High-speed rail bearing provided with reverse spherical roller track

A technology of spherical roller and deep groove ball bearings, which is applied in the field of high-speed rail bearings, can solve the problems of raceway indentation, bearing friction resistance and friction wear increase, rolling element indentation or peeling, etc., and achieve good high-speed stability and performance. Rigidity, reliable lubrication conditions, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

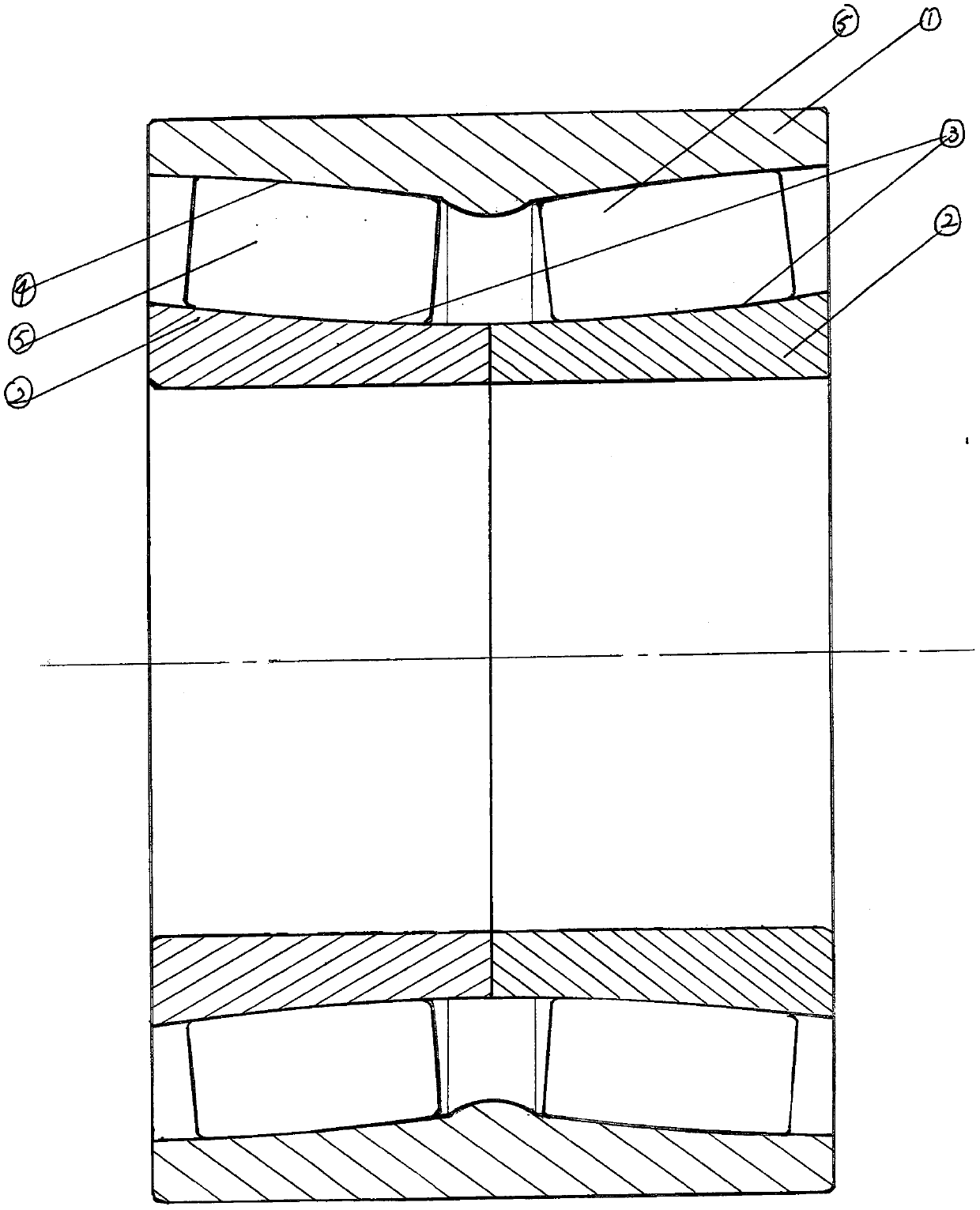

[0059] Such as figure 1 The shown high-speed rail bearing with reverse spherical roller track includes: two double-half inner rings 2, one outer ring 1, two rows of spherical rollers 5, and the outer circumference of the two double-half inner rings 2 Each is provided with a circle of reversed spherical roller tracks, two double-half inner rings 2 are coaxially arranged on the inner circumference of the outer ring 1, and the outer circumference after the two double-half inner rings 2 are combined to form a common reverse To the spherical roller track 3, the radius of curvature of the common reverse spherical roller track 3 is greater than the radius of the bearing roller circumferential track,

[0060] The distance between the two ends of the inner circumference of the outer ring 1 is respectively provided with a ring of spherical roller tracks 4. The spherical roller tracks 4 form an angle of 5 degrees with the vertical axis of the bearing, and spherical rollers are respective...

Embodiment 2

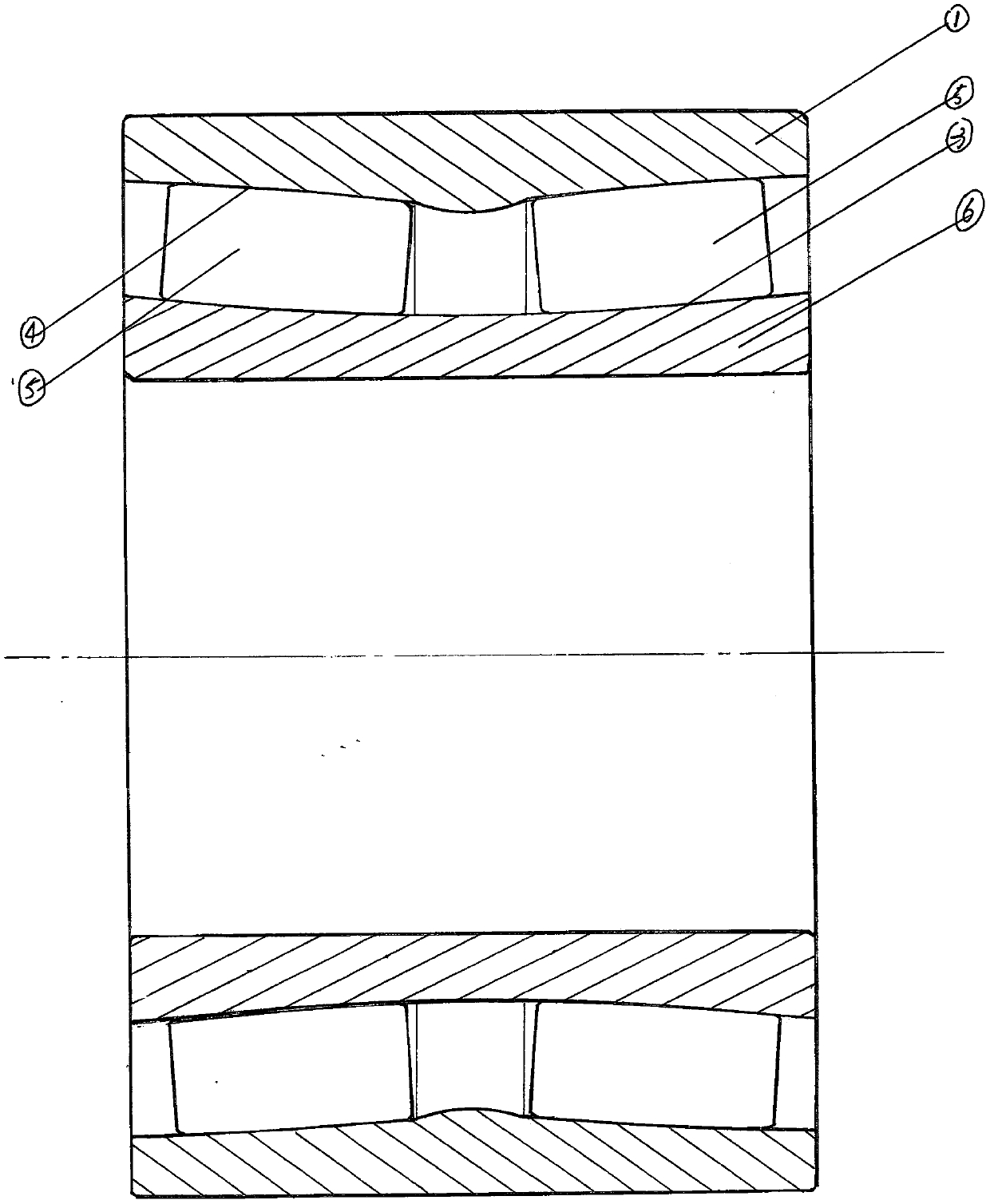

[0062] Such as figure 2 The shown high-speed rail bearing with reversed spherical roller tracks includes: two inner rings 6, one outer ring 1, two rows of spherical rollers 5, and the outer circumference of the inner ring 6 is provided with a common reversed ring. Toward the spherical roller track 3, the radius of curvature of the shared reverse spherical roller track 3 is greater than the radius of the circumferential track of the bearing rollers.

[0063] The two ends of the inner circumference of the outer ring 1 are provided with a ring of spherical roller tracks 4 corresponding to the distance between them. The spherical roller tracks 4 form an angle of 5 with the vertical axis of the bearing, and spherical rollers 5 are respectively arranged in the spherical roller tracks 4. , and the reverse spherical roller bearing structure is formed by combining the spherical roller 5 and the common reverse spherical roller track 3 provided on the outer circumference of the inner ri...

Embodiment 3

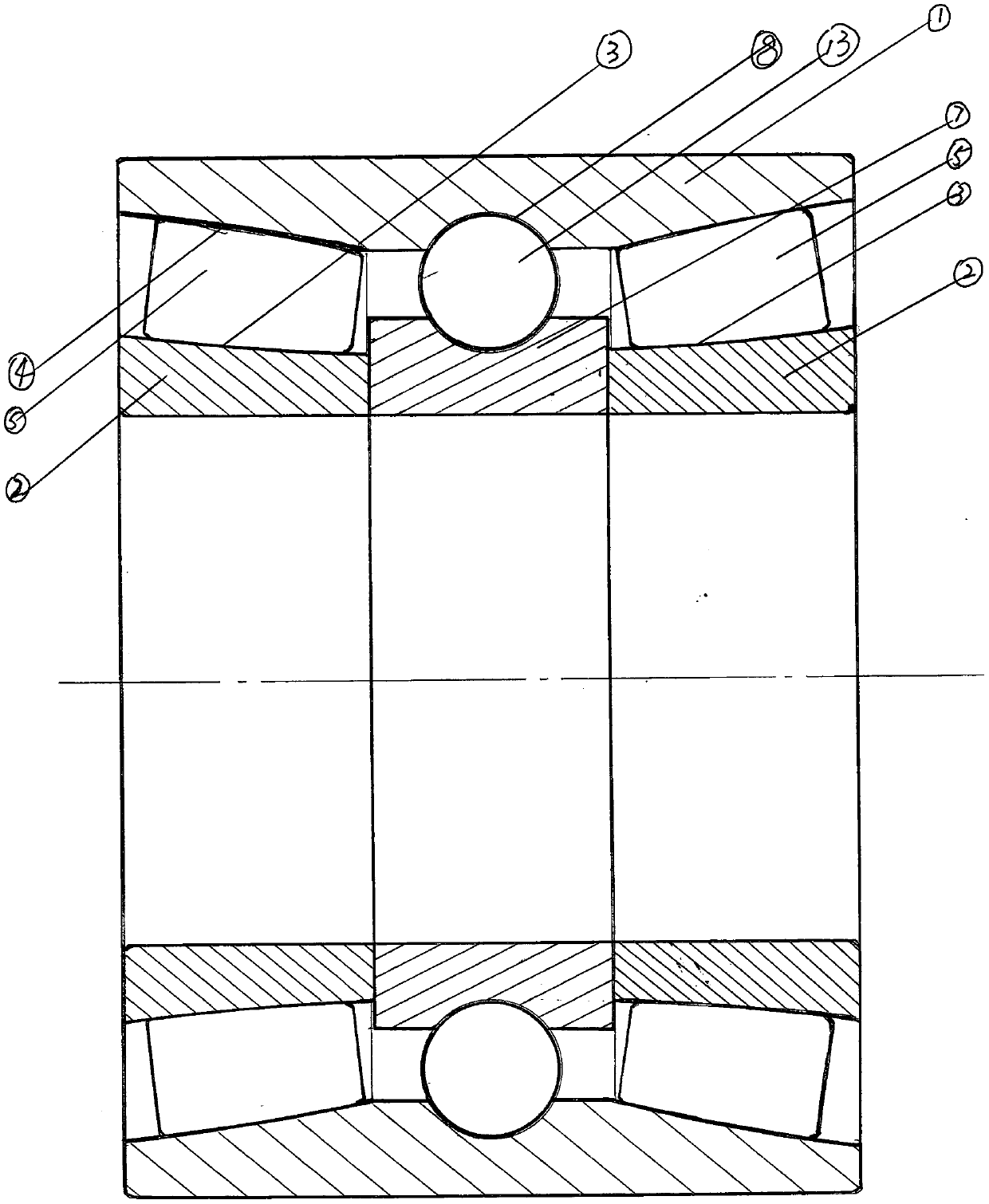

[0065] Such as image 3 The shown high-speed rail bearing with reverse spherical roller track includes: an outer ring 1, two double-half inner rings 2, a deep groove ball bearing inner ring 7, a row of spherical rolling elements 13, two For the volleyball surface roller 5, a circle of deep groove spherical rolling body track 8 is set in the middle of the axial distance of the inner circumference of the outer ring 1, and a spherical rolling body 13 is arranged in the deep groove spherical rolling body track 8, and the deep groove spherical rolling body The two ends of the track 8 are provided with a circle of spherical roller track 4 corresponding to the distance between them. The spherical roller track 4 forms an angle of 5 degrees with the vertical axis of the bearing, and spherical rollers 5 are respectively arranged in the spherical roller track 4. ,

[0066] The inner ring 7 of the deep groove ball bearing is arranged between the two double-half inner rings 2, and corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com