Bearing

A bearing and intermediate bearing technology, applied in the directions of bearings, bearing components, shafts and bearings, etc., can solve the problems of relatively low rotational speed requirements of shredders, large friction force of sliding bearings, and high bearing costs, and achieve low cost, The effect of large coating area and small loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

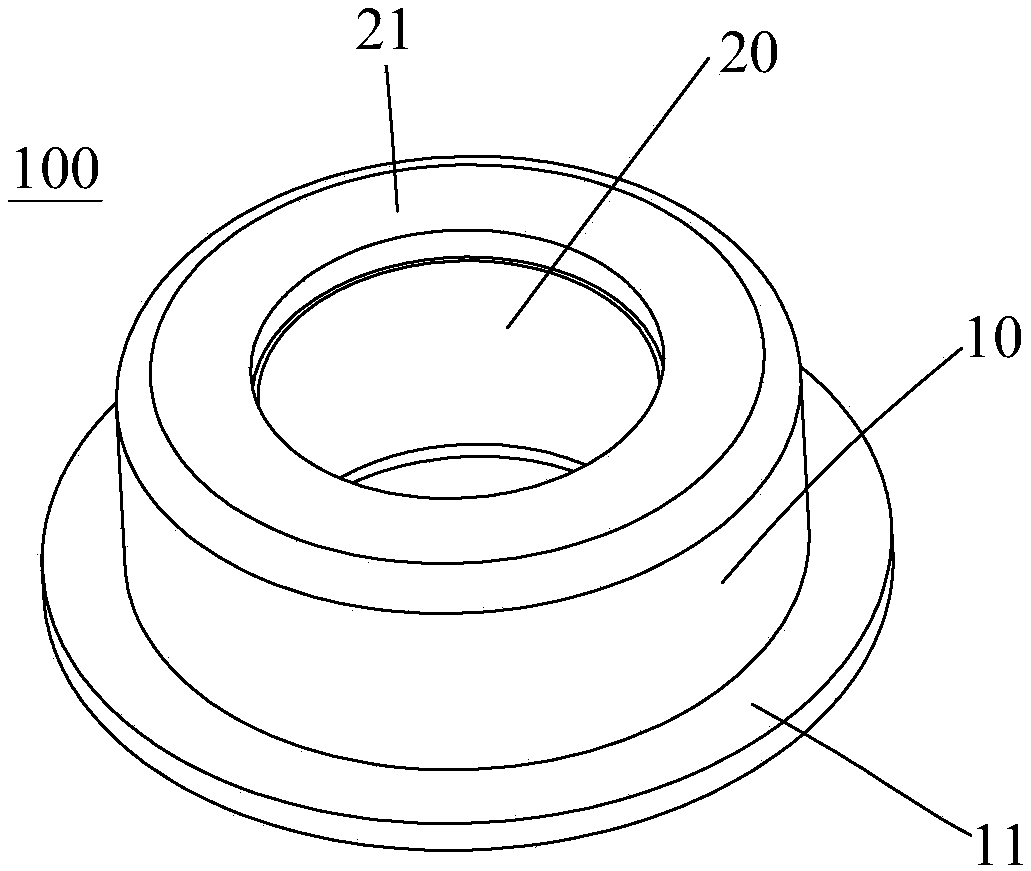

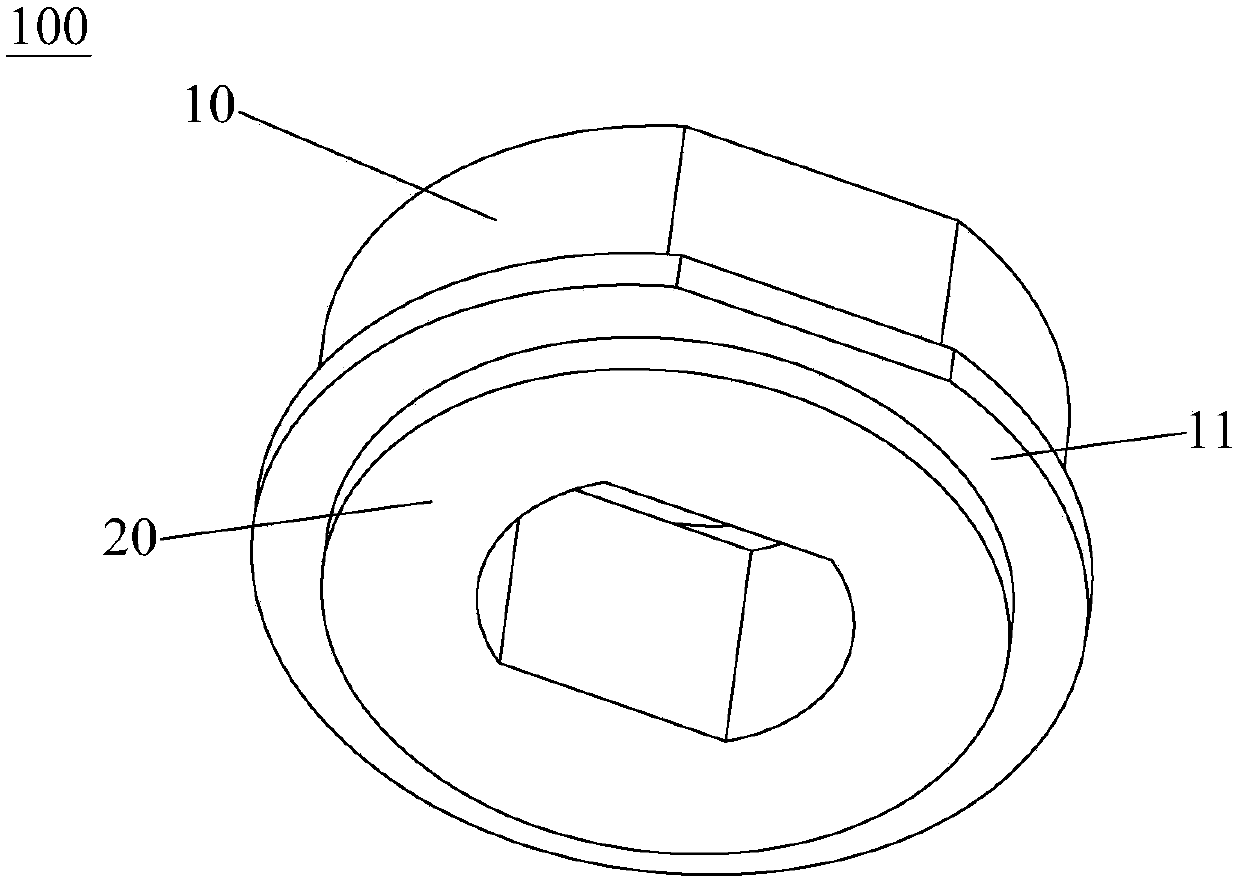

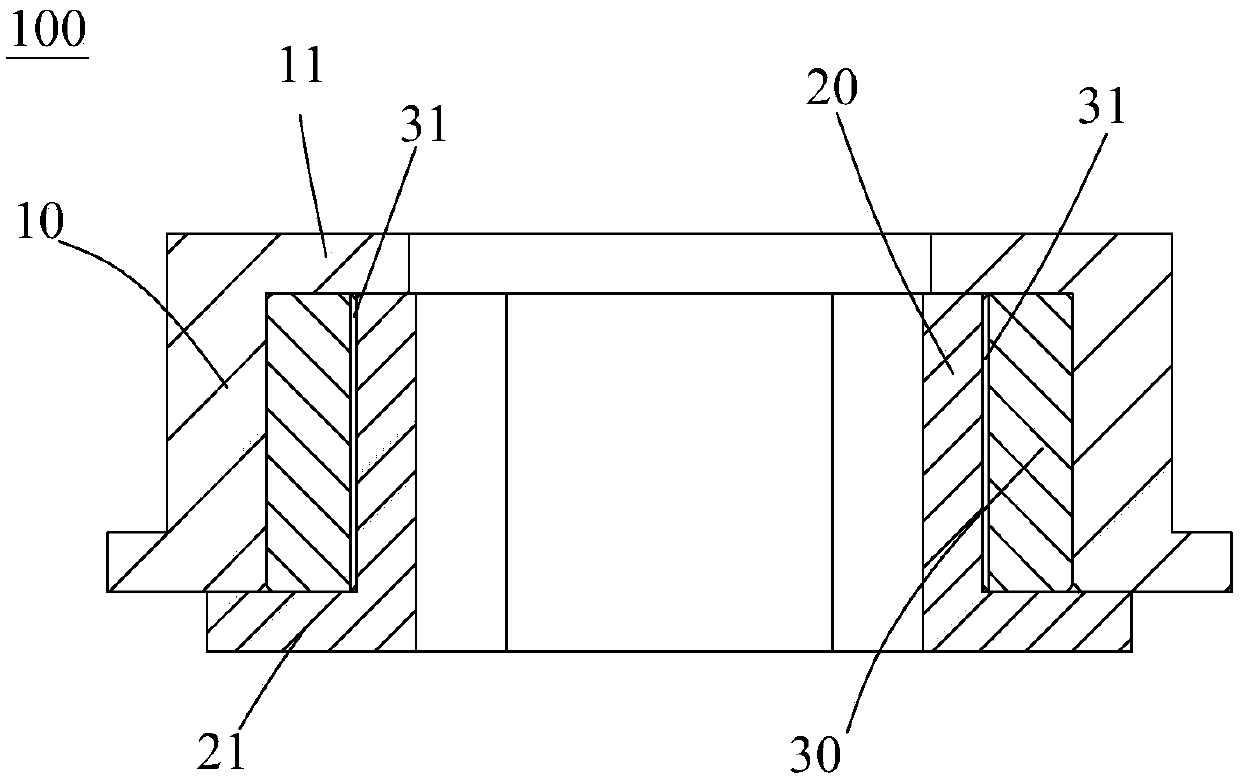

[0033] refer to Figure 1 to Figure 3 , the present invention discloses a bearing 100, comprising an inner shaft sleeve 20, an outer shaft sleeve 10 and an intermediate bearing sleeve 30, the intermediate bearing sleeve 30 is slidingly sleeved outside the inner shaft sleeve 20, and the outer shaft sleeve 10 The sliding sleeve is arranged outside the middle bearing sleeve 30, so that the outer shaft sleeve 10, the middle bearing sleeve 30 and the inner shaft sleeve 20 are assembled and matched with each other.

[0034] refer to Figure 4 to Figure 6 , the inner surface of the intermediate bearing sleeve 30 is concavely provided with a plurality of inner oil guide grooves 31 along its axial direction, and a plurality of concave arc convex s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com