A kind of automatic production process of soft magnetic manganese zinc ferrite granular material

A manganese-zinc ferrite and production process technology, which is applied in the field of automatic production process of soft magnetic manganese-zinc ferrite granular materials, can solve the problems of large equipment loss, press and mold wear, easy delamination, etc., and achieve service life The effects of elongation, increased pressing density, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

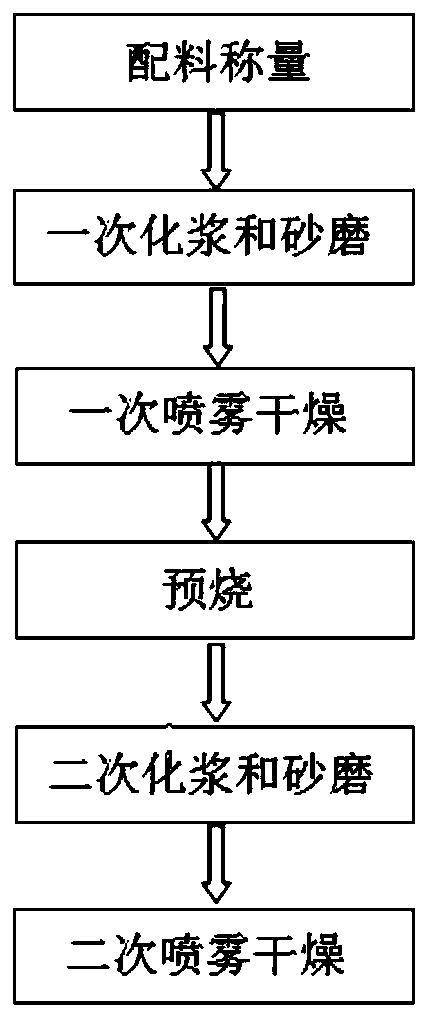

[0031] figure 1 It is a flow chart of the automatic production process of the soft magnetic manganese zinc ferrite granular material of the present invention. The automatic production process of the soft magnetic manganese zinc ferrite granular material of the present embodiment is specifically carried out according to the following steps:

[0032] 1) Weighing of ingredients: Weigh the raw materials as follows: Fe 2 o 3 : 55mol%, ZnO: 15mol%; Mn 3 o 4 : 30mol%; where Fe 2 o 3 The purity of ZnO is 99.9%, the purity of ZnO is 99.9%, the Mn 3 o 4 The Mn content of the Mn is 72%; the present embodiment adopts the ferrous formula, that is, the Mn content is greater than 50% in the formula, which improves the initial magnetic permeability of the material;

[0033] 2) Primary pulping and sand milling: Add the raw materials into a sand mill, add dispersant A ammonium citrate ammonium citrate for wet grinding, the addition amount is 1% of the total amount of raw materials, and ...

Embodiment 2

[0039] The automatic production process of the soft magnetic manganese zinc ferrite granular material of the present embodiment is specifically carried out according to the following steps:

[0040] 1) Weighing of ingredients: Weigh the raw materials as follows: Fe 2 o 3 : 50mol%, ZnO: 25mol%; Mn 3 o 4 : 25mol%; where Fe 2 o 3 The purity of ZnO is 99.99%, the purity of ZnO is 99.95%, the Mn 3 o 4 The Mn content is 71%;

[0041] 2) Primary pulping and sand milling: Add raw materials into a sand mill, add dispersant A ammonium citrate for wet grinding, the addition amount is 3% of the total raw materials, and grind until the particle size is d50<1.0um;

[0042] 3) primary spray drying: spray drying to obtain powder;

[0043] 4) Pre-burning: Put the powder in step 3) into the rotary kiln for pre-burning at a uniform speed. The temperature of the rotary kiln is 800°C, and the holding time is 20min. 25+25)°C / h=31°C / h, cooling down to room temperature, among them, T 0 =800...

Embodiment 3

[0047] The automatic production process of the soft magnetic manganese zinc ferrite granular material of the present embodiment is specifically carried out according to the following steps:

[0048] 1) Weighing of ingredients: Weigh the raw materials as follows: Fe 2 o 3 : 55mol%, ZnO: 20mol%; Mn 3 o 4 : 25mol%; where Fe 2 o 3 The purity of ZnO is 99.95%, the purity of ZnO is 99.95%, the Mn 3 o 4 The Mn content is 72.4%;

[0049] 2) Primary pulping and sand milling: Add the raw materials into a sand mill, add dispersant A ammonium citrate for wet grinding, the addition amount is 2% of the total amount of raw materials, and grind until the particle size is d50<1.0um;

[0050] 3) primary spray drying: spray drying to obtain powder;

[0051] 4) Pre-burning: Put the powder in step 3) into the rotary kiln for pre-burning at a uniform speed. The temperature of the rotary kiln is 700°C, and the holding time is 30min. 20+25)°C / h=30°C / h, cooling down to room temperature, among...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com