Columnar carbon granules taking illite, low-temperature flux and walnut shell powder as main raw materials and preparation method thereof

A technology of walnut shell powder and the main raw material, which is applied in the field of carbon materials, can solve the problems of reduced carbon particle adsorption performance, increased energy consumption, and increased production costs, and achieves the effects of high porosity, low cost, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

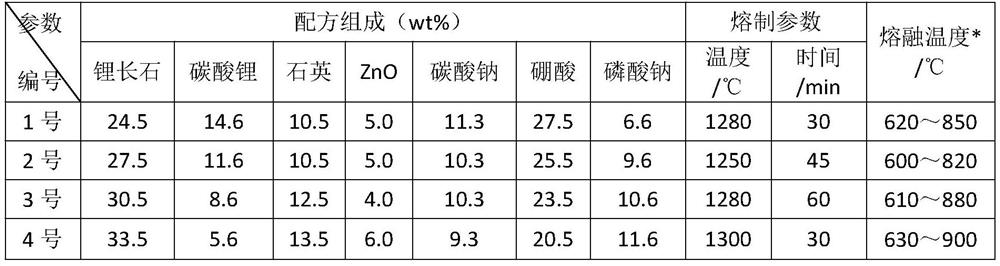

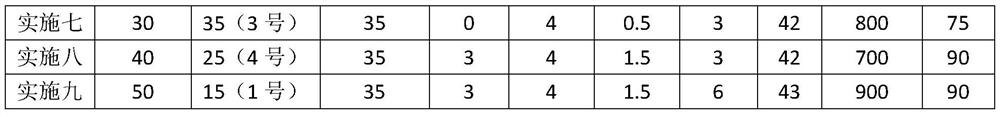

[0023] The embodiment of the present invention is a kind of columnar carbon particles with illite, low-temperature flux and walnut shell powder as main raw materials, which is composed of base material raw materials and auxiliary materials; wherein, the base material raw materials are illite powder 20-60wt%, low-temperature flux powder 10-40wt% of raw material, 20-70wt% of walnut shell powder; relative to the raw material of the base material, the auxiliary raw material and its dosage are TiO 2 Powder 0~10wt%, hydroxypropyl methylcellulose (HPMC) 4~6wt%, oleic acid 0.5~1.5wt%, glycerin 3~6wt%, water 40~50wt%; Lithium feldspar 23-35wt%, lithium carbonate 5-15wt%, quartz 10-15wt%, ZnO 4-6wt%, sodium carbonate 9-12wt%, boric acid 20-30wt%, sodium phosphate 6-12wt%.

[0024] The embodiment of the present invention illite comes from Hebei Chengde Renhe Mining Co., Ltd., and the mining area is located in Weichang Manchu and Mongolian Autonomous County, Chengde City. Its chemical com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com