Multi-pipe spraying device

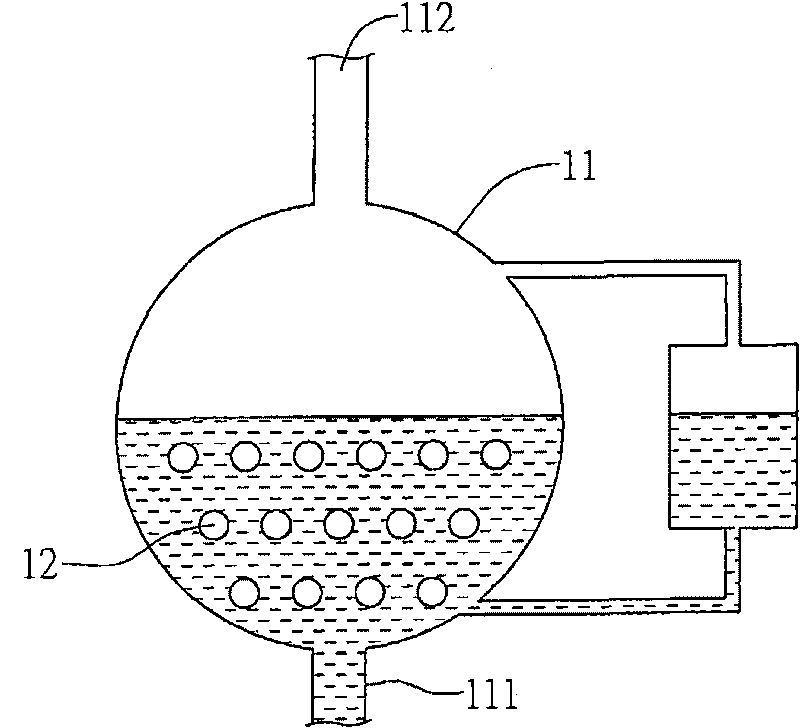

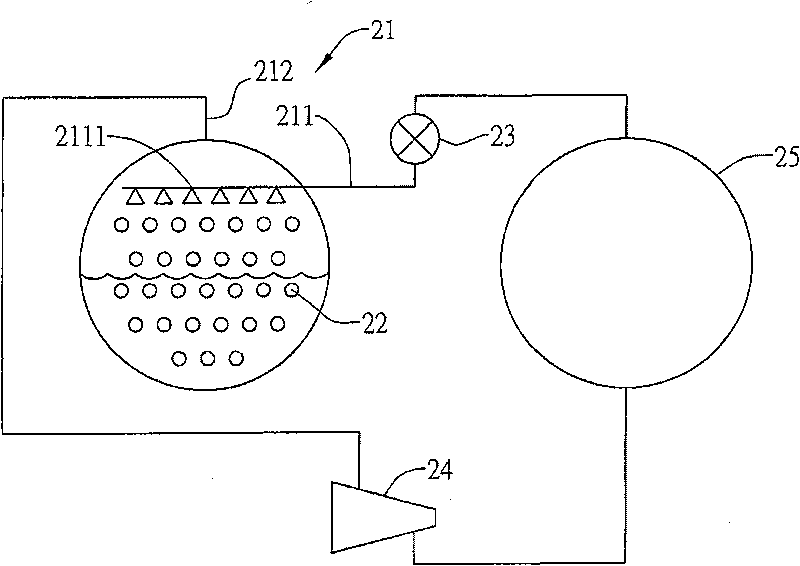

A multi-pipe, shower technology, used in fixed conduit assemblies, indirect heat exchangers, evaporators/condensers, etc., can solve problems such as uneven showering, increased maintenance costs, and difficult disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention are described below through specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

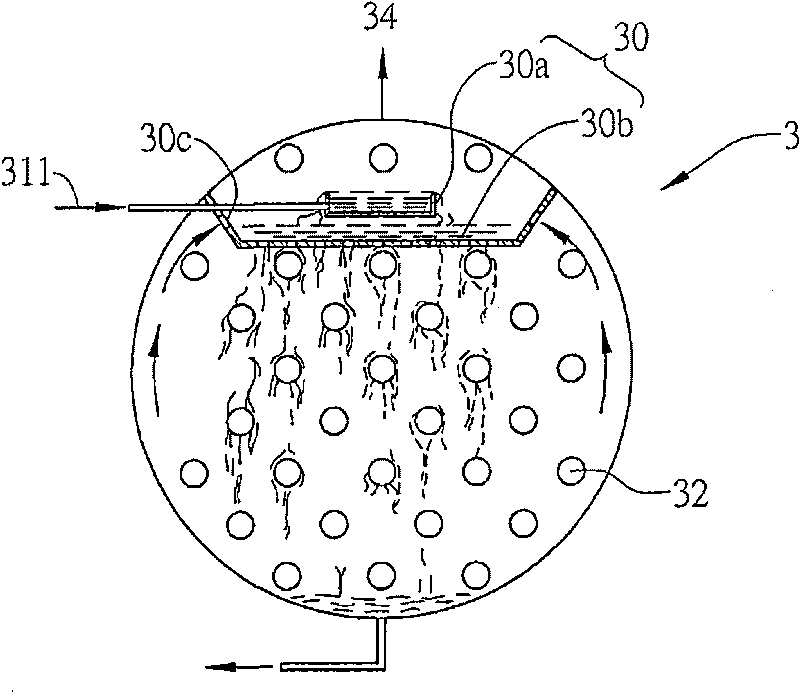

[0048] see Figure 5 with Image 6 , is a schematic diagram of the multi-pipe shower device of the present invention.

[0049]The basic component of the multi-pipe shower device is a body 51, which has a closed accommodation space, including: a first tube plate 513 and a second tube plate (not shown) disposed near both ends of the body 51 , an air outlet pipe 512 for discharging the gaseous refrigerant in the accommodating space, a connecting pipe 517 for introducing the gaseous refrigerant from the refrigerant source into the accommodating space, multiple tube plates formed on the first tube plate 513 and the second tube plate a plurality of openings 5111a and openings 5112a, and a plurality of shower pipes 5111 and a plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com