Method for directly reducing hot-pressing forging and rolling part/mechanical part product by utilizing powdery iron mine

A technology of mechanical parts and reduced iron, applied in chemical instruments and methods, solid separation, magnetic separation, etc., can solve the problems of scrap steel backlog and difficult to buy castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of powdery iron ore directly reduces the method for iron hot-press counterweight iron nugget (low-grade product), and the steps are as follows:

[0045] (1) Take the alkalinity R of 0.116 and the fineness of 140-160 purpose Hunan Shimen oolitic hematite powder, add 8% hematite powder weight additives to mix and moisten and grind, so that the basicity R is 0.45, and then add Anthracite with a particle size of 0-10mm, 30% by weight of iron ore powder, and a calorific value of 28590kJ / kg, mixed for 10 minutes;

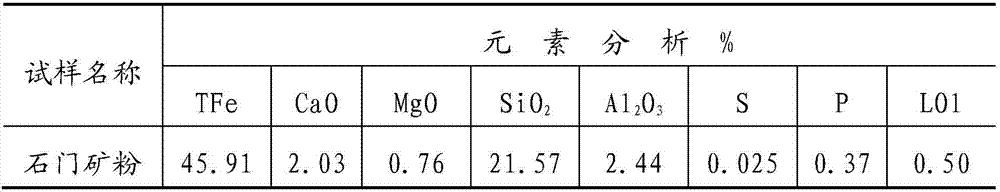

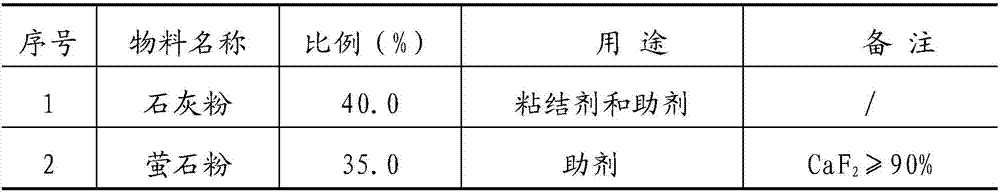

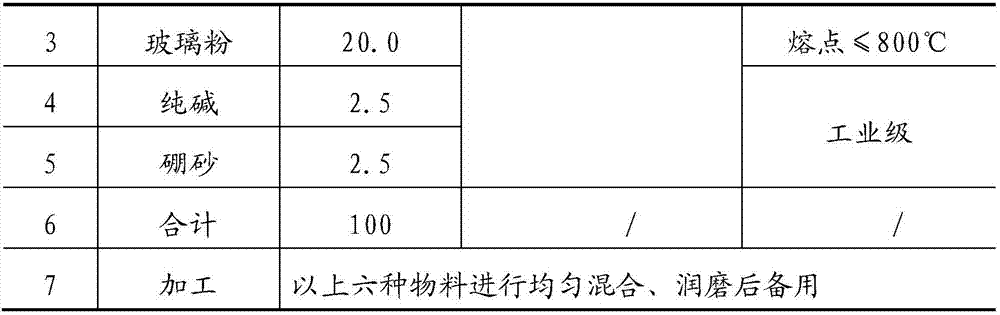

[0046] Among them, the index of Hunan Shimen oolitic hematite powder is shown in Table 1, and the additive formula is shown in Table 2.

[0047] Table 1

[0048]

[0049] Table 2

[0050]

[0051]

[0052] (2) Under the protection of inert gas, separate and reduce the slag and iron in the flame-chambered rotary kiln with a mixing diameter of ¢219mm×22000mm in step (1), and reduce it at 1080°C for 2.5h, and discharge the material under the protecti...

Embodiment 2

[0058] A kind of powdery iron ore directly reduces the method for iron hot-pressing machine part product (middle-grade product), and the steps are as follows:

[0059] (1) get basicity R and be 0.02, fineness be 140-180 purpose iron ore powder (selected from a certain ore dressing plant in Beipiao City, Liaoning Province), mix and grind according to the auxiliary agent that adds iron ore powder weight 2.5%, make it The basicity R is 0.21, then add bituminous coal with a particle size of 0-10mm, a calorific value of 22990kJ / kg, and a weight of 40% iron ore powder, and mix and grind for 10 minutes; the additive formula is shown in Table 4.

[0060] Table 4

[0061]

[0062] (2) Under the protection of inert gas, add the mixed material of step (1) into a flame-chambered rotary kiln with a diameter of ¢219mm×22000mm for separation and reduction of slag and iron, and reduce it at 1050°C for 2.8h, and discharge the material in pulverized coal Cool down to 150°C under protection;...

Embodiment 3

[0070] A method for powdery iron ore to directly reduce iron hot-pressed calcined products (medium-grade products), the steps are as follows:

[0071] (1) get alkalinity R and be 0.02, fineness be 140-180 purpose iron ore powder (selected from a certain ore dressing plant in Beipiao City, Liaoning Province), mix and moisten and grind according to the auxiliary agent that adds iron ore powder weight 3%, make it The basicity R is 0.26, then add bituminous coal with a particle size of 0-10mm, a calorific value of 22990kJ / kg, and 40% of the weight of iron ore powder, and mix and grind for 10 minutes; the additive formula is shown in Table 6.

[0072] Table 6

[0073]

[0074] (2) Under the protection of inert gas, add the mixed material of step (1) into a flame-chambered rotary kiln with a diameter of ¢219mm×22000mm for separation and reduction of slag and iron, and reduce it at 1050°C for 2.8h, and discharge the material in pulverized coal Cool down to 150°C under protection;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com