Adhesive type controlled-release fertilizer and preparation method thereof

A controlled-release fertilizer and adhesive technology, applied in the direction of inorganic fertilizers, ammonium salt fertilizers, fertilizer mixtures, etc., can solve the problems of slow effect and low utilization rate, achieve rapid effect, improve utilization rate, and ensure overall uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

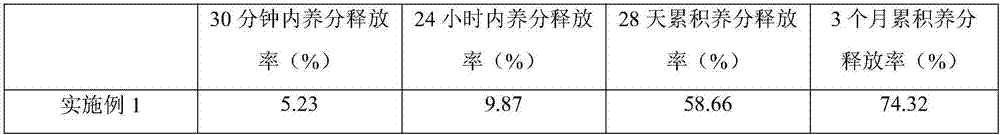

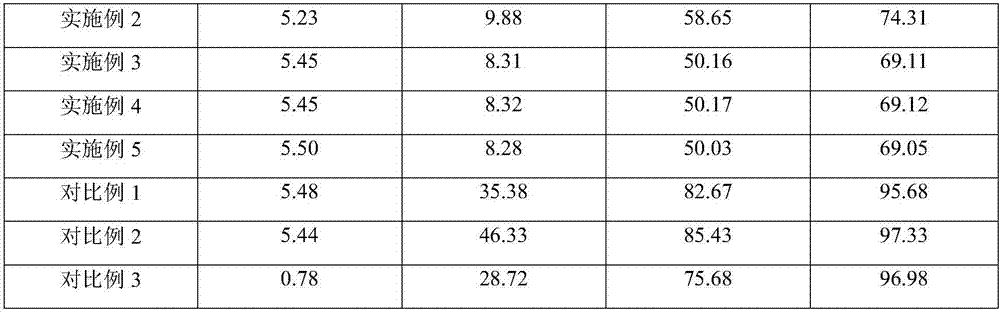

Examples

Embodiment 1

[0029] A preparation method of sticky type controlled-release fertilizer, the specific steps are as follows:

[0030] (1) Preparation of mixed adhesive: dissolve polyglycolic acid, polyamino acid and sodium lignosulfonate in water, then add pregelatinized starch, stir evenly, quickly add disproportionated rosin heated to melting in advance, under the action of ultrasonic oscillation , slowly add polyglycolide and urea-formaldehyde resin emulsion, and continue ultrasonic oscillation for 30 minutes to obtain a mixed adhesive for later use;

[0031] (2) the inorganic fertilizer component is added in the water of 0.3 times of weight, so that part of the inorganic fertilizer component dissolves;

[0032] (3) heating to boiling, adding the mixed adhesive obtained in step (1) while stirring, fully mixing, and continuing to stir until the moisture weight content of the mixture is lower than 10%;

[0033] (4) Heating to melting, spraying and granulating to make granules with a particl...

Embodiment 2

[0042] A preparation method of sticky type controlled-release fertilizer, the specific steps are as follows:

[0043] (1) Preparation of mixed adhesive: dissolve polyglycolic acid, polyamino acid and sodium lignosulfonate in water, then add pregelatinized starch, stir evenly, quickly add disproportionated rosin pre-heated to melt, under the action of ultrasonic oscillation , slowly add polyglycolide and urea-formaldehyde resin emulsion, and continue ultrasonic oscillation for 40 minutes to obtain a mixed adhesive for later use;

[0044] (2) the inorganic fertilizer component is added in the water of 0.4 times of weight, so that part of the inorganic fertilizer component dissolves;

[0045] (3) heating to boiling, adding the mixed adhesive obtained in step (1) while stirring, fully mixing, and continuing to stir until the moisture weight content of the mixture is lower than 10%;

[0046] (4) Heating to melting, spraying and granulating to make granules with a particle diameter...

Embodiment 3

[0055] A preparation method of sticky type controlled-release fertilizer, the specific steps are as follows:

[0056](1) Preparation of mixed adhesive: dissolve polyglycolic acid, polyamino acid and sodium lignosulfonate in water, then add pregelatinized starch, stir evenly, quickly add disproportionated rosin heated to melting in advance, under the action of ultrasonic oscillation , slowly add polyglycolide and urea-formaldehyde resin emulsion, and continue ultrasonic oscillation for 30 minutes to obtain a mixed adhesive for later use;

[0057] (2) the inorganic fertilizer component is added in the water of 0.4 times of weight, so that part of the inorganic fertilizer component dissolves;

[0058] (3) heating to boiling, adding the mixed adhesive obtained in step (1) while stirring, fully mixing, and continuing to stir until the moisture weight content of the mixture is lower than 10%;

[0059] (4) Heating to melting, spraying and granulating to make granules with a particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com