Temperature-sensitive printing paste and printing process thereof

A printing color paste and printing technology, which is applied in the field of printing and dyeing, can solve the problems of high formaldehyde content, insensitive color change, and poor safety of heat-sensitive printing color paste, and achieve improved color fastness and wearing performance, bright colors, and helpful effect on uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

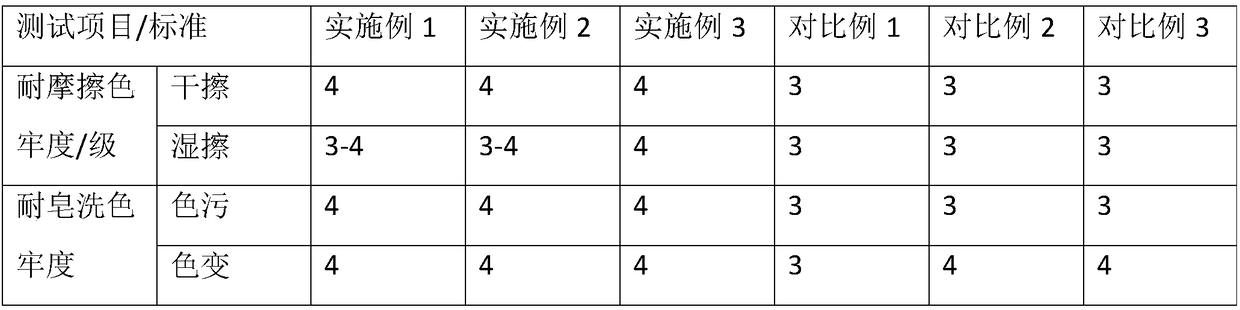

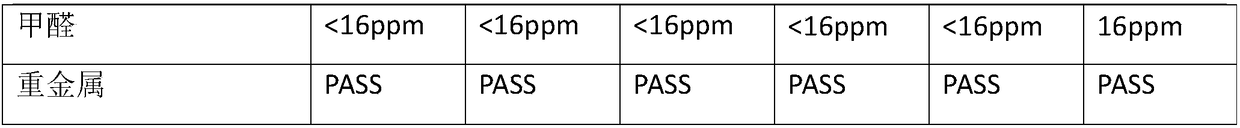

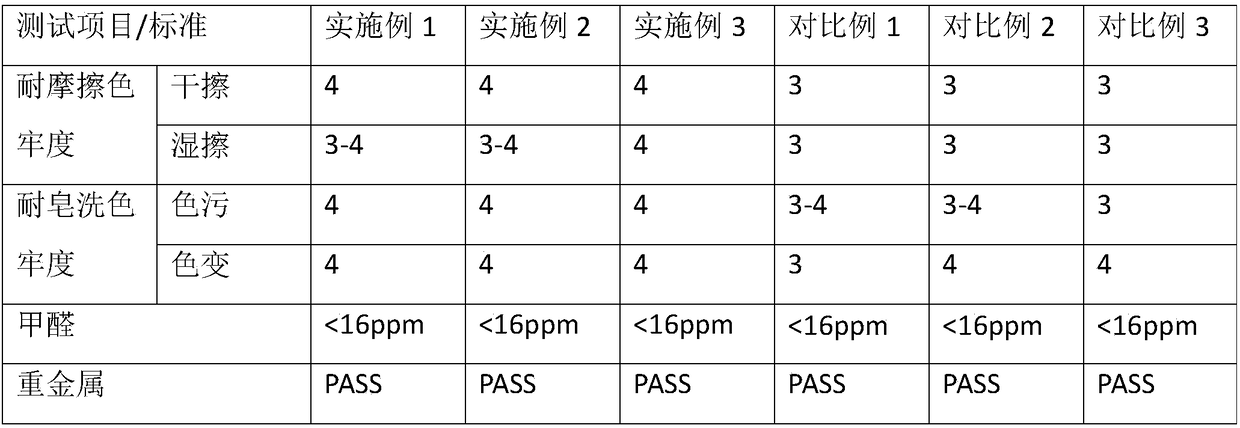

Embodiment 1

[0056] Mix 0.1 part of paint bright red, 0.1 part of paint blue, 0.1 part of paint yellow, 0.1 part of color-changing red, 0.1 part of color-changing yellow, 0.1 part of color-changing blue and 0.5 parts of adhesive, mix and stir evenly, set the stirring speed to 300rpm, stir for 5 minutes, add 10 parts of crosslinking agent, continue to stir for 5 minutes, then add 2 parts of thickener, continue to stir for 10 minutes to obtain the temperature-sensitive printing paste;

[0057] Wherein, the particle size of the binder is 130 μm.

Embodiment 2

[0059] Mix 2 parts of paint red, 2 parts of paint blue, 2 parts of paint yellow, 5 parts of color-changing red, 5 parts of color-changing yellow, 5 parts of color-changing blue and 3 parts of adhesive, and stir evenly. Set the stirring speed to 650rpm and stir for 5 minutes. Add 50 parts of cross-linking agent, continue to stir for 5 minutes, then add 5 parts of thickener, continue to stir for 10 minutes to obtain the temperature-sensitive printing paste;

[0060] Wherein, the particle size of the binder is 150 μm.

Embodiment 3

[0062] Mix 1 part of paint bright red, 1 part of paint blue, 1 part of paint yellow, 1.5 parts of discoloration red, 1.5 parts of discoloration yellow, 1.5 parts of discoloration blue and 1.3 parts of adhesive, set the stirring speed to 400rpm, stir for 5min, add 30 parts of cross-linking agent, continue to stir for 5 minutes, then add 3.5 parts of thickener, continue to stir for 10 minutes to obtain the temperature-sensitive printing paste;

[0063] Wherein, the particle size of the binder is 140 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com