Niobium target and preparation method of niobium target

A niobium target and niobium tube technology, applied in the target field, can solve the problems of inability to guarantee the uniformity of the grain structure and surface roughness of the niobium sputtering target, and achieve low surface roughness value, uniform internal grains, and surface roughness. good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The embodiment of the present invention discloses a method for preparing a niobium target, which includes the following steps:

[0034] a) Preheating the niobium tube blank, and applying glass powder on the surface of the preheated niobium tube blank;

[0035] b) hot-extruding the niobium tube blank obtained in step a), pickling the hot-extruded niobium tube blank, and heat-treating the pickled niobium tube blank;

[0036] c) Boring and milling the inner hole of the niobium tube blank obtained in step b) by using the first cutter to obtain a niobium target; the cutter head of the first cutter is a double cutter head or a single cutter head, and the cutter head of the first cutter The length of the rod is greater than 5000 mm, the double cutter heads are arranged in sequence along the axial direction at the working end of the cutter rod, and the blade inclination angle of the cutter heads is a negative value.

[0037] According to the present invention, it is first nece...

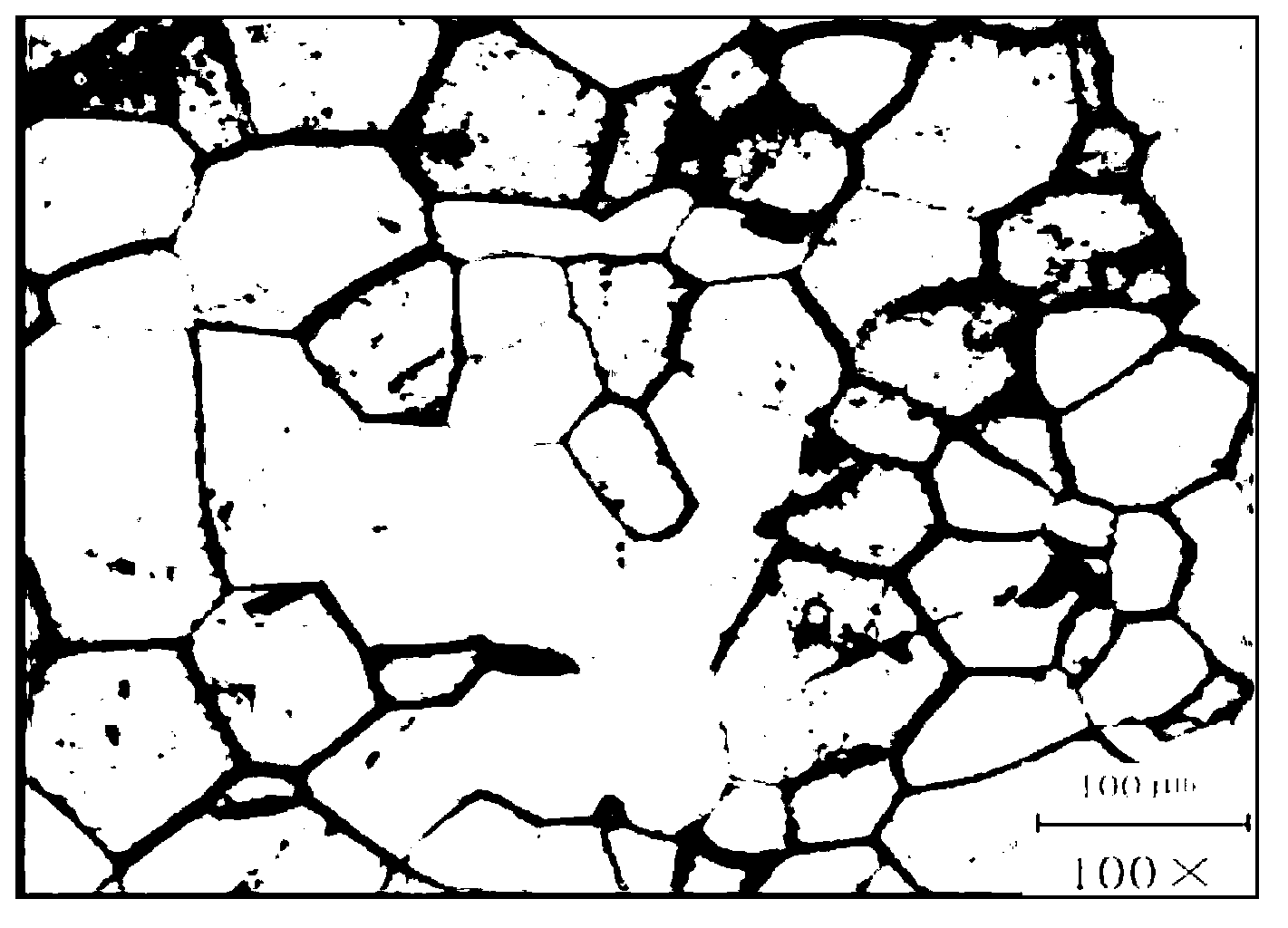

Embodiment 1

[0062] Step 1. Obtain niobium oxide by aluminothermic reduction of niobium pentoxide, and smelt niobium oxide in a horizontal furnace and an electron beam furnace respectively to obtain a niobium ingot with a diameter of Φ190mm, a length of 390mm, and a chemical composition of Nb≥99.95%;

[0063] Step 2. Preheat the niobium ingot obtained in step 1 to 200°C, apply glass powder, heat the ingot to 400°C, keep it warm for 3 hours, upsetting the niobium ingot axially to 210mm, and stretching to 200×200×280mm;

[0064] Step 3. Pickling the niobium ingot obtained in step 2: HCl:HF:H2SO4=5:3:2 (volume ratio), pickling time for 10 minutes, remove surface impurities and glass powder, and observe the luster of niobium metal without impurities spots can be;

[0065] Step 4. Carry out heat treatment to the niobium ingot obtained in step 3: the heat treatment temperature is 1000° C., and the holding time is 60 min;

[0066] Step 5. Upsetting the niobium ingot obtained in step 4 to 220mm, ...

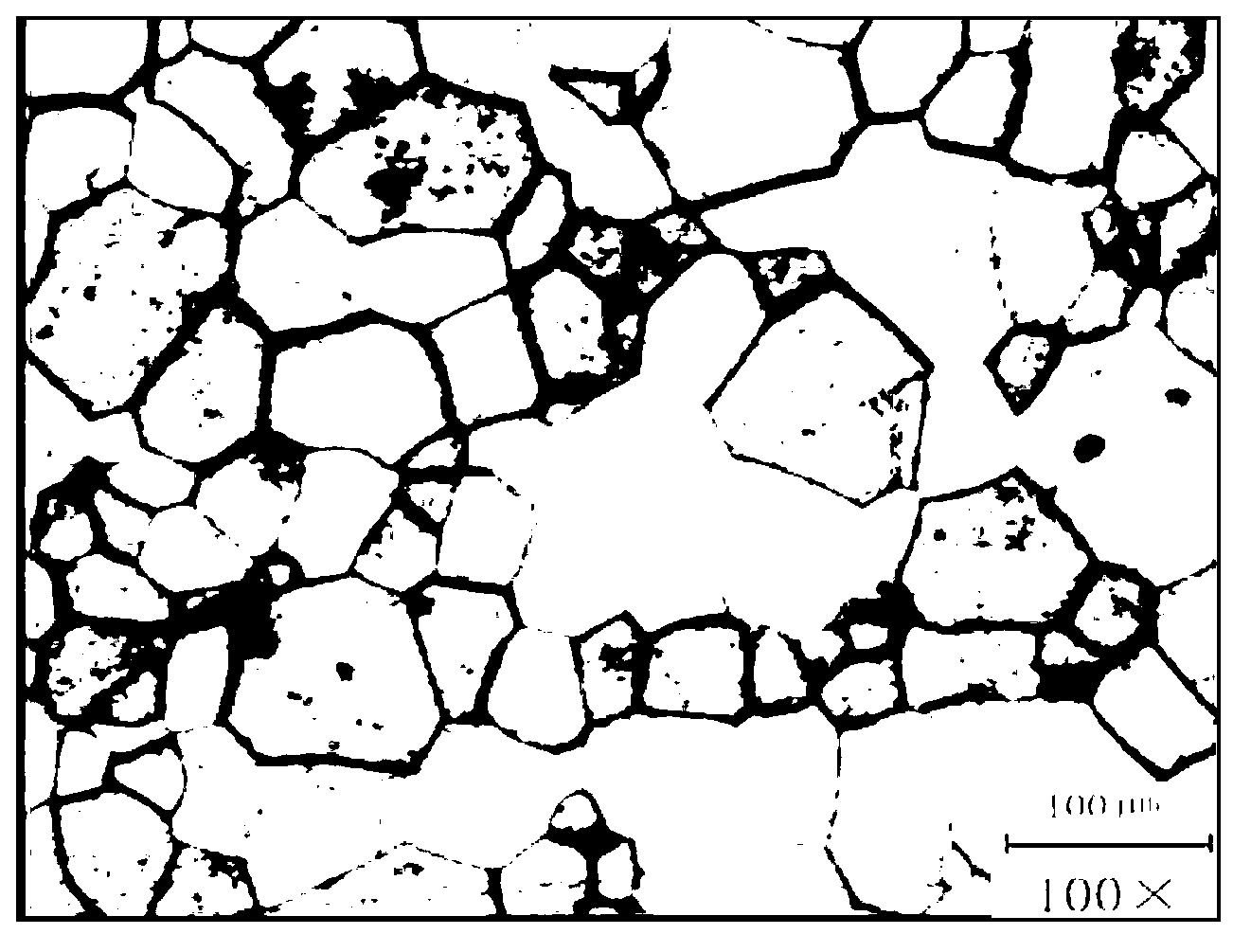

Embodiment 2

[0081] Step 1. Obtain niobium oxide by aluminothermic reduction of niobium pentoxide, and smelt niobium oxide in a horizontal furnace and an electron beam furnace respectively to obtain a niobium ingot with a diameter of Φ290mm, a length of 620mm, and a chemical composition of Nb≥99.95%;

[0082] Step 2. Preheat the niobium ingot obtained in step 1 to 200°C, apply glass powder, heat the ingot to 400°C, keep it warm for 3 hours, upsetting the niobium ingot axially to 340mm, and stretching to 280×280×520mm;

[0083] Step 3, pickling the niobium ingot obtained in step 2: HCl: HF: H 2 SO 4 =5:3:2 (volume ratio), pickling time is 10 minutes, remove surface impurities and glass powder, and the niobium metal luster can be seen without specks by naked eyes;

[0084] Step 4. Carry out heat treatment to the niobium ingot obtained in step 3: the heat treatment temperature is 1000° C., and the holding time is 60 min;

[0085] Step 5. Upsetting the niobium ingot obtained in step 4 to 290...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com