Preparation process of high-strength wear-resistant concrete

A preparation process and concrete technology, applied in the field of concrete, can solve the problems of concrete surface crushing, concrete fracture, affecting the use of concrete, etc., and achieve the effects of reducing solidification, reducing loss, reducing time and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

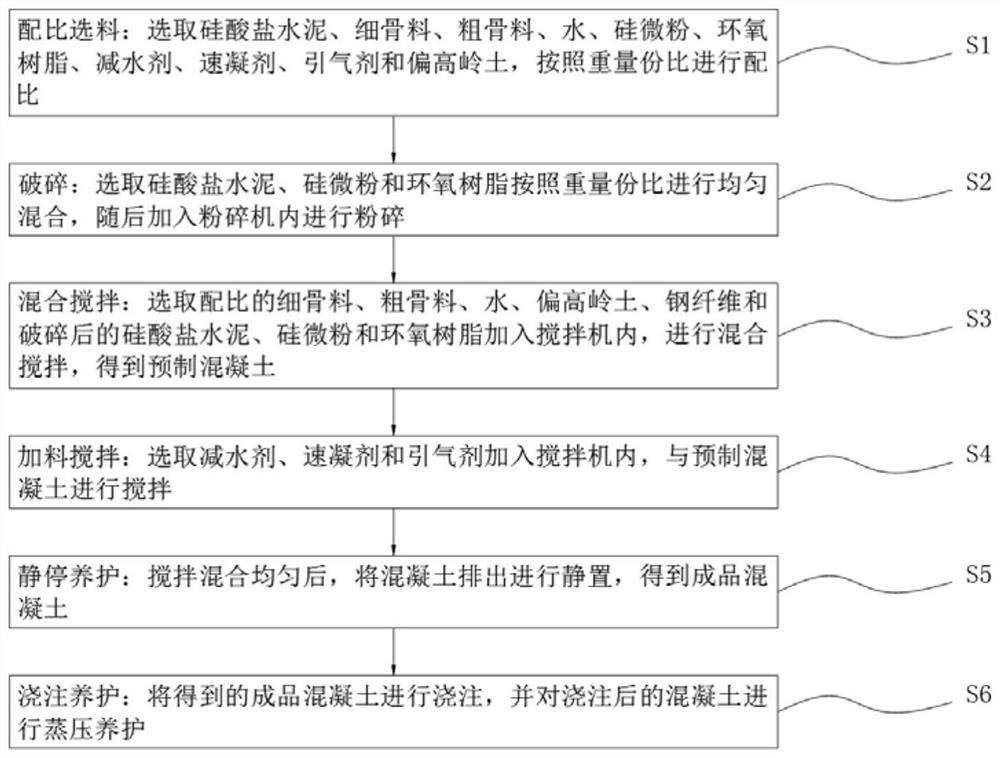

[0043] Such as figure 1As shown, the present invention provides technical scheme, a kind of preparation technology of high-strength wear-resistant concrete, and concrete is made up of following components by weight:

[0044] 350 parts of Portland cement, 700 parts of fine aggregate, 1150 parts of coarse aggregate, 185 parts of water, 30 parts of silicon micropowder, 65 parts of epoxy resin, 8 parts of steel fiber, 2.5 parts of water reducing agent, 9 parts of accelerator , 0.4 parts of air-entraining agent, 53 parts of metakaolin. The fine aggregate is mountain sand, the particle size of the fine aggregate is 2.2mm, the coarse aggregate is crushed stone, the particle size of the fine aggregate is 5.7mm, and the water reducer is specifically lignosulfonate water reducer and melamine-based high-efficiency water-reducing agents, the accelerator is specifically potassium silicate-based accelerators, and the air-entraining agent is specifically alkylaromatic sulfonic acid-based ai...

Embodiment 2

[0054] Such as figure 1 As shown, the present invention provides technical scheme, a kind of preparation technology of high-strength wear-resistant concrete, and concrete is made up of following components by weight:

[0055] 300 parts of Portland cement, 500 parts of fine aggregate, 950 parts of coarse aggregate, 180 parts of water, 20 parts of silicon micropowder, 50 parts of epoxy resin, 5 parts of steel fiber, 1 part of water reducing agent, 6 parts of accelerator , 0.15 parts of air-entraining agent, 40 parts of metakaolin.

[0056] The fine aggregate is specifically mountain sand, the particle size of the fine aggregate is 2mm, the coarse aggregate is crushed stone, the particle size of the fine aggregate is 5mm, and the water reducing agent is specifically lignosulfonate water reducing agent. The coagulant is specifically a potassium silicate type accelerator, and the air-entraining agent is specifically an alkyl aromatic hydrocarbon sulfonic acid type air-entraining a...

Embodiment 3

[0066] Such as figure 1 As shown, a preparation process of high-strength wear-resistant concrete, the concrete is composed of the following components by weight: 400 parts of Portland cement, 900 parts of fine aggregate, 1250 parts of coarse aggregate, 190 parts of water, silica powder 40 parts, 80 parts of epoxy resin, 12 parts of steel fiber, 4 parts of water reducing agent, 12 parts of accelerator, 0.6 parts of air-entraining agent, 65 parts of metakaolin.

[0067] The fine aggregate is specifically one or more of mountain sand and lake sand, the particle size of fine aggregate is 2.4mm, the specific coarse aggregate is pebble, the particle size of fine aggregate is 6.5mm, and the specific water reducer is Naphthalene-based high-efficiency water-reducing agents and melamine-based high-efficiency water-reducing agents. The accelerator is specifically aluminate-type accelerators, and the air-entraining agent is specifically fatty alcohol sulfonate-type air-entraining agents. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com