Transition trolley for supporting heavy-load anchor rod

A technology of bolt support and trolley, which is used in the installation of bolts, support devices, drilling equipment, etc., can solve the problems of poor interchangeability and lack of interchangeability, and achieve uniform load, easy on-site replacement, and smooth movement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

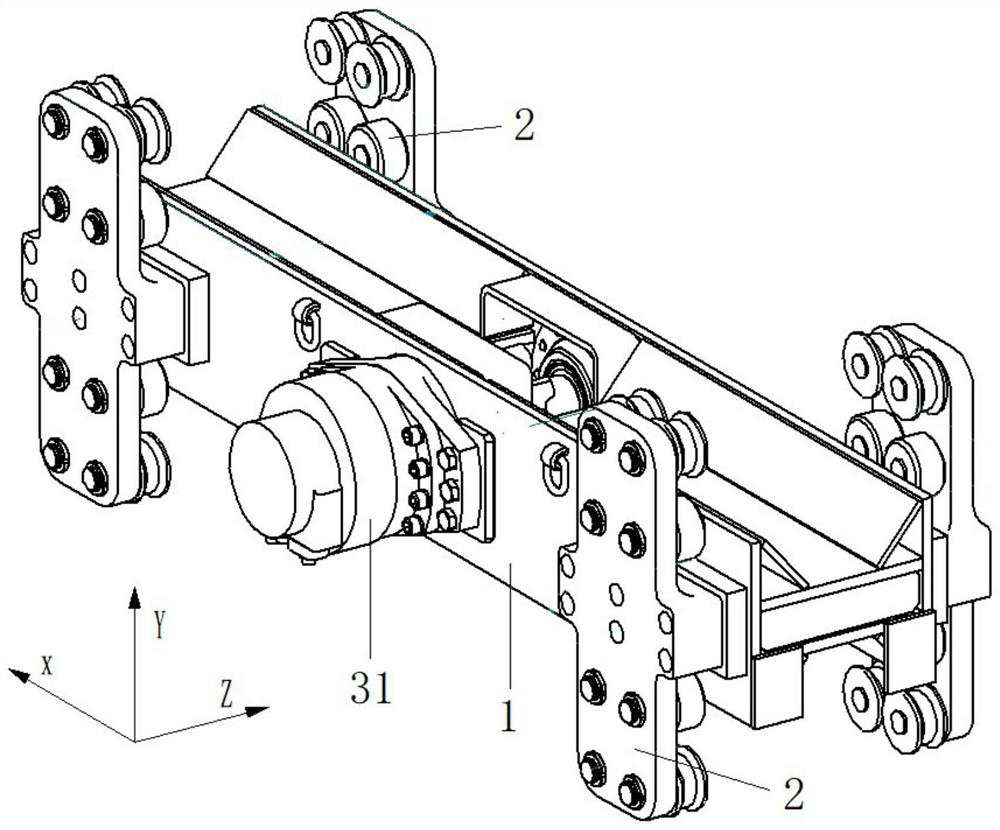

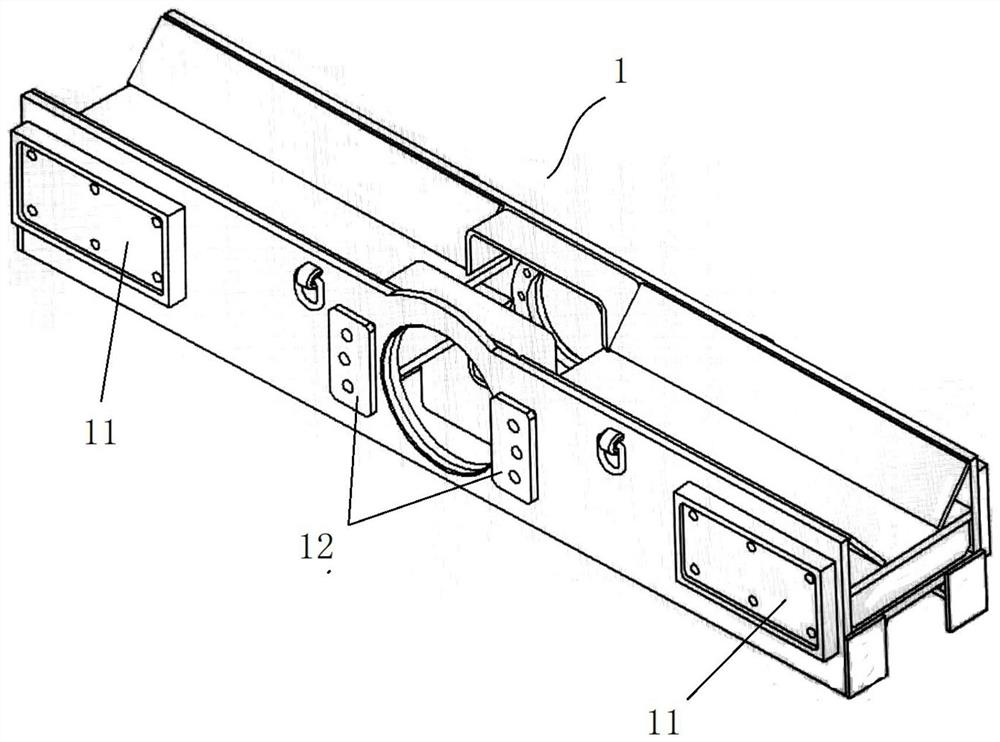

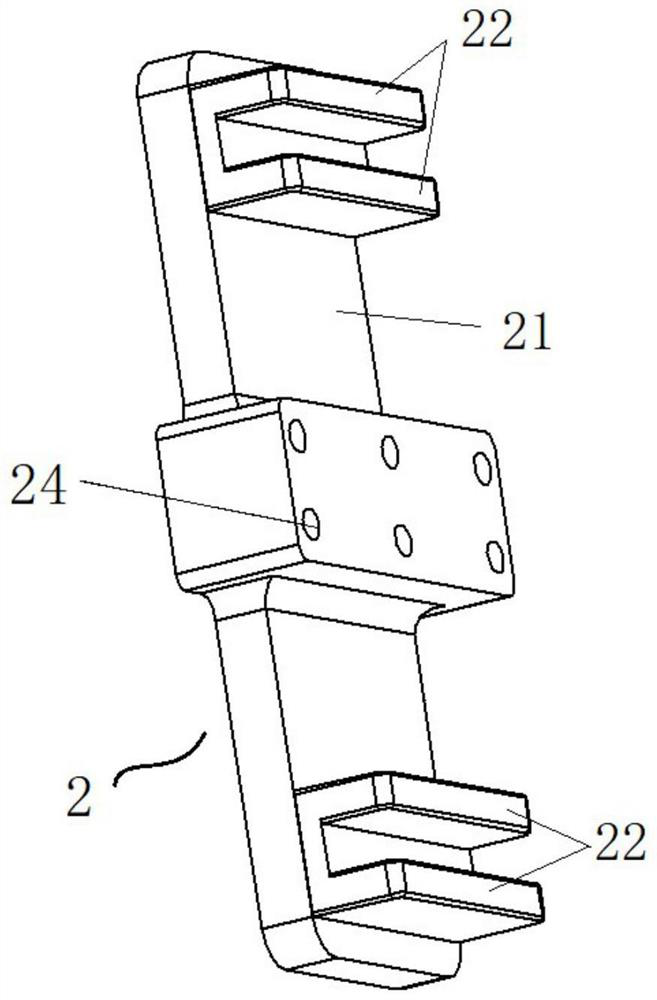

[0039] The invention discloses a transition trolley (which can be referred to simply as trolley) for heavy-duty bolt support, such as Figure 1-10 As shown, it includes a vehicle frame 1, a group of driving devices and four groups of limiting devices 2. The frame is a frame structure welded by high-strength thick steel plates, which is the skeleton part of the trolley, with high structural strength and rigidity. The driving device provides power and the required speed for the trolley to walk. The limit device forms a pair of left-right symmetrical "groove structures" with opposite notches at the upper and lower parts of the front and rear ends of the trolley. extending in the length direction. Because the position-limiting devices at the top of the front and rear ends of the vehicle frame can be clamped on the telescopic arm 4 from the left and right directions, the position-limiting devices at the bottom of the front and rear ends of the vehicle frame can be clamped on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com