Feeding device for rare earth waste water processing

A technology of feeding device and waste water, applied in the field of rare earth processing, can solve the problems of partial solidification and the material cannot be heated, and achieve the effect of reducing excessive load, avoiding solidification, and avoiding waste of defective products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the following describes the technical solutions in the specific embodiments of the present invention clearly and completely to further illustrate the present invention. Obviously, the described specific implementations The modes are only a part of the embodiments of the present invention, rather than all modes.

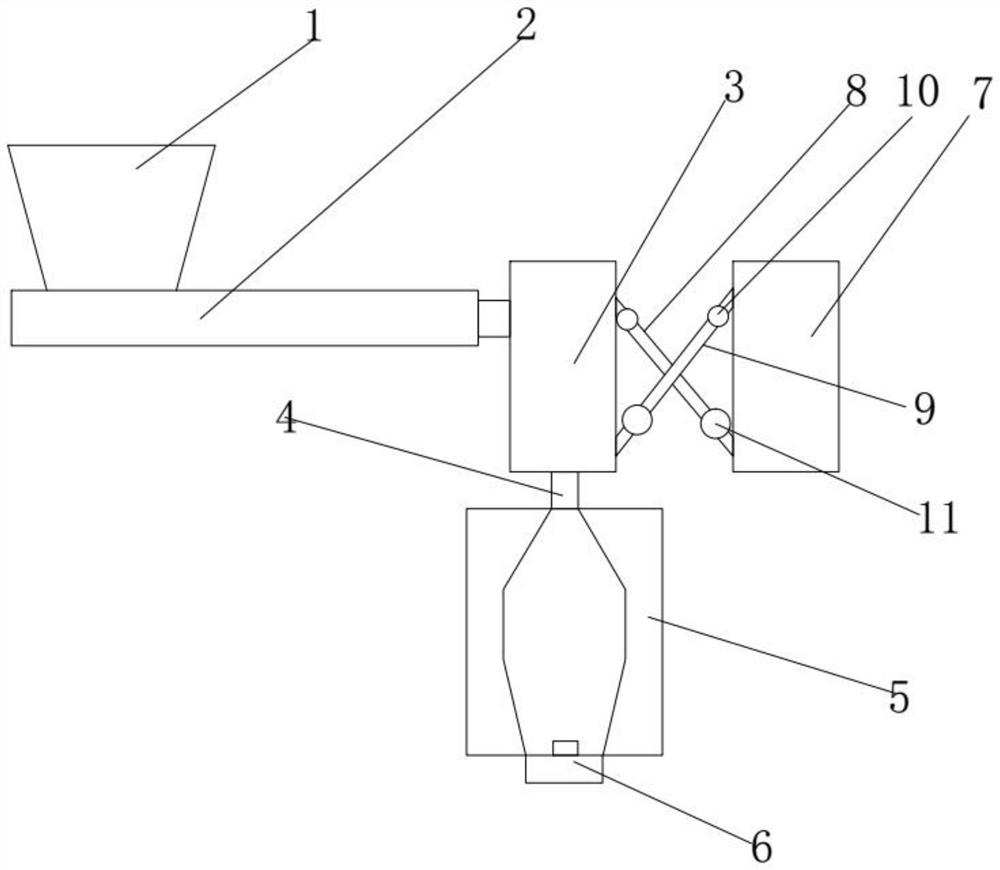

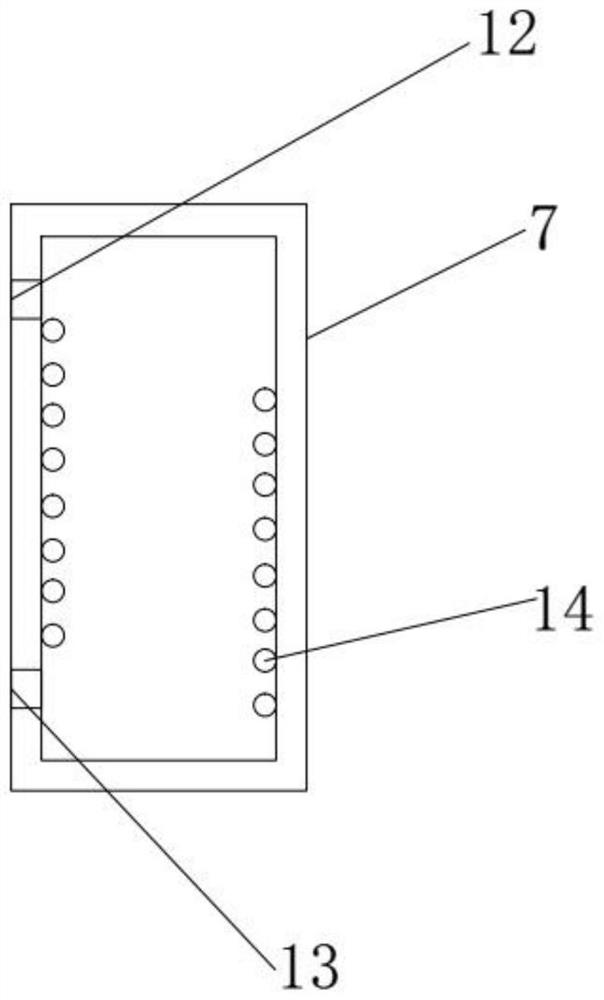

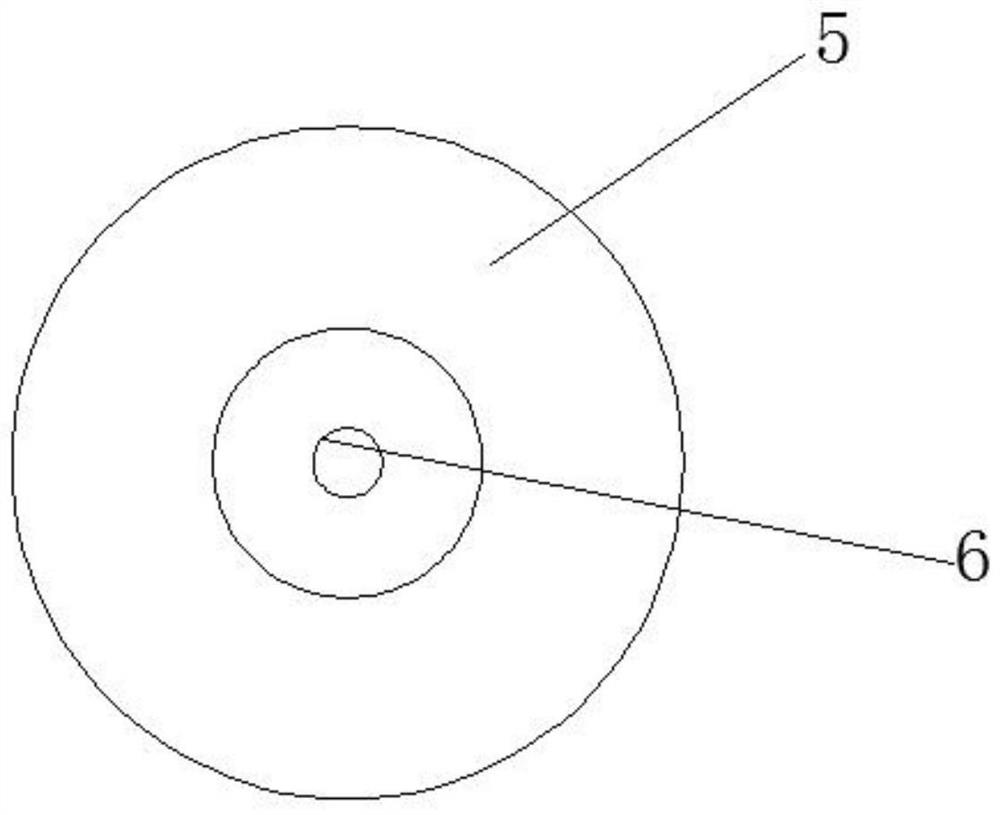

[0017] See Figure 1~3 In the embodiment of the present invention, a feeding device for rare earth wastewater processing mainly includes a wastewater pumping body, which consists of a hopper 1, a conveying pipe 2, an intermediate tank 3, a communication nozzle 4, and a thermal evaporation concentration tank 5. And the emptying nozzle 6 is formed, the discharge port of the hopper 1 is butt-connected with the feed port of the conveying pipe 2, the conveying pipe 2 melts and extrudes the material, and the discharge port of the conveying pipe 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com