Molten slag discharging devices and plasma furnace

A technology of discharge device and plasma furnace, applied in the field of ion furnace, can solve the problems of melting body scarring and clogging the slag discharge pipe, and achieve the effect of avoiding solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

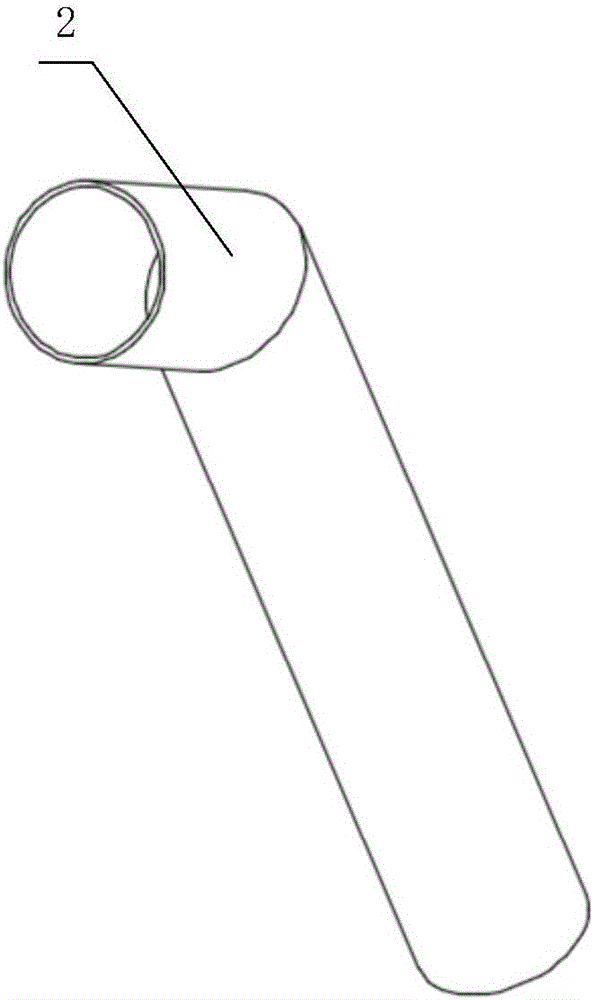

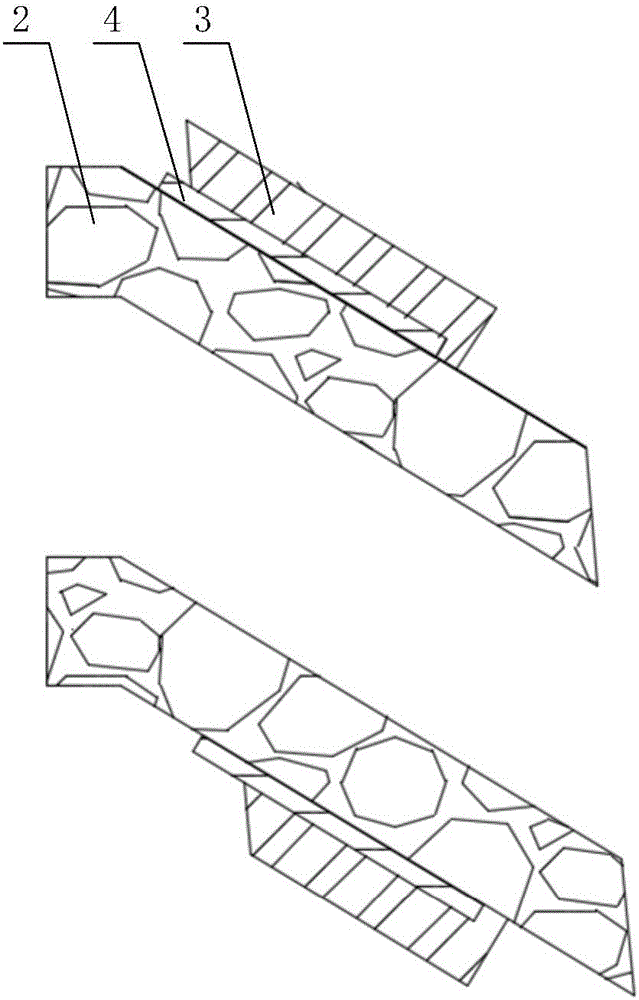

[0038] figure 1 It is a structural schematic diagram of the slag discharge device described in the embodiment of the present invention; figure 2 for figure 1 A cross-sectional view of the slag discharge device;

[0039] Such as Figure 1-2 As shown, the present invention provides a slag discharge device, which includes a slag discharge pipe 2 for discharging the molten material. The outer layer of the slag discharge pipe 2 is provided with a thermal insulation bushing 3. There is a heating element 4 between them.

[0040] The invention provides a slag discharge device, through the slag discharge pipe 2, the thermal insulation bushing 3 on the outer layer of the slag discharge pipe 2, and the heating element 4 between the slag discharge pipe 2 and the thermal insulation bushing 3, the high-temperature melt When discharged from the slag discharge pipe 2, the high-temperature melt can be kept at a high temperature by the heating of the heating element 4, thereby preventing t...

Embodiment 2

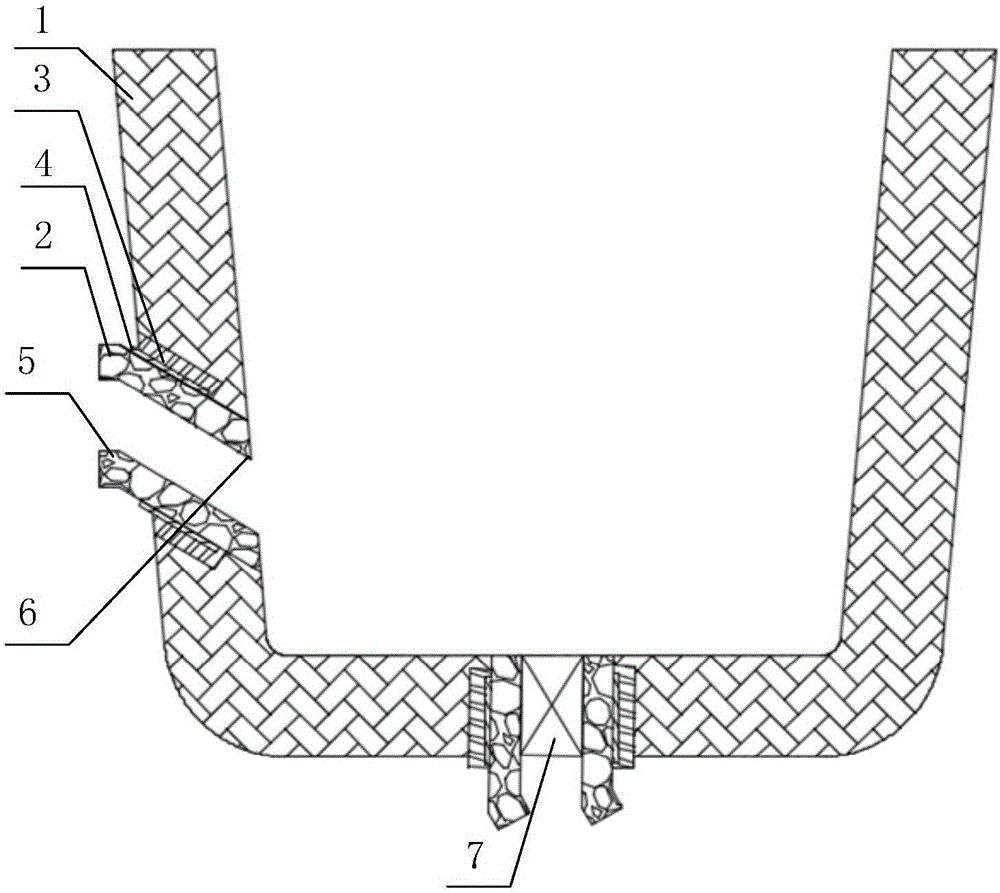

[0060] image 3 It is a structural schematic diagram of the plasma furnace described in the embodiment of the present invention.

[0061] The present invention also provides a plasma furnace, comprising a furnace body 1 and the slag discharge device described in the present invention, at least one slag discharge device is provided; the slag discharge device is arranged obliquely on the side wall of the furnace body 1, and the slag discharge device The height of the outlet bottom 5 of the slag discharge pipe of the device is higher than the height of the top 6 of the slag discharge pipe inlet.

[0062] The slag discharge pipe 2 is installed obliquely on the furnace body 1, and the height of the bottom 5 of the slag discharge pipe outlet is higher than the height of the top 6 of the slag discharge pipe inlet, which can effectively increase the residence time of solid waste in the high-temperature furnace and facilitate the melting of the melt The degree of uniformity and vitrif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com