Abrasive belt for sanding device

a technology of abrasive belts and sanding devices, which is applied in the field of abrasive belts, can solve the problems that work pieces cannot be effectively sanded, ground or abraded by the sand belt, so as to facilitate the sanding or grinding or abrading operation and increase the working life of the sanding bel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

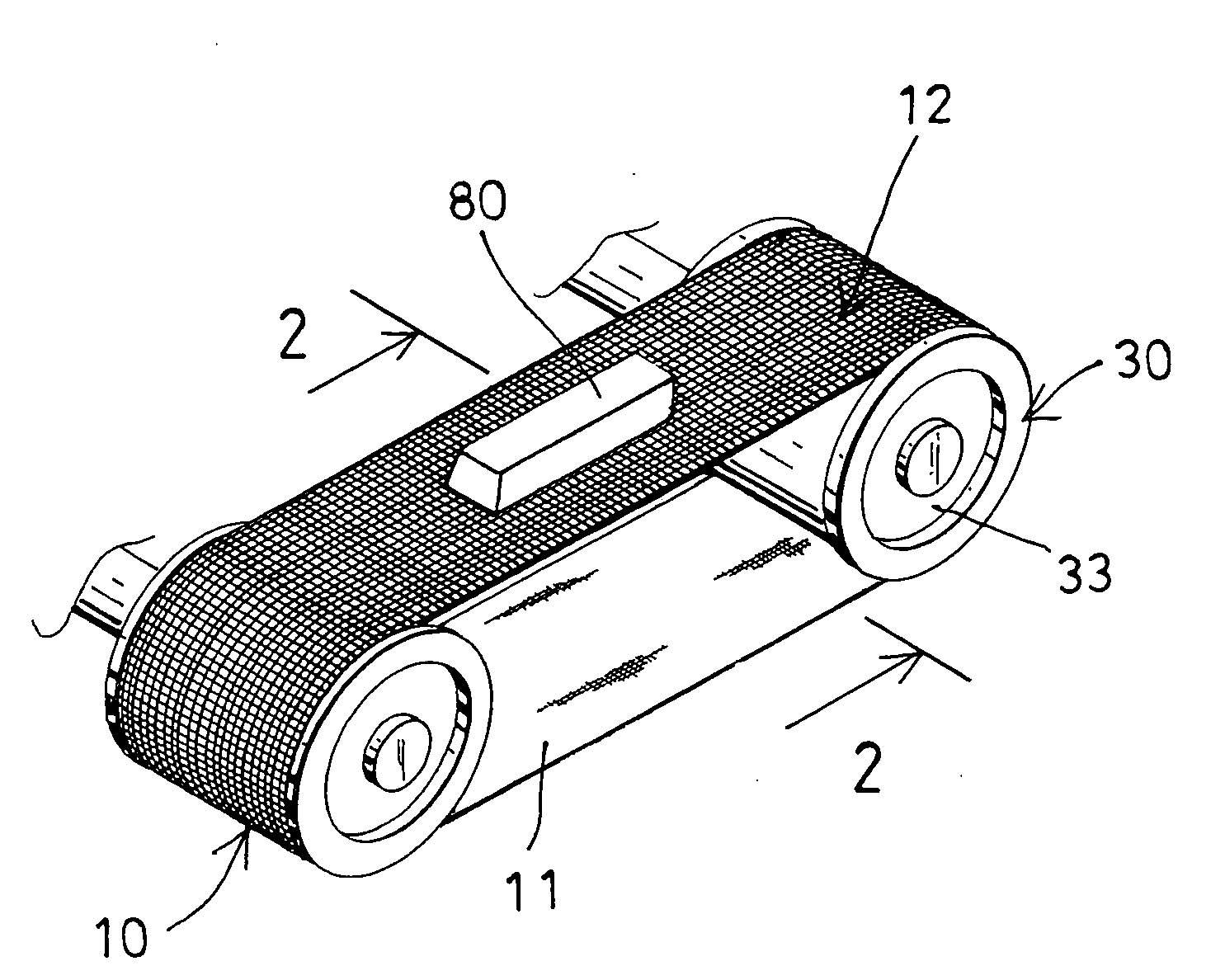

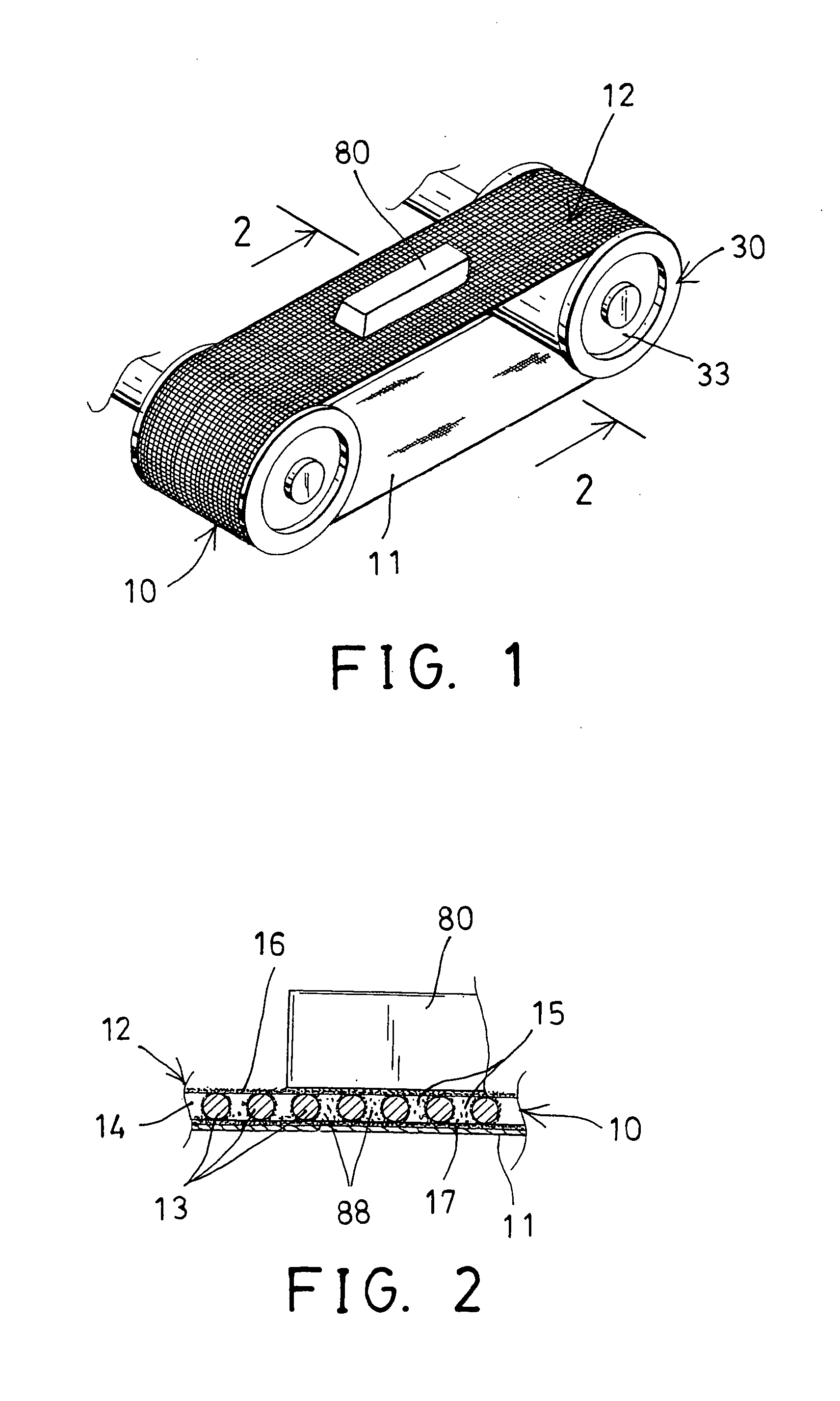

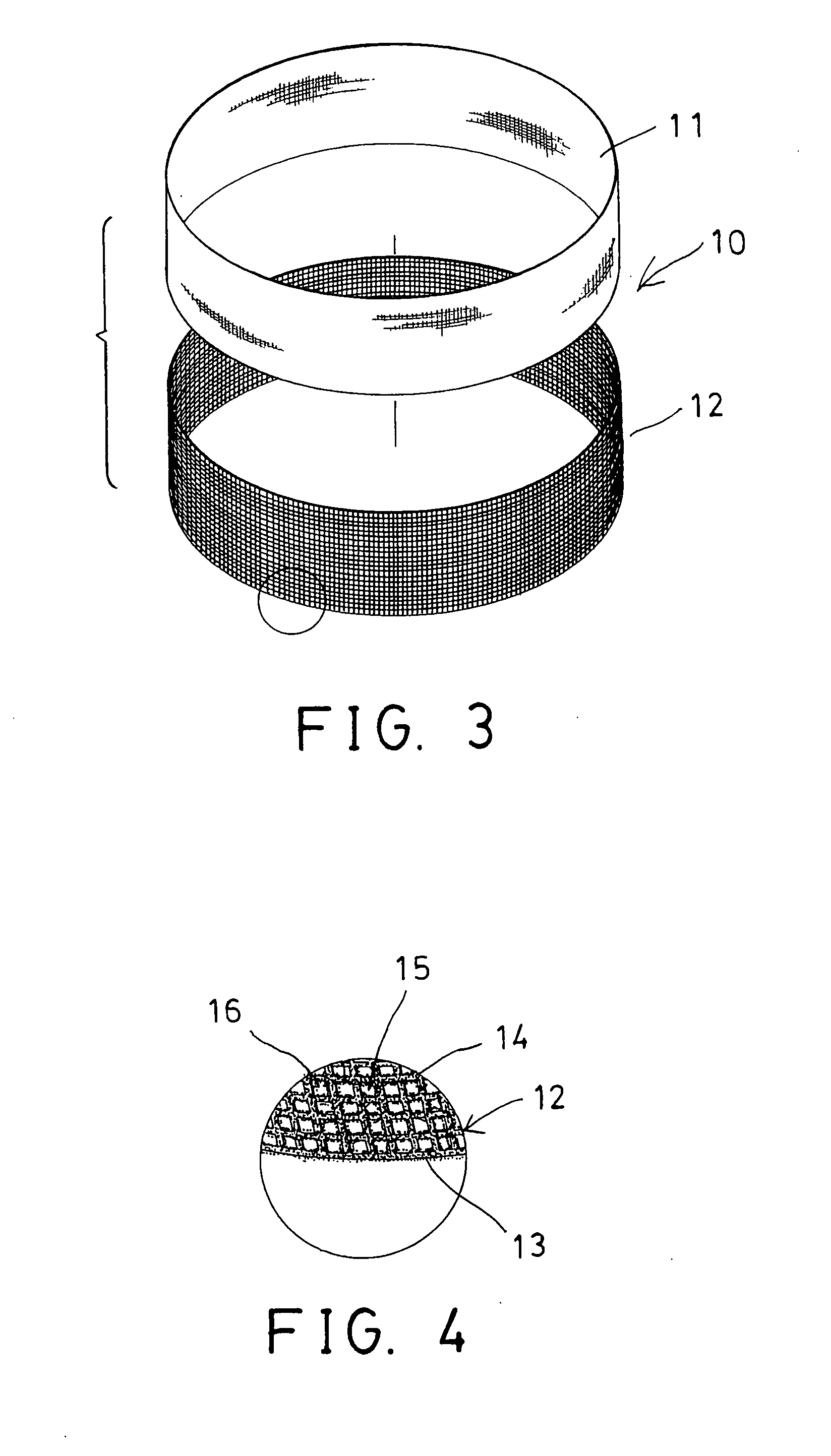

[0021]Referring to the drawings, and initially to FIGS. 1-3, an abrasive belt 10 in accordance with the present invention comprises a planar base layer or member 11, and a net layer or member 12 attached to or engaged onto the base member 11 for forming an endless belt member and for engaging around the pulleys or rollers 33 of a sanding or grinding or abrading machine 30 and for sanding or grinding or abrading work pieces 80.

[0022]As shown in FIGS. 2 and 4, the net member 12 includes a number of longitudinal fibers or fibers or cords 13 and a number of lateral fibers or fibers or cords 14 woven together or secured or welded together as a non-woven structure for forming a number of spaces or compartments or eyelets 15 among or between the cords 13, 14 and for receiving the dust or cut chips 88 (FIG. 2) that will be generated or ground or abraded from the work pieces 80 by the abrasive belt 10.

[0023]The abrasive belt 10 further include a number of sanding or grinding or abrading sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com