niobium target.

Owner:NINGXIA ORIENT TANTALUM IND

Moisture permeation and water proofing fabric, and preparation process thereof

InactiveCN102619092ASolve the weakness that it is easy to expand when exposed to waterGood moisture permeabilityFibre treatmentCoated surfaceMoisture permeation

The present invention discloses a moisture permeation and water proofing fabric, and a preparation process thereof. According to the fabric, a prime coat comprises: a polyurethane resin, butanone, toluene, water, 1,6-diisocyanatohexane and N-methylethanolamine; a first surface coating and a second surface coating comprise a polyurethane resin, butanone, toluene, water and N-methylethanolamine. The preparation process comprises: mixing 1,6-diisocyanatohexane and a main resin; mixing water and butanone to form a solvent; adding the solvent to the main resin mixing solution in at least 6 times; filtering the resulting mixed solution with a nylon net to obtain a filtered main resin solution; carrying out a deaeration treatment to form a prime coat slurry; blending a surface coating slurry with a matching solution viscosity of 3500-6000 mpas; coating the prime coat slurry on the surface of the base cloth to form the prime coat, and drying; coating the surface coating slurry on the surface of the prime coat in 2 times to form the surface coatings, and drying. In the prior art, micropores in the hydrophilic moisture permeation processing coating fabric are not uniform, and are easily expanded when contacting the water. With the present invention, the disadvantages in the prior art are solved, and the moisture permeation performance of the fabric is improved.

Owner:KUNSHAN HUAYANG NEW MATERIAL

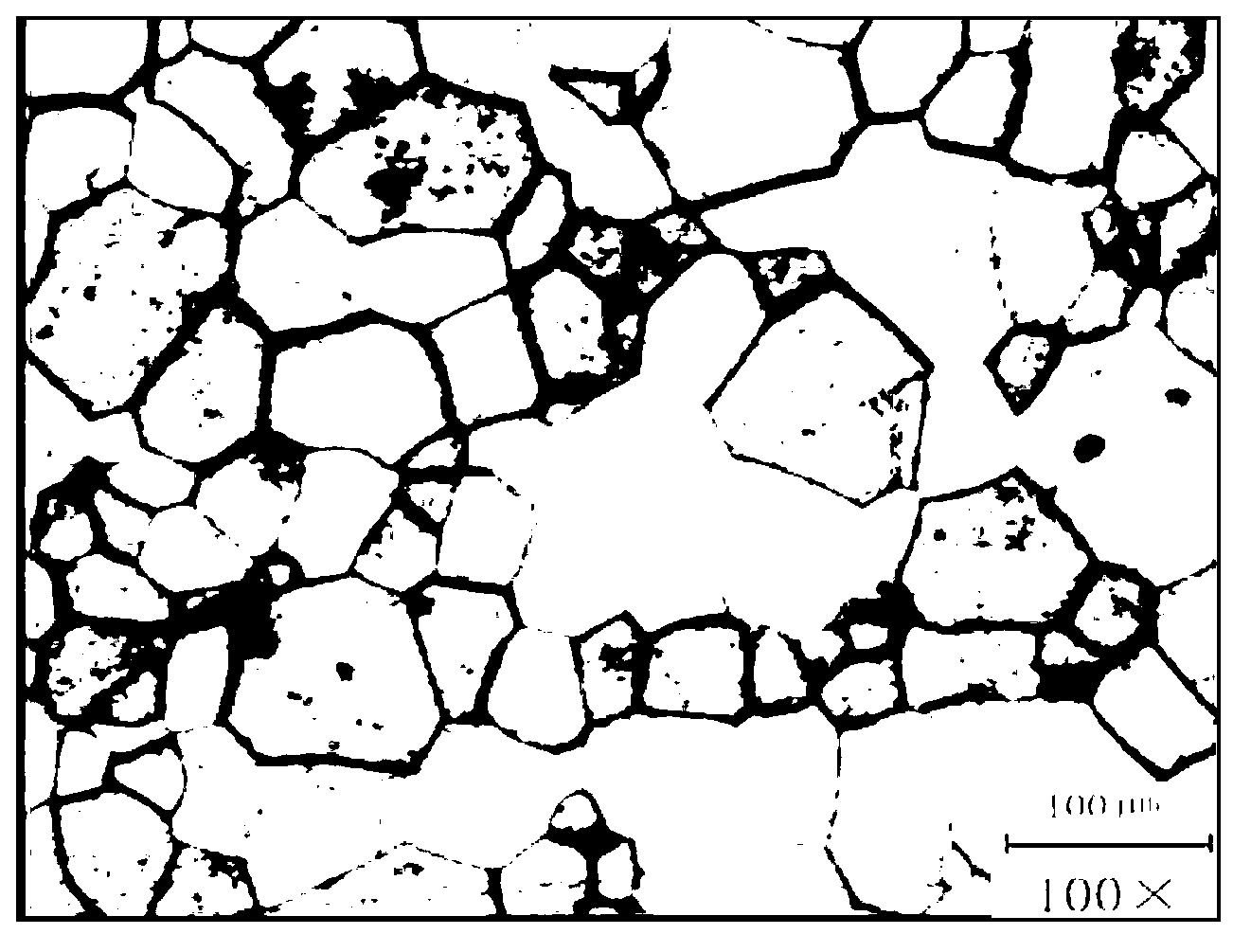

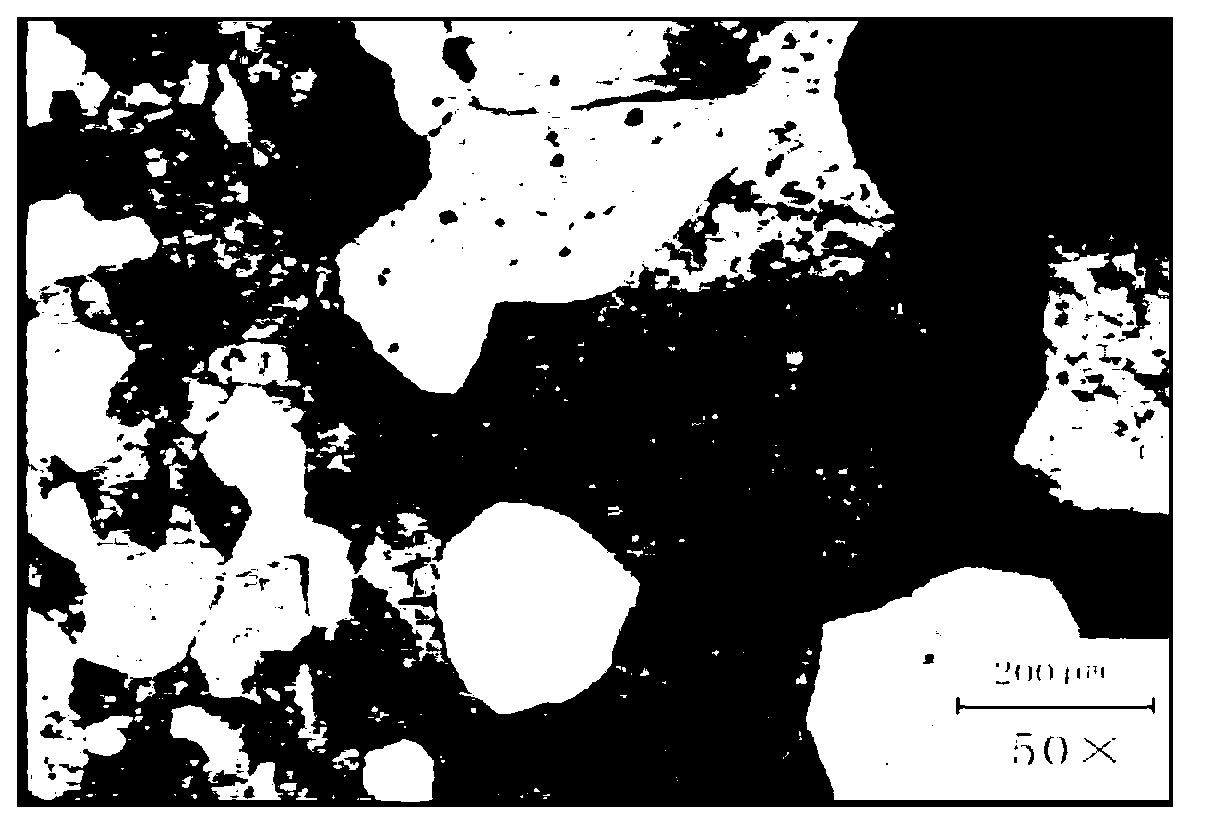

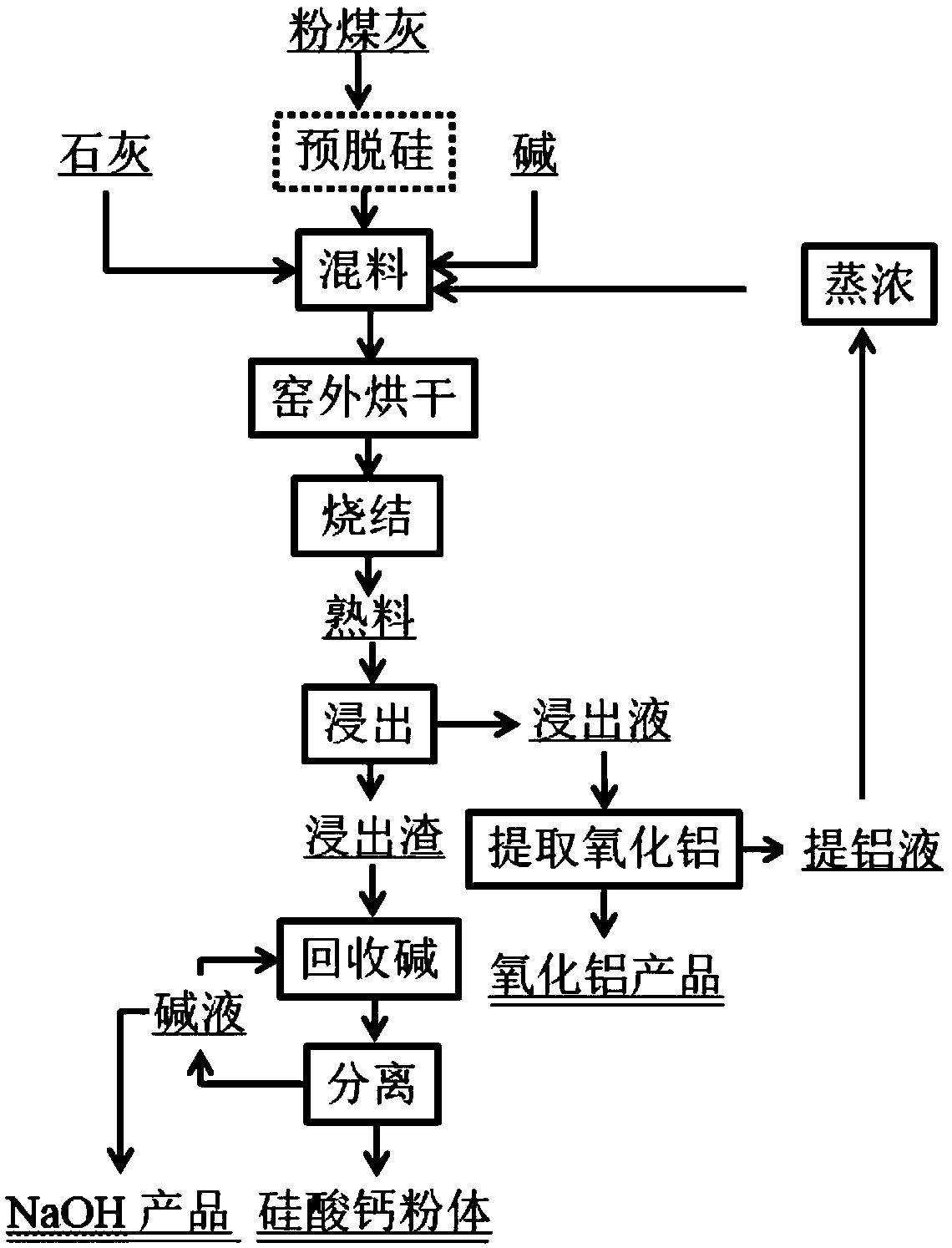

Method for comprehensively utilizing fly ash

InactiveCN109231225ARealize resource processingContributes to uniformityAlkaline-earth metal silicatesAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationCalcium silicateDecomposition

The invention relates to a method for comprehensively utilizing fly ash. The method comprises the following steps: S1, mixing and preparing materials: mixing and preparing the fly ash, lime, alkali and a mother solution and drying to obtain mixed raw materials; S2, sintering: carrying out sintering reaction on the mixed raw materials at the temperature of 800 to 1250 DEG C, so as to obtain sintered clinker; S3, carrying out leaching reaction: carrying out the leaching reaction on the sintered clinker; carrying out liquid-solid separation to obtain leaching residues and a leaching solution; S4,carrying out aluminum extraction treatment: treating the leaching solution by utilizing evaporation, concentration and crystallization, seed crystal decomposition and carbonization decomposition or any combination of former three manners, so as to obtain an aluminum extraction mother solution and an Al(OH)3 or NaAlO2 crystal; after concentrating the aluminum extraction mother solution, returningback to S1; S5, carrying out dealkalization on the leaching residues: mixing the leaching residues and a sodium hydroxide solution and carrying out dealkalization reaction; carrying out solid-liquid separation to obtain calcium silicate powder and alkali liquid; S6, recycling the alkali liquid of S5. According to the method provided by the invention, aluminum oxide and silicon oxide in the fly ashare recycled; the extraction rate of the aluminum oxide can reach 90 percent or more and nearly no pollutants are discharged; nearly all components of the fly ash are recycled and utilized; the effects of recycling treatment and high-additional-value comprehensive utilization of the fly ash are realized.

Owner:NORTHEASTERN UNIV LIAONING

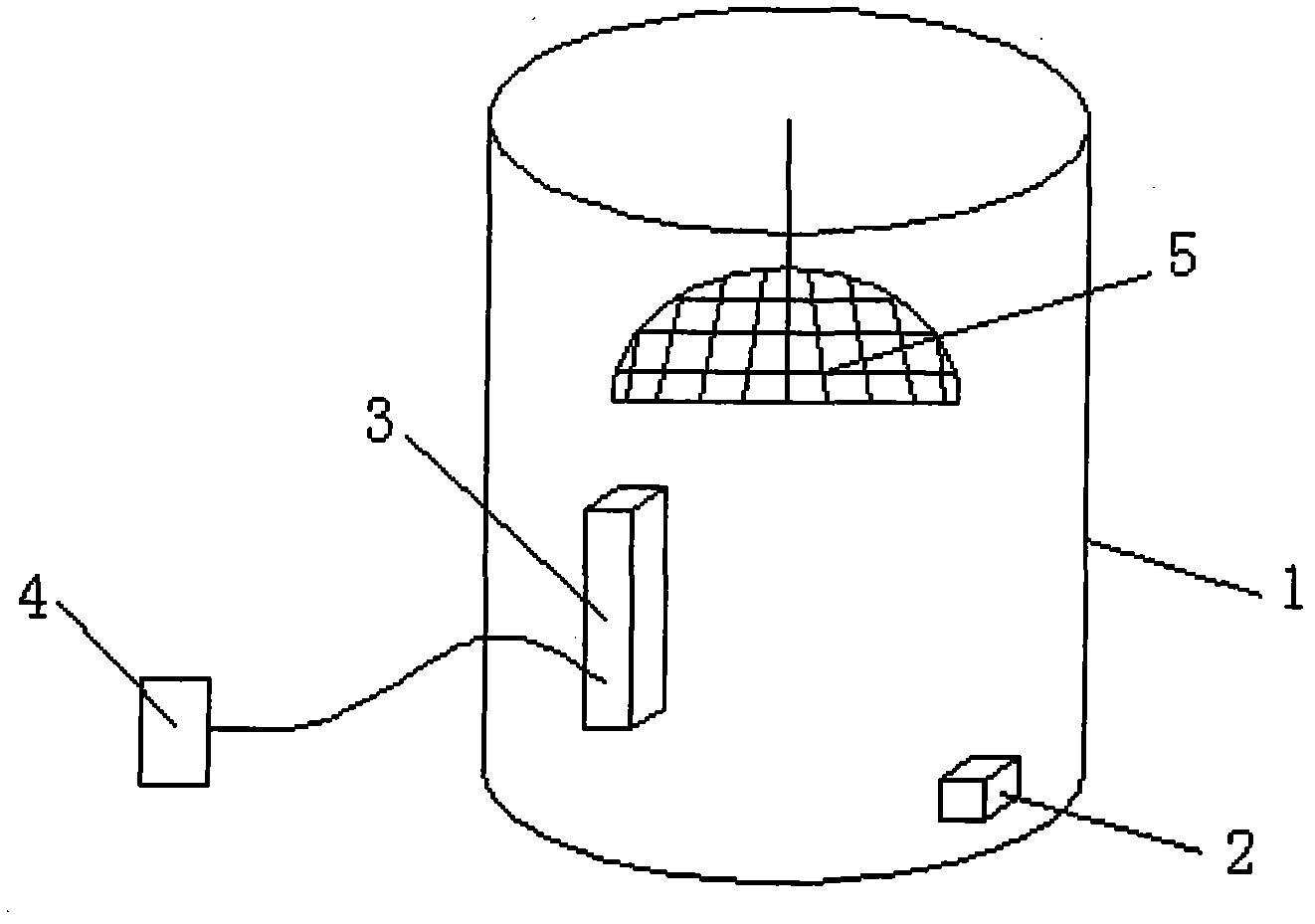

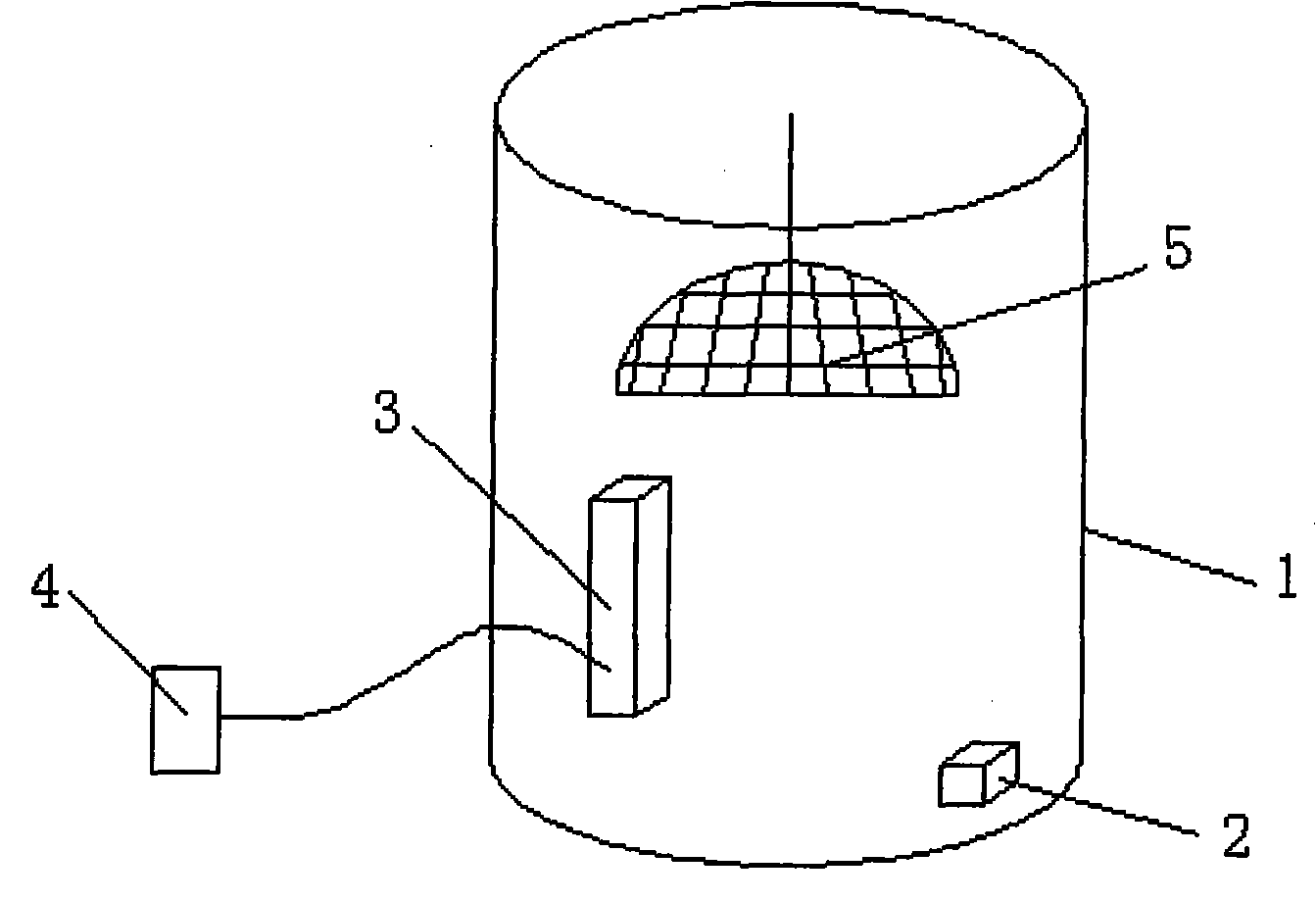

Ion plating device

InactiveCN101956161AHigh film strengthGood compactnessVacuum evaporation coatingSputtering coatingFilm materialIon source

The invention discloses an ion plating device and relates to a device for plating through the vacuum evaporation, sputtering or ion injection of a coating forming material, in particular to an ion plating device. The device comprises a plating furnace and a film material arranged in the plating furnace. The device is characterized in that the plating furnace is internally provided with an ion source for emitting plasma, and the ion source is used for emitting plasma to heat the film material to ensure that the film material becomes steam and is uniformly plated on a glass sheet to effectively enhance the film layer strength, thus the plating compactness is better, the reject ratios due to scraping, spot stains, and the like in the production process of lenses are reduced, and the yield of the process is effectively improved; the ion source is arranged on the middle rear part of the plating furnace so as to be beneficial to the uniformity of the ion emitting angle of the ion source to realize uniformly plating; and argon is added to mixed gas, which can increase the ion density and prolong the service life of lamp filaments of the ion source.

Owner:苏州五方光电科技有限公司

Shock-resistant corrosion-resistant aluminum alloy softball bat material and preparing method thereof

The invention discloses a shock-resistant corrosion-resistant aluminum alloy softball bat material and a preparing method thereof, and relates to the technical field of aluminum alloys. The shock-resistant corrosion-resistant aluminum alloy softball bat material comprises, by weight percentage, 0.3%-0.5% of Si, 0.8%-1.1% of Mg, 0.1%-0.3% of Mn, 0.3%-0.5% of Cu, 0.4%-0.7% of Fe, 3.5%-3.9% of Zn, 0.1%-0.3% of Li, 0.1%-0.3% of Cr, 0.3%-0.5% of Ti, 0.1%-0.3% of Ce, 0.05%-0.1% of Sc and the balance Al. All elements and contents in the alloy are reasonably optimized, the good mechanical property anddecay resistance are achieved, melt is subject to vibration scattering under a certain frequency in the preparing process, grains can be effectively refined, refining and homogenization of material organization and a second phase are facilitated, a casting ingot is subject to homogenization treatment through three-stage continuous temperature rise, the homogenization degree is more high, the mechanical property of the alloy can be further improved, the material organization is improved, the alloy material obtained after heat treatment has the good strength, hardness and corrosion resistance,the material is used for a softball bat, acute impact of balls to a bat body can be borne for a long period, cracking deformation is not prone to occurrence, and the service life is long.

Owner:TIANCHANG ZHENGMU ALUMINUM TECH

Water-soluble peelable paint and preparation method thereof

InactiveCN108676437APromote sheddingAvoid the problem of scratching the surface of the materialCoatingsCelluloseButyrate

The invention belongs to the technical field of peelable paint, and particularly relates to water-soluble peelable paint and a preparation method thereof. By aiming at the defect that the existing peelable paint mostly aims at the metal surface protection, so that organic solvents harmful to the environment are used. The water-soluble peelable paint is characterized by being prepared from the following ingredients in parts by weight: 100 to 250 parts of acetate butyrate carboxyethyl cellulose, 680 to 900 parts of acrylic resin, 10 to 30 parts of carbon micro nanometer materials, 12 to 15 partsof peeling accelerators, 3 to 10 parts of film forming auxiliary agents, 3 to 10 parts of wetting agents, 10 to 15 parts of dispersing agents, 0 to 30 parts of thickening agents and 110 to 180 partsof water. The water-soluble peelable paint is applicable to the temporary protection on nonmetal material surfaces of ceramics, glass, plastics and the like.

Owner:四川迈克兰诺气泡科技有限公司

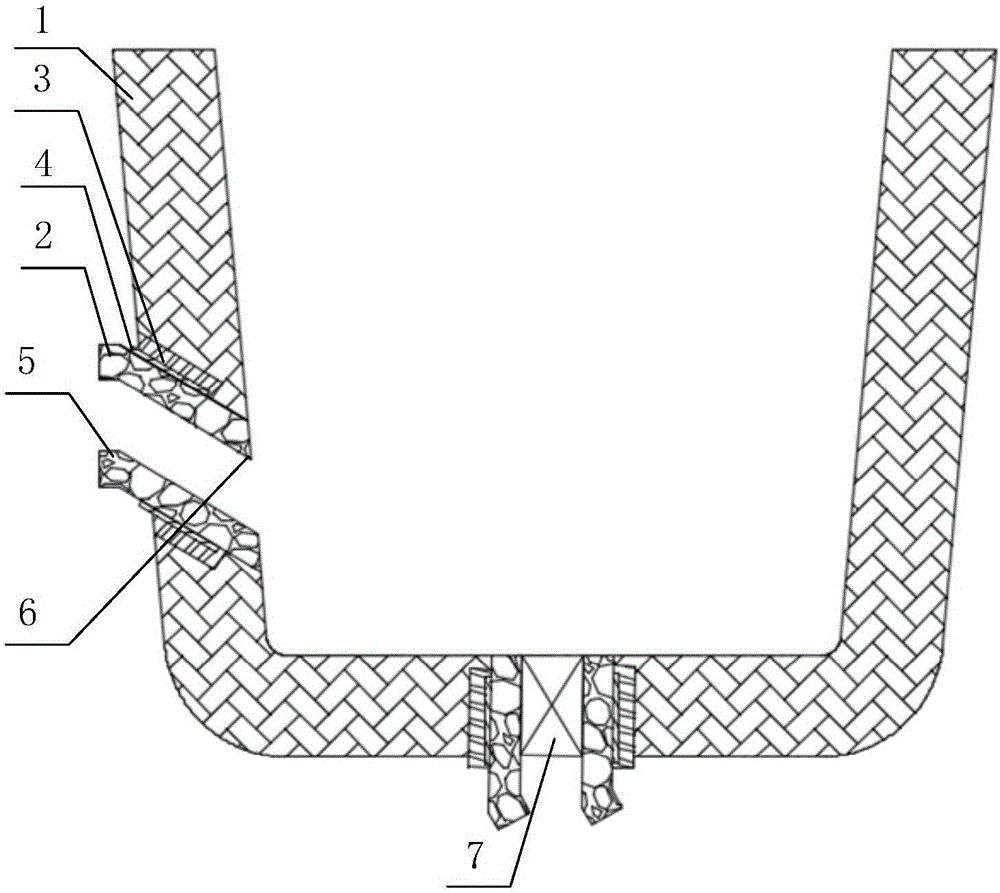

Molten slag discharging devices and plasma furnace

ActiveCN106287744APrevent solidificationAvoid scarring, fromIncinerator apparatusMolten saltMolten slag

The invention provides molten slag discharging devices and a plasma furnace. Each molten slag discharging device comprises a slag discharging pipe for discharging melt; an outer layer of the slag discharging pipe is provided with a heat preservation lining sleeve; and a heating element is arranged between the slag discharging pipe and the heat preservation lining sleeve. The plasma furnace comprises a furnace body and the molten slag discharging devices. The number of the molten slag discharging devices is at least two. One of the molten slag discharging devices is obliquely arranged on the side wall of the furnace body, and the bottom of an outlet of the slag discharging pipe of the molten slag discharging device is higher than the top of an inlet of the slag discharging pipe. The other molten slag discharging device is perpendicular to the bottom of the furnace body, and a switch is arranged in the slag discharging pipe of the molten slag discharging device.

Owner:浙江民生源环保设备有限公司

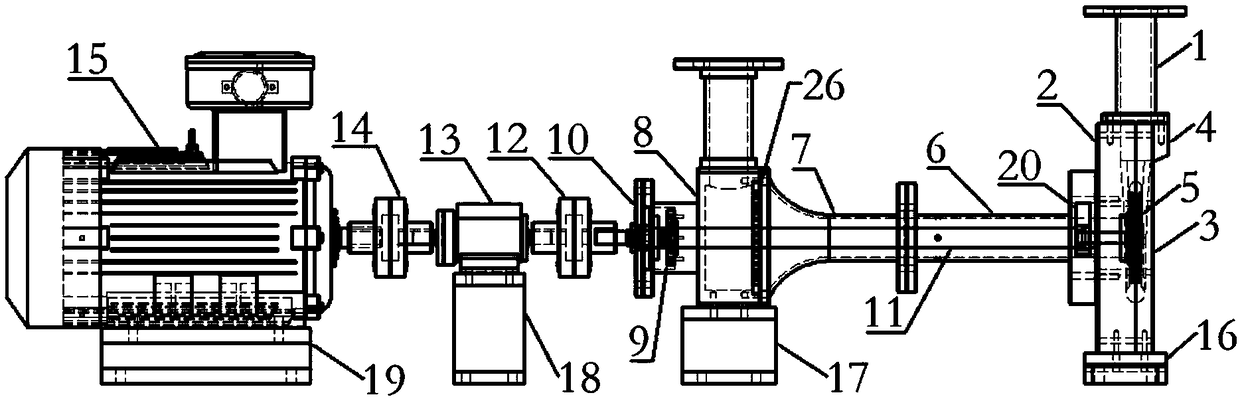

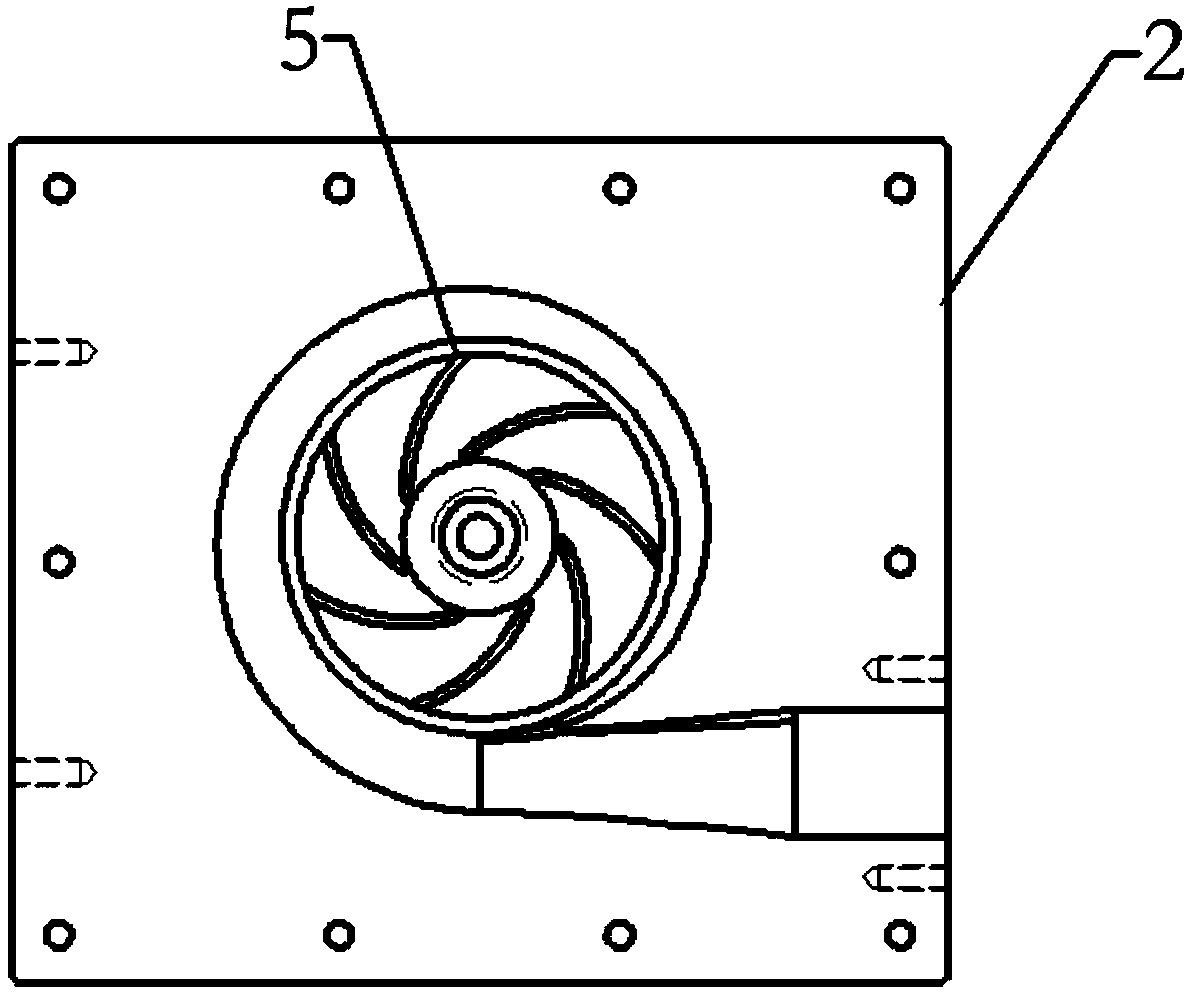

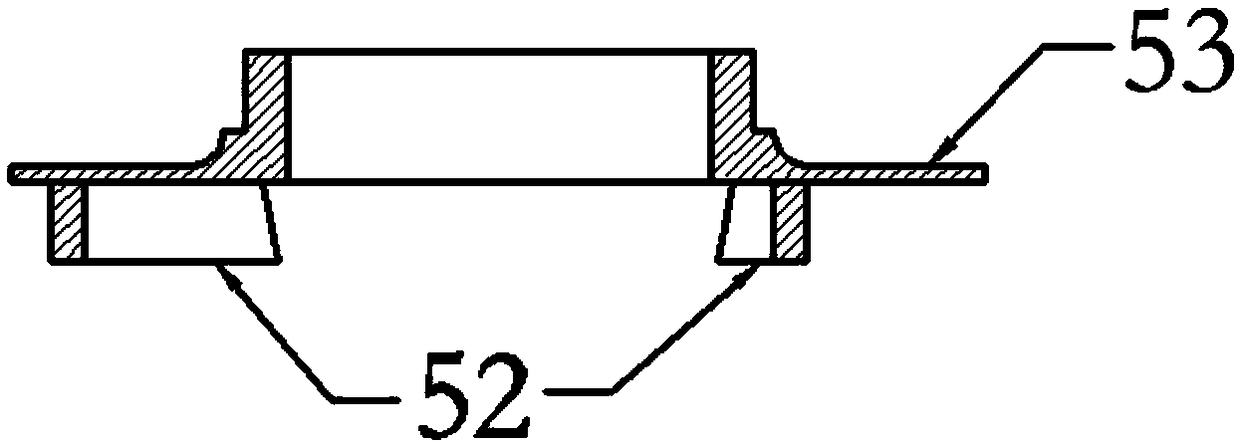

Flowing observation device for internal gas-liquid phase of centrifugal pump

InactiveCN109296566AReduce disturbanceGood light transmissionPumpsNon-positive displacement fluid enginesEngineeringOrganic glass

The invention discloses a flowing observation device for an internal gas-liquid phase of a centrifugal pump. The flowing observation device comprises a water inlet part, a water outlet part, a box anda power transmission part; and pump shafts are arranged at the centers inside the water outlet part, the water inlet part, the box and the power transmission part. According to the visual observationdevice disclosed by the invention, the problems that an existing testing device is limited to an internal flowing observation area of the centrifugal pump, and is complex in structure and low in operability are solved. By utilizing the characteristics of the smooth surface and the good light transmission property of organic glass, a centrifugal pump experimental device is designed to middle and lateral water inlet through a certain means, so that the water inlet end and the power transmission part are on the same side, an impeller rear cover plate faces outwards, thus a complete flowing imageinside a whole impeller can be shot by a high-speed camera in the direction of the impeller rear cover plate; and the structure is simple, mounting is convenient, the application range is wide, operation is convenient and fast, the effective means is provided for an internal flow field observation experiment of the centrifugal pump, and the quite high practical value is achieved.

Owner:XIAN UNIV OF TECH

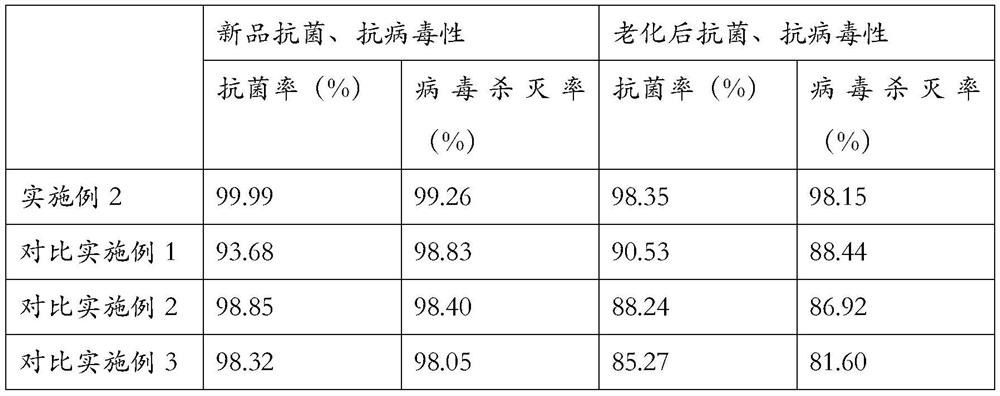

Antibacterial and antiviral coating and preparation method thereof

InactiveCN112552749AImprove use valueEasy to useWax coatingsAntifouling/underwater paintsAnti bacterialDefoaming Agents

The invention belongs to the technical field of coating processing, and particularly relates to an antibacterial and antiviral coating and a preparation method thereof, and the antibacterial and antiviral coating comprises the following substances in parts by weight: 75-80 parts of film-forming resin, 10-15 parts of emulsion, 6-9 parts of film-forming aid, 0.5-1.5 parts of defoamer, 0.5-1 part ofwetting agent, 4-8 parts of modified filler, 2-4 parts of antibacterial additive and 0.1-0.3 part of amine neutralizer. The coating is good in antibacterial and antiviral capacity, simple in preparation method and easy to apply and popularize.

Owner:简珍霞

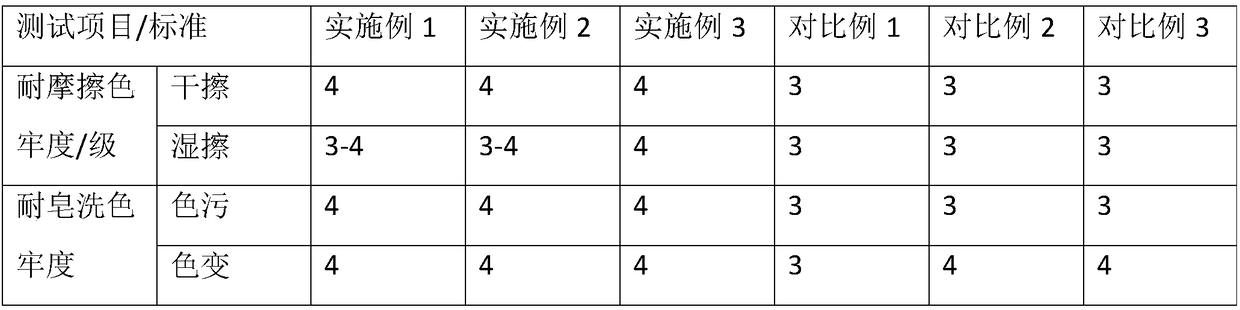

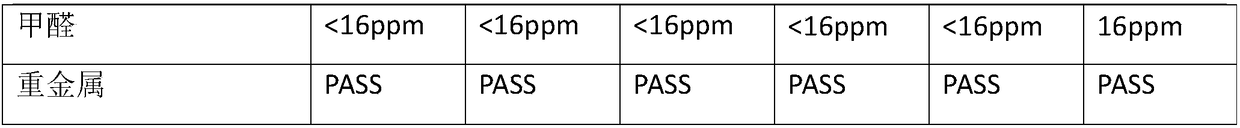

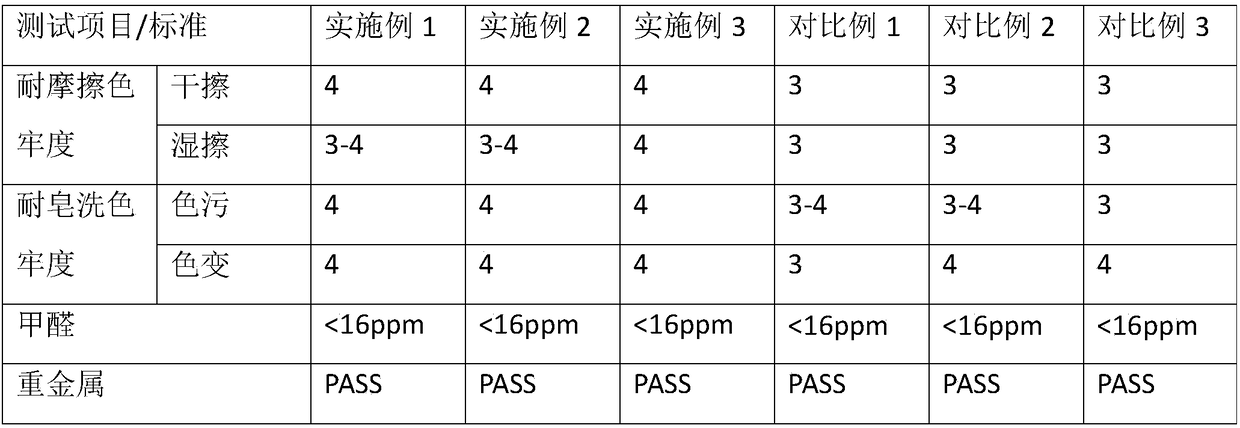

Temperature-sensitive printing paste and printing process thereof

The invention discloses temperature-sensitive printing paste, which is prepared from the following raw materials in parts by weight: 0.5 to 3 parts of a binder, 0.5 to 19 parts of a temperature changematerial, 10 to 50 parts of a crosslinking agent and 2 to 5 parts of a thickener. Meanwhile, the invention further provides a temperature-sensitive color printing process, comprising the following steps: S1, slurrying: uniformly mixing the binder, the temperature change material, the crosslinking agent and the thickener to obtain the temperature-sensitive printing color paste; S2, bleaching and dyeing; S3, setting before printing; S4, printing: feeding the temperature-sensitive printing paste obtained in the step S1 into a screen, and covering cloth by the temperature-sensitive printing pasteto obtain printed cloth C; S5, drying and baking: drying and baking the printed cloth C. The temperature-sensitive printing paste has the beneficial effects that the temperature-sensitive printing paste is high in safety and high in color change sensitivity; the printing process is simple; the color of the prepared color change cloth sensitively changes with temperature, and the color change cloth is firm in color, high in safety and suitable for being used in infant products.

Owner:游晟纺织科技(深圳)有限公司

Method for biologically testing chemoreception potential of plant root system secretions

InactiveCN102172128BContributes to uniformityControl interferenceHorticulture methodsPlant rootsSecretion

The invention relates to a method for biologically testing chemoreception potential of plant root system secretions, belonging to the field of biological test technology.The method comprises the following steps: preparing agar liquid with a concentration less than or equal to 0.3% with water; sterilizing the agar liquid and pouring the agar liquid into a culture dish; disinfecting the donor plantand sowing the donor plant in the culture dish; sealing the culture dish, keeping the culture dish in a culture room with a temperature of 25-28 DEG C for 12 hours and culturing for 10-14 days in thebright / dark environment; removing all plants to be tested from the 11th day to the 15th day; disinfecting the receptor plant and sowing the receptor plant in the culture dish with the donor plant removed; sealing the culture dish, keeping the culture dish in a culture room with a temperature of 25-28 DEG C for 12 hours and culturing for 5-7 days in the bright / dark environment; then taking out thereceptor plant to measure growth amount thereof and growth amount of the receptor plant not affected by the donor plant; calculating influence of the plant root system secretions on the growth of thereceptor plant according to the measured growth amount to carry out chemoreception potential assessment.The invention is characterized by excluding competition among plant species for water and nutrient and fully reflecting effects the donor plant root system secretions have on the receptor plant.

Owner:云南省农业科学院生物技术与种质资源研究所

Niobium target and preparation method of niobium target

ActiveCN103009000BReduce surface roughness valueImprove surface qualityVacuum evaporation coatingSputtering coatingNiobiumSurface roughness

Provided is a method for preparing a niobium target material, including: firstly hot extruding a niobium tube blank, and then processing an inner hole of the hot extruded niobium tube blank, thereby obtaining a niobium target material. During a process for preparing a niobium target material of the present invention, the surface of a niobium tube blank is firstly coated with a glass powder, and because the surface of the niobium tube blank is spray-coated with the glass powder, it has a better lubrication effect during an extrusion process, so that the surface quality of the niobium tube blank is better; the subsequent hot extrusion processing and heat treatment facilitate the refinement and homogenization of grains of the niobium tube blank; and finally, the extruded niobium tube blank is machined, and the inner hole of the niobium tube blank is bored and milled by special cutters, so that broken chips can be continuously discharged from the inner hole, avoiding the problem of the influence of accumulation of the broken chips in the inner hole on the surface processing of the inner hole, thereby obtaining a niobium target material with interior uniform grains and a relatively low value of surface roughness. Also provided is a niobium target material.

Owner:NINGXIA ORIENT TANTALUM IND

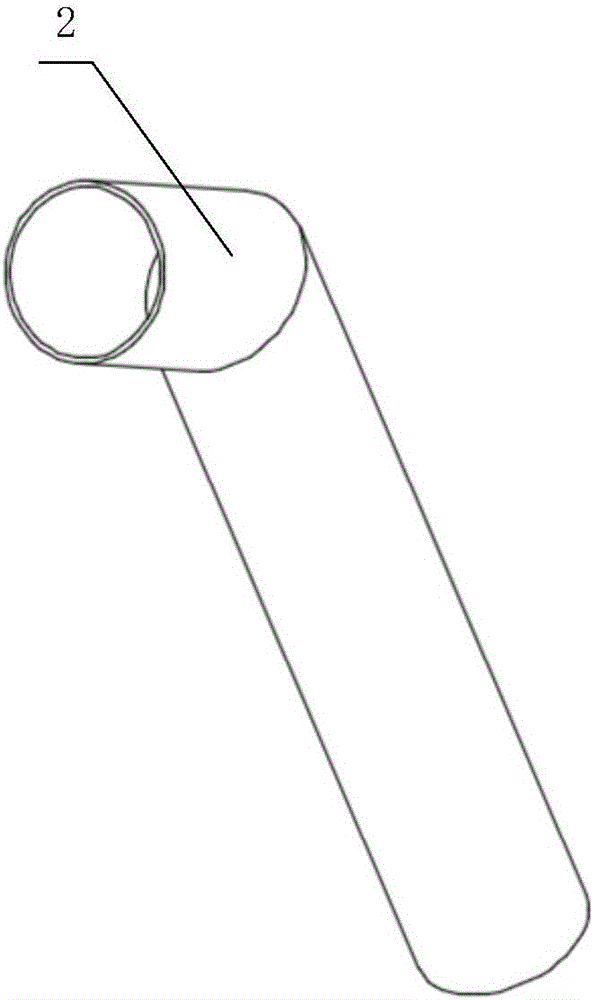

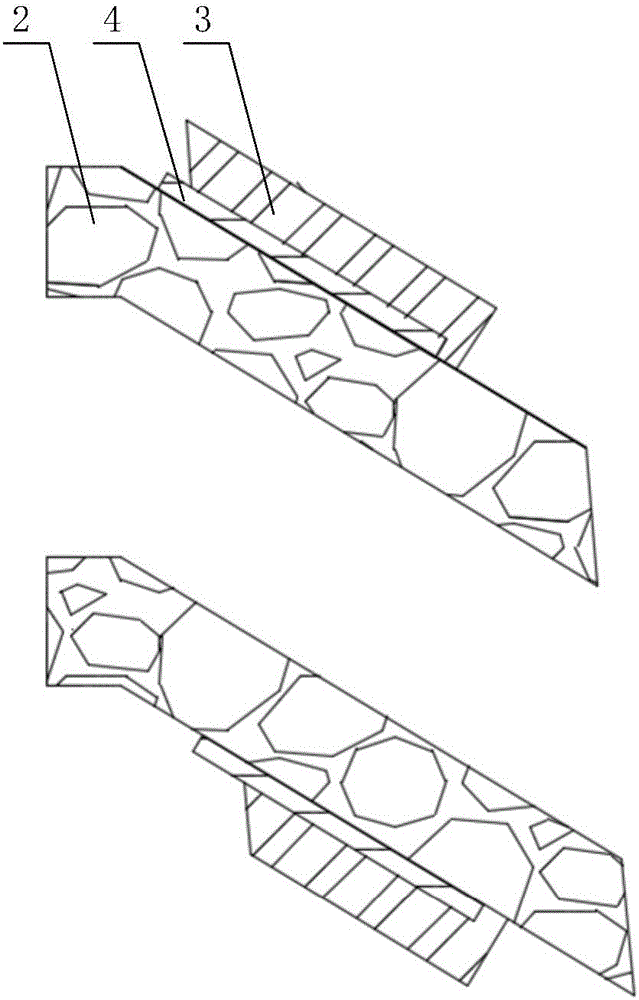

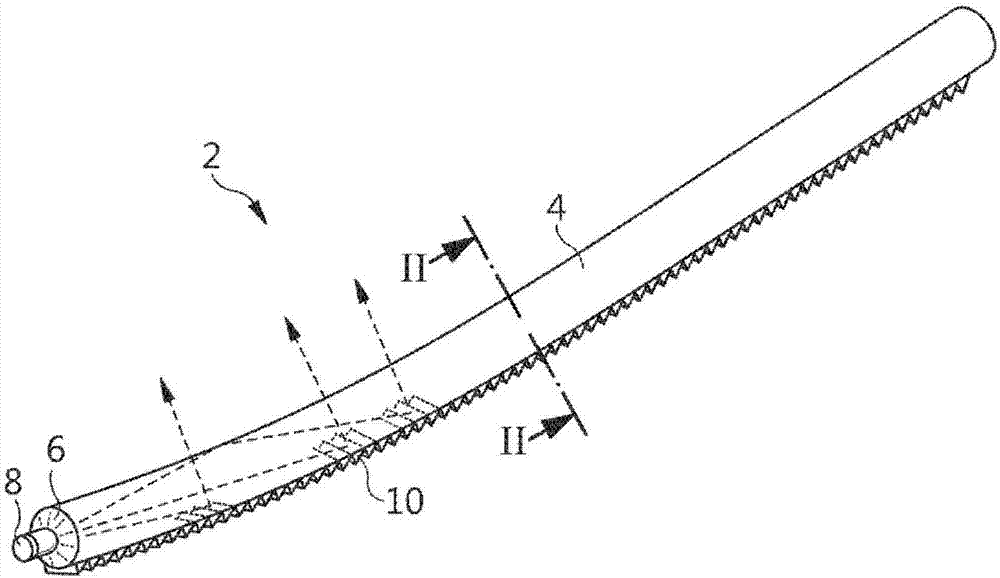

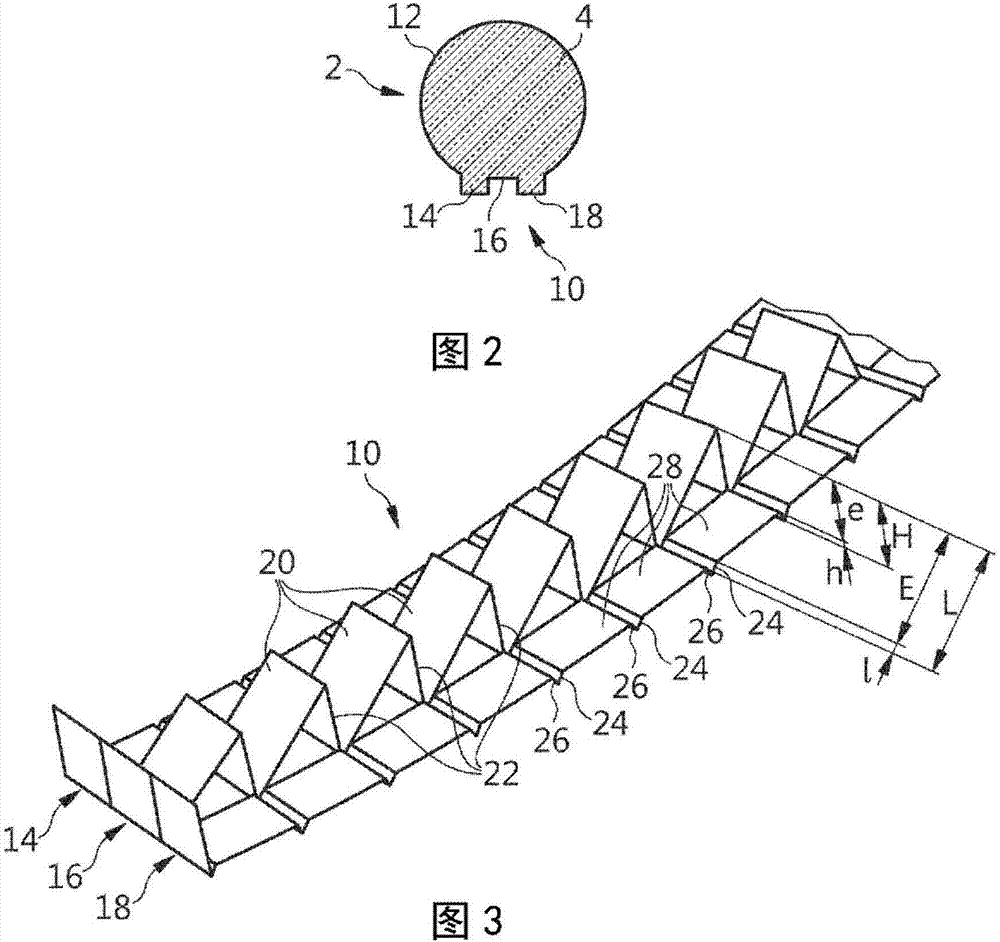

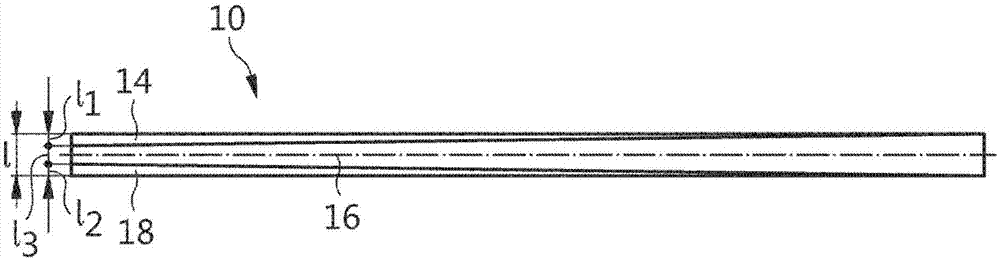

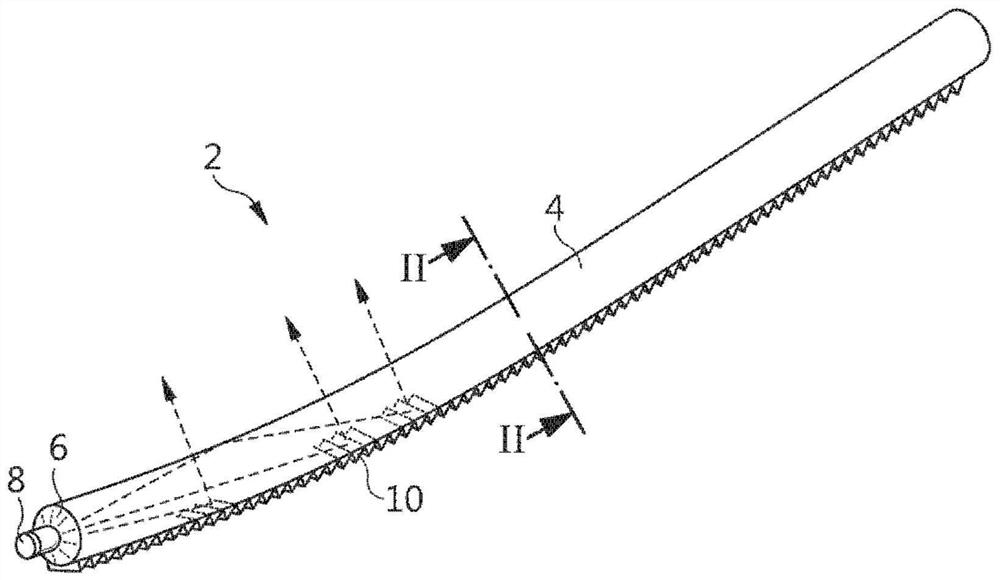

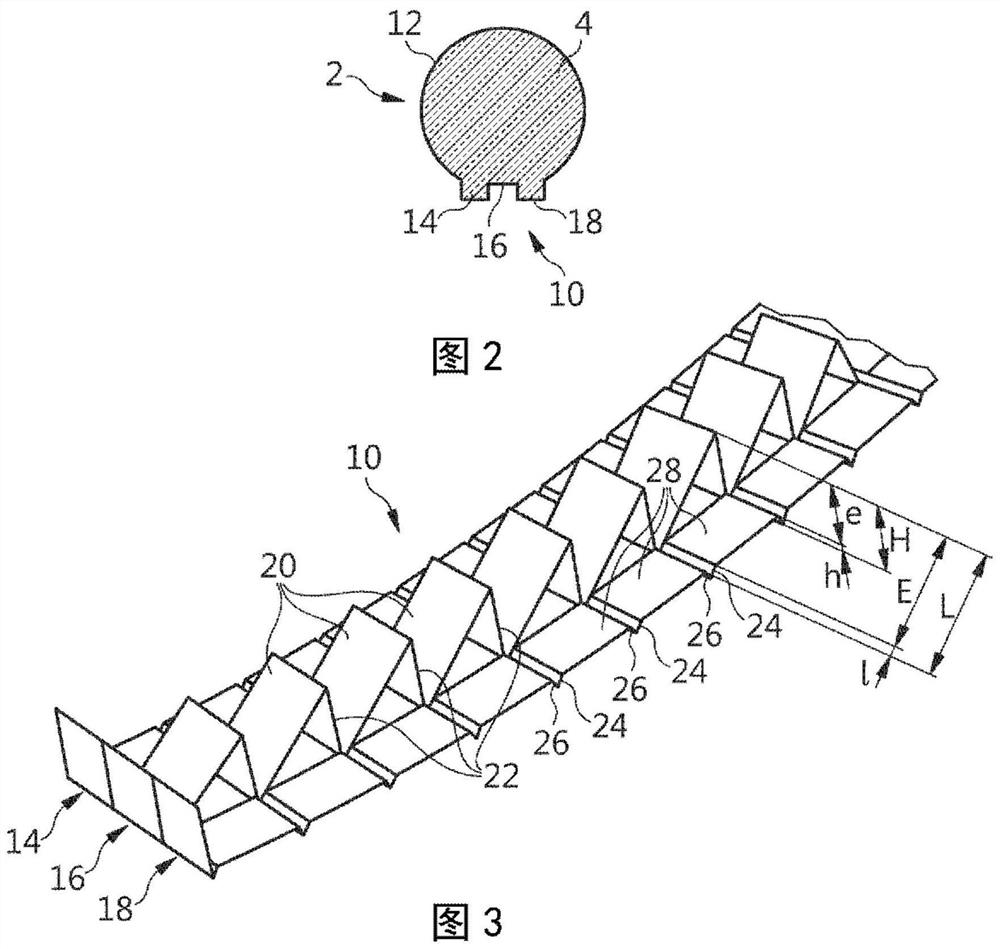

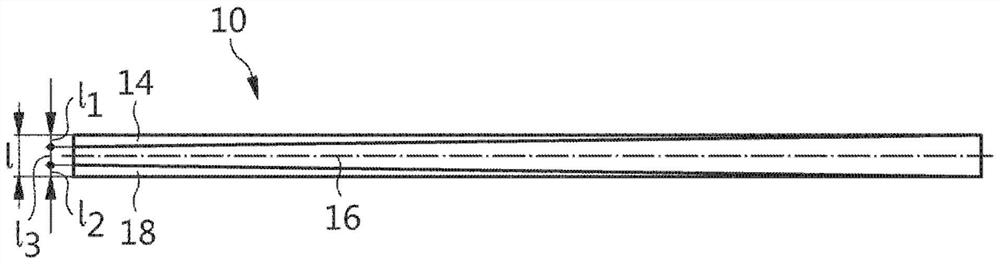

Lightguide with means to compensate for gradual losses of light along the guide

ActiveCN107208866AGuaranteed uniformityContributes to uniformityMechanical apparatusVehicle headlampsLight beamOptoelectronics

The invention relates to a lightguide (2) including a transparent body (4) which is generally elongate in a main direction, an outer facet (12) forming a dioptre with the environment of said body, a first row (16) of angled facets (20) capable of reflecting the rays in order to output same, and at least one second row (14, 18) of reflecting facets (24) which are smaller than the corresponding reflecting facets (20) of the first row (16). The light reflected by the one or more second rows complements the light beam from the first row. The widths of the first row and the second rows can gradually increase or decrease, respectively, as the distance from the light source increases so as to compensate for the gradual losses of light passing through the lightguide.

Owner:VALEO VISION SA

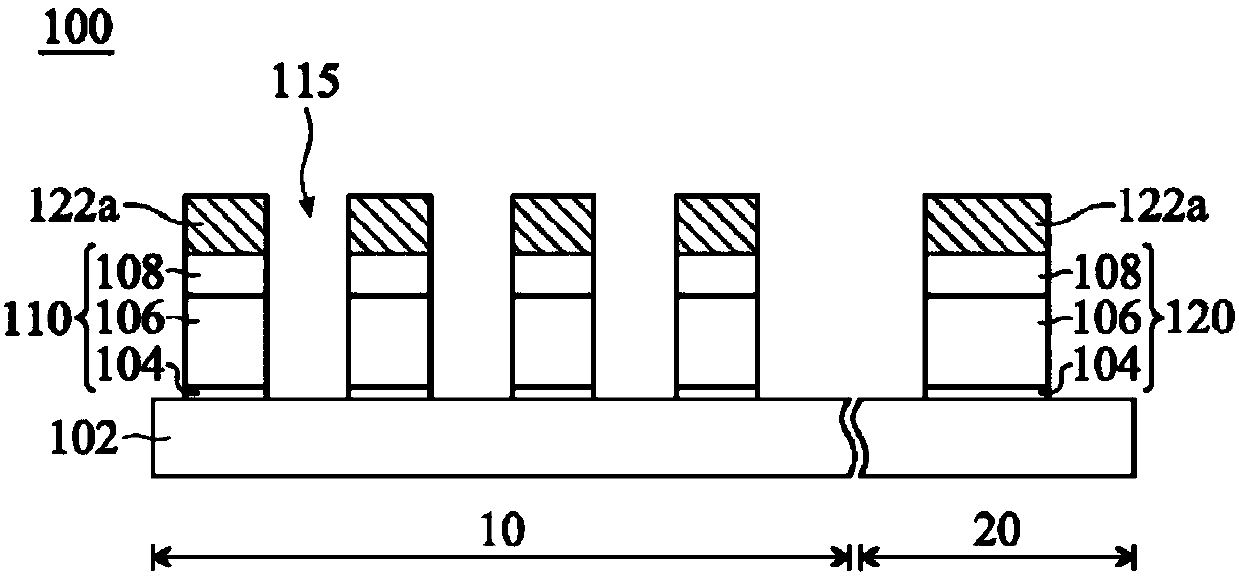

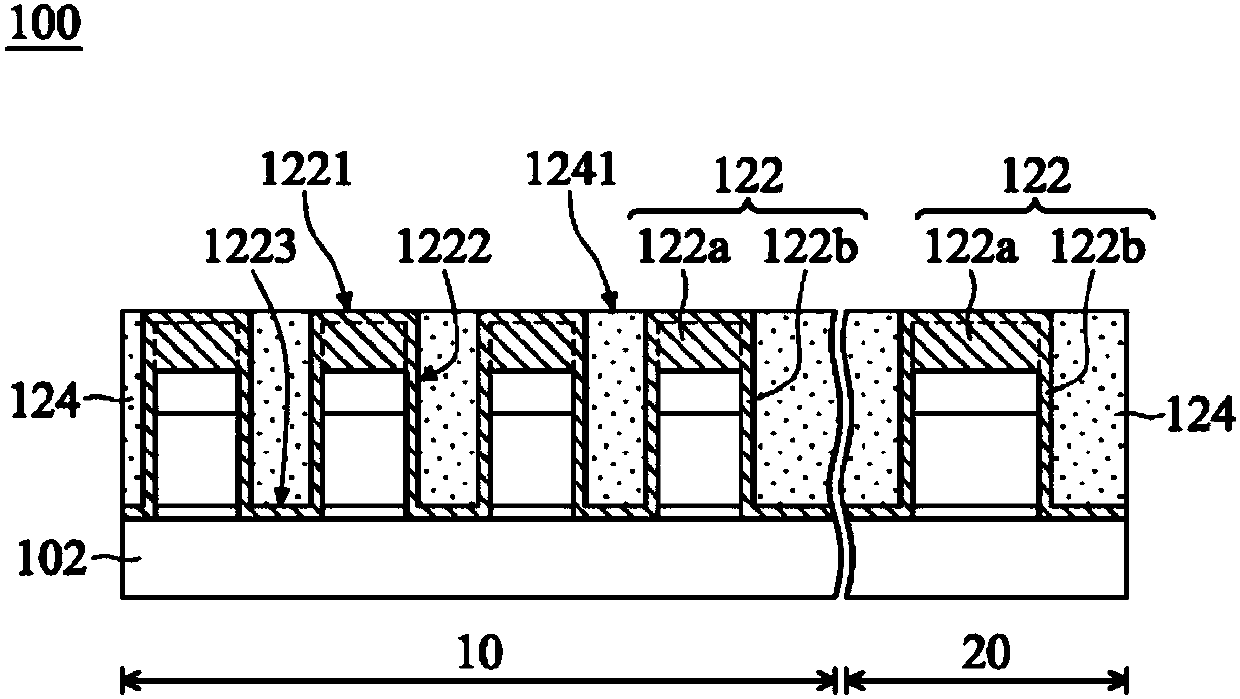

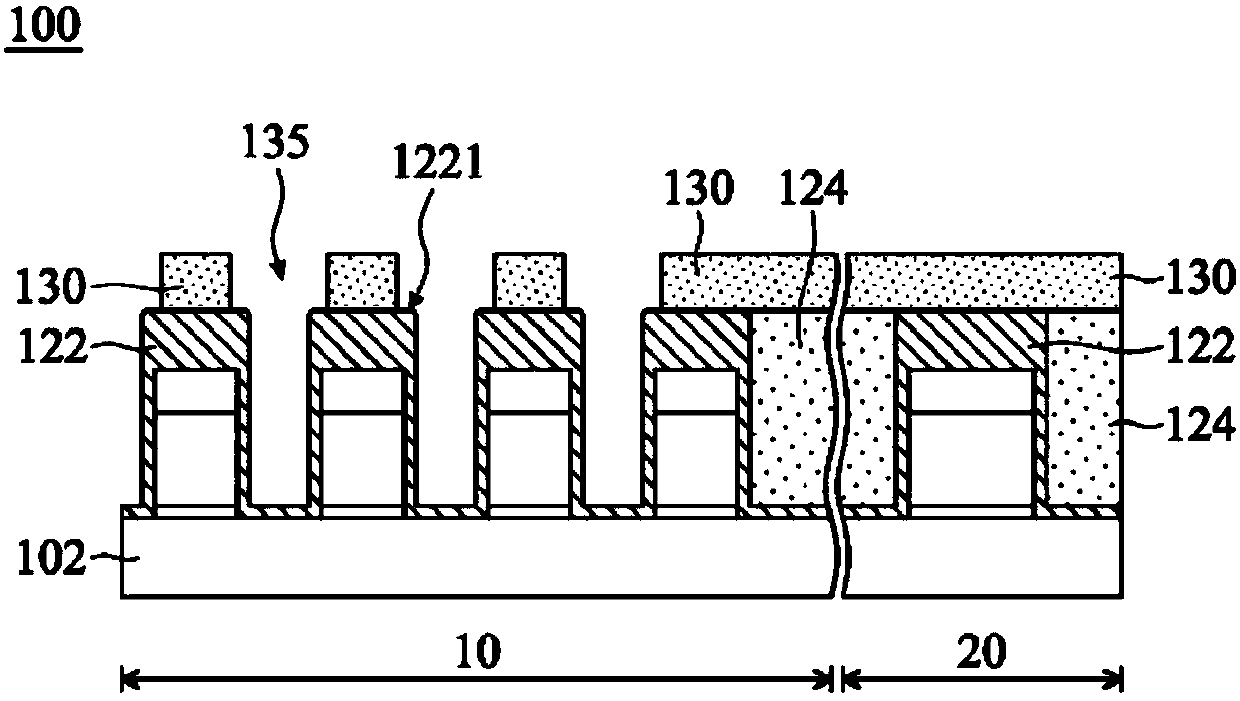

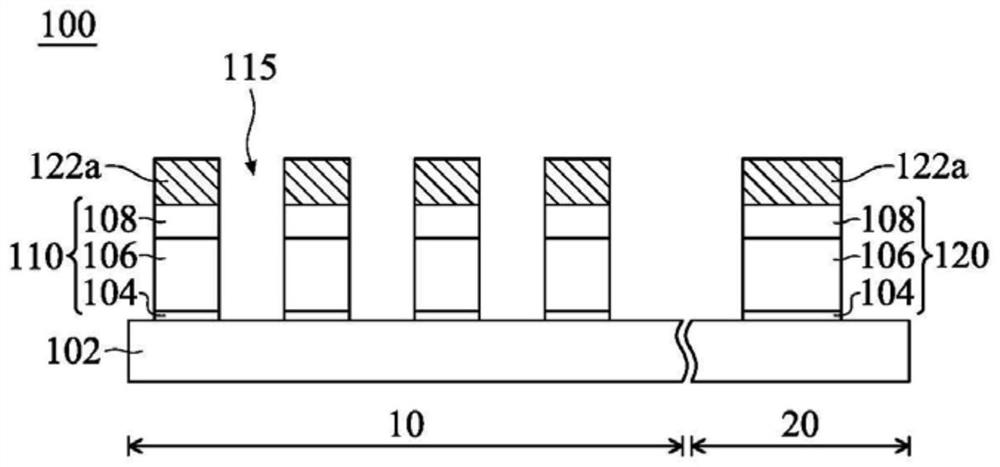

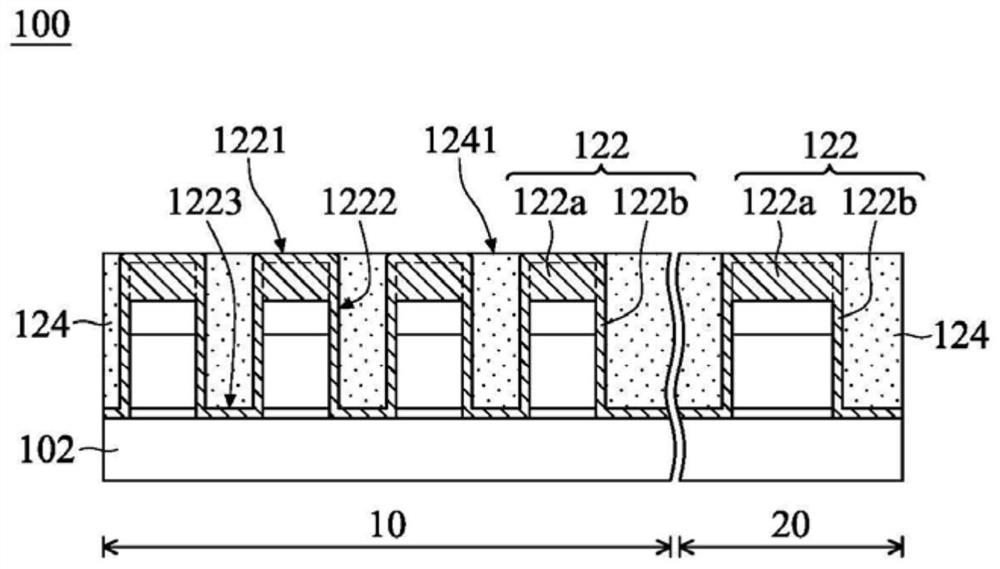

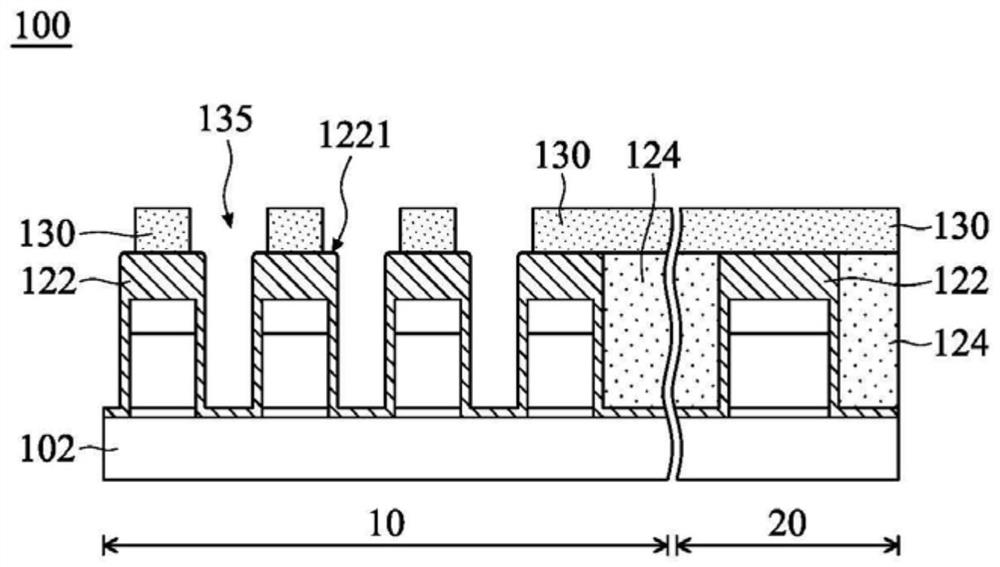

Memory device and manufacturing method thereof

ActiveCN110391241AImprove reliabilityImprove yield rateSolid-state devicesSemiconductor devicesDielectric layerPhysics

The invention provides a memory device and a manufacturing method thereof. The memory device includes a substrate, multiple first grid electrode structures, a first dielectric layer, a second dielectric layer, a third dielectric layer, and a contact plug. The first grid electrode structures are formed on the substrate of an array region. The first dielectric layer is formed on the top surface andthe sidewall of the first grid electrode structures. The second dielectric layer is formed on the first dielectric layer and is in direct contact with the first dielectric layer. The second dielectriclayer and the first dielectric layer are made of same materials. The third dielectric layer is formed between the first grid electrode structures and defines a plurality of contact holes exposing thesubstrate. The contact plug is filled in the contact holes.

Owner:WINBOND ELECTRONICS CORP

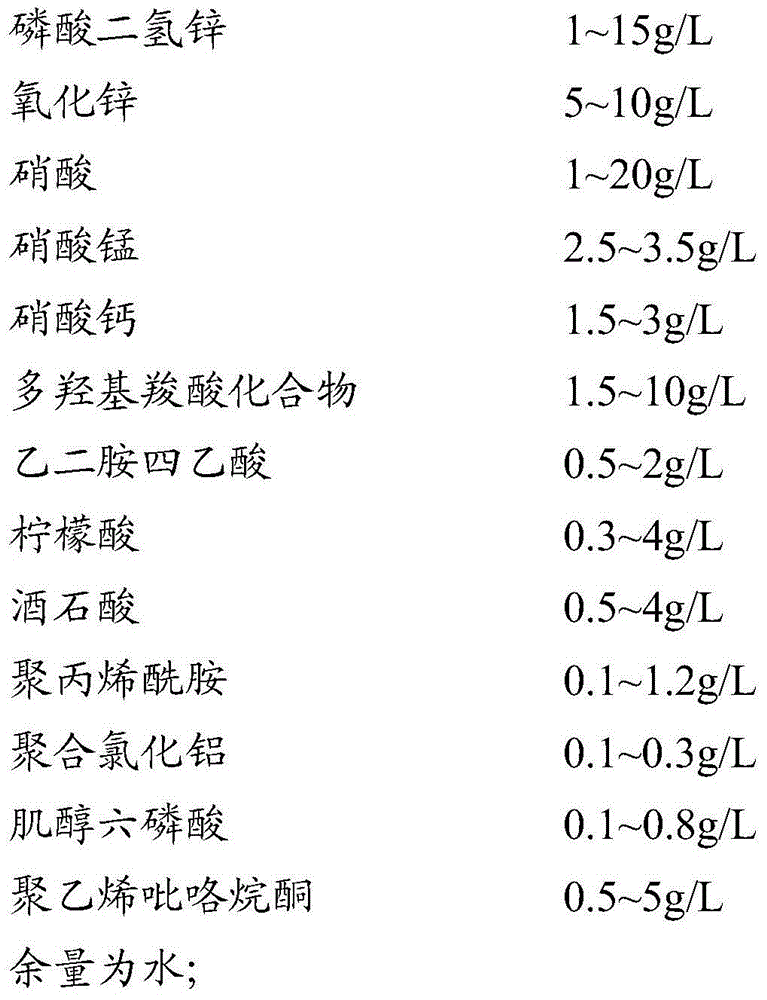

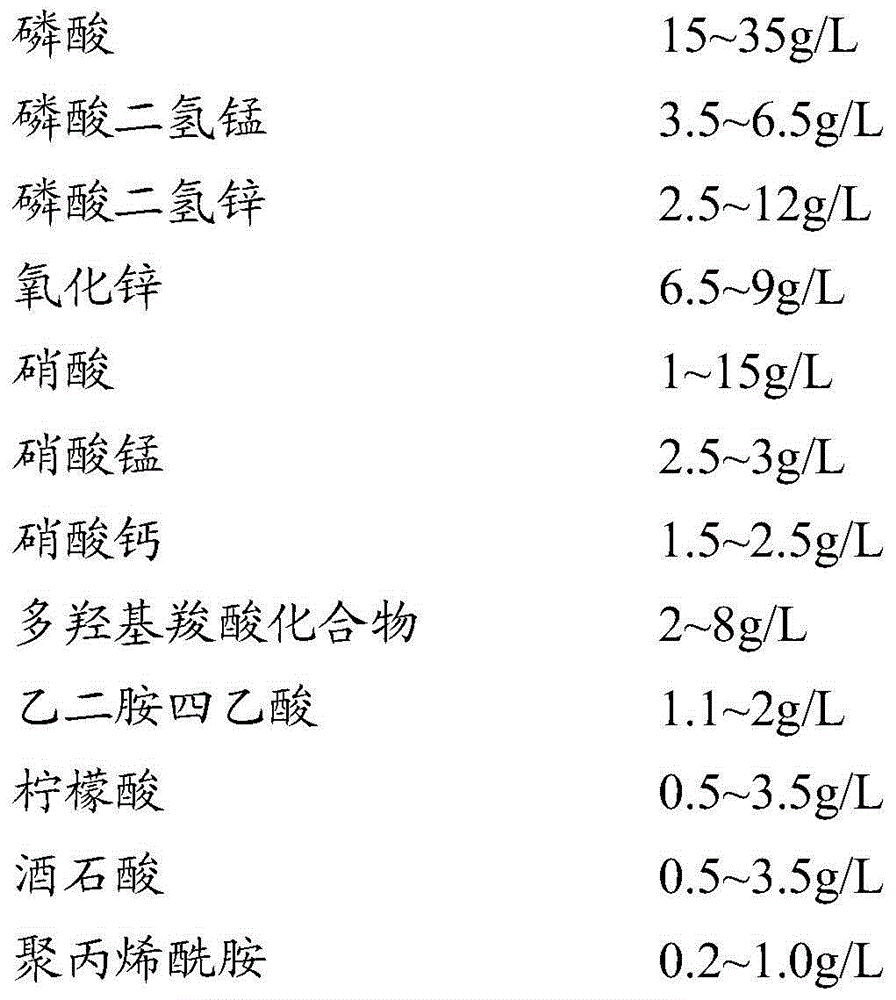

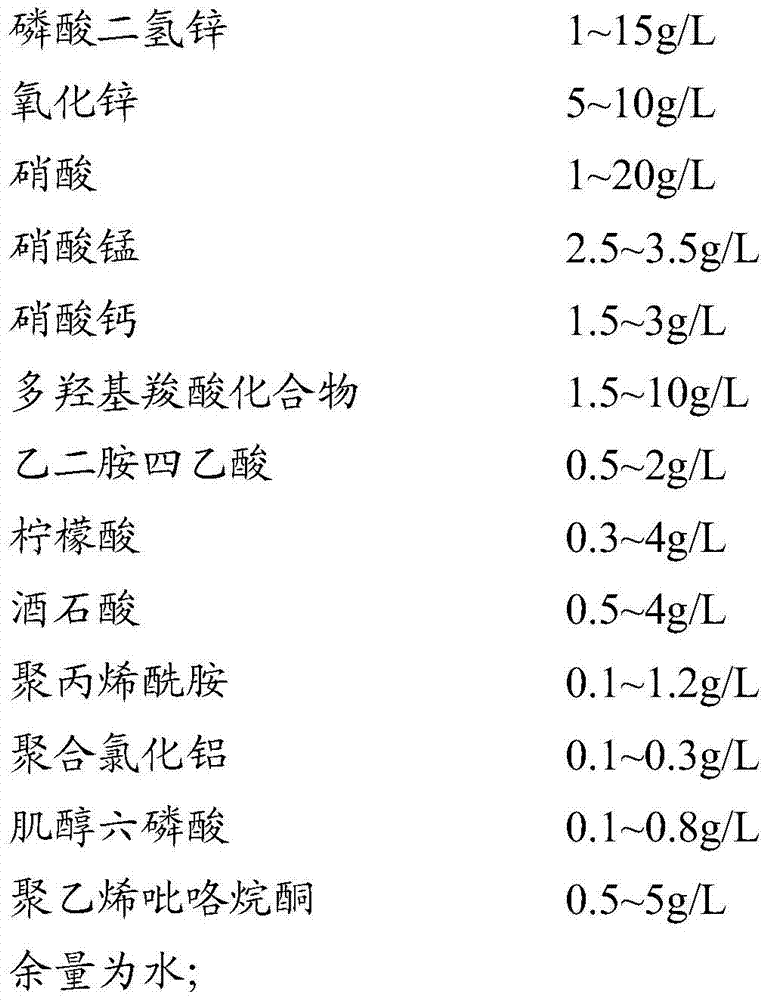

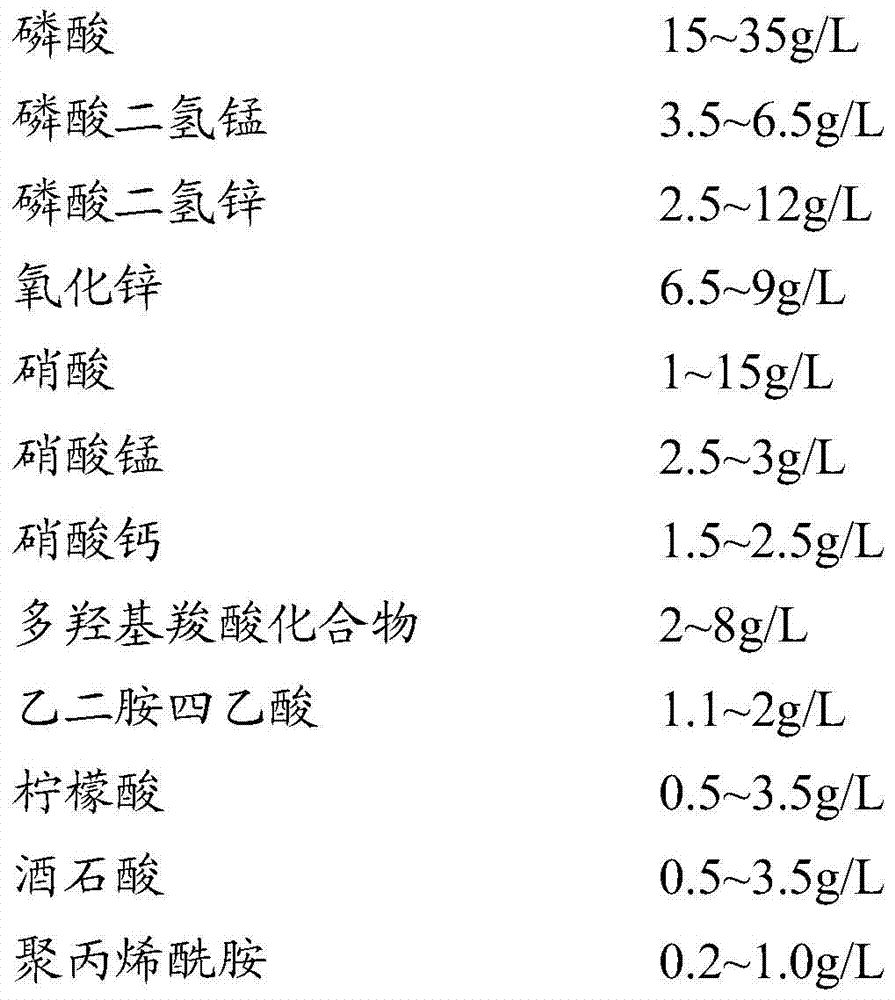

Special phosphating solution for car and preparing method of phosphating solution

ActiveCN104962894AContributes to uniformityDifficult to growMetallic material coating processesEcological environmentPhosphate

The invention provides a special phosphating solution for cars and a preparing method of the phosphating solution, and belongs to the field of industrial phosphating solutions. The phosphating solution comprises phosphoric acid, nitric acid, zinc oxide, manganous dihydrogen phosphate, zinc dihydrogen phosphate, manganous nitrate, calcium nitrate, polyvinylpyrrolidone, polyhydroxy carboxylic acid compound, ethylenediamine tetraacetic acid, citric acid, tartaric acid, phytic acid, aluminium polychlorid and polyacrylamide. The phosphating solution prepared by the method is good in stability, simple in process operation, less in phosphating sediment, fast in film building speed, and uniform and fine in film layer and has better anticorrosion, adhesive force of each metal part with a coating is enhanced, and the phosphating solution has the characteristics of capability of saving materials and energy, reasonable functions, low cost, convenience in use and capability of meeting the industrialized production requirements of the cars, and the product does not harm human body health and damage ecological environment in and after use.

Owner:DALIAN BETRUST ENVIRONMENTAL PROTECTION TECH CO LTD

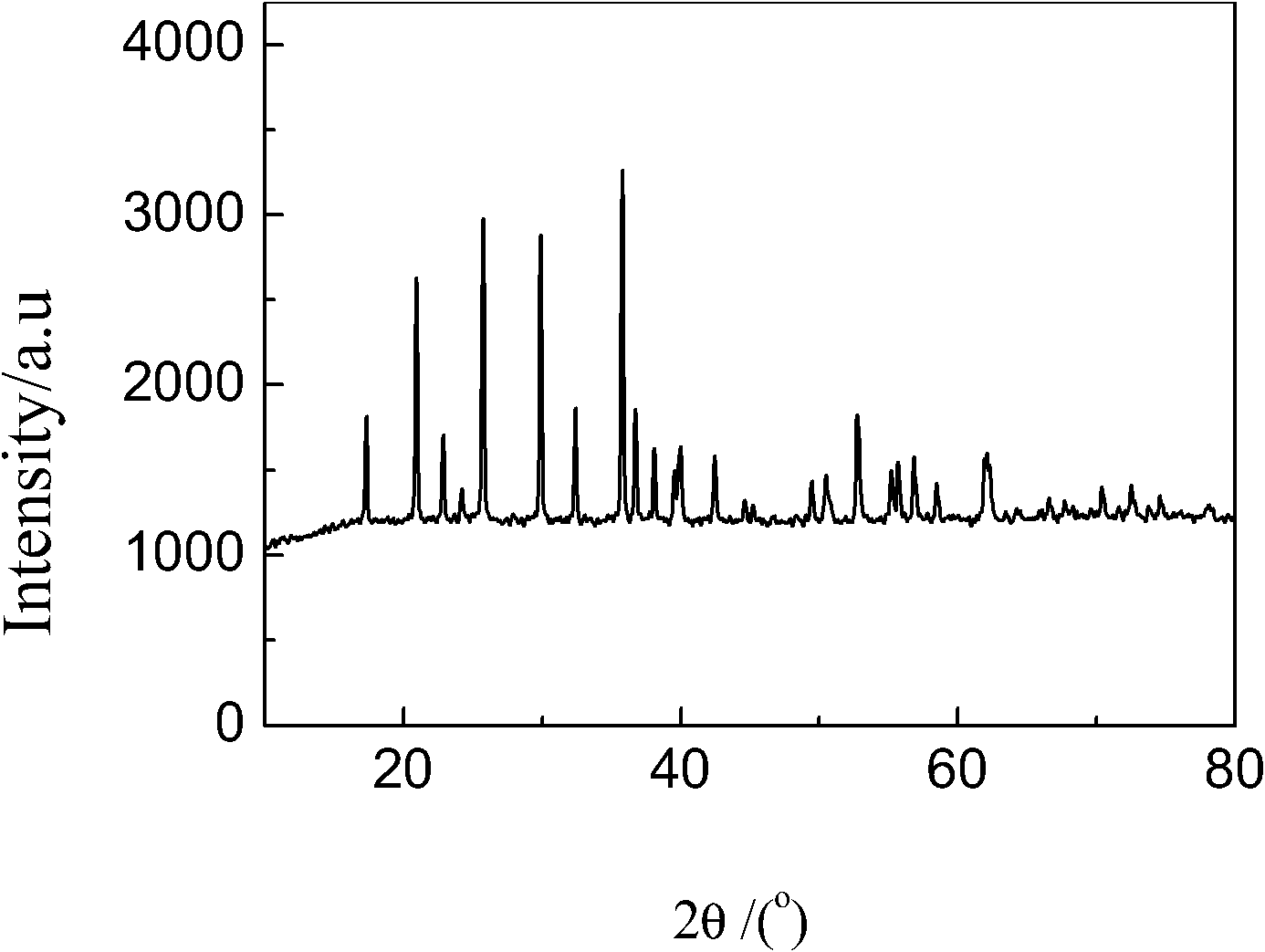

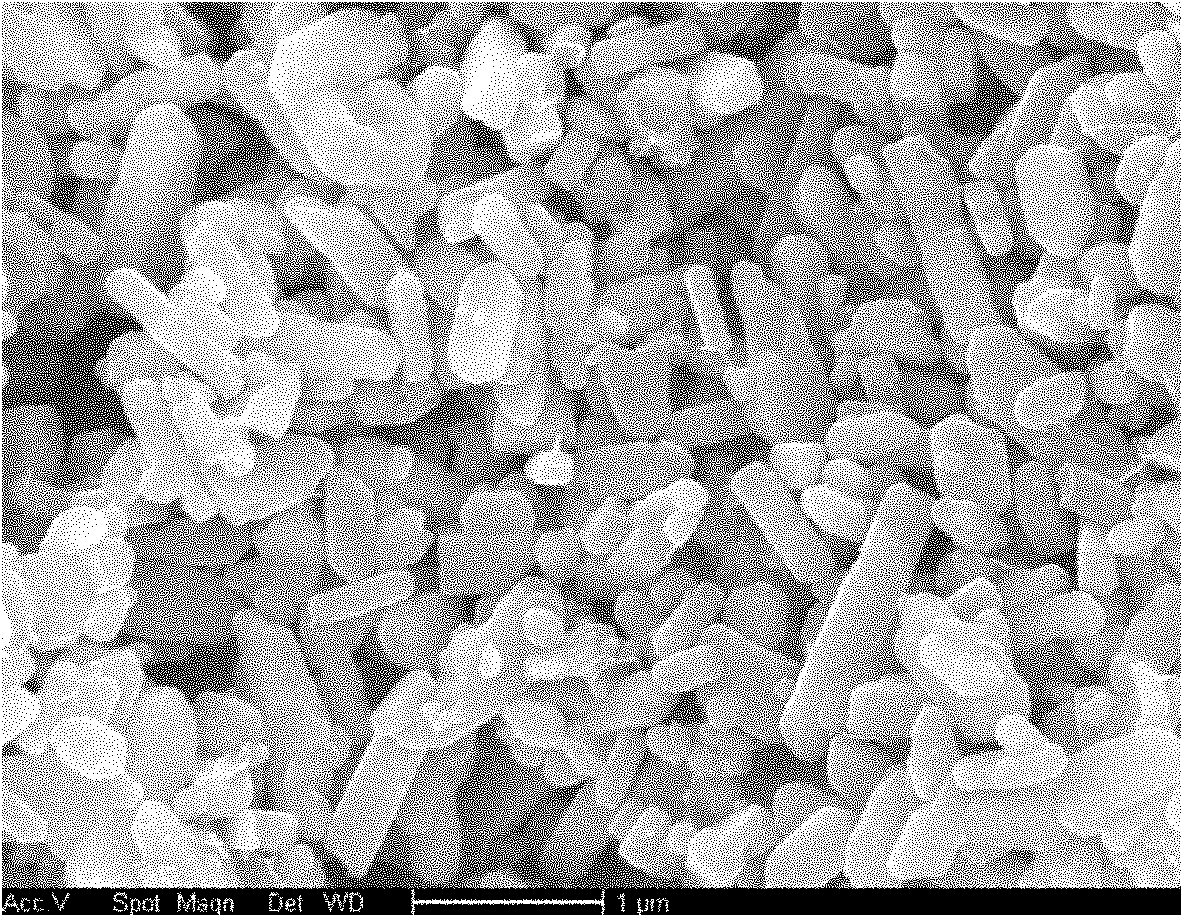

Manufacturing method of high-performance silicon nitride sealing ring

The invention discloses a manufacturing method of a high-performance silicon nitride sealing ring. The manufacturing method comprises the following steps: 1, preparing raw materials: silicon nitride powder, magnesium oxide, aluminum oxide and yttrium oxide; 2, adding the raw materials and an adhesive to absolute ethyl alcohol and mixing uniform so as to obtain silicon nitride composite powder slurry; 3, carrying out spray granulation on the silicon nitride composite powder slurry by adopting a closed-ring granulation mode so as to prepare silicon nitride granulated powder; 4, carrying out cool isostatic pressing treatment molding after carrying out compression molding on the silicon nitride granulated powder so as to prepare a silicon nitride ring blank; and 5, sintering the silicon nitride ring blank at a 1-8MPa nitrogen atmosphere and 1750-1850DEG C to prepare the silicon nitride sealing ring. The relative density of the made silicon nitride sealing ring is larger than or equal to 99.5%, the strength is larger than or equal to 800MPa, the HV hardness is larger than or equal to 1600, and the fracture toughness can reach 6.5-7.5MPa.m<1 / 2>. The manufacturing method greatly meets the application of the silicon nitride material in the aspects of sealing ring markets, particularly mechanical sealing.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

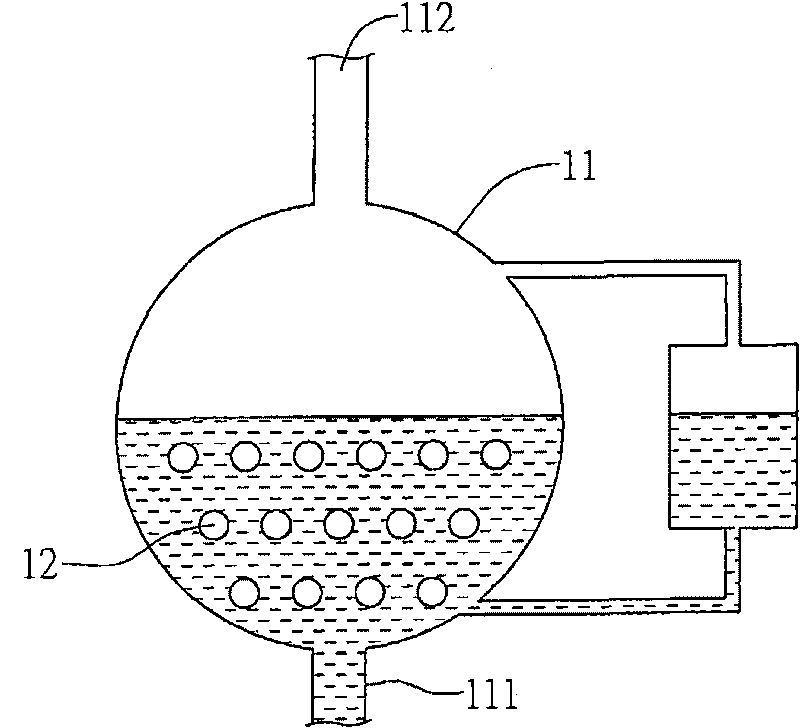

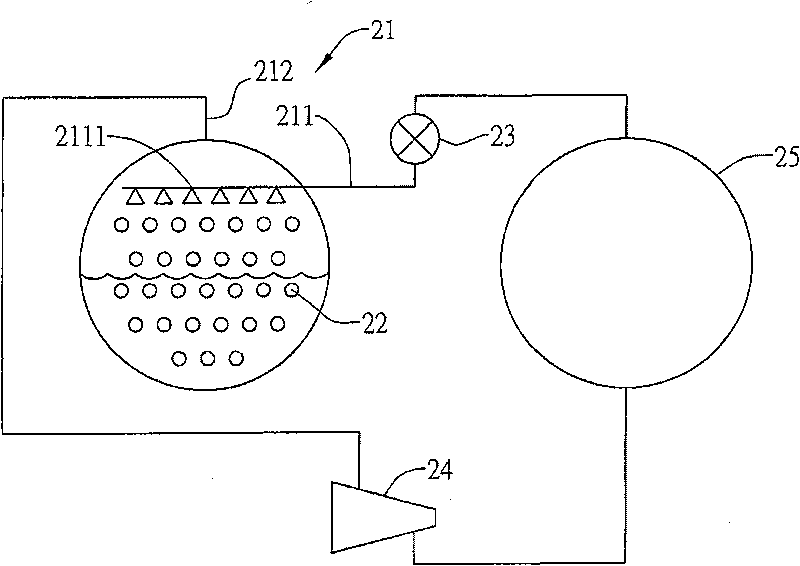

Multi-pipe spraying device

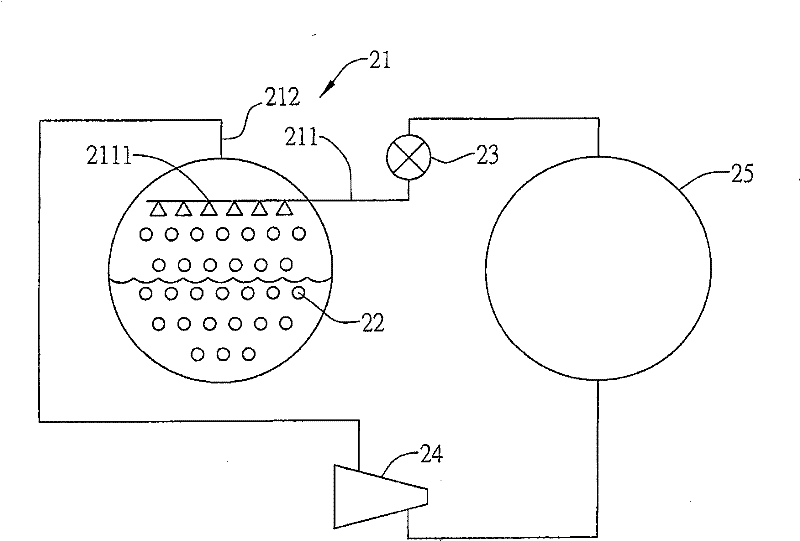

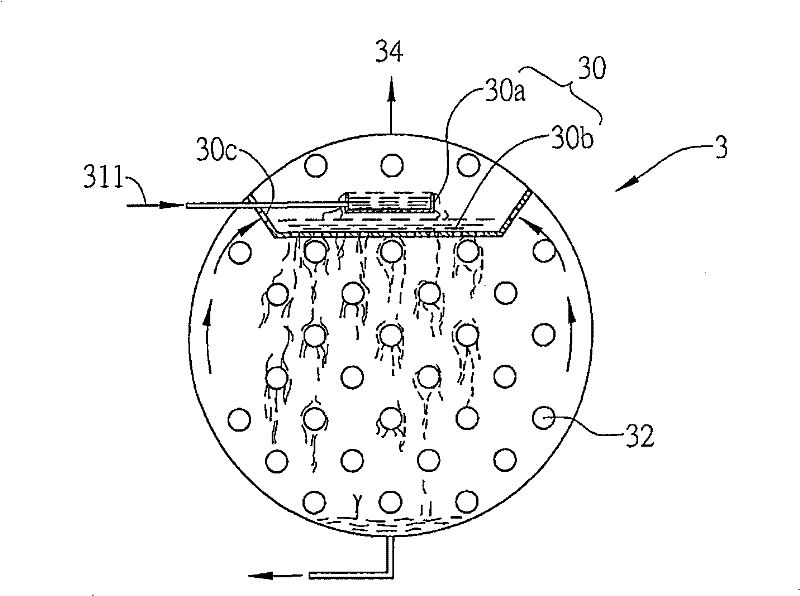

ActiveCN101749893ASprinkle evenlyContributes to uniformityEvaporators/condensersStationary conduit assembliesMechanical engineeringHeat transfer

The invention relates to a multi-pipe spraying device which comprises a body forming a closed accommodating space, a spraying pipe positioned at the upper part and a heat transfer pipe positioned at the lower part are arranged in the accommodating space, and the multi-pipe spraying device also comprises a gas outlet pipe which is used for discharging a gaseous cold medium in the accommodating space and a communicating pipe for introducing the gaseous cold medium of a cold medium source into the accommodating space; and the multi-pipe spraying device further comprises a gas-liquid separation device which is connected with the cold medium source for separating the gaseous cold medium with a liquid cold medium in the cold medium source and the spraying pipe which conveys the liquid cold medium to the body and is used for carrying out heat exchange on the heat transfer pipe and conveying the gaseous cold medium into the body. The multi-pipe spraying device can not only retain the advantages of a traditional spray type heat exchange system, but also achieve the effects of simply controlling the spraying pressure for realizing even spraying, reducing the damages of a compressor due to hydraulic liquid compression and controlling the spraying flow rate through the combination of the elements.

Owner:IND TECH RES INST

Y and Sr-containing iron alloy for hot-dip galvanized high-thermal-conductivity iron crucible

InactiveCN108588575AGood welding performanceAccelerated corrosionHot-dipping/immersion processesSheet steelCrucible

The invention discloses a Y and Sr-containing iron alloy for a hot-dip galvanized high-thermal-conductivity iron crucible and a processing technology thereof. The alloy comprises 0.2-0.4 wt.% of Ca,0.2-0.3 wt.% of Sr, 0.4-0.6 wt.% of Re, 0.2-0.4 wt.% of Y, 0.8-1.5 wt.% of V, 0.4-0.5 wt.% of Hf and the balance iron. According to the alloy and the processing technology thereof, the alloy is cast and hot-rolled into a steel plate to form the hot-dip galvanized iron crucibl so that the heat transfer capability of the iron crucible and the uniformity of the thickness of a galvanized layer can begreatly improved; and the service life of the iron crucible is prolonged from 7-10 years to 20 years and longer, and the effects of improving the production efficiency and saving the cost are achieved.

Owner:GUANGZHOU YUZHI TECH CO LTD

Moisture-permeable waterproof film used for fabric and fabrication process thereof

ActiveCN102555380BSolve the weakness that it is easy to expand when exposed to waterGood moisture permeabilitySynthetic resin layered productsLaminationSlurryMoisture

The invention discloses a moisture-permeable waterproof film used for a fabric and a fabrication process thereof. According to the invention, a primary coating comprises polyurethane resin, butanone, toluene, water, hexane diisocyanate and N-methylethanolamine, and a first and second surface coatings comprise polyurethane resin, butanone, toluene, water and N-methylethanolamine. The fabrication process comprises the following steps: mixing hexane diisocyanate with main resin; mixing water with butanone to form a solvent which is put into a main resin mixed solution in at least six steps; filtering the mixed solution with a nylon net so as to obtain a filtered main resin mixed solution and carrying out deaeration treatment so as to form a primary coating slurry; preparing a surface coating slurry with the viscosity of a conjugate solution being 3500 to 6000 mpas; coating the primary coating slurry on the surface of release paper to form the primary coating, with coated weight being 4 to 6 g / m<2>; coating the surface coating slurry on the surface of the primary coat to form the surface coatings; and drying the release paper with the surface coatings and peeling the surface coatings off the release paper. According to the invention, the disadvantages that existing hydrophilic moisture permeable processing coating fabrics have nonuniform micropores and easily swell when contacting with water are overcome, and therefore, moisture permeable performance of a fabric itself is improved.

Owner:KUNSHAN HUAYANG NEW MATERIAL

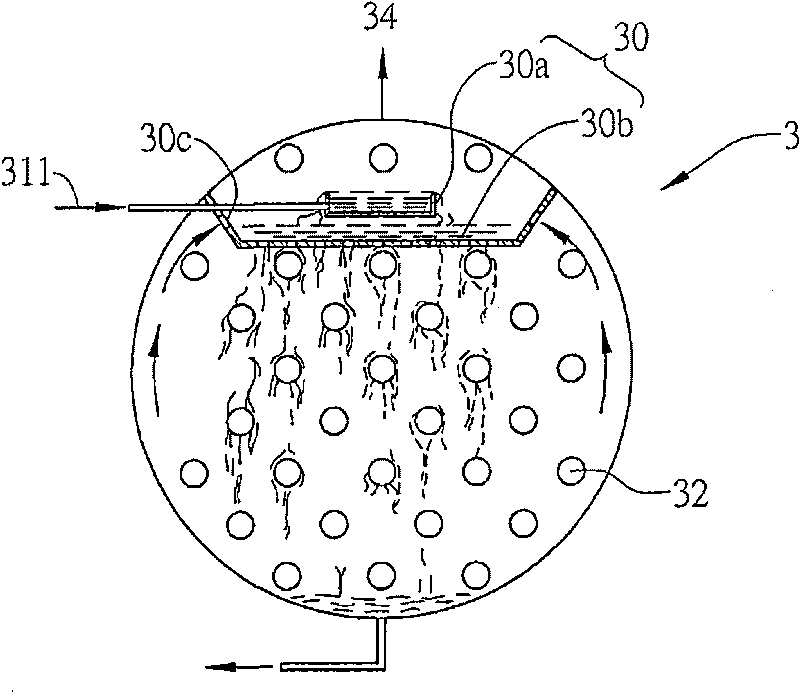

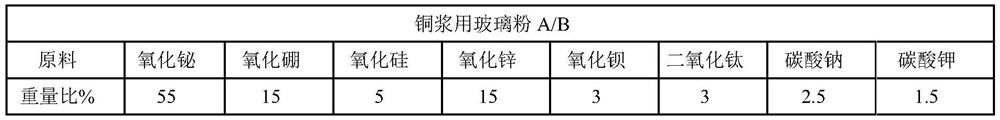

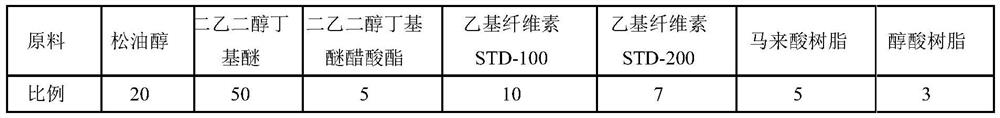

Medium-temperature sintering lead-free copper paste suitable for PZT sensor and preparation method of medium-temperature sintering lead-free copper paste

PendingCN114512260ASimple preparation processEasy to implementNon-conductive material with dispersed conductive materialCable/conductor manufactureZirconium dioxideMaterials science

The invention relates to the technical field of PZT sensors, in particular to medium-temperature sintering lead-free copper paste suitable for a PZT sensor and a preparation method of the medium-temperature sintering lead-free copper paste, and the lead-free copper paste comprises the following components in parts by mass: 70-80 parts of copper powder, 1-5 parts of lead-free glass, 1-5 parts of an inorganic additive and 15-25 parts of an organic carrier; the copper powder is one or two of superfine spherical powder and flaky micro powder; the lead-free glass is a mixture composed of glass powder A and glass powder B, the softening point of the glass powder A is 480-520 DEG C, and the softening point of the glass powder B is 520-560 DEG C; the inorganic additive is selected from one or two of electronic-grade bismuth oxide powder or superfine zirconium dioxide; the organic carrier comprises the following components in parts by mass: 70-80 parts of a solvent, 10-20 parts of ethyl cellulose, 5-10 parts of a macromolecular resin material and 1-5 parts of a flatting agent; on the premise of ensuring the conductivity, the silver powder is replaced by the copper powder, and meanwhile, the problem of binding force between the softened medium-temperature sintered glass and the ceramic substrate is solved.

Owner:西安英诺维特新材料有限公司

Multi-pipe spraying device

ActiveCN101749893BSprinkle evenlyContributes to uniformityEvaporators/condensersStationary conduit assembliesEngineeringMechanical engineering

The invention relates to a multi-pipe spraying device which comprises a body forming a closed accommodating space, a spraying pipe positioned at the upper part and a heat transfer pipe positioned at the lower part are arranged in the accommodating space, and the multi-pipe spraying device also comprises a gas outlet pipe which is used for discharging a gaseous cold medium in the accommodating space and a communicating pipe for introducing the gaseous cold medium of a cold medium source into the accommodating space; and the multi-pipe spraying device further comprises a gas-liquid separation device which is connected with the cold medium source for separating the gaseous cold medium with a liquid cold medium in the cold medium source and the spraying pipe which conveys the liquid cold medium to the body and is used for carrying out heat exchange on the heat transfer pipe and conveying the gaseous cold medium into the body. The multi-pipe spraying device can not only retain the advantages of a traditional spray type heat exchange system, but also achieve the effects of simply controlling the spraying pressure for realizing even spraying, reducing the damages of a compressor due to hydraulic liquid compression and controlling the spraying flow rate through the combination of the elements.

Owner:IND TECH RES INST

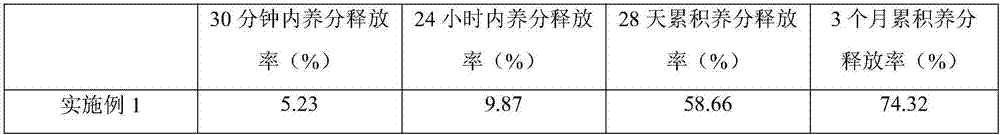

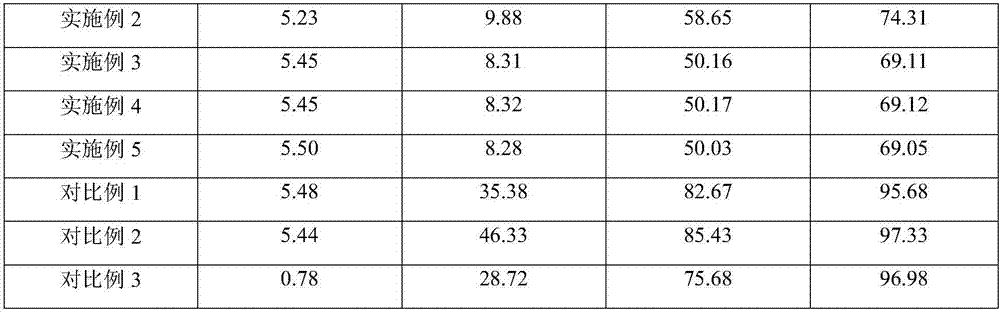

Adhesive type controlled-release fertilizer and preparation method thereof

InactiveCN107879829AFacilitated releaseIncrease profitSuperphosphatesAmmonium salt fertilisersEmulsionControl release

The invention provides an adhesive type controlled-release fertilizer and a preparation method thereof. The preparation method comprises the following steps: dissolving one part of inorganic fertilizer components, uniformly mixing the inorganic fertilizer components with a mixed adhesive, and mutually coating the inorganic fertilizer components and the mixed adhesive to prepare a granular fertilizer, wherein after application, the inorganic fertilizer components on the surface can be rapidly released, and the efficacy is fast. The mixed adhesive is prepared from polyglycolic acid, polyamino acid, pregelatinized starch, disproportionated rosin, polyglycollide, urea resin emulsion and the like. The prepared fertilizer is naturally degraded after applied, and along with degradation of the mixed adhesive, the inorganic fertilizer components coated in the fertilizer are slowly released, the controlled release aim is achieved, and the utilization rate of the fertilizer is improved.

Owner:长沙善道新材料科技有限公司

Vehicle-specific phosphating solution and preparation method thereof

ActiveCN104962894BContributes to uniformityDifficult to growMetallic material coating processesEcological environmentPhosphate

The invention provides a vehicle-specific phosphating solution and a preparation method thereof, belonging to the field of industrial phosphating solutions. The phosphating solution includes phosphoric acid, nitric acid, zinc oxide, manganese dihydrogen phosphate, zinc dihydrogen phosphate, manganese nitrate, calcium nitrate, polyvinylpyrrolidone, polyhydroxy carboxylic acid compound, ethylenediaminetetraacetic acid, citric acid, tartaric acid, muscle acid Alcohol hexaphosphoric acid, polyaluminum chloride and polyacrylamide. The phosphating solution prepared by the method of the present invention has good stability, simple process operation, less phosphating residue, fast film forming speed, uniform and fine film layer, good corrosion resistance, and enhanced adhesion between metal parts and coatings. Moreover, the phosphating solution has the characteristics of saving materials and energy, reasonable functions, and the product does not endanger human health or damage the ecological environment during and after use; it is low in cost, easy to use, and can meet the requirements of industrialized production of vehicles.

Owner:DALIAN BETRUST ENVIRONMENTAL PROTECTION TECH CO LTD

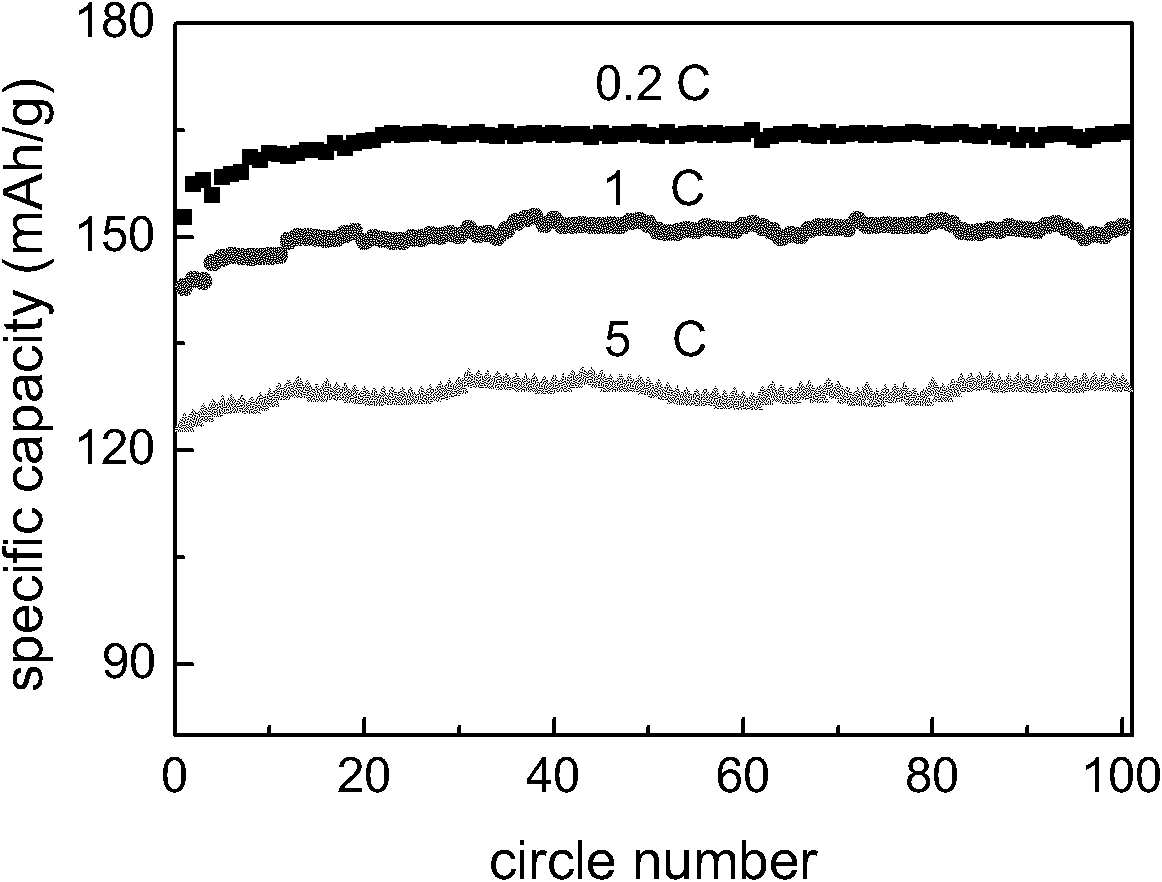

Method for preparing lithium iron phosphate compound anode material

InactiveCN102104144BGuaranteed uniformityGuaranteed finenessCell electrodesLithium iron phosphateSURFACTANT BLEND

The invention discloses a method for preparing a lithium iron phosphate compound anode material. In the method, a lithium source compound, an iron source compound, a phosphorus source compound and a carbon source compound serve as raw materials according to the mol ratio of Li:Fe:P:C of 0.9-1.2:0.95-1:1:0-1; and polyoxyethylene serves as a surfactant. The method has less process steps, shortens aproduction period, saves cost, improves the electric conductivity of a lithium iron phosphate compound material to the maximum by utilizing least carbon, and simultaneously improves the content of active substances in the material.

Owner:CHANGZHOU HECO NEW ENERGY TECH CO LTD

Light guide with means for compensating progressive loss of light along the light guide

ActiveCN107208866BGuaranteed uniformityContributes to uniformityMechanical apparatusVehicle headlampsLight guideLight beam

The invention comprises a light guide (2) comprising a transparent body (4) substantially elongated in a main direction, having an outer surface (12) forming a diopter with the environment of said body; a first a row (16) of inclined surfaces (20), said first row (16) of inclined surfaces (20) adapted to reflect light rays so that they emerge; and at least one second row (14, 18) of reflective surfaces (24), said At least one second row (14, 18) of reflective surfaces (24) has smaller dimensions than the corresponding first row (16) of reflective surfaces (20). Light reflected by the second row or rows is added to the beam from the first row. The width of the first row and the second row can be gradually increased and decreased respectively from the light source in order to compensate for the progressive loss of light traveling in the light guide.

Owner:VALEO VISION SA

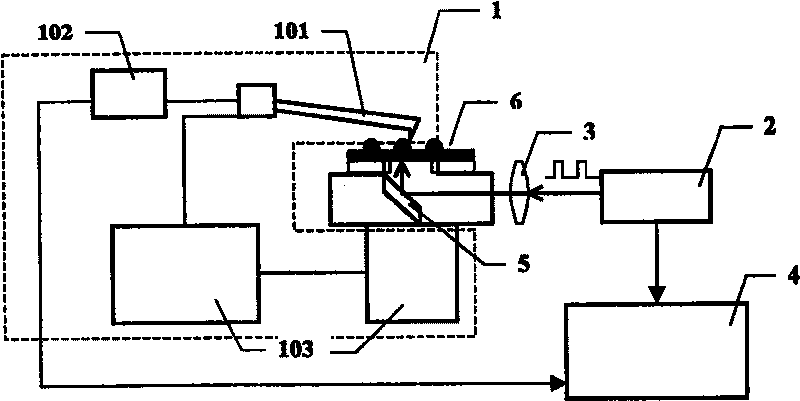

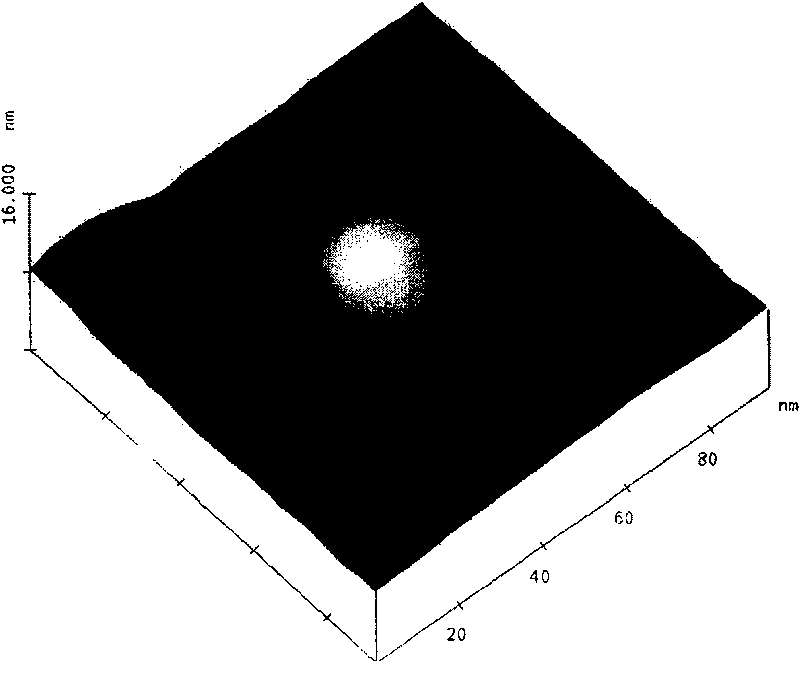

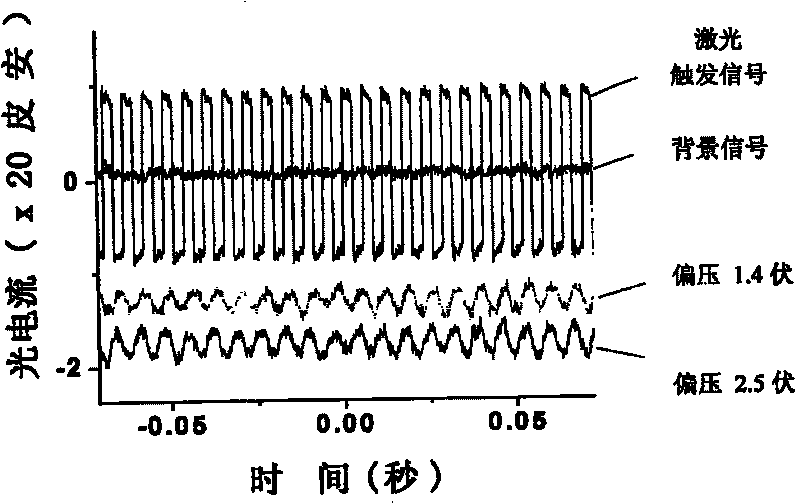

Equipment and method for measuring photoelectric performance of semiconductor nanometer structure

ActiveCN1793874BImprove comparabilityContributes to uniformityMaterial analysis using wave/particle radiationSurface/boundary effectOpto electronicScanning probe microscopy

A method for measuring photoelectric property of semiconductor nanostructure utilizes accurate space positioning and controlling ability of scan probe microscopic system to use conductive needle pointas nanoelectrode and to use back incoming mode to lead pulse laser into region to be tested of sample for exerting structure scanning on sample and simultaneously obtaining optical excited electricalproperty of specific nanoregion. The device for realizing said method is also disclosed.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

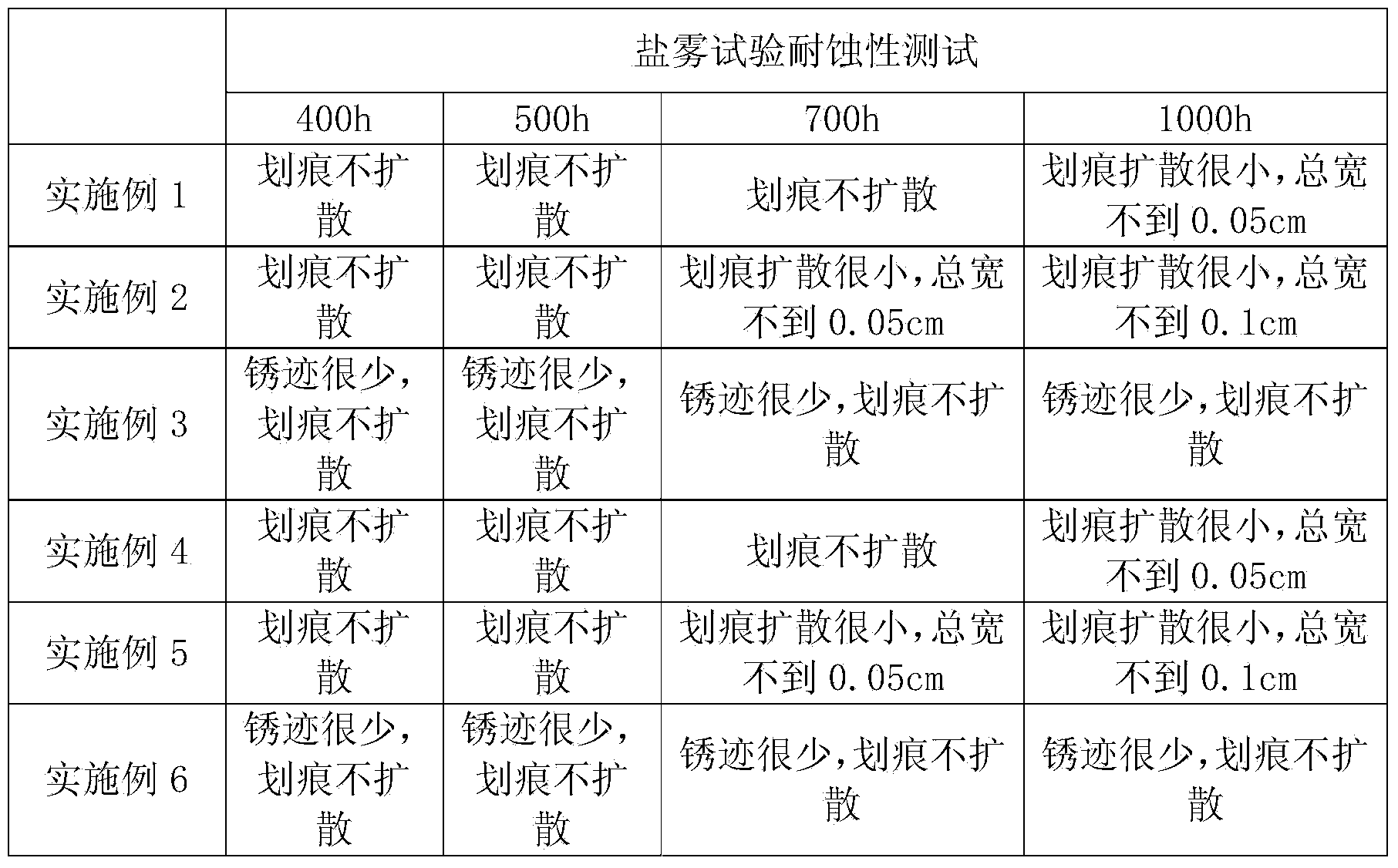

Universal environment-friendly non-phosphorus phosphating solution

ActiveCN102808172BContributes to uniformityReduced corrosion resistanceMetallic material coating processesSalt spray testSodium nitrite

The invention discloses a universal environment-friendly non-phosphorus phosphating solution, which comprises the following components in percentage by weight: 3 to 5 percent of ammonium zirconium hexafluoride, 5 to 7 percent of nitric acid, 1.5 to 2 percent of boric acid, 0.4 to 0.6 percent of ethylene diamine tetraacetic acid, 3 to 3.4 percent of sodium nitrite, 1 to 2.5 percent of zinc molybdate and the balance of water. An adhesion test and a salt spray test show that the non-phosphorus phosphating solution has a good effect on improvement in the adhesion force of a metal substrate and a surface coating, the adhesion force obtained by the adhesion test is over 1 grade, and the adhesion force obtained by the salt spray test can be maintained for 1,000 hours; and the non-phosphorus phosphating solution is convenient to prepare and significant for environmental protection.

Owner:ANHUI QIMING SURFACE TECH

Memory device and manufacturing method thereof

ActiveCN110391241BImprove reliabilityImprove yield rateSolid-state devicesSemiconductor devicesEngineeringDielectric layer

The present invention proposes a memory device and a manufacturing method thereof. The memory device includes a substrate, a plurality of first gate structures, a first dielectric layer, a second dielectric layer, a third dielectric layer and contact plugs. These first gate structures are formed on the substrate of the array area. The first dielectric layer is formed on the top surface and sidewalls of the first gate structure. The second dielectric layer is formed on the first dielectric layer and in direct contact with the first dielectric layer. The second dielectric layer is made of the same material as the first dielectric layer. The third dielectric layer is formed between the first gate structures and defines a plurality of contact holes exposing the substrate. Contact plugs are filled in the aforementioned contact holes.

Owner:WINBOND ELECTRONICS CORP

High-thermal-conductivity and high-temperature-resistance pan material for zinc-aluminum alloy hot dip coating and process of high-thermal-conductivity and high-temperature-resistance pot material

InactiveCN108728776AReduced service lifeShort lifeHot-dipping/immersion processesDip-coatingMachining process

The invention discloses a high-thermal-conductivity and high-temperature-resistance pan material for zinc-aluminum alloy hot dip coating and a machining process of the high-thermal-conductivity and high-temperature-resistance pan material. The high-thermal-conductivity and high-temperature-resistance pan material comprises, by weight, 1.2-1.5% of Li, 0.2-0.4% of Ti, 0.3-0.5% of Ba, 9.0-10.5% of Cr, 5.0-8.0% of Ni, 2.0-4.0% of Mn, 2.0-3.0% of Sn, 0.2-0.4% of B, and the balance Fe. The development and industrialization of the material provides a solution of material science for solving the current problems that existing iron pans are too short in service life and inconvenient to replace and mount in hot dip coating zinc-aluminum alloy production. The implementation and industrialization of the material is of great importance in solving the current industry status in China and improving the product international competitiveness of the metallurgical industry in China.

Owner:GUANGZHOU YUZHI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com