Heating method of concrete post stressed beam channel and heating device

A heating device and heating method technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult to remove water, low heating efficiency, large steam beam, etc., to avoid heat dissipation, high heating efficiency, Fast heating effect

Inactive Publication Date: 2007-04-18

北京建工华创工程技术有限公司

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the post-tensioned beam is generally larger in size, the length is generally more than 24 meters, the longest can be more than 100 meters, the height is more than 3 meters, and the width is more than ten meters, so the required steam beam is relatively large, and the heat is transmitted from the outside to the inside of the channel slowly. , and the heat is lost to the ground and the environment, the heating efficiency is low, and the speed is slow, so it causes a lot of economic and time losses, and the method of introducing hot water in the tunnel is easy to cause water accumulation in the tunnel. It is difficult to remove the residual water, and after the temperature in the channel enters negative temperature, it will cause freezing and swelling.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

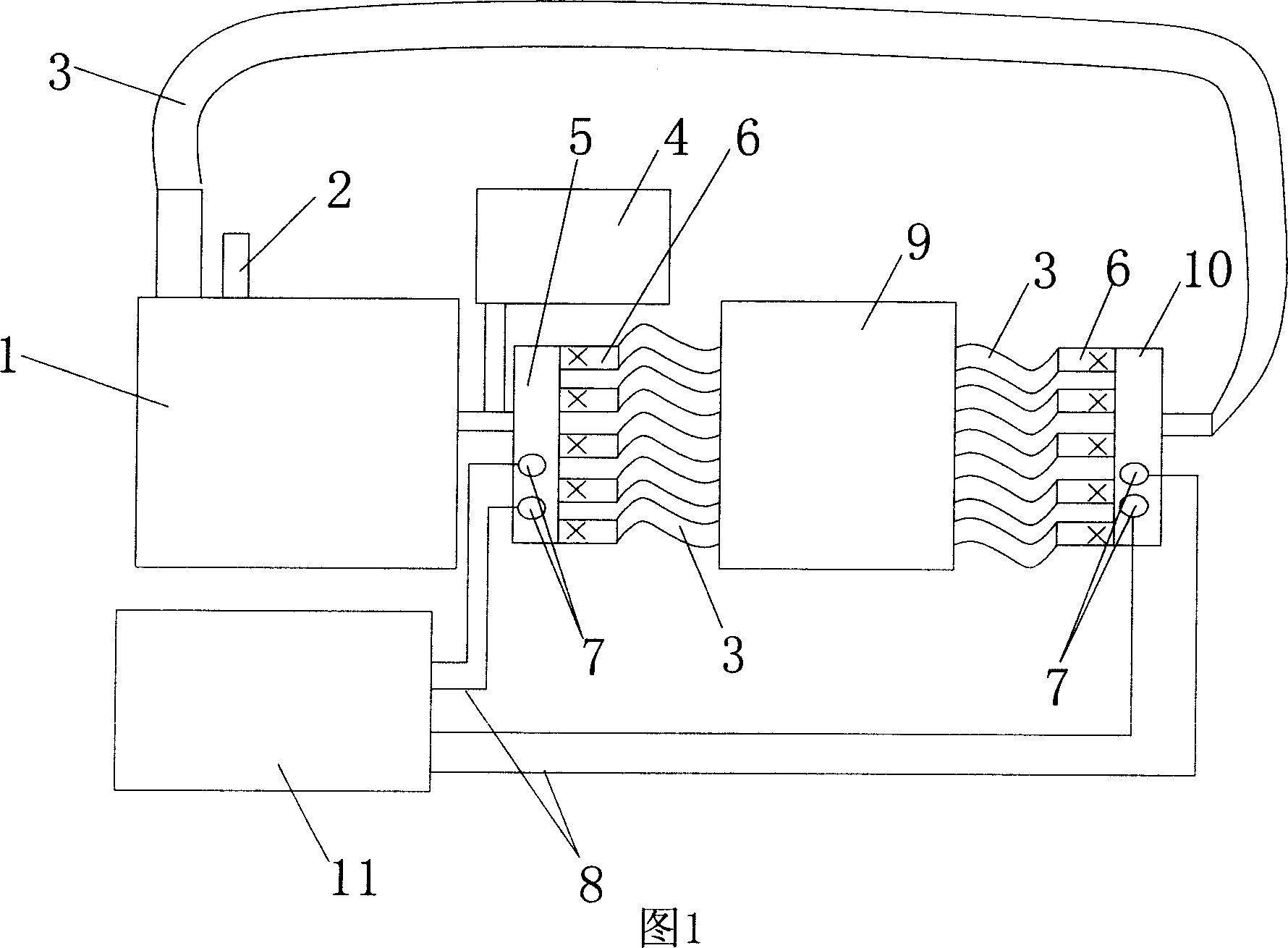

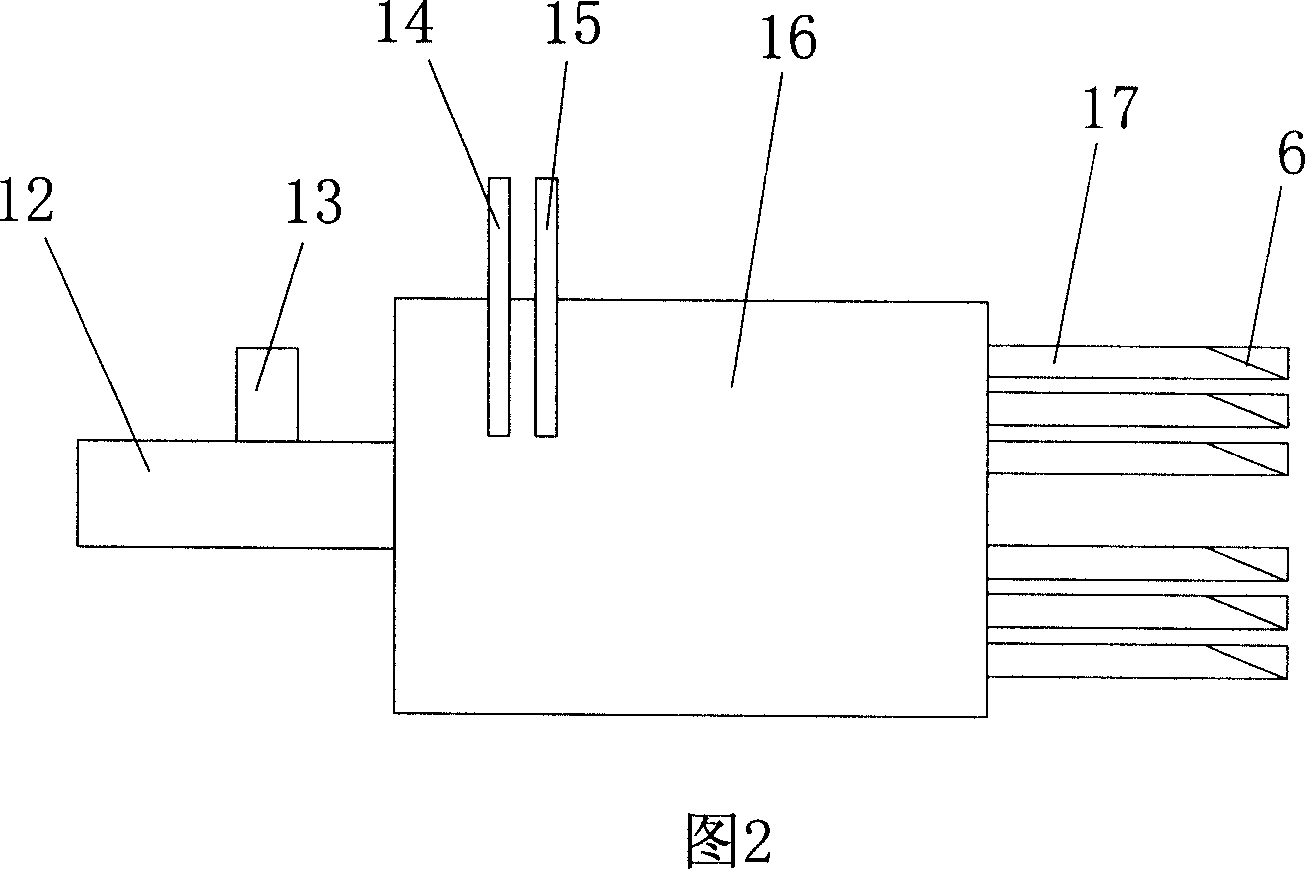

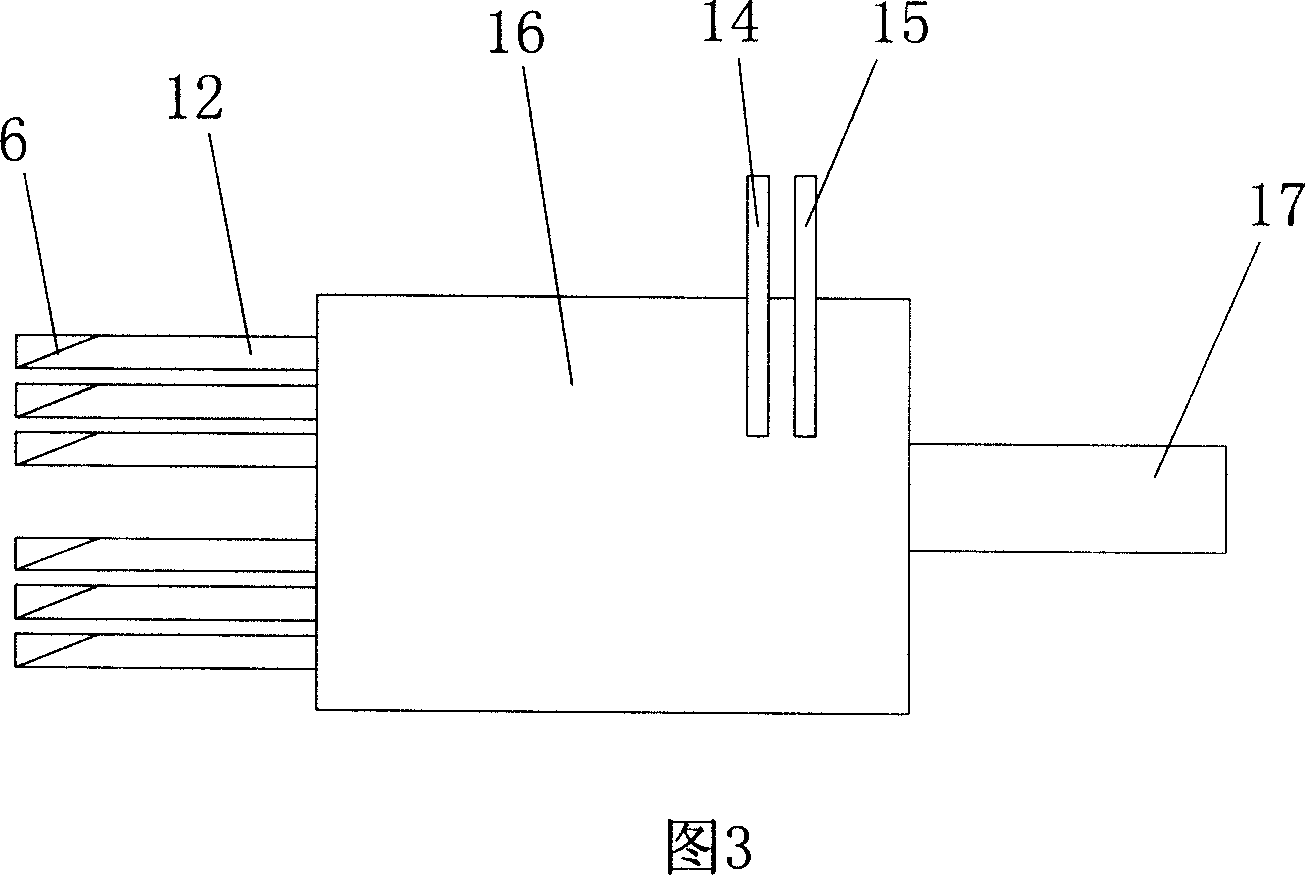

This invention discloses the methods and devices that the back beam hole heats and conserves in cryogenic conditions. The method adds heat air and steam in holes and leads to recycling use to hot air or hot steam. Heat the duct wall of concrete and anchors the heat head in the lateral fixation, so that the temperature of whole concrete reaches above 5 degree C and then grouting equipment will press grouting material into holes, through the duct wall the heat from concrete of curing the agent pressed into the filling. After grouting material, fix insulation material at beam anchors to avoid filling material freeze; thereby protection beams from freeze to crack. With beneficial effects of high efficiency, energy saving, construct safety.

Description

technical field [0001] The invention relates to a tunnel heating method and device, more precisely a method and a heating device for tunnel heating of concrete post-tensioned beams suitable for winter construction. technical background [0002] In recent years, with the continuous development of highway and railway construction, due to the tight construction period, it is inevitable to experience winter construction, especially in northern China, how to tap the potential of winter construction has become an important content of construction organization , as the prefabrication of post-tensioned beams, due to the particularity of the process, a reasonable construction process must be available to meet the construction requirements during winter construction, because it is winter construction, affected by the external low temperature and cold wind speed, the steam in the shed The curing temperature will be greatly affected, so thermal insulation measures are very important. Th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04G21/12E04G21/28E01D21/00

Inventor 佘海龙

Owner 北京建工华创工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com