Patents

Literature

49results about How to "Sanding easily" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

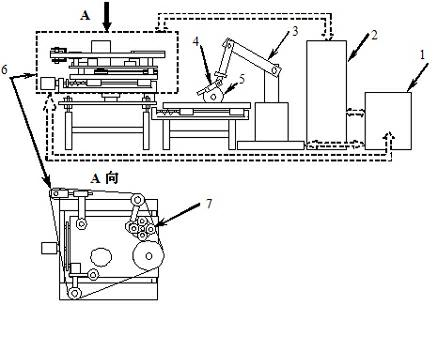

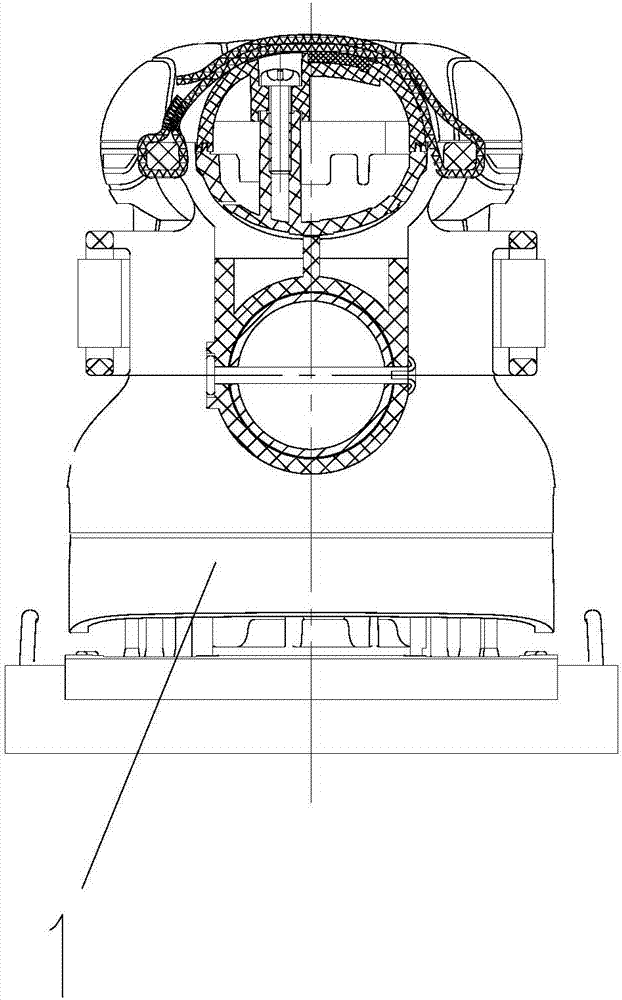

Automatic sanding and polishing device for industrial robot

InactiveCN102107384AGuaranteed positioning accuracyConsistent removalBelt grinding machinesContact forceAutomatic testing

The invention relates to an automatic sanding and polishing device for an industrial robot, wherein the industrial robot is served as the core of the device; the device comprises the industrial robot, an automatic shifting fixture, a polishing machine, and a force control program; and the device can be used for sanding and polishing the parts having complex exteriors, and is especially suitable for processing faucet, ironware, blade, and the like. A method for automatically sanding and polishing by using the device comprises the following steps: the automatic shifting fixture arranged on the tail end of the industrial robot is used for holding the parts; adjusting the position and posture of the industrial robot according to different areas for sanding or polishing of the parts; contacting the areas for sanding or polishing with a sanding belt of the polishing machine and keeping a certain contact force; controlling the size of the contact force by a force control mechanism; after finishing programming the whole surface of parts, using the industrial robot to perform the reprogramming operation; and sanding or polishing the parts having same exteriors in batch.

Owner:厦门煜雄智能机器人有限公司

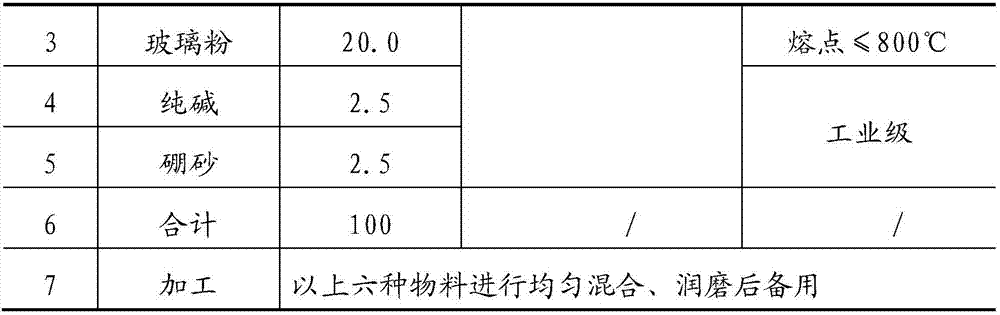

Composite multifunctional chemical unblocking agent

The composite multifunctional chemical unblocking agent consists of organic multifunctional unblocking agent in 50-100%, inorganic multifunctional unblocking agent in 5-35% and composite synergist 25-35%. Its main components include C7-C10 aromatic hydrocarbon organic solvent, polyethenoxy ether as surfactant, oil soluble water dispersed polyether demulsifier, T penetrator, polyether wetting agent, mutual solvent, insoluble scale converting agent, composite organic / inorganic acid, cationic polymer as clay stabilizer, water soluble polyether demulsifier, iron ion stabilizer, polyether wetting improver, corrosion assistant, corrosion retardant, cationic polymer as sand stabilizer, etc. The composite multifunctional chemical unblocking agent is injected into treated oil well to produce lasting unblocking effect 10 times that of earth acid.

Owner:CHINA NAT OFFSHORE OIL CORP +1

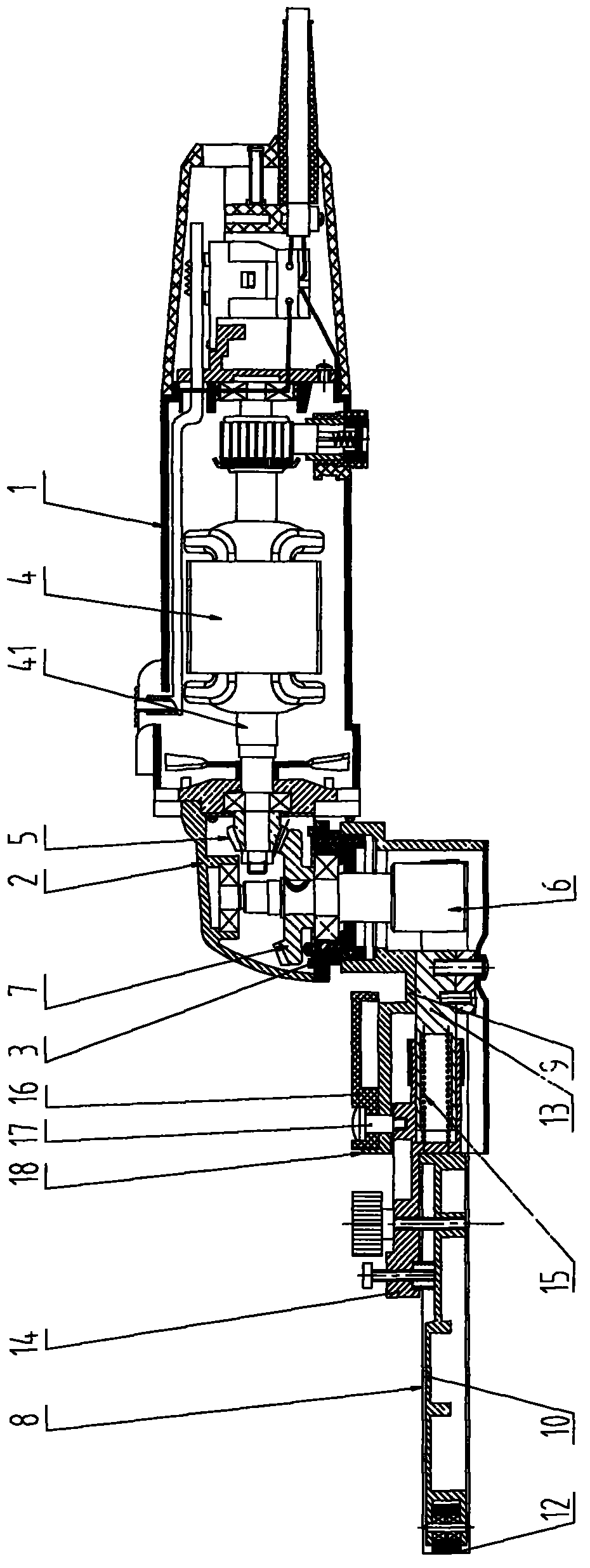

Hand-held electric belt sander

The invention provides a hand-held electric belt sander, which comprises a machine body part and a sanding belt installing part, wherein the machine body part comprises a machine case, a head case and a head case cover, the head case cover is provided with a first round connecting opening, two projected and mutually separated leaf springs are fixedly arranged on the outer circumferential wall of the first round connecting opening, the sanding belt installing part comprises a sanding belt, an installing support frame and a regulating rod, the regulating rod is arranged on the installing support frame, the installing support frame is provided with a second round connecting opening, the first round connecting opening is rotatablely inserted and connected into the second round connecting opening, in addition, the inner wall of the second round connecting opening is provided with a groove, when the installing support frame rotates relative to the head case cover, the two leaf springs can alternately fall into the groove, the installing support frame and the head case cover can be fixedly connected through a locking screw, and the sanding belt is arranged on the regulating rod and an output shaft. The sanding belt installing part of the hand-held electric belt sander can realize the rotating regulation relative to the machine body part, the sanding operation in a narrow work region is convenient, and in addition, the sanding on the groove and the inner hole can be conveniently realized.

Owner:宁波国图电机有限公司

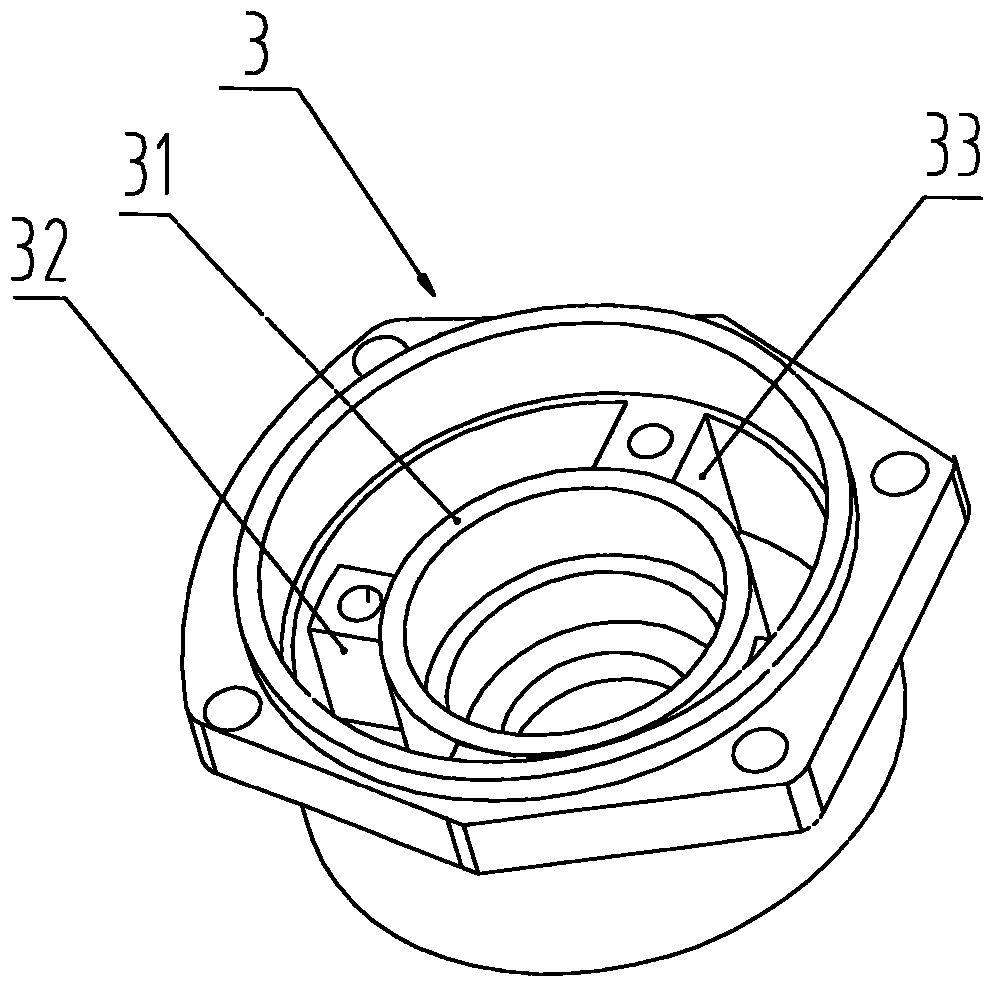

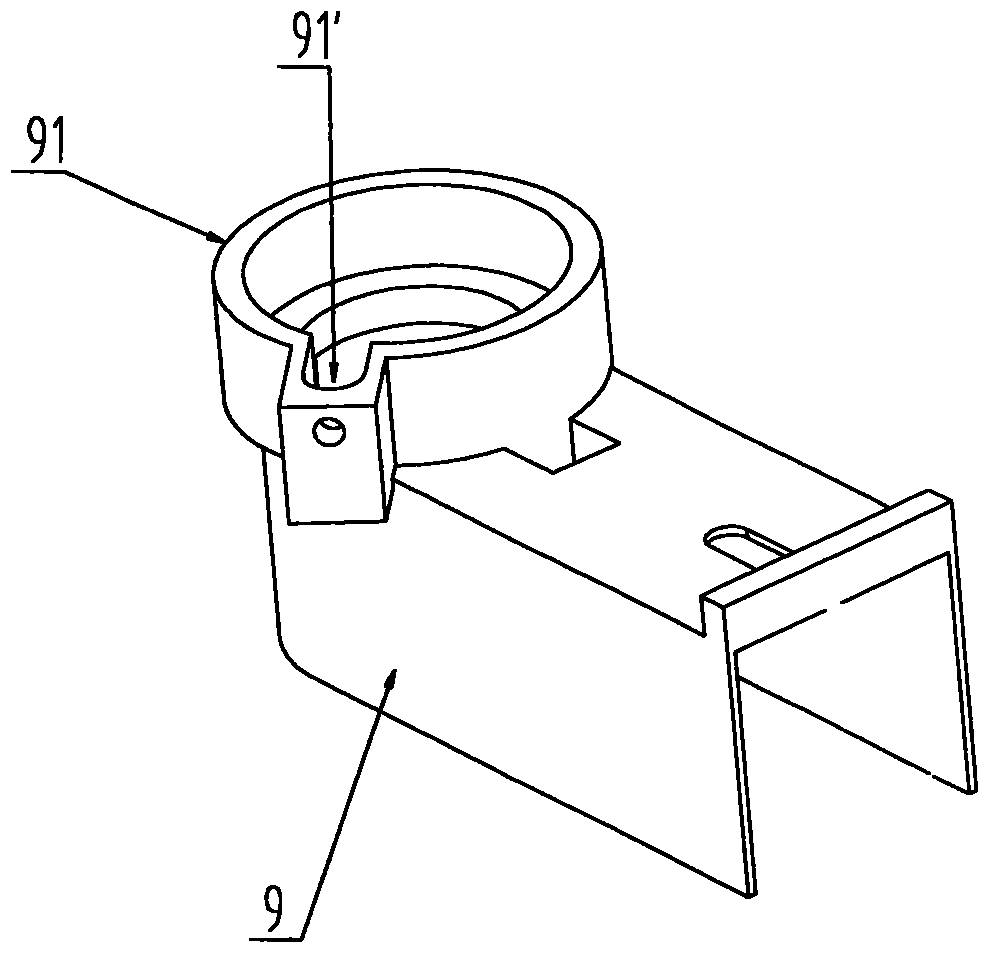

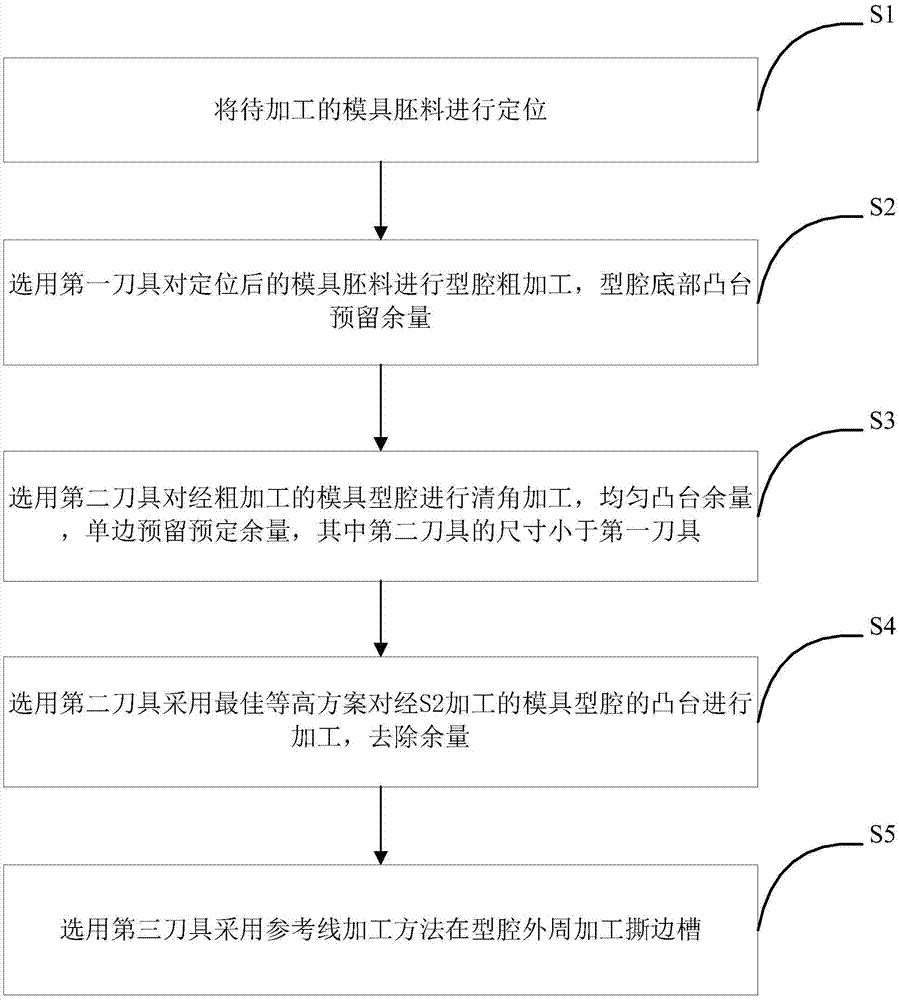

Machining process for sealing ring mold

The invention discloses a machining process for a sealing ring mold. In the machining course, firstly, a large cutter is adopted for rough machining a mold cavity; then a small cutter is selected and used, and a plurality of balances are cleared away through clearance angle machining to make the balances on a boss even; and finally a small cutter is selected and used, a best equal-height scheme is adopted for overall machining in place started from the middle, the bottom size is ensured, and cutter lapping defects are reduced; in addition, a torn edge groove is machined through a layering machining method, so that a machined single side of the torn edge groove is avoided, and the quality and precision of the torn edge groove are improved. The optimally designed machining process for the sealing ring mold is simple in process and reasonable in design. After overall machining is adopted for the boss at the bottom of the cavity, the cutter lapping defects in the cavity are lifted, so that sanding is convenient, and the work efficiency is improved. The machining precision of the mold is greatly improved, and scrapping of the mold is avoided.

Owner:安徽宁国中鼎模具制造有限公司

Porous superfine denier polyester pre-oriented yarn and preparation method thereof

InactiveCN103114344AMany holesSmall fineness of monofilamentFilament/thread formingMonocomponent polyesters artificial filamentFiberYarn

The invention relates to a porous superfine denier polyester pre-oriented yarn and a preparation method of the porous superfine denier polyester pre-oriented yarn. Terephthalic acid and ethylene glycol are adopted to be used as raw materials of polyester, and the existing production equipment of pre-oriented yarn (POY) is adopted. The main technological parameter of the porous superfine denier polyester pre-oriented yarn is: the diameter of spinneret plate microporous is 0.10-0.15 millimeter, the height of a slow cooling area is 80-150 millimeters, and the slow cooling area is combined with ring windchill; two nozzle oiling systems and reasonable winding tension and speed are adopted, the porous superfine denier polyester pre-oriented yarn which is 44-55 dtex / 192f is obtained, and the filament number of the porous superfine denier polyester pre-oriented yarn is 0.23-0.29 dtex. The porous superfine denier polyester pre-oriented yarn has the advantages of being plural in pore number, small in filament number, low in absolute intensity, small in bending rigidity, large in specific surface area and voidage, soft, light in weight and the like. Moreover, the porous superfine denier polyester pre-oriented yarn further has the advantages that filament aggregation has a good capillary core absorption effect and a better ventilation wet guiding function, added value is high, quality is good, production cost is low, the advantage of cost performance is obvious and application prospect is broad.

Owner:ZHONGRUN SCI & TECH

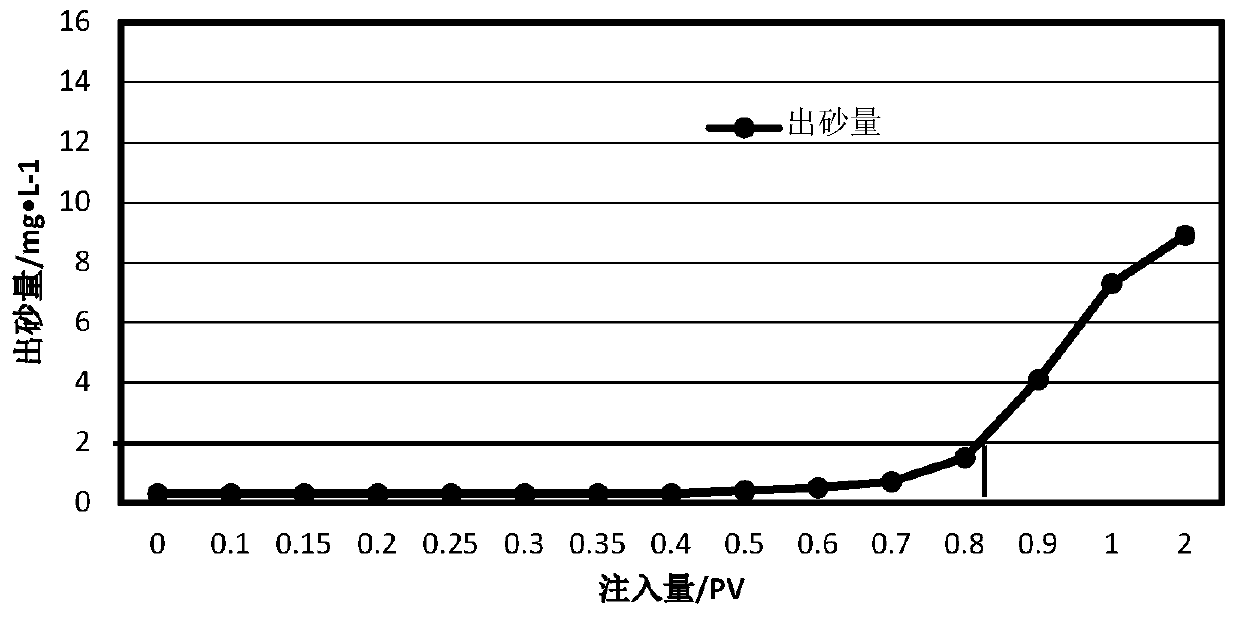

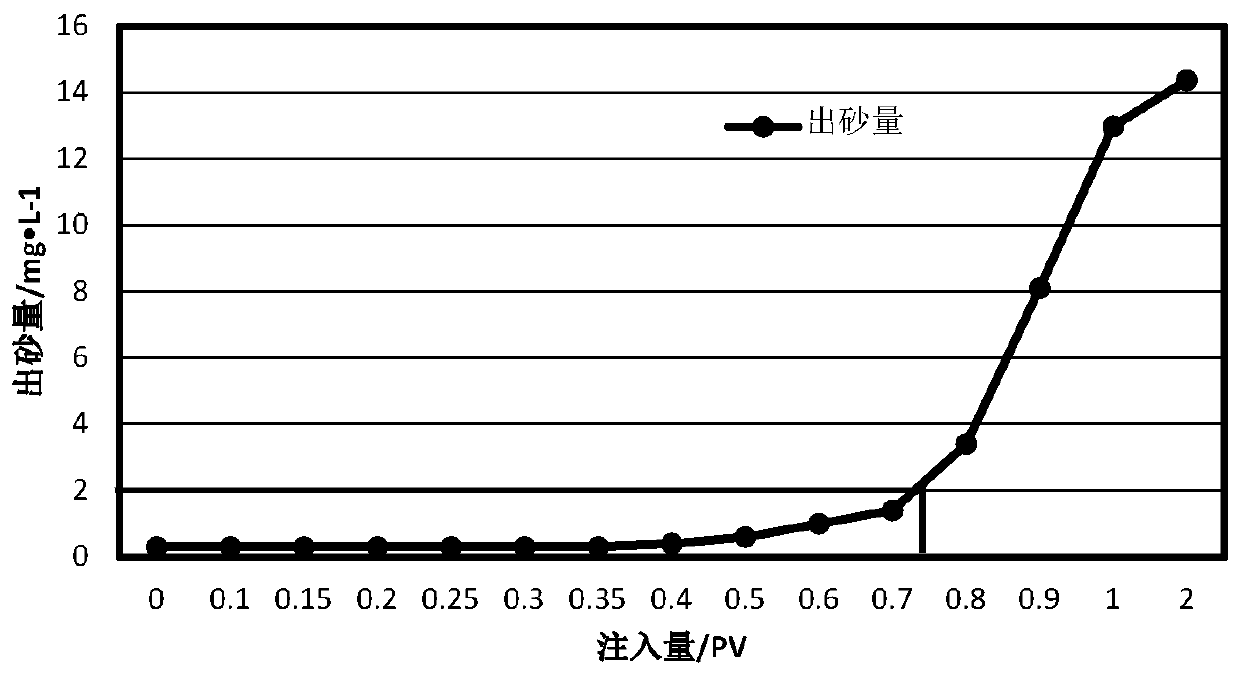

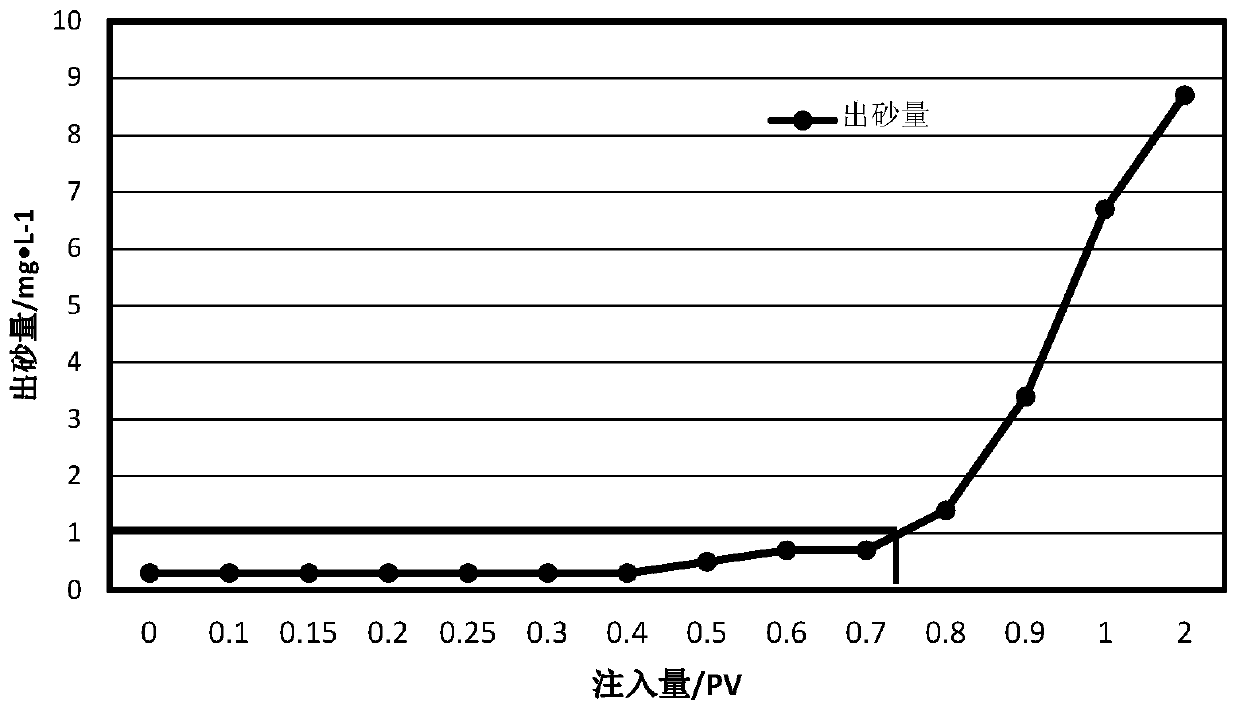

Microbial in-situ sand consolidation method for loose sandstone reservoir

The invention belongs to the technical field of microbial oil recovery, and in particular relates to a microbial in-situ sand consolidation method for a loose sandstone reservoir. The method comprisesthe following steps: screening a test block; preliminarily determining sand consolidation functional microorganisms and nutrients thereof; preliminarily determining sand consolidation functional microorganisms and nutrients thereof; preliminarily determining sand consolidation functional microorganisms and the injection amount of nutrients thereof; determining sand consolidation functional microorganisms and the injection amount of nutrients thereof; determining sand consolidation functional microorganisms and the injection rate of nutrients thereof; and carrying out on-site implementation and effect evaluation. The microbial in-situ sand consolidation method has the advantages of being reasonable, simple in process, easy to operate, safe and reliable, few in input and low in cost. Meanwhile, the sand production rate of the loose sandstone reservoir can be reduced effectively, the period of validity is prolonged and the liquid production capacity is improved, the sand production rateof an oil well is reduced by over 95%, the period of validity is over 3 years, and meanwhile, the liquid production capacity of the block is improved by over 100%. Therefore, the microbial in-situ sand consolidation method has a wide on-site application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite multifunctional chemical unblocking agent

InactiveCN1205299CImprove the blocking effectPossesses insoluble scale transformation abilityDrilling accessories

The invention relates to a composite multifunctional chemical plugging agent, which is composed of an organic multifunctional plugging agent, an inorganic multifunctional plugging agent and a composite synergist. The main components include carbon 7-10 aromatic hydrocarbon organic solvents, polyoxyethylene ether surfactants, oil-soluble water-dispersed polyether demulsifiers, T penetrants, polyether wetting agents, mutual solvents, and insoluble scale conversion agents , organic / inorganic compound acid, cationic polymer clay stabilizer, water-soluble polyether demulsifier, iron ion stabilizer, polyether wetting improver, dissolution aid, slow corrosion inhibitor, cationic polymer Sand stabilizer, etc. Inject 50-100% aqueous solution of organic multi-functional plugging remover, 5-35% aqueous solution of inorganic multi-functional plugging remover, and 25-35% aqueous solution of composite synergist into oil-water wells according to the usual method of using plugging remover, To play their respective effects and synergistic effect, the retarding effect of the plugging agent is excellent, which is 10 times that of conventional earth acid.

Owner:CHINA NAT OFFSHORE OIL CORP +1

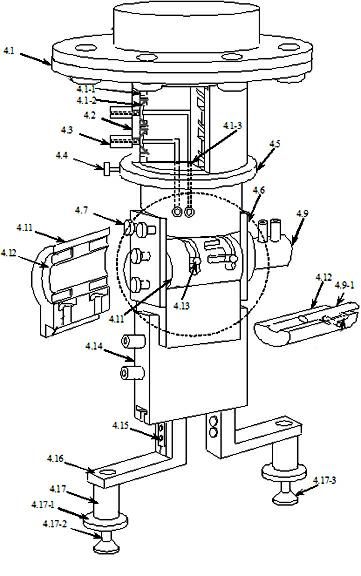

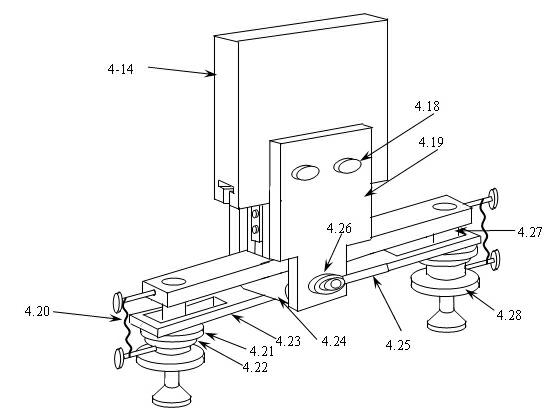

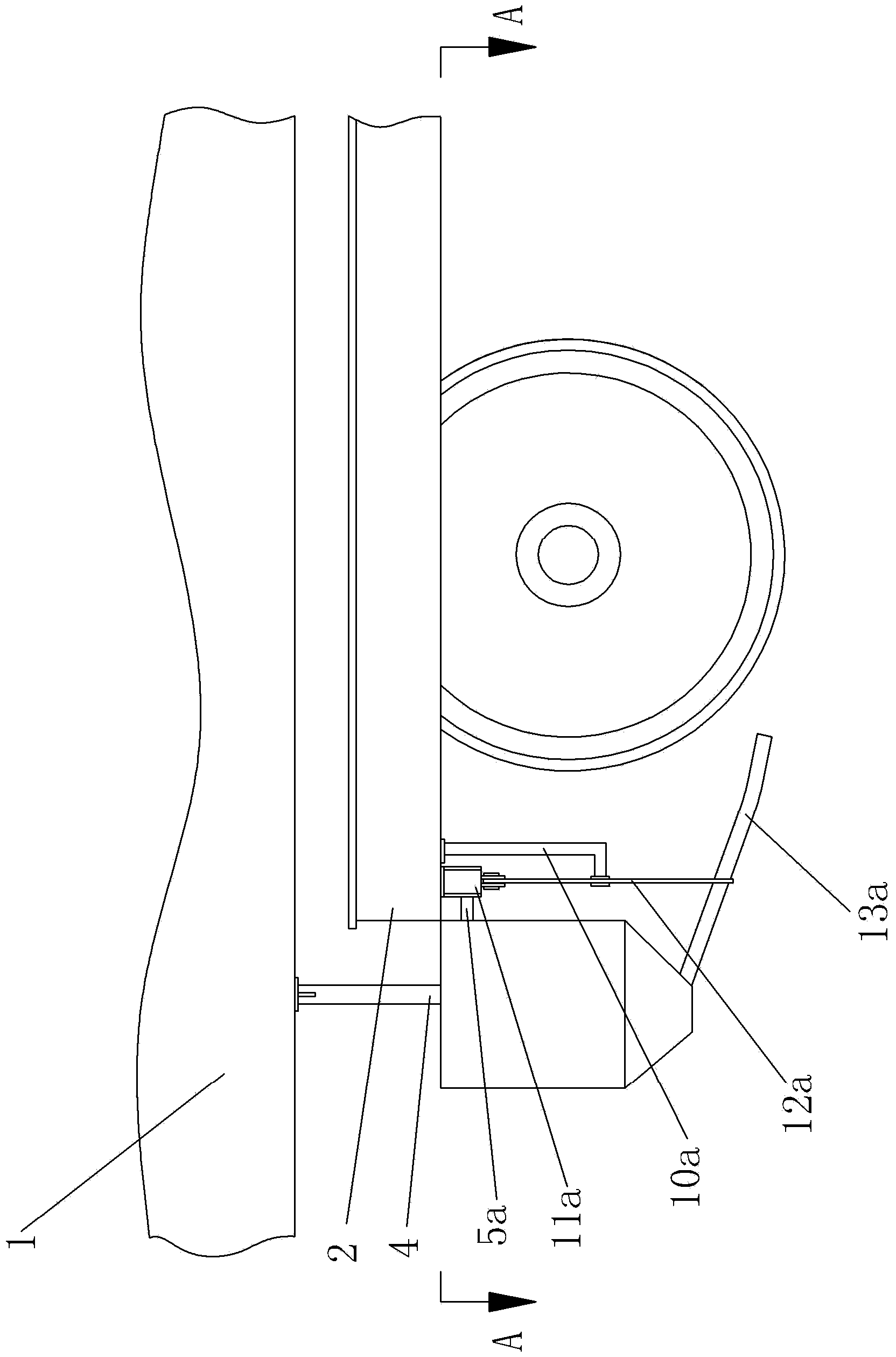

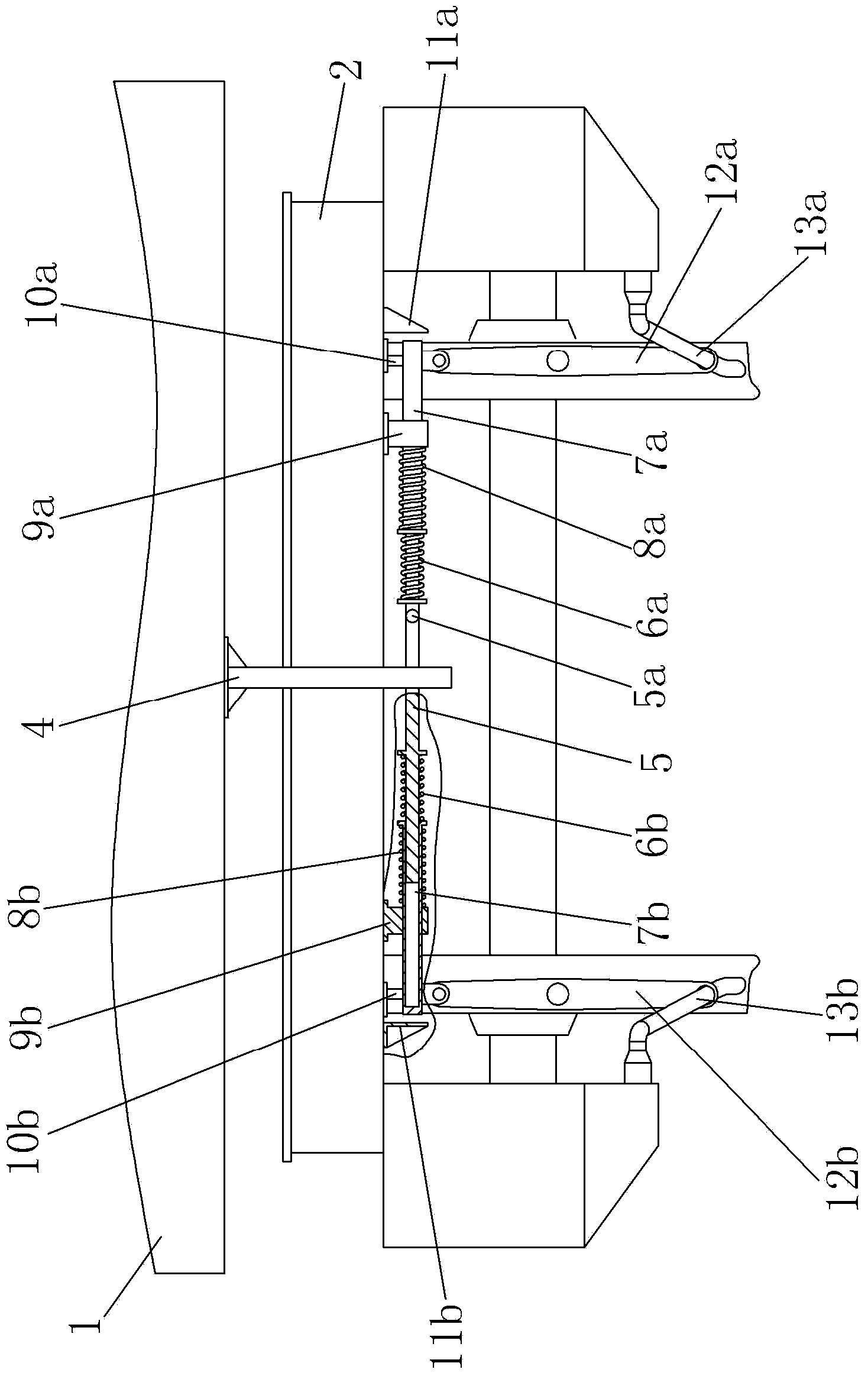

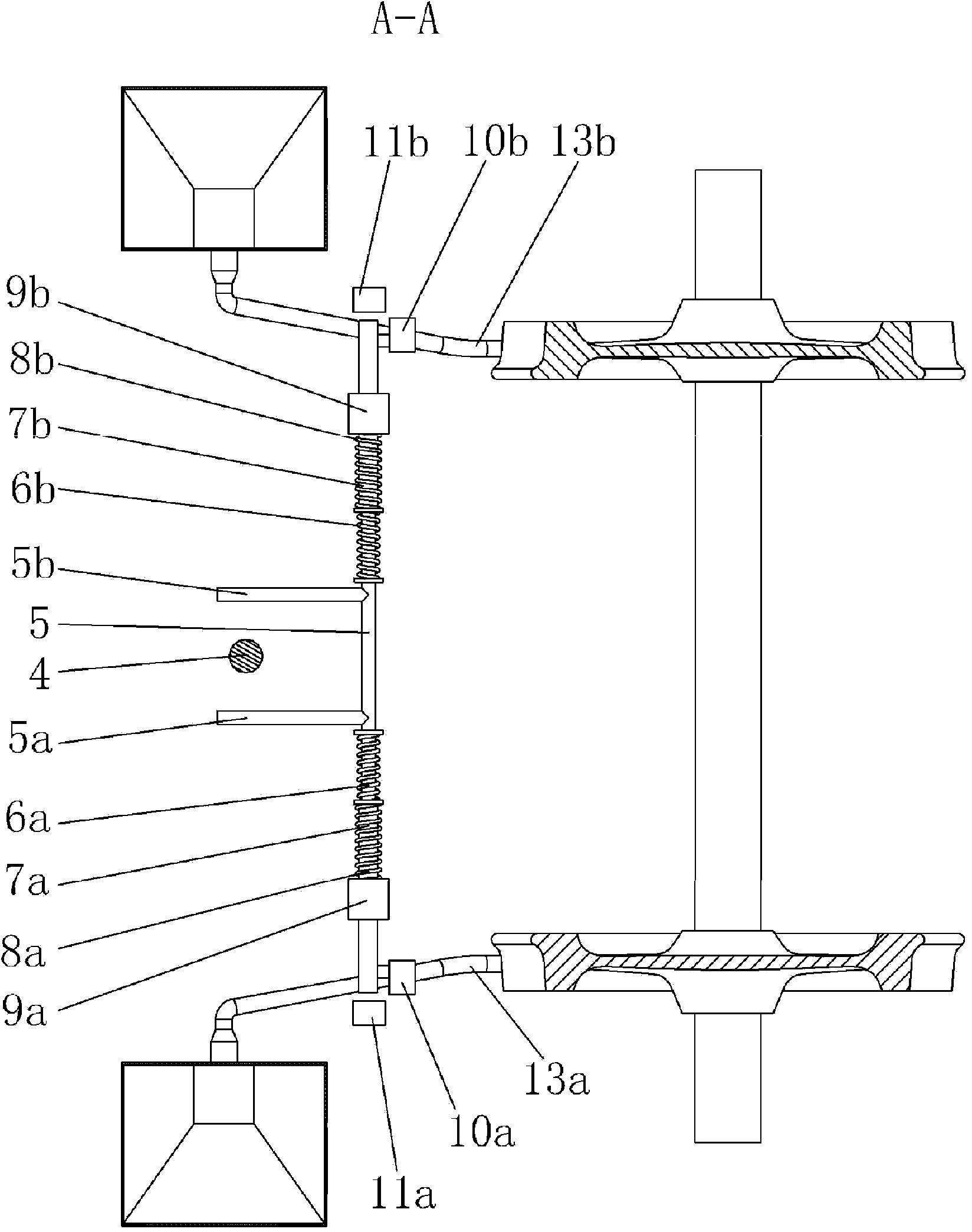

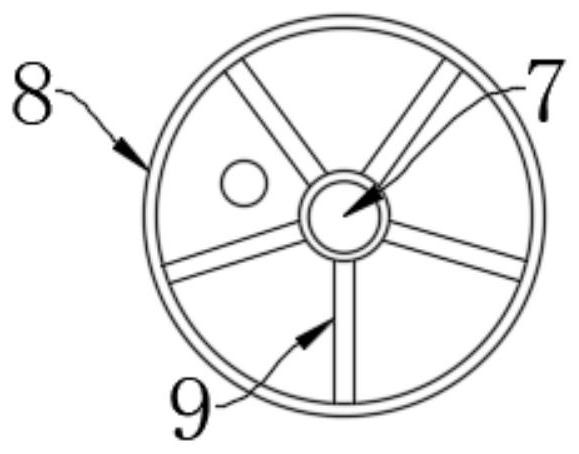

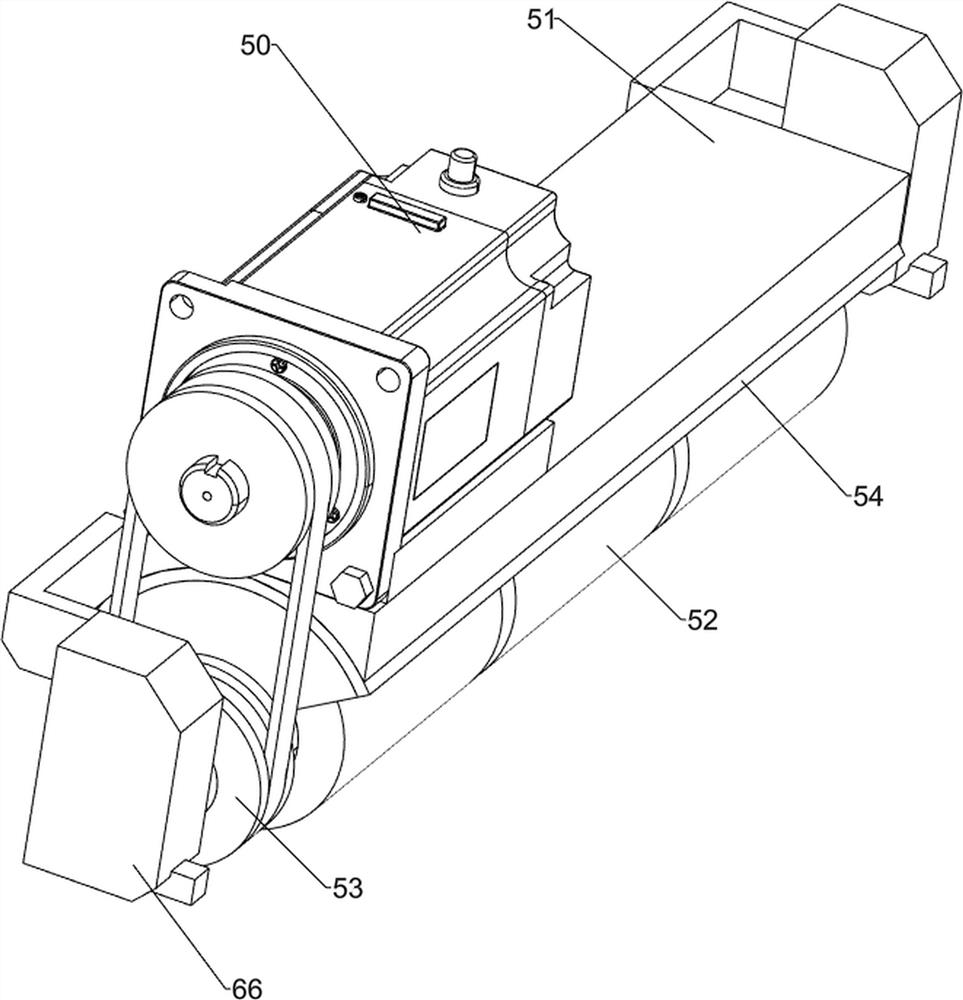

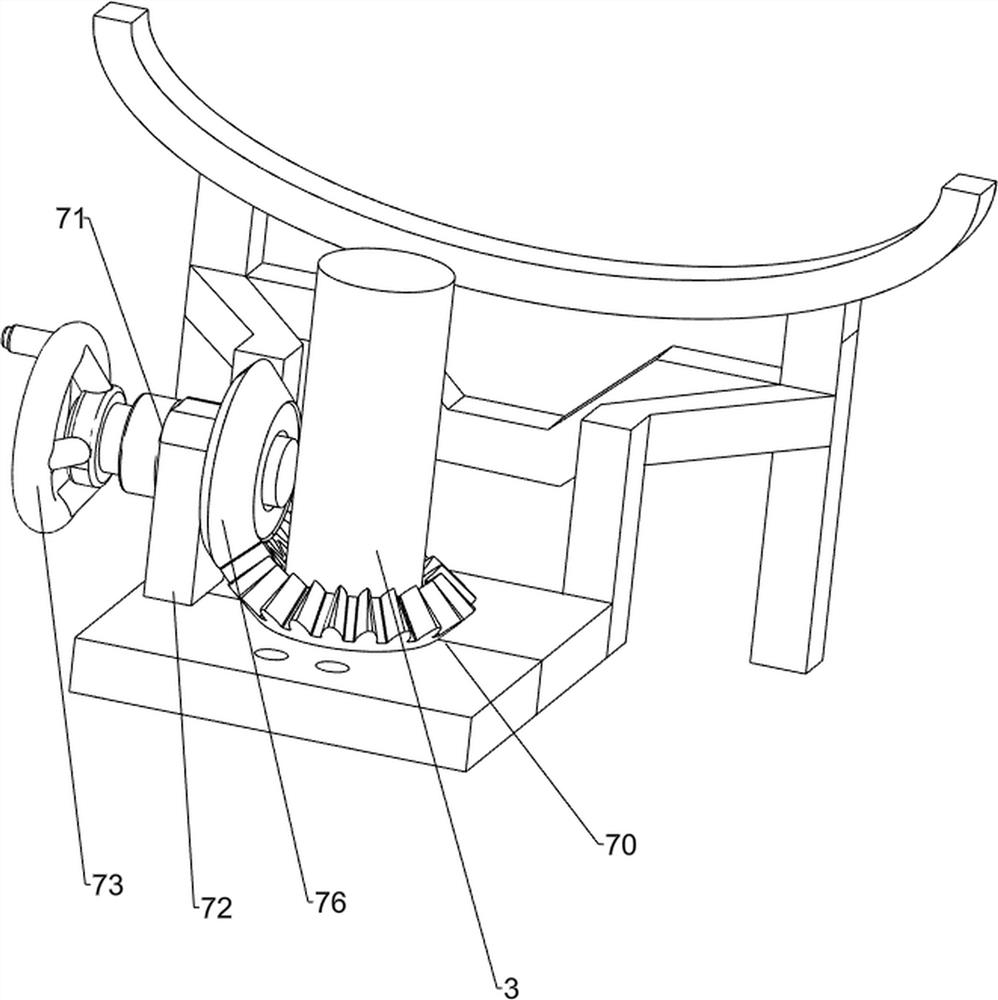

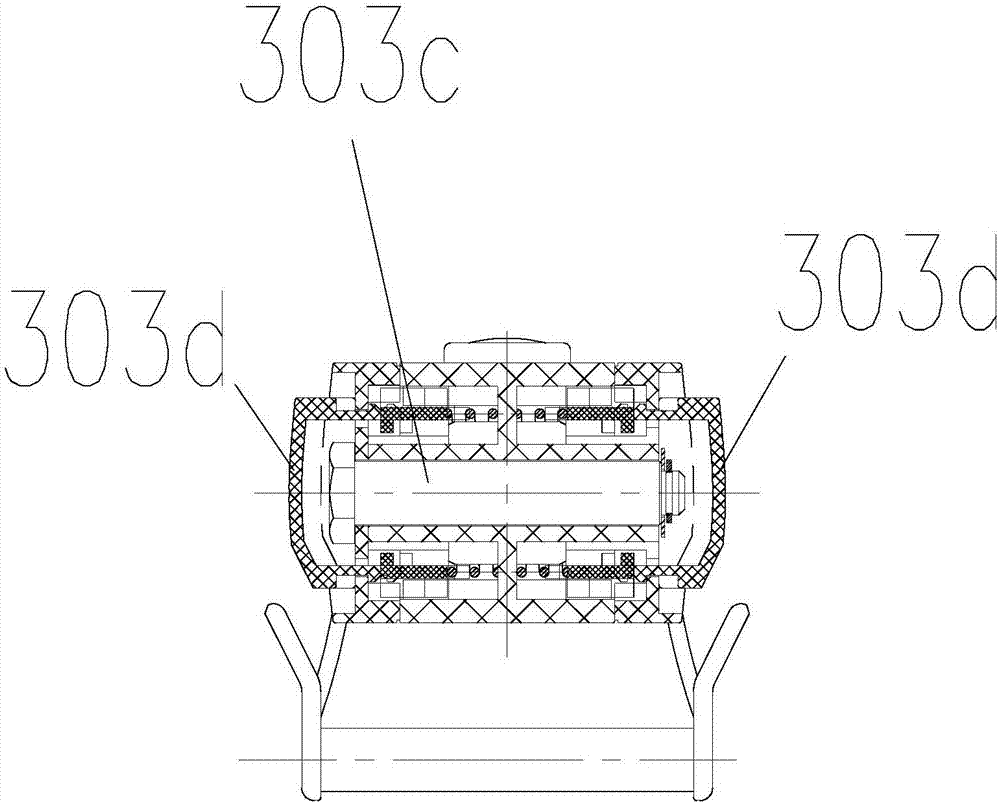

Through-curve anti-deflection mechanism for sanding device at end part of locomotive car body

Owner:SOUTHWEST JIAOTONG UNIV

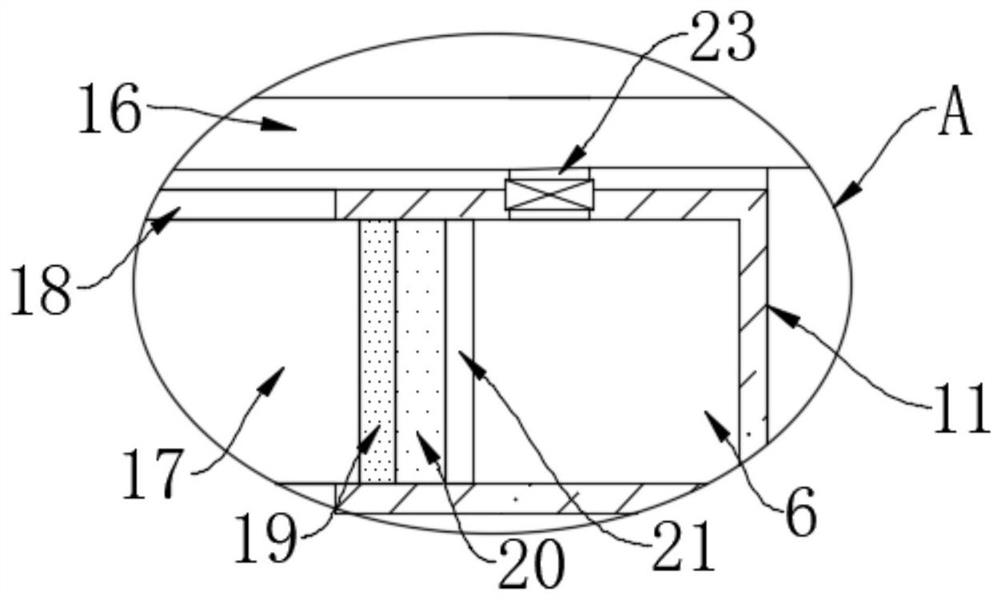

UV paint wood floor coating technology capable of imitating reinforced plate style

InactiveCN106914394AStrong covering powerHigh whitenessPretreated surfacesSpecial surfacesCoating systemUltraviolet

The invention discloses a UV paint wood floor coating technology capable of imitating the reinforced plate style. The technology comprises the steps that grinding treatment is conducted on a plain panel of a floor, and dust is removed; the floor is coated with white waterborne primer paint in a roller coating mode with the coating amount of 15-20 g / m<2> and treated with a roughening brush and passes through an infrared drying channel; the floor is coated with a waterborne UV coloring agent in a roller coating mode for coloring with the coating amount of 10-20 g / m<2> and treated with the roughening brush, passes through the infrared drying channel and ultraviolet lamps and is placed to be air-dried; the floor is coated with waterborne glaze in a roller coating mode with the coating amount of 10-20 g / m<2> and manually brushed off and passes through the infrared drying channel; the UV paint coating technology is completed through a UV paint coating system. Accordingly, a wood floor produced through the technology is high in color decorous feeling and good in stereoscopic sensation; compared with an existing UV waterborne coloring technology for the wood floor, the technology is suitable for the coating style of wood floors exported to Europe, advantages on treatment of some low-level wood floor materials are achieved, and the usage rate of the wood floors can be increased.

Owner:JIANGSU HIMONIA TECH

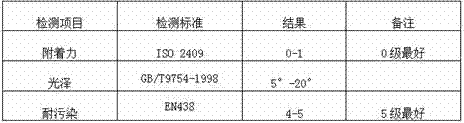

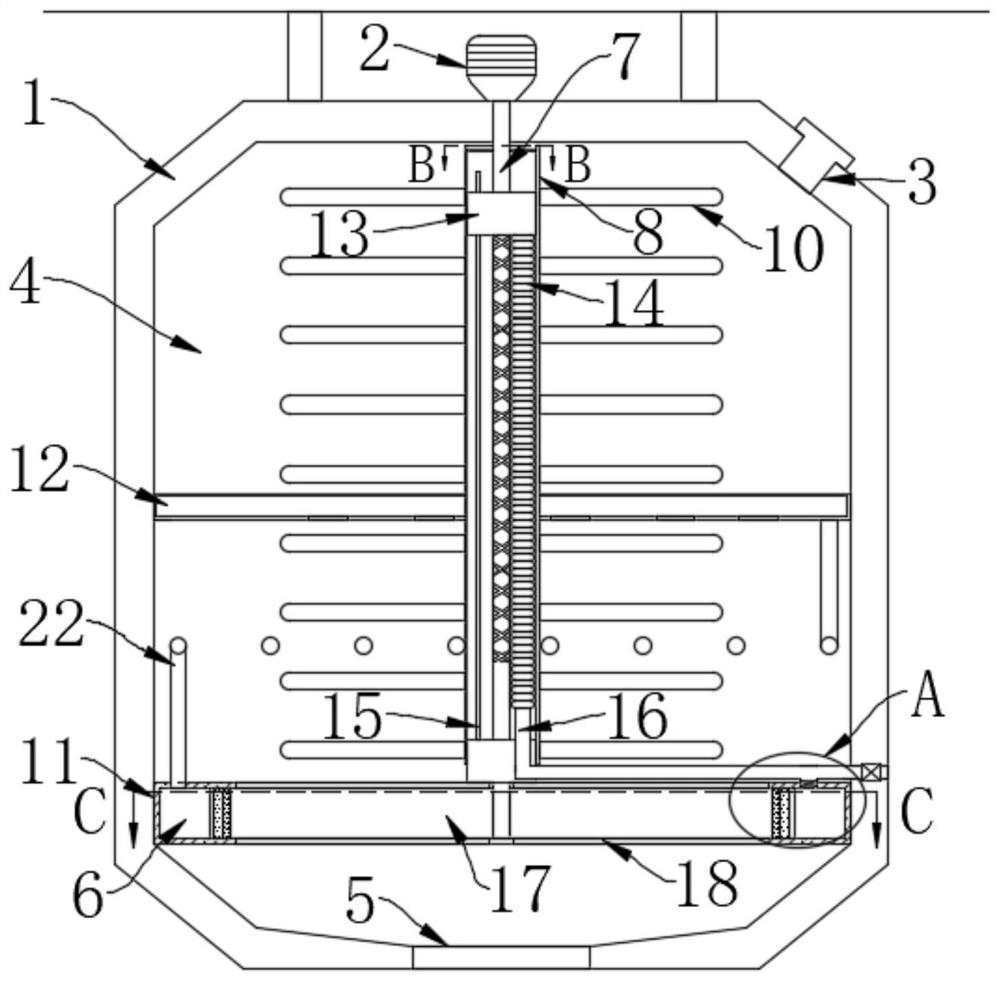

Heating type gravel scattering equipment for urban rail transit

PendingCN112092837ANot easy to solidifySanding easilyAir heatersLocomotivesElectric machineryRail transit

Heating type gravel scattering equipment for urban rail transit comprises a shell and a stirring mechanism. The upper end of the shell is fixedly connected with a vehicle through a plurality of vertical rods, a treatment chamber is formed in the shell, and gravel is arranged in the treatment chamber; and the stirring mechanism comprises a connecting pipe arranged in the treatment chamber, a rotating rod is arranged in the connecting pipe, the rotating rod is fixedly connected with the inner wall of the connecting pipe through a plurality of connecting rods, the upper end of the rotating rod isrotatably connected with the inner top of the treatment chamber, and a motor is mounted at the upper end of the shell. When the equipment is in use, gravel can be stirred, gravel can be discharged intermittently, use of the gravel is saved, the gravel can be heated in the stirring process, and the situation that the gravel is affected with damp, solidified and hardened, so that the sand discharging efficiency is affected is avoided.

Owner:霍伸伸

Elastic thermal insulation exterior wall putty

InactiveCN103351697AImprove insulation effectImprove energy efficiencyFilling pastesEmulsionWeather resistance

The invention discloses elastic thermal insulation exterior wall putty. The exterior wall putty is prepared from the following components in parts by weight: 12-14 parts of elastic pure acrylic emulsion, 16-18 parts of elastic silicone-acrylate emulsion, 1-2 parts of sodium hexametaphosphate, 3-5 parts of polyacrylonitrile fiber, 0.5-1.5 parts of defoaming agent, 0.4-0.8 part of anti-mildew agent, 1-2 parts of hydroxymethyl cellulose, 0.6-1 part of ethylene glycol, 10-12 parts of attapulgite, 6-8 parts of sepiolite powder, 16-20 parts of -320-mesh coarse whiting powder, 6-8 parts of hollow glass microspheres and 18-22 parts of water. In the invention, the putty has favorable thermal insulation performance and excellent properties such as permeation prevention, weather resistance, water resistance and the like so as to be capable of meeting the requirement for exterior wall decoration.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

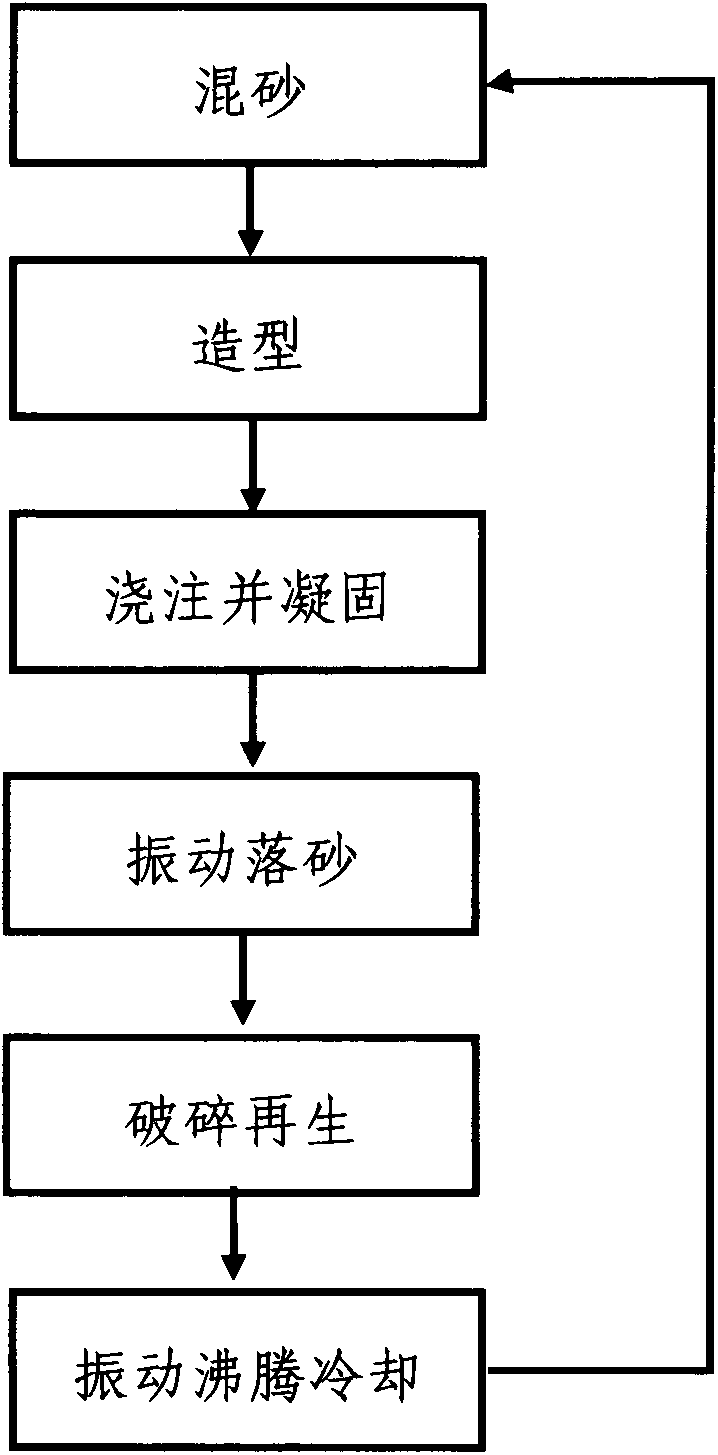

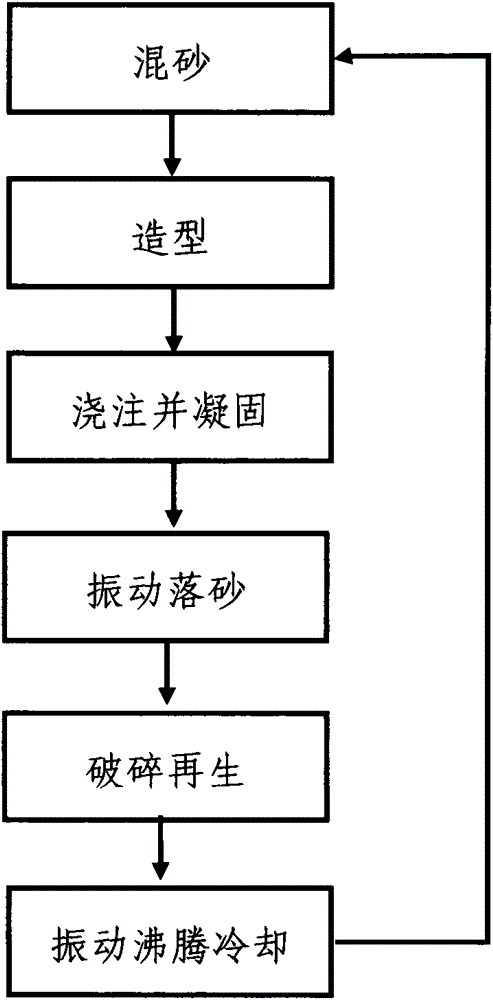

Glass bottle die casting piece manufacturing process cyclically using molding sand

ActiveCN103817287AHigh strengthImprove impact resistanceFoundry mouldsMould handling/dressing devicesDie castingBreakage rate

The invention discloses a glass bottle die casting piece manufacturing process cyclically using molding sand. According to the invention, a manufactured glass bottle die casting piece has an accurate size and no subcutaneous blowholes; sand discharging of castings is convenient after molding, used sand can be regenerated and reused and has a low breakage rate and small loss in the process of regeneration of the used sand, and the reuse rate of the used sand is high; the process produces little dust, little pollution and no phenol and formaldehyde.

Owner:CHANGSHU WEIHENG MOLD MFG

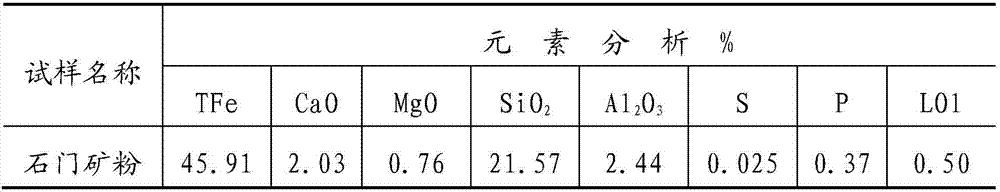

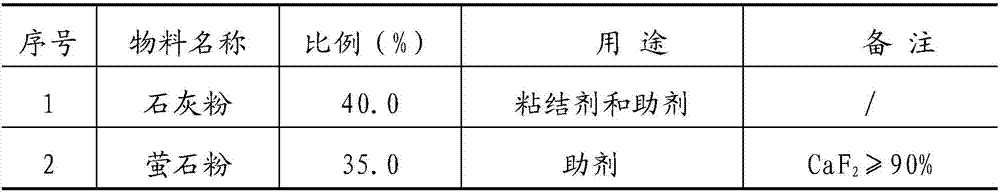

Method for directly reducing hot-pressing forging and rolling part/mechanical part product by utilizing powdery iron mine

The invention belongs to the field of black metal metallurgy, and particularly relates to a method for directly reducing a hot-pressing forging and rolling part / mechanical part product by utilizing powdery iron mine. A majority of cast iron and blanks of cast steel mechanical parts can be replaced by a product prepared by the invention, and steel rolling materials such as forging materials or steel billets, steel ingots, and plate blanks are produced by adopting the method disclosed by the invention instead of a smelting steel-making method, and chemical metal iron powder can be co-produced. 95 to 98 percent of high-quality particle iron metal iron powder of TFe can be added with a part of alloy powder or non-metal powder, so that higher-end anti-corrosion, wear-resistant, high-temperature resistant and high-strength special steel part products or composite materials are subjected to hot-pressing forging. According to the method disclosed by the invention, a conventional method for fusing and smelting steel iron and fusing and casting and a technological process internationally can be overturned, and a new method for preparing solid-solid state smelting steel iron and mechanical parts with wide sources of raw materials, simple process, simple operation, low cost, energy conservation, environmental protection and circular economy and co-producing chemical engineering metal iron powder is created, and a new milestone for steel iron smelting and casting field is put up internationally.

Owner:山东省红森林新材料科技有限公司

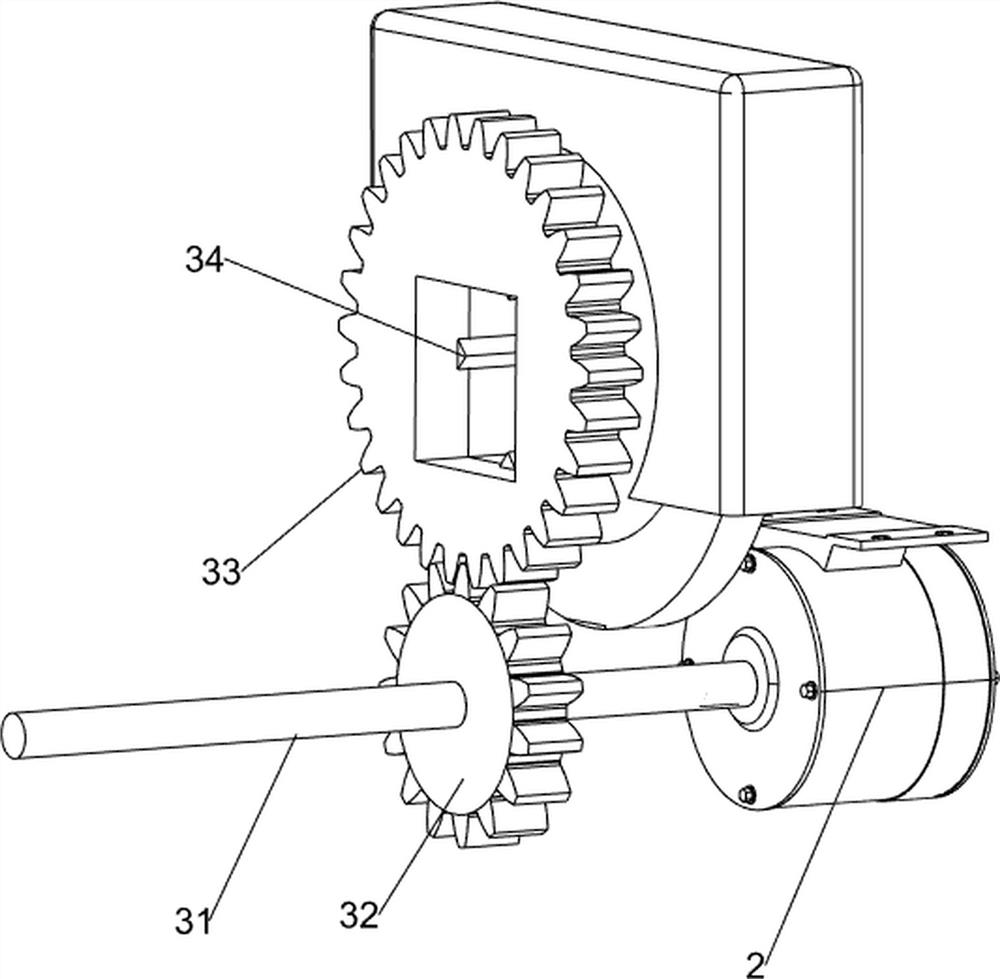

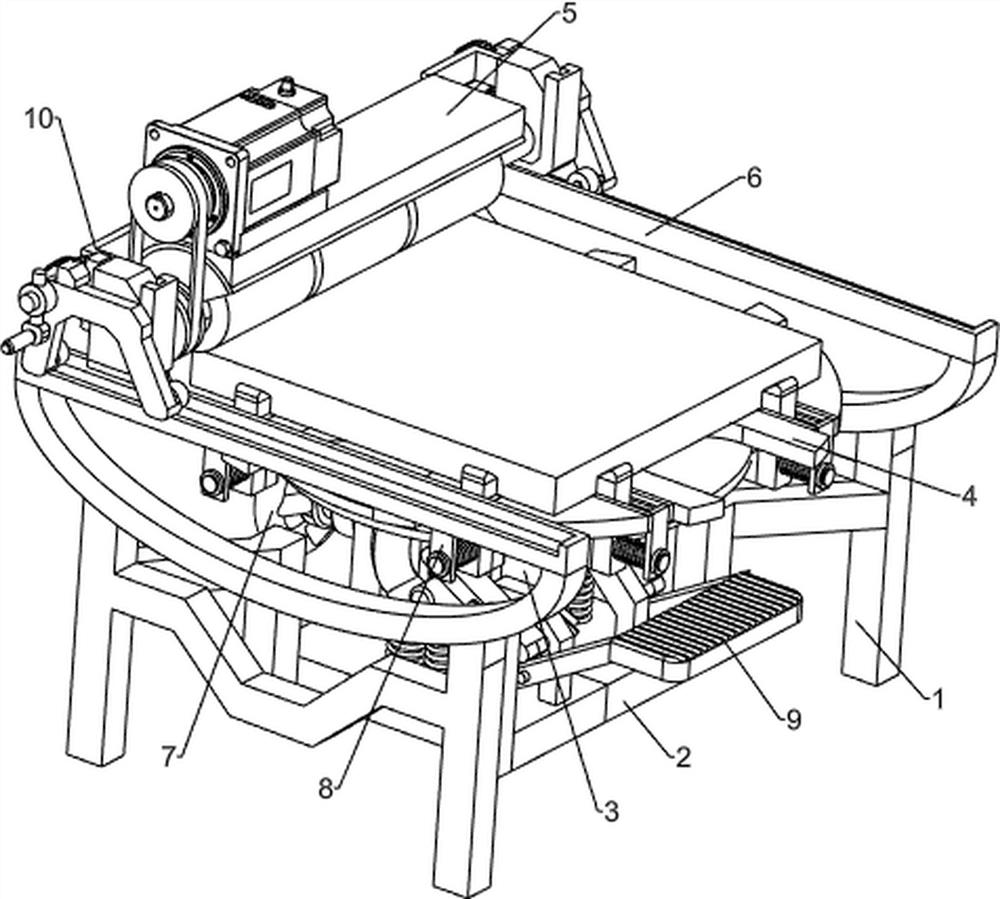

Strip-shaped wood block grinding equipment

PendingCN112643482AImprove securitySanding easilyGrinding machinesGrinding feedersElectric machineryWood plank

The invention relates to grinding equipment, in particular to strip-shaped wood block grinding equipment. The strip-shaped wood block grinding equipment is high in safety and efficiency. The strip-shaped wood block grinding equipment comprises a table, a motor, a first bearing seat, second bearing seats, a grinding mechanism and the like, wherein the motor is installed on the lower side of the rear portion of the table, the first bearing seat is arranged on the rear side of the upper middle portion of the table, the two second bearing seats are arranged on the right side of the table, the grinding mechanism is arranged on the rear side of the upper middle portion of the table and connected with an output shaft of the motor, and a pushing mechanism is arranged in the middle of the upper portion of the t able and connected with the output shaft of the motor. By means of the design of the pushing mechanism, wood boards can be automatically pushed into a grinding tool, people do not need to manually push wood blocks into the grinding tool, and people can grind the wood blocks more safely; and by means of the design of a feeding mechanism, multiple wood blocks can be ground, and people do not need to manually push the wood blocks one by one.

Owner:陈冬梅

UV-curable sanding primer

InactiveCN105315734AGood dispersionIncrease filling volumeAnti-corrosive paintsPerformance indexN-Butanol

The invention discloses UV-curable sanding primer which is characterized by comprising the following raw materials by weight: 60 to 65 percent of bisphenol A-type epoxy resin E-42, 2 to 3 percent of benzophenone, 20 to 30 percent of TPGDA, 10 to 15 percent of n-butanol, 2 to 3 percent of modified carborundum, 1 to 2 percent of nano SiO2, 0.5 to 0.8 percent of one or more antifoaming agents, and 0.4 to 0.6 percent of one or more dispersing agents. The UV-curable sanding primer has the advantages that as the volatility and the odor are low, the environmental pollution is low; the hardness is relatively high, the sanding property is excellent, the UV-curable sanding primer is easy to sand, and the filling capability reaches a certain extent; the curing speed is fast, and the production efficiency is high; being cured at ordinary temperature, the primer is suitable for various base materials; energy is saved, that is, the energy consumption is about 1 / 5 of that of the conventional coating; the performance indexes, of a coating made of the primer, in all aspects, such as wear resistance, acid and alkali resistance, salt spray resistance and gasoline resistance, of an organic solvent are all very high, and particularly, a paint film made of the primer is plump and outstanding in luster.

Owner:WUHU HONGKUN AUTO PARTS

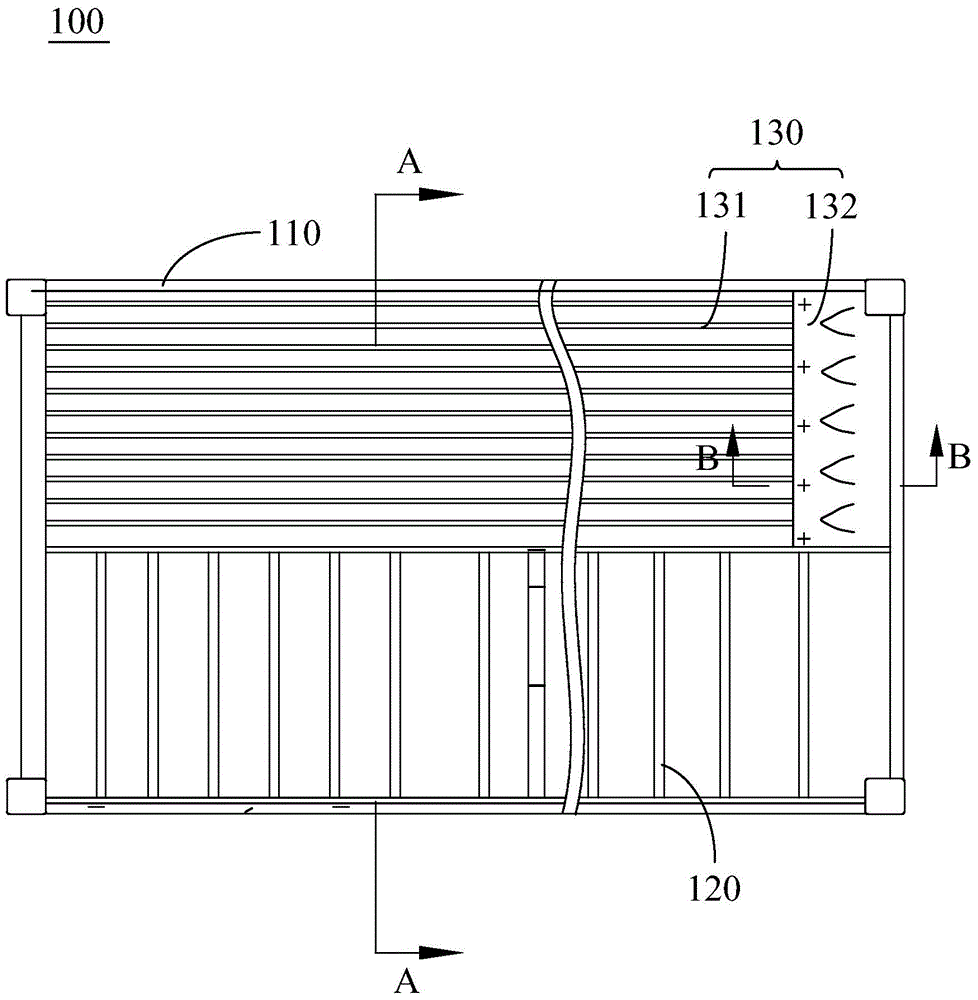

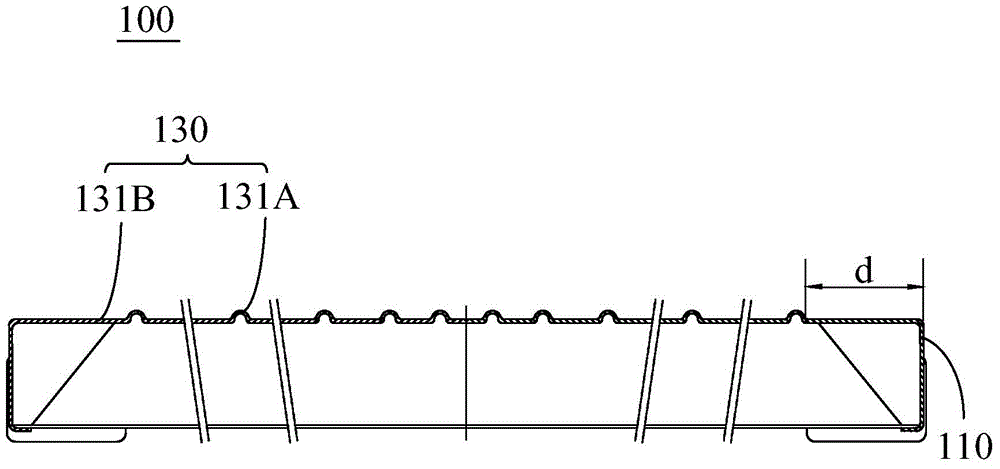

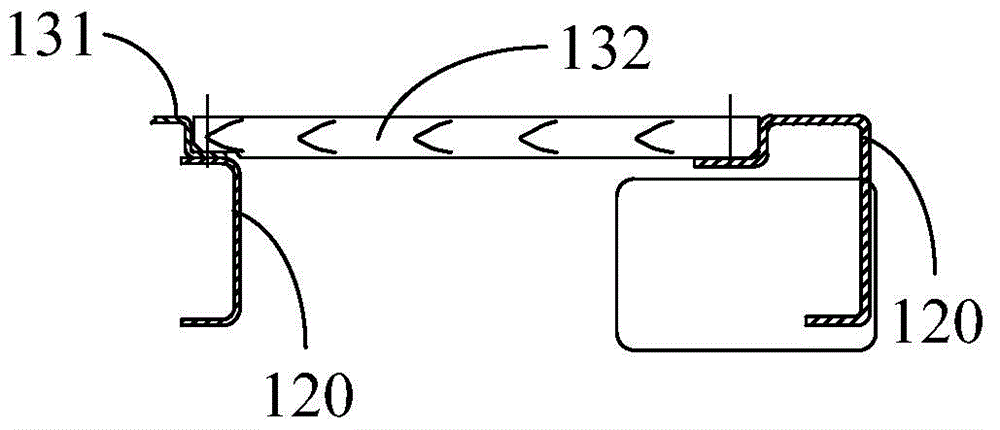

Container

Owner:CIMC CONTAINERS HLDG +1

Manufacturing process of glass bottle mold castings with recyclable molding sand

ActiveCN103817287BHigh strengthImprove impact resistanceFoundry mouldsMould handling/dressing devicesDie castingBreakage rate

The invention discloses a glass bottle die casting piece manufacturing process cyclically using molding sand. According to the invention, a manufactured glass bottle die casting piece has an accurate size and no subcutaneous blowholes; sand discharging of castings is convenient after molding, used sand can be regenerated and reused and has a low breakage rate and small loss in the process of regeneration of the used sand, and the reuse rate of the used sand is high; the process produces little dust, little pollution and no phenol and formaldehyde.

Owner:CHANGSHU WEIHENG MOLD MFG

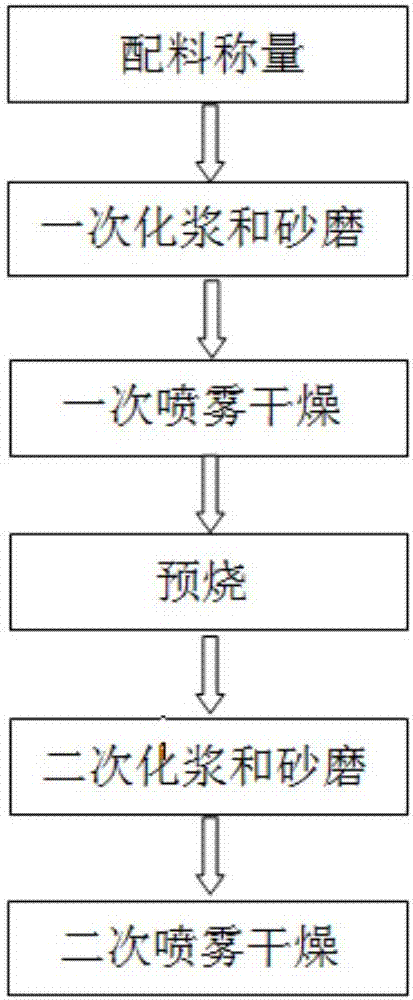

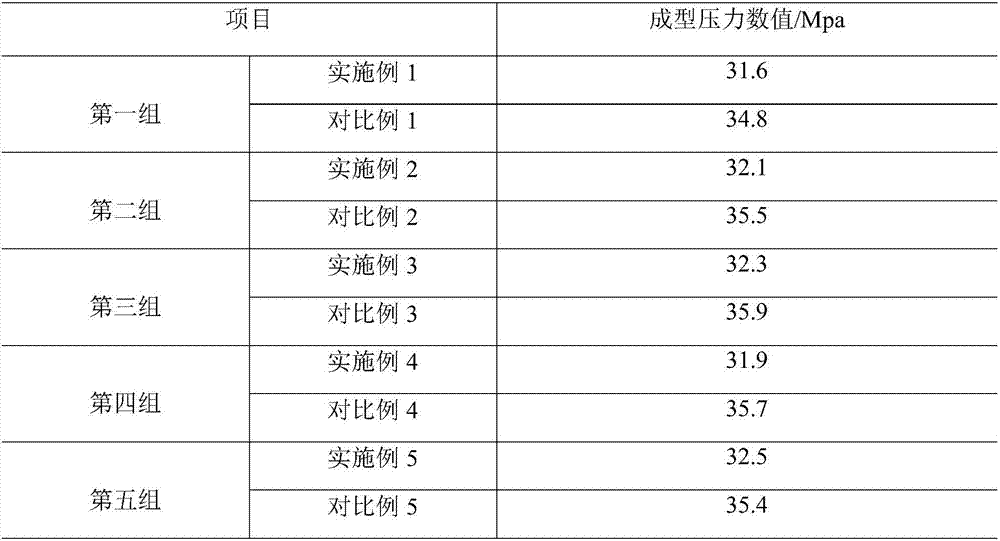

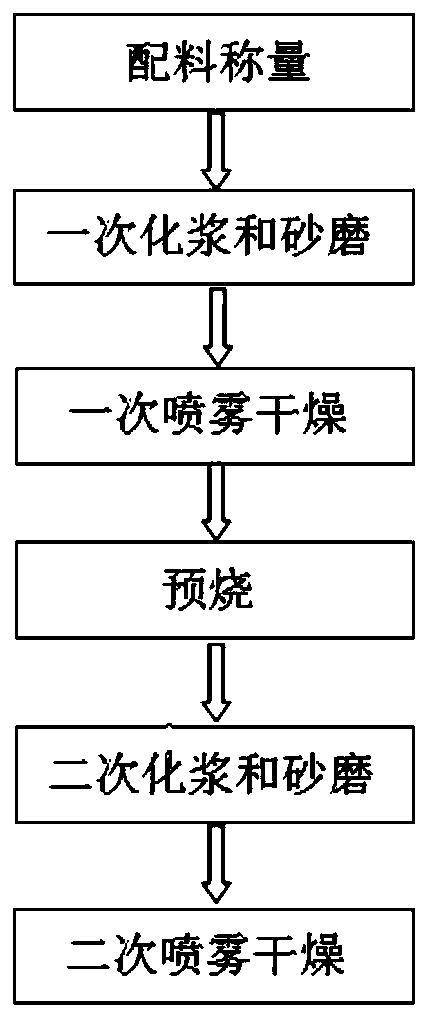

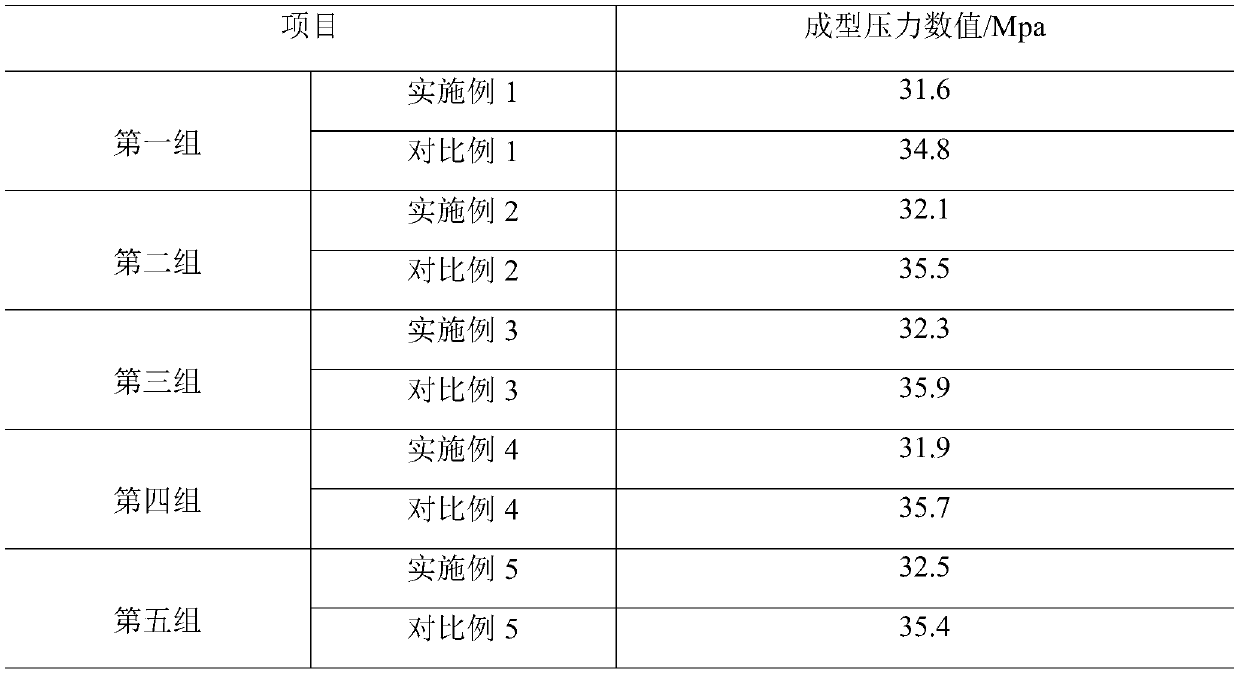

Automatic production process for soft magnetic manganese zinc ferrite granules

ActiveCN107129290AIncrease the pressing densityExtended service lifeInorganic material magnetismMagnetic corePlasticizer

The invention discloses an automatic production process for soft magnetic manganese zinc ferrite granules and belongs to the technical field of production of soft magnetic manganese zinc ferrite granules. The process comprises the following steps: batch weighing, primary pulping and grinding, primary spray-drying, pre-sintering, secondary pulping and grinding and secondary spray-drying, adding a plasticizer before secondary spray-drying, uniformly stirring and mixing, and performing spray-drying, wherein the plasticizer refers to a phthalic ester plasticizer. With the adoption of the phthalic ester plasticizer, on one hand, the plasticity of the powder is enhanced, plastic deformation (crushing) of powdered granules is easily caused, and the pressed density of a magnetic core is improved. Under the same strength condition of the magnetic core, the molding pressure of the granules can be reduced from 34-36Mpa to 31-33Mpa, the wear rate of a press is reduced by 0.1-0.5%, and the service life of the mold is prolonged by 0.1-0.5%; and the layering phenomenon in the magnetic core pressing process is reduced, and the production efficiency and product quality of the magnetic core are improved.

Owner:马鞍山新康达磁业有限公司

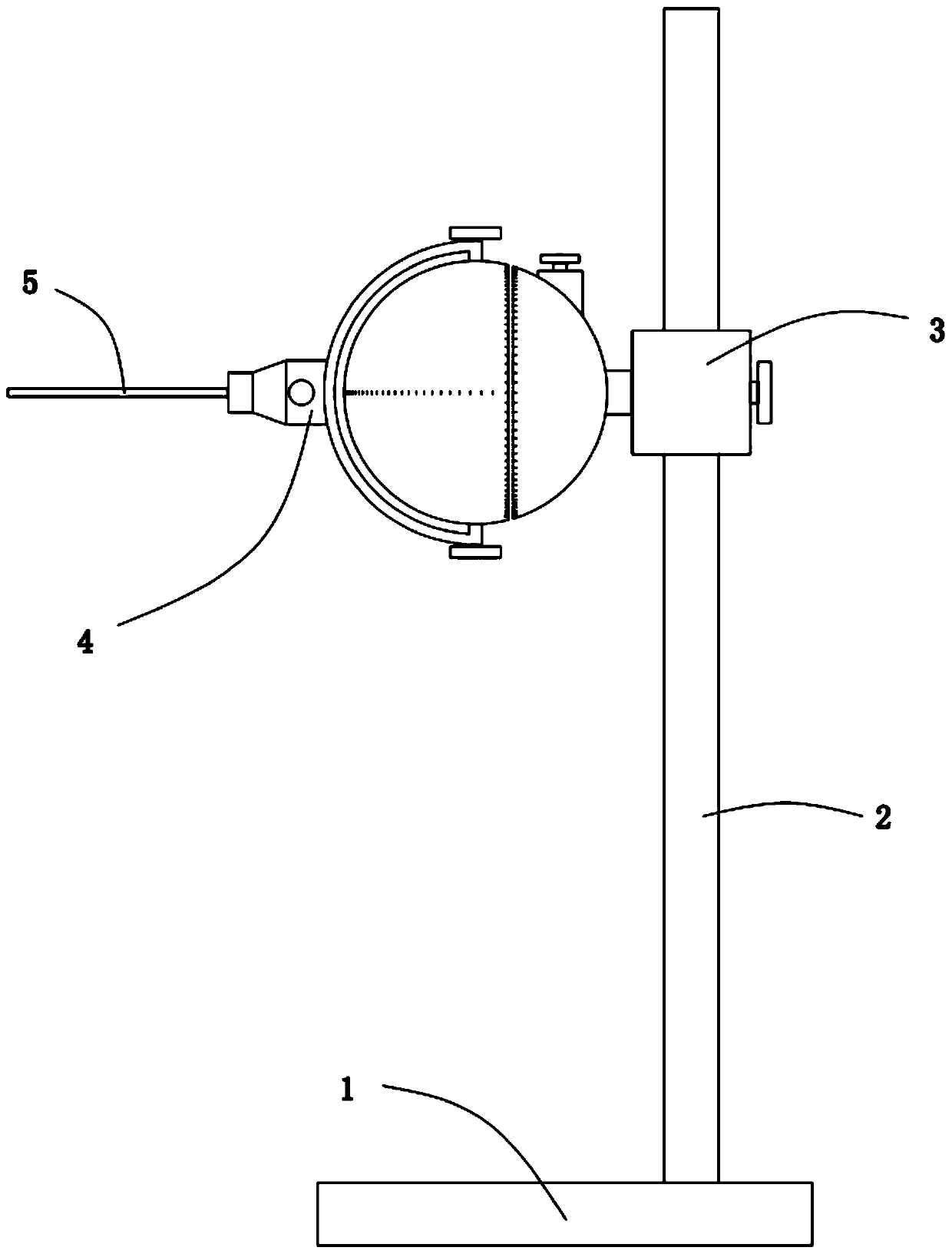

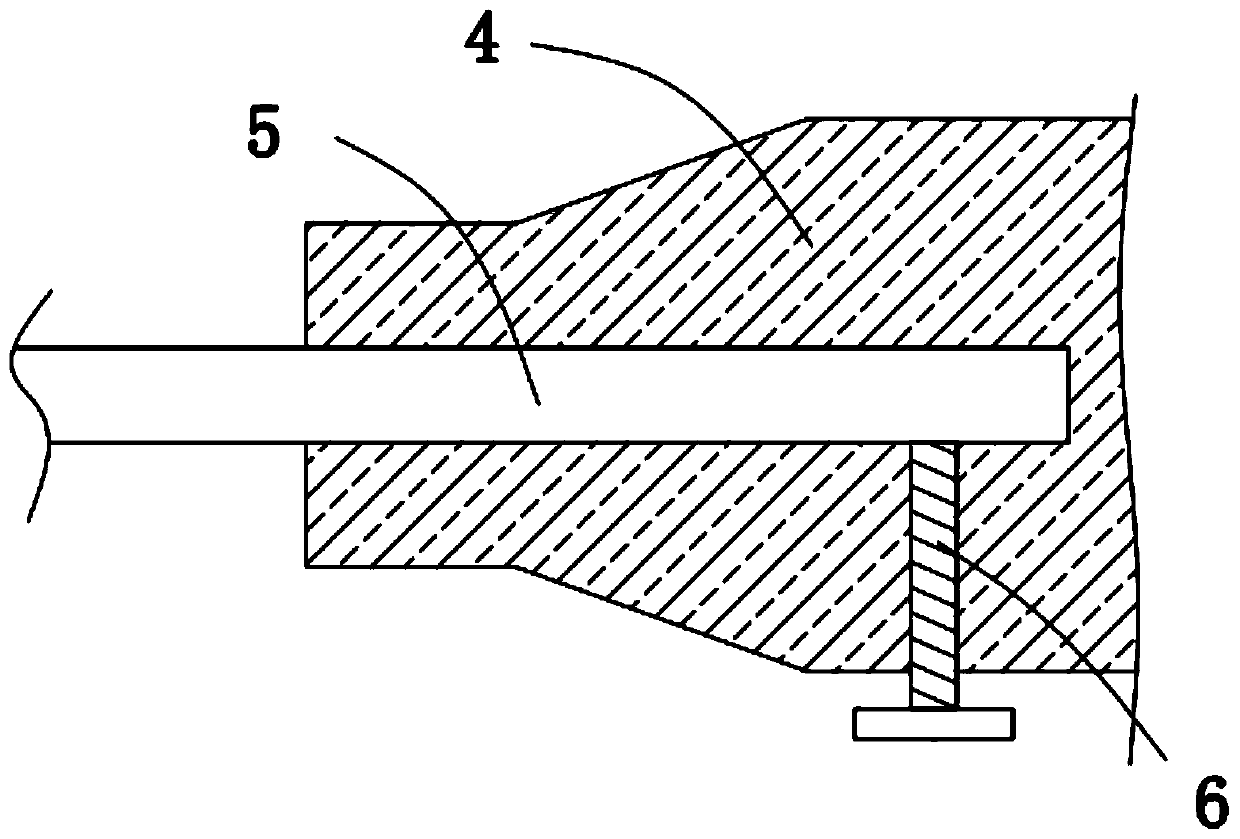

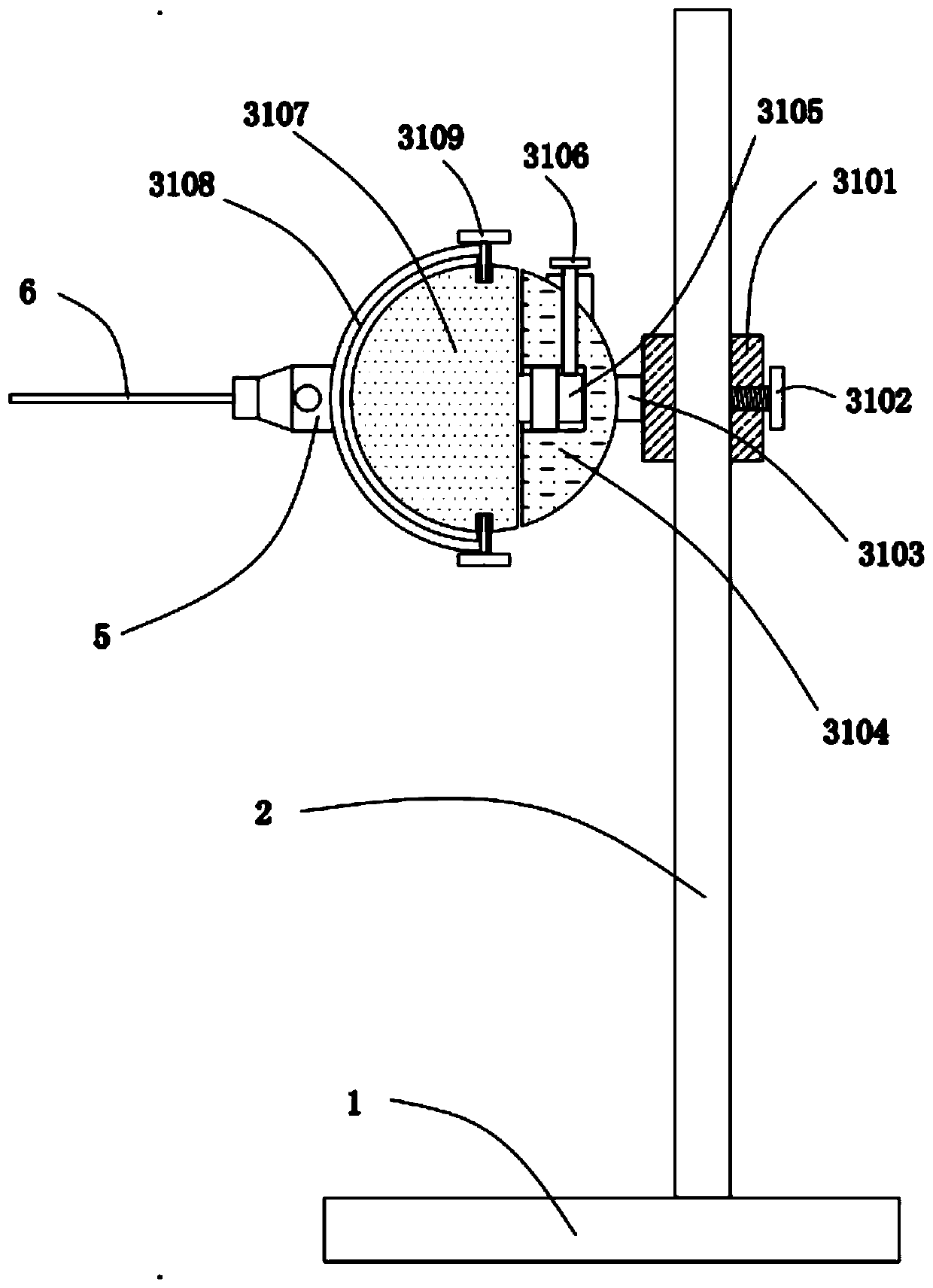

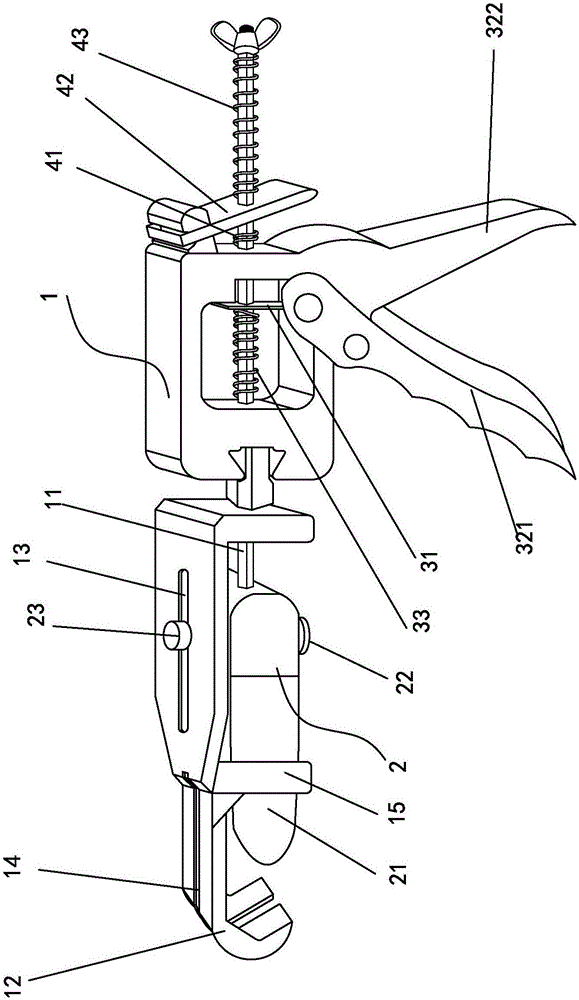

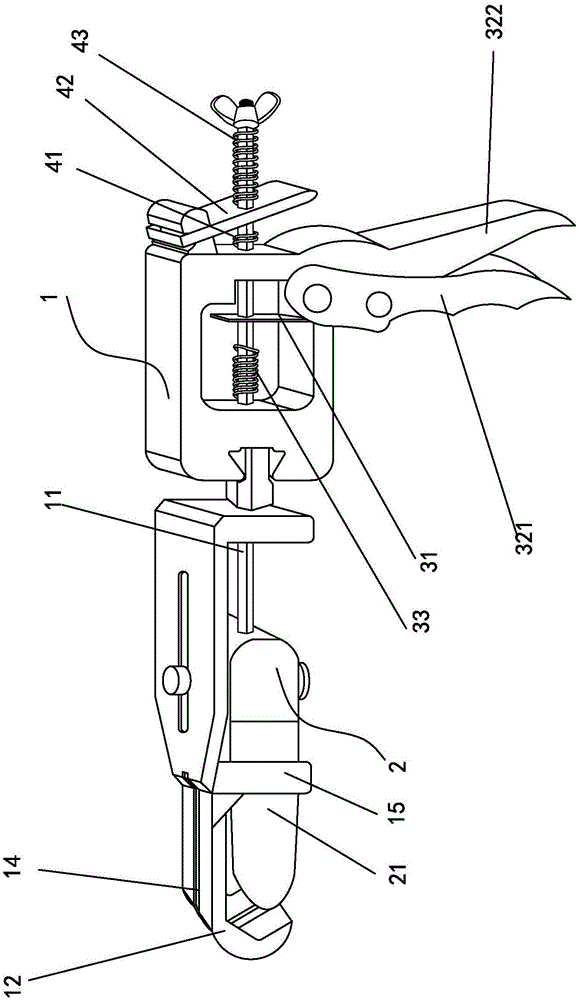

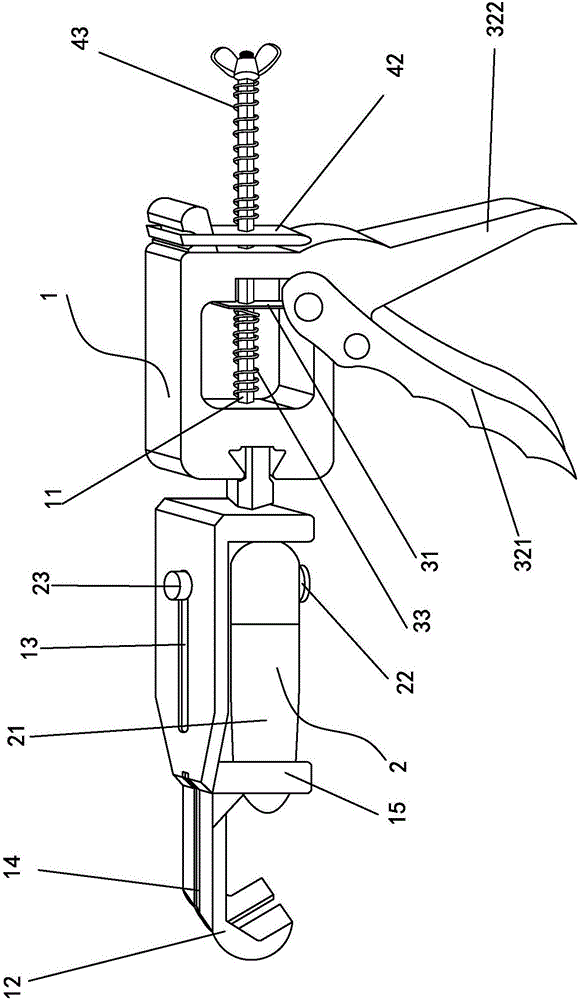

Sphere 360-degree universal fixed-point knife sharpening holder

PendingCN110587389ASanding easilyQuick sandingGrinding drivesOther manufacturing equipments/toolsComputer engineeringSharpening

The invention provides a sphere 360-degree universal fixed-point knife sharpening holder. The sphere 360-degree universal fixed-point knife sharpening holder includes a base, a support rod, an adjustment mechanism, a mounting base and a nicking tool; the support rod is fixedly installed on the top of the base; the adjustment mechanism is installed on the support rod; the mounting base is mounted on the adjustment mechanism; and the nicking tool is fixedly mounted on the mounting base. The sphere 360-degree universal fixed-point knife sharpening holder has the advantages of being convenient touse, simple in operation and capable of achieving accurate grinding of the nicking tool.

Owner:逍遥精雕(北京)珠宝文化发展有限公司 +1

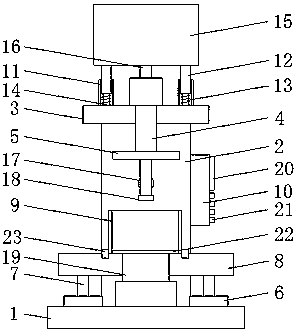

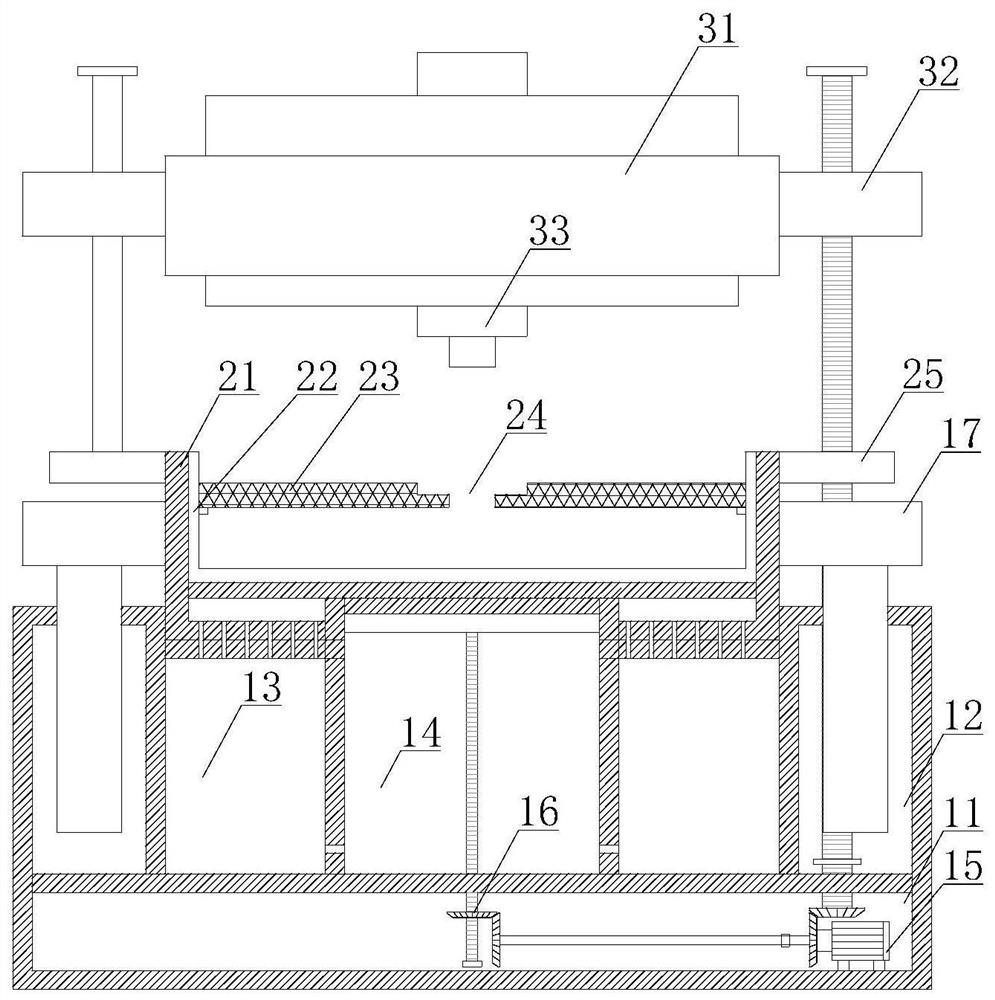

Self-feeding foundry sand molding machine

InactiveCN107626899ASolve the problem of not having the function of self-loadingSanding easilyMoulding machinesMould controlling devicesFoundryMolding machine

The invention discloses a self-feeding foundry sand molding machine. The self-feeding foundry sand molding machine comprises a base. A support plate is welded to the back face of the top of the base.A top plate is welded to the top of the support plate. A first air cylinder is connected to the top of the support plate through bolts. The bottom of the first air cylinder penetrates the top plate and extends to the bottom of the top plate. The bottom of the first air cylinder is connected with a pressure plate through bolts. The two sides of the top of the base are correspondingly connected withvibrating motors through bolts. Vibrating columns are movably connected to the tops of the vibrating motors. The tops of the vibrating columns are connected with a bottom plate through bolts. A sandbox is movably mounted on the top of the bottom plate. According to the self-feeding foundry sand molding machine, through the cooperation of a control box, telescopic sleeves, support rods, pressuresensors, support springs, a sand storage box, a sand outlet pipe, an electric telescopic rod and an electric valve, the problem that an existing foundry sand molding machine does not have the self-feeding function, complex feeding still cannot be solved, and consequently the production efficiency is low is solved.

Owner:李广辉

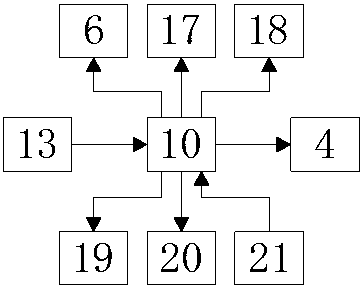

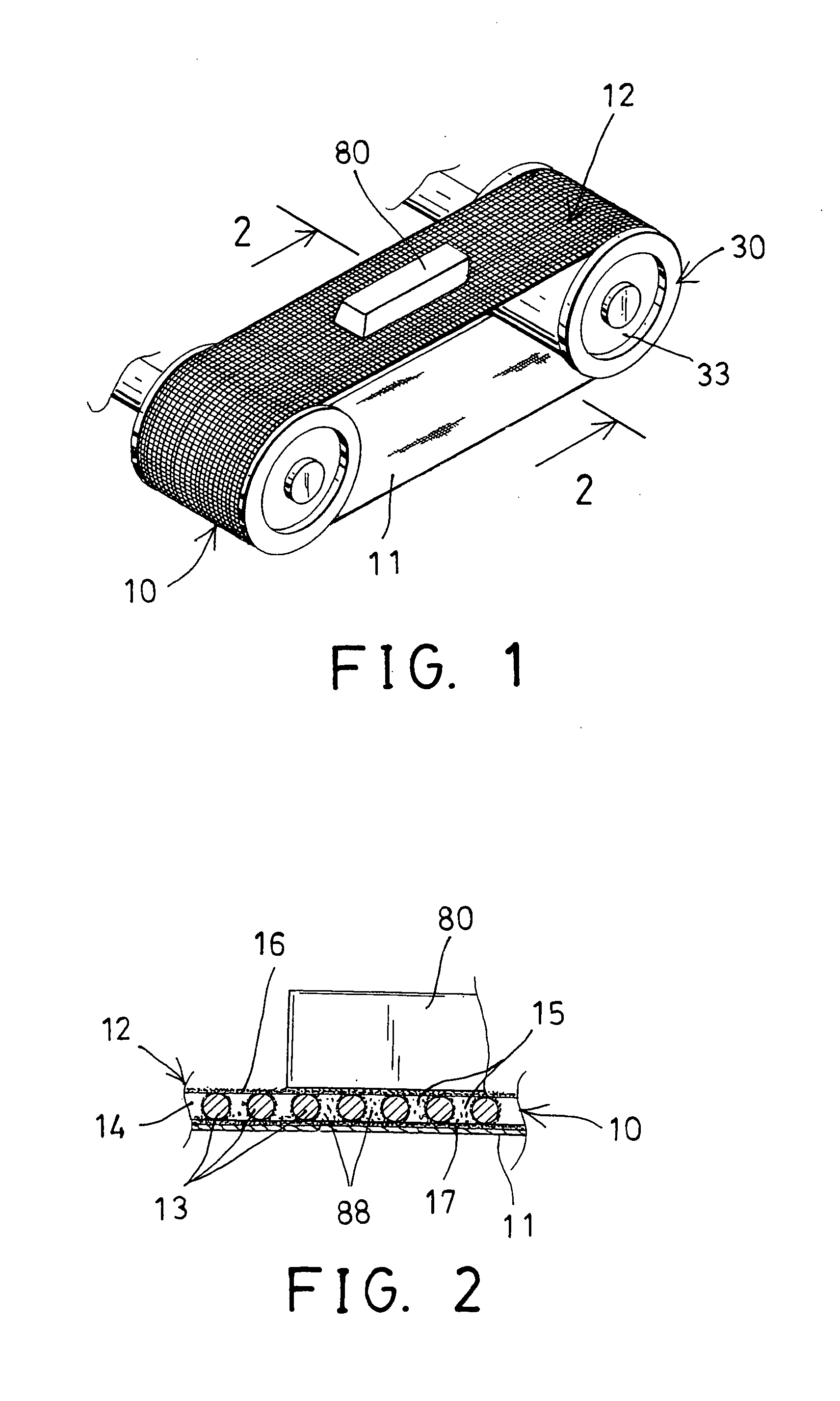

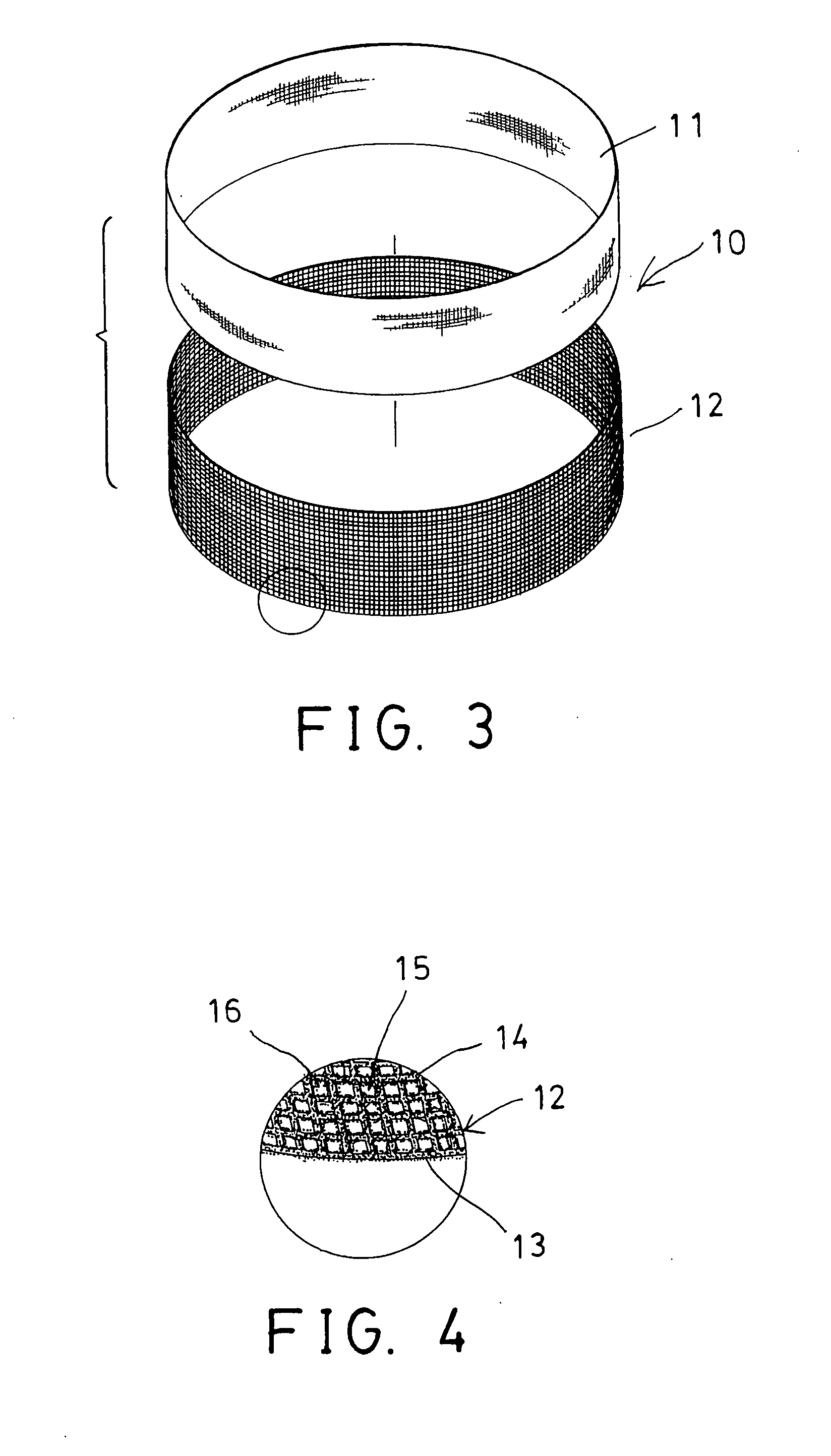

Abrasive belt for sanding device

InactiveUS20080261498A1Sanding easilyEasy to GrindAbrasion apparatusBrachial plexus - lateral cordEngineering

An abrasive belt includes a net member having a number of cords secured together for forming a number of eyelets between the cords, and a number of abrading particles applied onto the net member for engaging with a work piece and for abrading the work piece and for abrading cut chips from the work piece and for allowing the cut chips to be received and engaged in the eyelets of the net member. The abrading particles may be applied onto an outer portion or an inner portion of the net member. A base member may be attached or engaged in the net member for supporting the net member which may include a number of longitudinal cords and lateral cords secured together.

Owner:CHAO CHING CHI

Grain flour and making method thereof

InactiveCN107156633ARelease fullyAdd Nutritious FlavorFood ingredient as mouthfeel improving agentFlavorSorghum

A coarse cereal flour is made of soybeans, red beans, sorghum, Semen Euryales, red dates, peanuts, coix seeds and corn. The coarse cereal flour reserves the shells and the cores of above raw materials, increases the nutritional flavor, increases the medicinal effects, and avoids wastes, and white vinegar and rice wine are added to fully release nutrient elements in the materials. The raw materials are boiled and then are baked at a low temperature to fully release the nutrient elements, increase the flavor and reach a fragment dense taste, so the flour has soft and fragment mouthfeel, and the above treatment manner realizes easiness, time and labor saving and fineness of subsequent polishing.

Owner:ANHUI SHUANGLU FLOUR

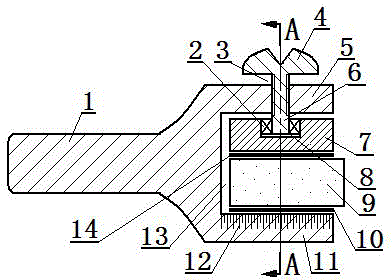

Pipe cutting machine

InactiveCN107433361ANot easy to slideEasy to operateTube shearing machinesEngineeringMechanical engineering

The invention discloses a pipe cutting machine. The pipe cutting machine comprises a main body, a cutter and a transmission mechanism; the main body is internally provided with a driving rod; the cutter is arranged at the front end of the driving rod, and the front end of the main body is of a hook-like structure; the transmission mechanism is in transmission connection with the driving rod to drive the driving rod to go forward, so that the cutter extrudes and cuts an object to be cut toward the front end of the hook-like structure in the main body; the transmission mechanism comprises a transmission piece and an operation handle which is in transmission connection with the transmission piece; and the driving rod is sleeved with the transmission piece to drive the driving rod to move. According to the pipe cutting machine, the hook-like front end and the cutter are matched to extrude and cut, compared with the different structure characteristics of an existing pipe cutting machine or a pipe cutting clamp, the pipe cutting machine has the characteristics that sliding is not easy to occur, operation is simple, efficiency is doubled, and repeated operation and using by a single hand can be realized.

Owner:漳州荣鑫五金机械有限公司

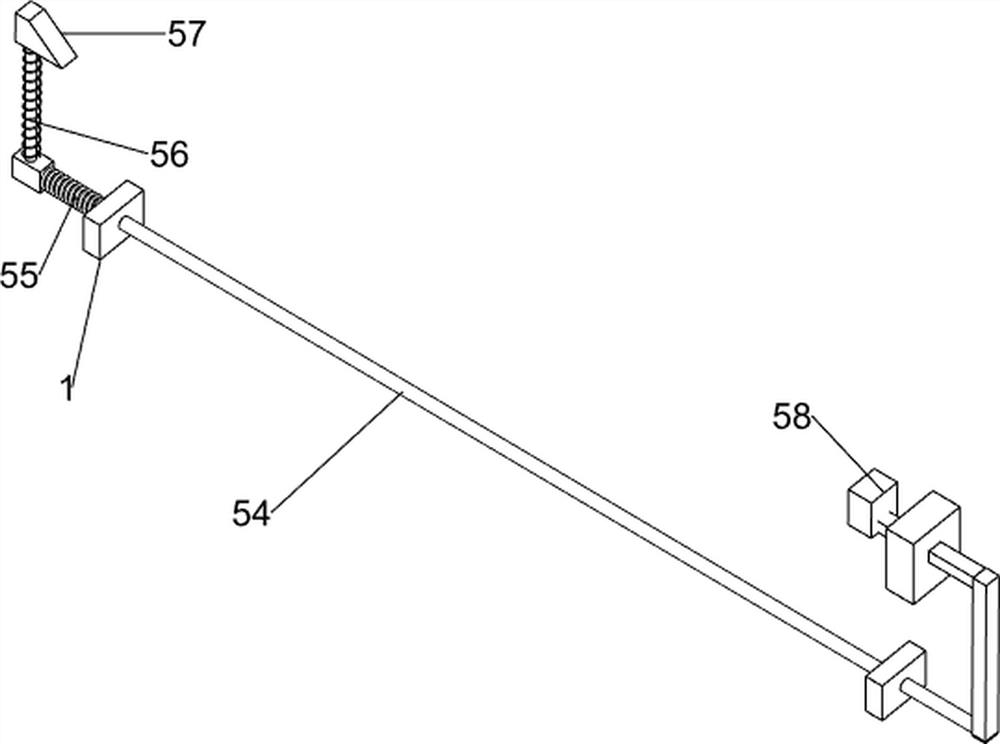

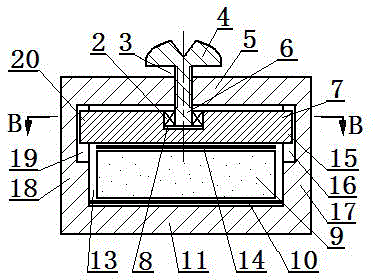

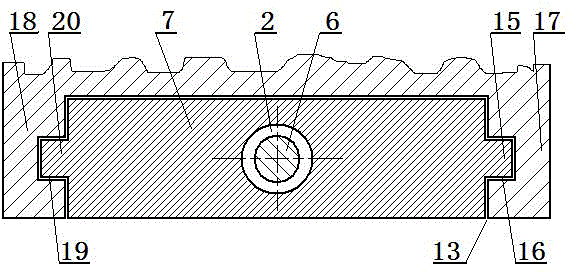

Clamping device for conveniently polishing wooden guitar string pillow/string bridge

ActiveCN104907930APrecision grindingSanding easilyGrinding work supportsMechanical engineeringGuitar

The invention discloses a clamping device for conveniently polishing a wooden guitar string pillow / string bridge. The clamping device comprises a handle and a clamping part which is integrally formed with the handle, wherein the upper clamping plate is provided with a threaded hole and the threaded hole is internally provided with a butterfly-shaped bolt; a small long groove I and a small long groove II are formed in the thick wall part of the inner walls of a left clamping plate and a right clamping plate respectively; a movable plate is arranged in the long groove; a round concave hole is formed in the central line of the upper end of the movable plate; the inner diameter of the round concave hole is tightly matched with the outer diameter of a bearing; the inner diameter of the bearing is tightly matched with the outer diameter of the lower part of a screw rod of the butterfly-shaped bolt; a protruding part I and a protruding part II on the central lines of the left and right ends of the movable plate can move in the small long groove I and the small long groove II up and down; a rubber layer II is arranged at the lower end of the movable plate; a rubber layer I is arranged at the upper end of the lower clamping plate; scales are arranged on the end faces of the front and rear ends of the lower clamping plate. With the adoption of the structure, the wooden guitar string pillow / string bridge can be easily and accurately polished.

Owner:广东声凯乐器有限公司

Antibacterial emulsion paint and preparation method thereof

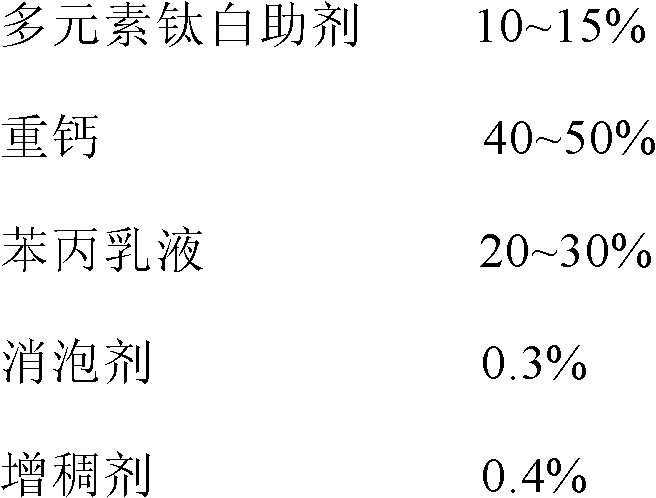

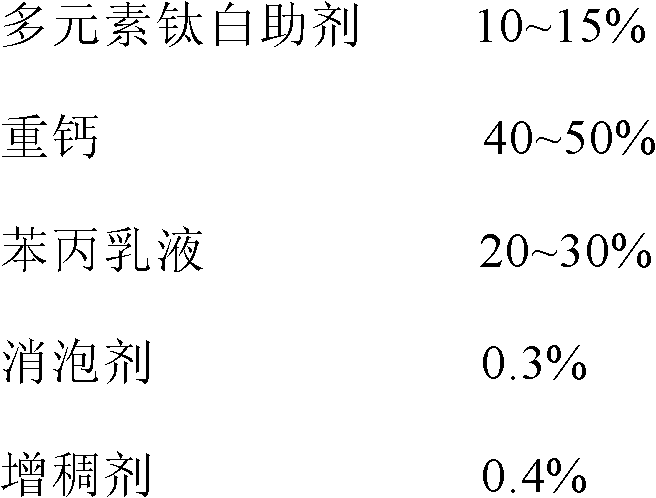

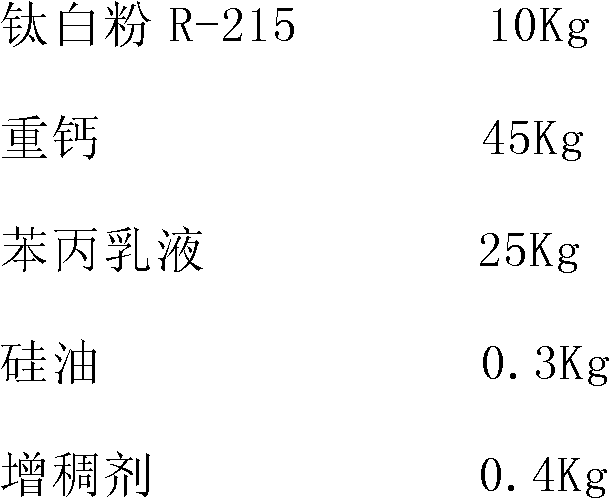

The invention relates to an anti-bacterial emulsion paint. The paint comprise following ingredients, by weight: 0 to 15% of a multi-element titanium white auxiliary agent, 40 to 50% of ground calcium carbonate, 20 to 30% of styrene acrylic emulsion, 0.3% of an antifoaming agent, 0.4% of a thickening agent, and the balance being water. The paint comprises a plurality of raw materials containing no gas which is harmful and volatilizable. Preparation method is simple. The paint is green and friendly to environment, does no harm for human, and processes high water and corrosion resistances, and excellent application properties.

Owner:TIANJIN LANGWEI BAILI TECH CO LTD

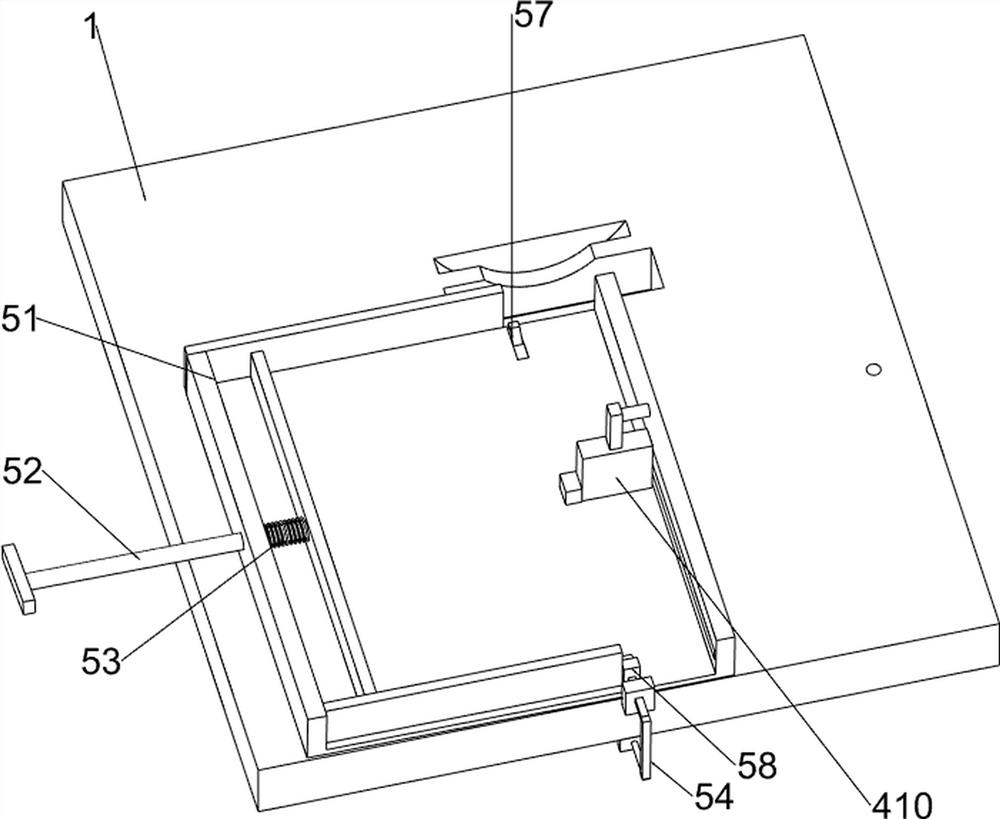

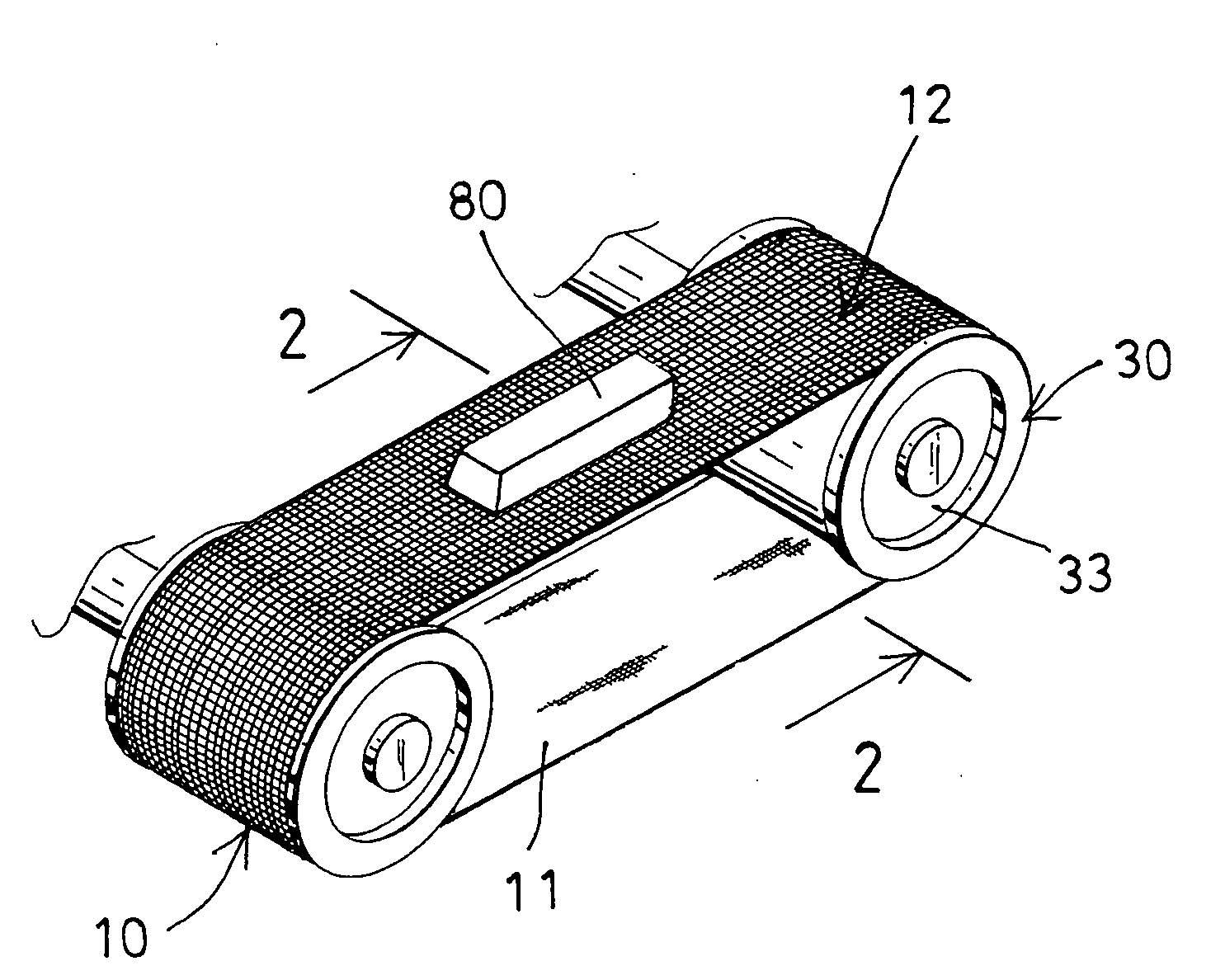

High-end equipment manufacturing steel plate surface grinding equipment

ActiveCN112720113AEasy effectSanding easilyGrinding drivesGrinding work supportsPolishingStructural engineering

The invention relates to polishing equipment, in particular to high-end equipment manufacturing steel plate surface polishing equipment. According to the high-end equipment manufacturing steel plate surface grinding equipment provided by the invention, the surface of a steel plate can be easily ground, the steel plate can be rotated to be fully ground, automatically clamped and fixed and easily unlocked and loosened, and rotation of the steel plate and movement of a grinding wheel are autonomously controlled. The high-end equipment manufacturing steel plate surface grinding equipment comprises supporting legs, a base, a rotating rod, a workbench, a transmission mechanism and a polishing mechanism, wherein the supporting legs are symmetrically arranged on the ground; the base is connected between the lower parts of the inner sides of the supporting legs; the middle of the upper part of the base is rotatably connected with the rotating rod; the upper side of the rotating rod is connected with the workbench; the transmission mechanism is arranged between the upper parts of the supporting legs; and the polishing mechanism is arranged on the transmission mechanism. According to the high-end equipment manufacturing steel plate surface grinding equipment provided by the invention, a pedal is treaded to drive a warping plate to rotate anticlockwise, a fixing rod and an arc-shaped supporting plate are pushed to move downwards, and a steel plate is loosened, so that the effect of unlocking and loosening the steel plate more easily and conveniently is achieved, and manpower is saved.

Owner:广东锐创图压力容器设备有限公司

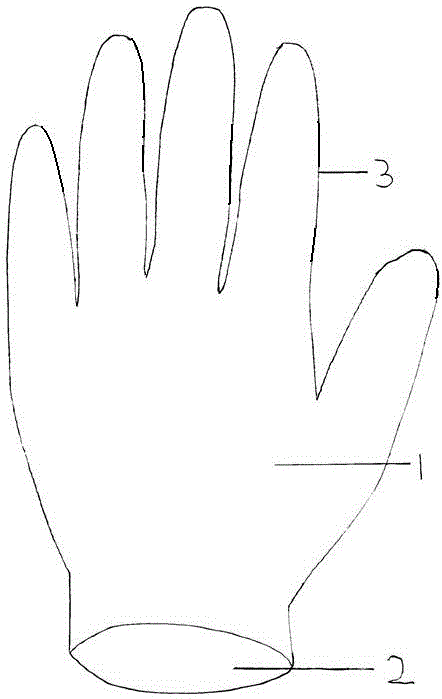

Glove type abrasive cloth

InactiveCN106625299ASanding easilyAbrasion apparatusProtective garmentEngineeringMechanical engineering

The invention discloses glove type abrasive cloth which is a hollow glove body. The interior of the hollow glove body is made of a soft material suitable for making contact with hands. Grinding sand is densely distributed on both the front side and the back side of the exterior of the hollow glove body. In use, a user wears the glove type abrasive cloth on one hand and then holds a hand piece with the other hand so as to grind the hand piece on the abrasive cloth back and forth, and uneven portions can be grinded back and forth just by bending fingers; and during grinding, after the abrasive cloth is severely abraded, the user wears the glove type abrasive cloth on the other hand, then the glove type abrasive cloth seems like a new one, and grinding can be continued.

Owner:王建明

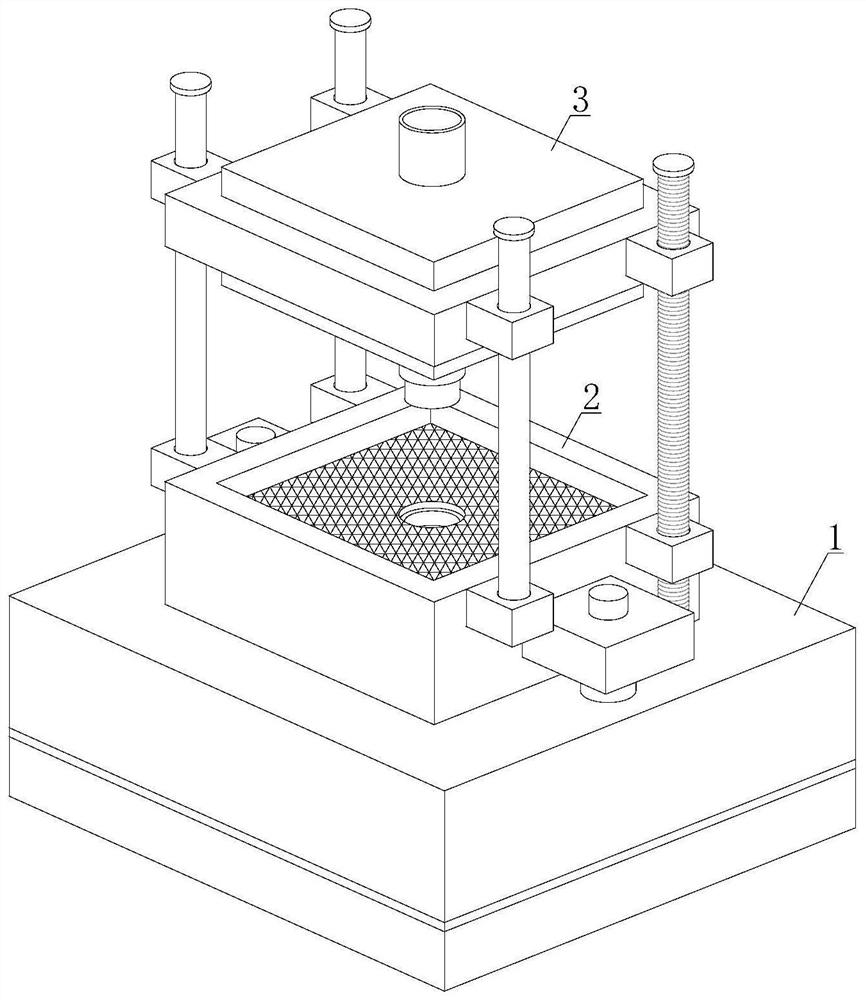

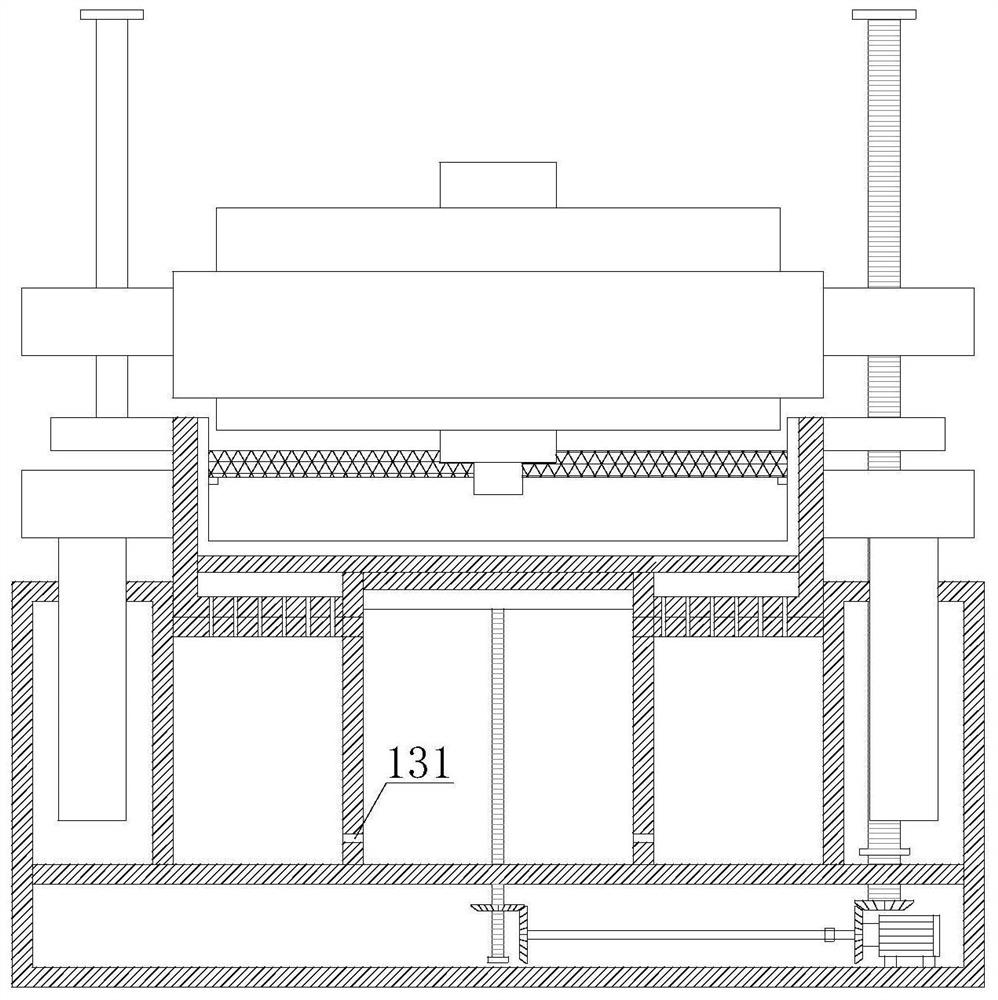

Metal forming device with coated sand cooling mechanism and implementation method thereof

InactiveCN112475239AImprove cooling effectEasy to demouldMoulding toolsFoundry mouldsMetal formingElectric machine

The invention discloses a metal forming device with a coated sand cooling mechanism. The metal forming device comprises a base, a mold assembly and a pressing assembly. An operator fills a cooling cavity with cooling water, fills a sand storage cavity with sand, places metal in an outer shell and starts a forward and reverse rotation motor to work. The invention further discloses an implementationmethod of the metal forming device with the coated sand cooling mechanism. The forward and reverse rotation motor rotates reversely, a first bevel gear can drive a second bevel gear and a third bevelgear to rotate, a fourth bevel gear is perpendicularly engaged and connected with the third bevel gear, then the fourth bevel gear can rotate, the fourth bevel gear can drive a top disc to move upwards when rotating, so that a linkage disc can eject a metal piece out of the outer end of the outer shell, namely, when the forward and reverse rotation motor works, the movement of the pressing pieceand the movement of the top disc can be triggered at the same time, the operation cost is reduced, the use effect is good, the pressing piece is completely lifted, the cooling work can be finished, and the metal part forming work can be conveniently completed.

Owner:薛王飞

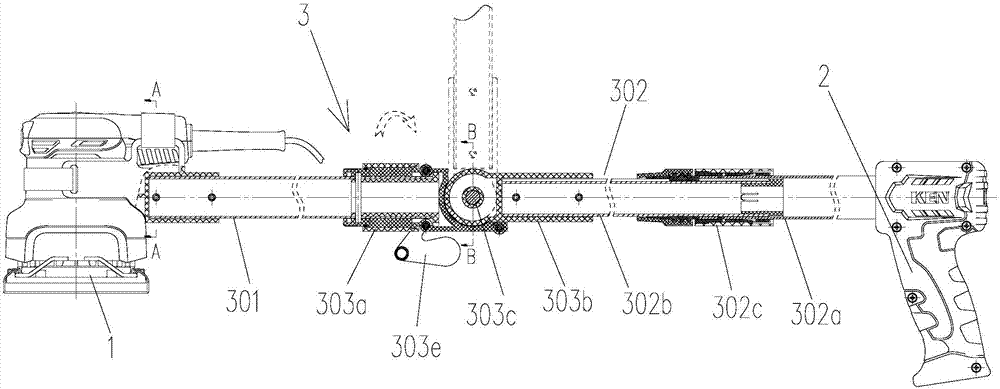

Handheld sander

PendingCN108000301AImprove accessibilityReduce work intensityPortable grinding machinesSanderEngineering

The invention discloses a handheld sander. The handheld sander comprises a machine head and a machine handle. The machine head and the machine handle are connected through a telescopic and bendable connecting arm. During practical application of the sander, through stretching, contraction and bending actions of the connecting arm, the machine head of the sander can conduct sanding treatment on positions, where conventional sanders cannot touch easily, of large table boards or in high places or in small and narrow spaces quite conveniently, the reachability of the sander is improved, and the working intensity and difficulty of operators are lowered.

Owner:KEN HLDG CO LTD +1

A kind of automatic production process of soft magnetic manganese zinc ferrite granular material

ActiveCN107129290BAct as a binding agentImprove plasticityInorganic material magnetismPlasticizerManganese

The invention discloses an automated production process for soft magnetic manganese-zinc ferrite granular materials, and belongs to the technical field of soft magnetic manganese-zinc ferrite granular material production. The process includes the following steps: ingredient weighing, primary slurrying and sand grinding, primary spray drying, pre-calcination, secondary slurrying and sand grinding, and secondary spray drying. Before the secondary spray drying, add water to the slurry. Add a plasticizer, stir and mix, and then spray dry. The plasticizer is a phthalate ester plasticizer. The use of phthalate ester plasticizers on the one hand enhances the plasticity of the powder. The powder particles are prone to plastic deformation (breaking), and the pressing density of the magnetic core is increased. Under the same strength conditions of the magnetic core, the molding pressure of the pellets can be reduced. From 34 to 36Mpa to 31 to 33Mpa, the wear rate of the press is reduced by 0.1 to 0.5%, and the service life of the mold is extended by 0.1 to 0.5%; the delamination phenomenon during the core pressing process is reduced, and the production of the magnetic core is improved. efficiency and product quality.

Owner:马鞍山新康达磁业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com