Machining process for sealing ring mold

A mold processing and sealing ring technology, applied in the field of sealing rings, can solve the problems of oversize, unilateral mold tearing groove, mold scrapping, etc., to achieve the effect of facilitating sanding, ensuring bottom size, and improving quality and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

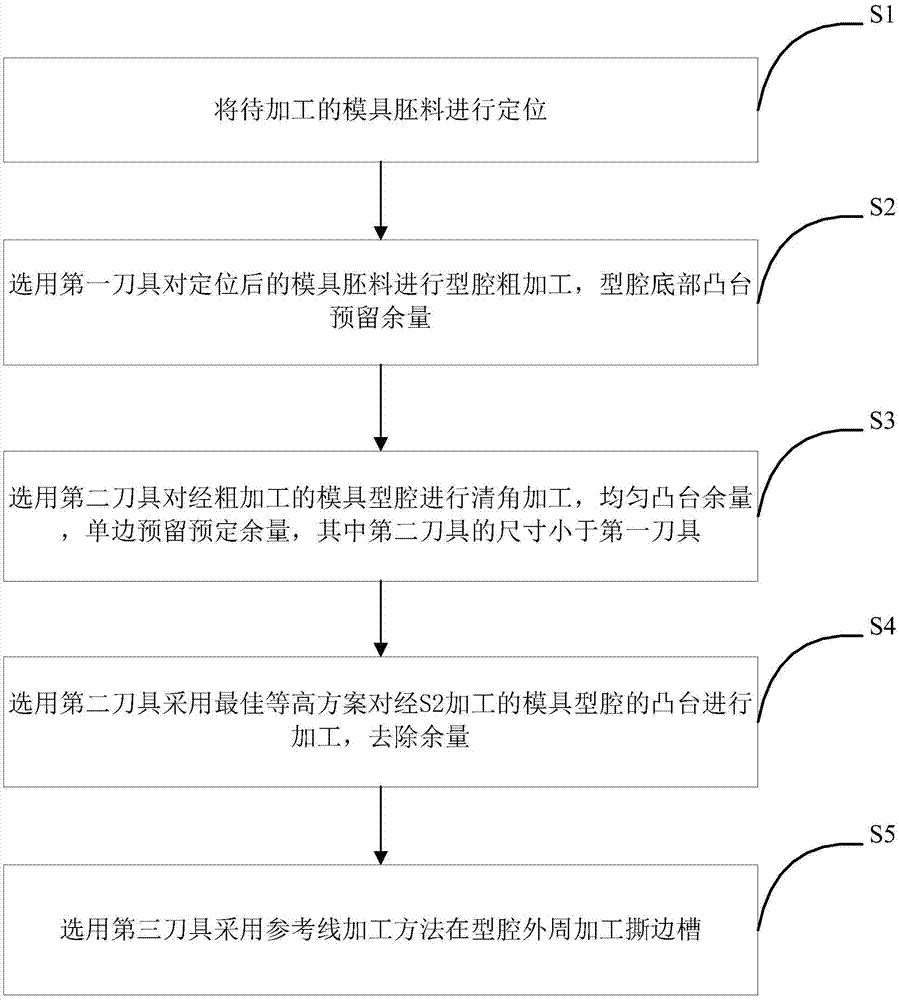

[0018] Such as figure 1 as shown, figure 1 It is a schematic flow chart of a sealing ring mold processing technology proposed by the present invention.

[0019] refer to figure 1 , a kind of sealing ring mold processing technology that the present invention proposes, comprises the following steps:

[0020] S1. Position the mold blank to be processed;

[0021] S2. Select the first tool to rough the mold cavity after positioning, and reserve a margin for the boss at the bottom of the cavity;

[0022] S3. Select the second tool to perform corner-clearing processing on the rough-processed mold cavity, uniform boss margin, and reserve a predetermined margin on one side, wherein the size of the second tool is smaller than the first tool, and the predetermined margin is 0.01-0.02mm, preferably, the predetermined margin is 0.015mm;

[0023] S4. Select the second tool and use the best contour plan to process the mold cavity boss processed by S2 from the middle of the cavity to rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com