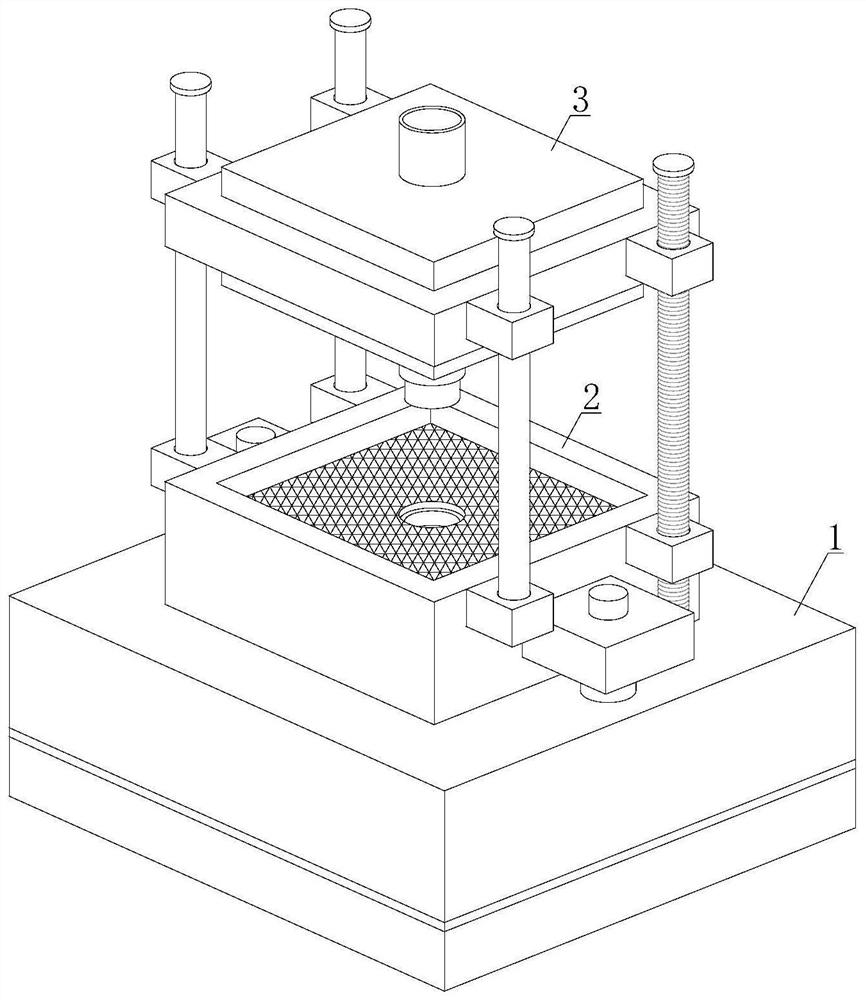

Metal forming device with coated sand cooling mechanism and implementation method thereof

A cooling mechanism and metal forming technology, used in casting and forming equipment, metal processing equipment, casting molds, etc., can solve the problems of long forming time, poor use effect, adhesion, etc., and achieve the effect of easy cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach , 1 Embodiment approach

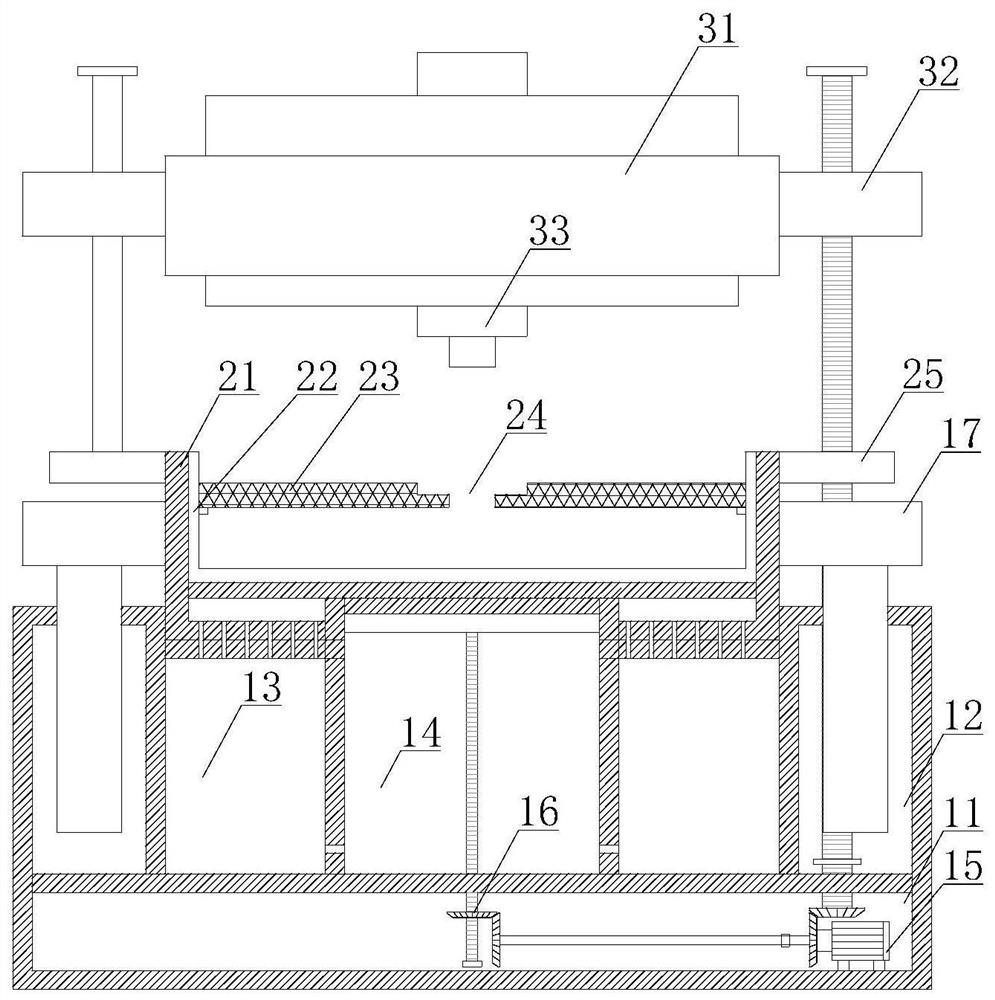

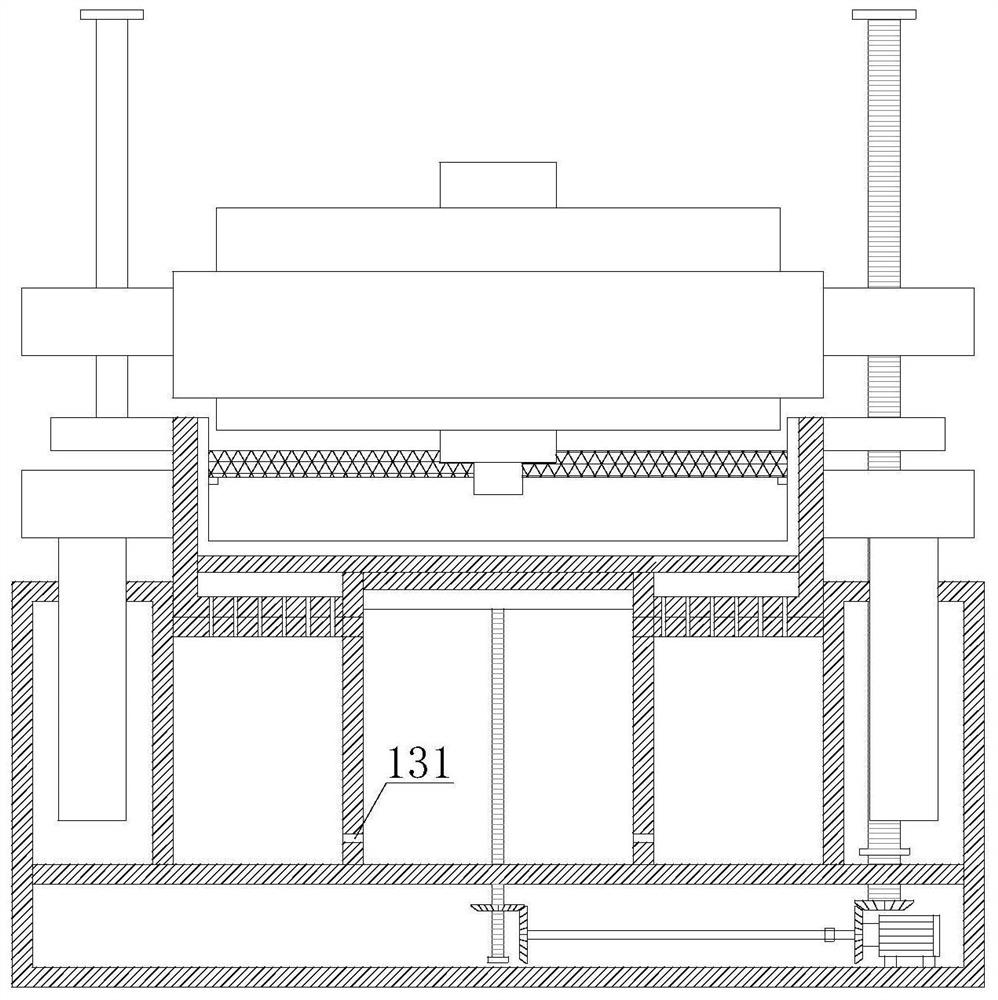

[0042] In order to further and better explain the above-mentioned embodiments, the present invention also provides an embodiment, a method for implementing a metal forming device with a sand-coated cooling mechanism, comprising the following steps:

[0043] Step 1: The operator fills the cooling chamber 13 with cooling water, and fills the sand storage chamber 12 with sand;

[0044] Step 2: place the metal inside the outer casing 21, and turn on the forward and reverse motor 151 to work;

[0045] Step 3: The lower pressure piece 31 drives the lower pressure head 33 to block the through hole 24, and the lower pressure piece 31 is attached to the upper end of the outer shell 21;

[0046] Step 4: Turn on the vacuum pump 173 so that the sand in the sand storage chamber 12 is sprayed out from the nozzle 174 and coated on the outer surface of the metal;

[0047] Step 5: Turn on the forward and reverse motor 151 to make it rotate in the reverse direction, the lower pressing member 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com