Glass bottle die casting piece manufacturing process cyclically using molding sand

A manufacturing process and glass bottle technology, which is applied in the direction of manufacturing tools, machinery for cleaning/processing of casting materials, casting molds, etc. , to achieve the effect of reducing the amount of sand used, reducing the cleaning workload, and good collapsibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0026] The technical scheme of concrete implementation of the present invention is:

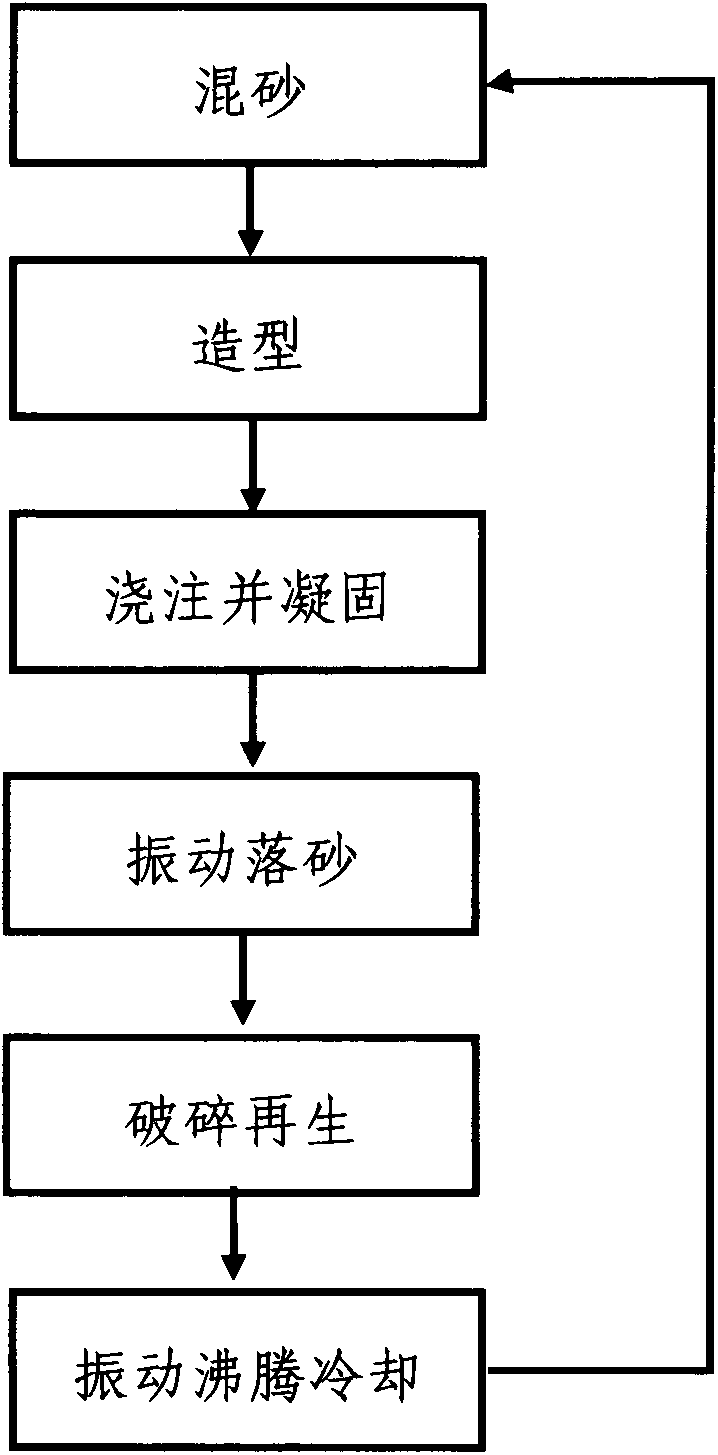

[0027] Such as figure 1 Shown, a kind of glass bottle mold casting manufacturing process that molding sand can be recycled comprises the steps:

[0028] 1) Sand mixing: drop into molding sand and composite inorganic binder in continuous sand mixer and carry out sand mixing; The input amount of described composite inorganic binder is 3.5%-4.5% (preferably 3.5%, 4% of molding sand quality) % or 4.5%); the molding sand is composed of 0-15% new sand and 85%-100% recycled sand;

[0029] 2) Modeling: Turn on the shaking table, put the mixed molding sand into the sand box equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com