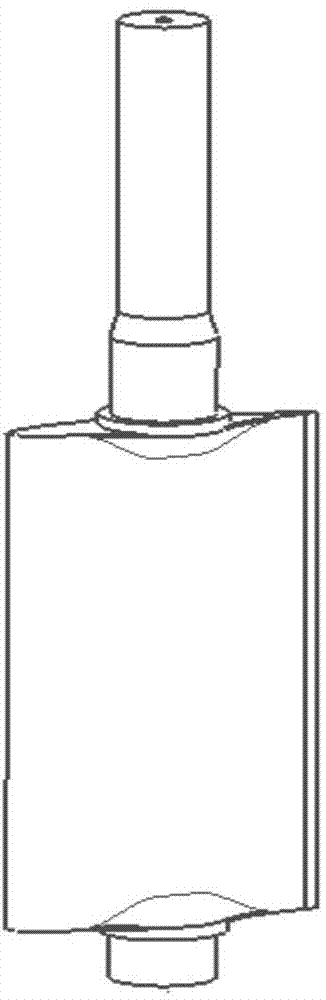

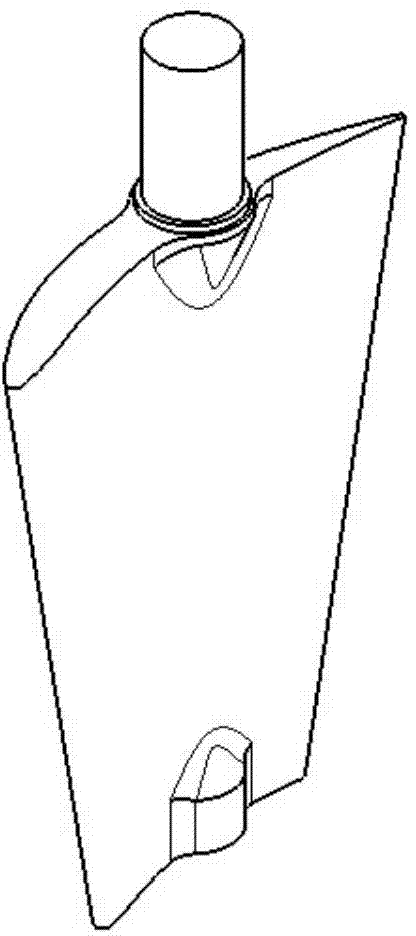

Manufacturing method for through-flow turbine continuous variable cross-section movable guide vanes through electroslag smelting casting

A tubular water turbine, electroslag casting technology, applied in the field of high requirements, electroslag casting tubular water turbine continuous variable cross-section movable guide vane, high-performance tubular water turbine movable guide vane manufacturing process, can solve the problem Unable to produce continuously changing cross-section castings and other problems, to achieve the effects of good fatigue resistance and crack extension, improved utilization rate, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] The electroslag casting blank of guide vane of tubular hydroelectric generator was prepared by low alloy steel 20SiMn.

[0083] Power parameters: According to the size of the casting, the geometry of the electrode and the crystallizer, the initial casting voltage is 50V, and the current is 6500A. The casting process is adjusted according to the calculation formula.

[0084] Through the electroslag casting process, the 20SiMn steel blank is formed by a crystallizer with a set shape. Its chemical composition is:

[0085] Table 4

[0086] C Si mn P S Cr Ni Cu Fe 0.20 0.7 1.20 0.020 0.013 0.010 0.10 0.10 margin

[0087] In order to eliminate the internal stress of castings and develop the potential of mechanical properties of materials, timely heat treatment is required, using anti-cracking heat treatment + normalizing + tempering process, and adopting other heat treatments according to actual performance and process requirements to...

Embodiment 2

[0092] The guide vane blank of 06Cr13Ni4Mo steel tubular hydro-generator was prepared by electroslag melting.

[0093] Power consumption parameters: According to the size of the casting, the geometry of the electrode and the crystallizer, the initial casting voltage is 75V, and the current is 12000A. The casting process is adjusted according to the voltage and current formula.

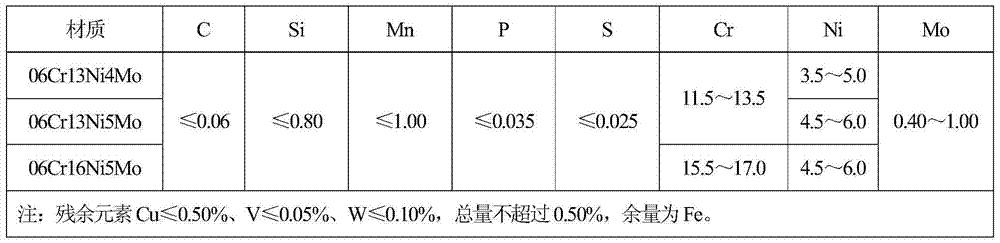

[0094] Through the electroslag casting process, the 06Cr13Ni4Mo steel blank is formed by a crystallizer with a set shape. Its chemical composition is:

[0095]

[0096] In order to eliminate the internal stress of castings and develop the potential of mechanical properties of materials, timely heat treatment is required, using anti-cracking heat treatment + normalizing + tempering process, and adopting other heat treatments according to actual performance and process requirements to optimize the comprehensive performance of castings.

[0097] In this embodiment, the thermal cracking prevention and ...

Embodiment 3

[0101] The guide vane blank of 06Cr13Ni5Mo steel tubular hydro-generator was prepared by electroslag melting.

[0102] Power consumption parameters: According to the size of the casting, the geometry of the electrode and the crystallizer, the initial casting voltage is 50V, and the current is 7500A. The casting process is adjusted according to the voltage and current formula.

[0103] Through the electroslag casting process, the 06Cr13Ni5Mo steel blank is formed by a crystallizer with a set shape. Its chemical composition is:

[0104]

[0105] In order to eliminate the internal stress of castings and develop the potential of mechanical properties of materials, timely heat treatment is required, using anti-cracking heat treatment + normalizing + tempering process, and adopting other heat treatments according to actual performance and process requirements to optimize the comprehensive performance of castings.

[0106] In this embodiment, the thermal cracking prevention and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com