Antibacterial emulsion paint and preparation method thereof

A latex paint and antibacterial technology, applied in the field of latex paint, can solve the problems of difficult to improve the contrast ratio of paint products, weather resistance, stable production efficiency, high price of titanium dioxide, and limited usage, and achieve performance improvement and performance reduction. Consumption and reduction of working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

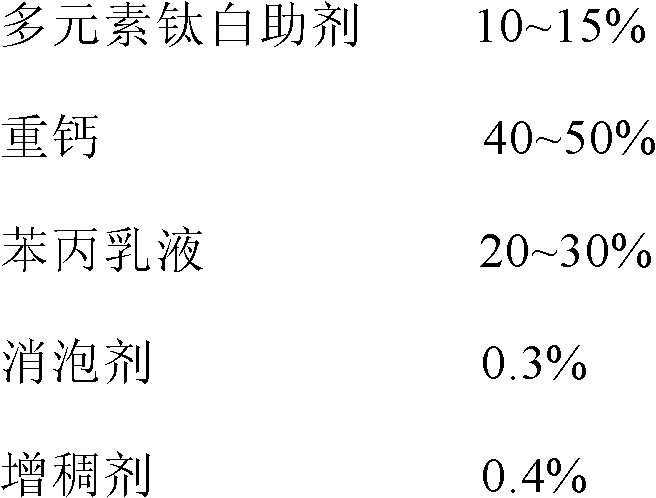

[0022] A kind of antibacterial latex paint, its raw material component and weight are:

[0023]

[0024] The balance is water.

[0025] In the present embodiment, the heavy calcium is 800 mesh heavy calcium powder.

[0026] In this embodiment, the thickener is a polyurethane thickener.

[0027] A preparation method for antibacterial latex paint, the method may further comprise the steps:

[0028] (1) Put deionized water and 1 / 2 of the defoamer into the dispersion tank, turn on the stirring device, and control the rotation speed to 600r / m;

[0029] (2) Put multi-element titanium dioxide additives, styrene-acrylic emulsion and heavy calcium into the mixed solution of deionized water and 1 / 2 defoamer that is stirred evenly, control the rotation speed of the stirring device at 1200rpm, and disperse at a high speed for 15min;

[0030] (3) After high-speed dispersion, sand-mill and filter the mixture to control the fineness of the sample to be less than 50um, and finally add t...

Embodiment 2

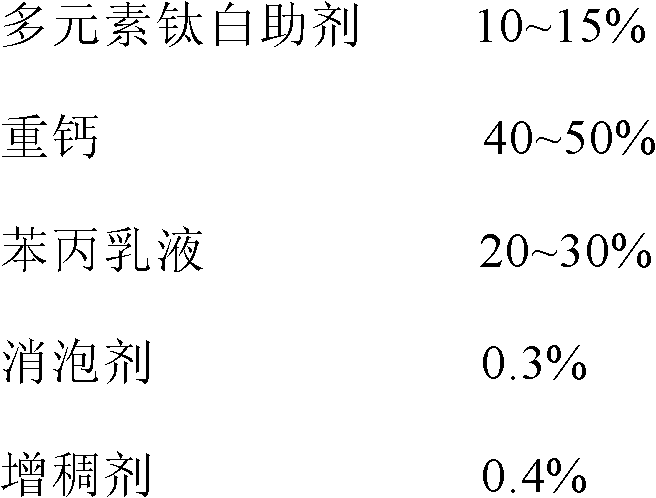

[0032] A kind of antibacterial latex paint, its raw material component and weight are:

[0033]

[0034] The balance is water.

[0035] In the present embodiment, the heavy calcium is 800 mesh heavy calcium powder.

[0036] In this embodiment, the thickener is a polyurethane thickener.

[0037] The preparation method is the same as in Example 1.

Embodiment 3

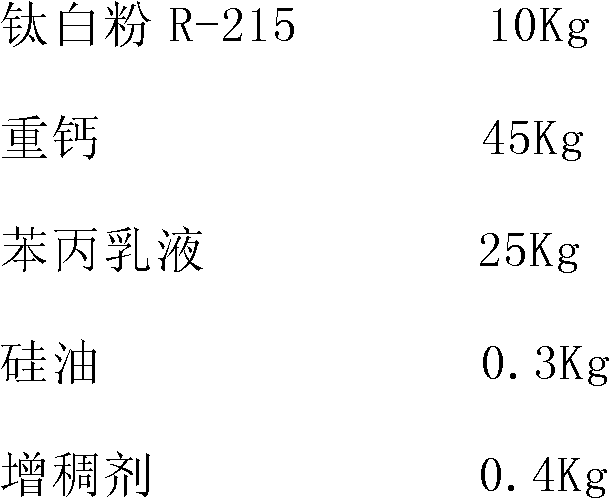

[0039] A kind of antibacterial latex paint, its raw material component and weight are:

[0040]

[0041] The balance is water.

[0042] In the present embodiment, the heavy calcium is 800 mesh heavy calcium powder.

[0043] In this embodiment, the thickener is a polyurethane thickener.

[0044] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com