Medium-temperature sintering lead-free copper paste suitable for PZT sensor and preparation method of medium-temperature sintering lead-free copper paste

A sensor and medium temperature technology, applied in the direction of cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, electrical components, etc., can solve the problem of affecting the bonding force between the electrode layer and the ceramic substrate, affecting the performance of the PZT sensor, and affecting the electrode layer. Uniformity of distribution and other issues to achieve the effects of low cost, easy implementation, performance improvement and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention is described clearly and completely below, obviously, the described embodiments are only some embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

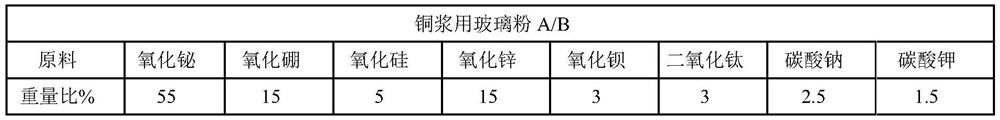

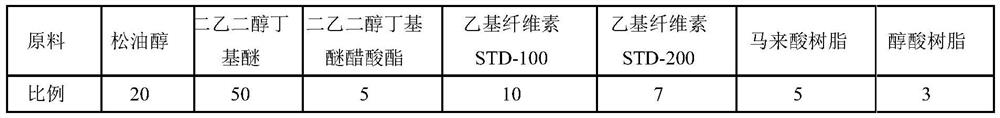

[0032] A lead-free copper paste suitable for medium-temperature sintering of PZT sensors comprises the following components in parts by mass: 70 to 80 parts of copper powder, 1 to 5 parts of glass powder, 1 to 5 parts of inorganic additives, and 15 to 25 parts of organic carrier.

[0033] The copper powder in the lead-free copper paste should be one or both of ultrafine spherical powder and flaky micropowder, and the particle size selection should meet the requirements of ultrafine spherical powder. , to ensure that the silver powder has a good melting state during sinteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com