Patents

Literature

60results about How to "Avoid freezing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

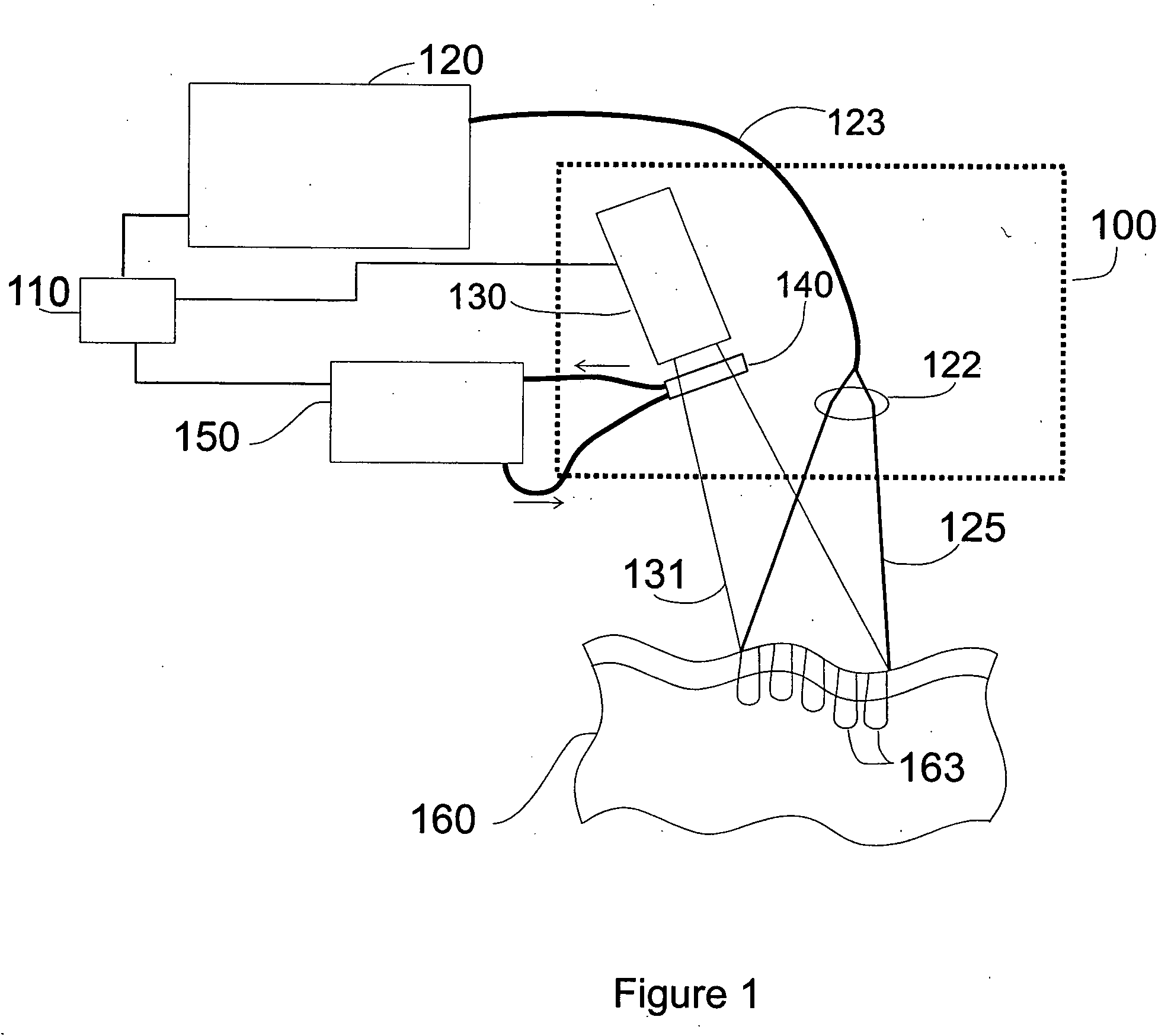

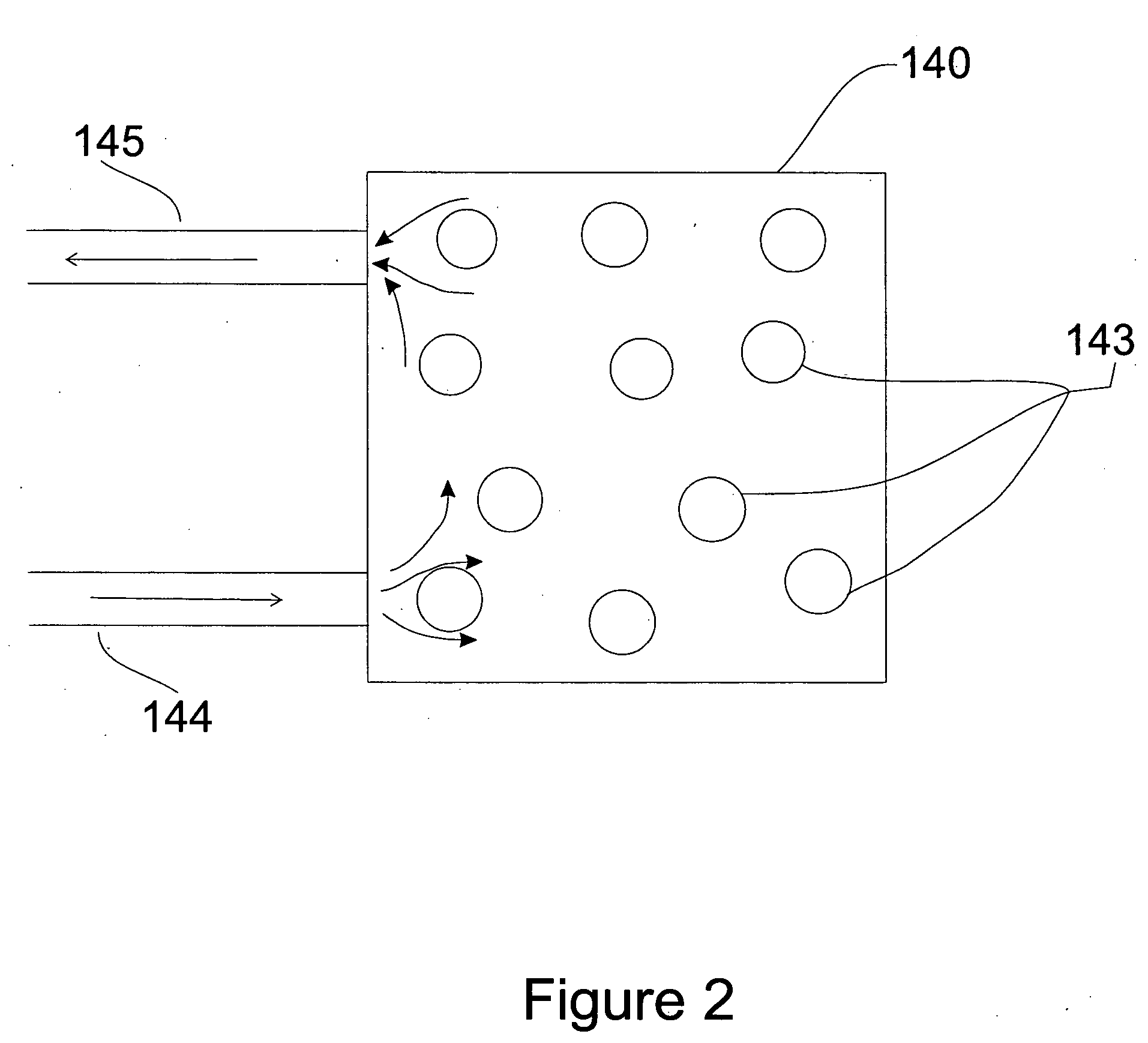

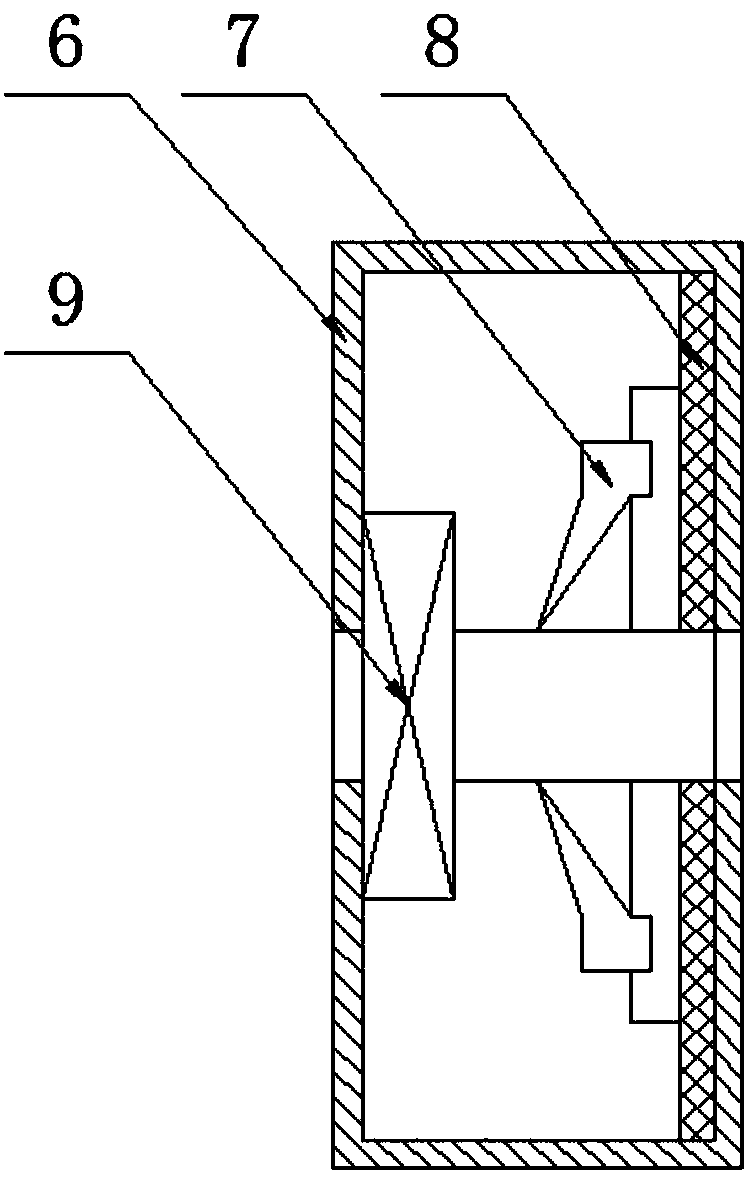

Patterned thermal treatment using patterned cryogen spray and irradiation by light

InactiveUS7780656B2Avoid freezingAvoid burningSurgical instruments for coolingIrradiationThermal treatment

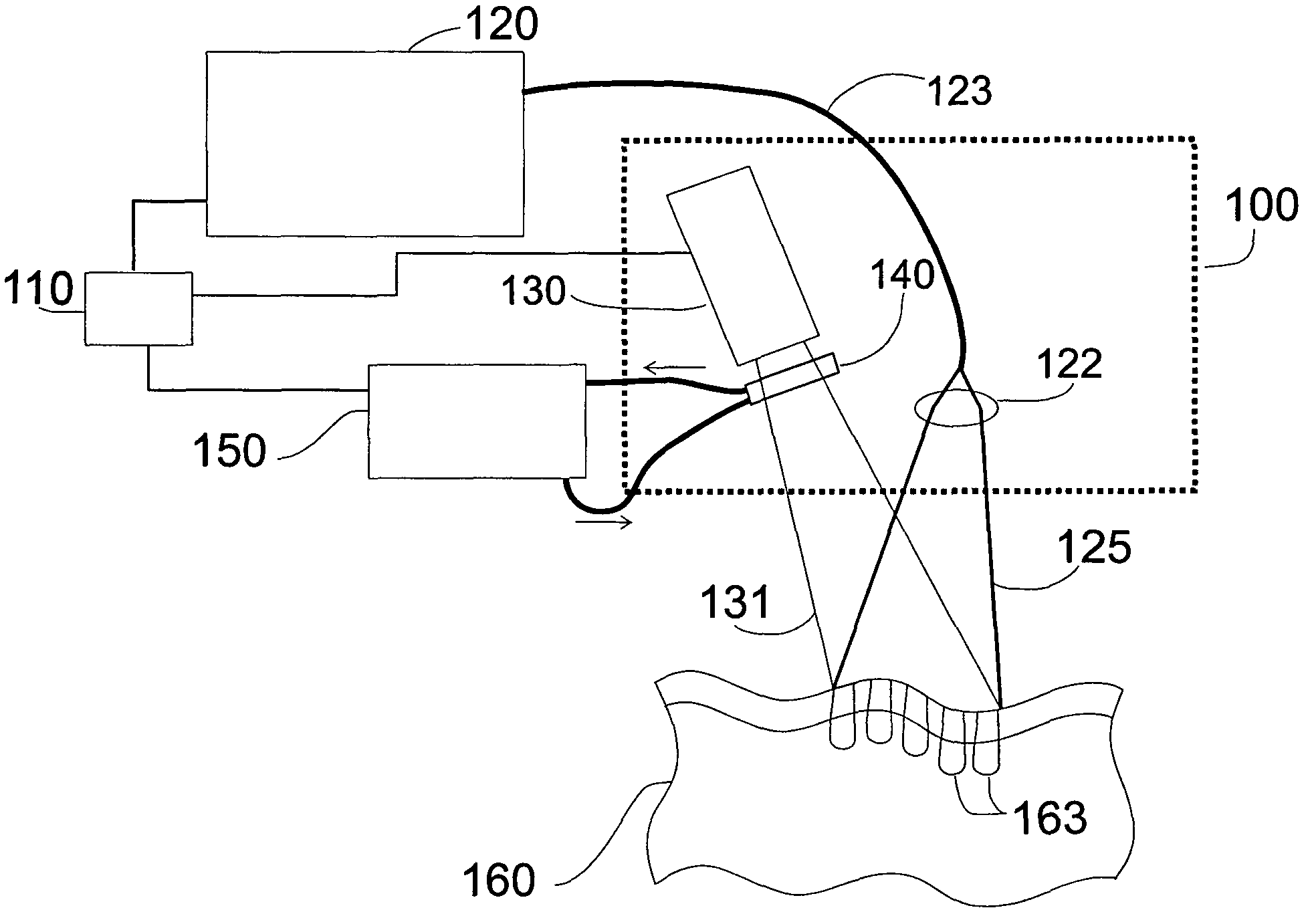

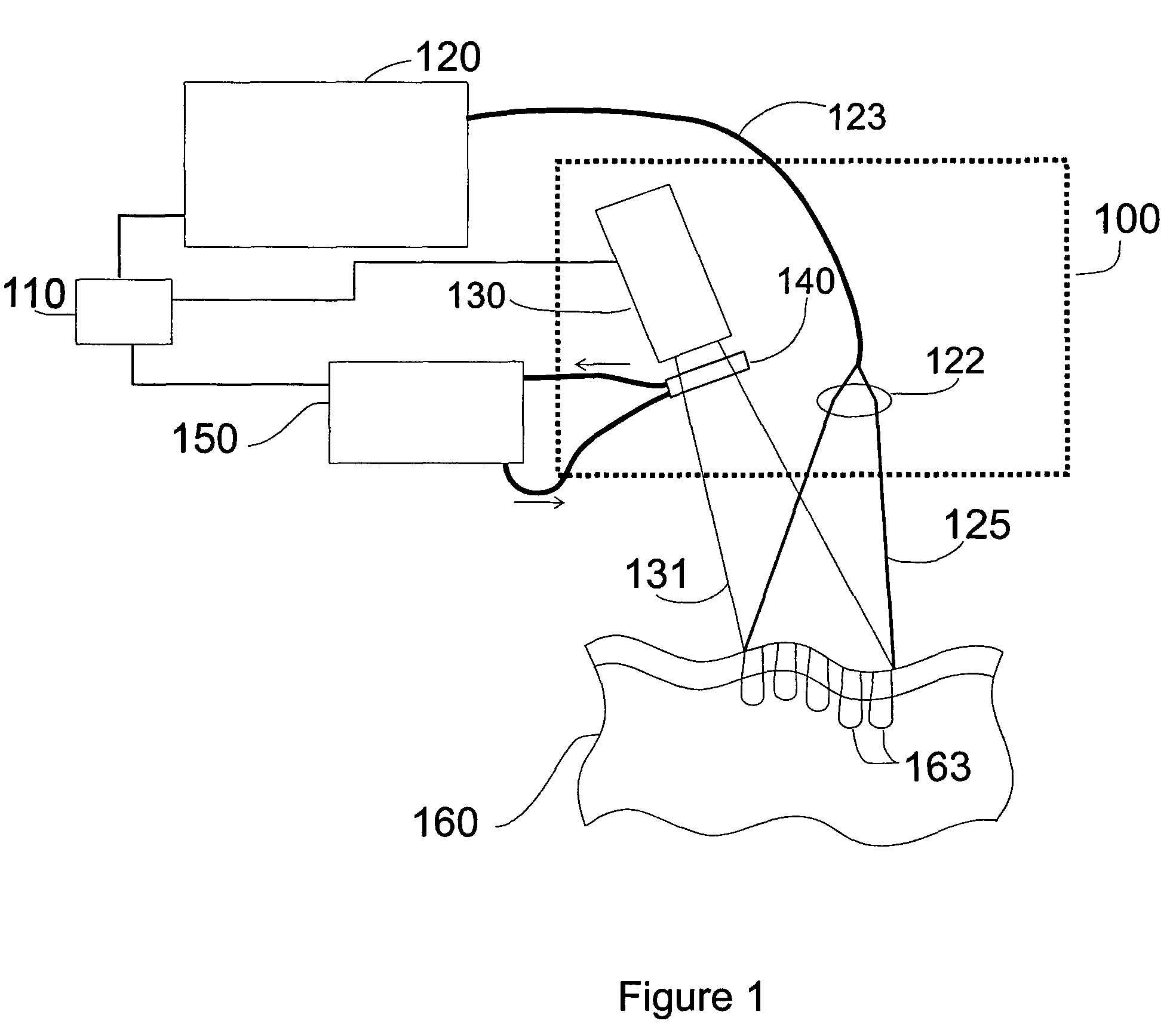

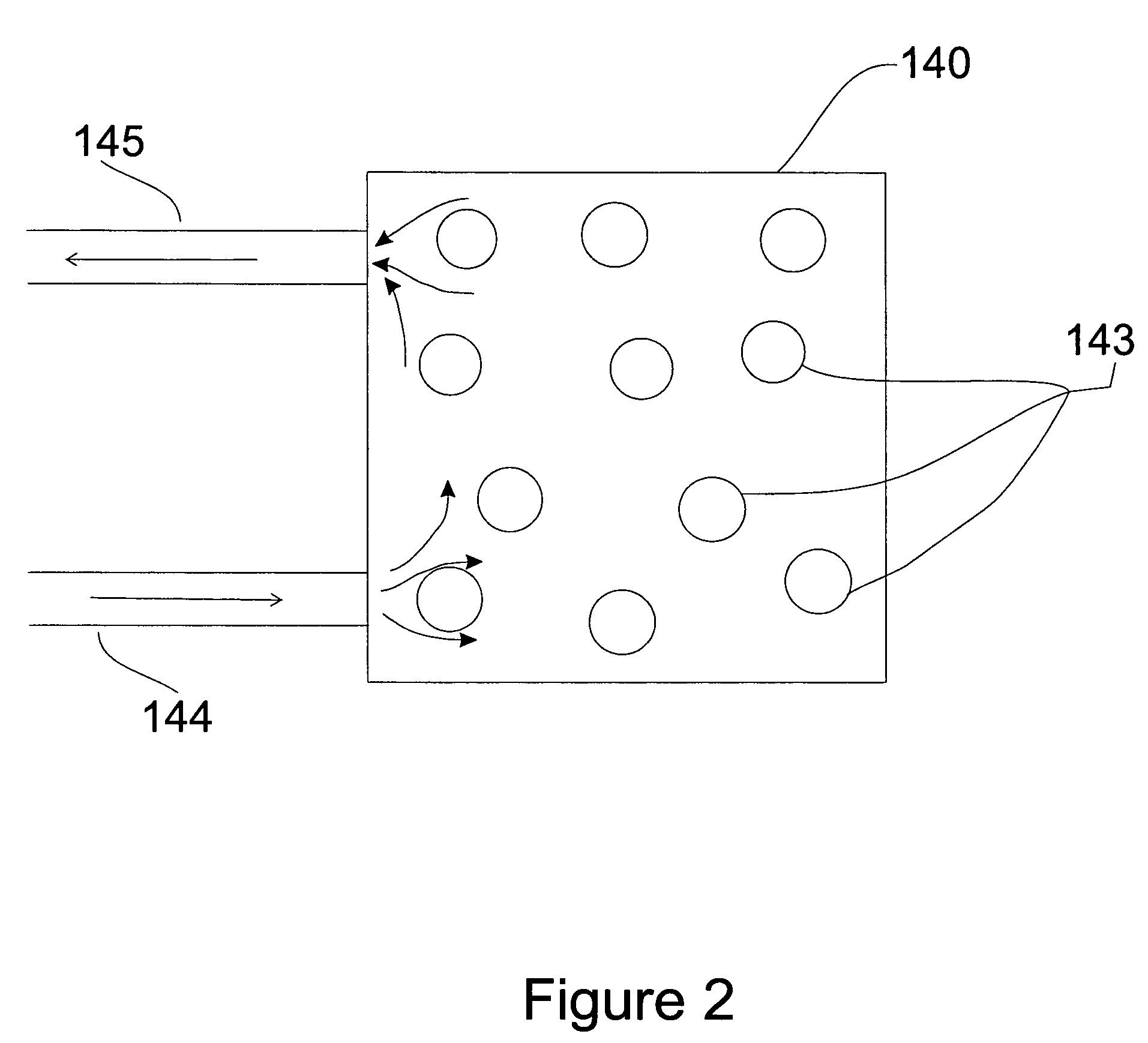

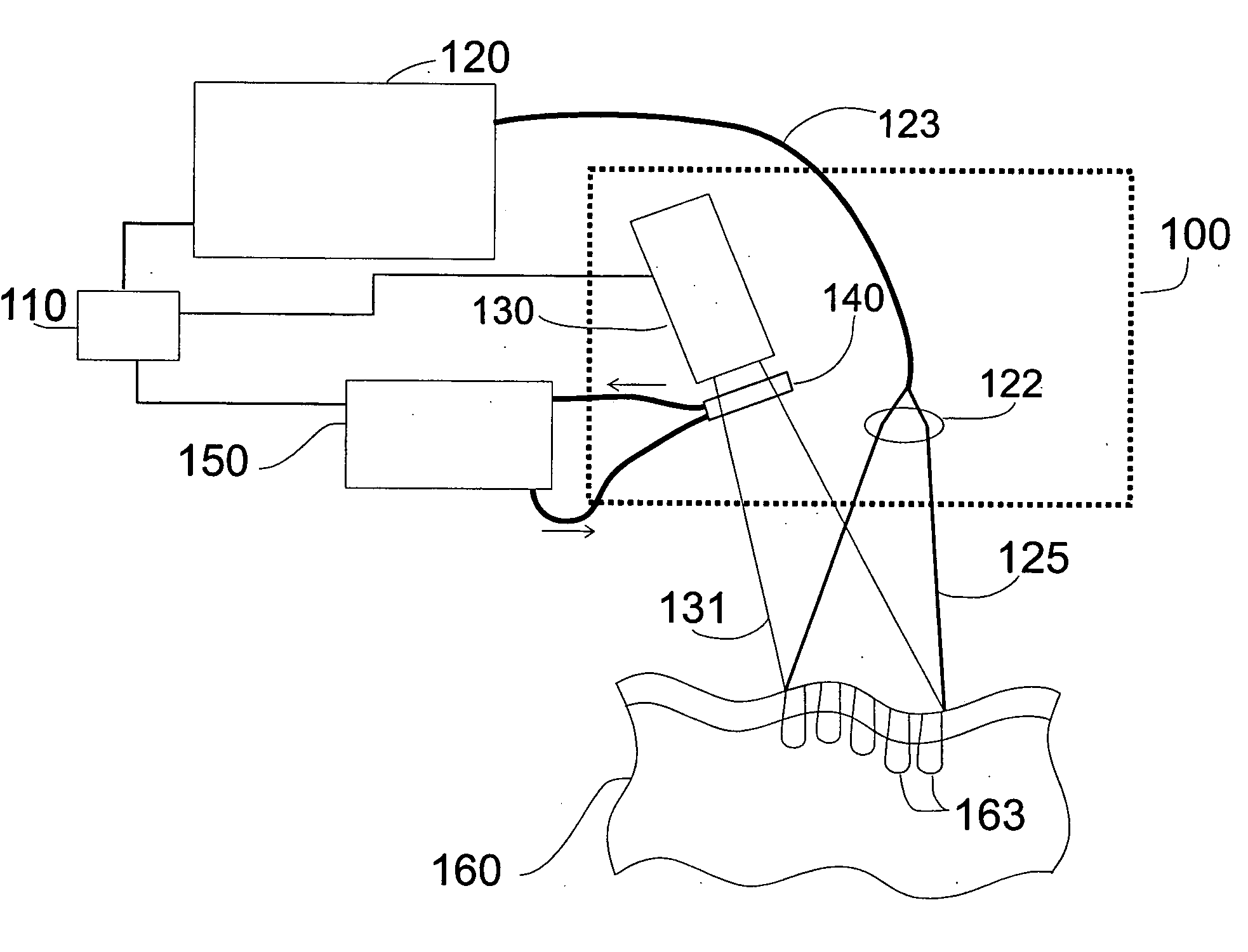

A spray of cryogen is patterned to create a pattern of cooled regions on a target tissue for cosmetic dermatological treatment. In one embodiment, the cryogen is patterned using a heated mask. An optical source is configured to irradiate the target tissue in a region at least partially overlapping the cooled regions to create a pattern of treatment zones. A control unit adjusts the timing of between the cryogen and optical pulses.

Owner:RELIANT TECH INC

Patterned thermal treatment using patterned cryogen spray and irradiation by light

InactiveUS20070118098A1Avoid burningAvoid freezingSurgical instruments for coolingIrradiationThermal treatment

A spray of cryogen is patterned to create a pattern of cooled regions on a target tissue for cosmetic dermatological treatment. In one embodiment, the cryogen is patterned using a heated mask. An optical source is configured to irradiate the target tissue in a region at least partially overlapping the cooled regions to create a pattern of treatment zones. A control unit adjusts the timing of between the cryogen and optical pulses.

Owner:RELIANT TECH INC

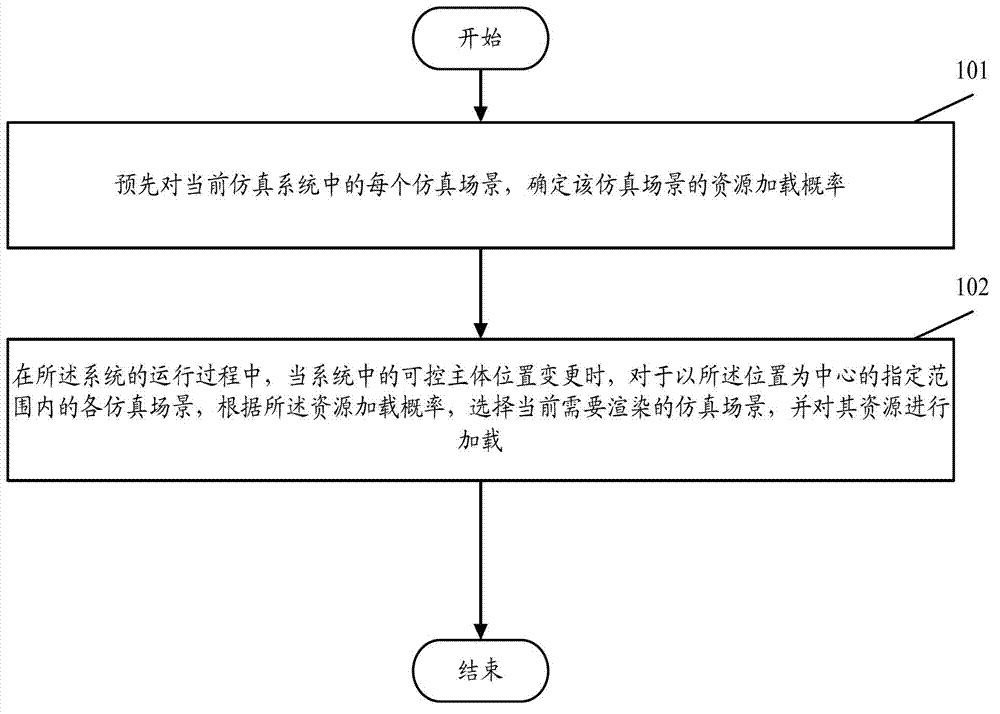

Resource loading method

ActiveCN102736940AImprove accuracyAvoid freezingProgram loading/initiatingSpecial data processing applicationsSimulation

The invention discloses a resource loading method, which comprises the following steps of: (a), determining the resource loading probability of each simulation scene in a current system in advance; and (b), when the position of a controllable main body in the system is changed in the running process of the system, selecting a simulation scene currently to be rendered from the simulation scenes in a specified range taking the position as the center according to the resource loading probabilities, and loading resources of the simulation scene. By the method, resource pre-loading accuracy can be improved, and the problem of unsmoothness caused by waiting for resource loading is solved.

Owner:BEIJING PIXEL SOFTWARE TECH

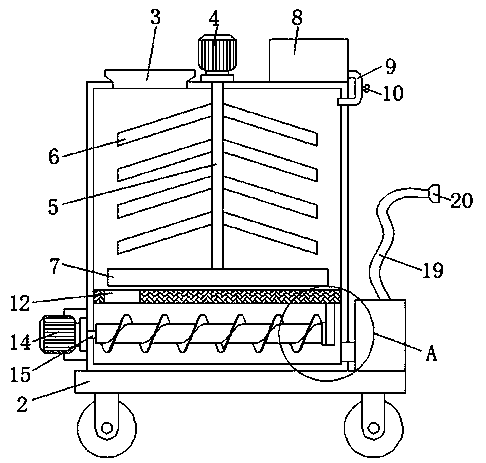

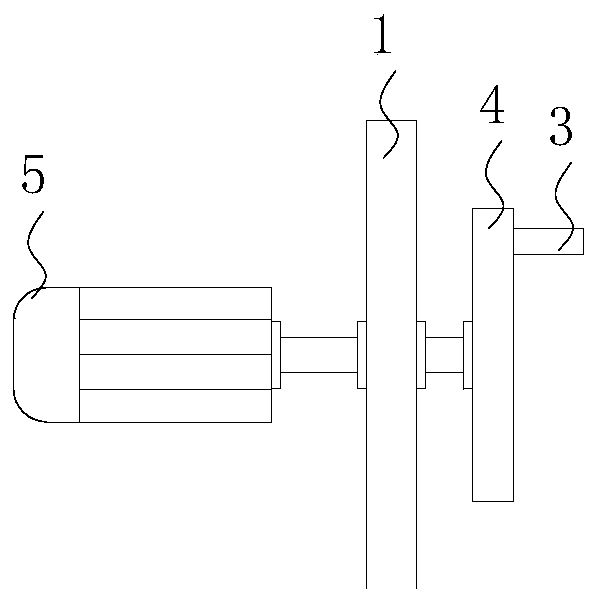

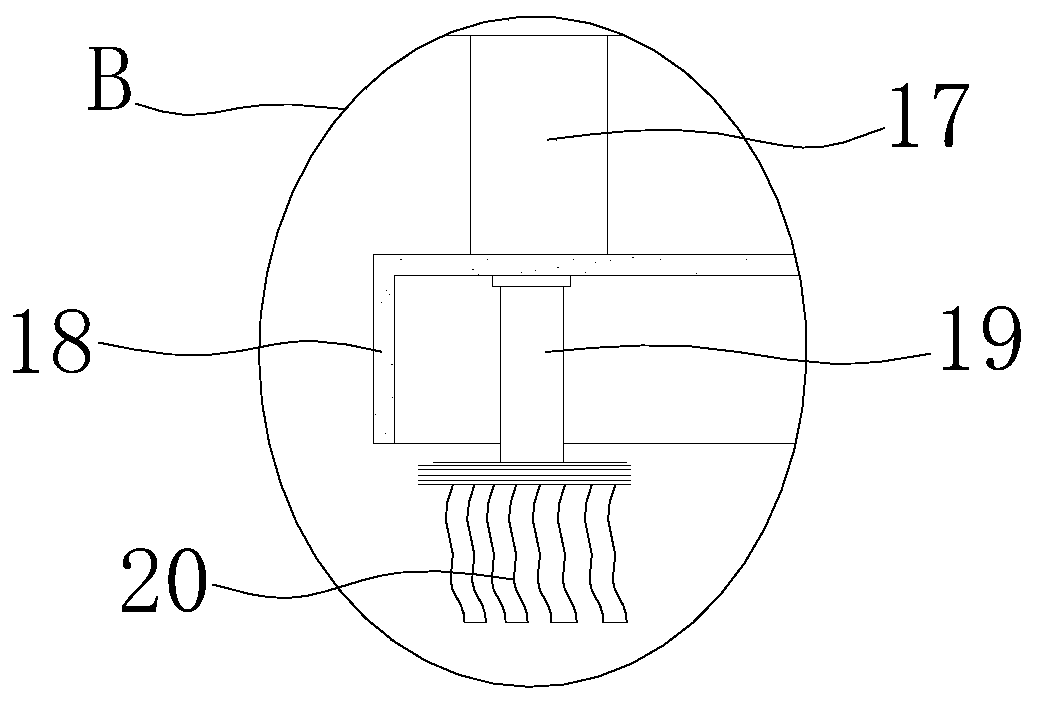

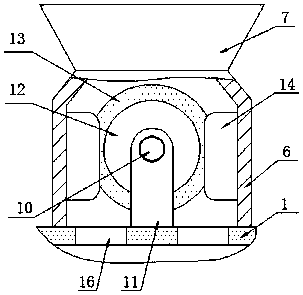

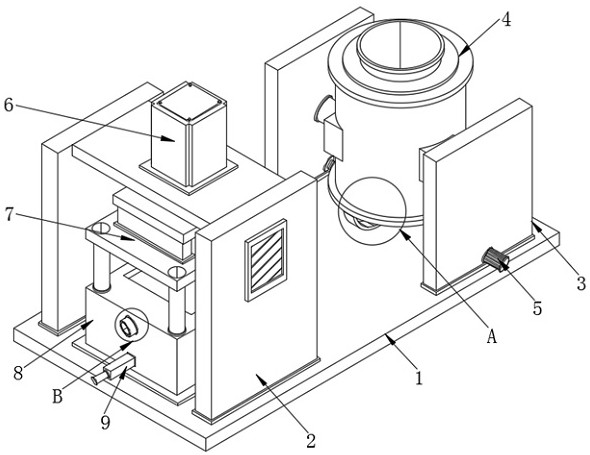

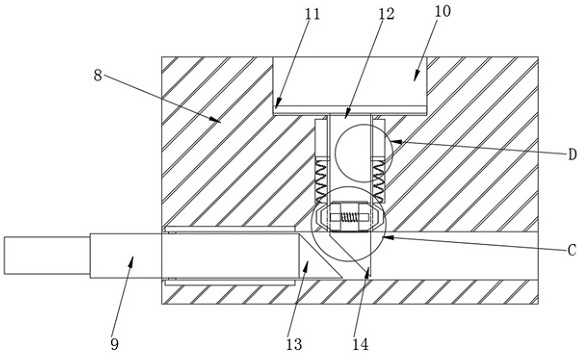

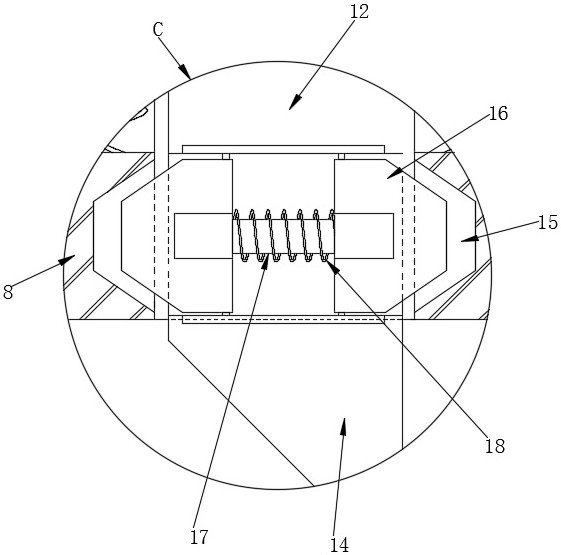

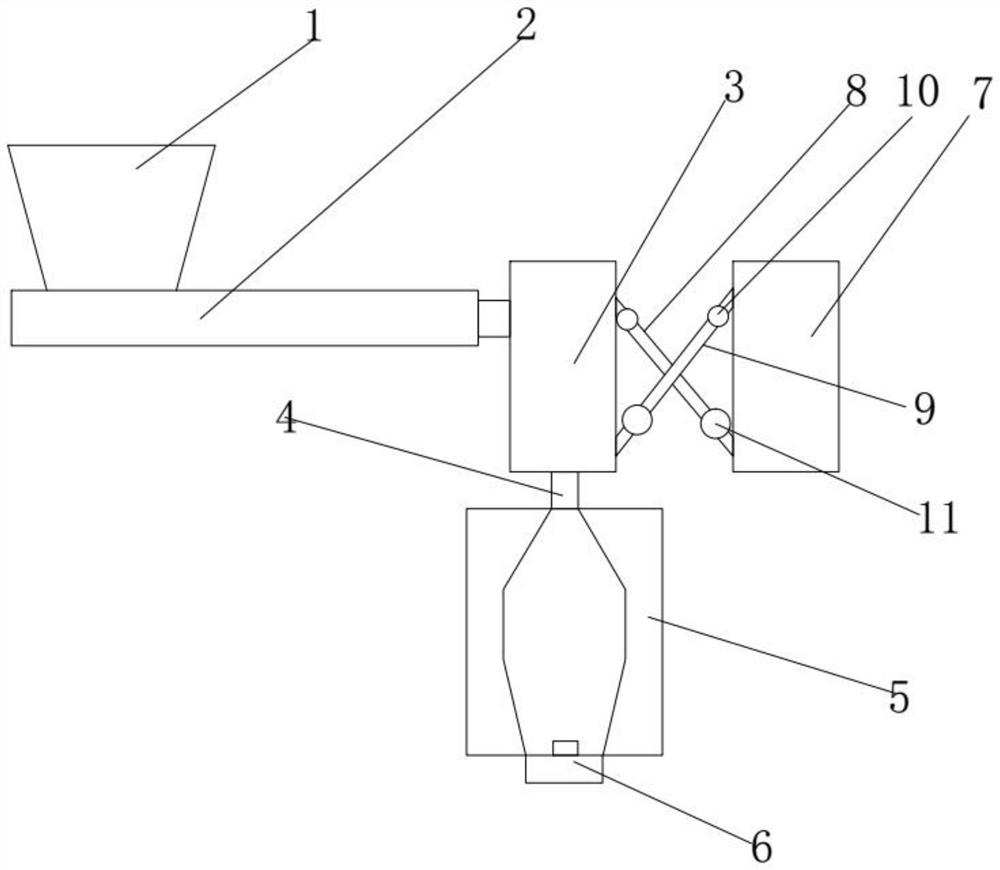

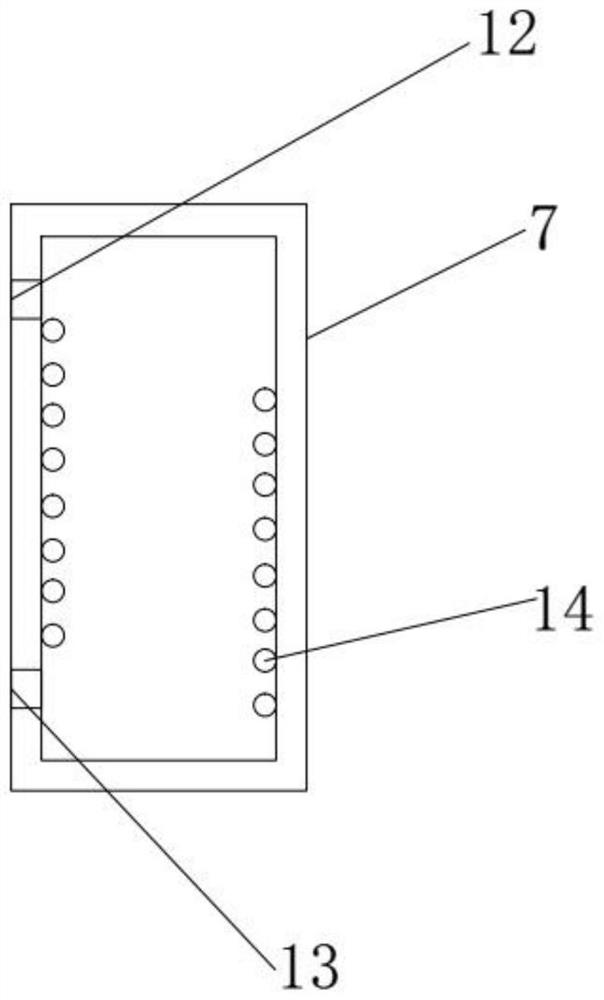

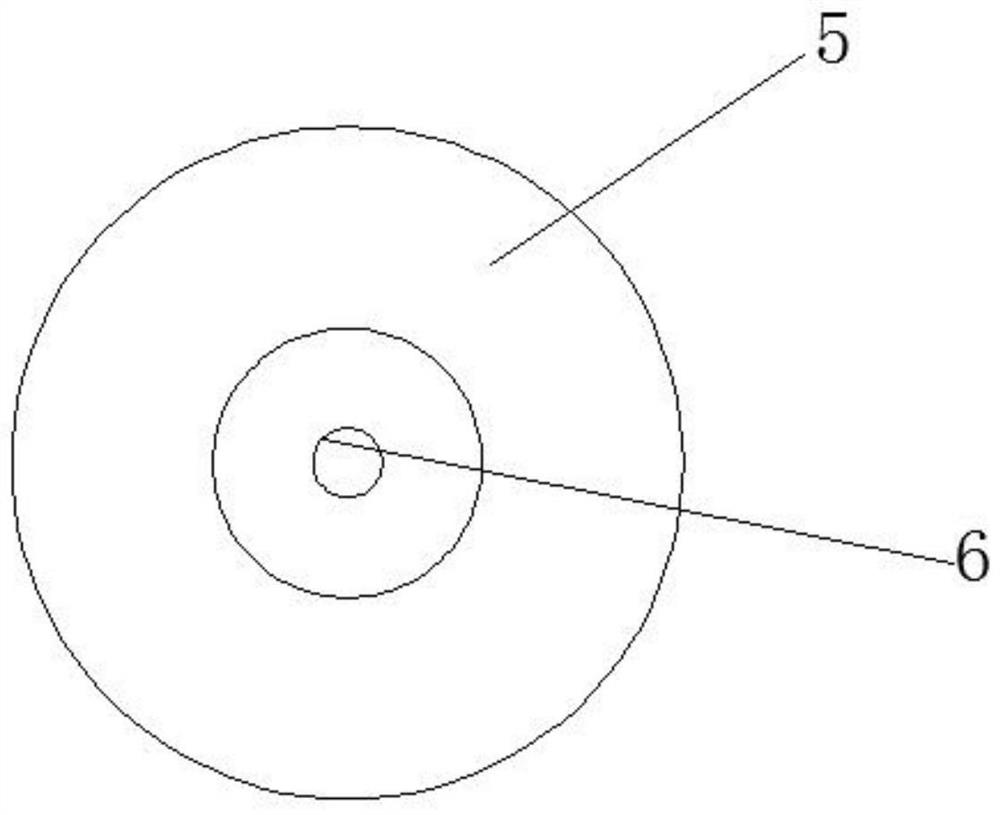

Efficient mortar spraying machine

The invention relates to the technical field of mortar spraying machines and discloses an efficient mortar spraying machine. The efficient mortar spraying machine comprises an equipment body, whereina base is fixedly connected to the bottom of the equipment body, a feeding pipe is communicated to the top of the equipment body, and a first motor is fixedly connected to the middle of the top of theequipment body; an output shaft of the first motor is fixedly connected with a rotating rod, and one end, far from the first motor, of the rotating rod extends into the equipment main body in a penetration manner; stirring blades which are arrayed in an equal interval manner are fixedly connected to the outer surface of the rotating rod; a sweeping plate is fixedly connected to one end, in the equipment body, of the rotating rod; and a water tank is fixedly connected to the top of the equipment body. According to the efficient mortar spraying machine, the problems that mortar in an existing mortar spraying machine is solidified during the long-term spraying, and the spraying quality is influenced are solved, the effective spraying of the mortar is realized, and the situation that the mortar in equipment is dried and solidified during long-term spraying is avoided.

Owner:WUXI KONSTANT POWER TECH CO LTD

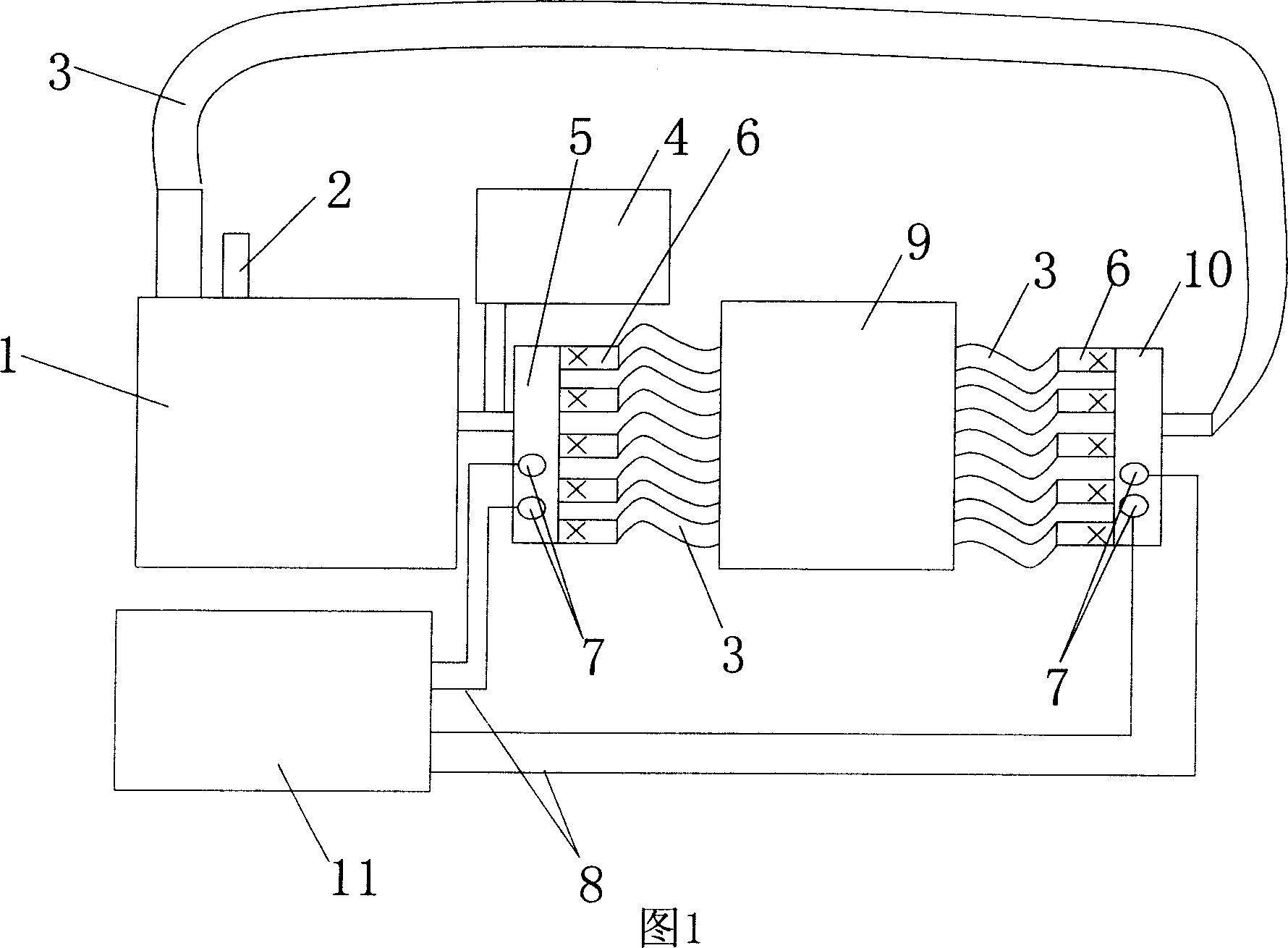

Heating type gravel scattering equipment for urban rail transit

PendingCN112092837ANot easy to solidifySanding easilyAir heatersLocomotivesElectric machineryRail transit

Heating type gravel scattering equipment for urban rail transit comprises a shell and a stirring mechanism. The upper end of the shell is fixedly connected with a vehicle through a plurality of vertical rods, a treatment chamber is formed in the shell, and gravel is arranged in the treatment chamber; and the stirring mechanism comprises a connecting pipe arranged in the treatment chamber, a rotating rod is arranged in the connecting pipe, the rotating rod is fixedly connected with the inner wall of the connecting pipe through a plurality of connecting rods, the upper end of the rotating rod isrotatably connected with the inner top of the treatment chamber, and a motor is mounted at the upper end of the shell. When the equipment is in use, gravel can be stirred, gravel can be discharged intermittently, use of the gravel is saved, the gravel can be heated in the stirring process, and the situation that the gravel is affected with damp, solidified and hardened, so that the sand discharging efficiency is affected is avoided.

Owner:霍伸伸

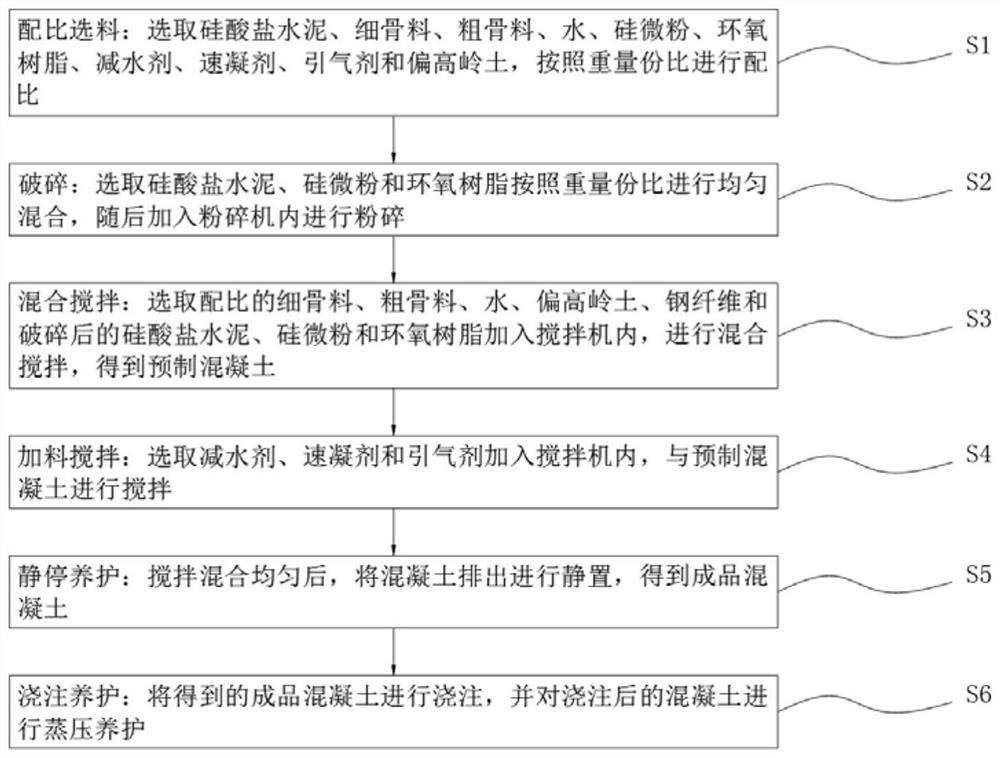

Preparation process of high-strength wear-resistant concrete

The invention discloses a preparation process of high-strength wear-resistant concrete. The concrete is prepared from the following components in parts by weight: 300 to 400 parts of Portland cement,500 to 900 parts of fine aggregate, 950 to 1250 parts of coarse aggregate, 180 to 190 parts of water, 20 to 40 parts of silica powder, 50 to 80 parts of epoxy resin, 5 to 12 parts of steel fiber, 1 to4 parts of a water reducing agent, 6 to 12 parts of an accelerator, 0.15 to 0.6 part of an air entraining agent and 40 to 65 parts of metakaolin. The structure of the concrete is scientific and reasonable; the preparation method is safe and convenient to use; and the prepared concrete is high in strength and not prone to damage during heavy pressing and collision, the overall strength of the prepared concrete during use is improved, the wear resistance of the concrete is improved, and the setting rate of the concrete is increased, so the market competitiveness of the prepared concrete is improved.

Owner:卫凤仪

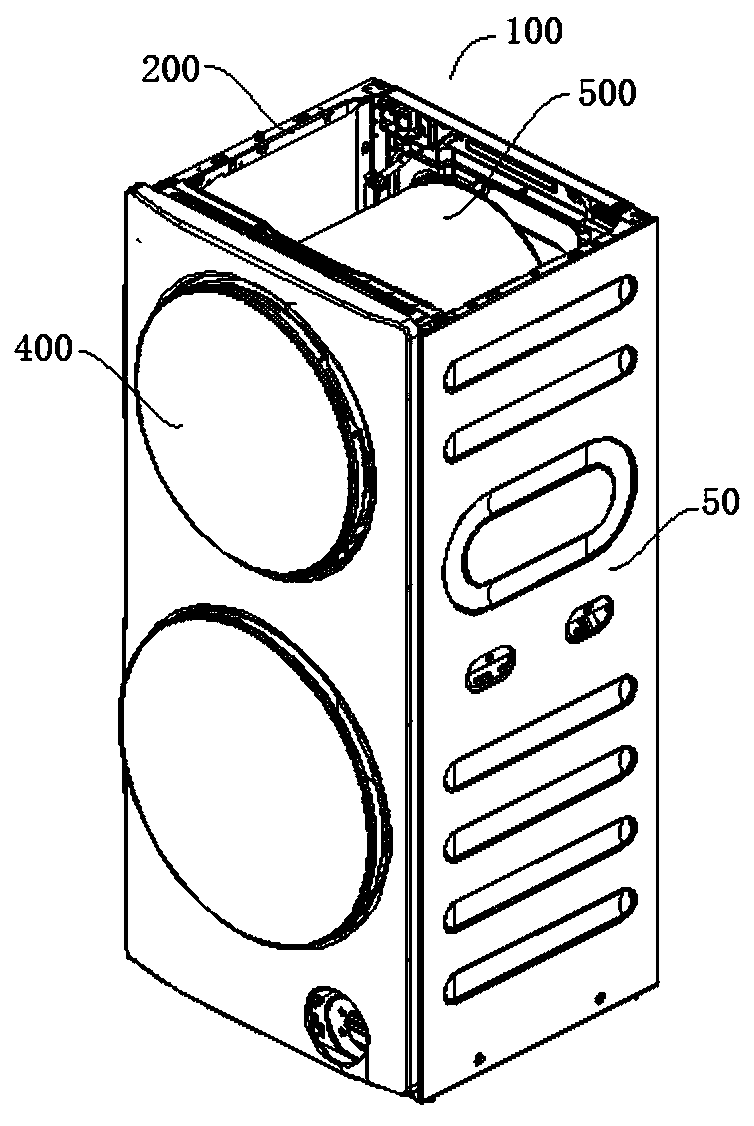

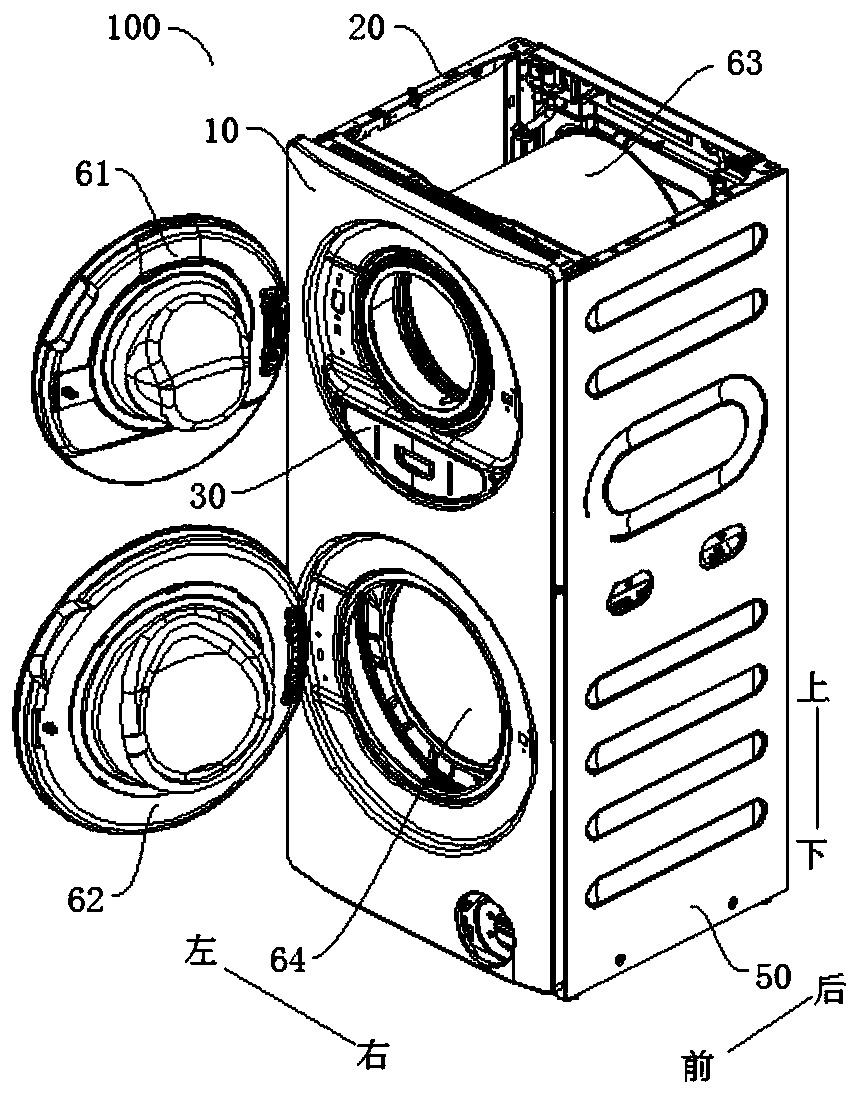

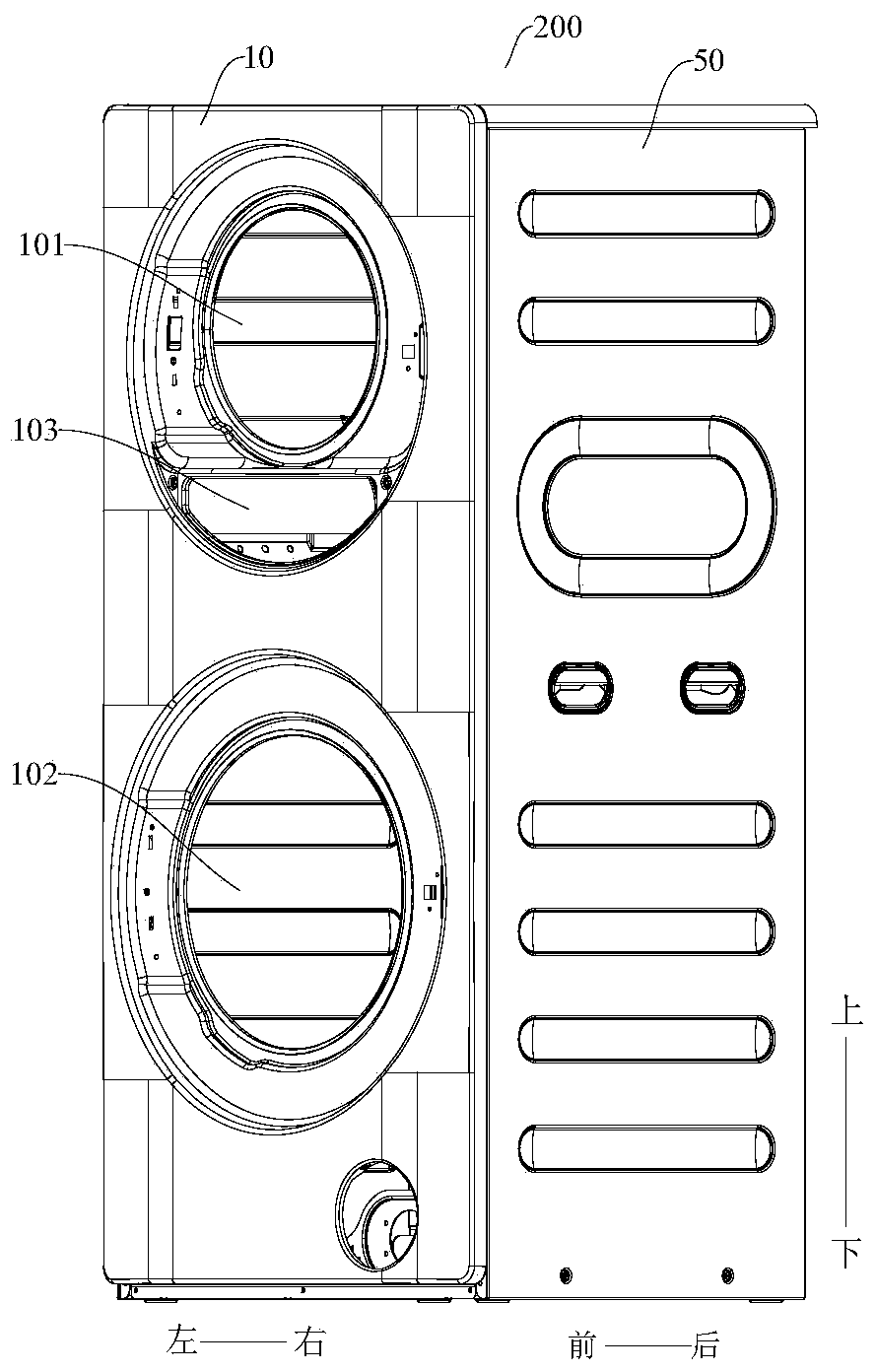

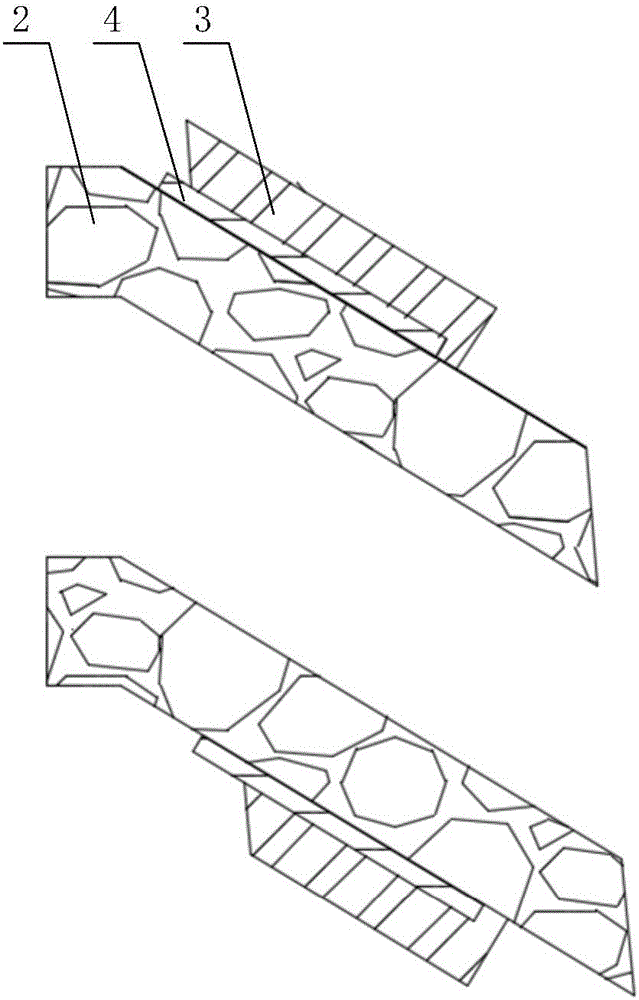

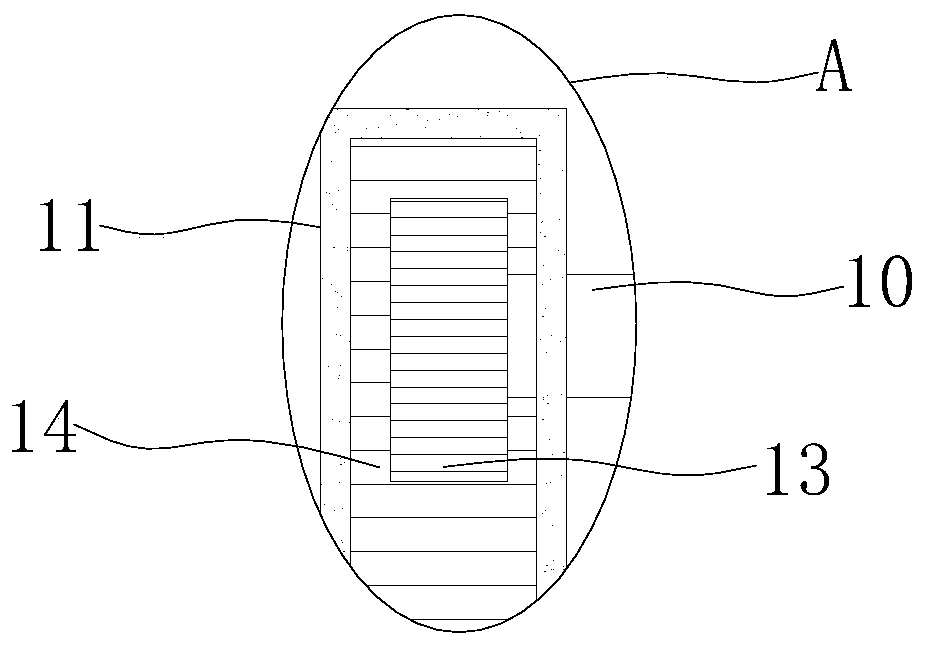

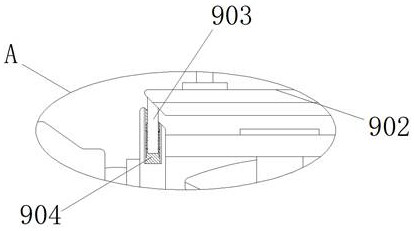

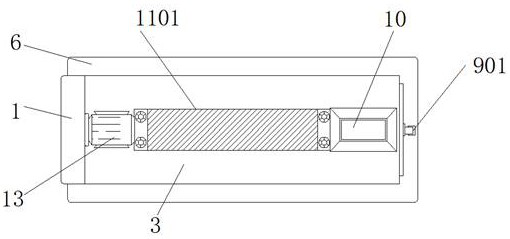

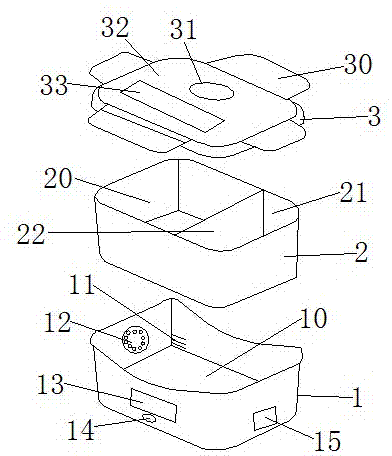

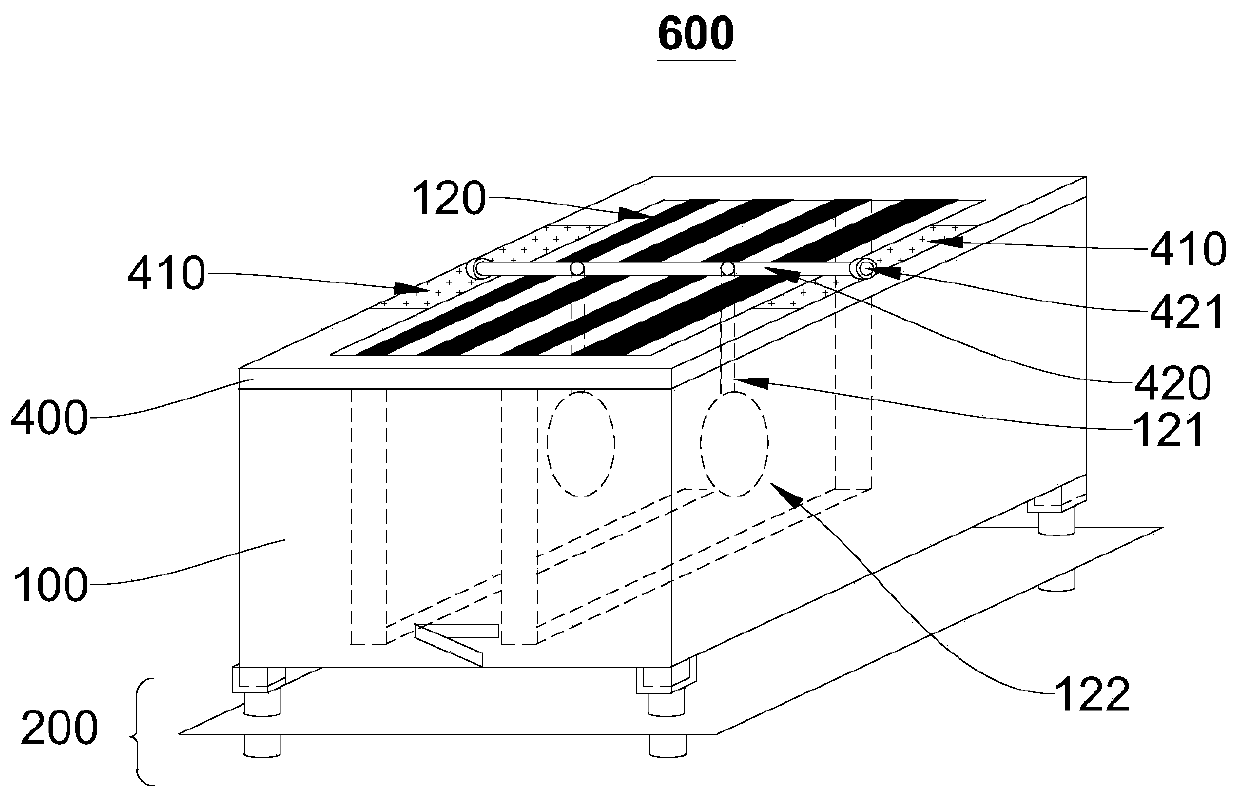

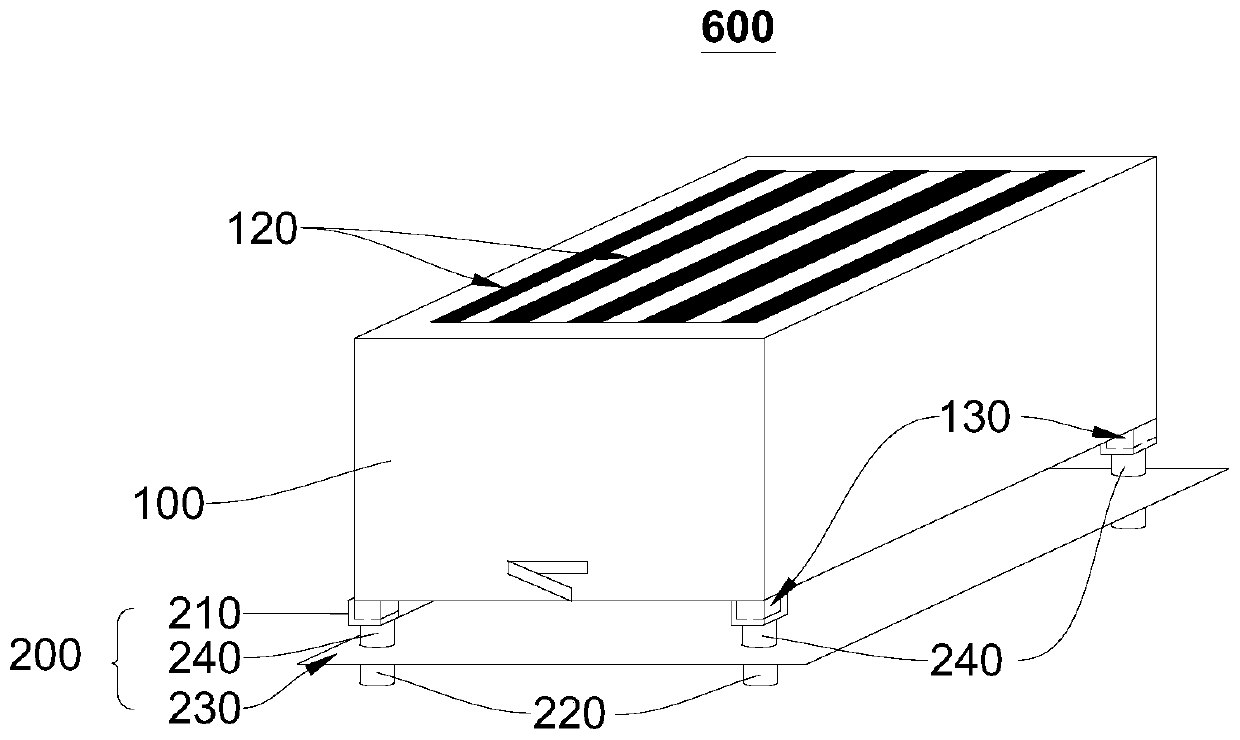

Clothes treatment equipment and putting component thereof as well as putting device

ActiveCN111218798AAvoid liquid residueAvoid freezingOther washing machinesTextiles and paperProcess engineeringMechanical engineering

The invention discloses clothes treatment equipment and a putting component thereof as well as a putting device. The putting component comprises a putting box and a liquid discharging component, wherein the putting box is provided with a main flow passage, a first flow passage and a second flow passage; the main flow passage switchably communicates with one of the first flow passage and the secondflow passage; the first flow passage communicates with a first wash bucket of the clothes treatment equipment; the second flow passage communicates with a second wash bucket of the clothes treatmentequipment; the putting box is further provided with a liquid discharging flow passage; the liquid discharging component is arranged on the putting box and is configured to control the on-off of the liquid discharging flow passage; the liquid discharging component disconnects the liquid discharging flow passage under a condition that the putting component supplies liquid to the first wash bucket orthe second wash bucket; and the liquid discharging component conducts the liquid discharging flow passage under a condition that the putting component stops supplying liquid to the first wash bucketand the second wash bucket. According to the putting component of the clothes treatment equipment, the liquid in the main runner can be discharged through a drainage channel, and risks such as frost crack damage to the putting box are avoided.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

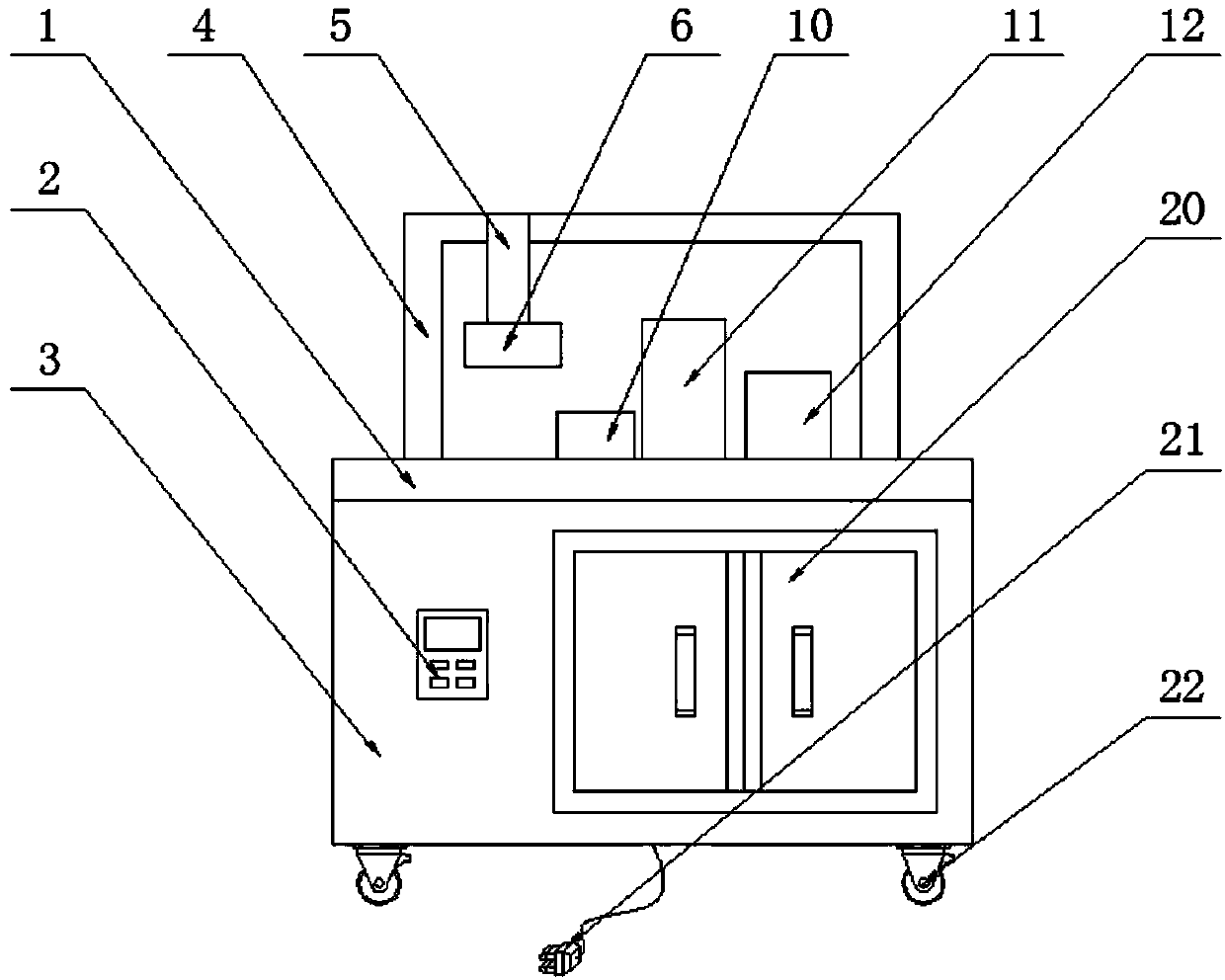

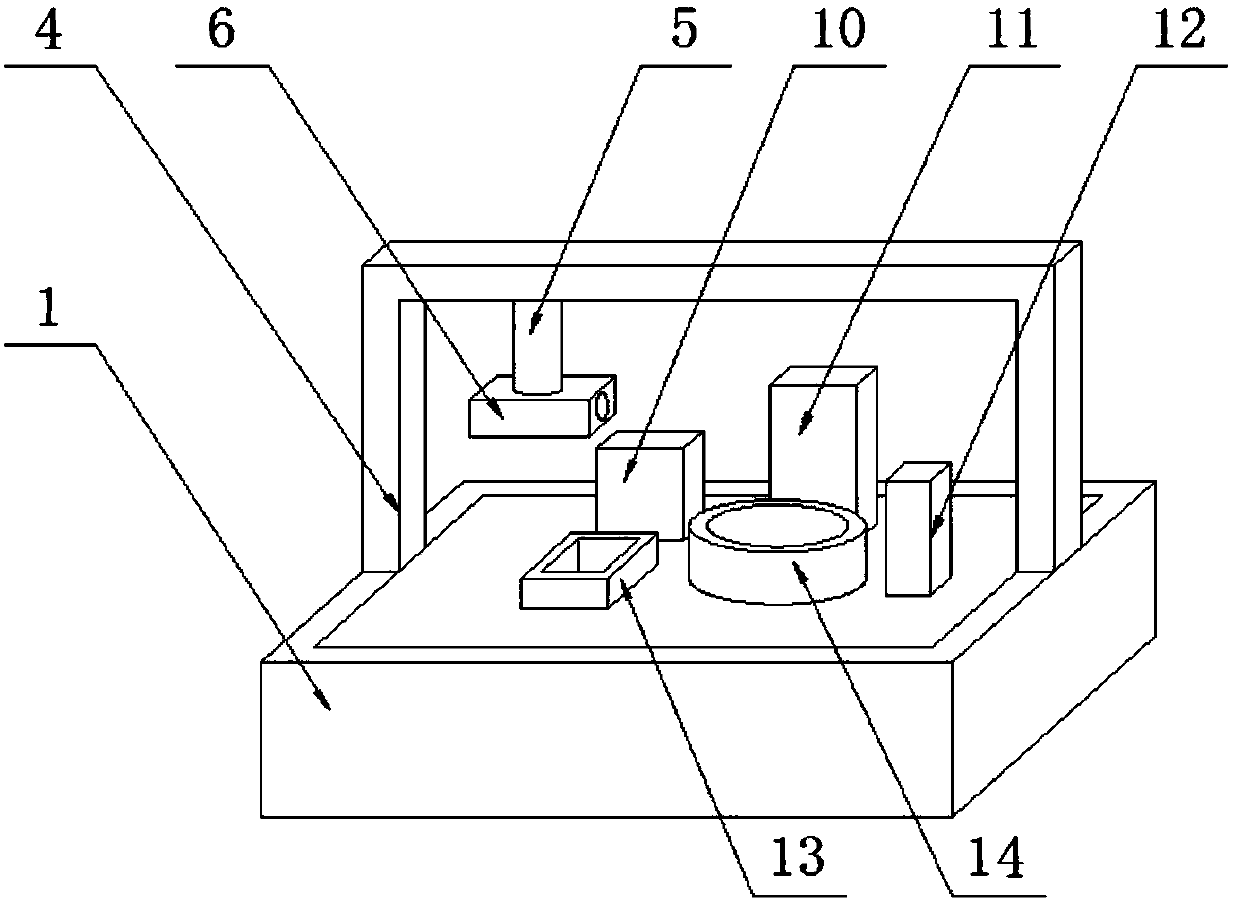

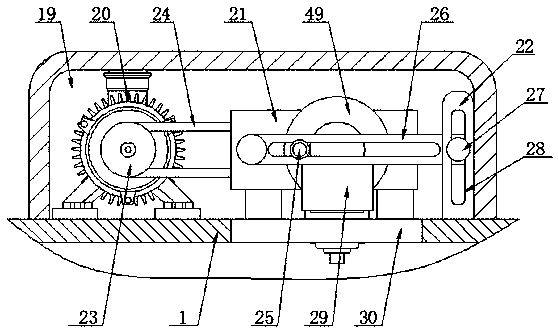

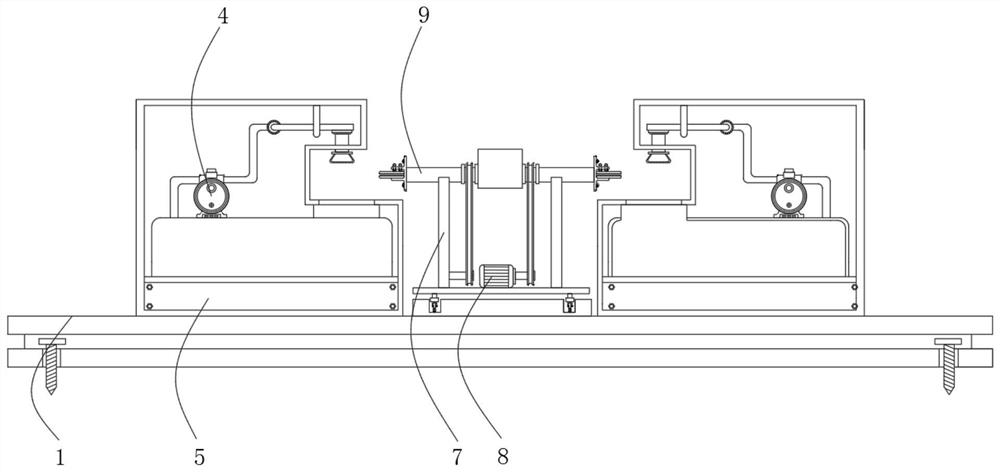

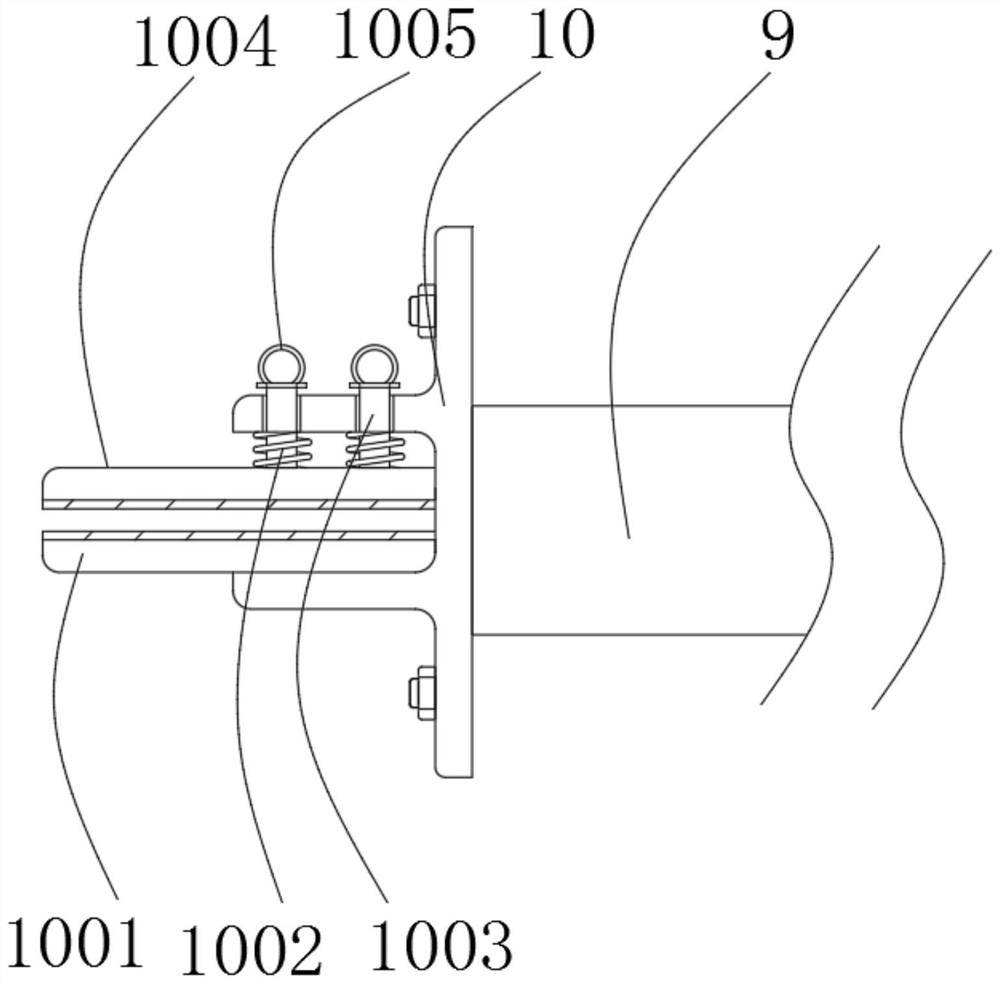

Fully automatic wire cutting tin dipping machine

PendingCN108054621ACutting is effectiveReduce volumeLine/current collector detailsWire cuttingEngineering

The invention discloses a fully automatic wire cutting tin dipping machine, which comprises a work table, a control plate, a machine case, a moving frame, an electric push rod, a clamp plate, a peeling cutter, a fixing plate, a cutting machine, a welding flux dripping mechanism, a tin dipping mechanism, a trimming mechanism, a welding flux groove, a tin water groove, a transmission shaft, a stirring frame, a stirring motor, a heating machine, a heat conduction plate, a box door, an external connection plug and moving wheels, wherein the work table is arranged on the top of the machine case through screw bolts; the moving frame is arranged on the top of the work table through screw bolts; the electric push rod is arranged at one side of the moving frame; the clamp plate is arranged at the bottom of the electric push rod through screw bolts; a wire cutting machine is arranged inside the clamp plate through screw bolts; the peeling cutter is correspondingly arranged at one side of the wire cutting machine and is connected with the fixing plate through screw bolts. The tin dipping machine has the advantages that the size is small; the moving is convenient; the wires can be effectivelycut, peeled and dipped with tin; the work efficiency is greatly improved.

Owner:东莞市恒海自动化设备有限公司

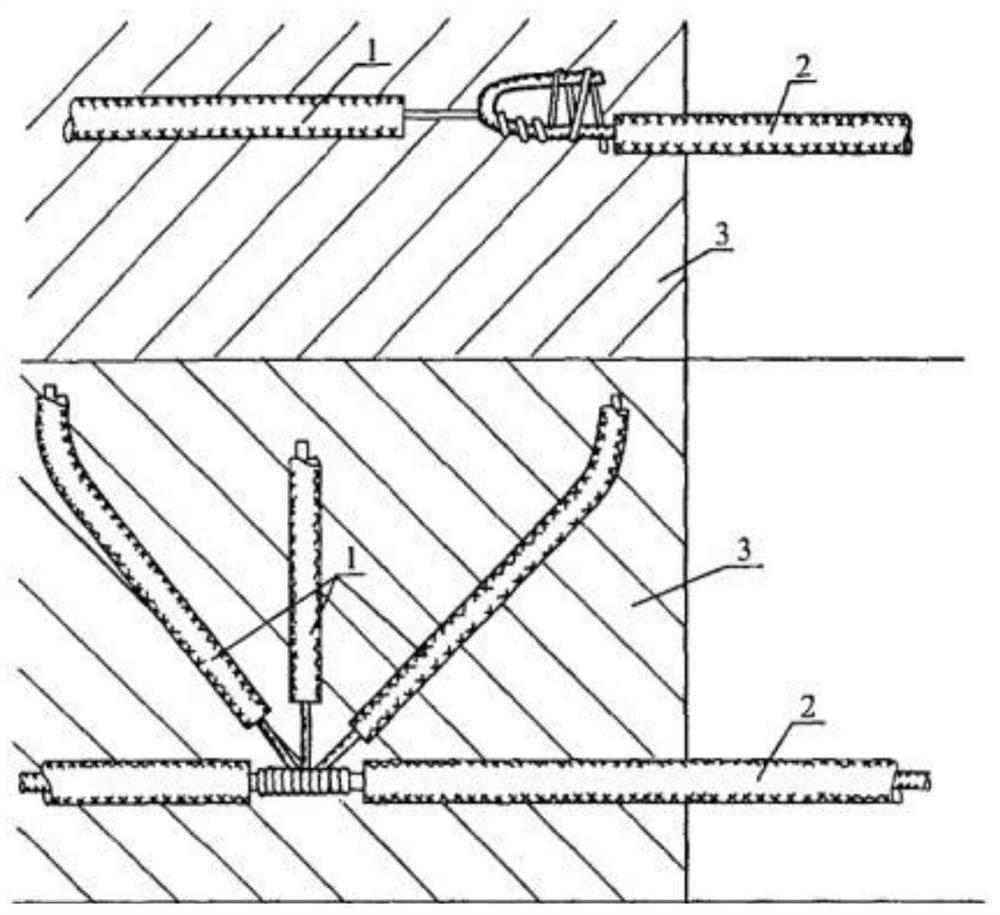

Heating method of concrete post stressed beam channel and heating device

InactiveCN1948668AAvoid freezingPrevent heat dissipationBridge erection/assemblyBuilding material handlingFilling materialsHeating efficiency

Owner:北京建工华创工程技术有限公司

Fluorescence in-situ hybridization method for endosymbiotic bacteria in insect ovary

InactiveCN108179202AAvoid freezingAvoid the tedious process of slicingMicrobiological testing/measurementStainingFluorescence

The invention relates to a fluorescence in-situ hybridization method for endosymbiotic bacteria in an insect ovary. The method comprises following steps: the insect ovary is dissected under a microscope, the dissected insect ovary is transferred to a glass slide, an insect tissue stationary liquid is added for fixation, and a destaining solution is added for destaining; pre-hybridization and hybridization staining are performed on a specimen, and an eluant is added for elution after hybridization is completed; finally, a sample is sealed with glycerin, and observation and photographing are performed under a confocal microscope. By means of the method, a good cell staining effect can be kept, the operation can be simplified, time can be shortened, reagents can be saved and the cost can be reduced. Several endosymbiotic bacteria in the ovary can be subjected to multiple staining simultaneously, a good staining effect is obtained, and the method is simple, convenient, rapid and economical.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

Molten slag discharging devices and plasma furnace

ActiveCN106287744APrevent solidificationAvoid scarring, fromIncinerator apparatusMolten saltMolten slag

The invention provides molten slag discharging devices and a plasma furnace. Each molten slag discharging device comprises a slag discharging pipe for discharging melt; an outer layer of the slag discharging pipe is provided with a heat preservation lining sleeve; and a heating element is arranged between the slag discharging pipe and the heat preservation lining sleeve. The plasma furnace comprises a furnace body and the molten slag discharging devices. The number of the molten slag discharging devices is at least two. One of the molten slag discharging devices is obliquely arranged on the side wall of the furnace body, and the bottom of an outlet of the slag discharging pipe of the molten slag discharging device is higher than the top of an inlet of the slag discharging pipe. The other molten slag discharging device is perpendicular to the bottom of the furnace body, and a switch is arranged in the slag discharging pipe of the molten slag discharging device.

Owner:浙江民生源环保设备有限公司

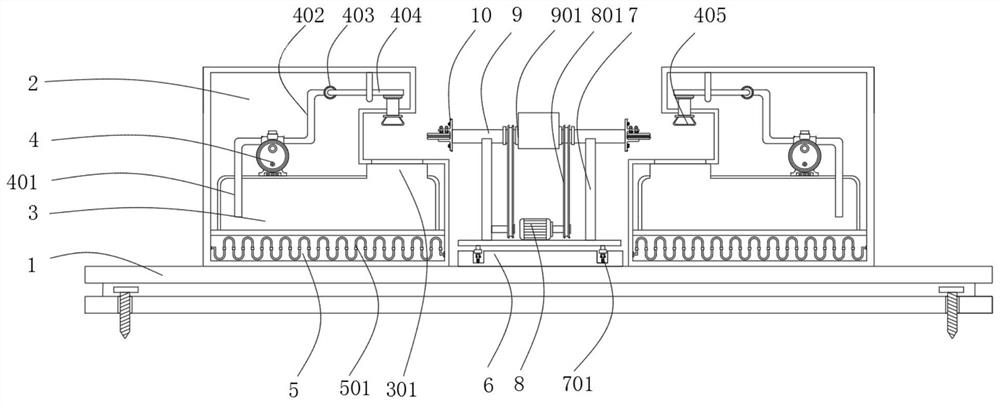

Leather waxing treatment device for garment production

InactiveCN110982962AReduce work intensityImprove work efficiencyLeather surface finishingWax treatmentElectric machinery

The invention discloses a leather waxing treatment device for garment production, and relates to the technical field of leather garment waxing. The leather waxing treatment device for garment production comprises a bottom plate. A first side rack, a vertical plate and a second side rack are welded to the outer surface of the top of the bottom plate. A top plate is welded to the top of the first side rack and the top of the second side rack. A heat preservation box is welded to the outer surface of the top of the top plate. A hose is fixedly installed on the outer surface of the bottom of the top plate. A nozzle is fixedly installed at the free end of the hose. A hole is formed in the first side rack. A limiting plate is welded to the outer surface of the bottom of the top plate. A motor iswelded to the outer surface of the rear side of the limiting plate, and an output shaft of the motor penetrates through the limiting plate. According to the invention, a traditional manual waxing mode is replaced, the working efficiency of workers is improved, a natural air drying cooling mode is replaced, and the rapid cooling performance of leather garments after waxing is improved.

Owner:湖州钧皓服饰有限公司

Building outer wall aging repairing device and repairing method

The invention belongs to the technical field of building outer wall repairing, and particularly relates to a building outer wall aging repairing device and repairing method. The building outer wall aging repairing device comprises a machine box, a display mechanism and a hoisting mechanism, wherein the display mechanism and the hoisting mechanism are arranged on the two sides of the top end of themachine box correspondingly; the display mechanism comprises a supporting rod, a rotating shaft and a display screen; the supporting rod is located at the top end of the machine box and is in screw joint and fixed to the machine box; the display screen is located at the top end of the supporting rod; a bearing mechanism is additionally arranged at the bottom end of a spraying device; the bearingmechanism drives a bearing box to move left and right through a moving air cylinder to be attached to the wall face and used for bearing broken wall skin scraped off during wall face spraying repairing and spraying scattered spraying materials, the situation of object falling from high altitudes is avoided, and the stability and safety of high-rise building outer wall face repairing are enhanced;and a servo motor used for driving a stirring shaft to rotate is arranged, materials in a coating containing cavity can be stirred and mixed, the situation that coating is solidified due to long-timestanding is avoided, and the uniformity of the spraying materials is enhanced.

Owner:嘉兴博睿创业服务有限公司

Rope head glue dipping device for rope for clothing

InactiveCN110965238AAvoid destructionAvoid inhalationTextile treatment containersTextile treatment machine arrangementsAdhesive glueElectric machinery

The invention discloses a rope head glue dipping device for a rope for clothing, and relates to the technical field of clothing. The rope head glue dipping device for the rope for clothing comprises aglue dipping box; four groups of supporting legs are mounted at the bottom of the glue dipping box by welding; first supporting plates are mounted on the adjacent side walls of the supporting legs bywelding; a protective cover is arranged above the glue dipping box; a mounting plate is mounted on the rear side of the protective cover by welding; a first motor is mounted at the bottom of the mounting plate by welding; a rotating rod is rotationally mounted on the outer wall of one side of the mounting plate; an output shaft of the first motor is fixedly connected with the rotating rod througha coupling; a connecting rod is rotationally mounted on the adjacent side walls of the protective cover; a supporting seat is mounted on the outer wall of one side of the glue dipping box by welding;and a first shell is mounted at the top of the supporting seat by welding. The rope head glue dipping device is ingenious in design, glue precipitation is effectively prevented, the glue dipping uniformity is improved to a certain extent, and the quality of rope head glue dipping is improved.

Owner:湖州邦族服饰有限公司

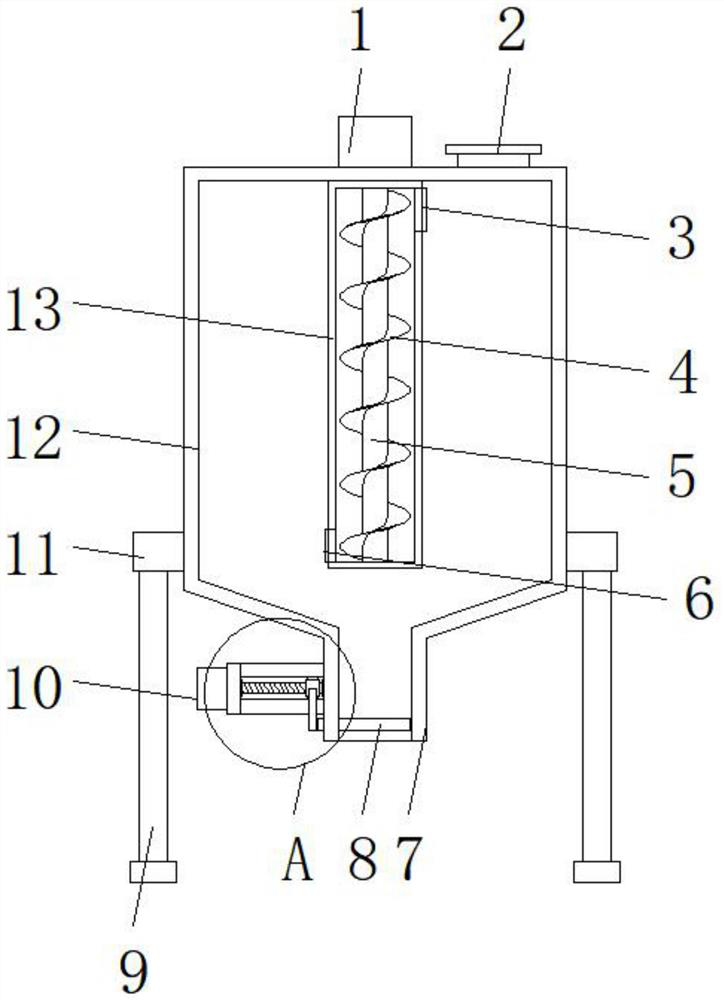

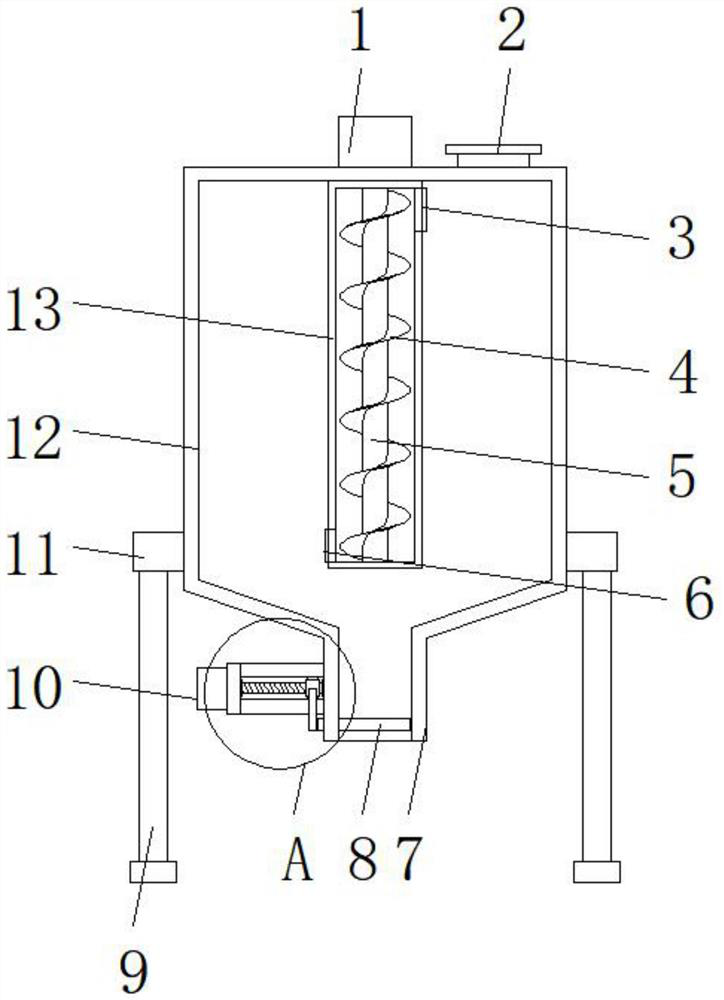

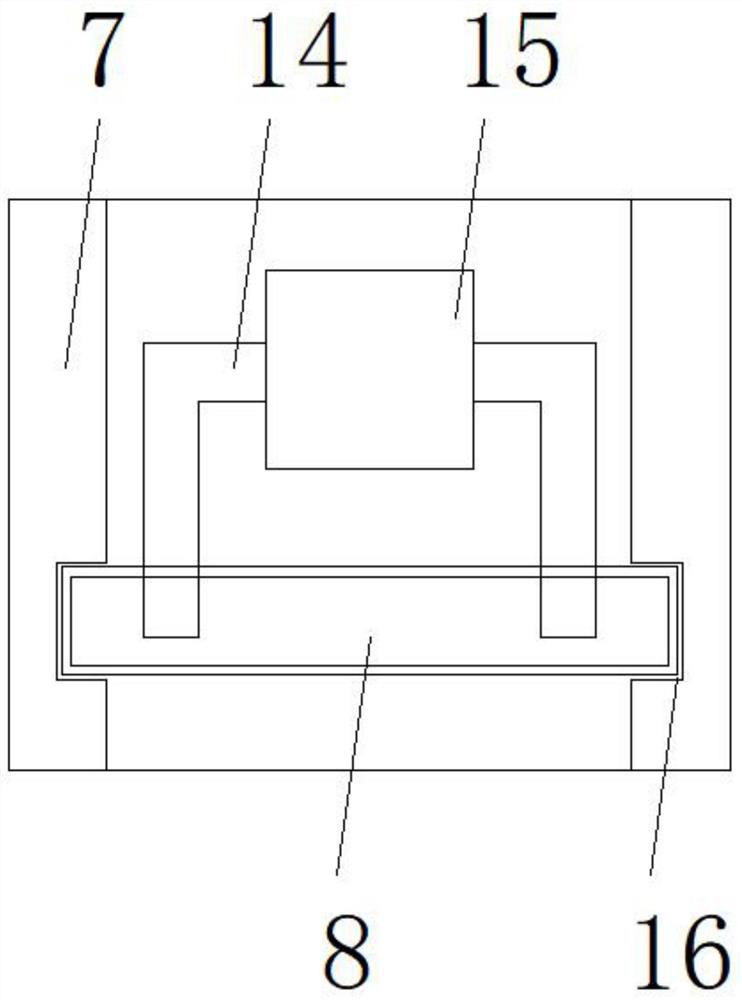

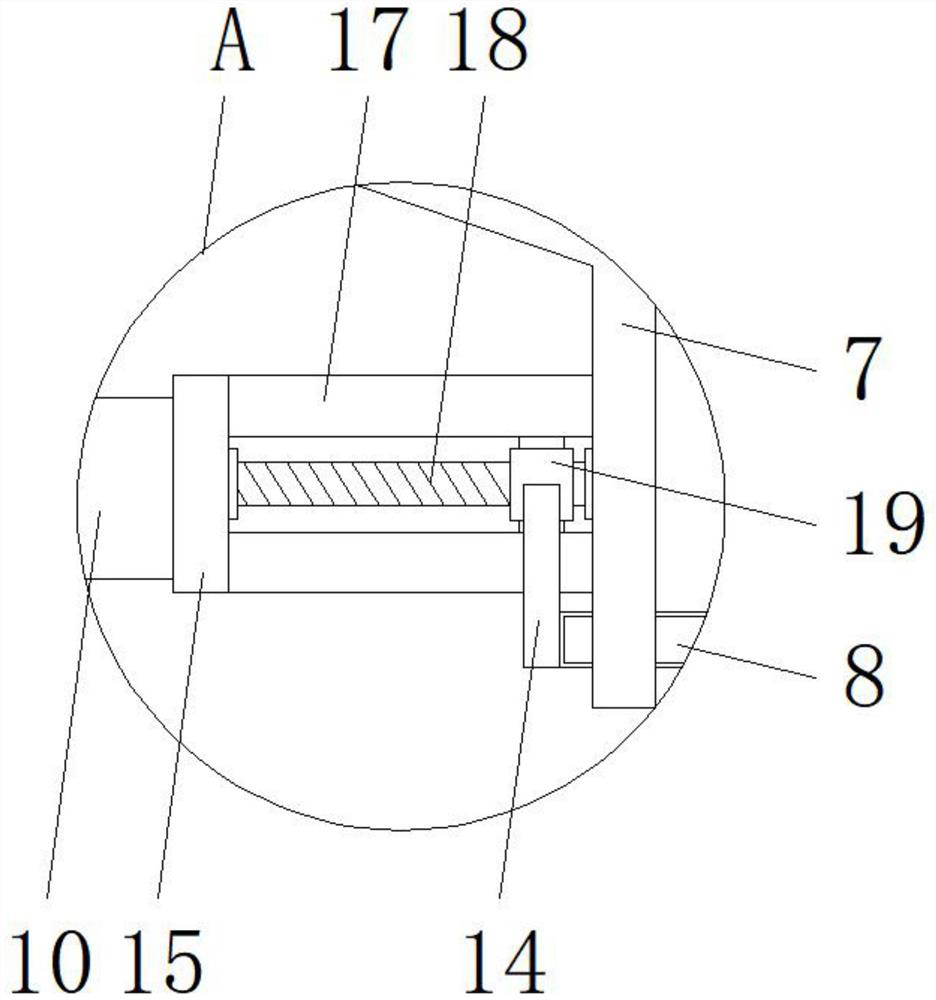

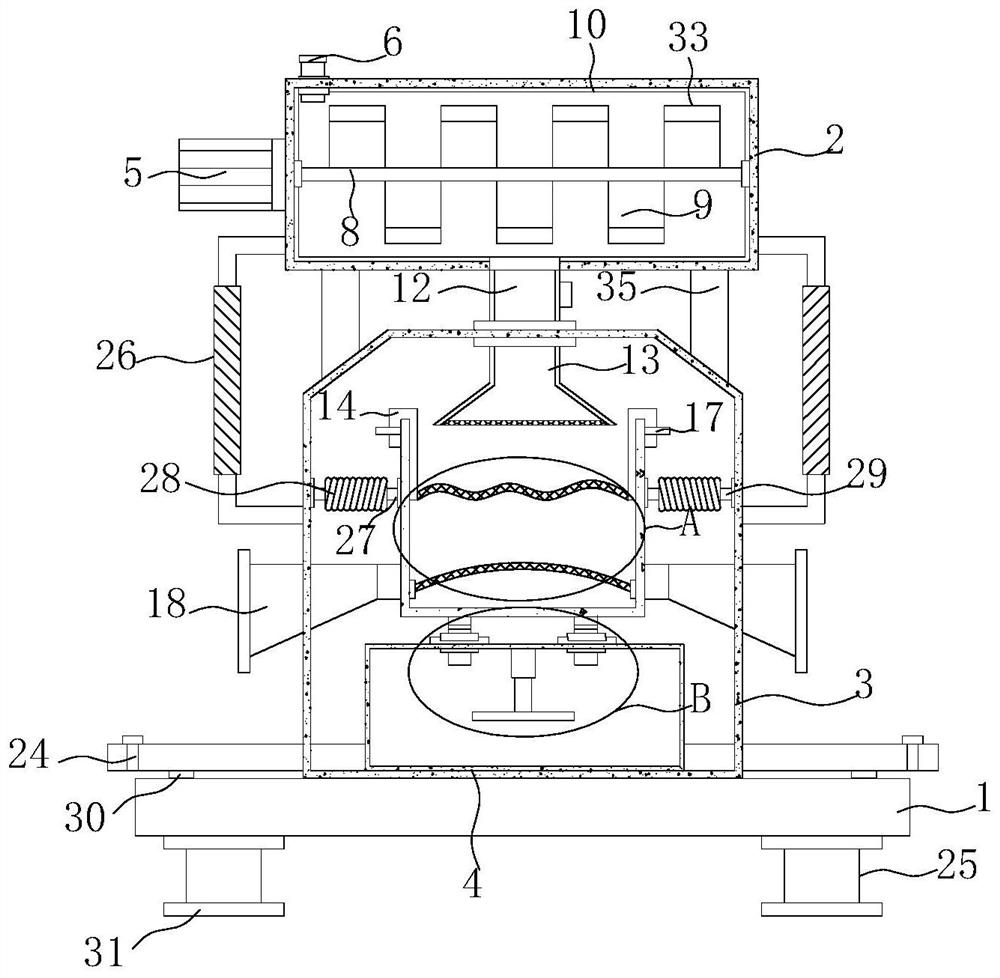

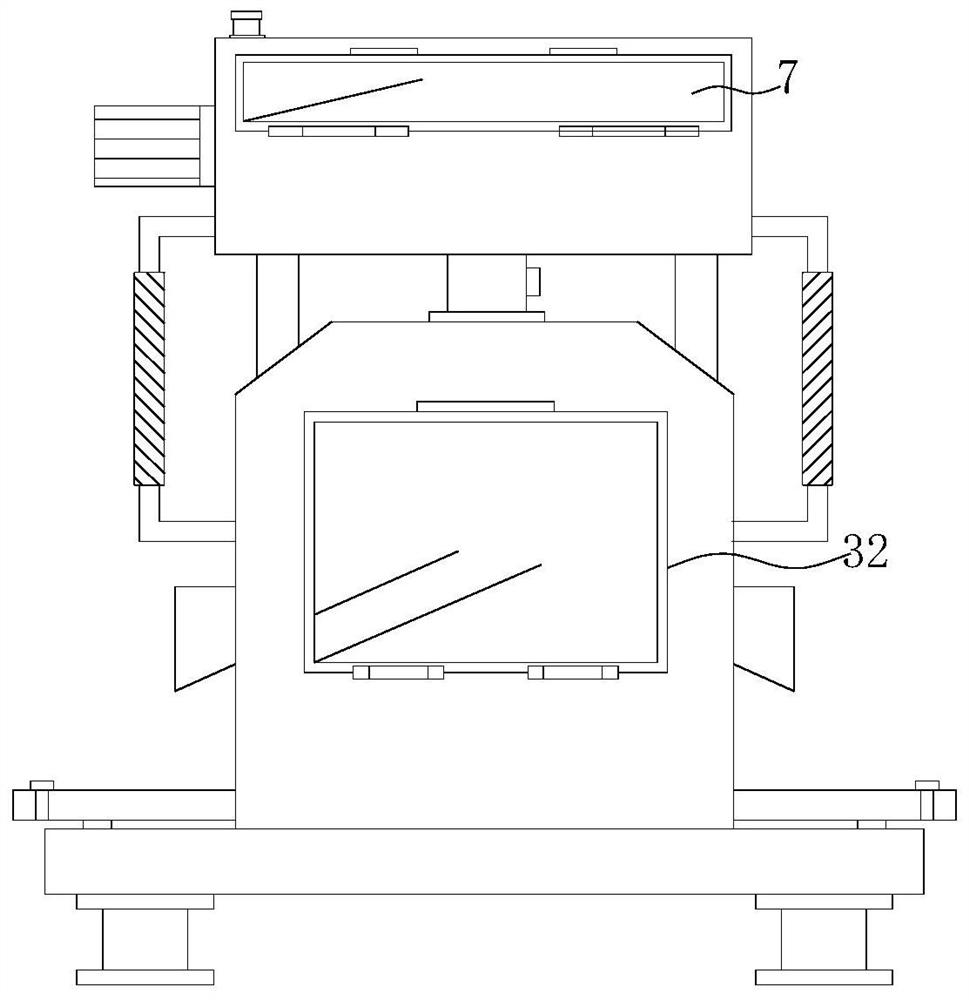

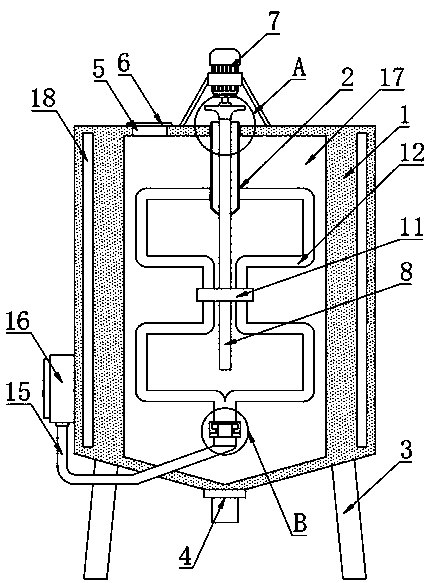

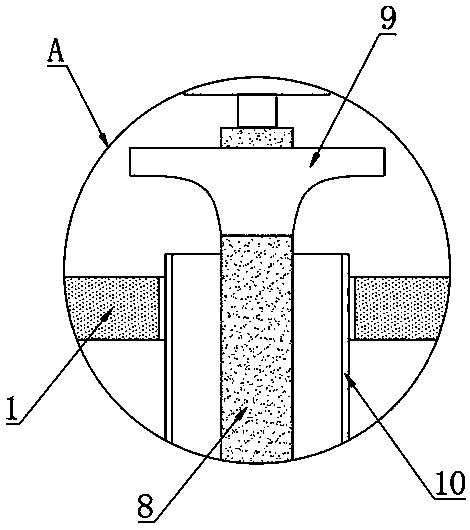

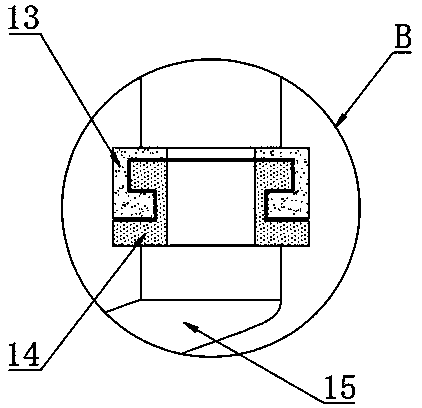

Cement bin with discharging control function

ActiveCN113044417AAvoid freezingEasy to useLarge containersTank wagonsStructural engineeringCement Material

The invention discloses a cement bin with a discharging control function. The cement bin comprises a discharging pipe, a cement bin body and a stirring box, wherein a fixing block is welded to the side end face of the cement bin body, supporting legs are installed at the lower end of the fixing block, the discharging pipe is arranged at the lower end of the cement bin body, a mounting groove extending to the inner wall of the discharging pipe is formed in the side end of the discharging pipe, limiting plates which are symmetrically distributed are welded to the side end face of the discharging pipe, mounting plates are welded to the tail ends of the limiting plates, threaded rods are rotatably mounted between the mounting plates and the discharging pipe, movable blocks are mounted on the threaded rods in a threaded mode, connecting rods are welded to the side ends of the movable blocks, a discharging baffle is welded to the tail ends of the connecting rods, the outer side of the discharging baffle is wrapped with a rubber layer, the stirring box is welded to the inner wall of the upper end of the cement bin body, a rotating shaft is rotationally installed in the stirring box, and spiral blades are arranged on the rotating shaft. The cement bin has the advantages that cement solidification is prevented, and the discharging control function is achieved.

Owner:济南鹏发建筑机械有限公司

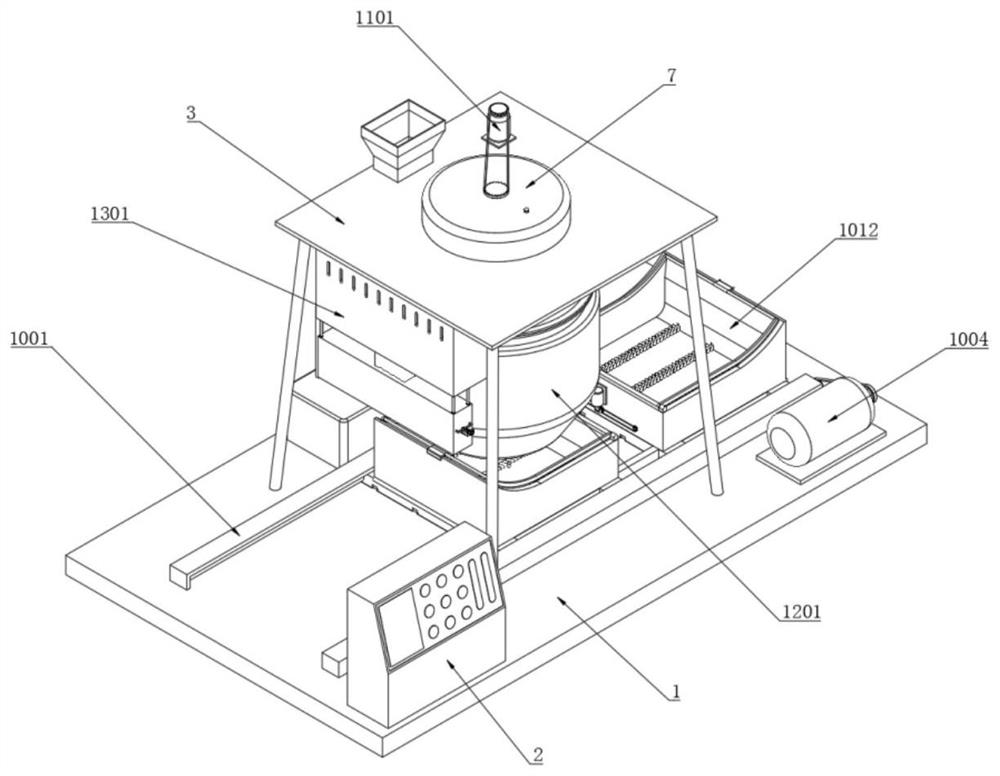

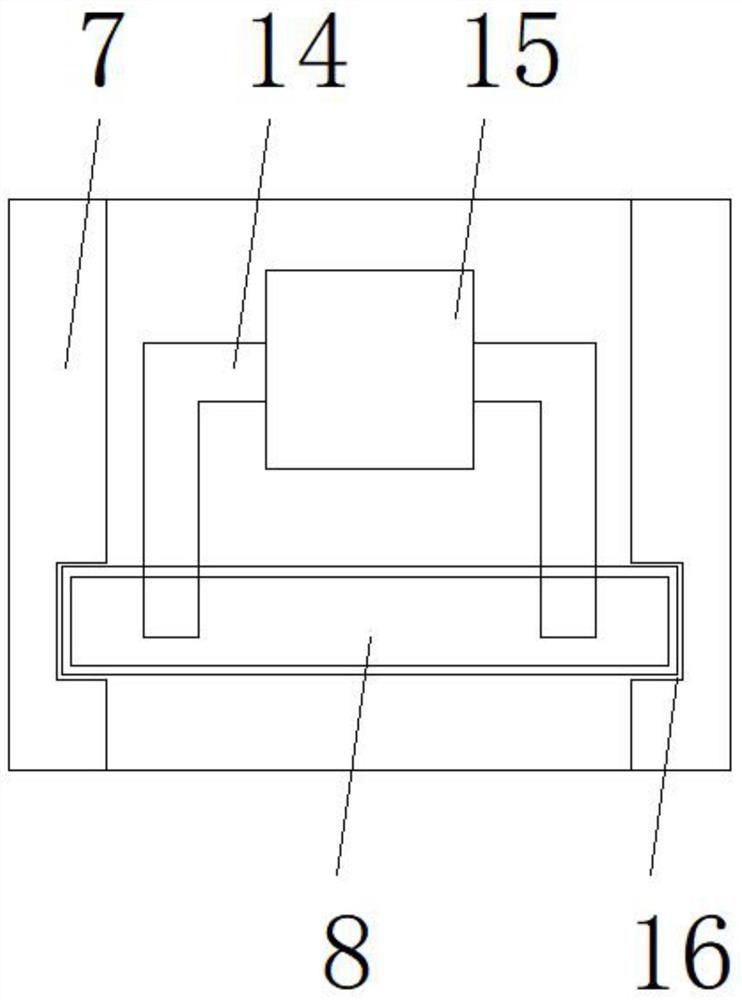

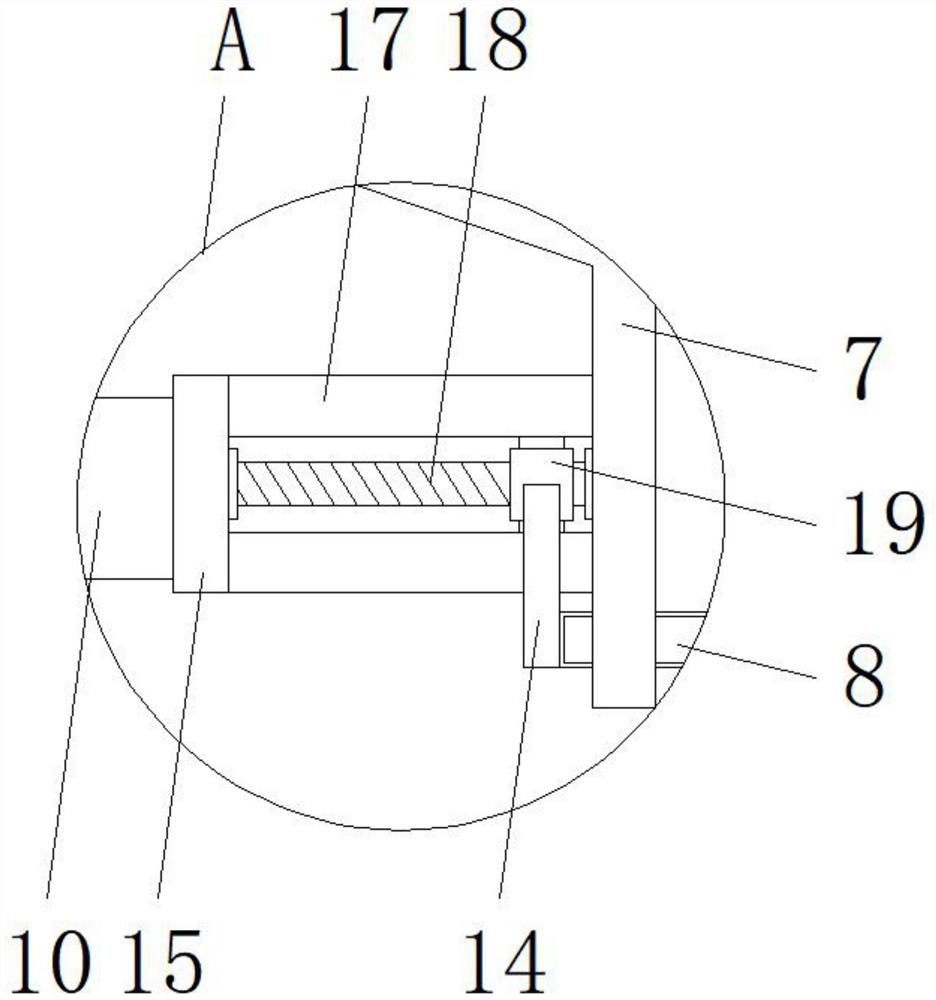

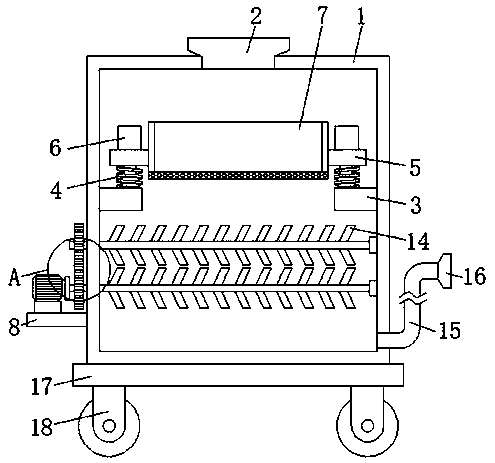

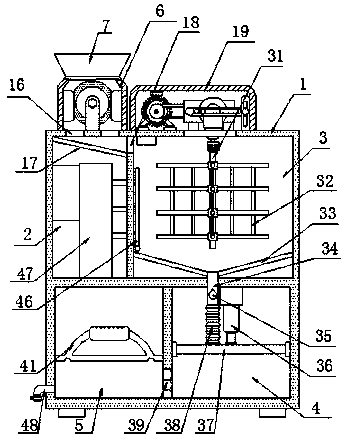

Mortar spraying machine with vibration screening function

InactiveCN108716276ASave screening processGuaranteed efficiencySievingScreeningAgricultural engineering

The invention relates to the technical field of mortar spraying machines and discloses a mortar spraying machine with a vibration screening function. The mortar spraying machine comprises an equipmentbody, wherein a feeding pipe is communicated to the top of the equipment body, fixing plates are fixedly connected to two sides of the inner wall of the equipment body, springs are fixedly connectedto the tops of the fixing plates, fixing blocks are fixedly connected to the tops of the springs, vibrators are fixedly connected to the tops of the fixing blocks, and a screening tank is fixedly connected between opposite sides of the two fixing blocks; and a support plate is fixedly connected to the left side surface of the equipment main body, a motor is fixedly connected to the top of the support plate through a cushion plate, and a first rotating shaft is fixedly connected to an output shaft of the motor. According to the mortar spraying machine, the problems that an existing mortar spraying machine is not capable of screening impurities, requires additional screening operations and is very inconvenient are solved, the screening-vibration integration is realized, the working efficiency is improved, and the troubles and the labor are saved.

Owner:WUXI KONSTANT POWER TECH CO LTD

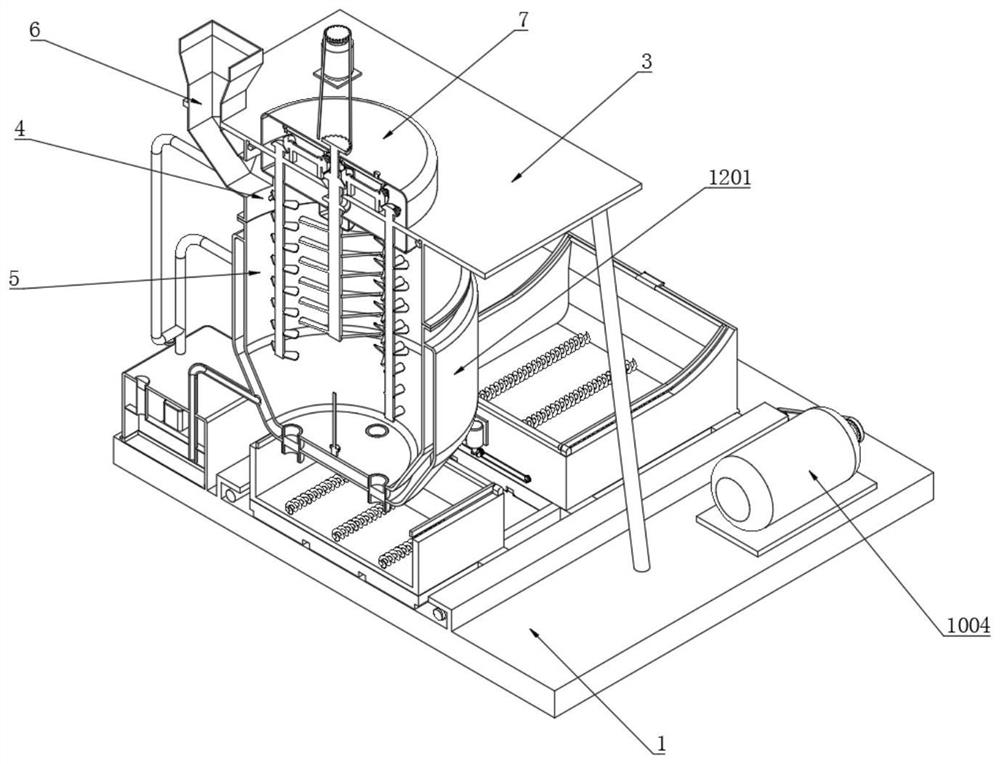

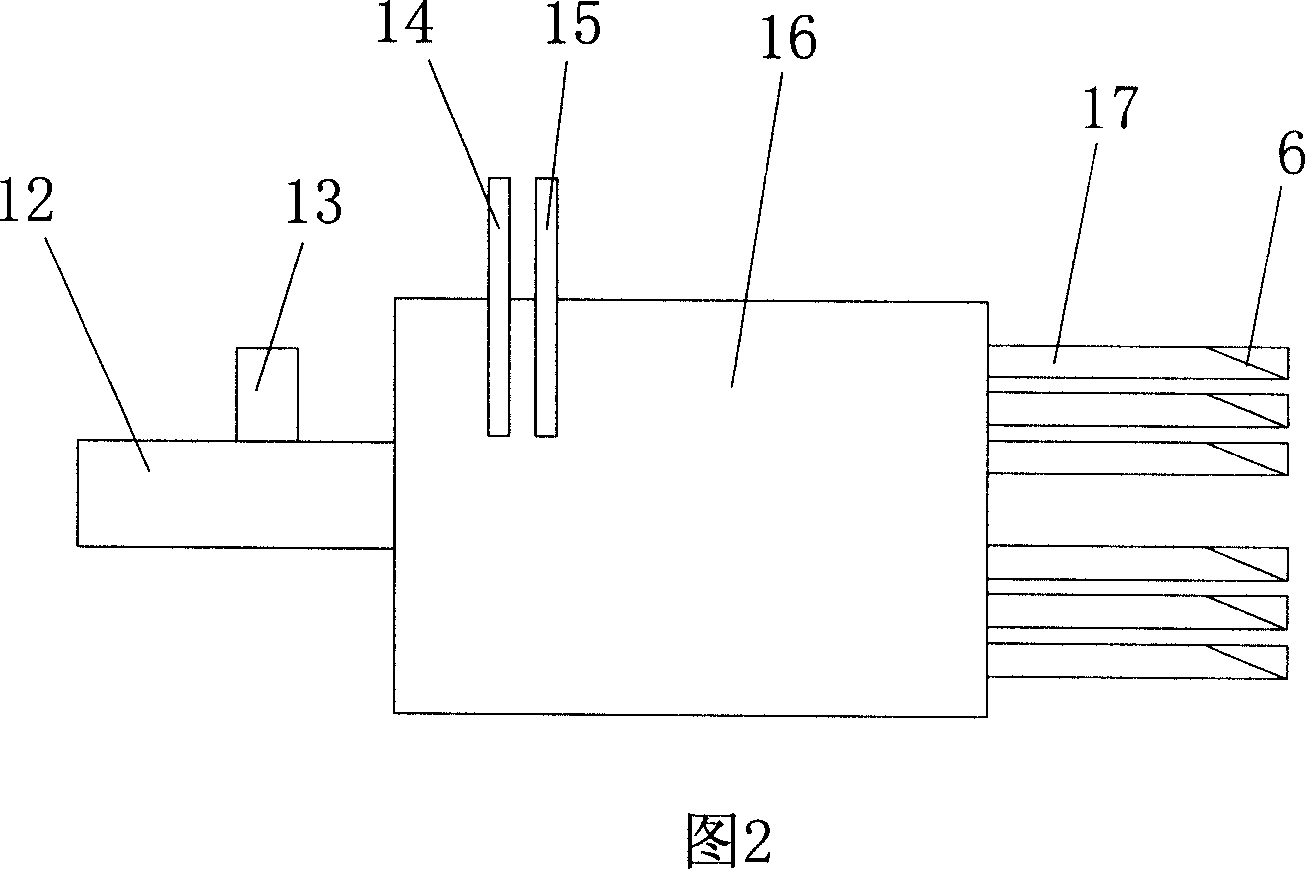

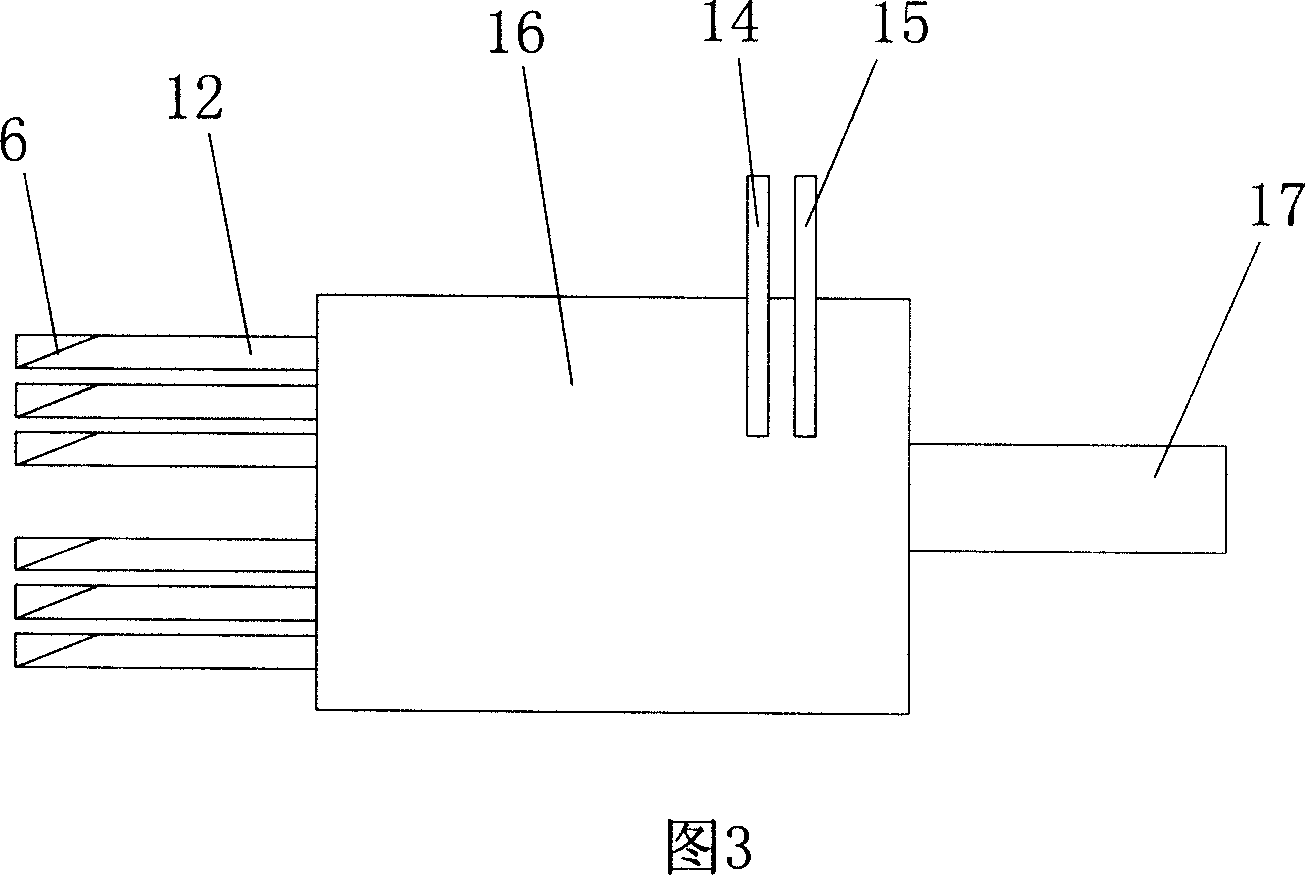

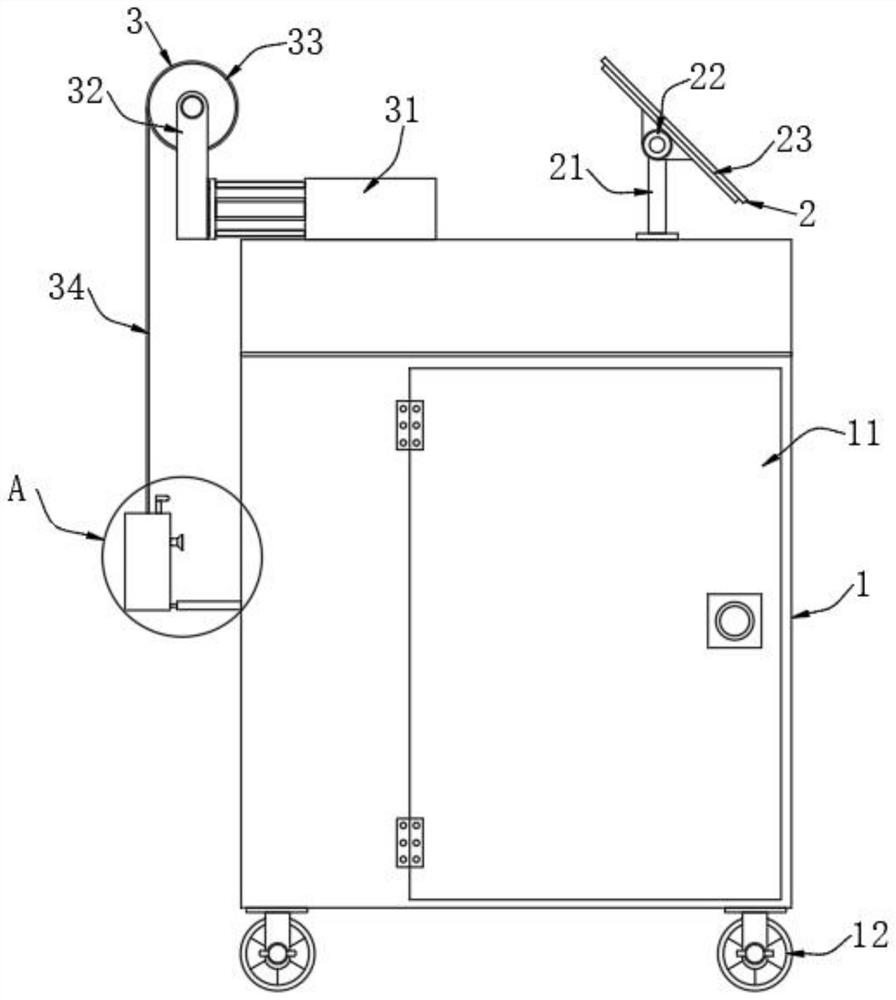

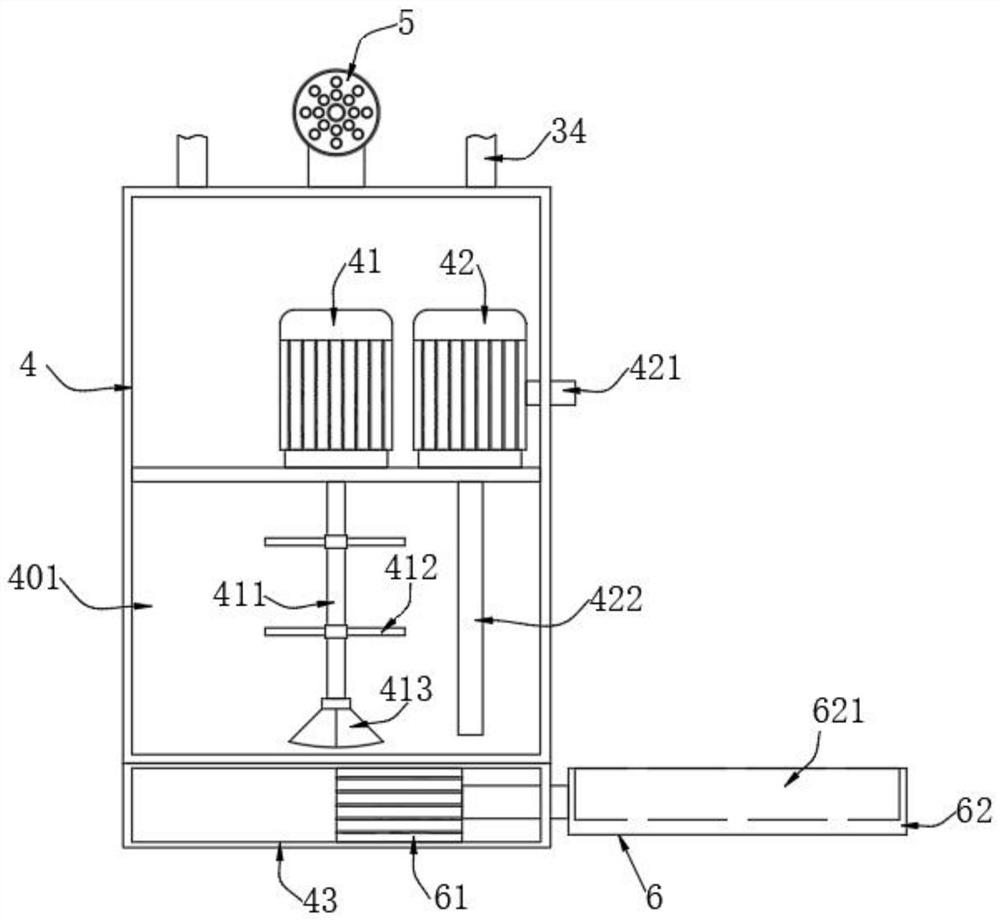

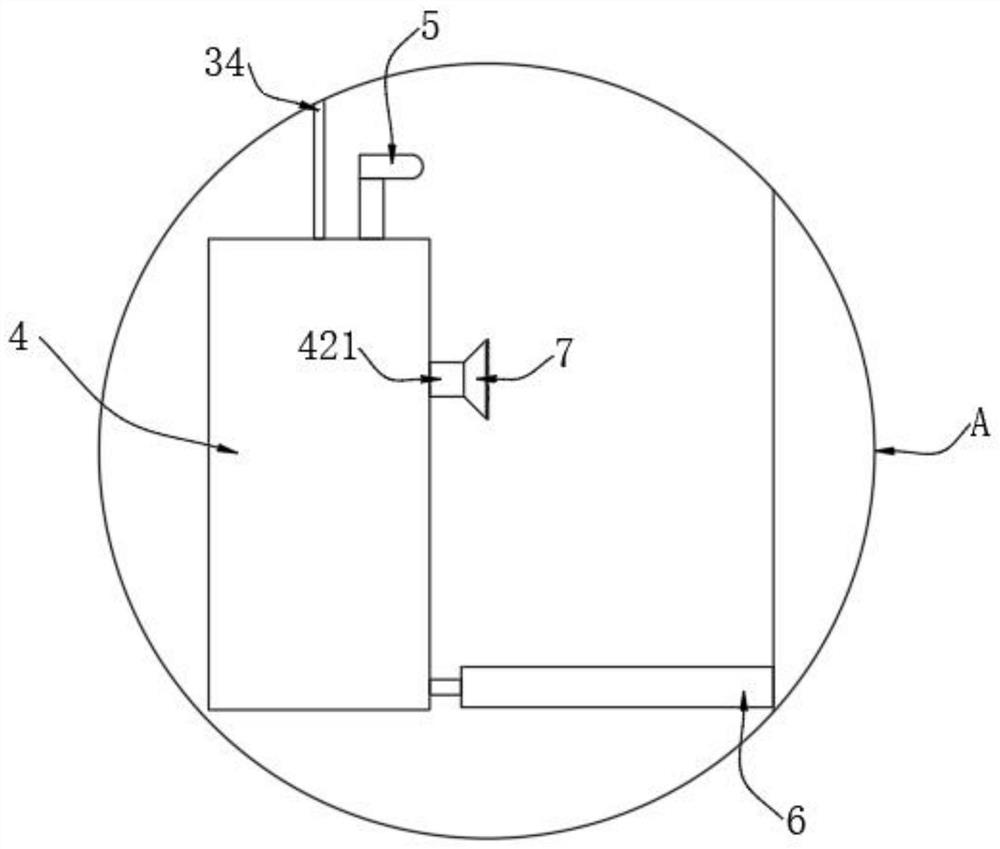

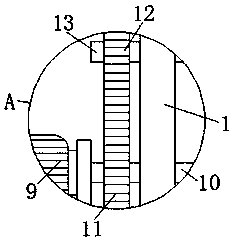

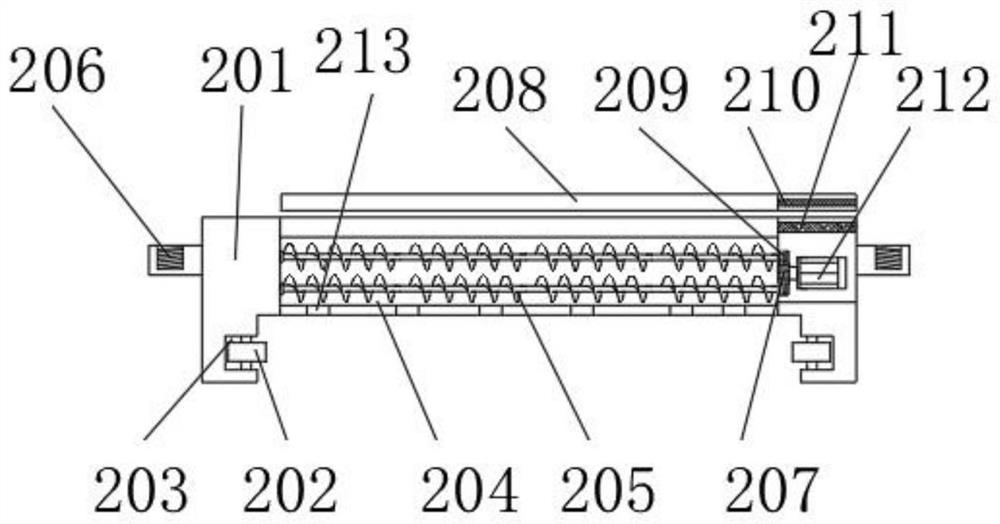

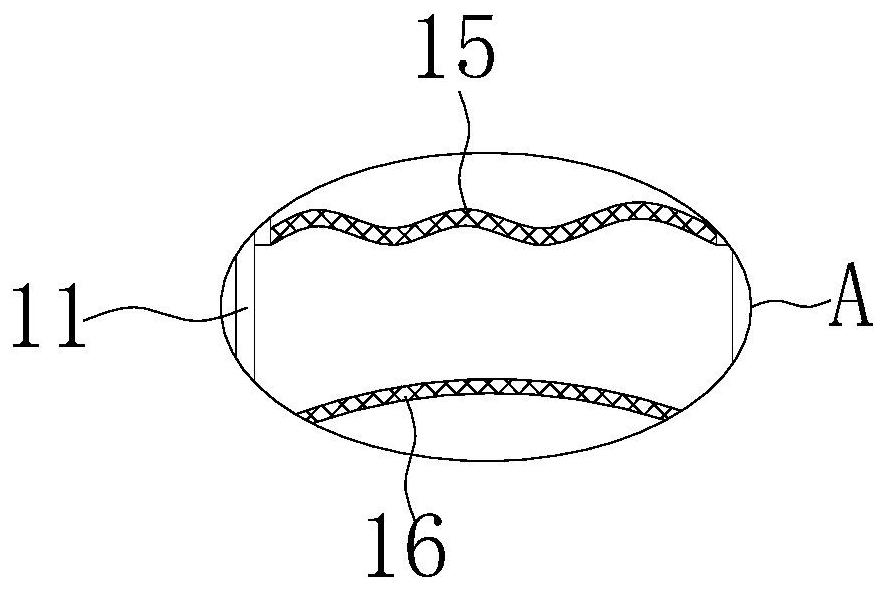

Aluminum liquid filtering and purifying device for efficient aluminum ingot production

ActiveCN110923464AQuality improvementEasy to installProcess efficiency improvementMetallurgyElectric machine

The invention discloses an aluminum liquid filtering and purifying device for efficient aluminum ingot production, and relates to the technical field of aluminum ingot production. The aluminum liquidfiltering and purifying device for efficient aluminum ingot production comprises a supporting platform and a stirring box, wherein the top outer surface of the supporting platform is fixedly providedwith a protection box and a fixing block; the outer surface of the top of the protection box is fixedly provided with a supporting rod, wherein one end of the supporting rod is fixedly connected withthe outer wall of the bottom of the stirring box; and a heating layer is laid inside the stirring box, a driving motor is fixedly installed on the outer surface of one side of the stirring box, and astirring main shaft is rotationally installed inside the stirring box. According to the aluminum liquid filtering and purifying device for efficient aluminum ingot production, double filters are adopted so that impurities in aluminum liquid can be filtered out, and the quality of the aluminum liquid is improved; and meanwhile, an irregular wave filter screen further has the advantage of being convenient to assembly and disassemble, so that the irregular wave filter screen is convenient to clean, the service life of the irregular wave filter screen is prolonged, and the working efficiency is indirectly improved.

Owner:沈阳市东盛金属制品有限公司

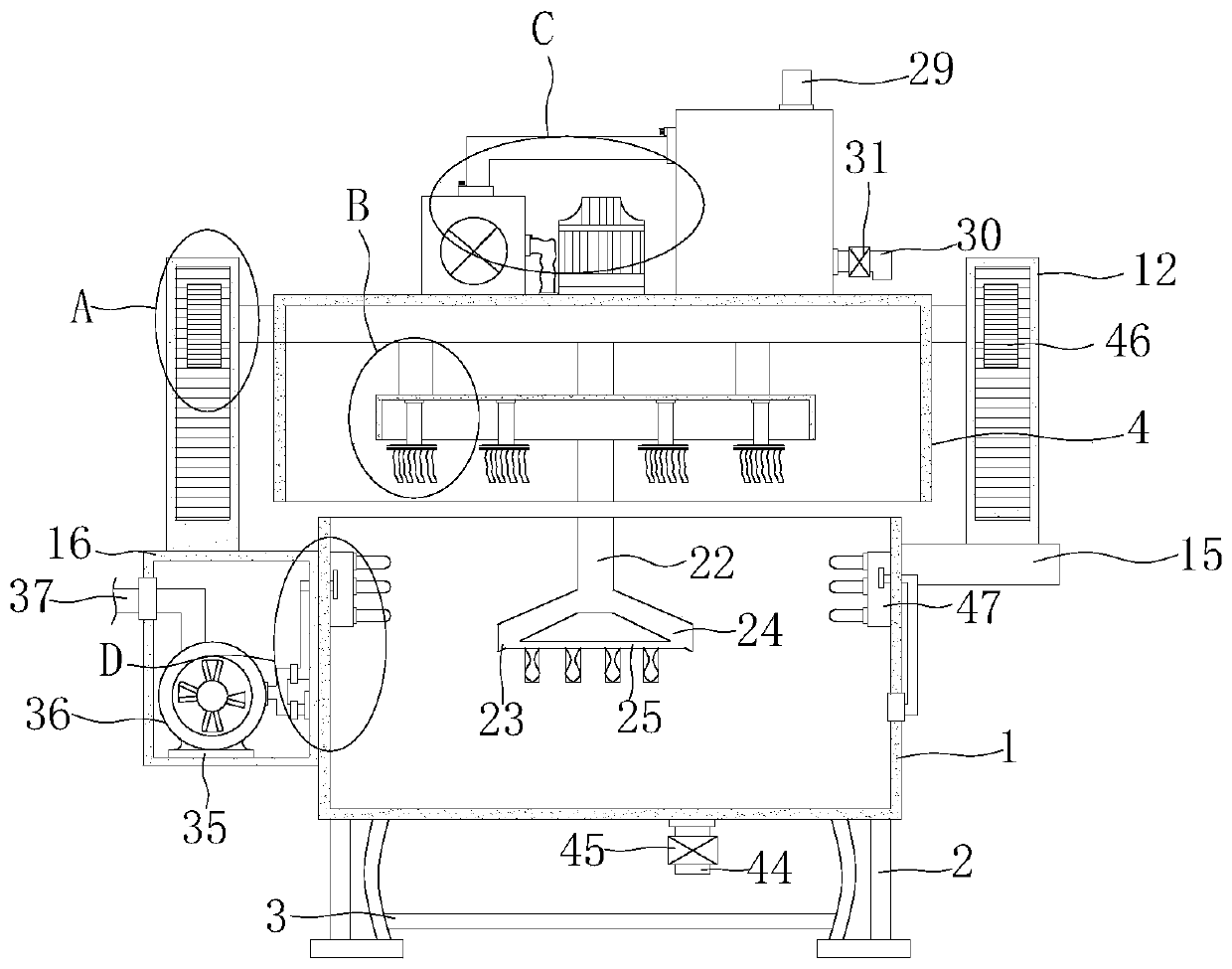

Asphalt material conveying system

PendingCN112320233AReasonable structurePrevent solidificationCleaningPackagingBituminous materialsMechanical engineering

The invention discloses an asphalt material conveying system. The asphalt material conveying system comprises a material conveying box, a discharging opening, a machine body and a servo motor, whereina machine opening is formed in one side of the top end of the machine body, a support is fixed to the top end of the machine body, the material conveying box is fixed to the top end of the support, and a belt box is fixed to one side of the material conveying box. According to the asphalt material conveying system, asphalt materials are fed through a feeding port in the upper portion of the material conveying box and enter the material conveying box, then the servo motor on one side of the top of the material conveying box is started, the servo motor drives a conveying roller in the materialconveying box to rotate through a conveying belt on one side, and then the spiral conveying process is conducted on asphalt; and in order to avoid solidification in the conveying process, a heating box is installed in the middle of the upper side of the material conveying box, heating wires in the heating box are used for heating, heat enters the material conveying box through holes in the bottomof the heating box for heating, the internal heat is increased, and then asphalt solidification is avoided; and the heating wires are clamped into clamping grooves in the two sides through clamping blocks on the two sides to be fixed, so that convenience is improved.

Owner:REED XINXIANG ROAD INC

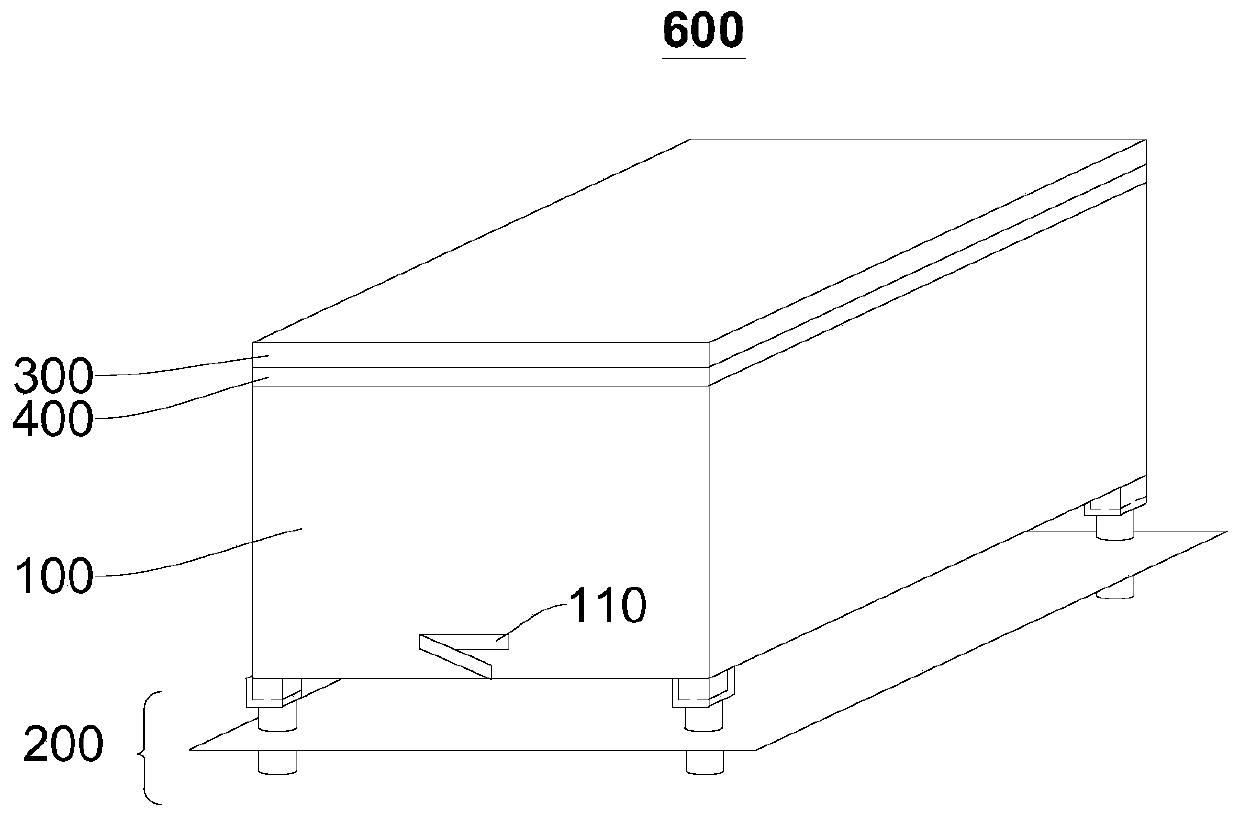

Heatable lunch box with sound alarming function

The invention discloses a heatable lunch box with a sound alarming function. The heatable lunch box mainly comprises a heating bottom box, a lunch box and a box cover; the lunch box is positioned on the heating bottom box; the box cover is positioned on the lunch box; the heating bottom box consists of a heating chassis, a display screen, a switch, a socket hole, a sounding hole, a calibrated scale, a temperature sensor and an alarm device; the lunch box consists of a left lunch box, a right lunch box and a partition positioned between the left lunch box and the right lunch box; the box cover consists of a fastener, a movable cover at the upper part of the box cover, air holes in the box cover and below the movable cover, and grooves. The heatable lunch box with the sound alarming function has the advantages of being high in safety performance, low in use cost, good in use benefits, and excellent in use performances.

Owner:杜杭华

Overwintering queen bee storage tank

The invention provides an overwintering queen bee storage tank, and relates to the technical field of bee breeding. An empty comb phenomenon occurs at the front part of a honeycomb in a beehive main body along consumption of overwintering feeds, so that the weight of the beehive main body is reduced, and the gravity center of a beehive shifts backwards; by virtue of an elasticity adjusting device,the front part of the beehive is slowly ascended, the beehive main body in a horizontal state inclines to present a gradually descending state, and a sliding component moves backwards above the beehive main body along the horizontal direction to drive a multi-chamber queen cage to move backwards towards the honeycomb, so that the multi-chamber queen cage is located in the center of bee groups allthe time, and the phenomenon that a queen bee dies due to freezing and starving is avoided; by virtue of the technique, the beehive can be used for storing multiple queen bees during overwintering, can meet a demand on requeening for propagation in advance in an apiary and can further meet demands on egg outputting of a breeding unit. The overwintering queen bee storage tank has important effectson advanced propagation of swarms and advanced application of fine-variety queen bees.

Owner:吉林省养蜂科学研究所

LED (light emitting diode) packaging adhesive processing device

ActiveCN110773062AGlue mixes quicklyImprove processing speedTransportation and packagingMixer accessoriesPhysicsElectric machinery

The invention discloses an LED (light emitting diode) packaging adhesive processing device which comprises a tank body, wherein a heating cavity, a mixing cavity, a filter pressing cavity and a degassing cavity are respectively formed in the inner cavity of the tank body; a feeding tank is fixedly connected with the top of the tank body; and a feeding hopper communicates with the top of the feeding tank. The invention relates to the technical field of LED packaging adhesive processing devices. By adopting the packaging adhesive processing device, raw materials are added along with the feedinghopper, and are grinded after being fed into the feeding tank, a grinding disc is driven to rotate by a first driving motor, raw materials of an adhesive liquid fall between the grinding disc and a grinding groove, the grinding disc is rotated to grind the materials in match with the grinding groove, then remaining large-granule materials in the adhesive liquid can be crushed rapidly, and the grinding efficiency can be high; and in addition, the gap between the grinding disc and the grinding groove is fixed, only raw materials of granules small enough can fall down, so that the raw materials of the adhesive liquid have no large-granule solids, and the processed packaging adhesive is good in quality when being compared with the prior art.

Owner:SHENZHEN ZOQE TECH CO LTD

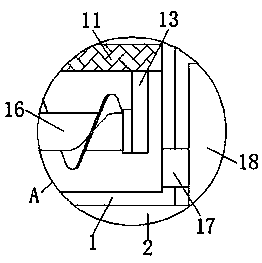

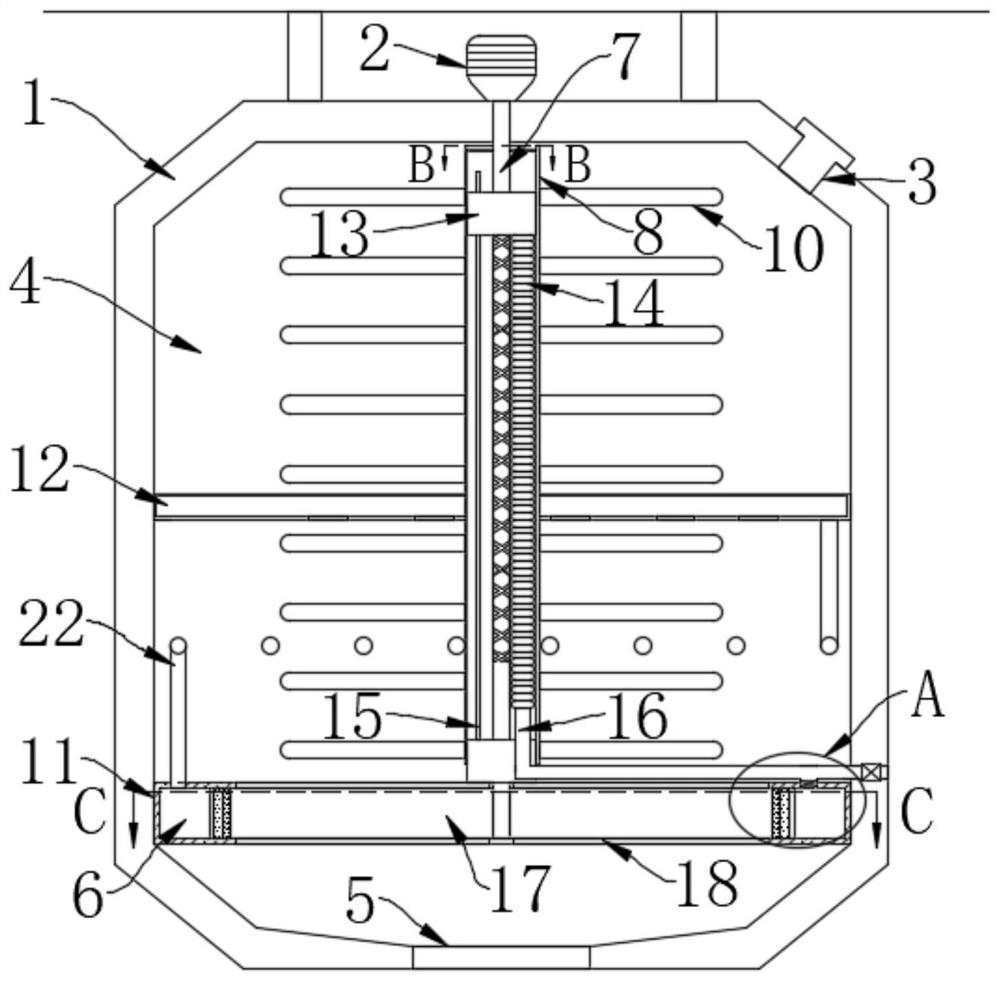

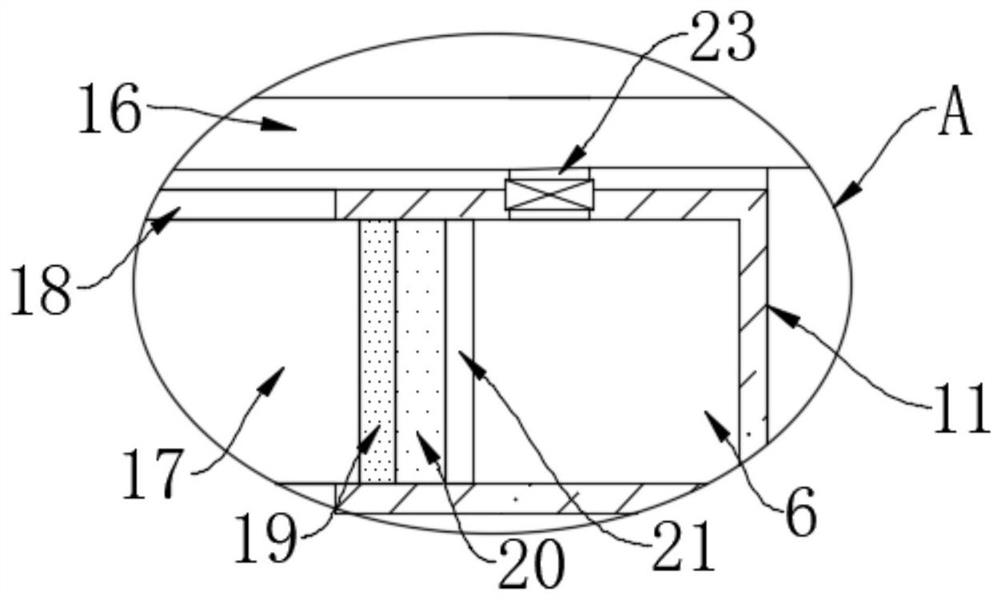

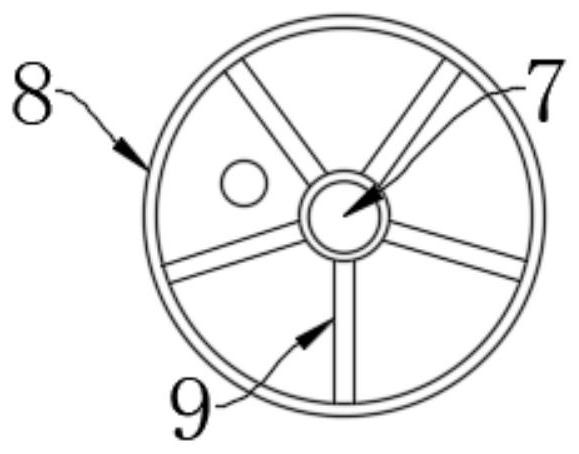

A cement silo with discharge control function

ActiveCN113044417BAvoid freezingEasy to useLarge containersTank wagonsSpiral bladeClassical mechanics

The invention discloses a cement silo with a discharge control function, which includes a discharge pipe, a cement silo body and a mixing box. The side end surface of the cement silo body is welded with a fixed block, and the lower end of the fixed block is equipped with a supporting leg. The discharge pipe is arranged at the lower end of the cement silo body, and the discharge pipe is provided with an installation groove extending to the inner wall of the discharge pipe from the side end, and the side end surface of the discharge pipe is welded with symmetrically distributed limit plates. A mounting plate is welded at the end of the plate, a threaded rod is installed between the mounting plate and the discharge pipe, a movable block is threaded on the threaded rod, and a connecting rod is welded at the side end of the movable block, and the end of the connecting rod A discharge baffle is welded at the place, and the outer side of the discharge baffle is wrapped with a rubber layer. The mixing box is welded to the upper inner wall of the cement silo body. A rotating shaft is installed in the mixing box, and a spiral blade is arranged on the rotating shaft. The invention has the advantages of preventing cement solidification and having the function of controlling material discharge.

Owner:济南鹏发建筑机械有限公司

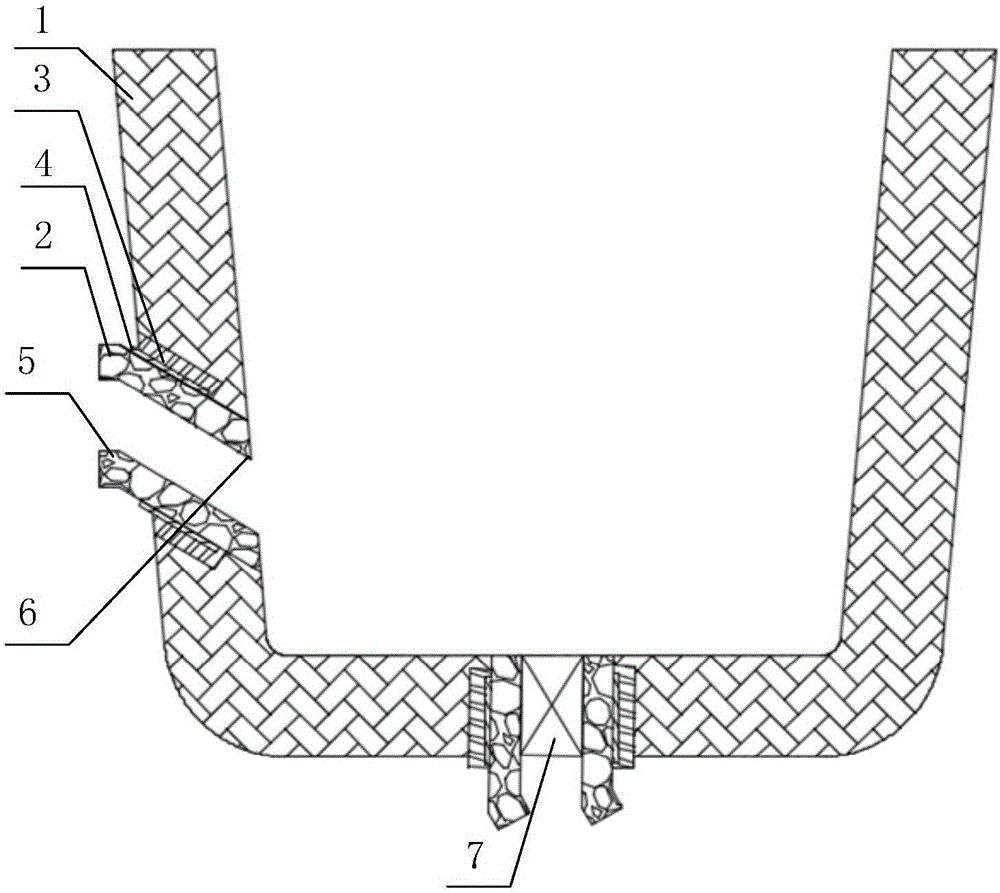

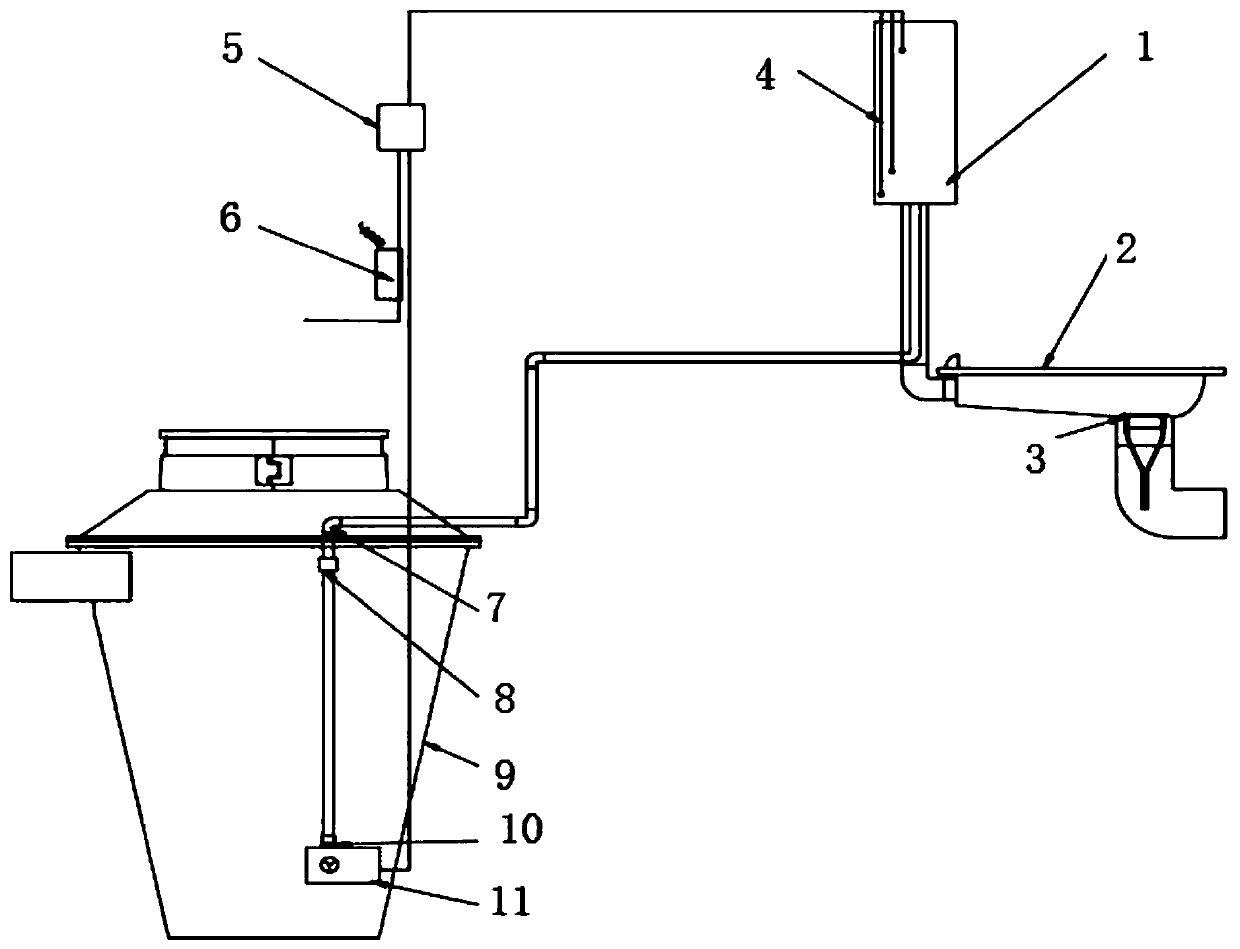

High-cold anti-freezing toilet flushing system

InactiveCN110565765APrevent water from freezingAvoid freezingLavatory sanitoryElectric heatingWater pipe

The invention discloses a high-cold anti-freezing toilet flushing system. The system comprises a water tank, a squatting pan and a water collecting tank; the squatting pan is located above the water collecting tank; the squatting pan is connected with the water tank through a water pipe; a submersible pump is arranged in the water collecting tank; a water level detection system is arranged in thewater tank; the water level detection system is connected with an automatic water lifting system; the automatic water lifting system is further connected with the submersible pump; and the submersiblepump is connected with the water tank through a pipeline. The high-cold anti-freezing toilet flushing system adopts geothermal energy, so that water is effectively prevented from being frozen, the water pipe is prevented from being frozen and cracked, electric heating is not needed to increase the room temperature, and the system is used as usual in winter.

Owner:魏隆基

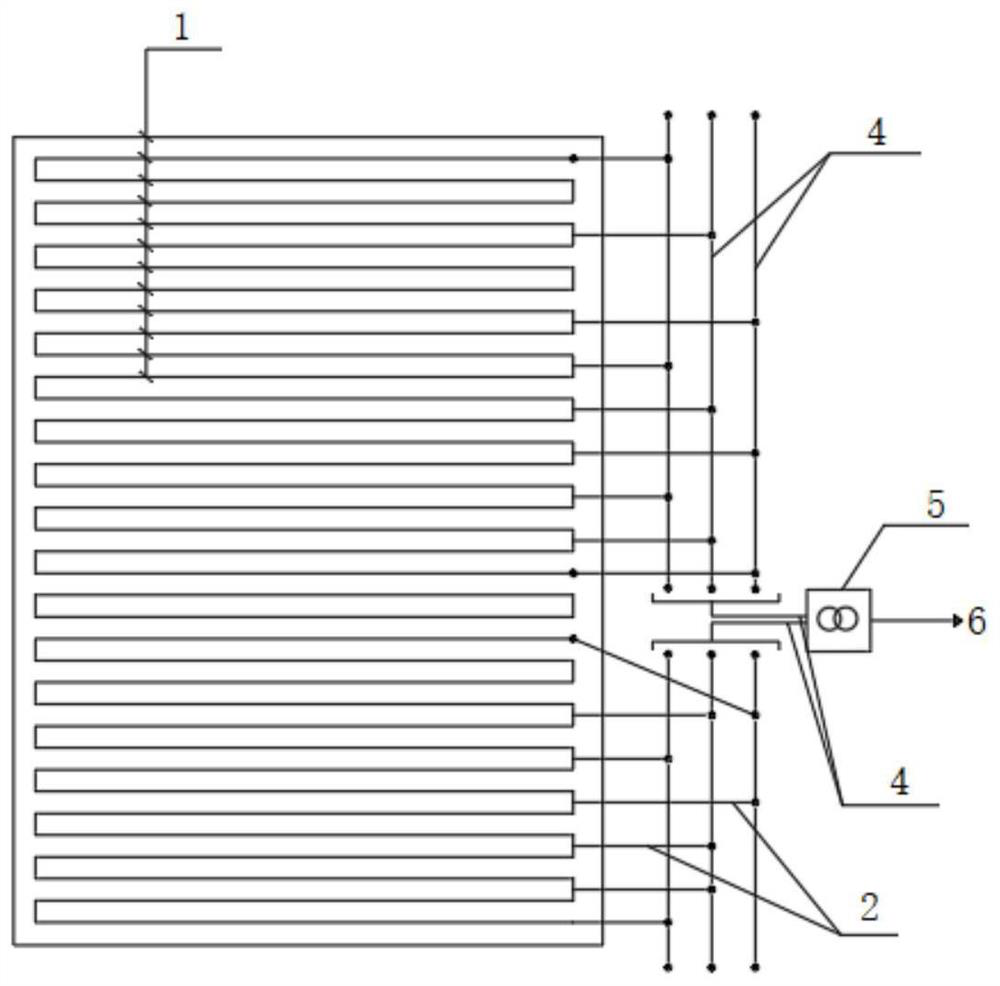

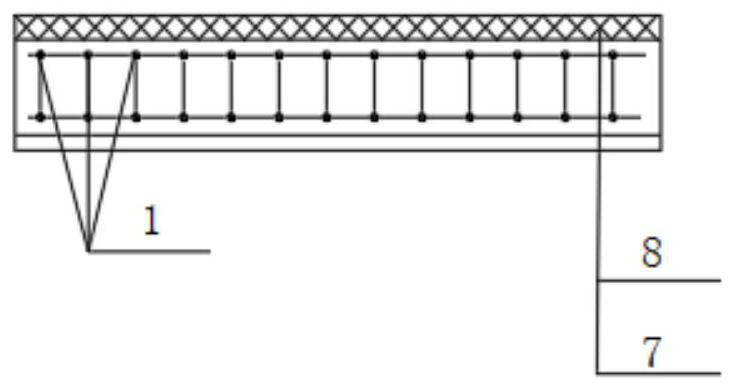

Concrete in-mold temperature control system applied to cold conditions

PendingCN112684825AAvoid freezingGuaranteed early strengthTemperatue controlBuilding material handlingRebarTemperature control

The invention discloses a concrete in-mold temperature control system applied to cold conditions, the control system comprises a heating device; the heating device is arranged on a steel bar to be poured and is connected with the steel bar, the heating device is connected with a power supply bus through a cable, and the heating device is poured in a concrete structure. The temperature required by initial setting and final setting of the concrete can be effectively controlled, early freezing of the concrete is avoided, the early strength of the concrete is guaranteed, mass concrete cracks are reduced, and the later strength and durability of the concrete meet the requirements.

Owner:CCCC SHANGHAI HARBOR ENG DESIGN & RES INST +2

A sand casting gating system for bracket castings

ActiveCN112077291BEffective deformationEffective ejectionMolten metal conveying equipmentsHydraulic cylinderEngineering

The invention discloses a sand casting pouring system for bracket-like castings. The invention relates to the technical field of casting and pouring. Two corresponding limiting plates are fixedly installed, a hydraulic cylinder is fixedly installed on the end surface of the concave plate, a casting mold is fixedly installed at a corner position on one side of the end surface of the bottom plate, and a template is fixed at the output end of the hydraulic cylinder; A pouring trough is opened at the middle position inside the pouring mold, and a resisting plate is movable inside the pouring trough, and a movable rod is fixed on the lower end surface of the resisting plate, and a second inclined plane resisting block is fixedly installed on the lower end surface of the movable rod. The casting pouring system can not only effectively move the collision plate upwards, thereby effectively ejecting the pouring model, which is convenient for external personnel to handle, but also can effectively avoid the solidification of the pouring liquid due to a long time.

Owner:山东宇信铸业有限公司

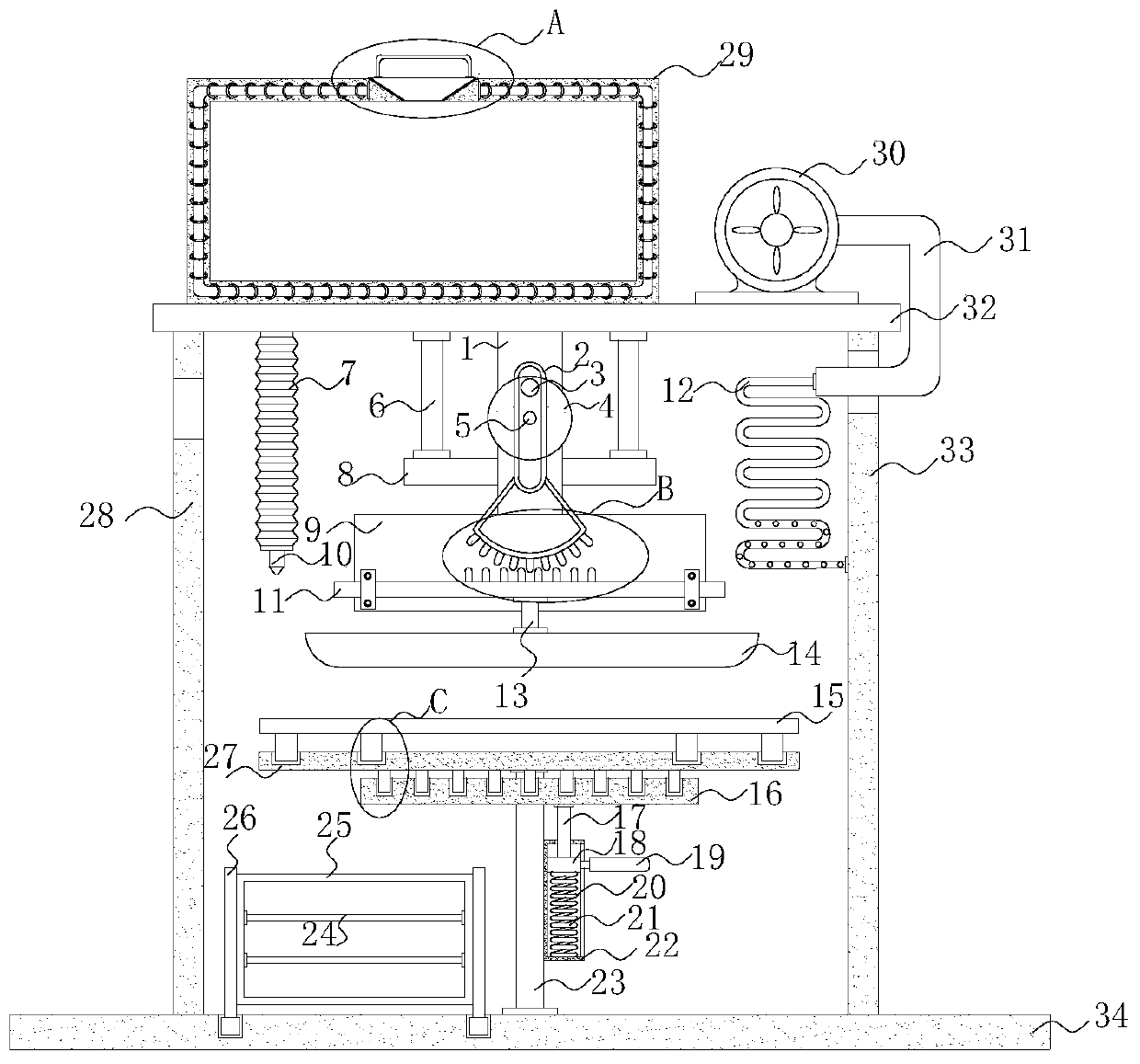

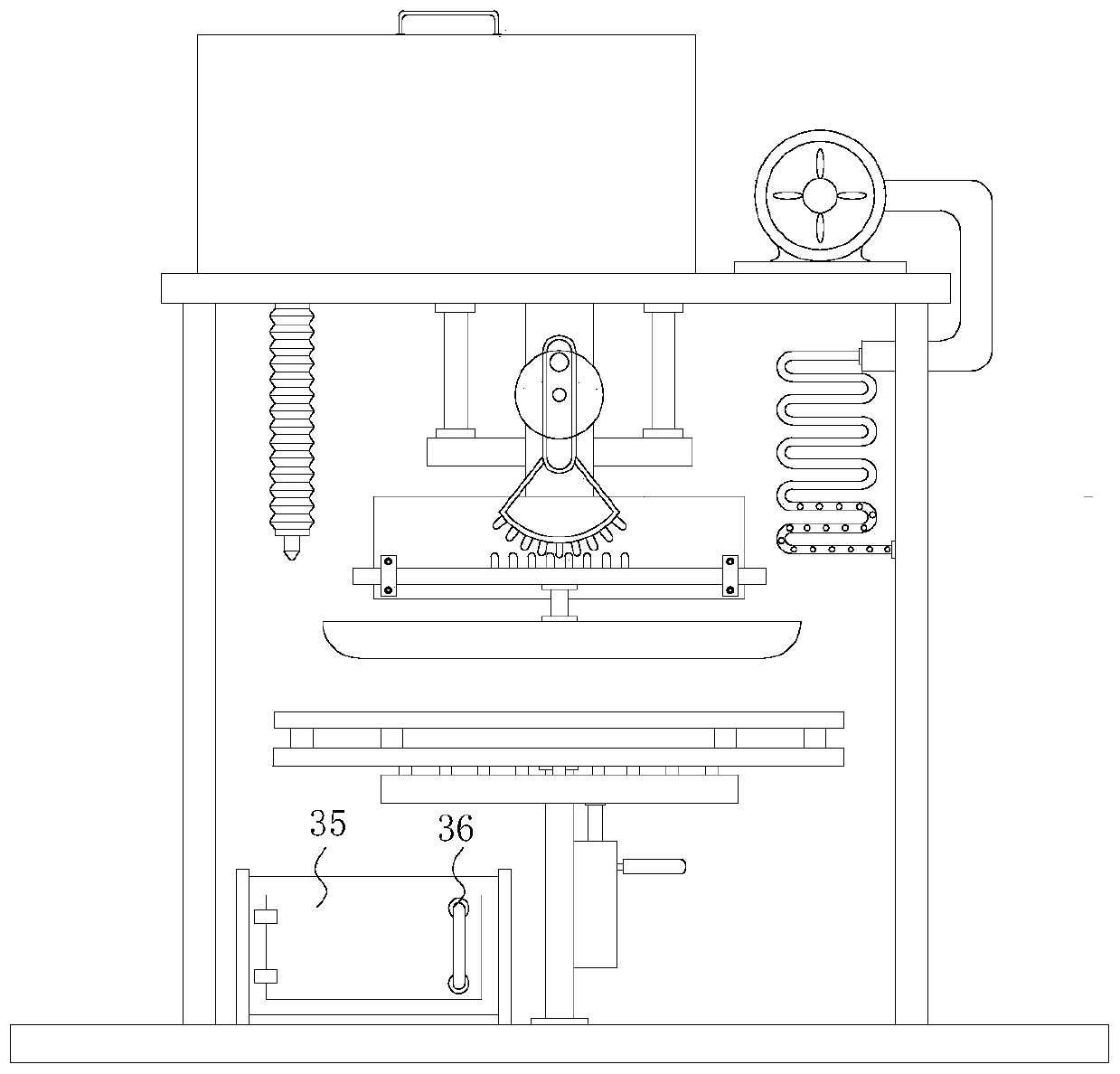

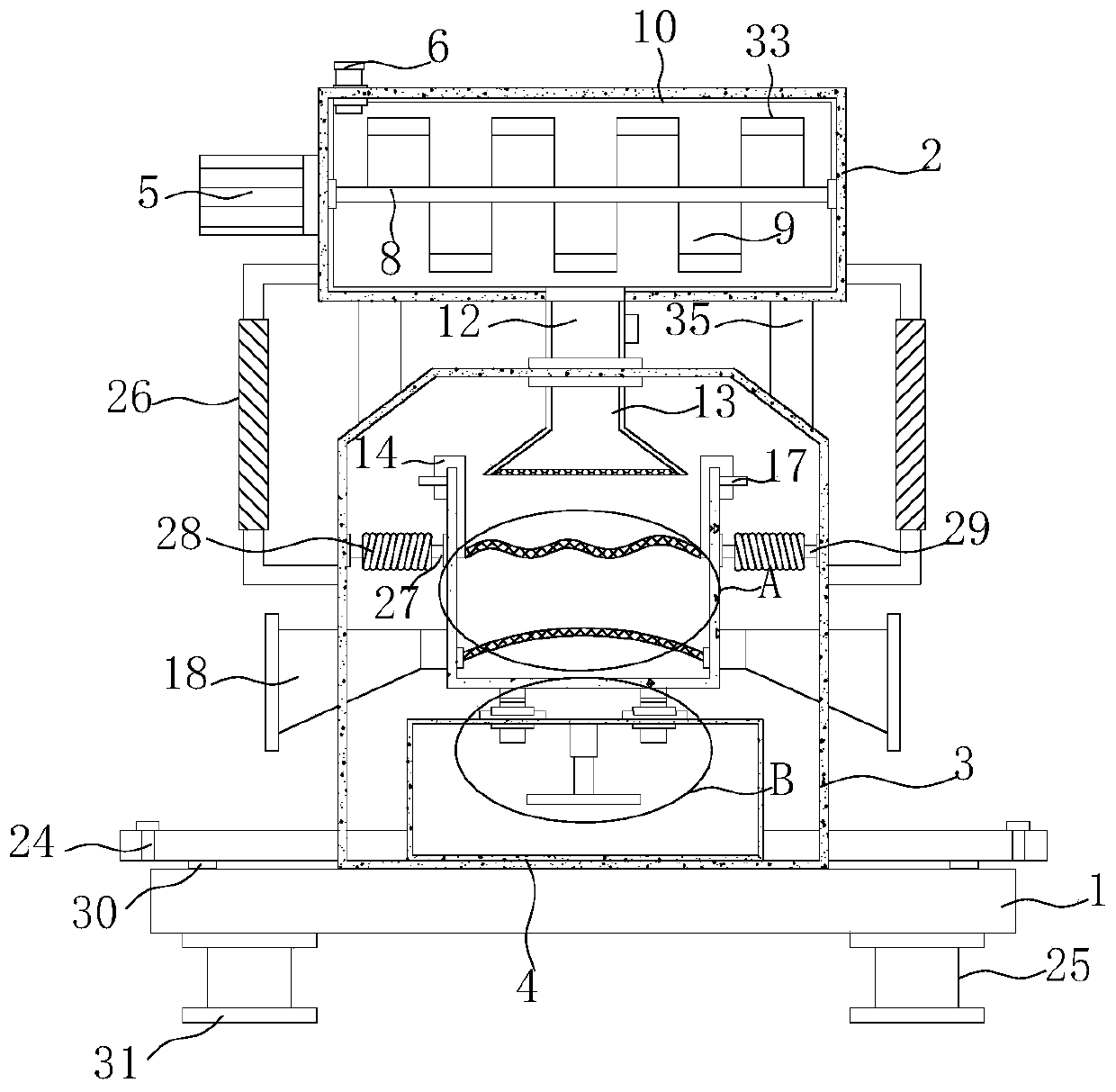

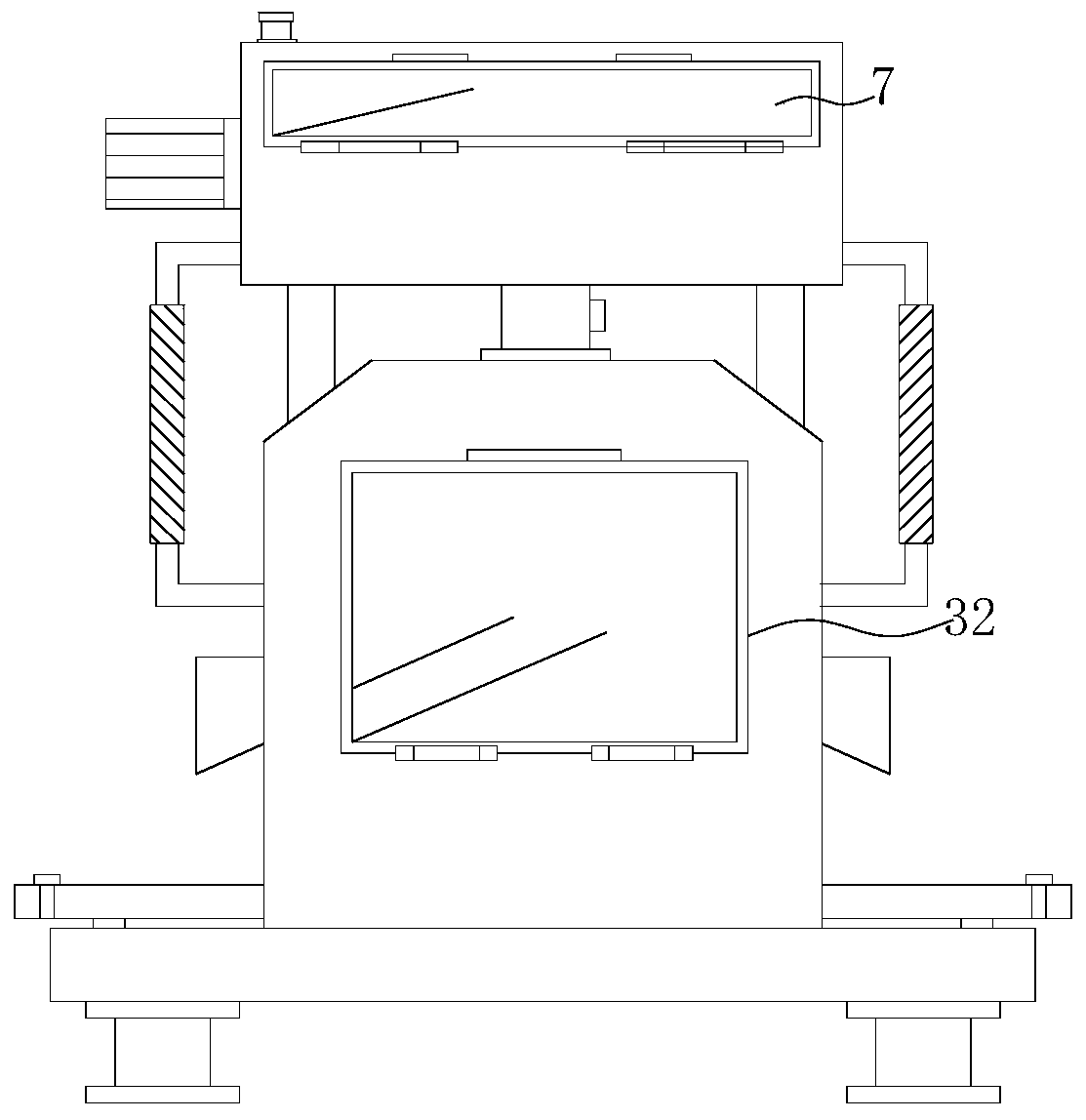

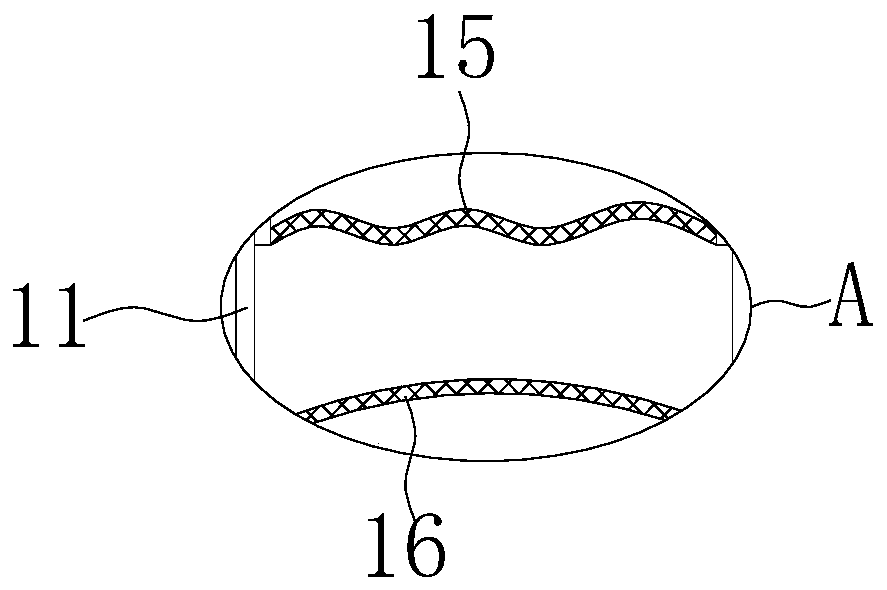

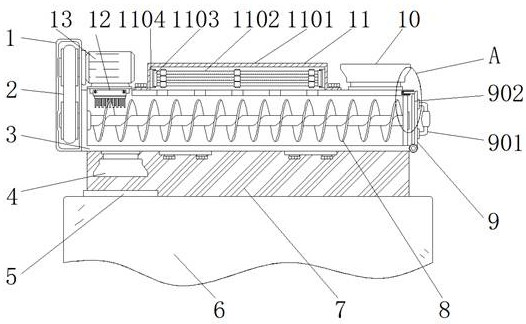

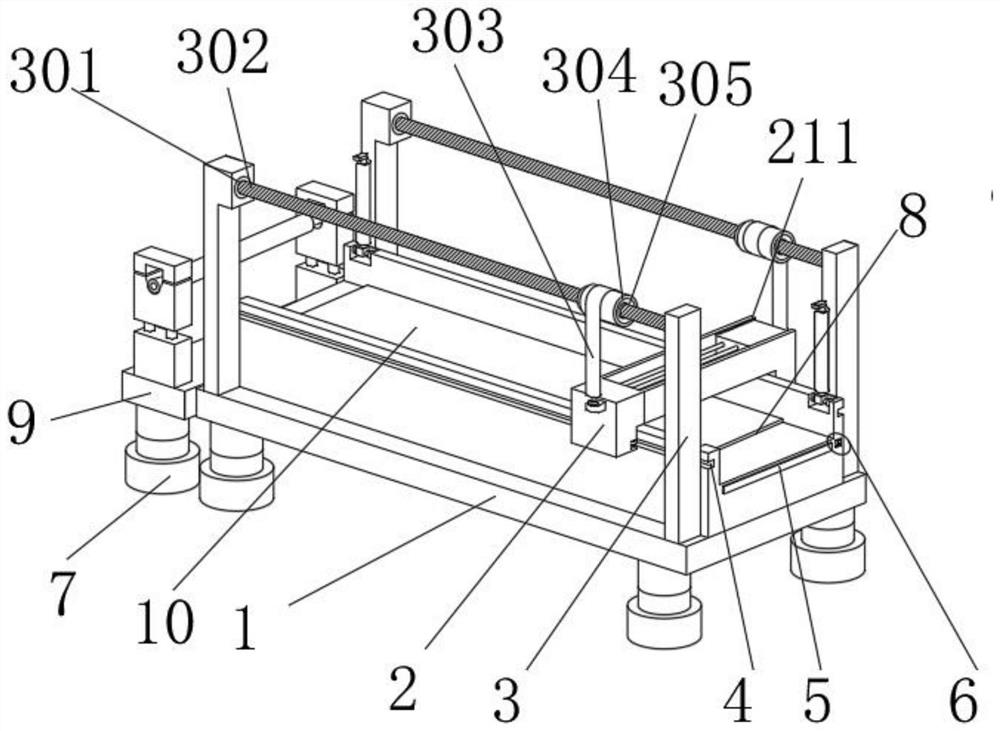

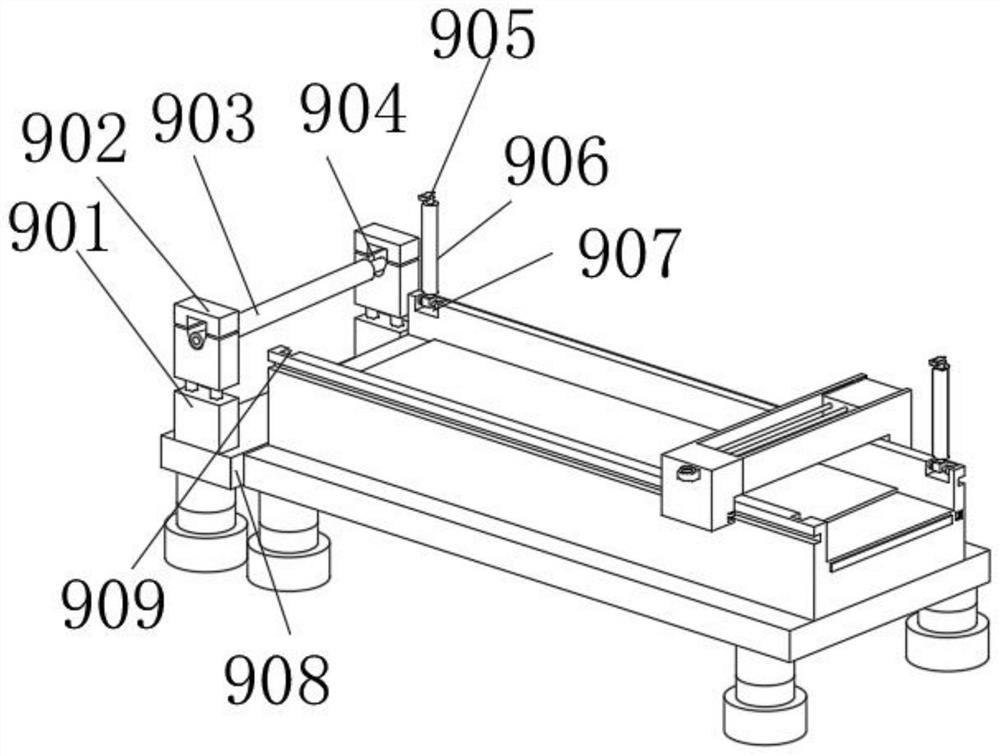

Automatic production equipment for food-grade polyurethane grain lifting belt and use method of automatic production equipment

ActiveCN114160362AReduce buildupAvoid freezingLiquid surface applicatorsConveyorsElectric machineryProcess engineering

The invention discloses automatic production equipment for a food-grade polyurethane grain lifting belt and a using method thereof.The automatic production equipment for the food-grade polyurethane grain lifting belt comprises a tension adjusting mechanism installed on the left side of a main body and used for adjusting the tension of the polyurethane grain lifting belt, and a processing groove is formed in the main body; a heating plate is mounted in the processing groove, a discharging mechanism is mounted in the limiting groove, a coating mechanism is mounted above the periphery of the main body, a discharging box in the discharging mechanism is matched with a motor A to drive a loosening screw rod to rotate, a polyurethane raw material and an auxiliary agent are continuously mixed and stirred, uneven mixing of the polyurethane raw material and the auxiliary agent is effectively prevented, and the coating effect is improved. The polyurethane raw materials are evenly coated through cooperation with the coating mechanism, the machining efficiency is improved, the tension of the lifting belt can be adjusted in time through the tension adjusting mechanism, the machining groove can be heated through the heating plate in the machining groove, the situation that the polyurethane raw materials on the bottom layer are solidified is prevented, and the machining quality is improved.

Owner:镇江经纬输送装备有限公司

A high-efficiency aluminum liquid filtration and purification device for aluminum ingot production

ActiveCN110923464BPrevent solidificationShorten the setting timeProcess efficiency improvementMetallurgyElectric machinery

Owner:沈阳市东盛金属制品有限公司

Hot melt adhesive transfer device

InactiveCN110963193AAvoid freezingEasy to storeLarge containersTank wagonsElectric machineEngineering

The invention discloses a transfer tank body. The transfer tank body is internally provided with a storage cavity, the storage cavity is internally provided with a heating mechanism, the bottom of thetransfer tank body is provided with a discharging port, and the top of the transfer tank body is provided with a feeding port; the heating mechanism comprises a motor, a rotating shaft is arranged onan output shaft of the motor and is in transmission connection with the output shaft of the motor, an airflow guide block is welded to the top end of the rotating shaft, and an air outlet pipe is arranged at the bottom of the airflow guide block. As the heating mechanism is arranged, the device can uniformly supply heat to the hot melt adhesive in the storage cavity, the situation that the hot melt adhesive is solidified is effectively avoided, the hot melt adhesive storage effect is good, the actual use effect is good, and the practicability is thus high.

Owner:湖州碧宁生物科技有限公司

Feeding device for rare earth waste water processing

The invention discloses a feeding device for rare earth waste water processing. The feeding device mainly comprises a waste water pumping main body, the waste water pumping main body is composed of ahopper, a conveying pipe, an intermediate tank, a communicating nozzle, a thermal evaporation concentration tank and an emptying nozzle, a discharging port of the hopper is in butt joint with a feeding port of the conveying pipe, and a discharging port of the conveying pipe is in butt joint with a feeding port of the intermediate tank; and a discharging opening in the bottom of the intermediate tank is in butt joint with the communicating nozzle. In the actual operation process, when materials are accumulated in the intermediate tank, double-tank circulation is achieved through a first communicating pipe and a second communicating pipe, in this way, excessive loads of the accumulated materials on the intermediate tank can be reduced, and meanwhile, the situation that the materials are solidified is avoided; and the situation that waste and defective materials are generated can be effectively avoided on the whole.

Owner:赣州中凯稀土材料有限公司

Electronic component gluing device

InactiveCN112399725AWon't hurtAvoid freezingNon-metallic protective coating applicationLiquid storage tankEngineering

The invention provides an electronic element gluing device. The device comprises a bottom plate, two shells are welded to the top of the bottom plate, a sliding rail is welded to the top of the bottomplate and located between the inner sides of the two shells, a support is embedded in the top of the sliding rail in a sliding mode, and pulleys are fixed to the bottom of the support through bolts.A shaft rod is installed at the top of the support, and fasteners are fixed to the two ends of the shaft rod through bolts. A heating chamber is installed at the bottom of a liquid storage tank, and when the device works, a heating pipe in the heating chamber operates, so that the heating chamber can directly heat liquid glue in the liquid storage tank, and the situation that the liquid glue is solidified, and consequently raw material waste is caused is avoided.

Owner:西安居正知识产权运营管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com