Flowing observation device for internal gas-liquid phase of centrifugal pump

An observation device, gas-liquid phase technology, applied in the direction of pumps, non-variable pumps, machines/engines, etc., can solve the problems of limited internal flow observation area, complex device structure, low operability, etc., and achieve strong practical value , good light transmission and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

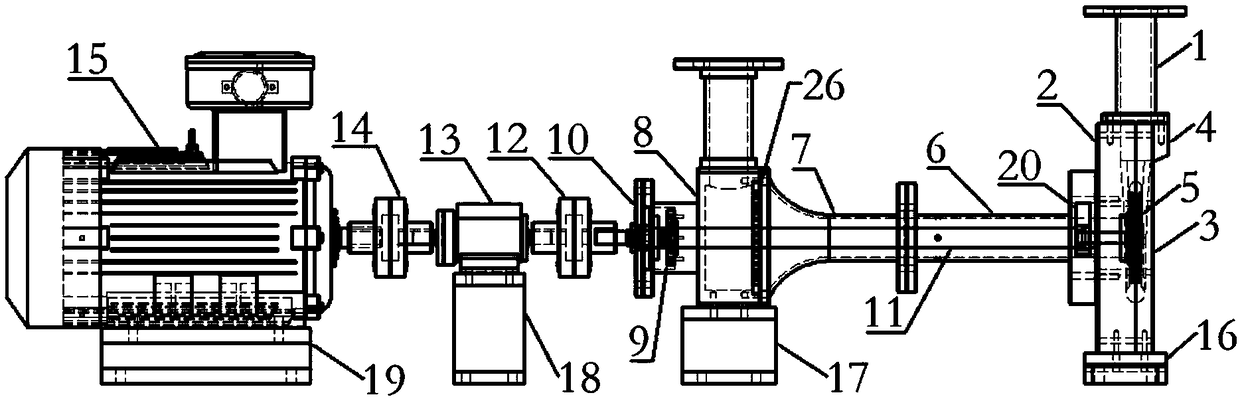

[0025] The gas-liquid phase flow observation device inside the centrifugal pump of the present invention, such as figure 1 and figure 2 As shown, it includes the water outlet part, the water inlet part, the box body 8 and the power transmission part, and the inner center of the water outlet part, the water inlet part, the box body 8 and the power transmission part is provided with a pump shaft 11;

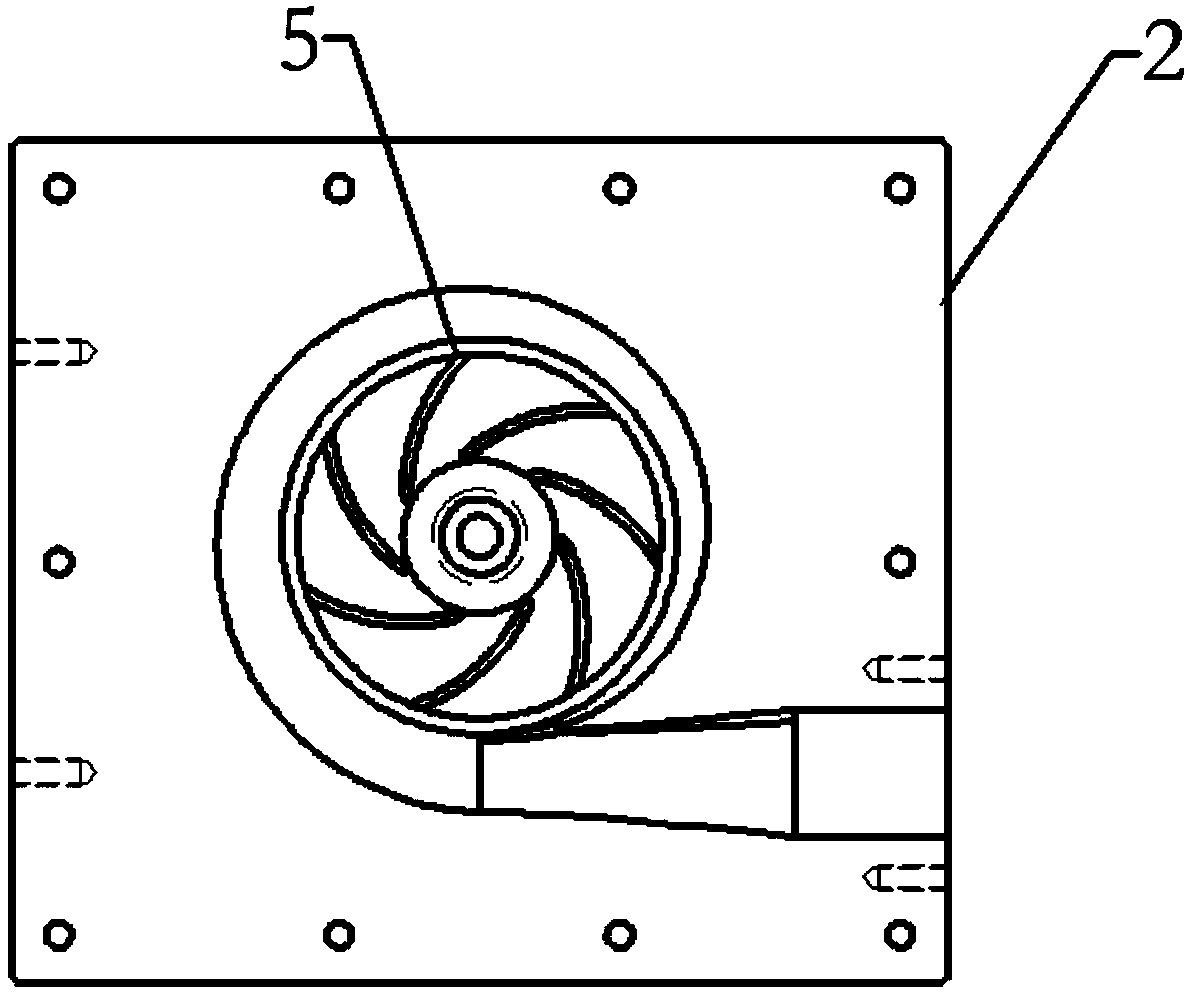

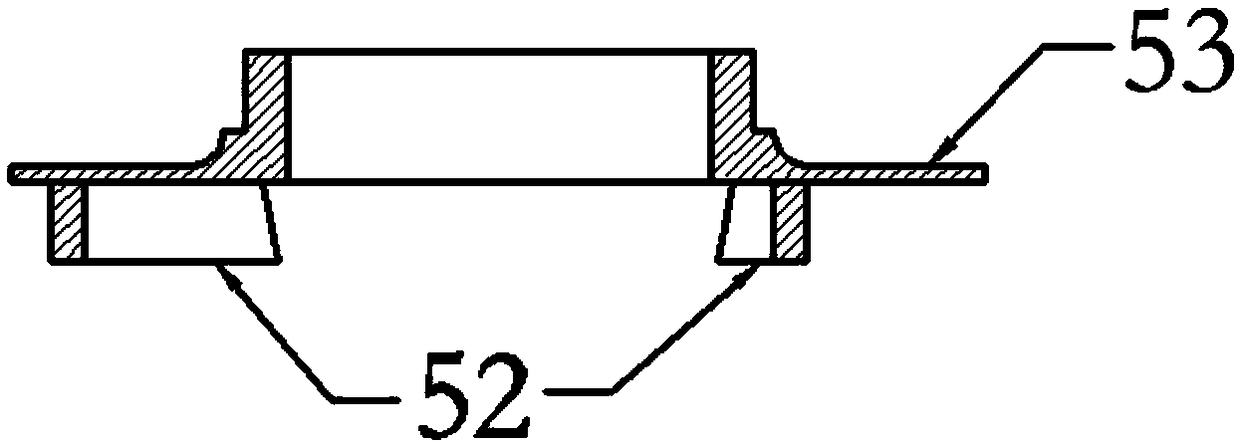

[0026] The water outlet part includes the outlet flange section 1, the upper end of the outlet flange section 1 is detachably connected to the test pump system by bolts, the lower end of the outlet flange section 1 is connected to the rectangular volute by bolts, and the right half of the volute 2 of the volute The upper end is connected with a fixed plate 4, and the upper surface of the fixed plate 4 has a threaded hole. The lower end of the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com