Patents

Literature

198results about How to "Effective deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

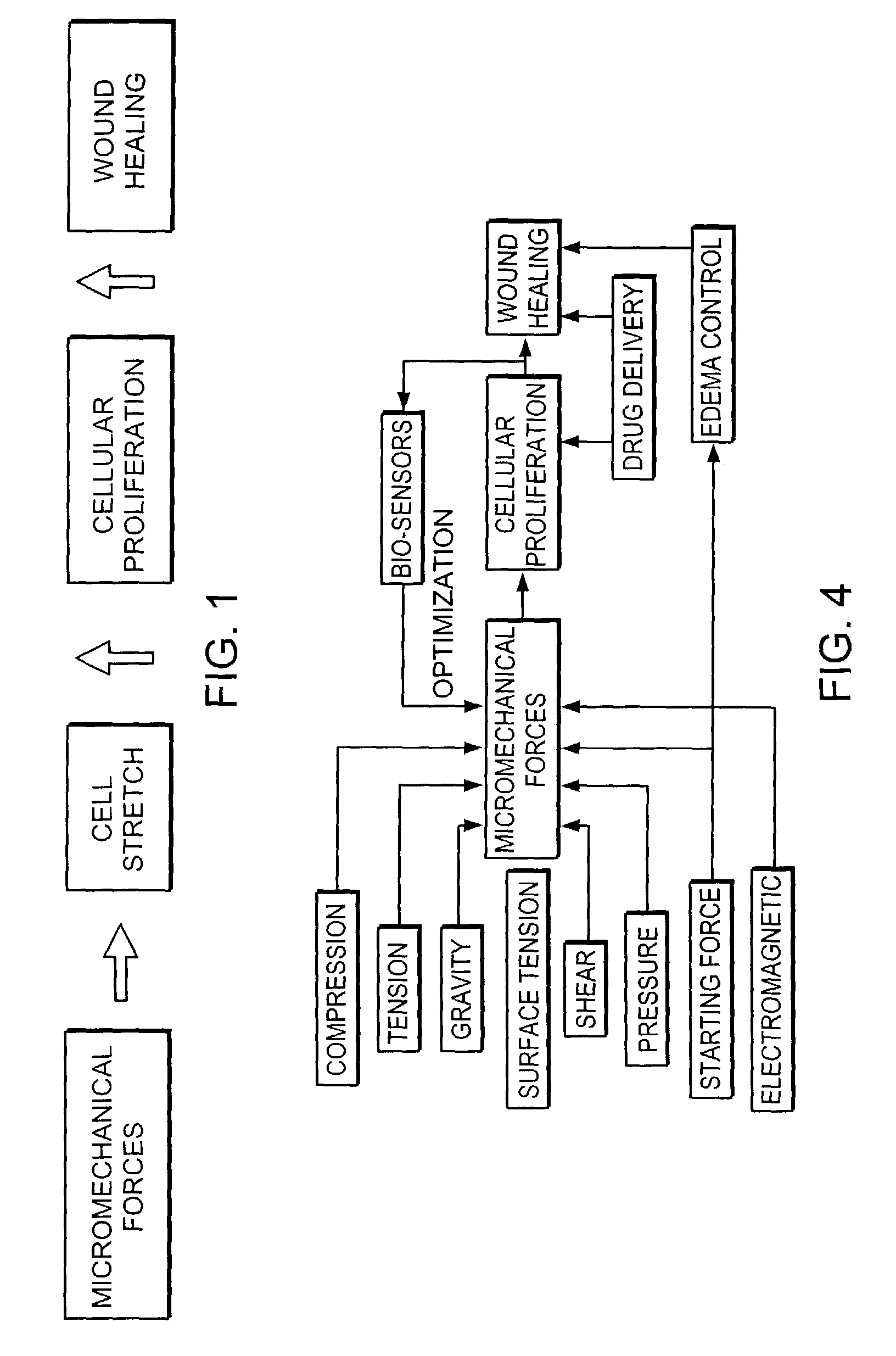

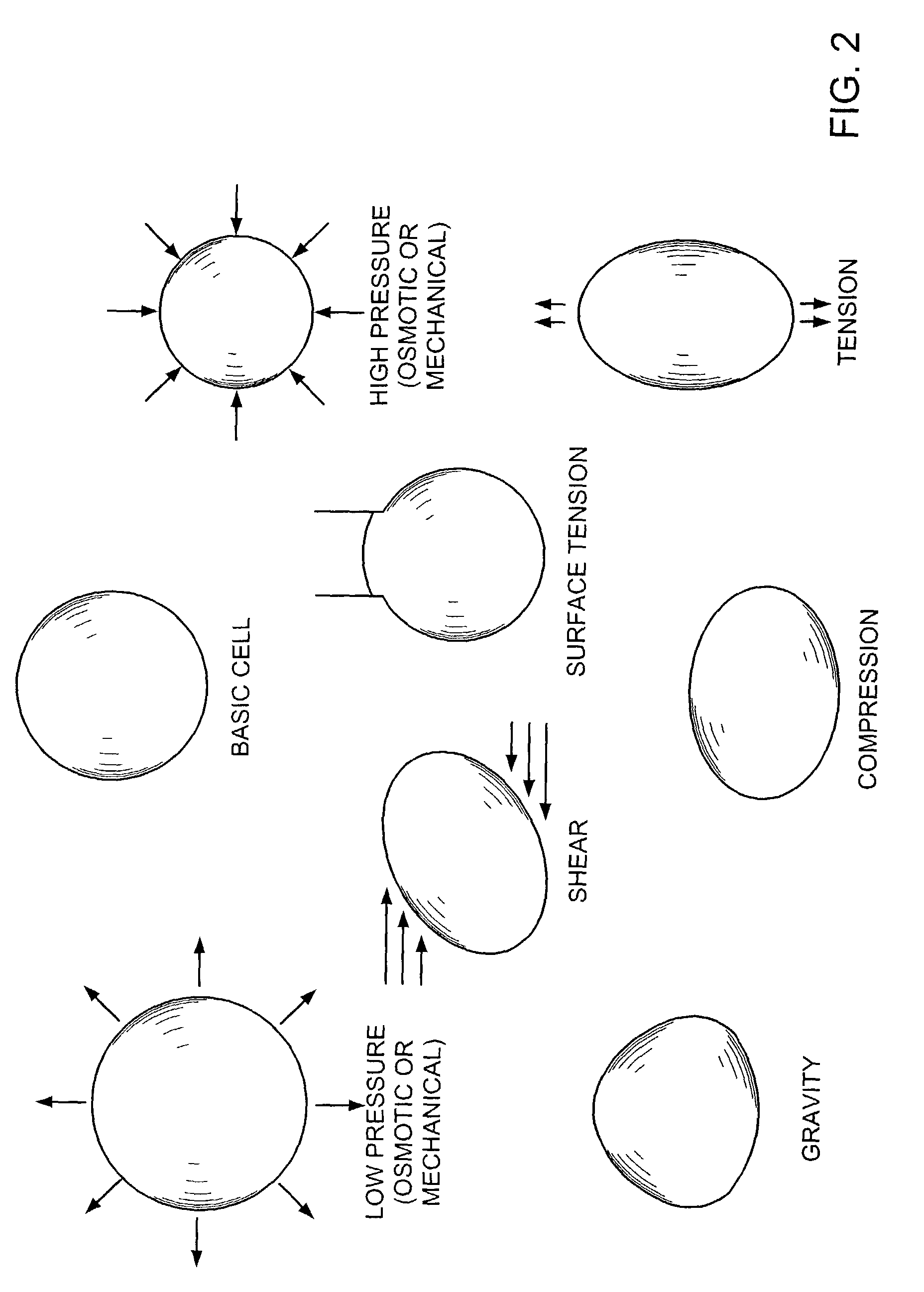

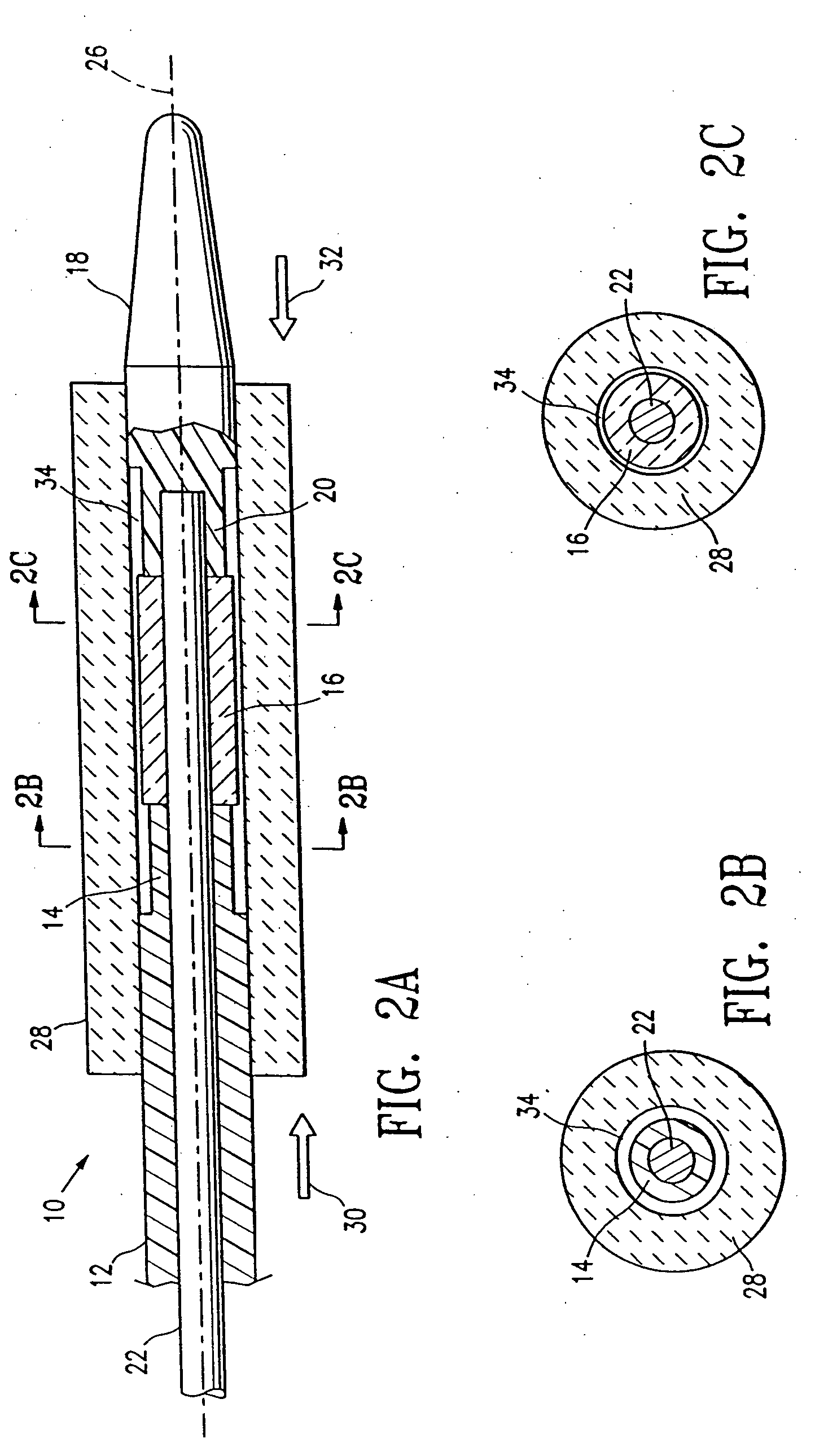

Methods and apparatus for application of micro-mechanical forces to tissues

InactiveUS7494482B2Accelerate tissue ingrowthEnhancing tissue repairNon-adhesive dressingsBone implantMicron scaleCell-Extracellular Matrix

Methods and devices for transmitting micromechanical forces locally to induce surface convolutions into tissues on the millimeter to micron scale for promoting wound healing are presented. These convolutions induce a moderate stretching of individual cells, stimulating cellular proliferation and elaboration of natural growth factors without increasing the size of the wound. Micromechanical forces can be applied directly to tissue, through biomolecules or the extracellular matrix. This invention can be used with biosensors, biodegradable materials and drug delivery systems. This invention will also be useful in pre-conditioned tissue-engineering constructs in vitro. Application of this invention will shorten healing times for wounds and reduce the need for invasive surgery.

Owner:MASSACHUSETTS INST OF TECH +2

Heat resistant coated member, making method, and treatment using the same

InactiveUS20040110016A1Increase resistanceAvoid deformationMolten spray coatingSurface reaction electrolytic coatingSurface layerRare earth

A coated member comprising a substrate of Mo, Ta, W, Zr or carbon and a coating of rare earth-containing oxide including a surface layer having a Vickers hardness of at least 50; or a coated member comprising a substrate having a coefficient of linear expansion of at least 4x10<-6 >(1 / K) and a coating of rare earth-containing oxide thereon is heat resistant and useful as a jig for use in the sintering of powder metallurgical metal, cermet and ceramic materials.

Owner:SHIN ETSU CHEM IND CO LTD

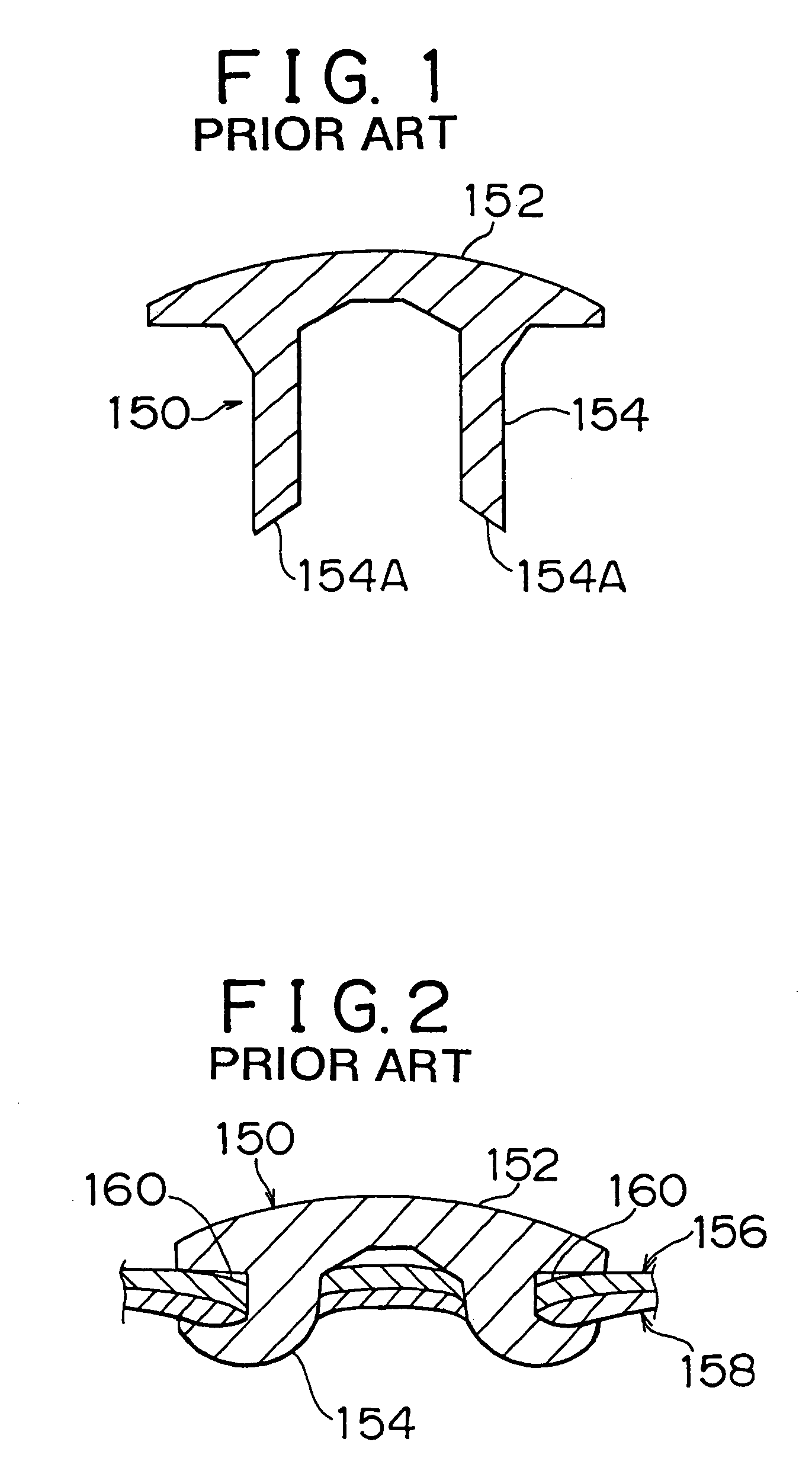

Rivet, riveted joint structure riveting apparatus, and riveting method

InactiveUS6988862B1Improved strengthImprove fastening strengthRivetsSheet joiningExtremity PartEngineering

A rivet is provided which includes axially opposite end portions at least one of which is more likely to be deformed radially outwards than a remaining portion thereof, and the remaining portion is more resistant to a load applied in an axial direction of the rivet than the axially opposite end portions. As one example, the rivet includes a head portion and a cylindrical portion that extends from the head portion, and a recess is formed in the head portion so as to be open to a top surface of the head portion.

Owner:TOYOTA JIDOSHA KK

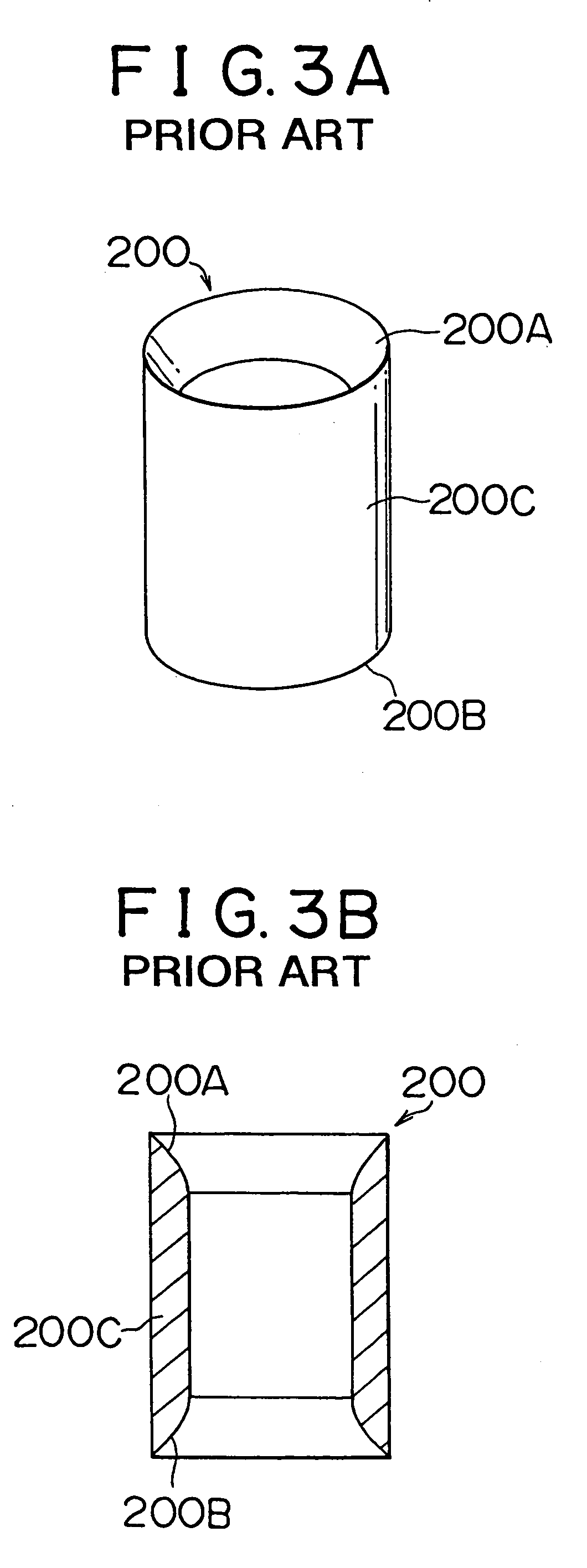

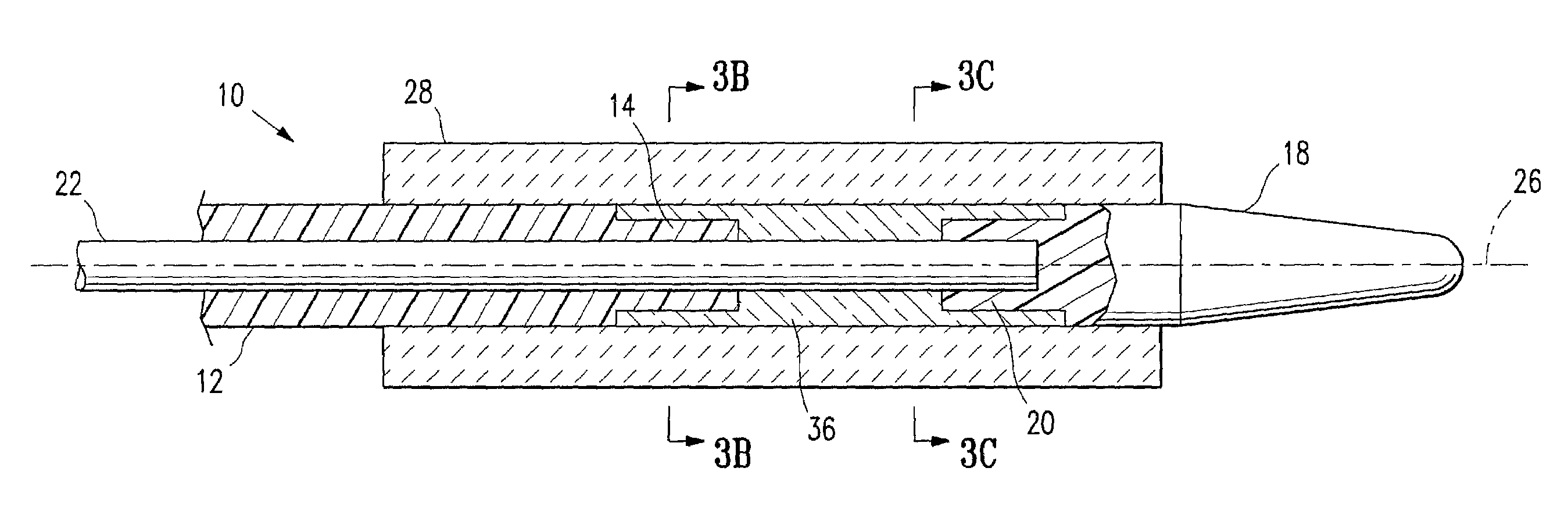

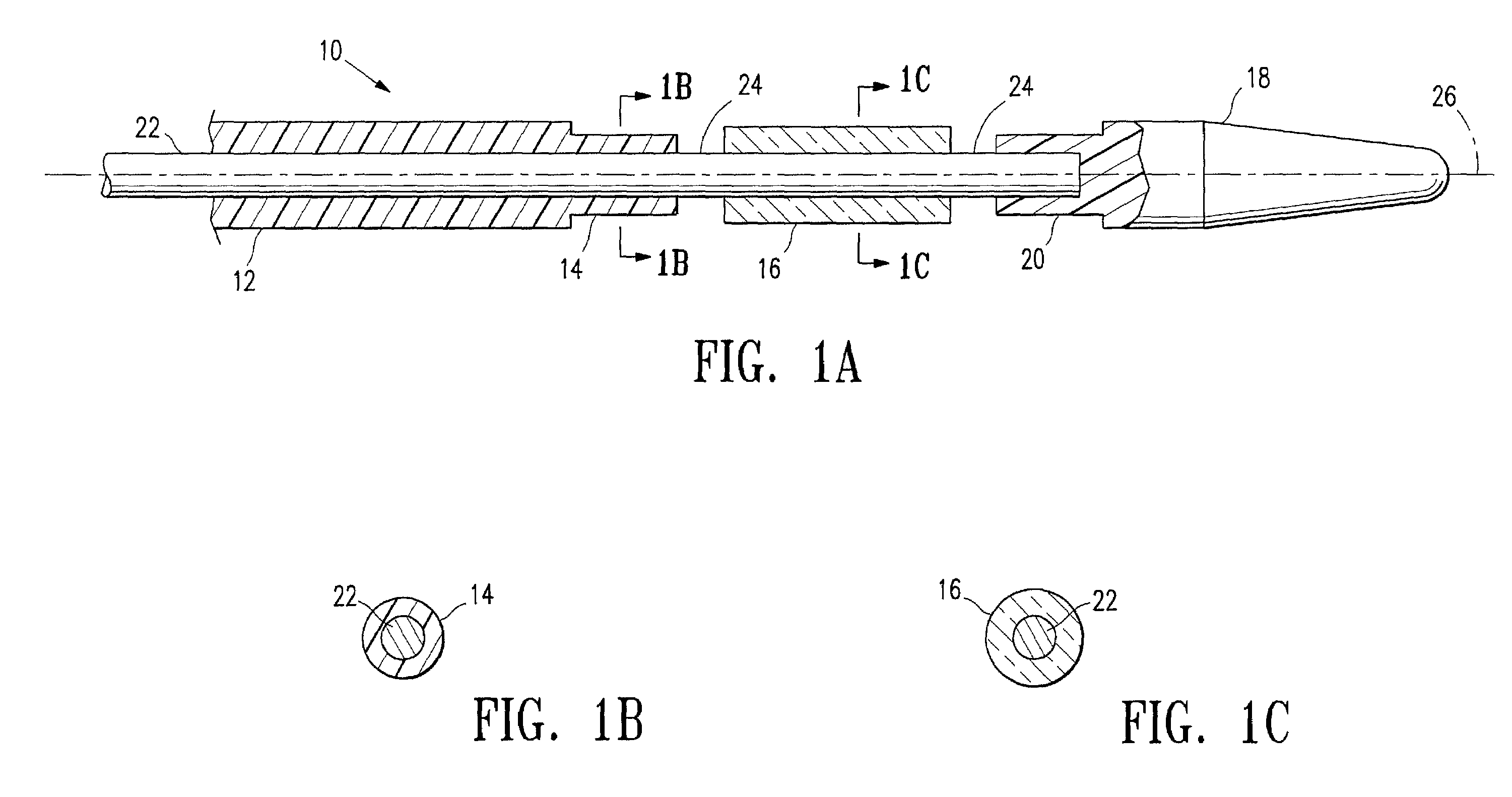

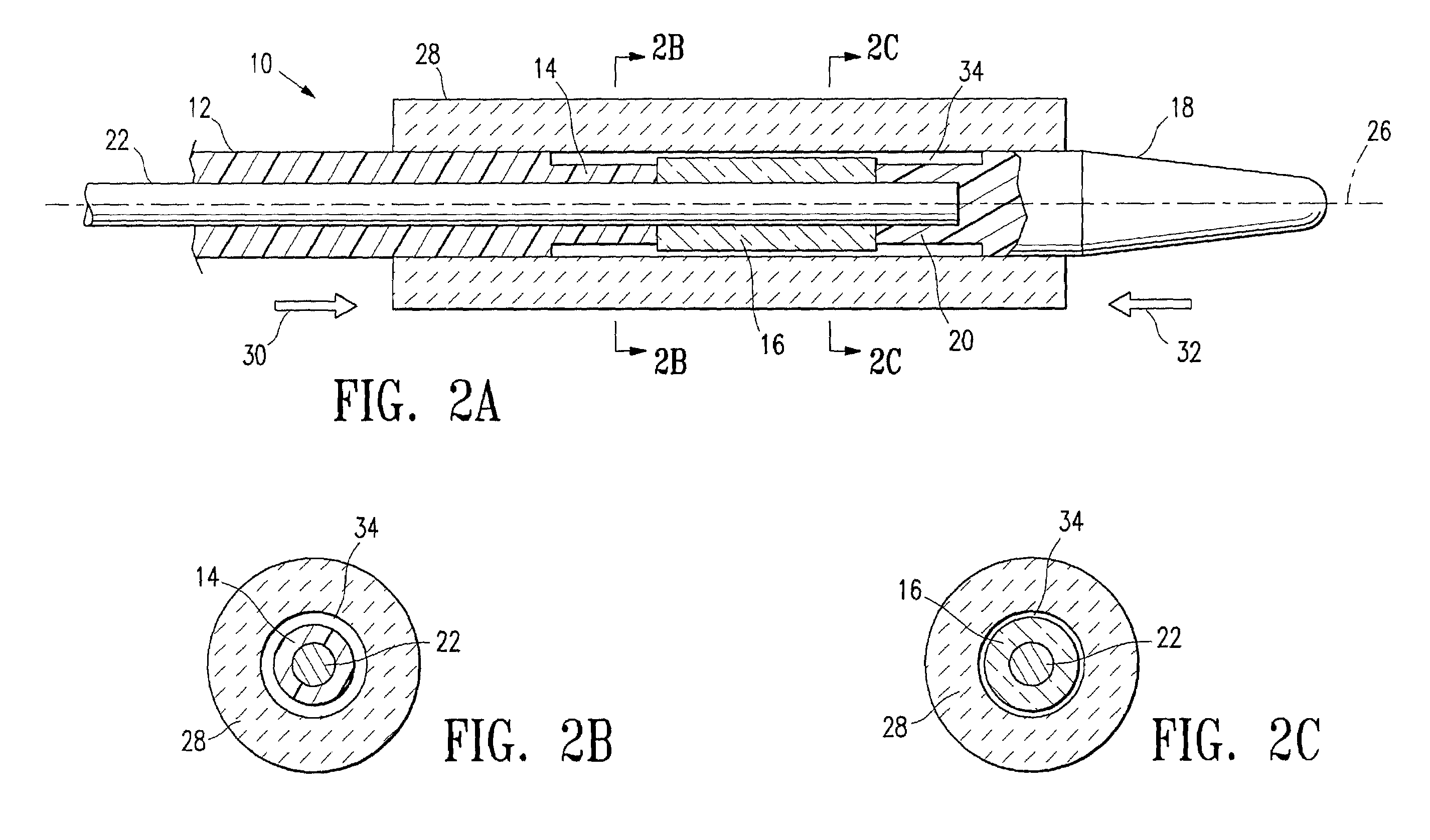

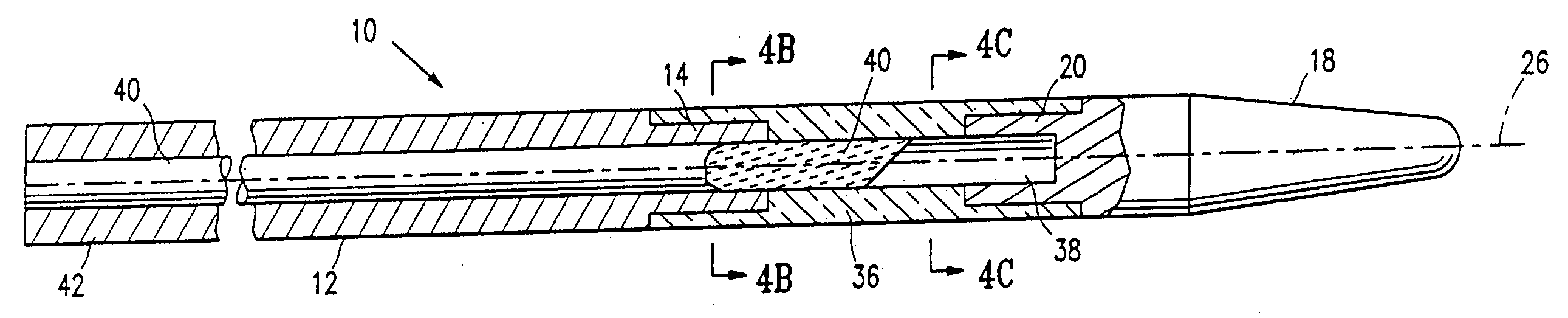

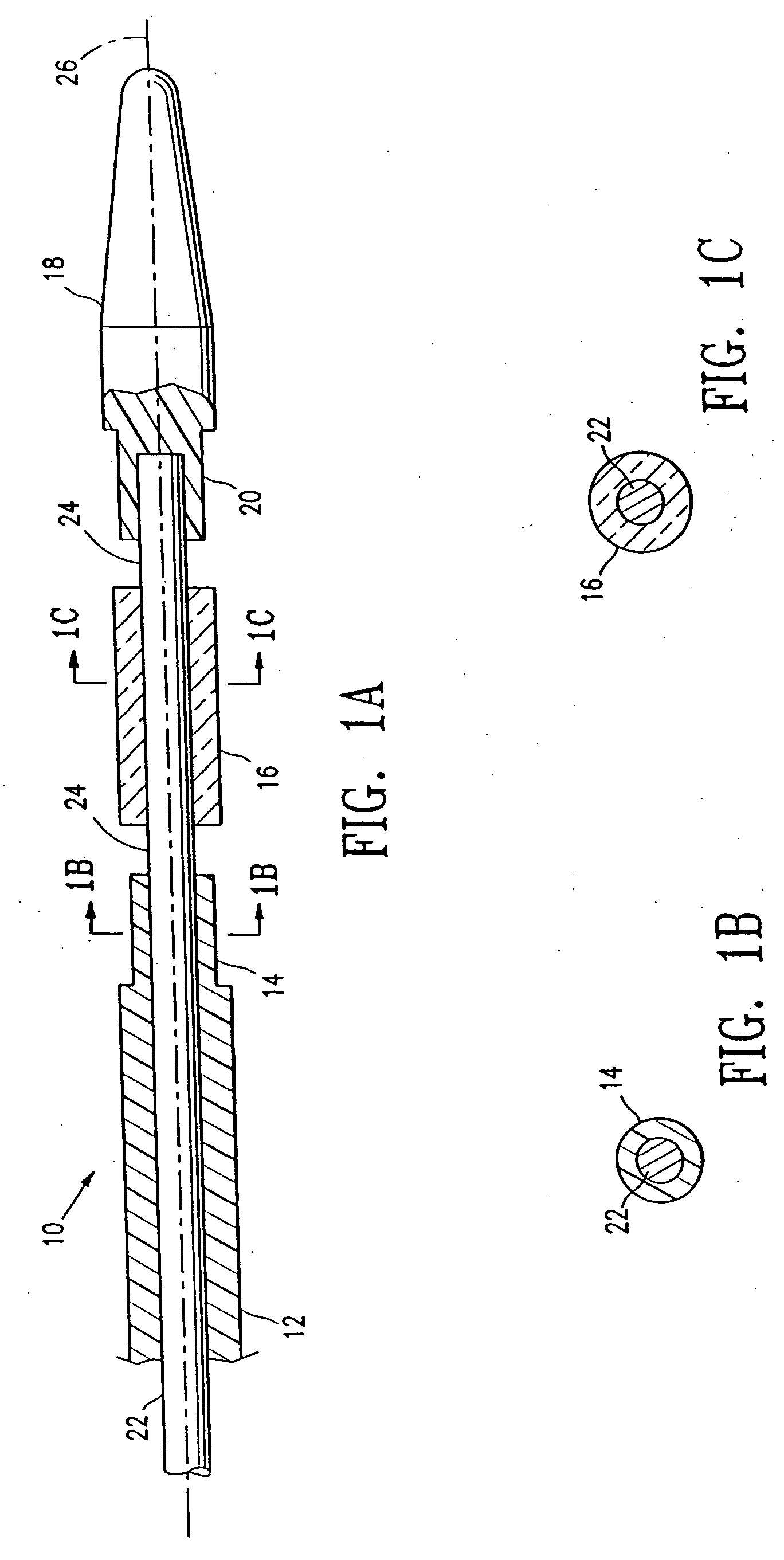

Methods for forming an optical window for an intracorporeal device and for joining parts

InactiveUS6974557B1Rapid flowing of meltedAvoid problemsInduction heatingLaminationEngineeringEndoscope

Optical windows for intracorporeal devices, intracorporeal devices comprising a window and a method for forming a window for an intracorporeal device are provided. The method comprises placing within a mold an assembly comprising a mandrel located within a pair of parts separated by a collar of window material, heating the window preform effective to cause the window material to soften, and applying force to urge together the pair of parts to deform the window material so as to form a window. The intracorporeal devices, such as imaging devices, include guidewires, catheters, endoscopes. In addition, the method is suitable for joining plastic parts to other parts, such as metal and ceramic parts.

Owner:ABBOTT CARDIOVASCULAR

Structure fabrication method

InactiveUS20090031548A1Guaranteed to workImprove efficiencyAssembly machinesElectrostatic generators/motorsEngineeringMechanical engineering

In a structure fabrication method for fabricating a structure including an inclined part inclined to a principal plane of a substrate by plastically deforming a work piece having the substrate with the principal plane, the structure fabrication method includes the steps of providing in the work piece a projection configured to protrude from a first surface and away from the principal plane of the substrate; and bending the work piece toward a second surface opposite to the first surface. The bending is accomplished by applying a force on a block including an inclined pressure plane that is abutted on the projection for plastically deforming the work piece, in which in bending the work piece, the direction of a first force applied on the work piece intersects with the direction of a second force of the inclined pressure plane pushing the projection.

Owner:CANON KK

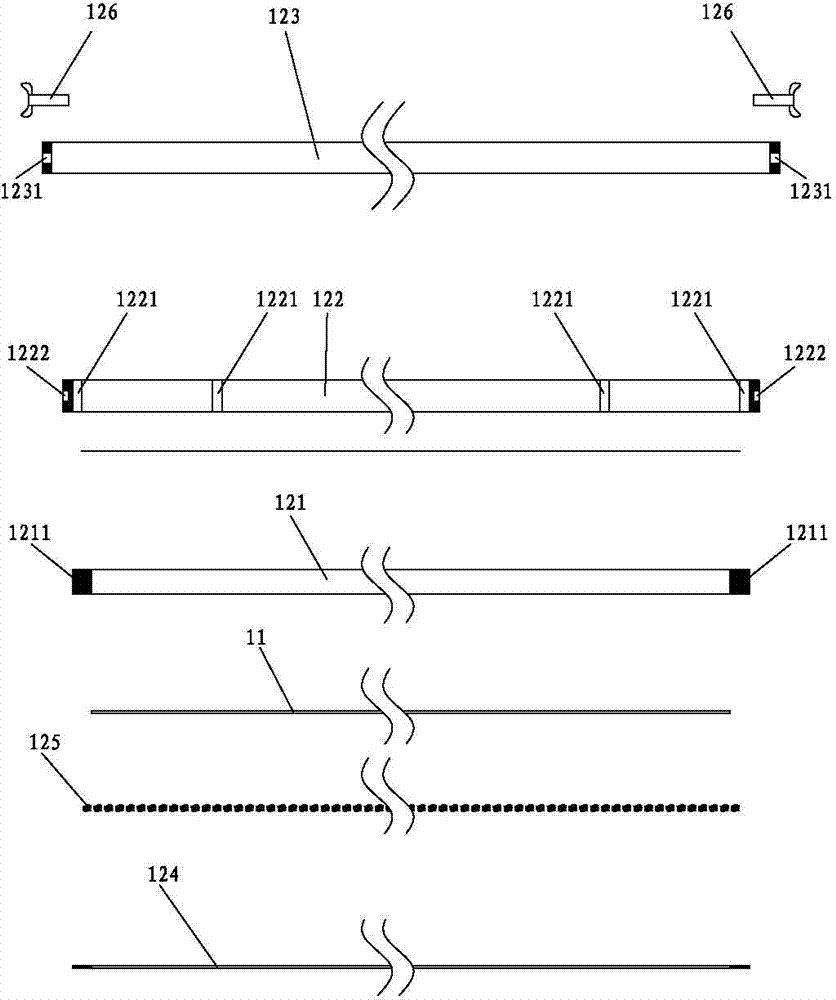

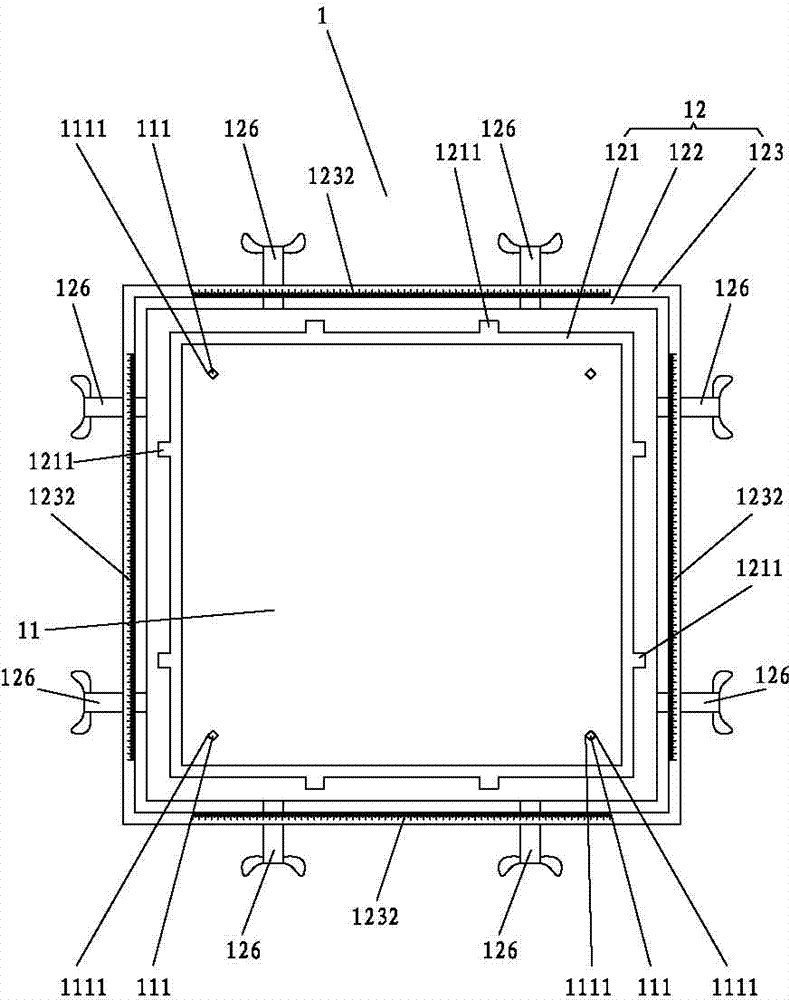

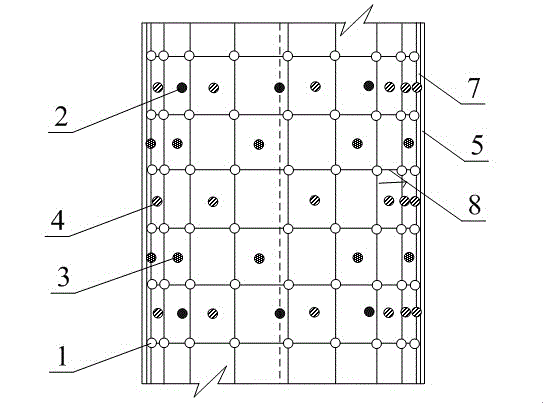

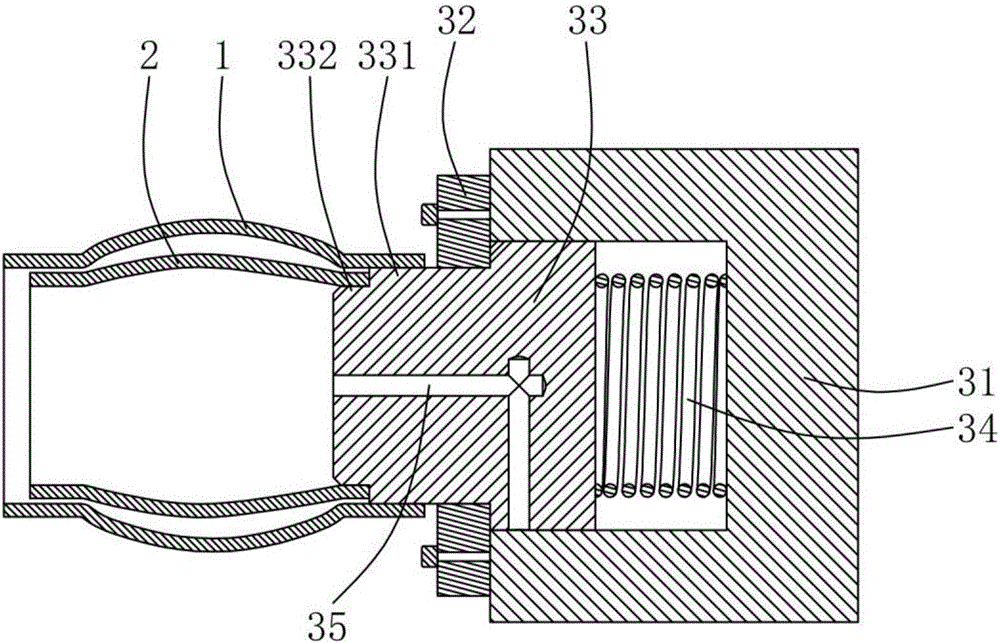

Silk screen printing plate, double-printing device, double-printing machine and double-printing process

ActiveCN104228321AAffect printing qualityGuaranteed printing qualityScreen printersScreen printingEngineering

The invention provides a silk screen printing plate. A screen frame comprises an inner screen frame, a middle screen frame and an outer screen frame. A sliding groove is formed in the middle screen frame. A sliding rail matched with the inner screen frame is formed on the inner screen frame. The middle screen frame is provided with a blocking frame. A plurality of springs are evenly distributed between the inner screen frame and the blocking frame. An adjusting bolt is arranged on the outer screen frame in a matched mode. A silk screen is provided with an adjusting aligning point. An adjusting aligning scale is arranged on the outer screen frame. Accordingly, by means of the silk screen printing plate, silk screen patterns can be adjusted and aligned effectively, high-quality double-printing is achieved, obvious deformation of the silk screen can be avoided effectively, and the printing quality of the silk screen patterns is guaranteed. The invention further provides a double-printing device, the double-station double-printing operation can be achieved, the silk screen printing plate is excellent in effect, and the double-printing efficiency and quality are improved remarkably. The invention further provides a double-printing machine which has the excellent effects of the silk screen printing plate and the double-printing device, and the double-printing efficiency and quality are improved remarkably. The invention further provides a double-printing process. The process is concise and clear and high in double-printing efficiency and quality.

Owner:SHISHI DECAI CHEM TECH

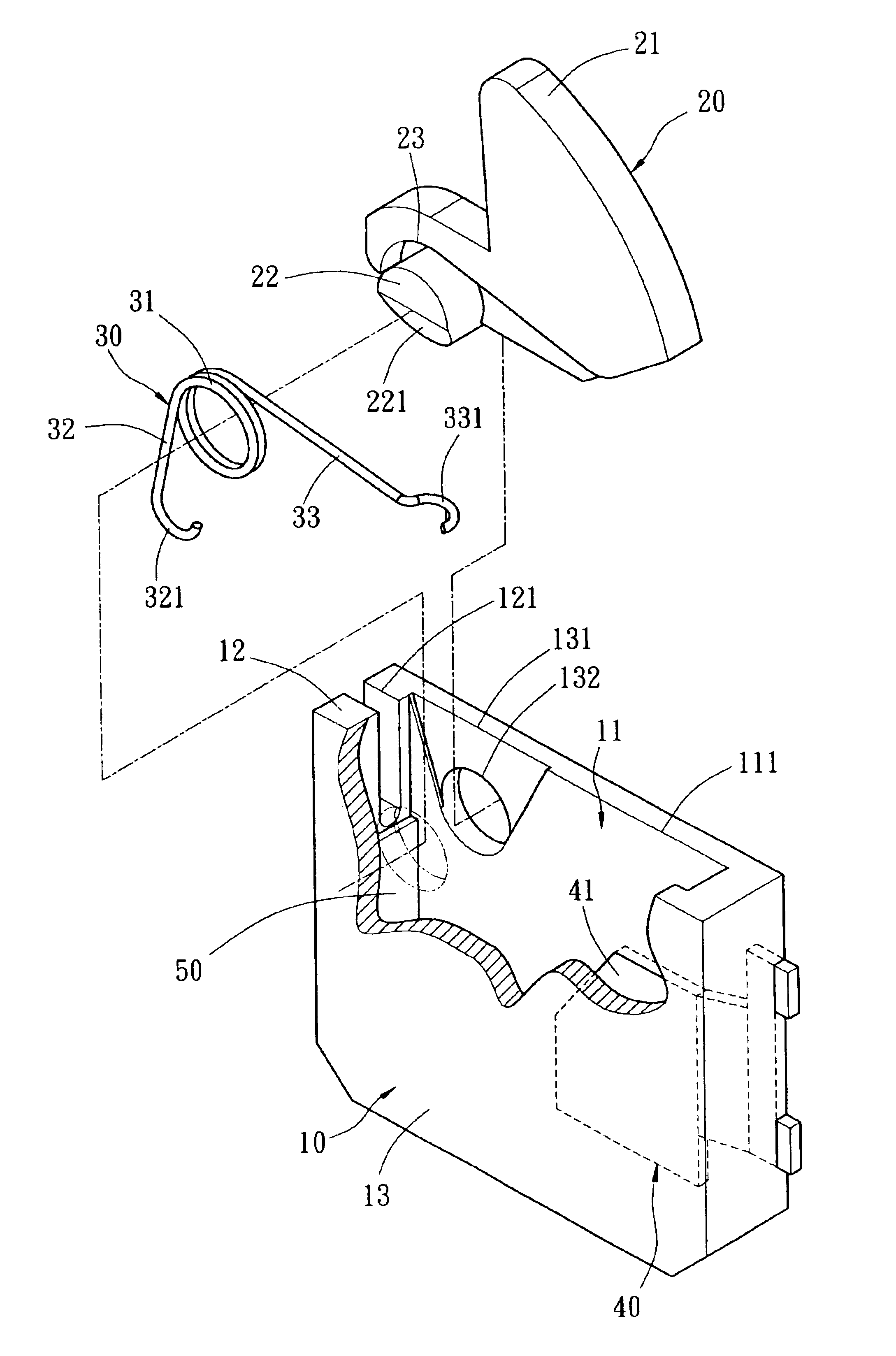

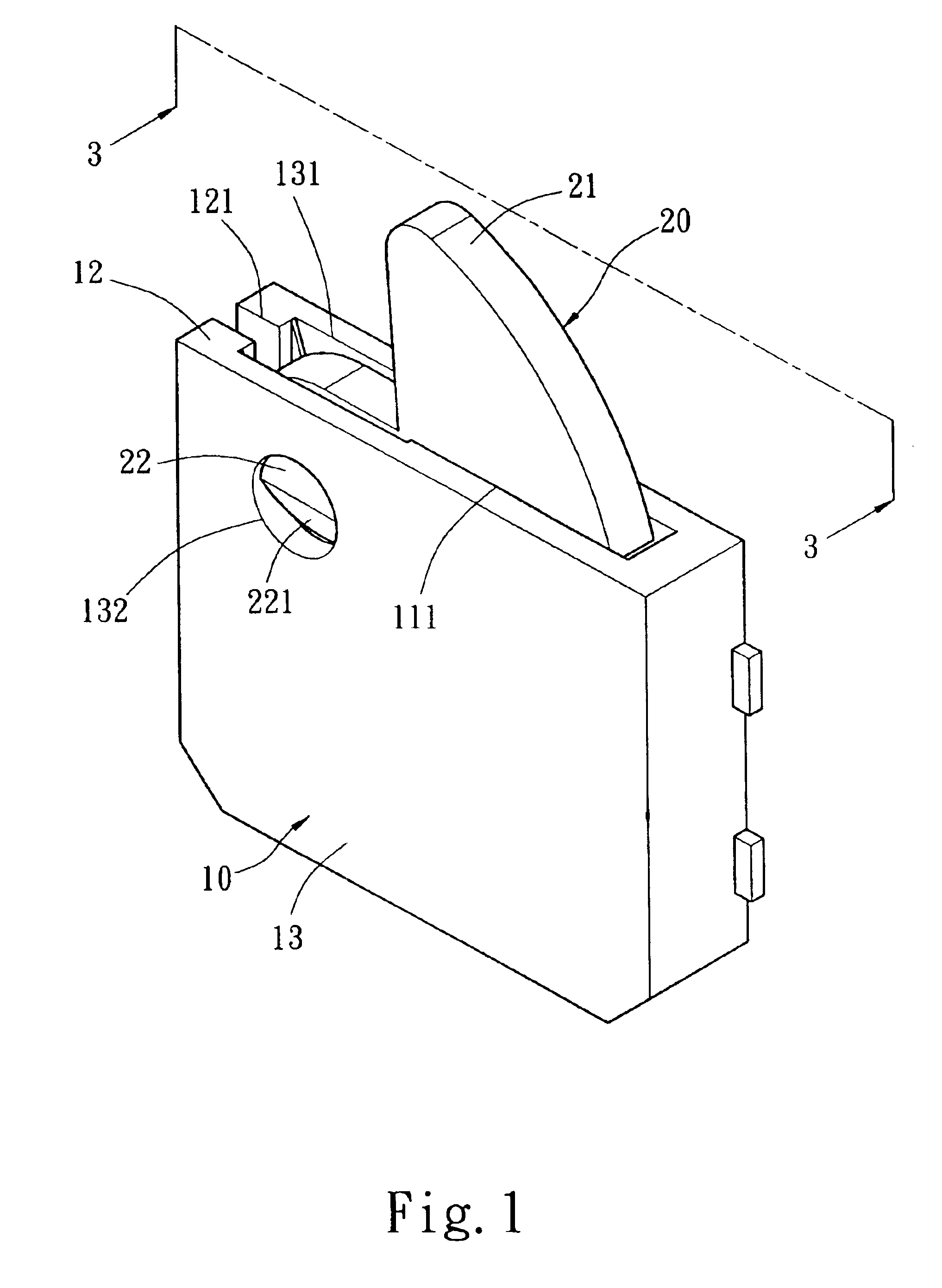

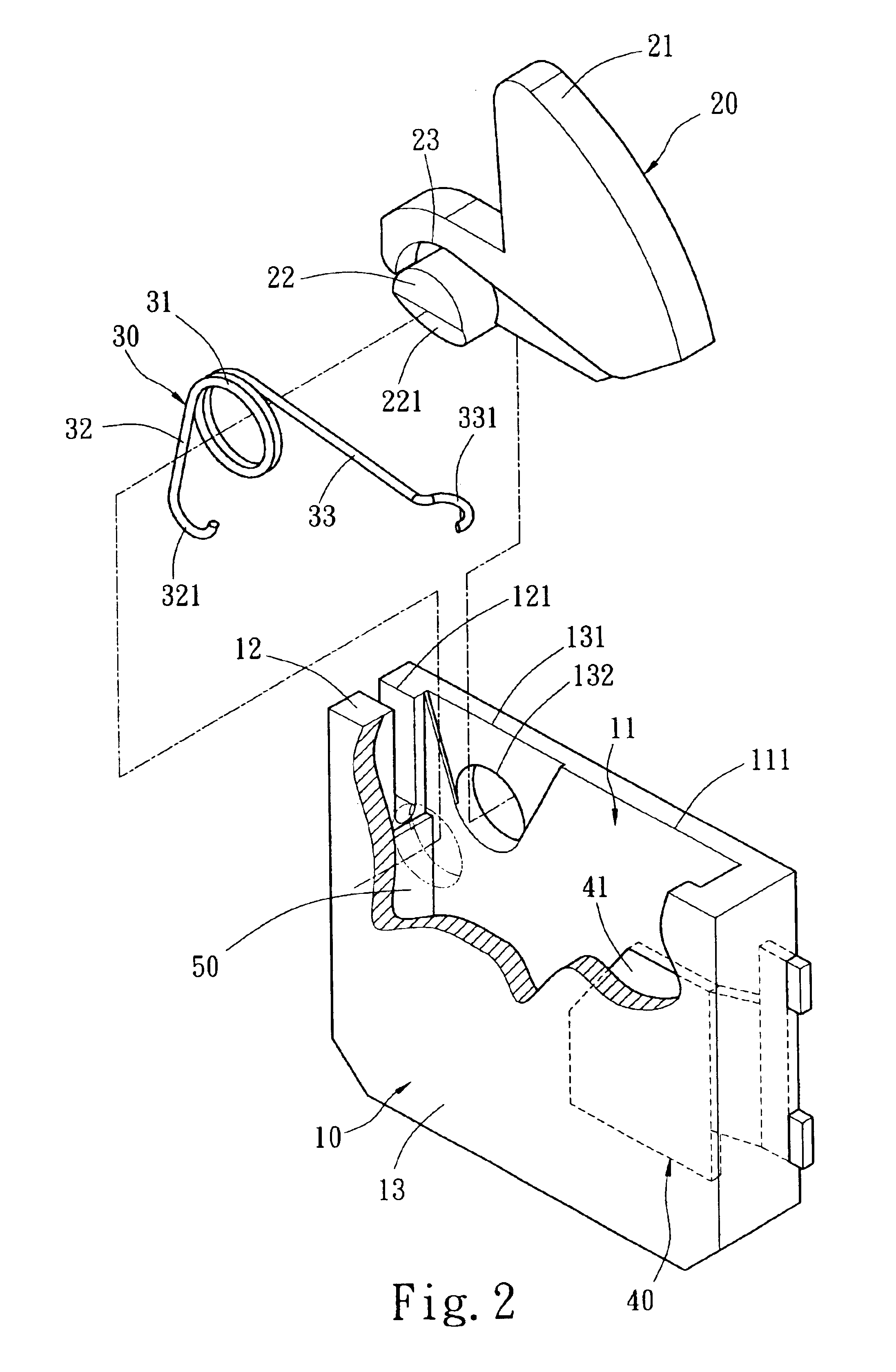

Microswitch

InactiveUS6917008B1Easy to assembleEasy to manufactureTumbler/rocker switchesContact engagementsControl signalPush-button

Owner:ZIPPY TECH

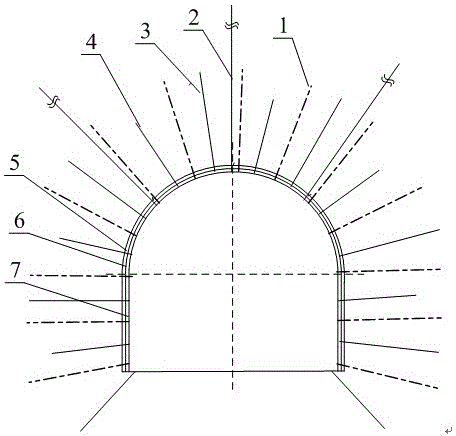

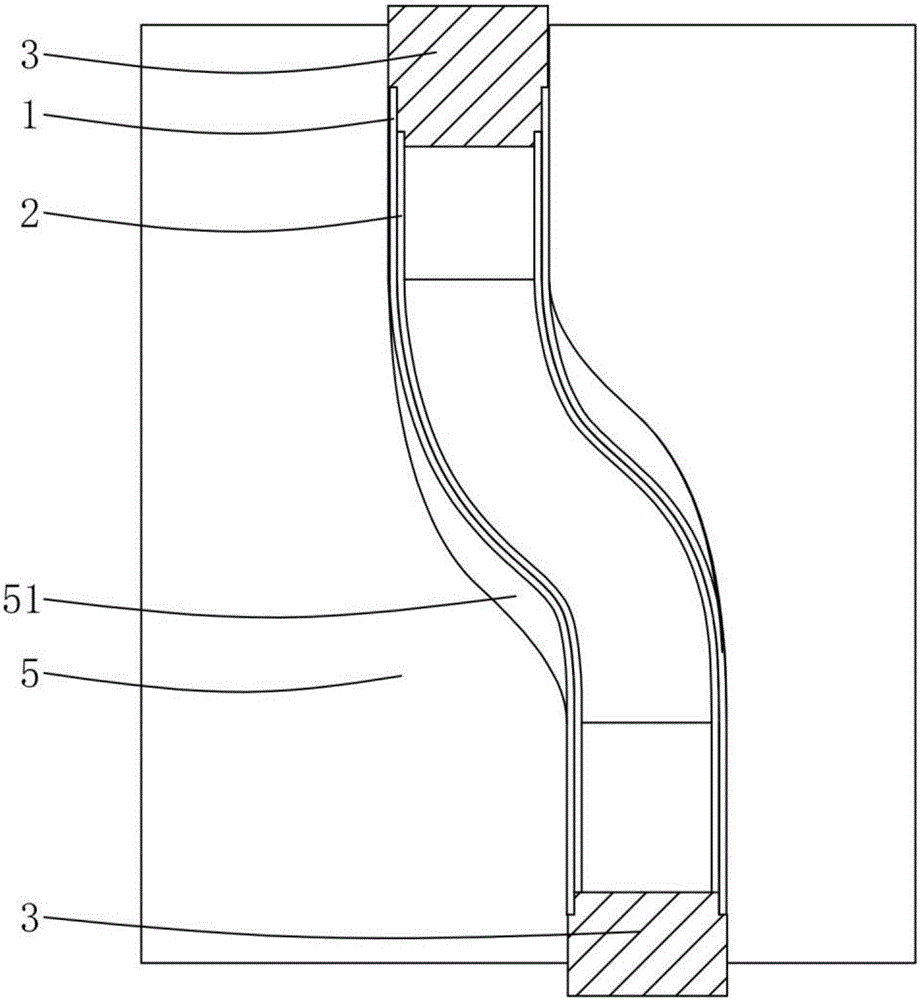

Supporting method of permeable soft broken rock stratum roadway

InactiveCN103603675AEffective deformationEffectively closedUnderground chambersTunnel liningSteel barCement slurry

The invention relates to a supporting method of a roadway in a coal mime, particularly to a supporting method of a permeable soft broken rock stratum roadway. The supporting method aims at solving the problems that soft broken rock stratum roadways especially permeable soft broken rock stratum roadways are poor in supporting effect, high in cost and the like. The supporting method comprises the steps of first concrete spraying; combined support through high strength deformed steel bar anchor rods and diamond metal nets; anchor cable installation; secondary concrete spraying; installation of chemical pulp grouting anchor rods; installation of cement slurry grouting anchor rods.

Owner:张瀚

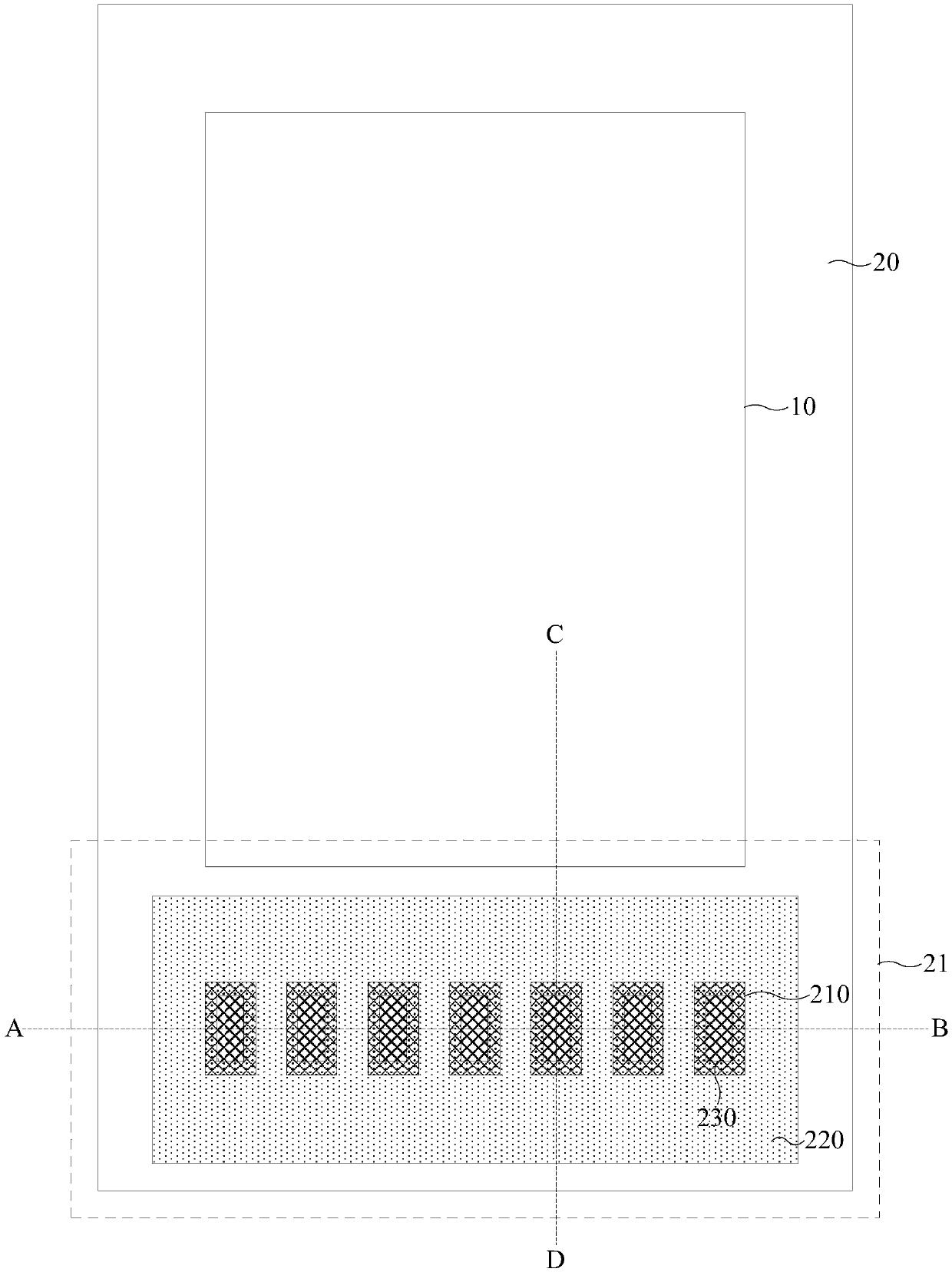

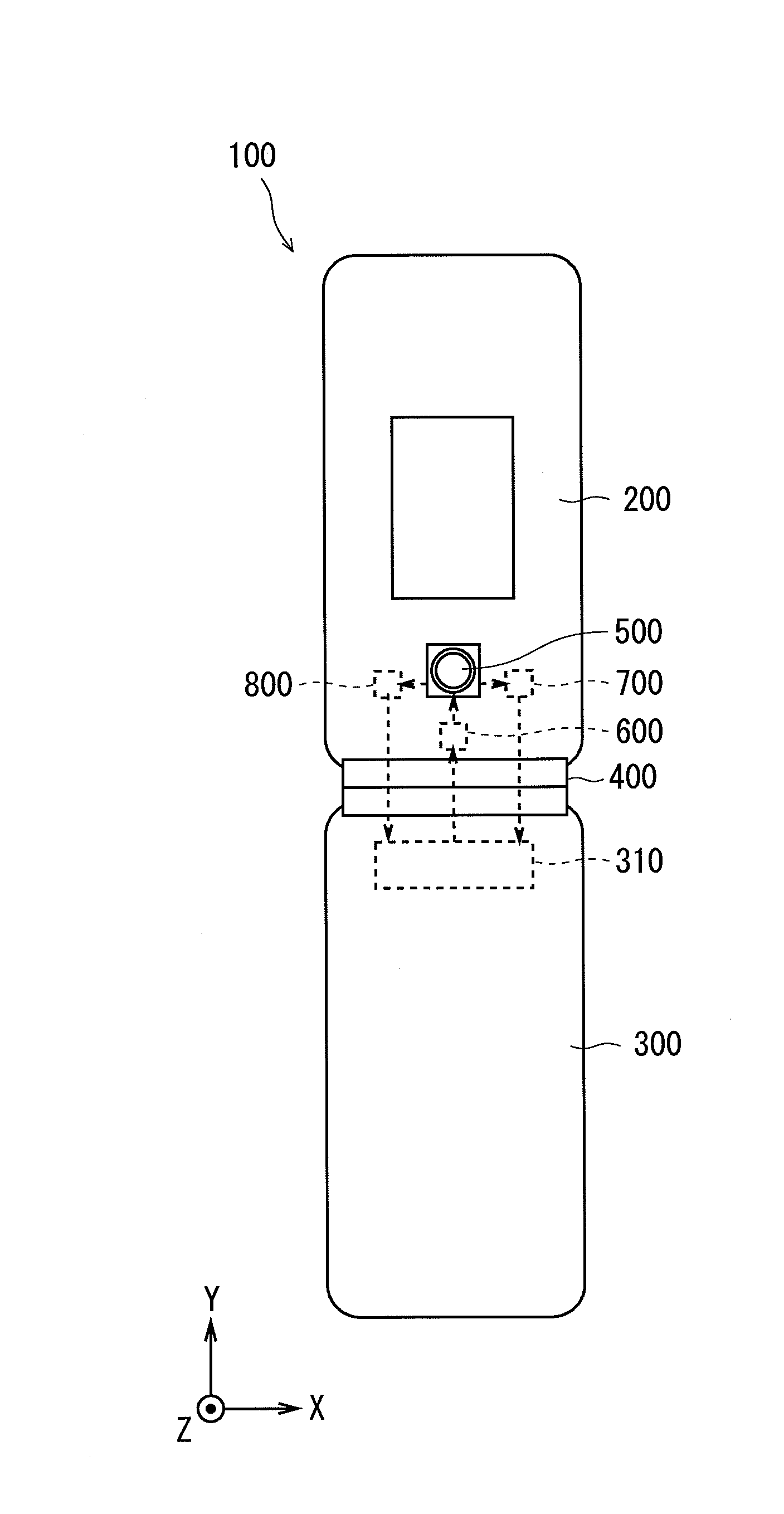

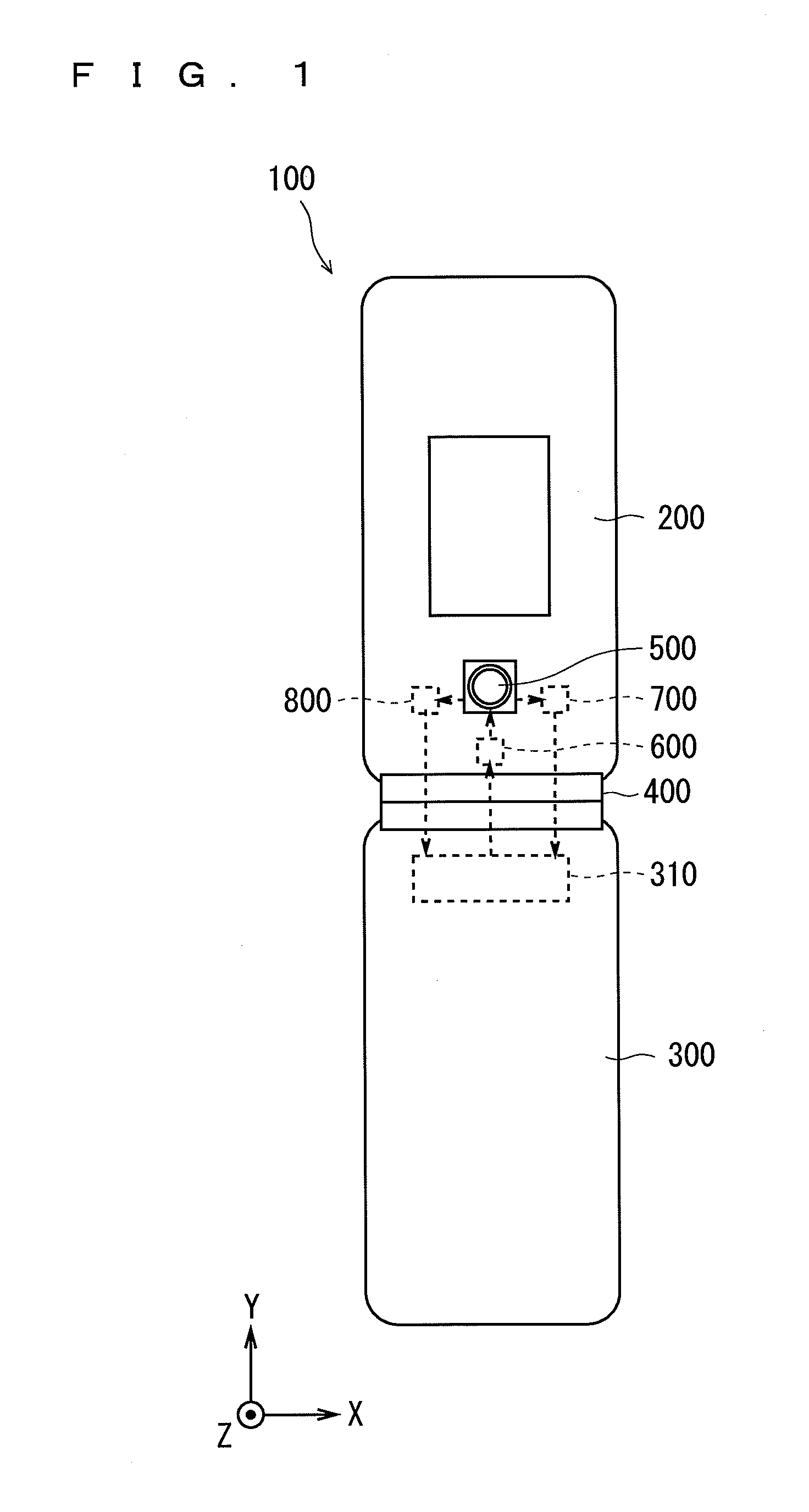

Array substrate, display panel and display device

InactiveCN109659304AAchieve electrical connectionEffective deformationSolid-state devicesNon-linear opticsElectrical connectionDisplay device

The invention discloses an array substrate, a display panel and a display device. The array substrate includes a display area and a non-display area disposed around the display area; the non-display area includes a binding area arranged at one side of the display area, and the binding area is provided with a plurality of binding pads; the array substrate comprises a substrate, a protection layer is arranged at one sides, far away from the substrate, of the binding pads, the protection layer comprises a plurality openings which are in one-to-one correspondence with the binding pads, and the openings penetrate the partial surfaces, where the binding pads are exposed, of the protection layer; and the thickness value of the protection layer is in a range of 0.3-0.6[Mu]m. According to the technical scheme provided by the embodiment, when the flexible printed circuit board and the array substrate are subjected to alignment deviation, a gold finger and conducting particles between the corresponding binding pads still can generate effective deformation to achieve electrical connection of the gold finger and the corresponding binding pads.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

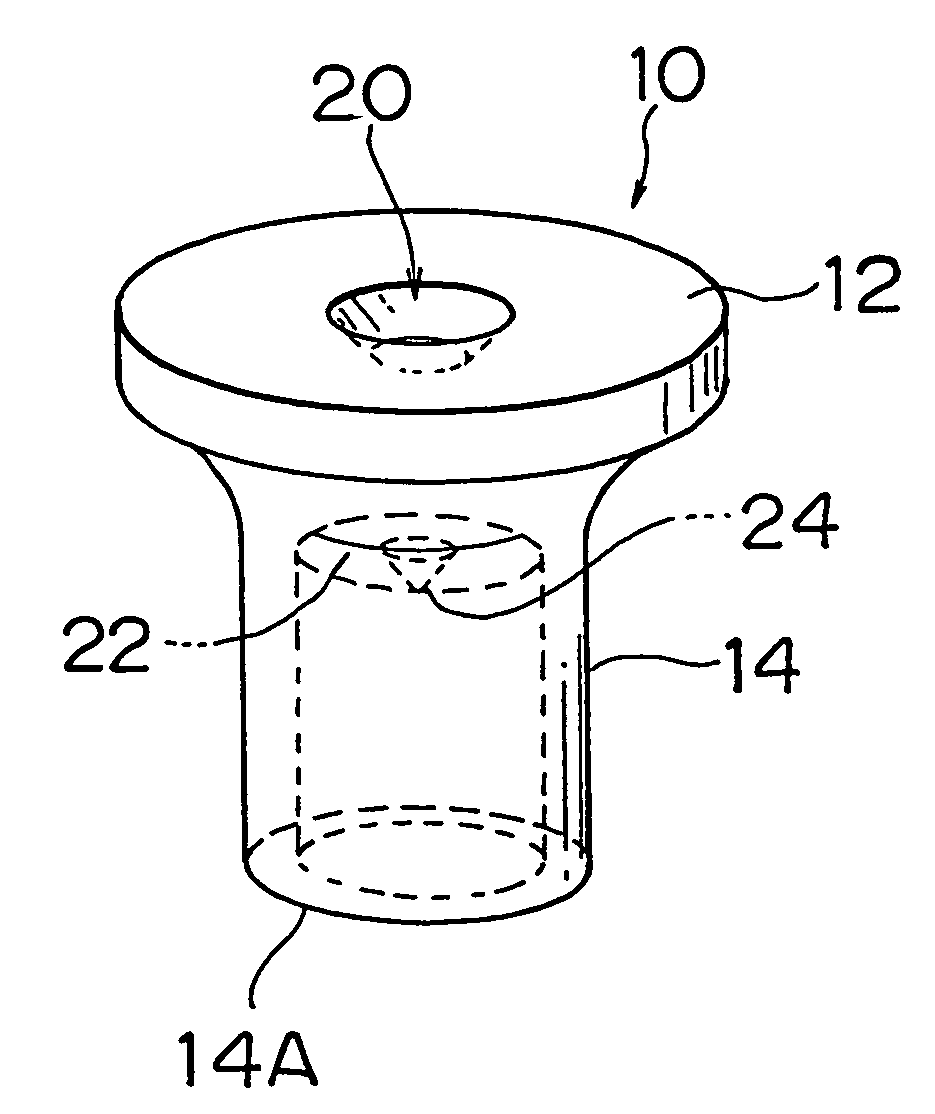

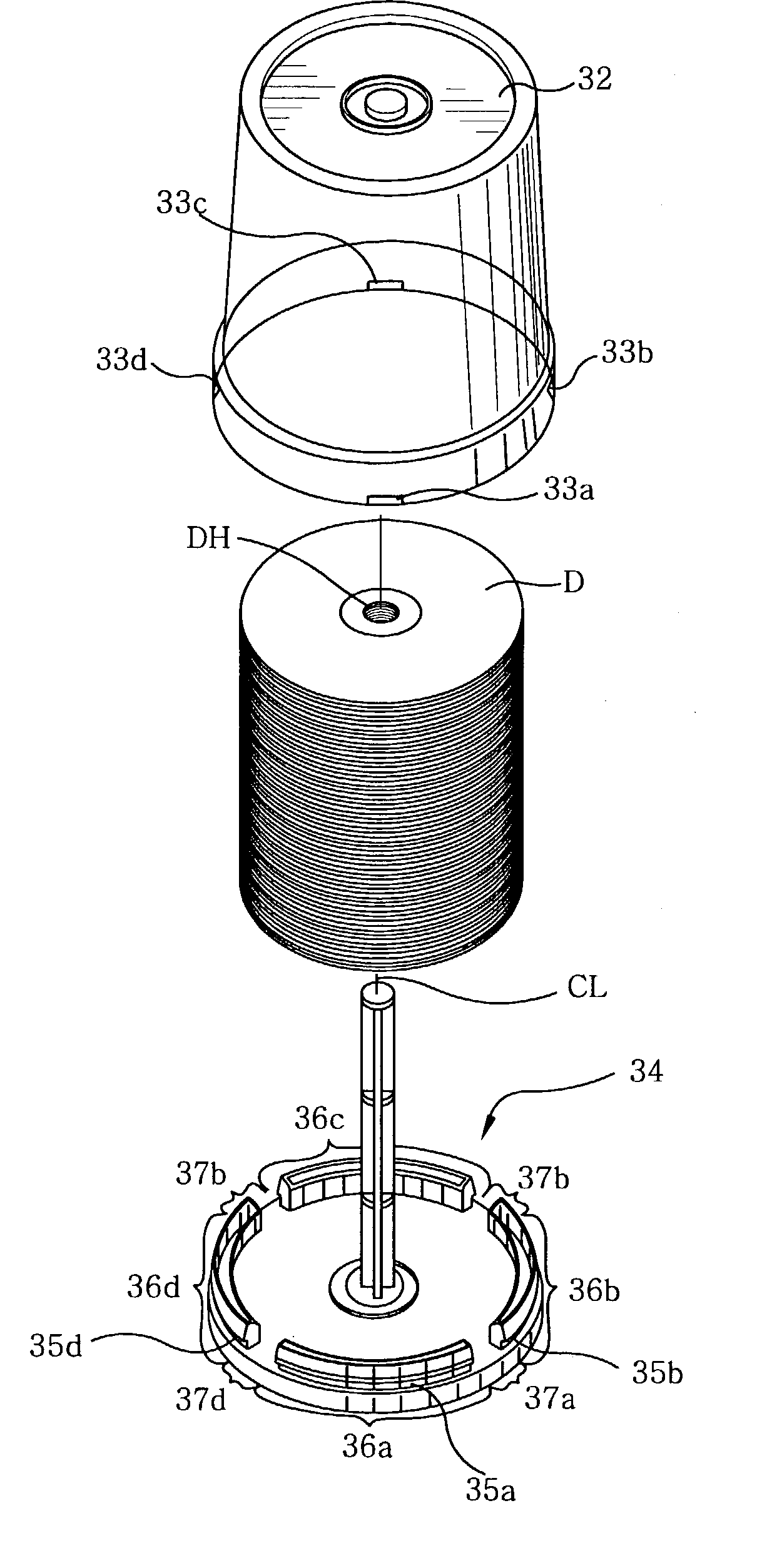

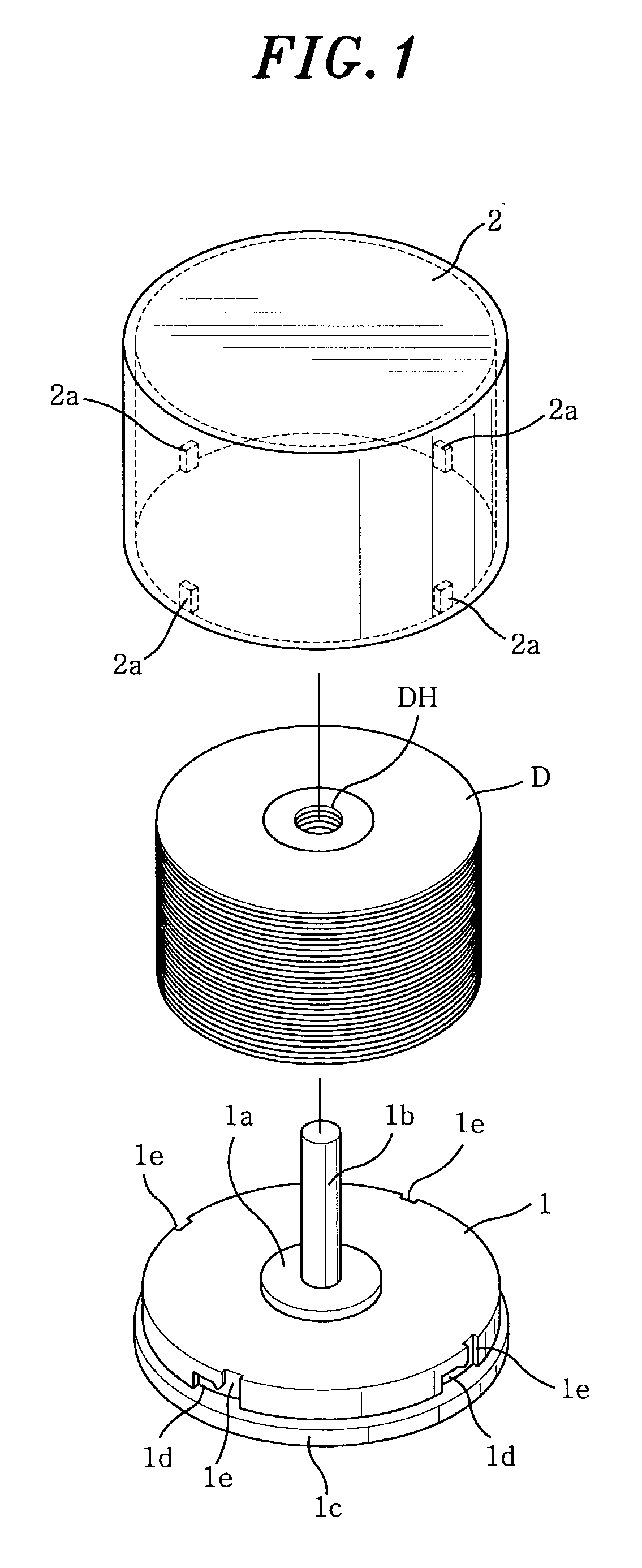

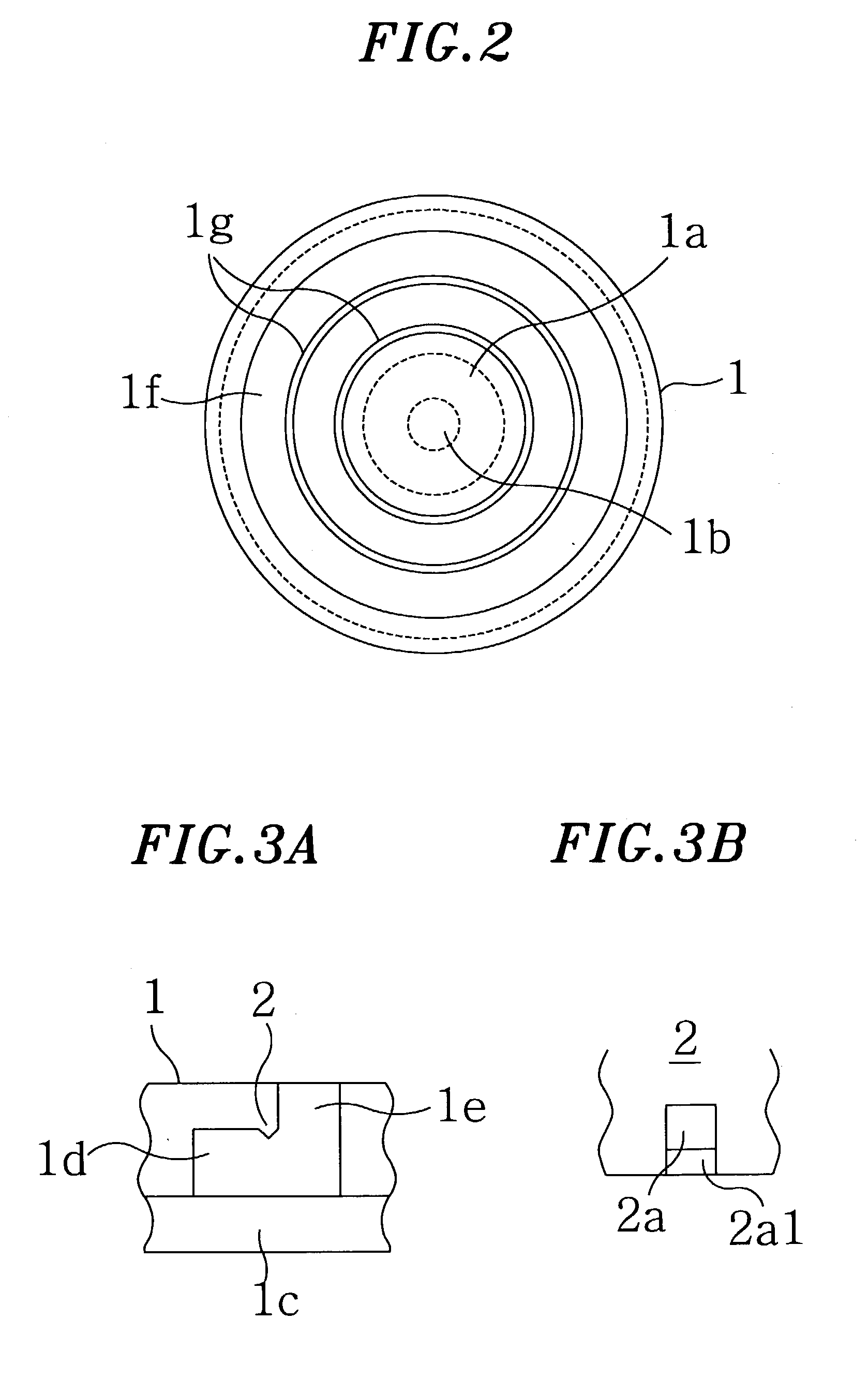

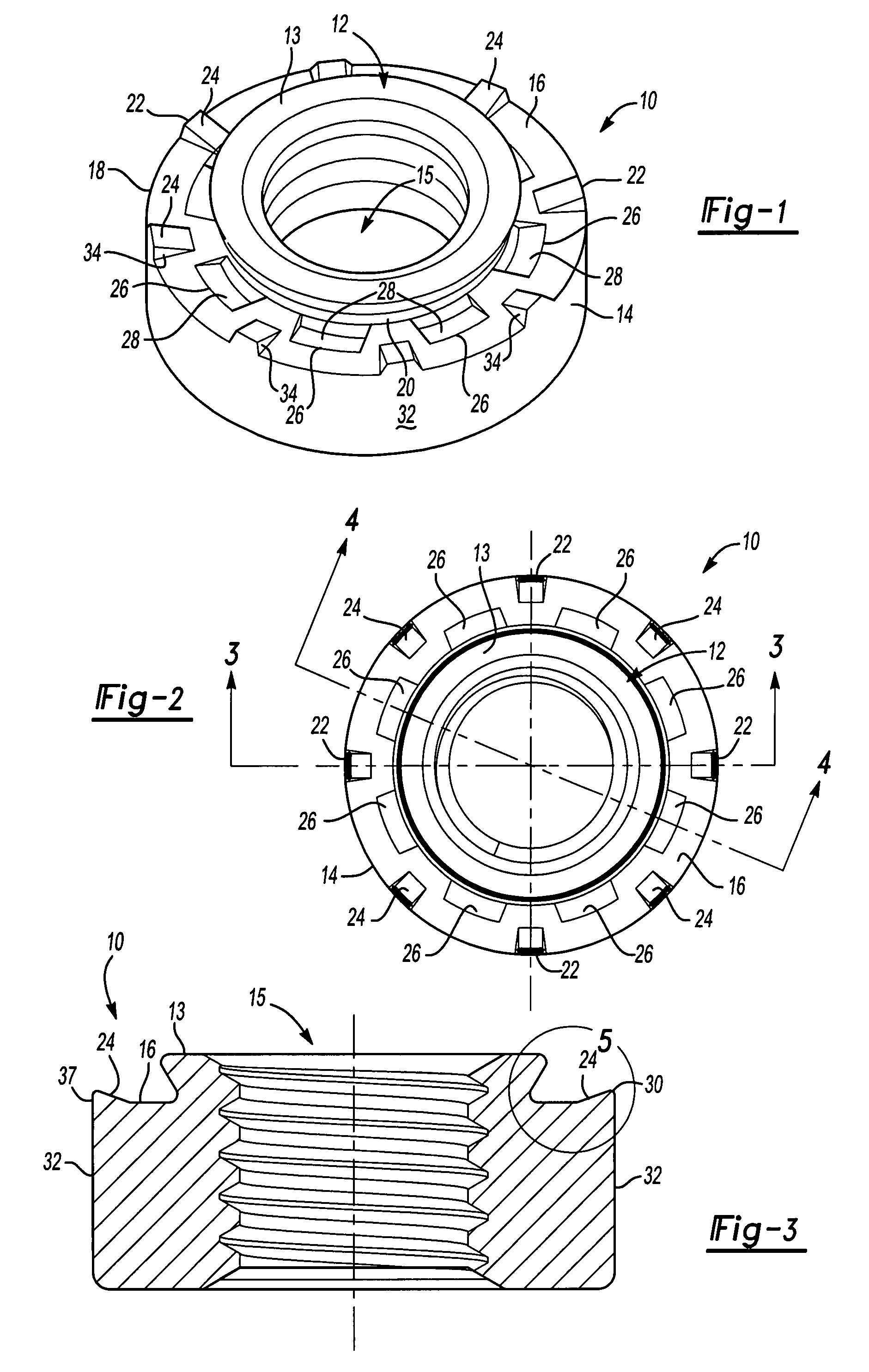

Disc package

InactiveUS7121405B2Effective deformationAvoid separationContainers for annular articlesApparatus modification to store record carriersClockwiseOptical disc

The present invention relates to a disc package having a structure in which a cover can be fixed on a base by simply pressurizing the cover with respect to the base in a base shaft axial direction and, at the same time, the cover can be prevented from being accidentally separated from the base while the disc package is being transported. Further, in the disc package, a cover once fixed on a base can be separated therefrom by rotating the cover along the circumference of the base in any direction, i.e., in either a clockwise or a counterclockwise direction. Furthermore, an end portion of a shaft can be fitted into a concave portion of a cover even in case the end portion of the shaft is not aligned with the concave portion of the cover.

Owner:TAIYO YUDEN KK

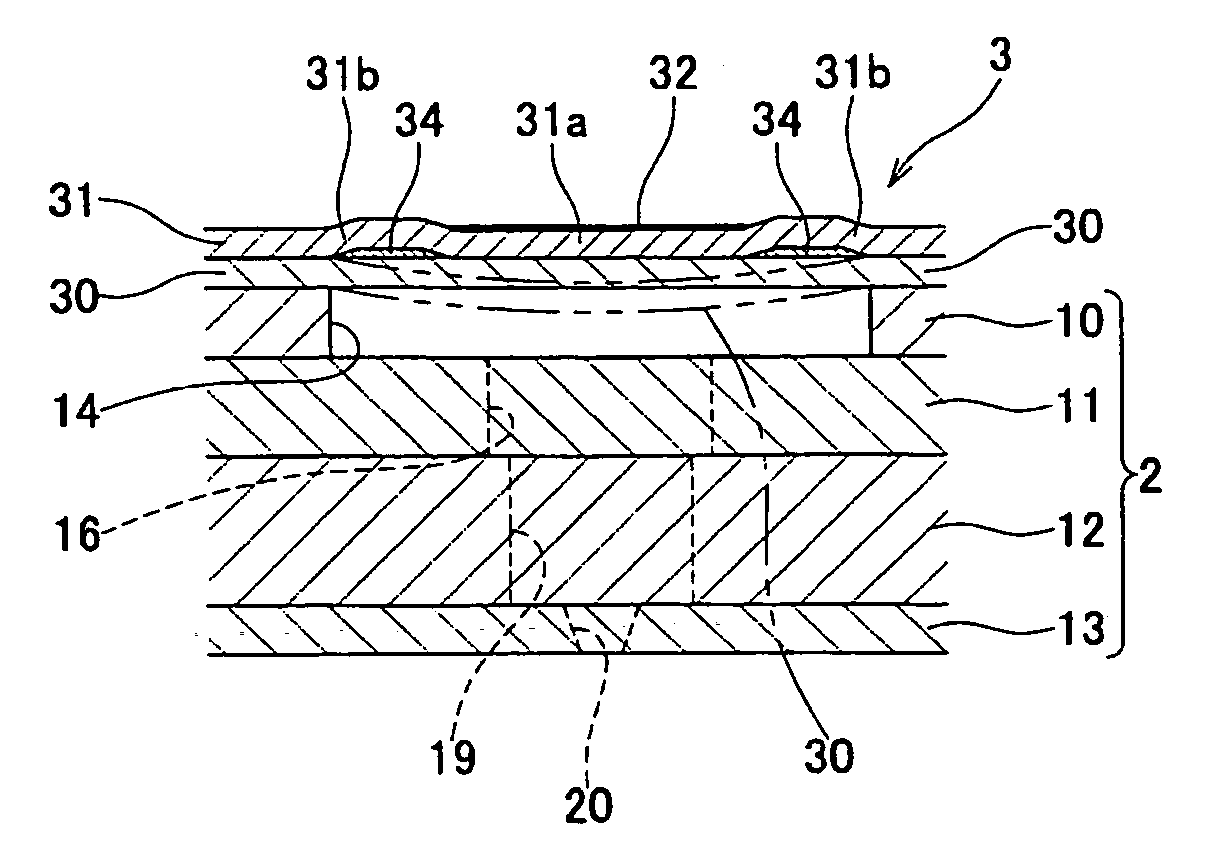

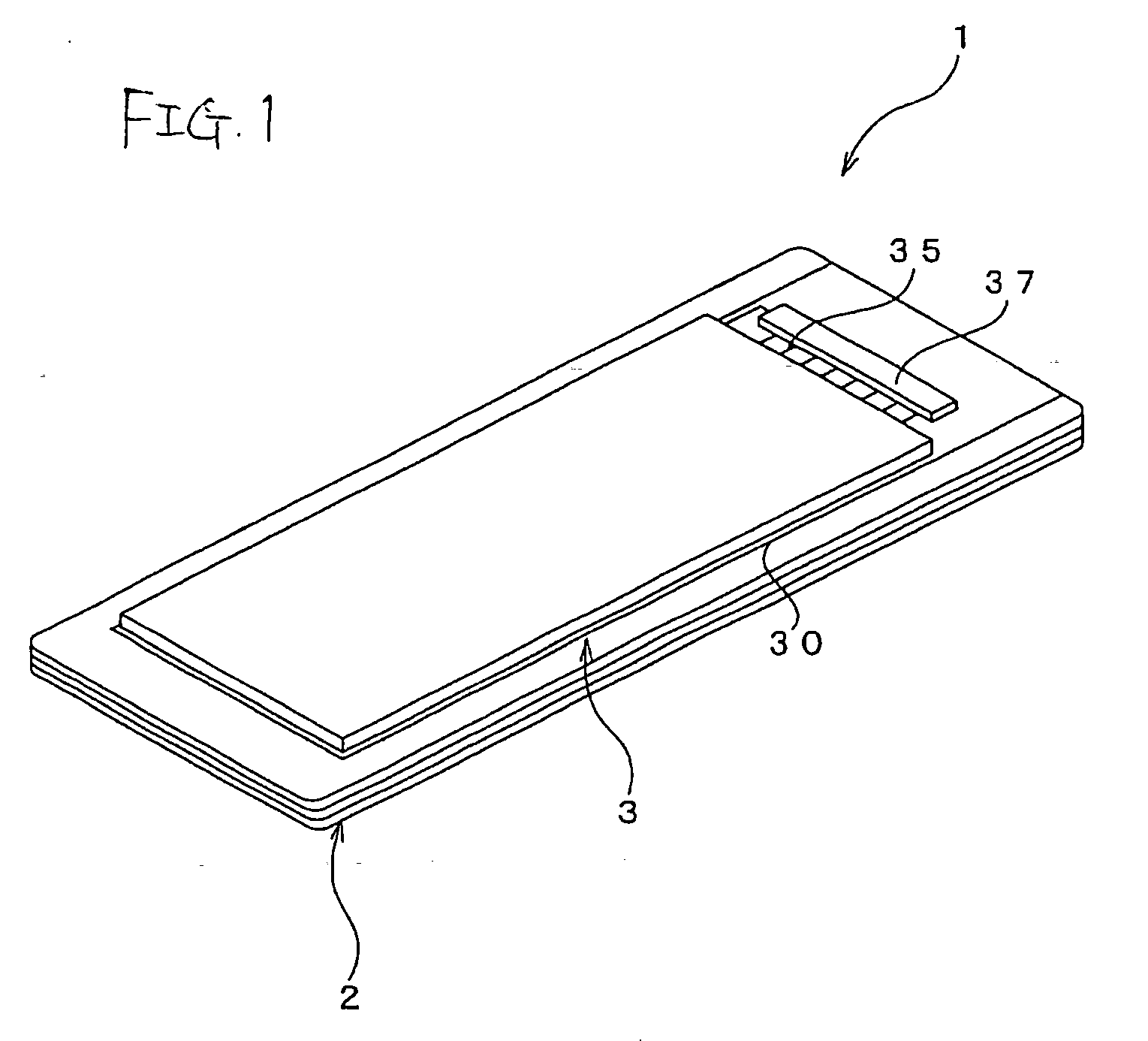

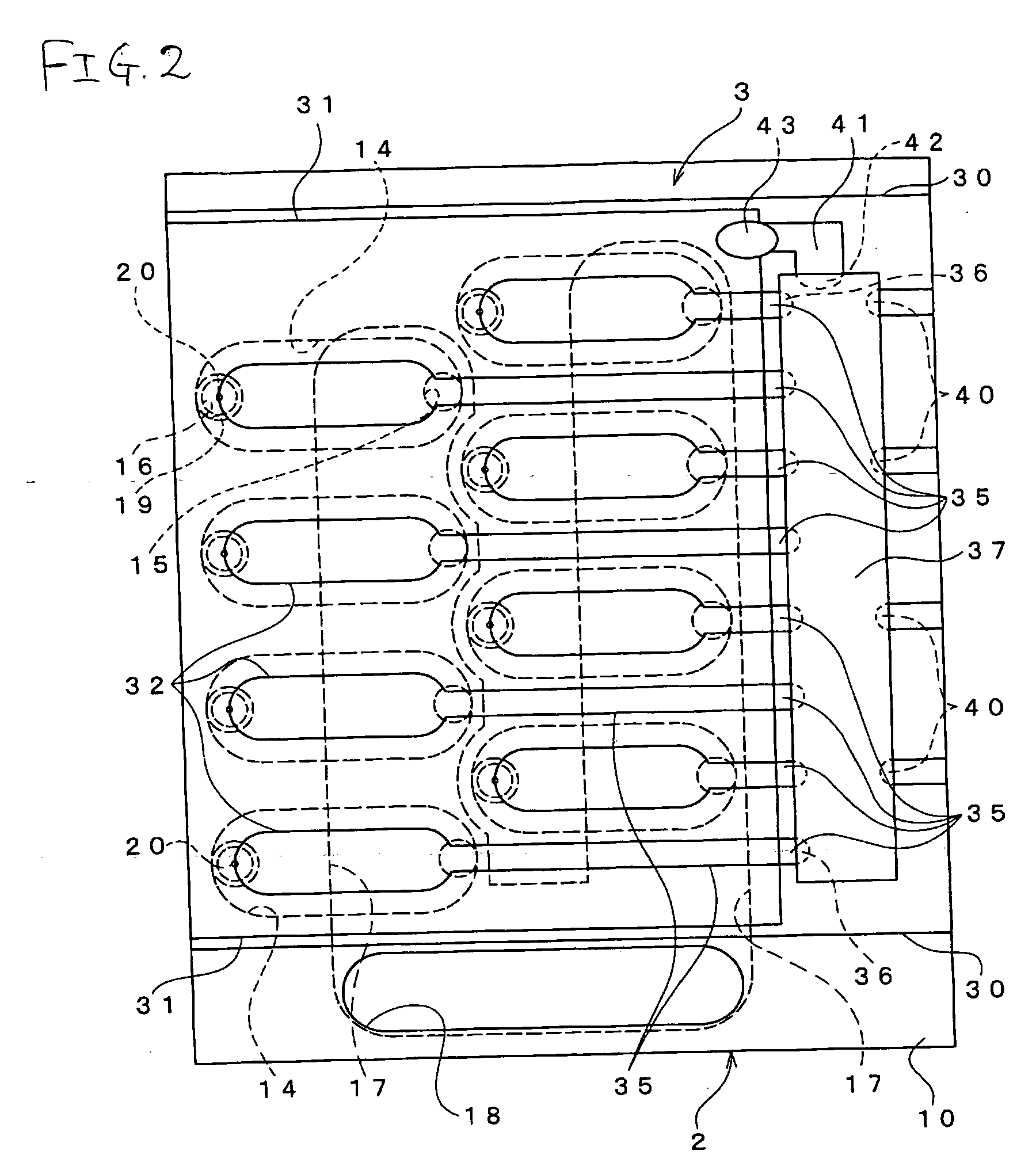

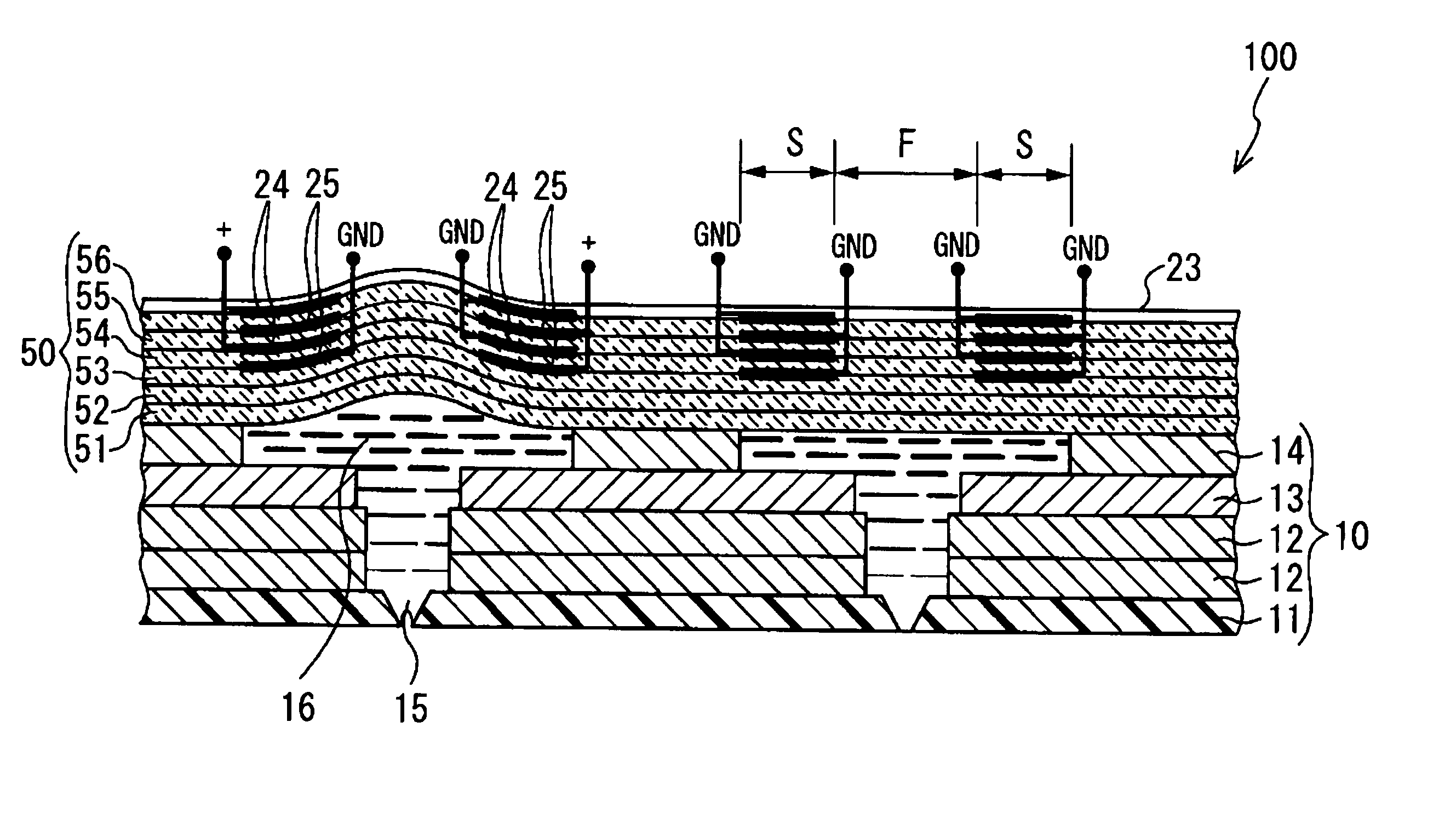

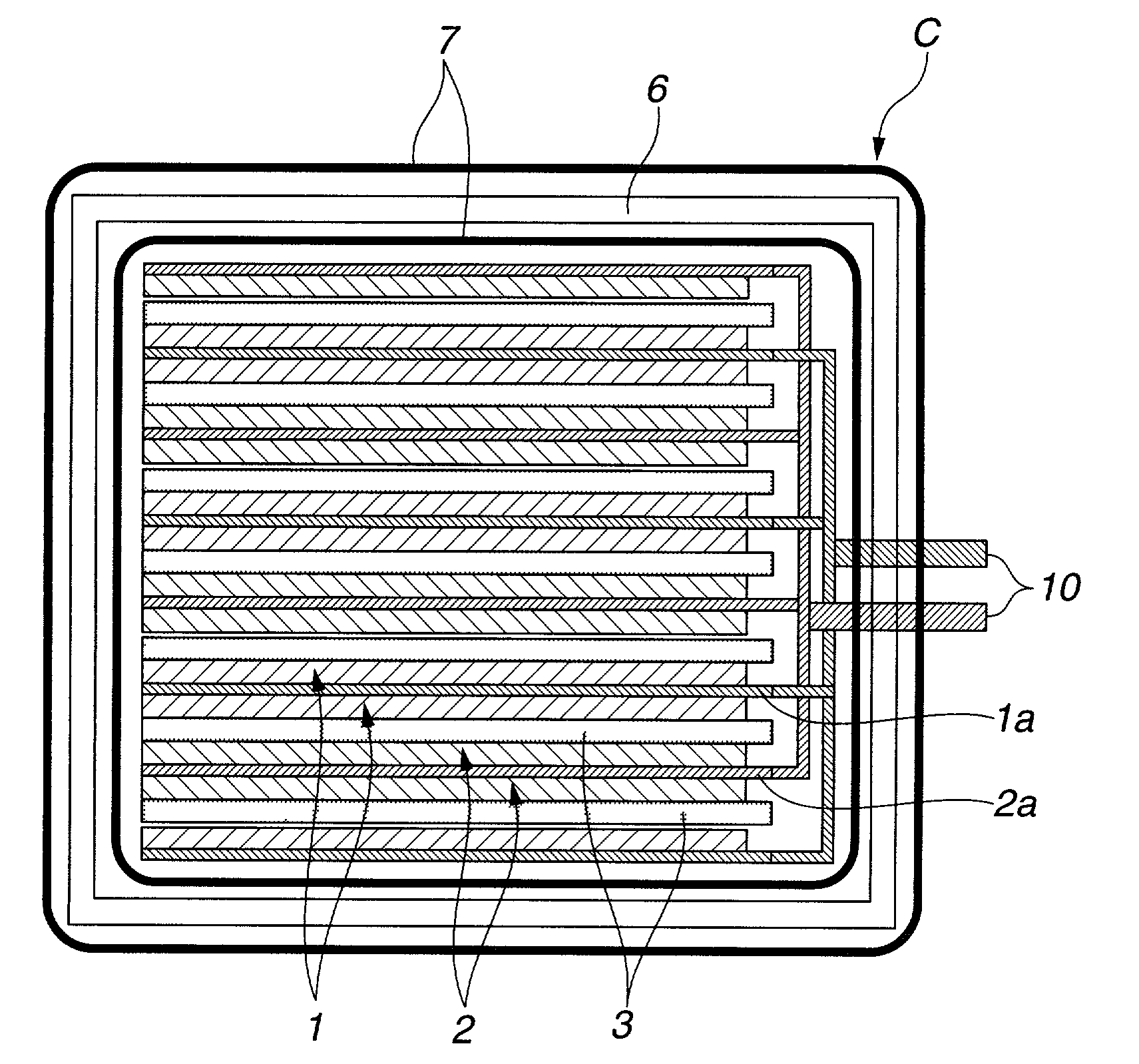

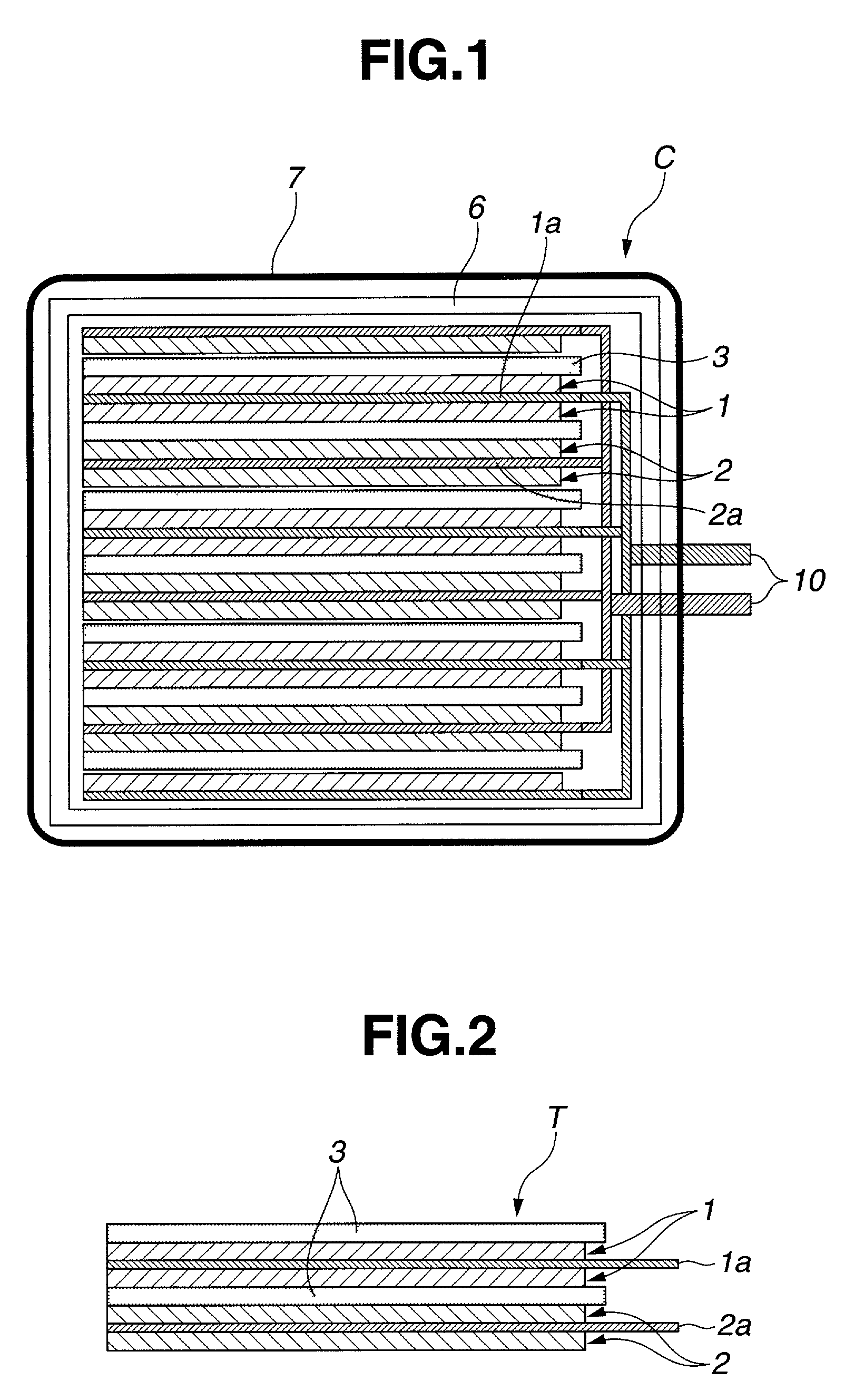

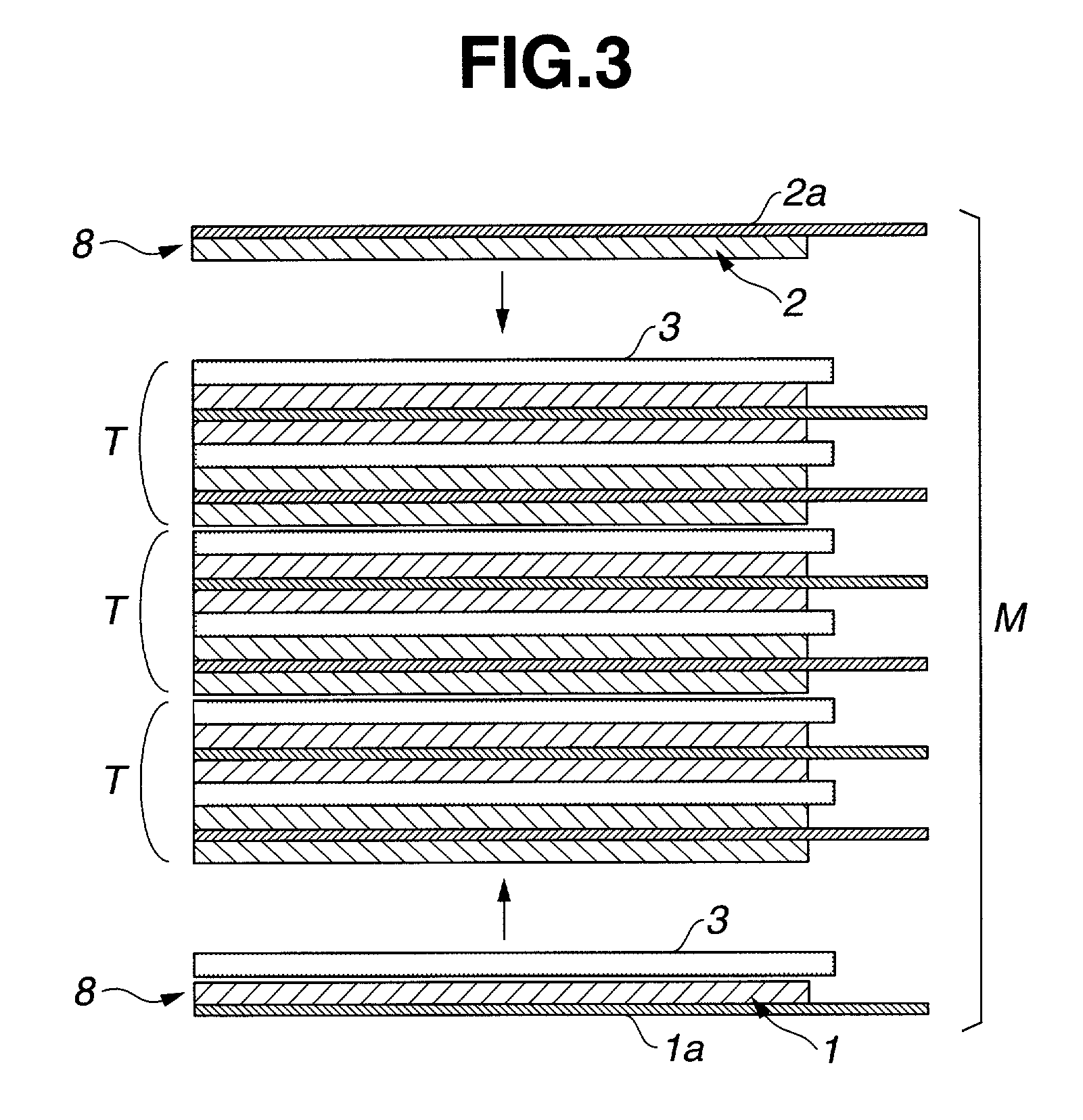

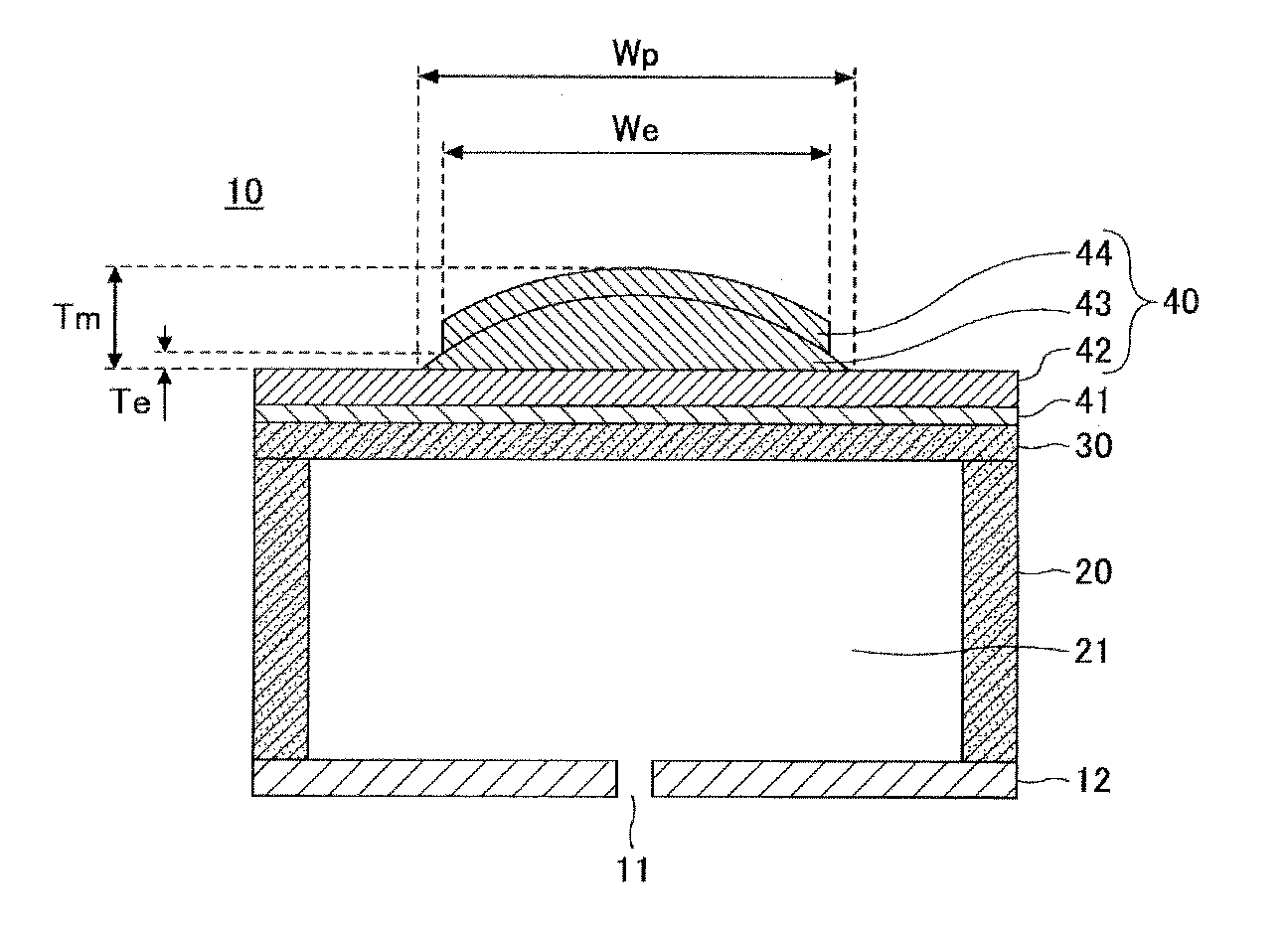

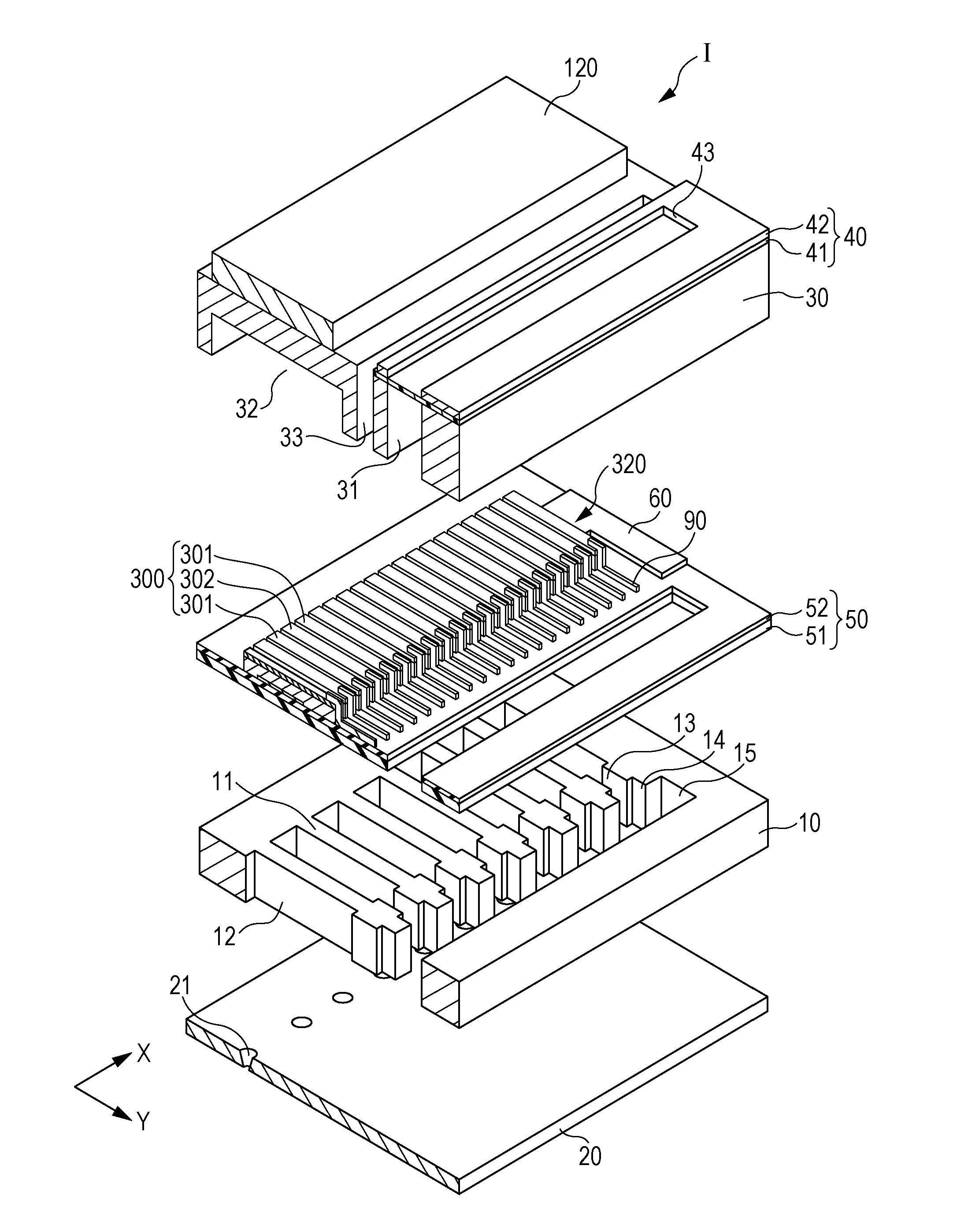

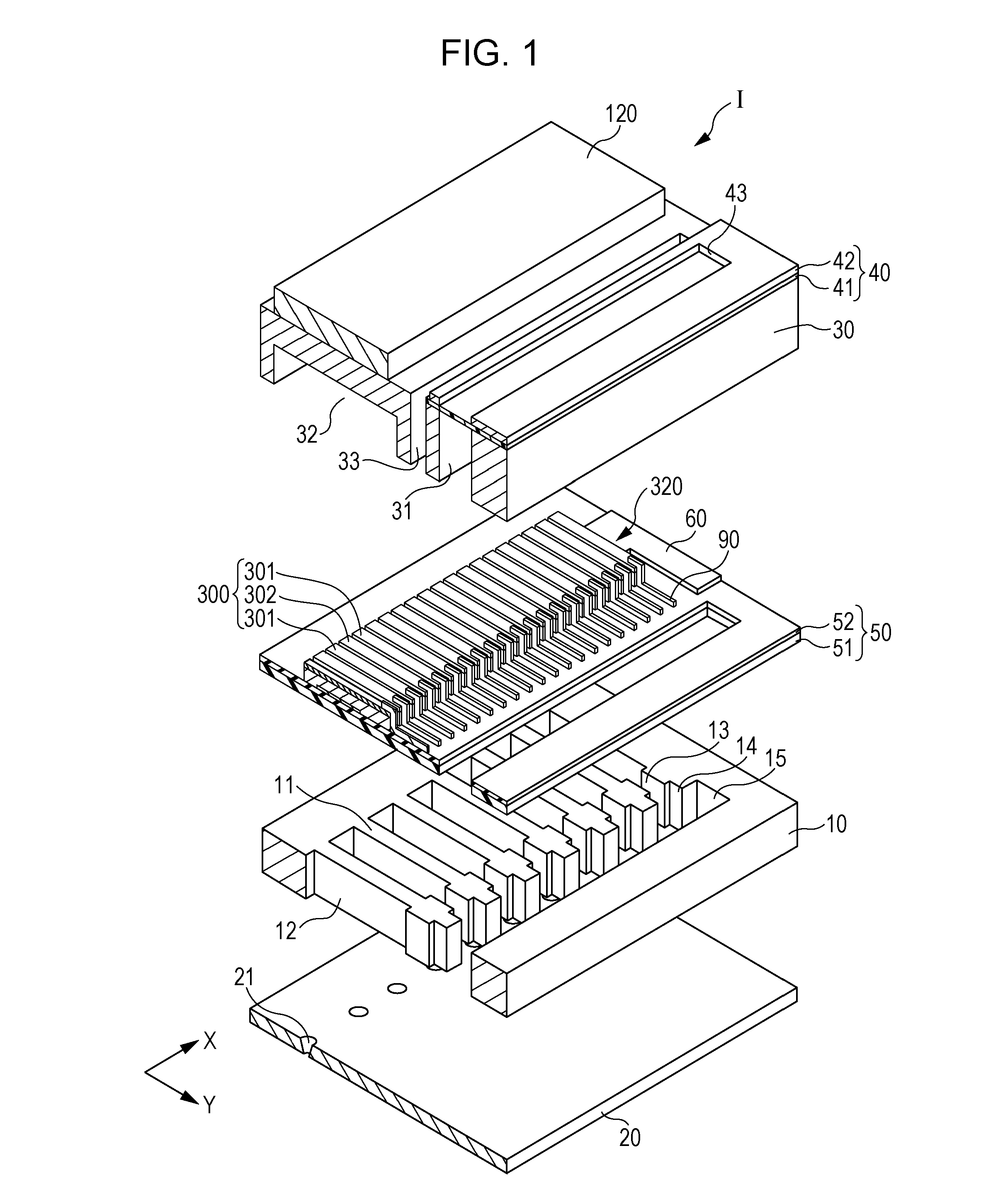

Liquid delivering device

ActiveUS20050285911A1Effective deformationReduce stiffnessPrintingElectricityPiezoelectric actuators

A liquid delivering device including: a flow passage unit having a plurality of pressure chambers each of which communicating with a liquid ejection port; a piezoelectric actuator for selectively changing the volume of the plurality of pressure chambers, the piezoelectric actuator including a plurality of individual electrodes corresponding to the plurality of pressure chambers, a common electrode opposing the plurality of individual electrodes, and a piezoelectric layer sandwiched between the plurality of individual electrodes and the common electrode; and a rigidity reduction section which reduces the rigidity of the piezoelectric actuator and which is provided in an area where at least the pressure chamber is formed and in a vicinity of the individual electrode, in perspective plan view.

Owner:BROTHER KOGYO KK

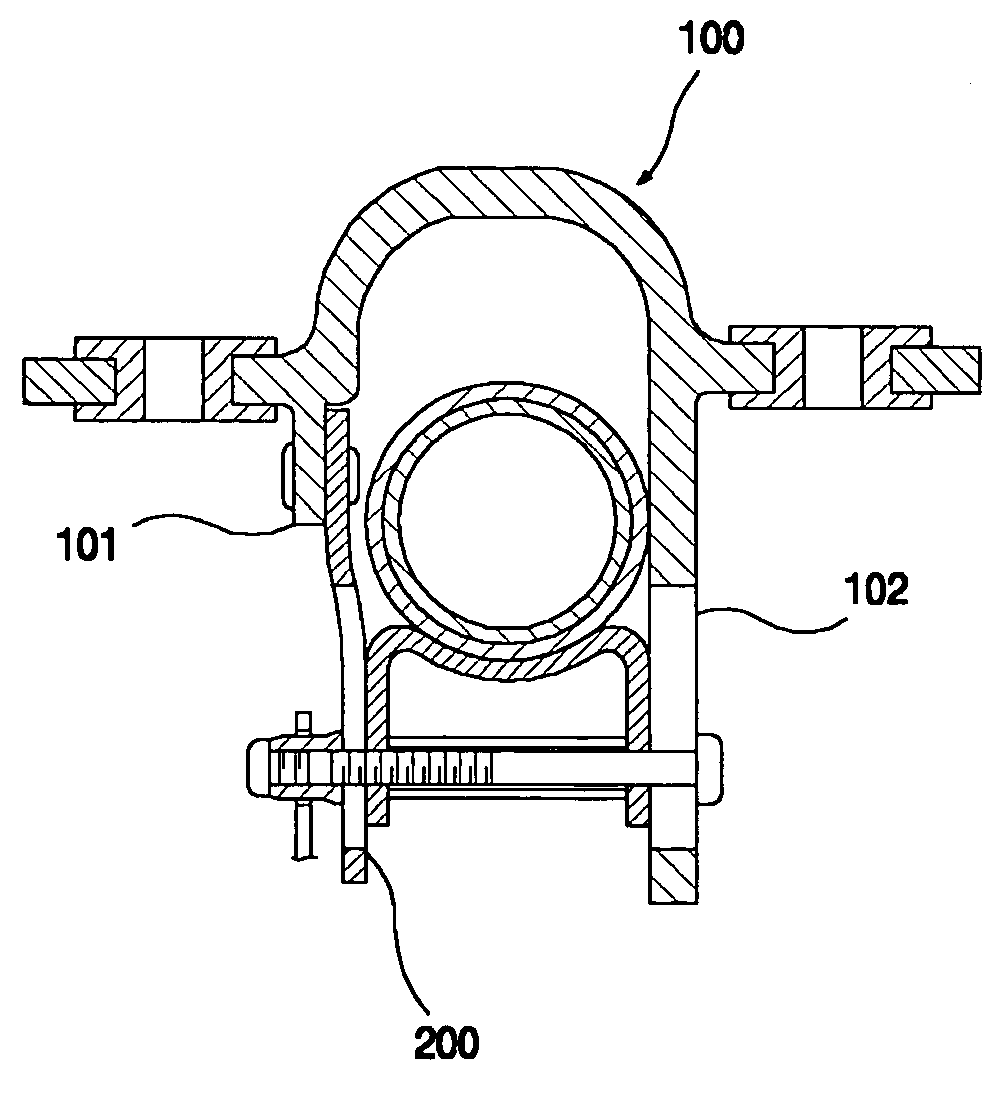

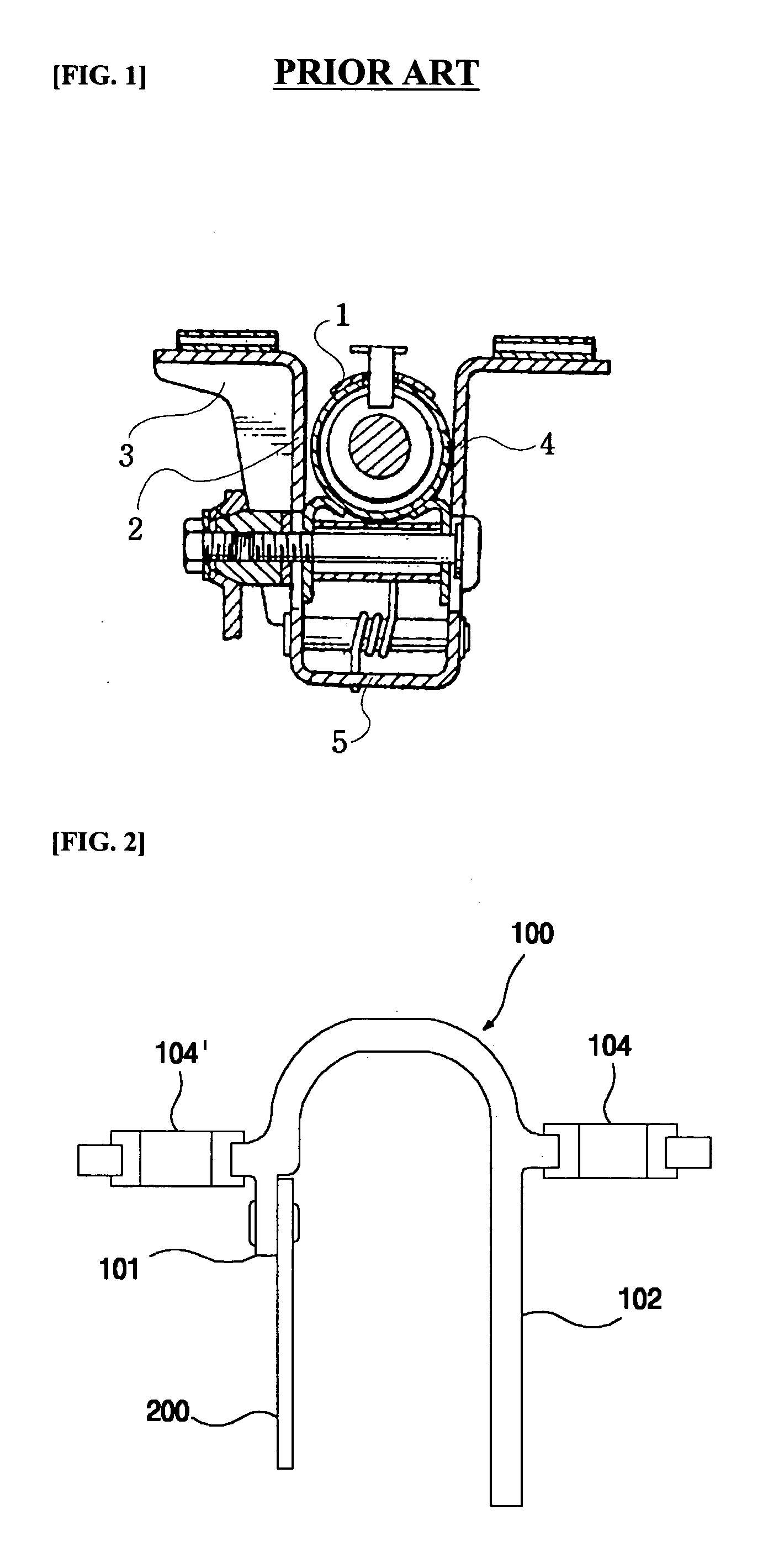

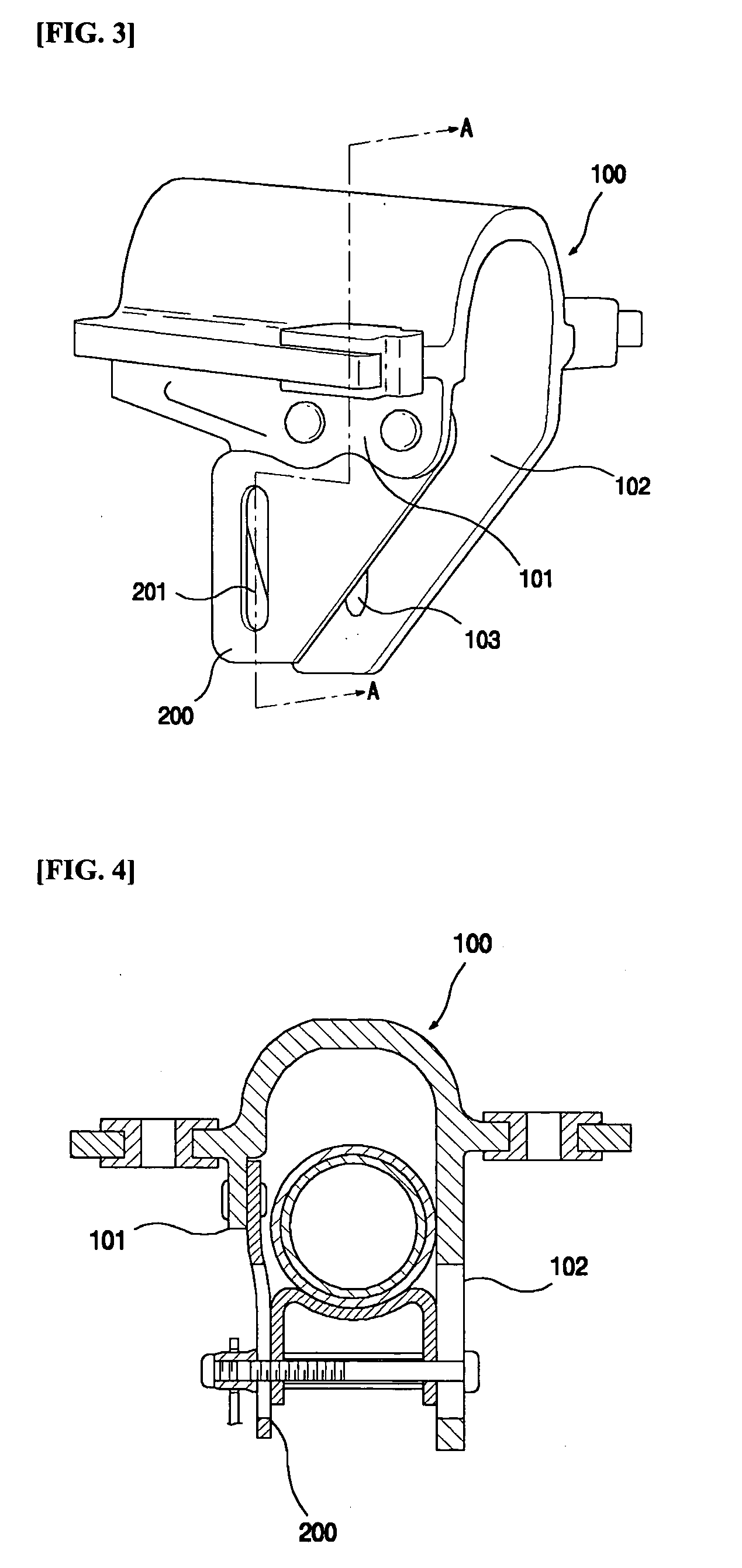

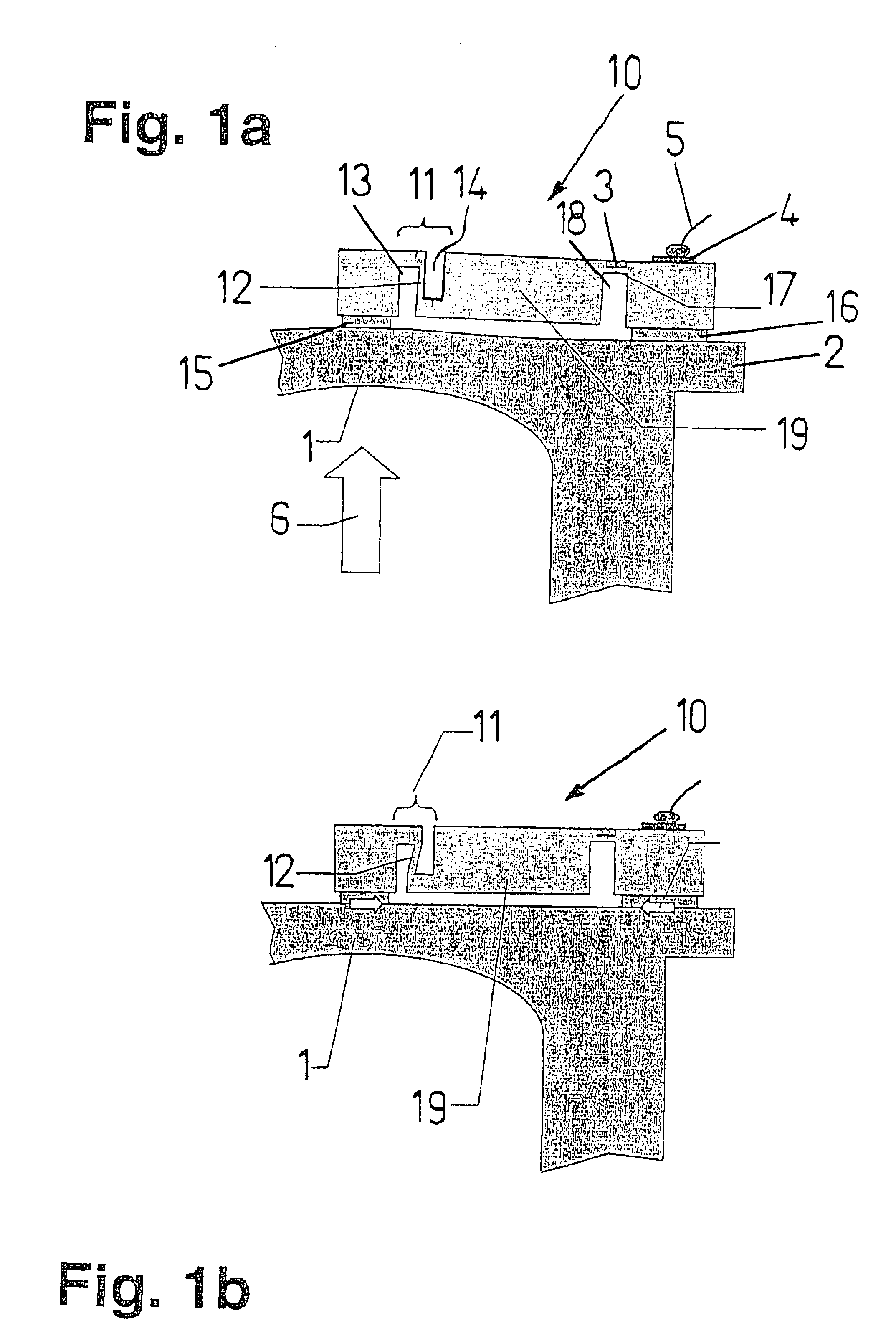

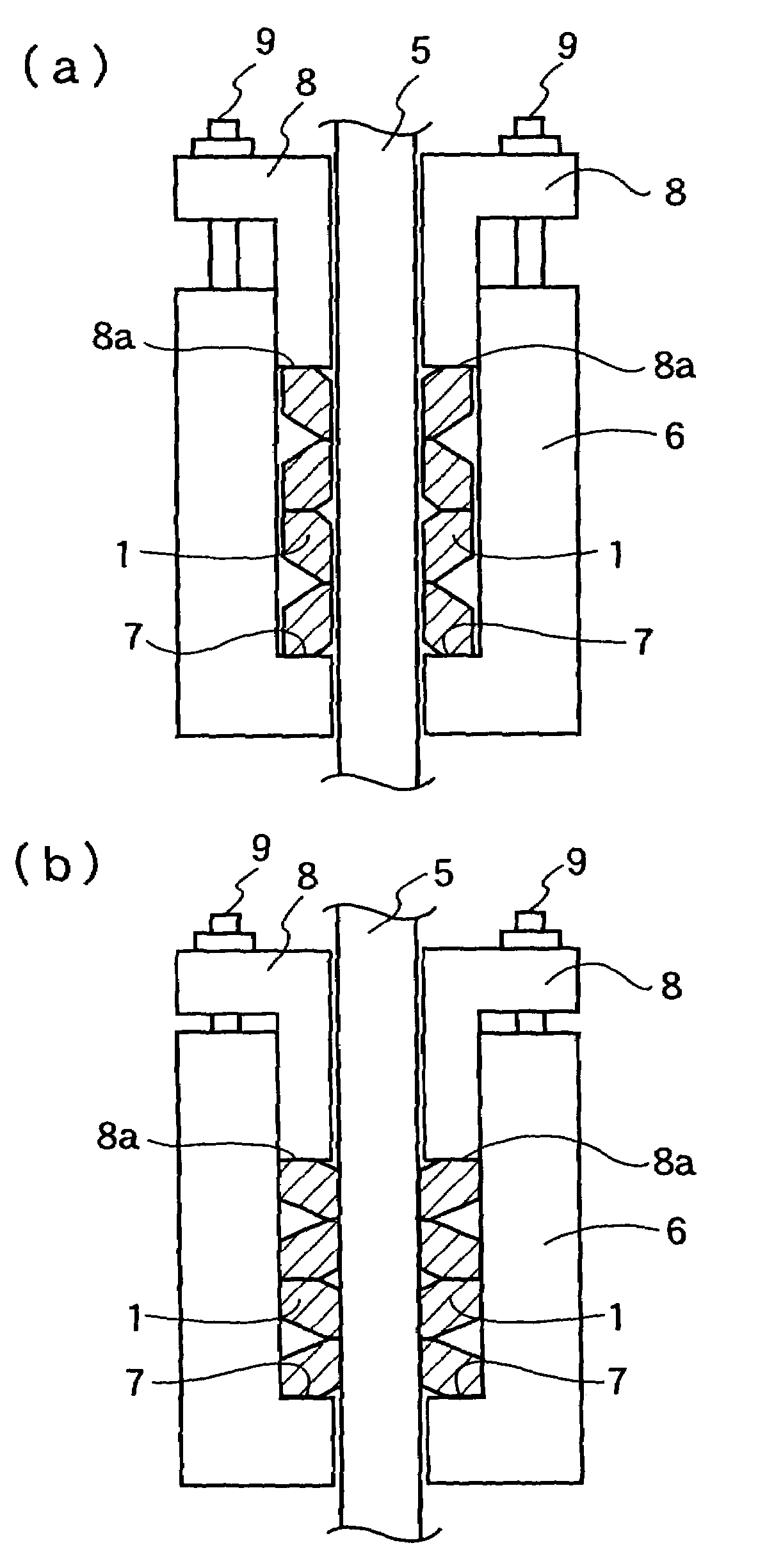

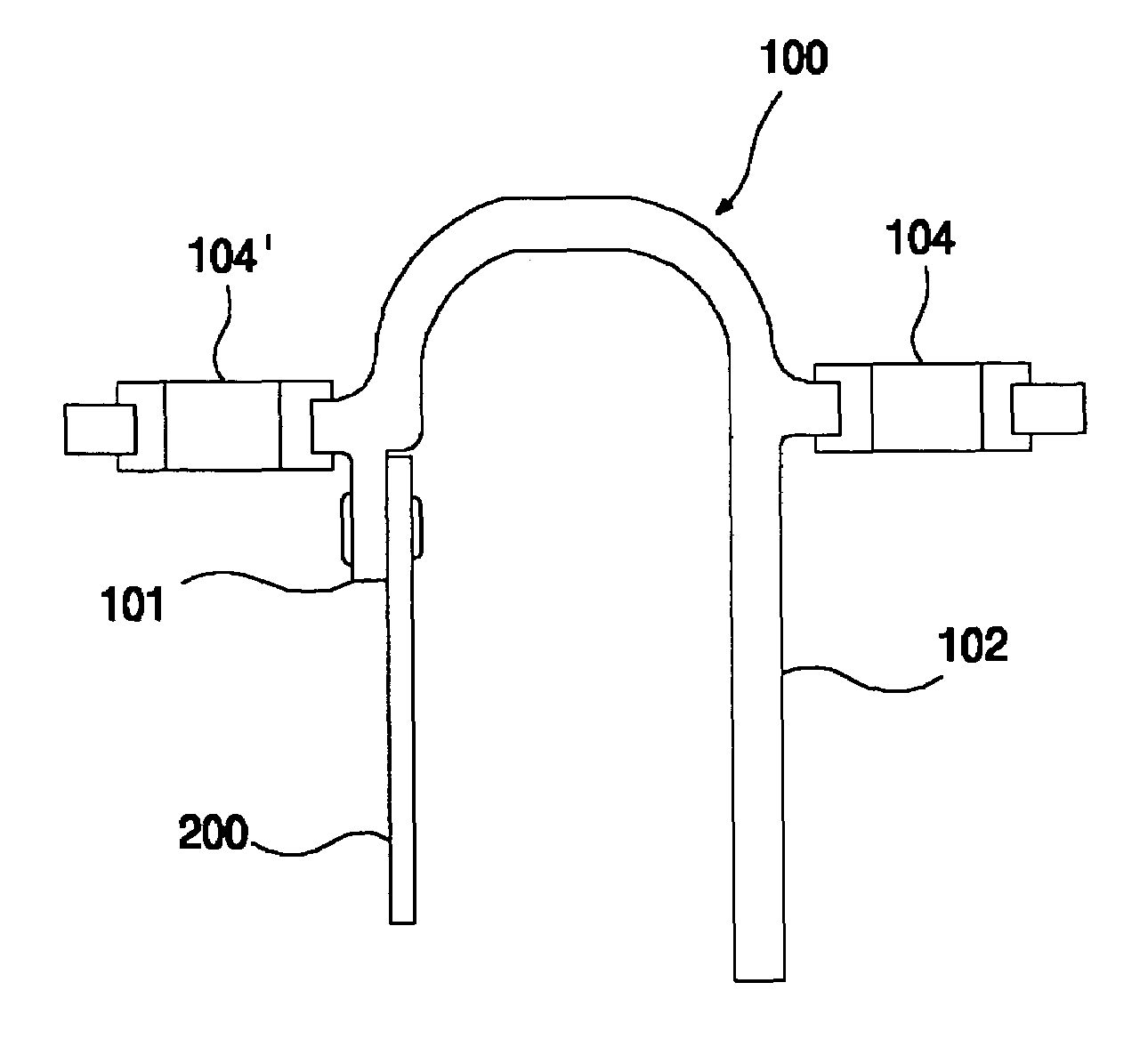

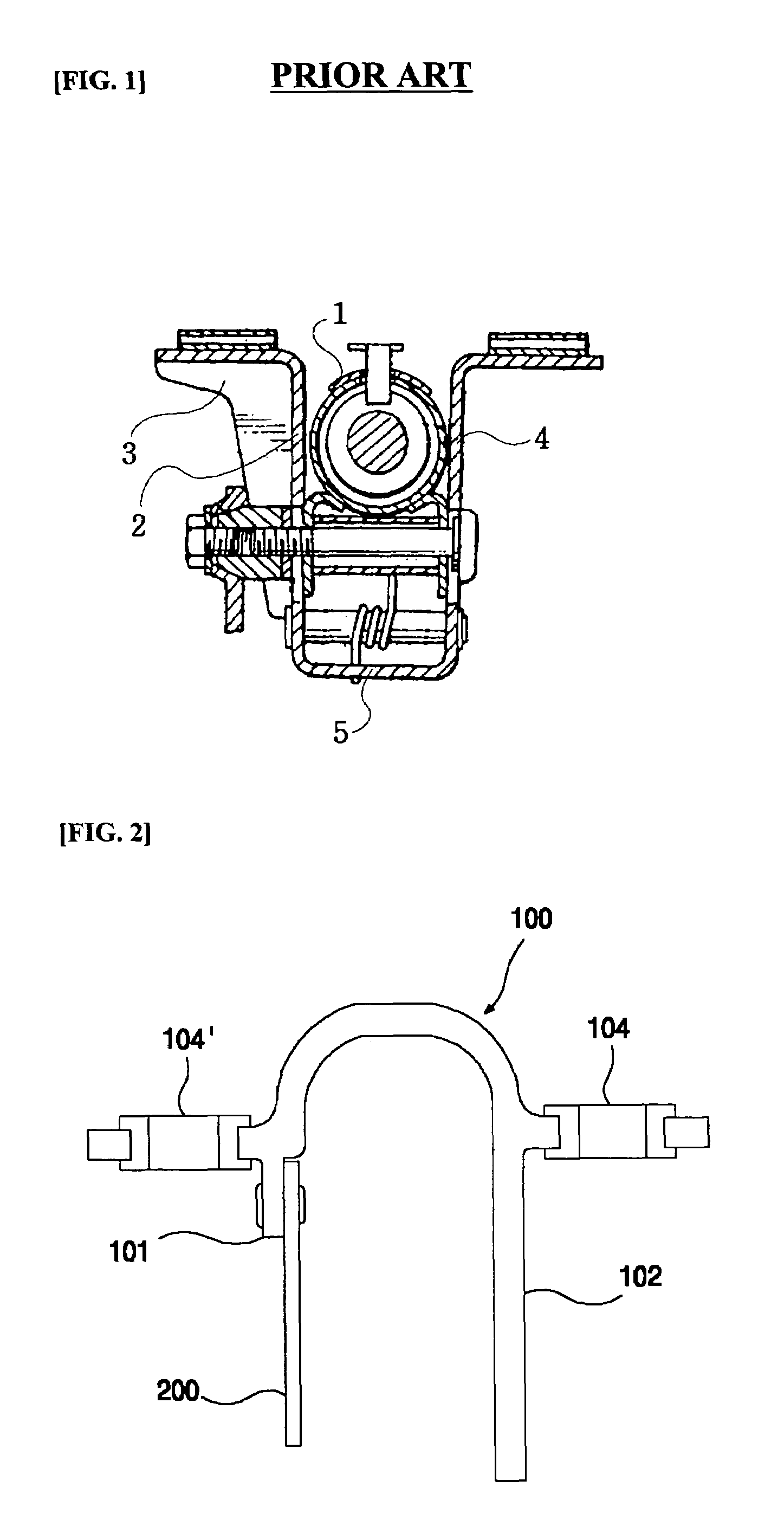

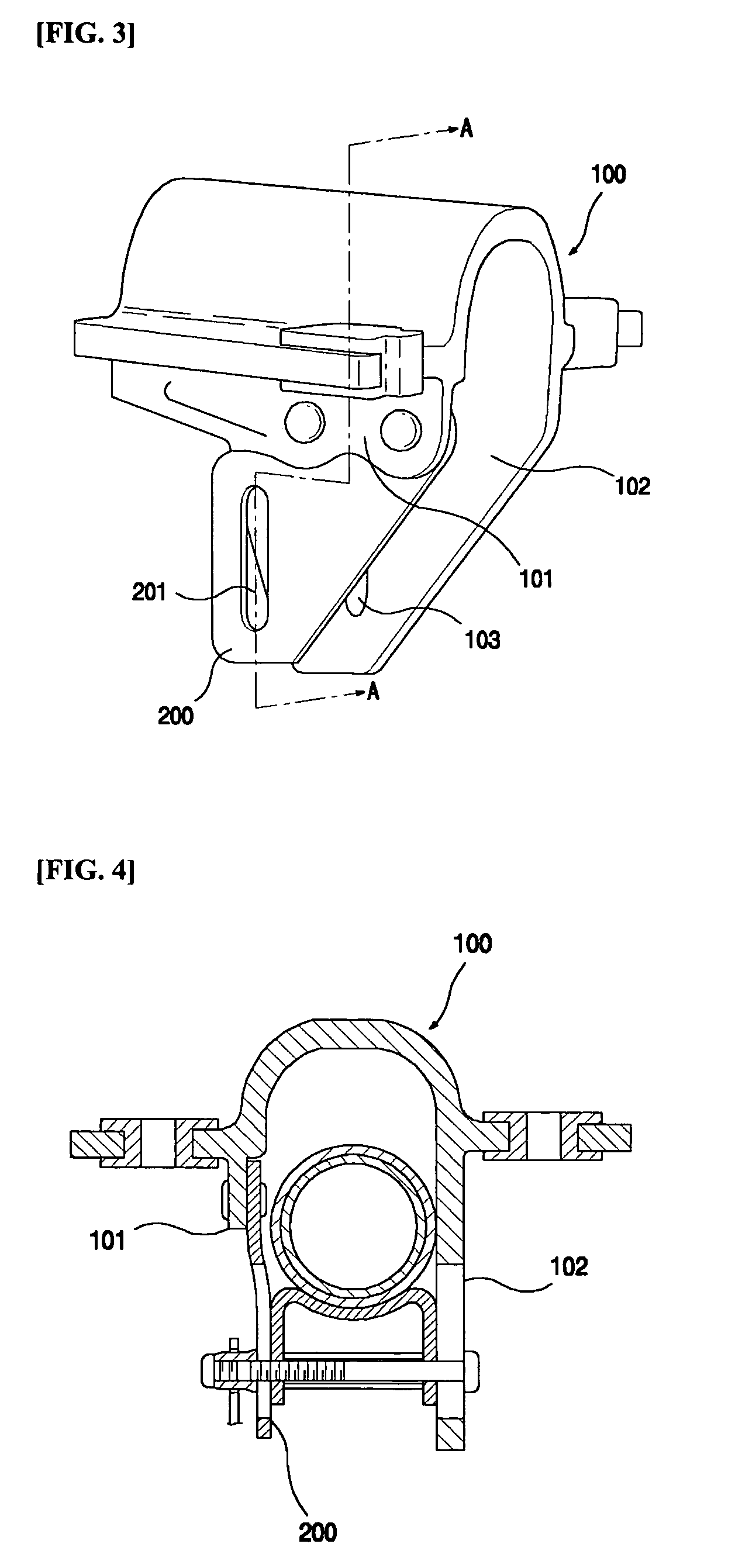

High rigid tilt device in a steering column for a vehicle

InactiveUS20050050978A1Stable supportReliably locking samePipe supportsCandle holdersSteering wheelSteering column

The present invention relates to a tilt device for allowing a steering column to be tilted so that a driver can adjust the position of a steering wheel to conform to his / her figure in order to more comfortably drive a vehicle. The tilt device of the invention has an effect in that it can impart a high supporting strength to the steering column while reliably locking the same.

Owner:HYUNDAI MOBIS CO LTD

Heavy metal pierce nut

Owner:PENN AUTOMOTIVE INC

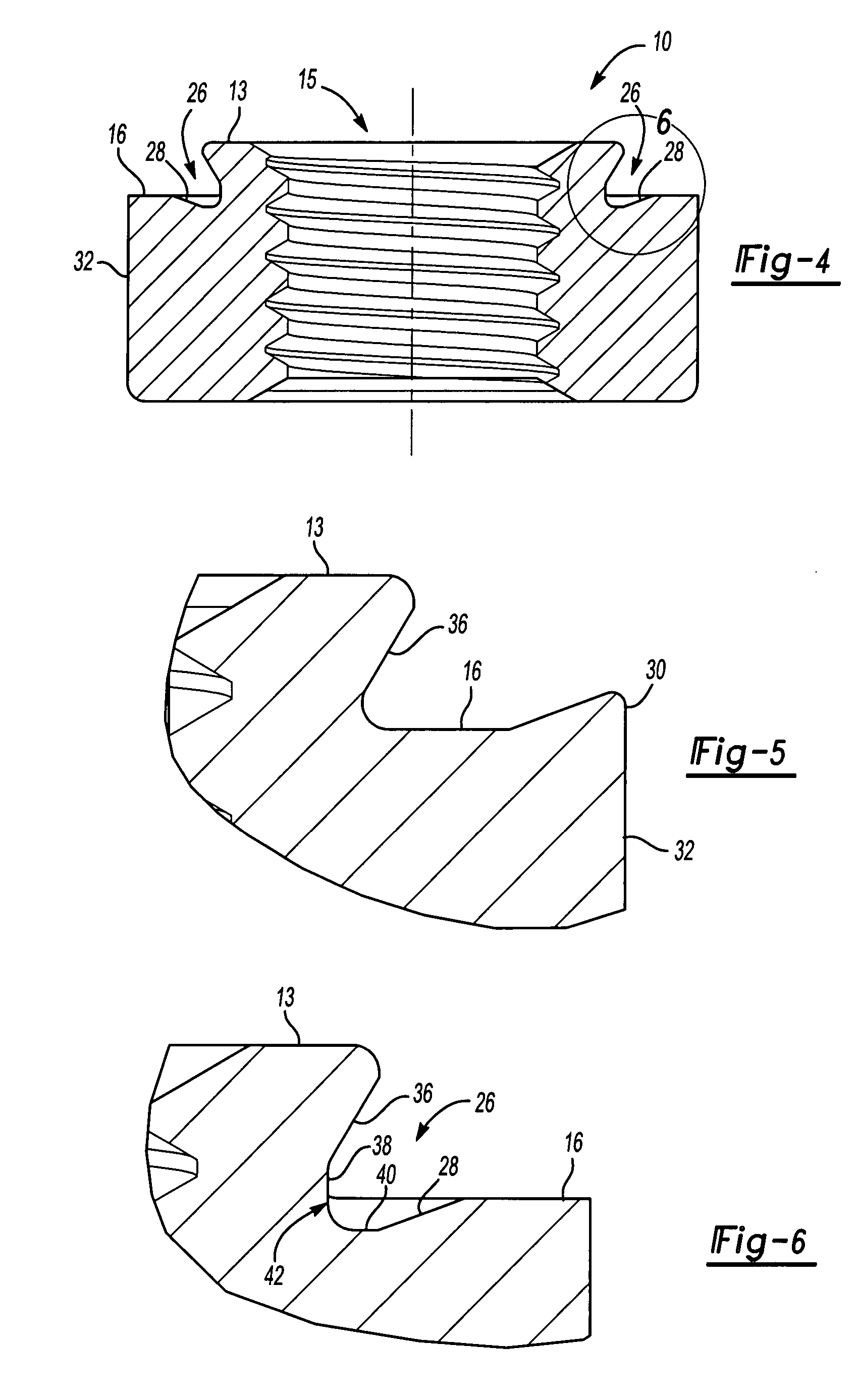

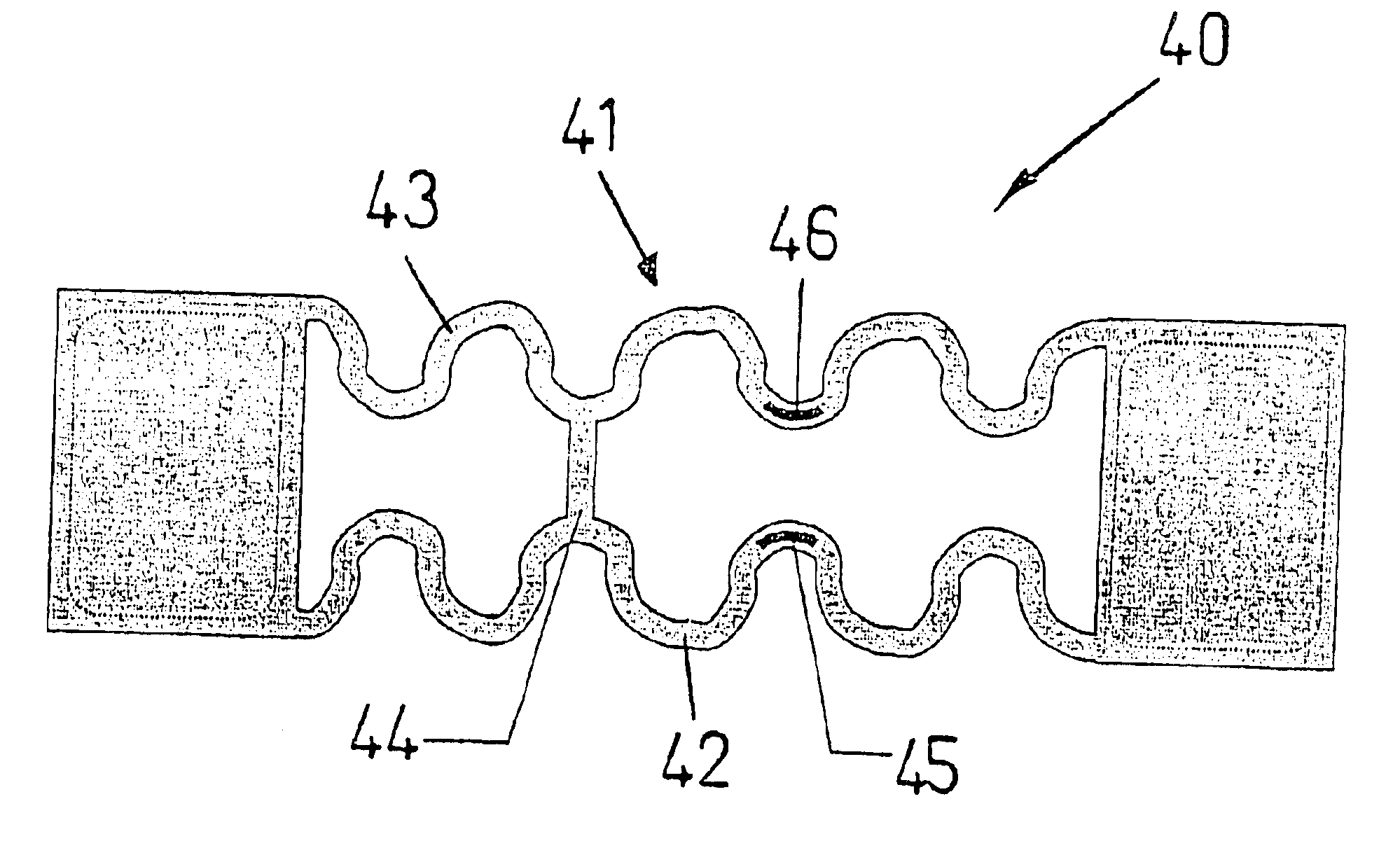

Micromechanical component and pressure sensor having a component of this type

InactiveUS6840111B2Decouple lateral and vertical stresses in the componentEasy to produceFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesEngineeringPressure sensor

A micromechanical component in which lateral deformations, i.e., deformations of the component parallel to its two main surfaces, are concentrated in a defined area of the component structure, making it possible to decouple lateral and vertical stresses in the component. The component structure includes at least one bellows-like structure in which lateral deformations of the component are concentrated. A pressure sensor having a micromechanical component of this type may be used, for example, for measured-value detection.

Owner:ROBERT BOSCH GMBH

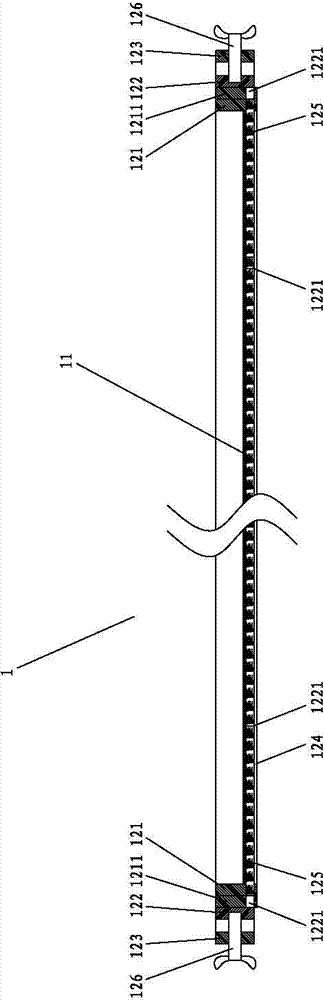

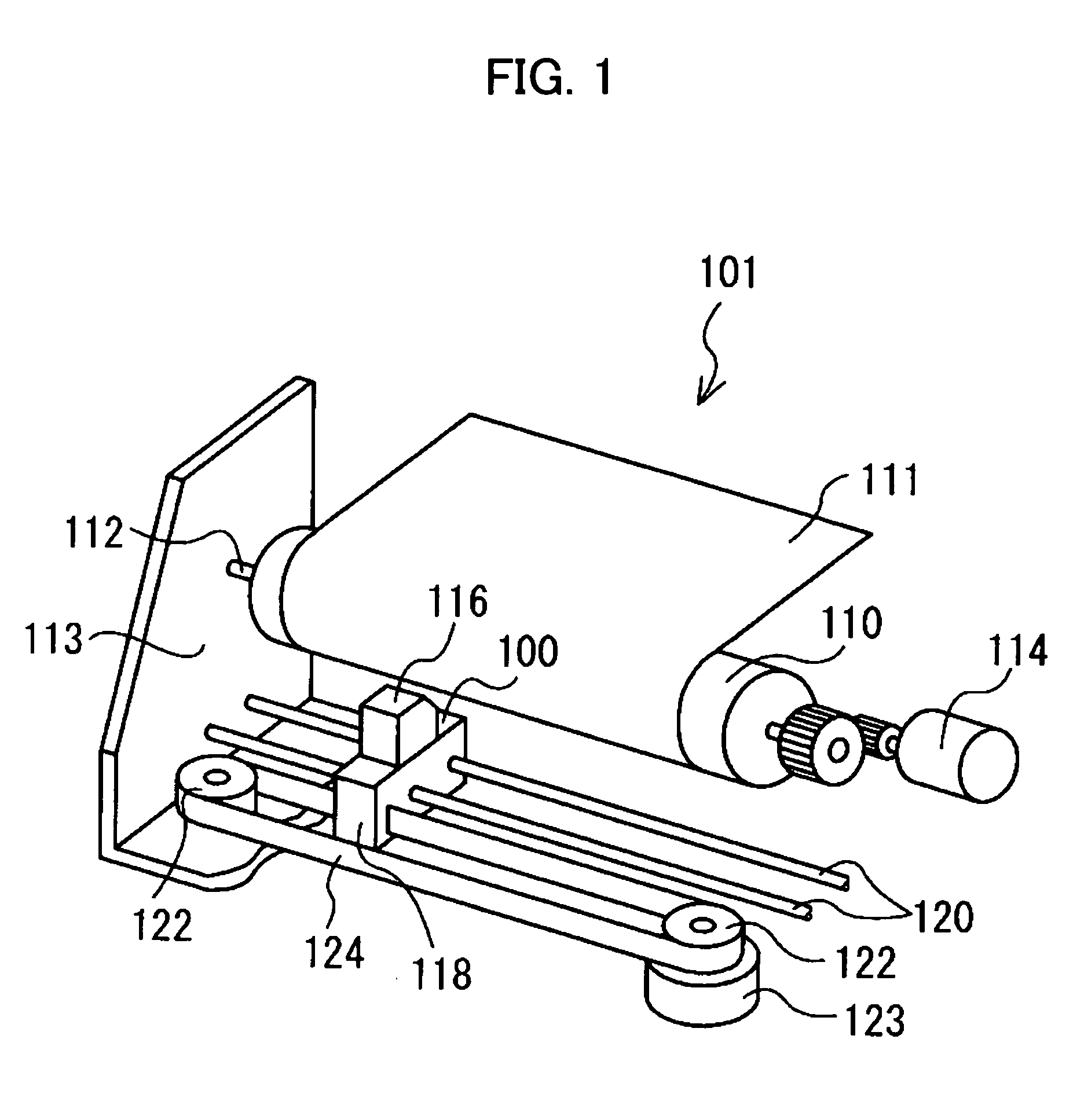

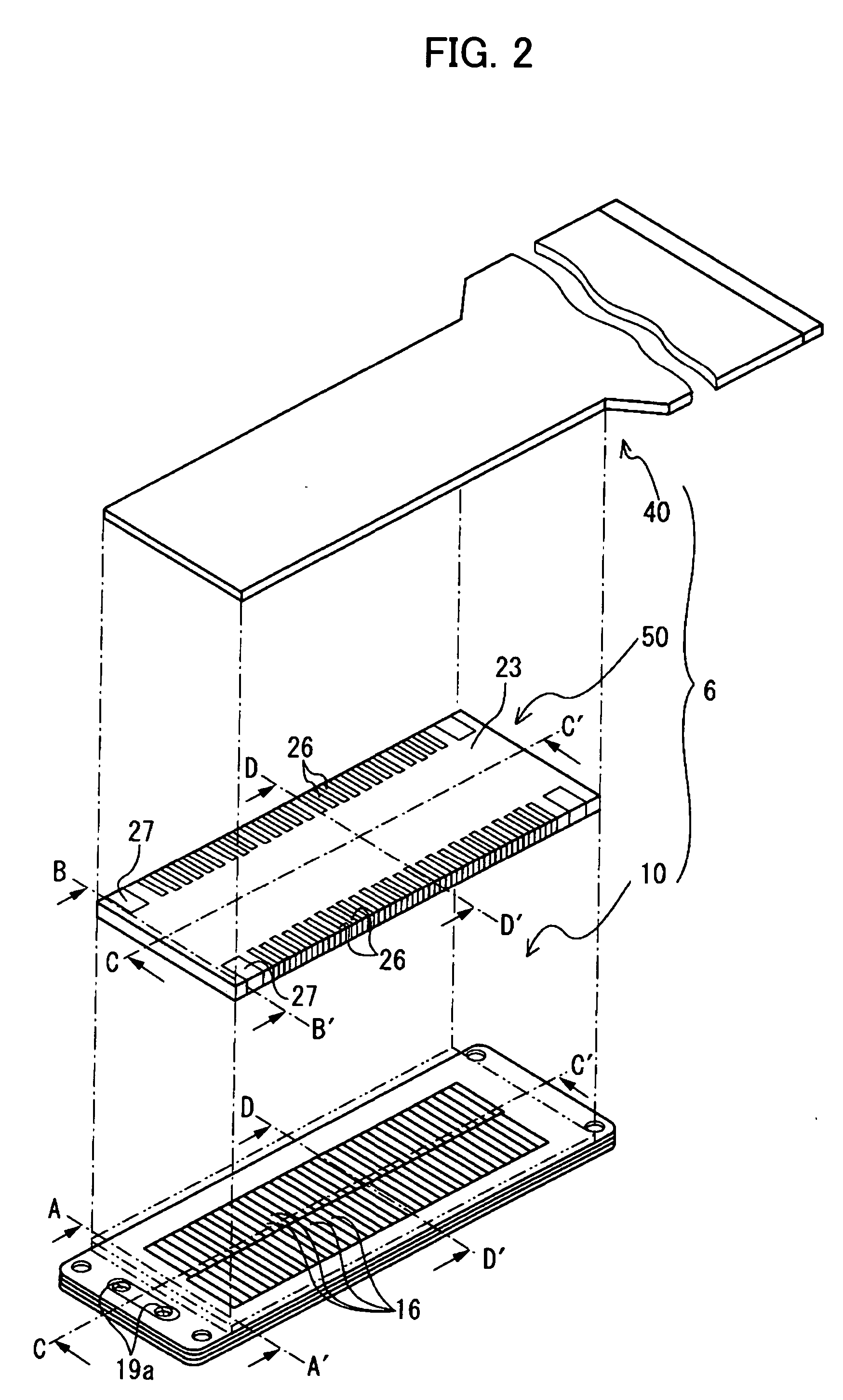

Liquid transporting apparatus and method for producing liquid transporting apparatus

ActiveUS20060152556A1Satisfactory energy efficiencyIncreased durabilityPrintingPiezoelectric actuatorsEngineering

An ink-jet head 501 as a liquid transportation apparatus includes pressure chambers 514, and a piezoelectric layer 503 having individual electrodes 532 and a vibration plate 530. When W is a length in the radial direction of pressure chambers 514, and A is a length in the radial direction of portions of individual electrodes 532 to which a drive voltage is applied, the portions being formed at areas each overlapping with one side portion, in the radial direction, of the edge portion of one of the pressure chambers 514, the length A in the radial direction of individual electrodes 532 is determined based on a relationship between the value of A / (W / 2) and an amount of deformation of the vibration plate 530 when the drive voltage is applied to the individual electrode 532, such that the amount of the deformation of the vibration plate 530 becomes great. Accordingly, a liquid transporting apparatus provided with the piezoelectric actuator which has excellent durability and more improved drive efficiency.

Owner:BROTHER KOGYO KK

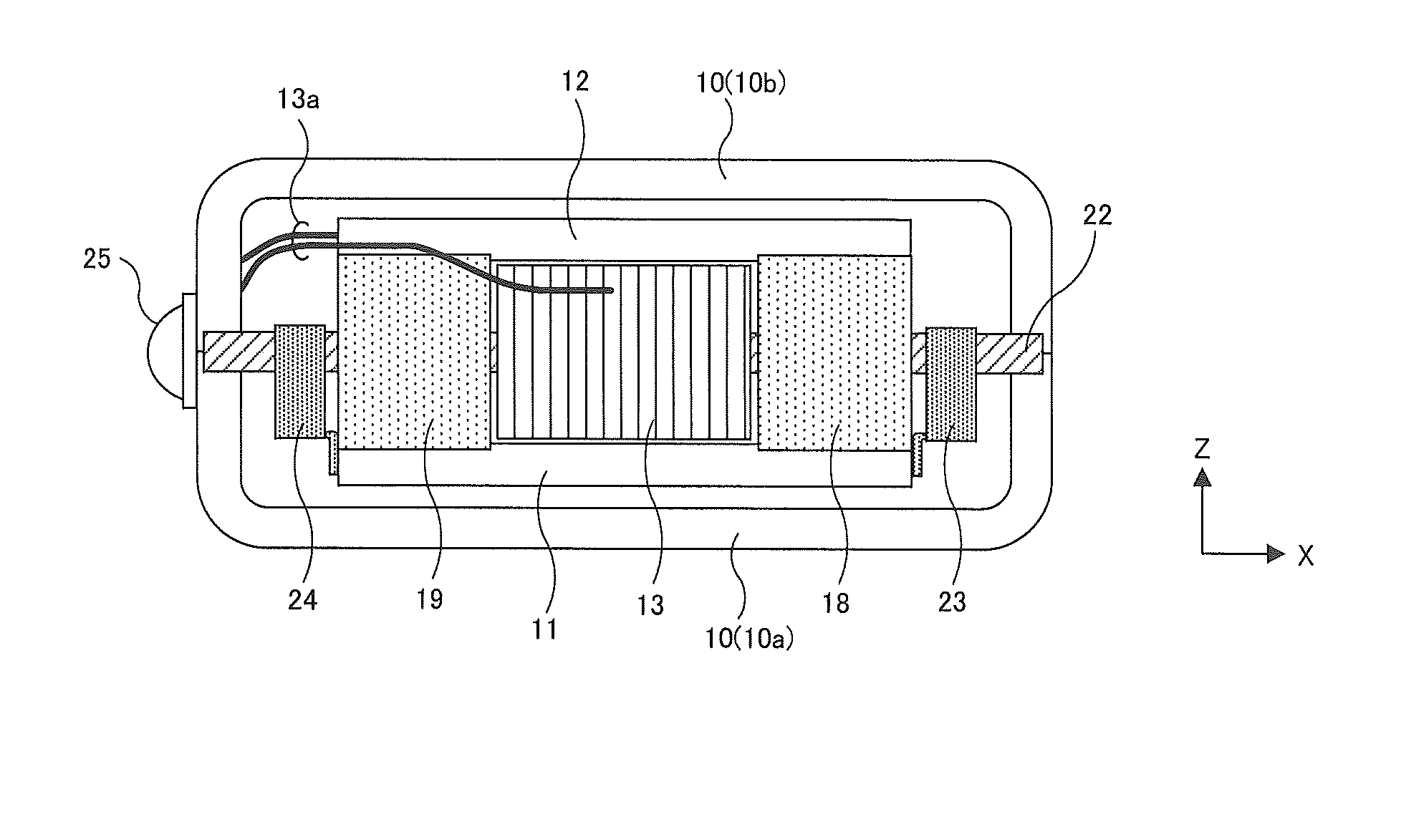

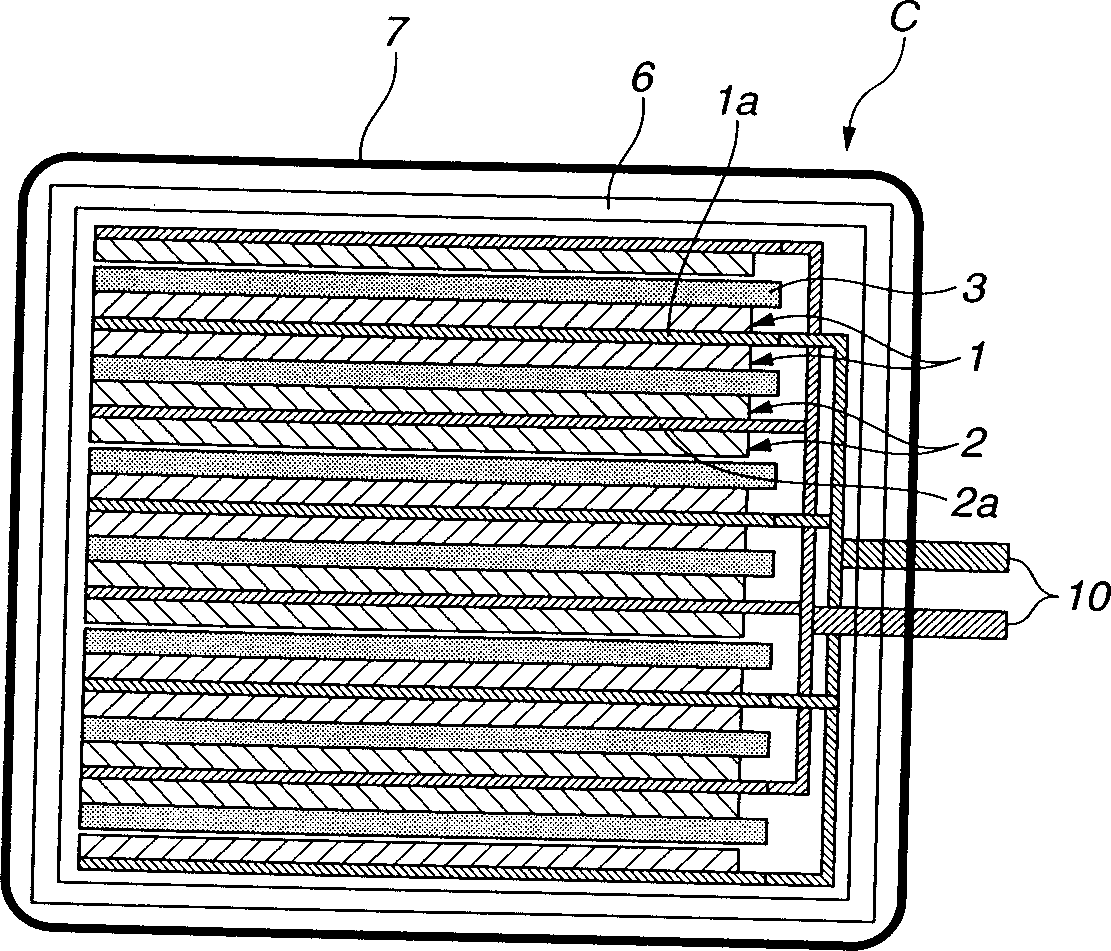

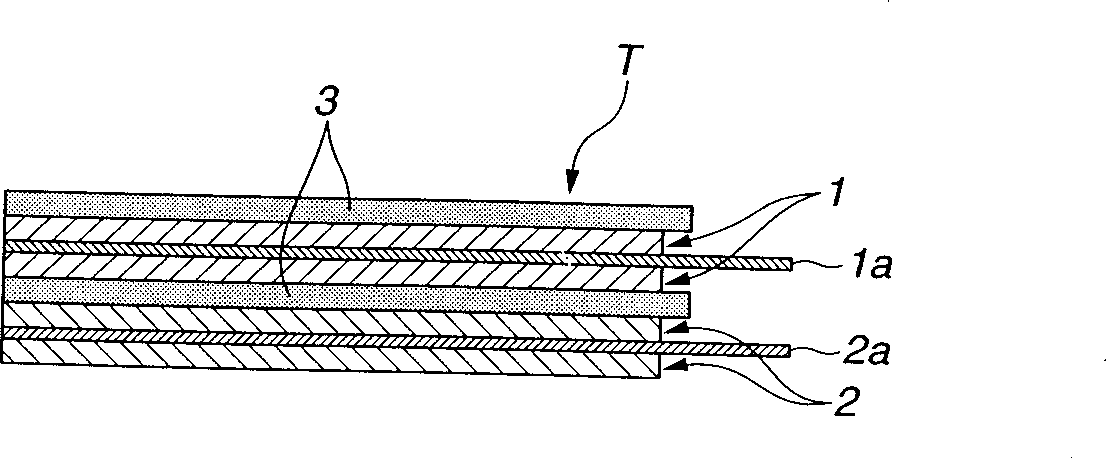

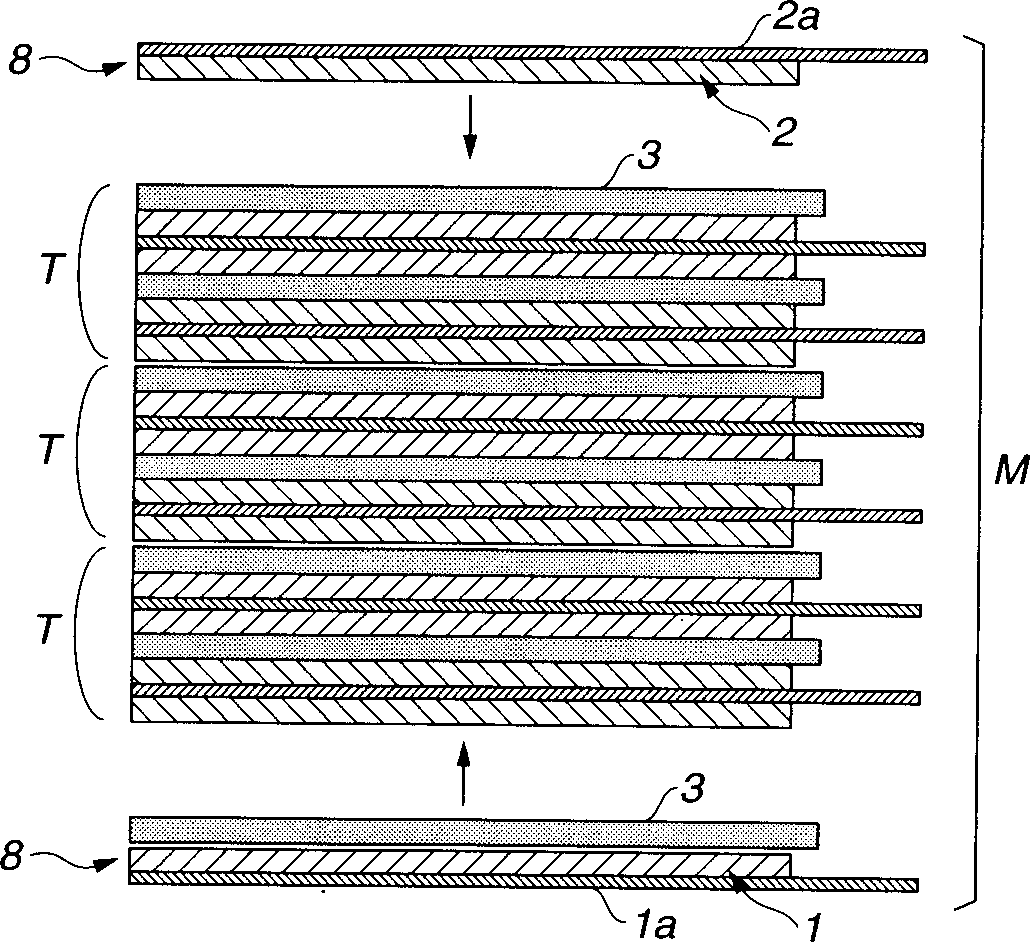

Lithium-based battery having extensible, ion-impermeable polymer covering on the battery container

InactiveUS7332242B2Improve safetyHigh tensile elongationPrimary cell maintainance/servicingLarge-sized flat cells/batteriesUnit structureEngineering

A lithium based battery includes a cell structure group formed by stacking unit cells each including a positive electrode, a negative electrode, and a separator interposed therebetween, or formed by repeatedly folding or winding an integral body of the unit cells; a battery container for containing the cell structure group; and an electrolyte, which is poured in the battery container after the cell structure group is contained in the battery container. The outer peripheral surface of the battery container is covered with an ion impermeable and extensible high polymer sheet having a tensile elongation percentage of 1% or more. With this configuration, even if there happens such a severe accident that nail pieces the battery or the battery is crashed, it is possible to prevent a large short-circuit current from flowing between the positive and negative electrodes, and hence to ensure a higher safety of the battery.

Owner:ITOCHU CO LTD

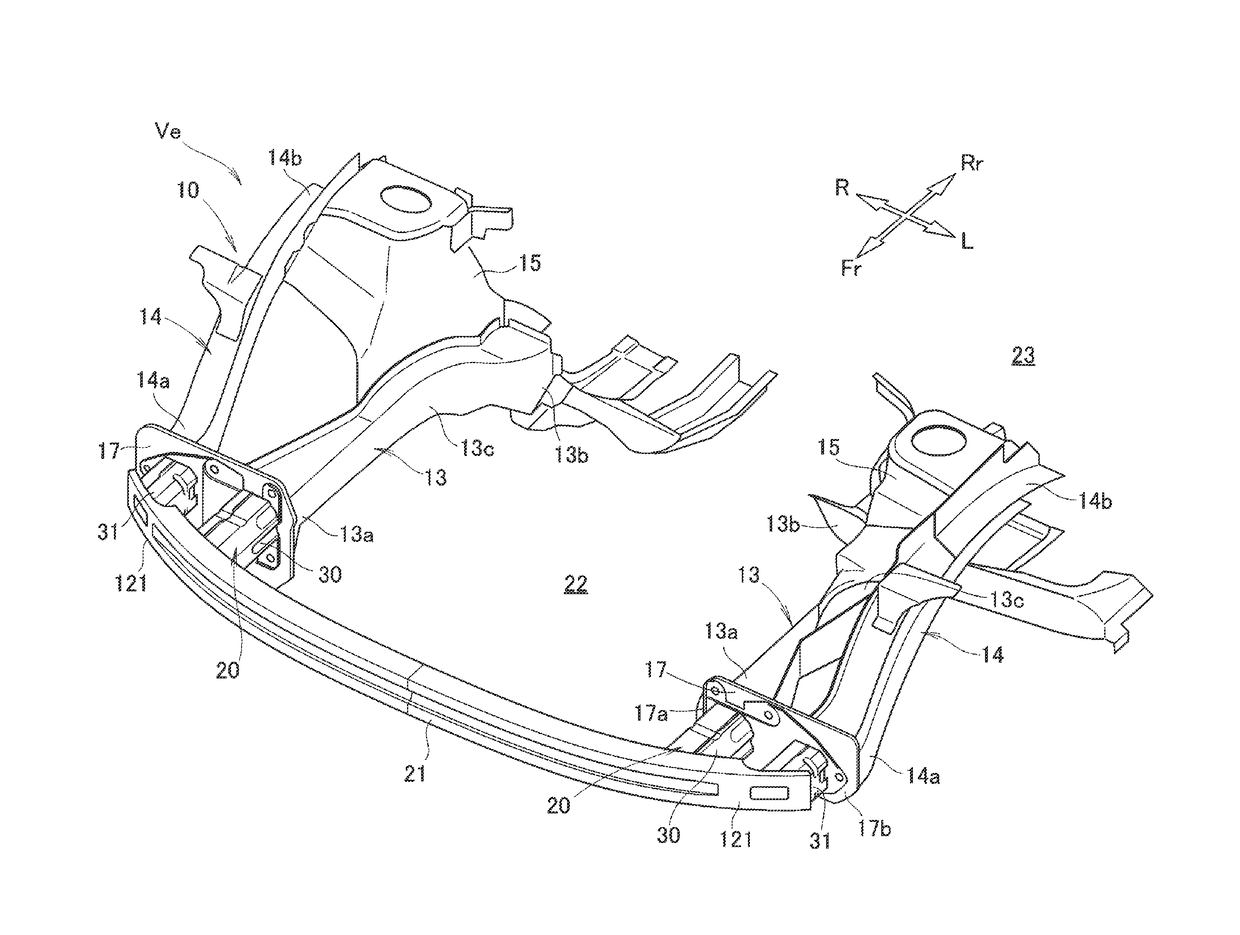

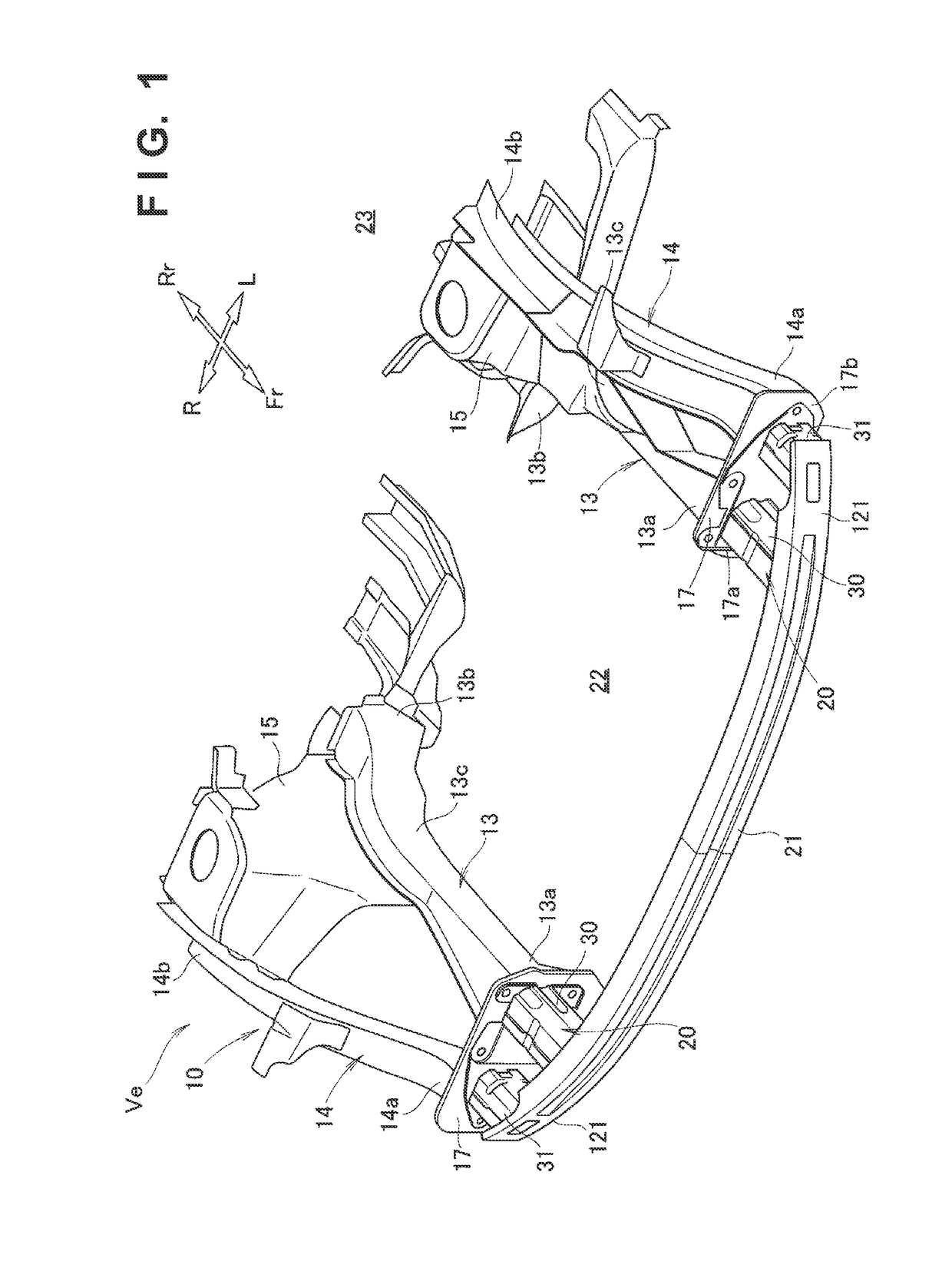

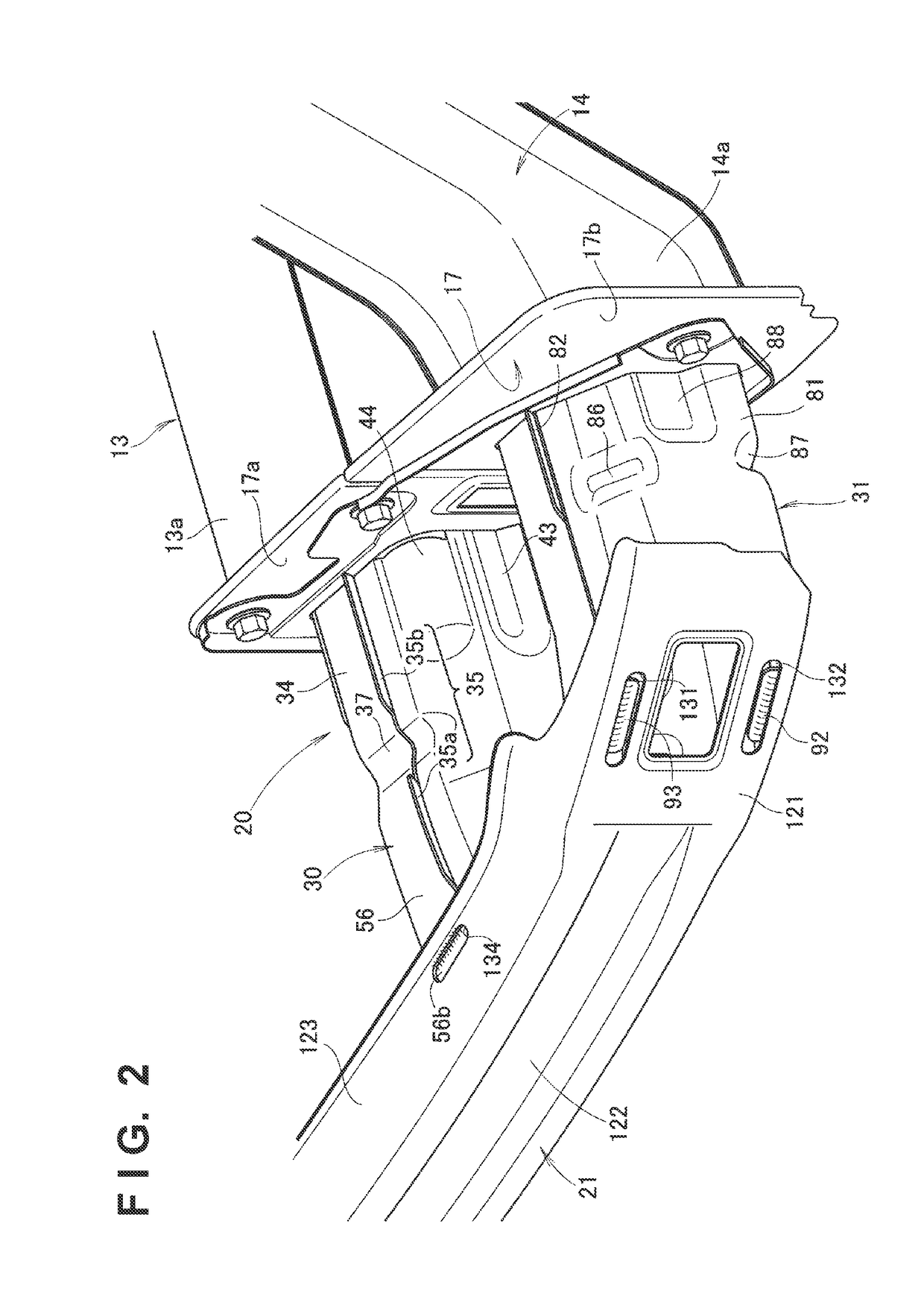

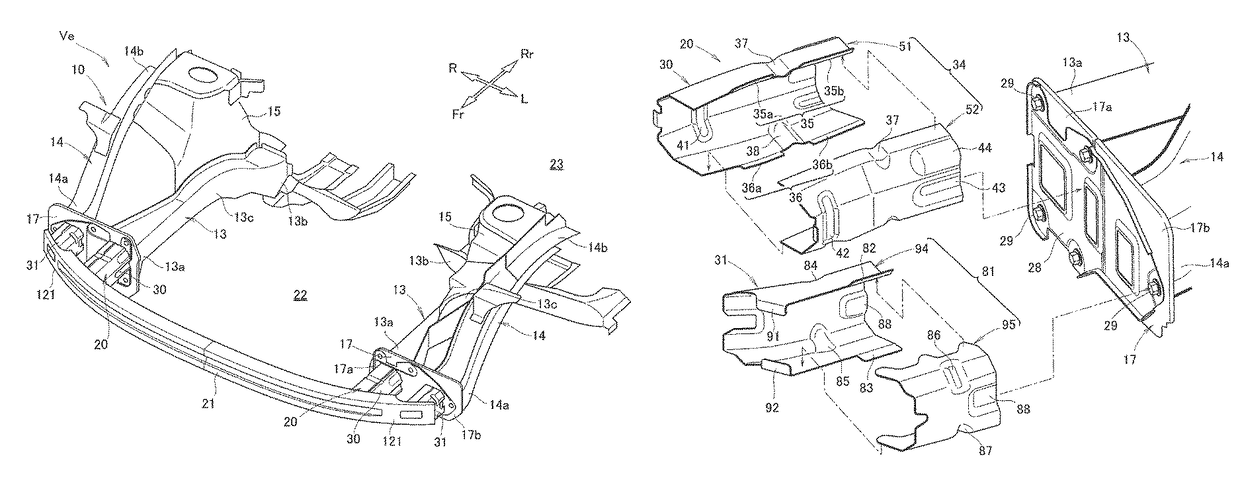

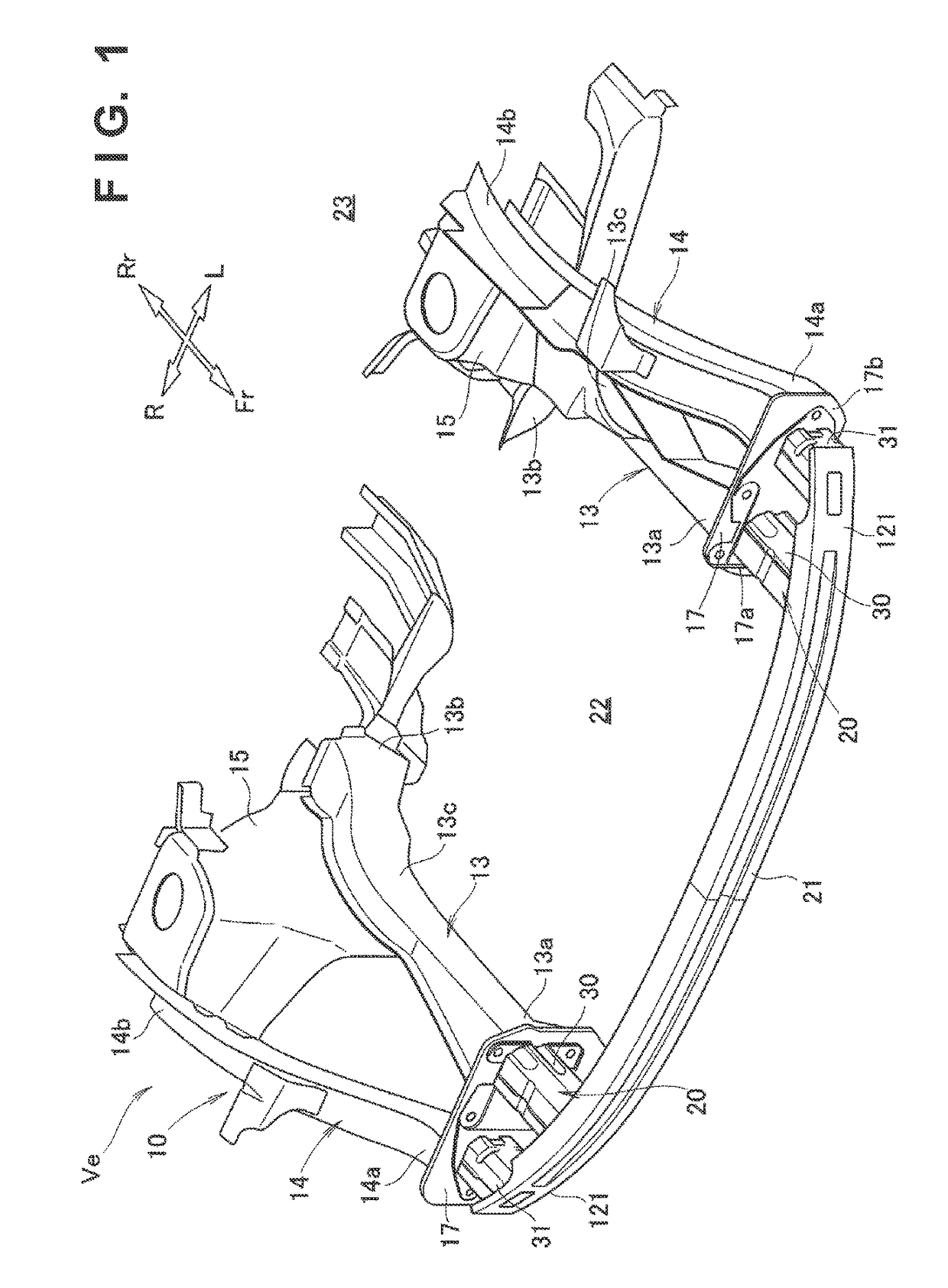

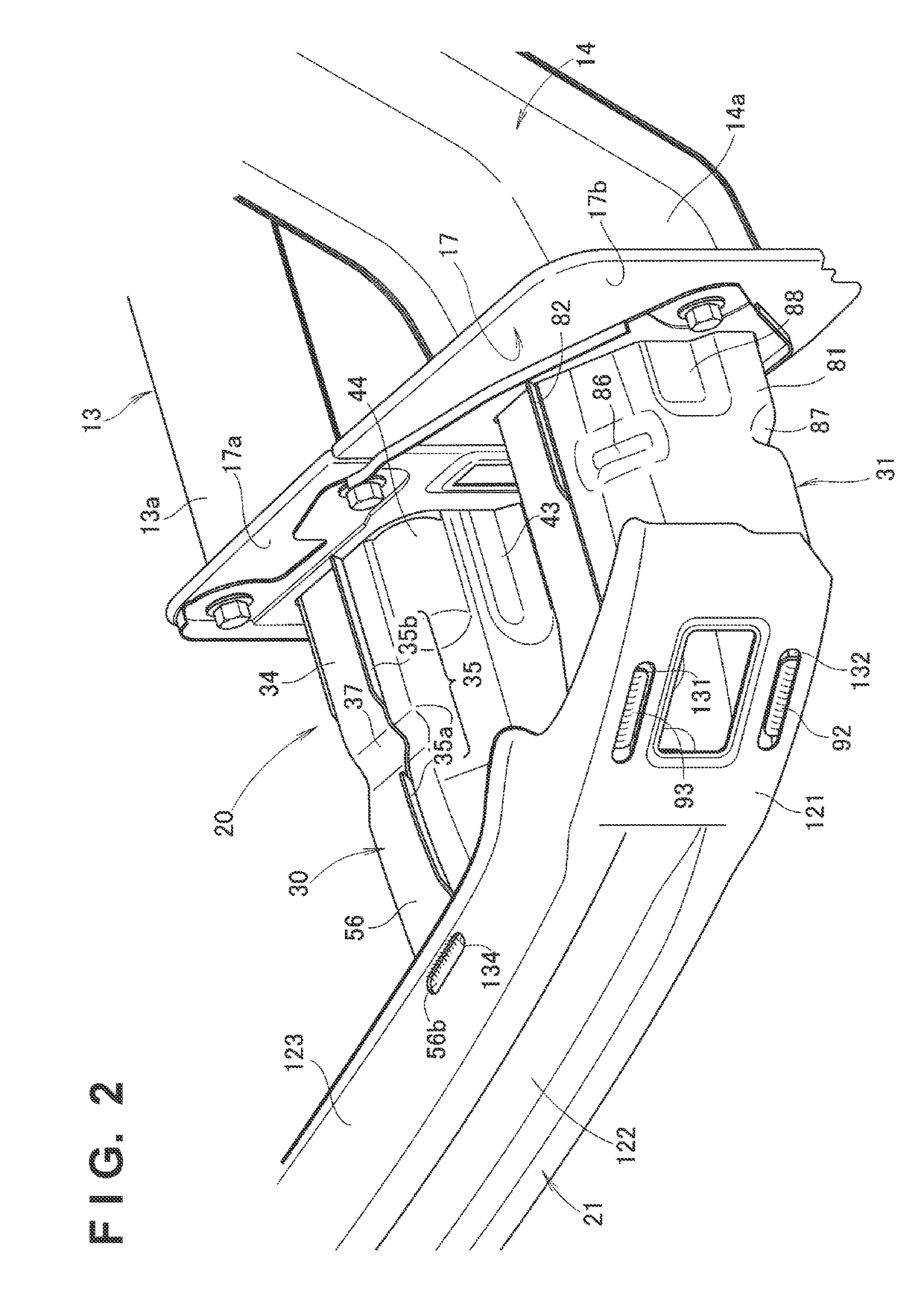

Vehicle body structure with impact absorbing part

ActiveUS20170106909A1Shorten the lengthFast transferPedestrian/occupant safety arrangementUnderstructuresEngineeringFlange

A vehicle body structure includes a frame impact absorbing part extending from the side of a left front side frame in the longitudinal direction of the vehicle body. The frame impact absorbing part includes first and second frame bending members that form a frame tubular body, upper and lower frame flanges projecting outward from the frame tubular body, upper and lower first fragile portions that divide the frame flanges in the longitudinal direction of the vehicle body, and a plurality of frame rigid portions formed at a rear end of the frame tubular body on the rear side of the vehicle body with respect to the first fragile portions.

Owner:HONDA MOTOR CO LTD

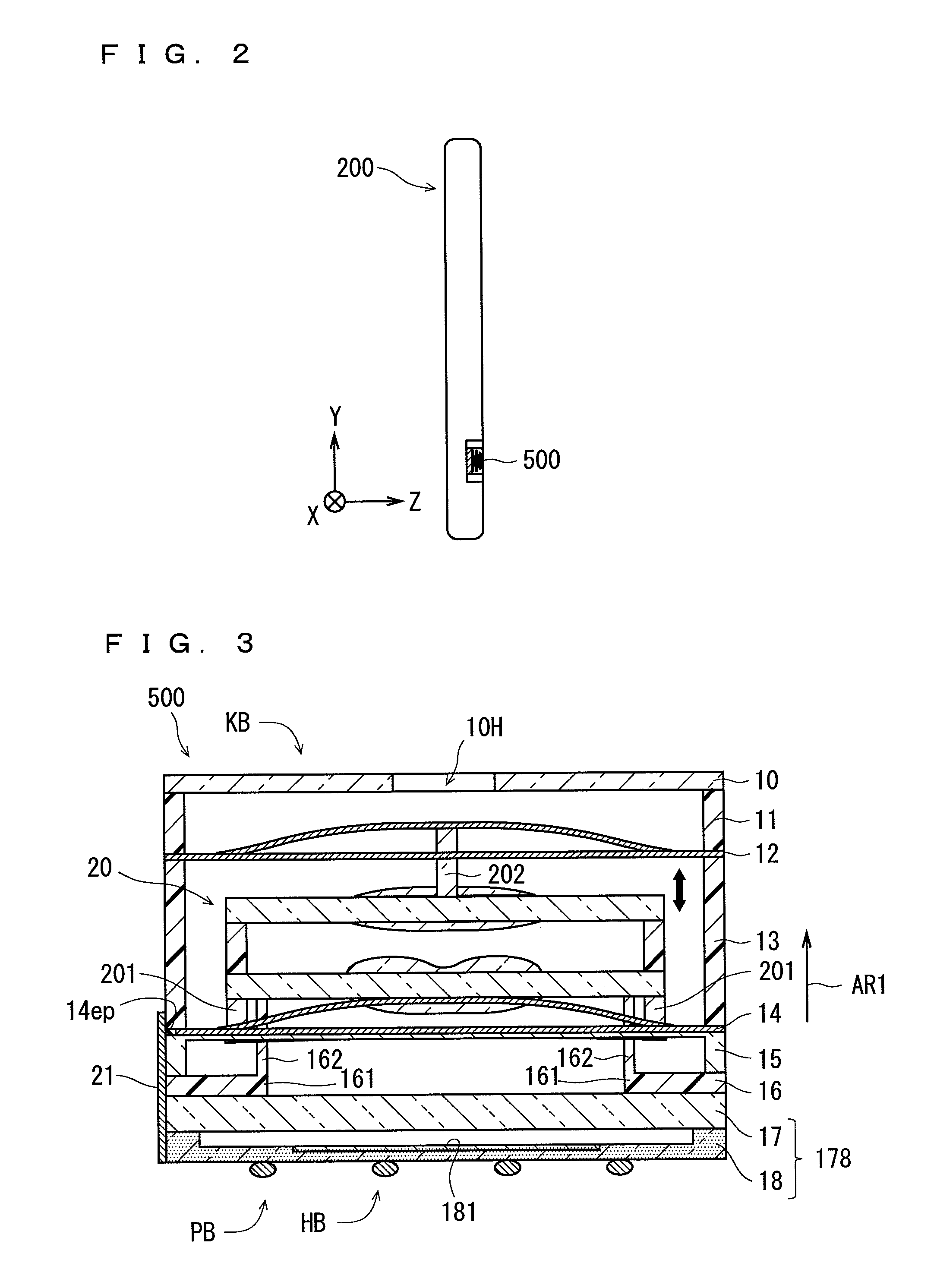

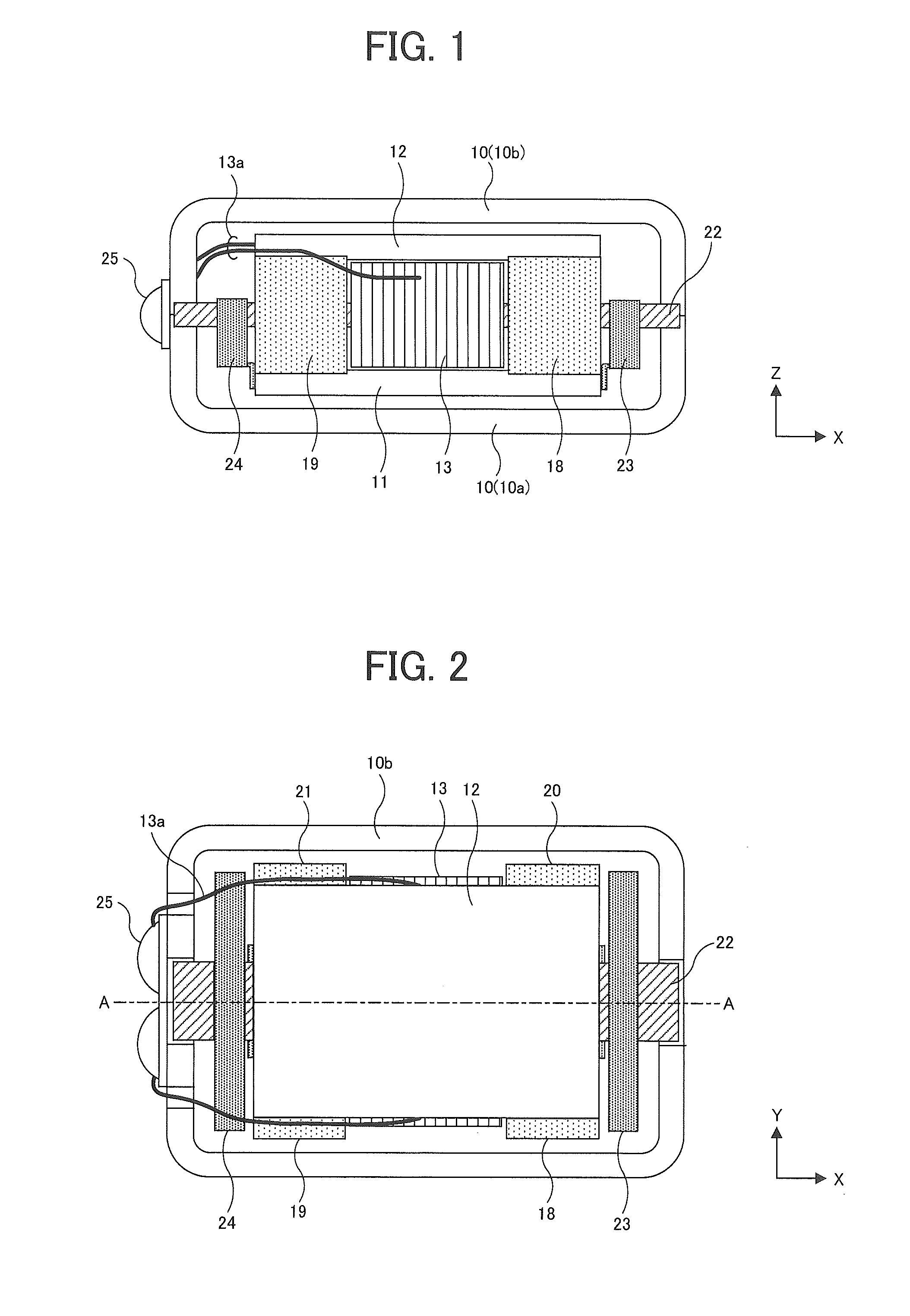

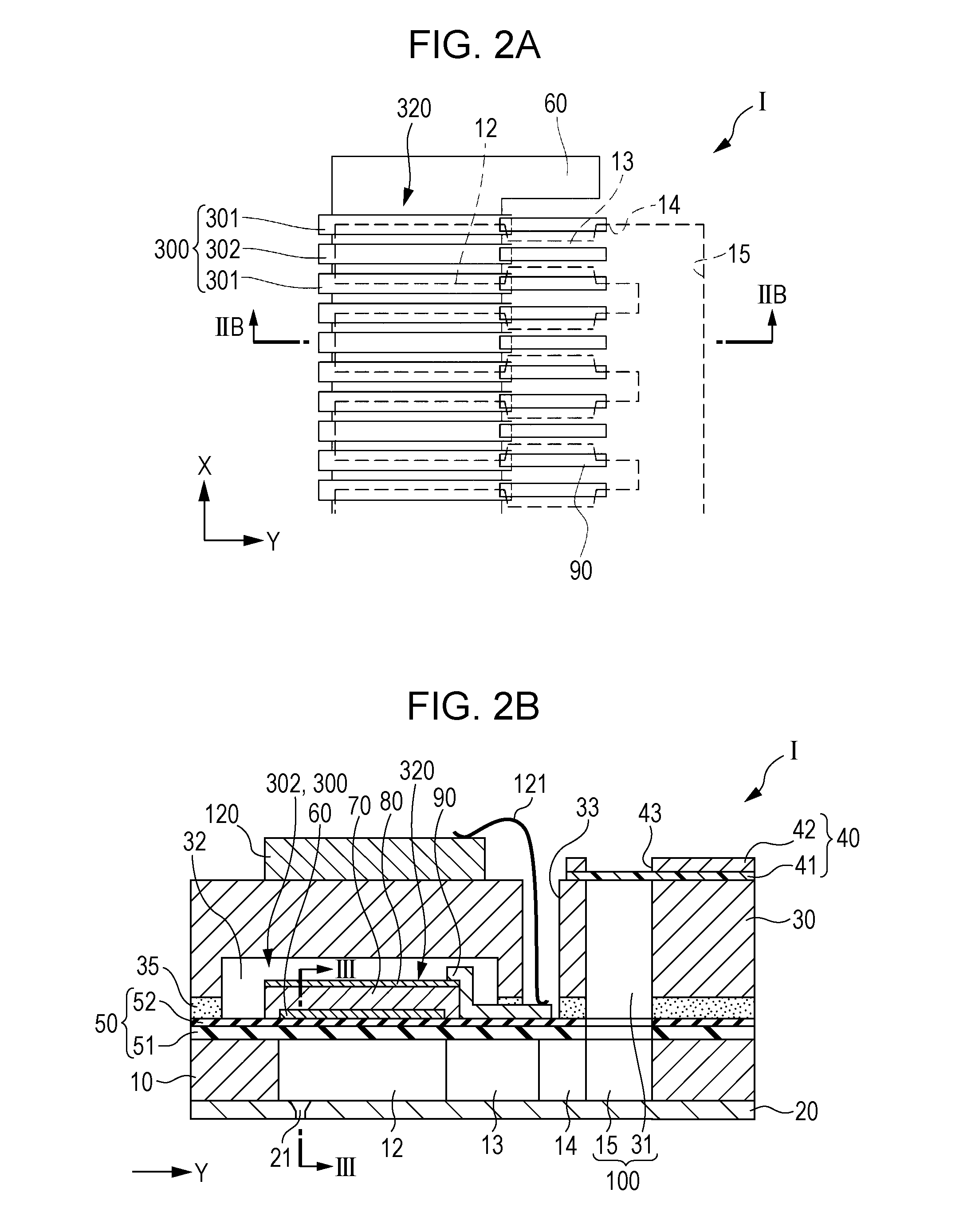

Actuator, drive device, and imaging device

InactiveUS8421908B2Increase freedomEasy to controlTelevision system detailsSemiconductor/solid-state device manufacturingElectrical resistance and conductanceEngineering

An object of the present invention is to provide an actuator allowing a control of displacement and configured to offer a high degree of freedom in designing, and a drive device and an imaging device including the actuator. To achieve the object, an actuator is adopted including a movable part deformable in accordance with heat generation and a control section controlling the amount of deformation of the movable part. In the actuator, the movable part is structured with a plurality of portions including a base portion, a force generating portion, and a heat generating portion being stacked, the force generating portion generating force in accordance with heating, the heat generating portion generating heat in accordance with a current supply. The control section controls the amount of deformation of the movable part by controlling the current supply to the heat generating portion based on an electrical resistance in the heat generating portion.

Owner:KONICA MINOLTA OPTO

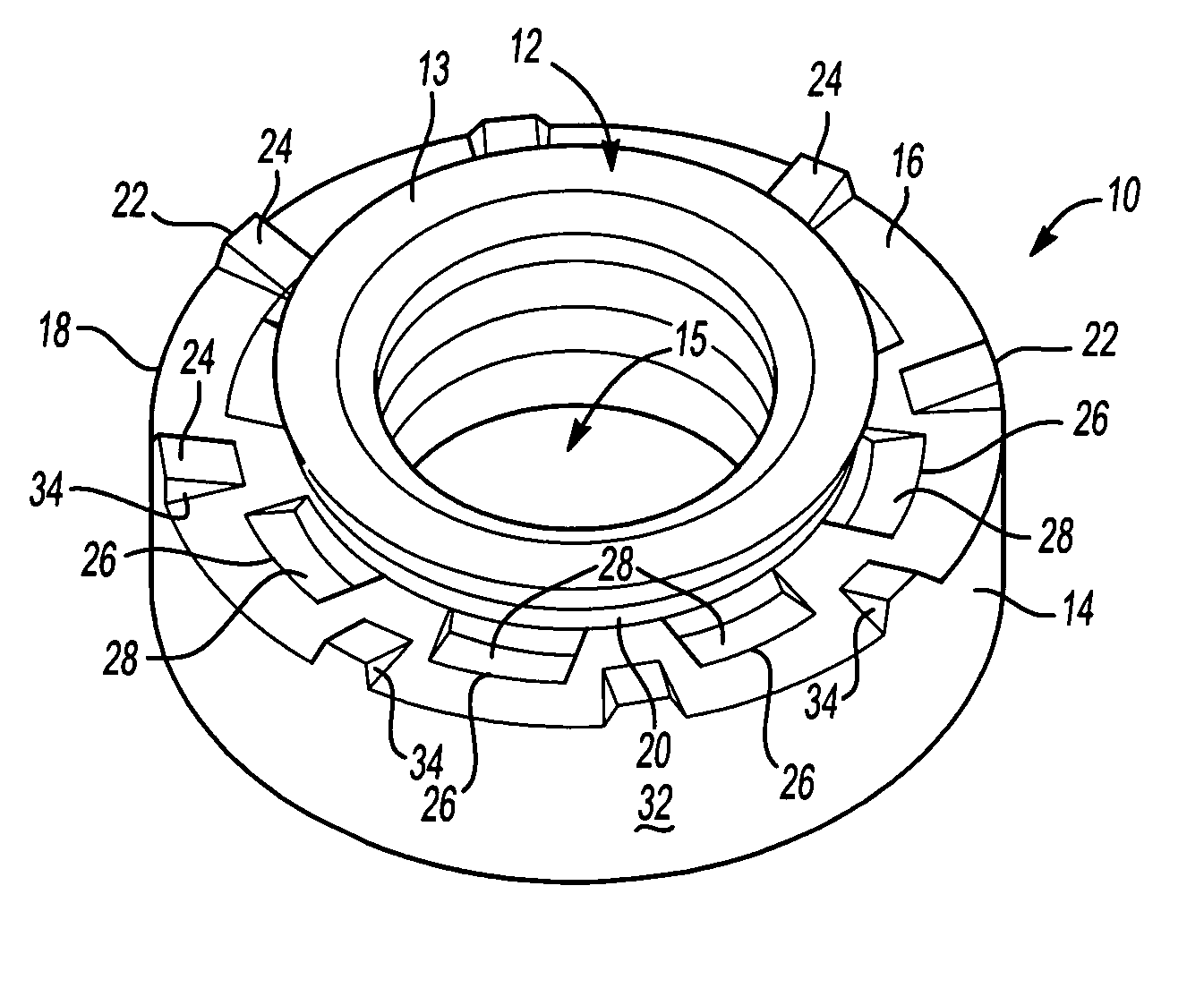

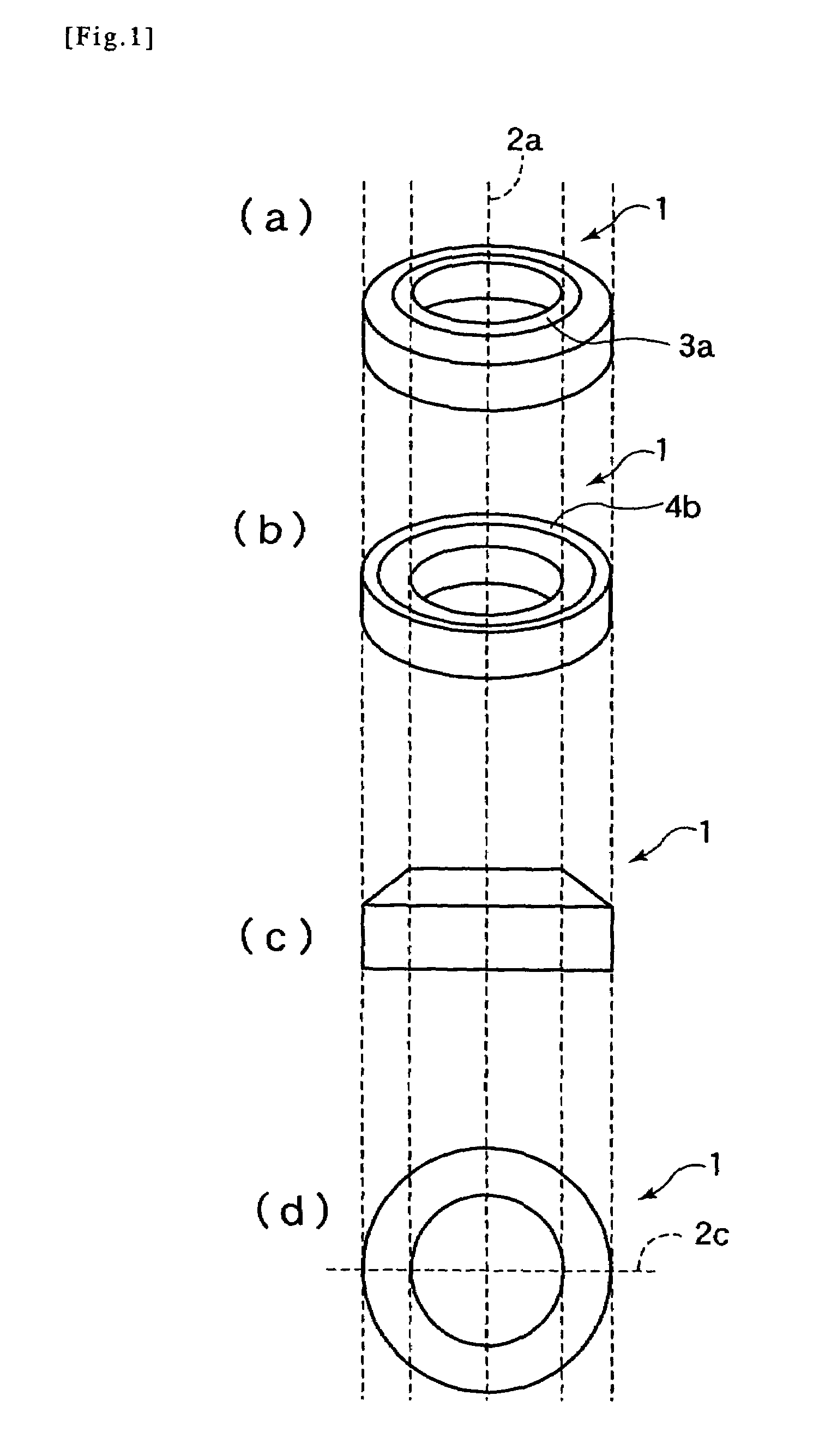

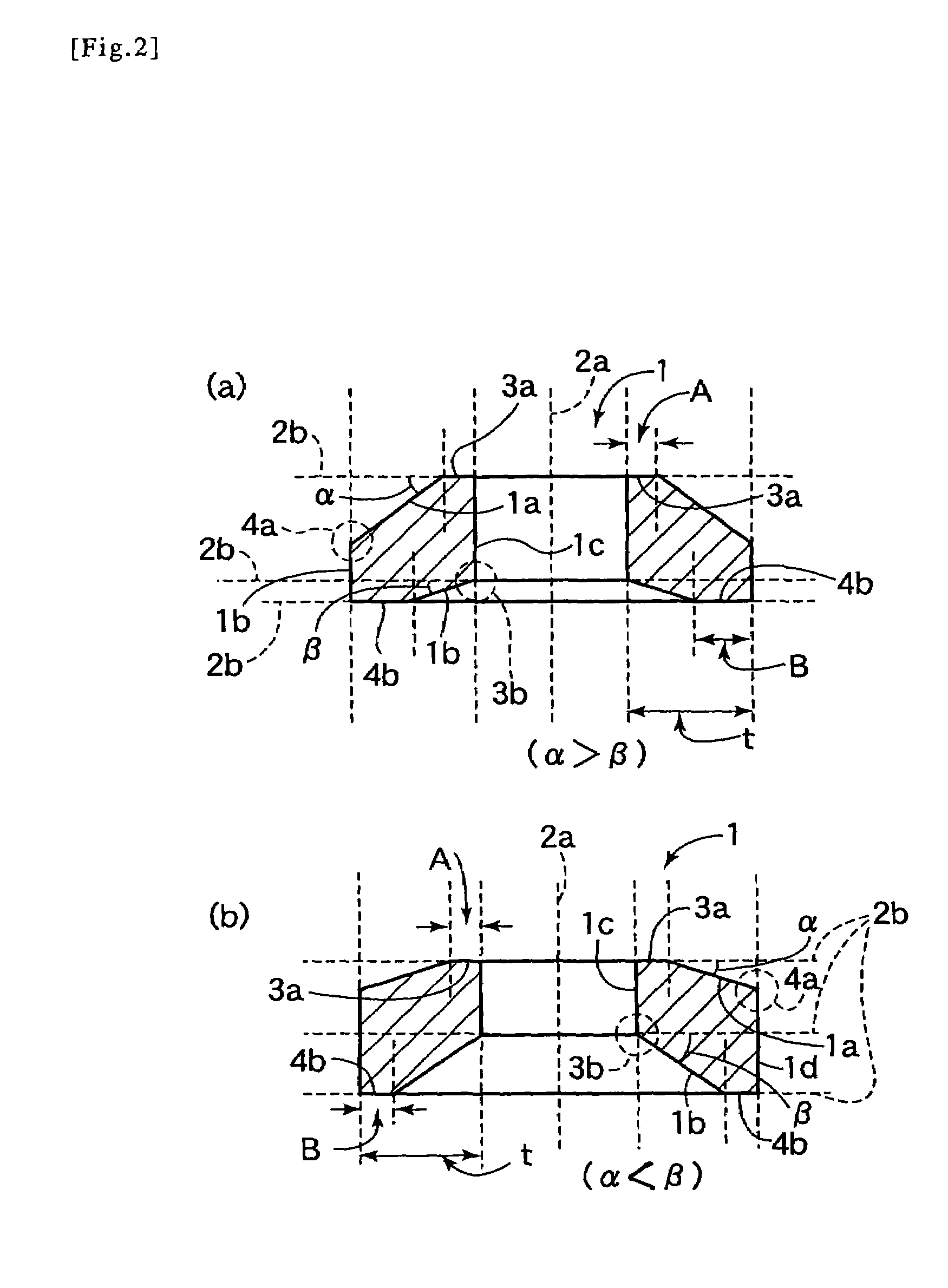

Gland packing and sealing apparatus comprising it

InactiveUS7011312B2Increased stability and tightnessGood effectSpindle sealingsEngine sealsReciprocating motionAcute angle

To provide a novel gland packing and a sealing apparatus comprising this, wherein the gland packing displays high and stable sealability for a stem and an inner wall surface of a stuffing box even for uses further requesting the movability (rotation and reciprocating movement), and further, gives excellent effects, such as decrease of moving resistance of a stem, shape stability, adaptability to a corroded and worn-out stem and stuffing box, function for receiving shafts, easiness of equipment, simplification of sealing structure, and compactness of a sealing apparatus. The gland packing, according to the present invention, is a ring packing of which the cross sectional shape is a quadrilateral, wherein both two edges at inner and outer diameter sides of the quadrilateral are parallel to a central axis of the gland packing, and wherein the other two edges have slopes of the same orientation as to an axis perpendicular to the central axis, with the gland packing being characterized in that an inner-diameter-side acute angle portion and an outer-diameter-side acute angle portion of the quadrilateral are made flat portions.

Owner:NIPPON VALQUA IND LTD

Vehicle body structure with impact absorbing part

ActiveUS9855971B2Effective deformationPedestrian/occupant safety arrangementUnderstructuresEngineeringFlange

A vehicle body structure includes a frame impact absorbing part extending from the side of a left front side frame in the longitudinal direction of the vehicle body. The frame impact absorbing part includes first and second frame bending members that form a frame tubular body, upper and lower frame flanges projecting outward from the frame tubular body, upper and lower first fragile portions that divide the frame flanges in the longitudinal direction of the vehicle body, and a plurality of frame rigid portions formed at a rear end of the frame tubular body on the rear side of the vehicle body with respect to the first fragile portions.

Owner:HONDA MOTOR CO LTD

Electromechanical transducer and electrocoustic transducer

ActiveUS20140270276A1Increase freedomImprove seismic performanceTransducer detailsBone conduction transducer hearing devicesMagnetic fluxElectric signal

An electromechanical transducer of the invention comprises a structural unit, an armature, and first and second elastic members. The structural unit includes at least one pair of magnets, a yoke conducting a magnetic flux generated by the magnets, and a coil supplied with an electric signal. The armature has an inner portion disposed to pass through an internal space of the structural unit and first and second outer portions protruding on both sides from the inner portion, and the armature constitutes a magnetic circuit with the structural unit via two regions through which components of the magnetic flux flow in directions opposite to each other in the inner portion. The first and second elastic members connect between the first and second outer portions of the armature and the structural unit, respectively.

Owner:RION COMPANY

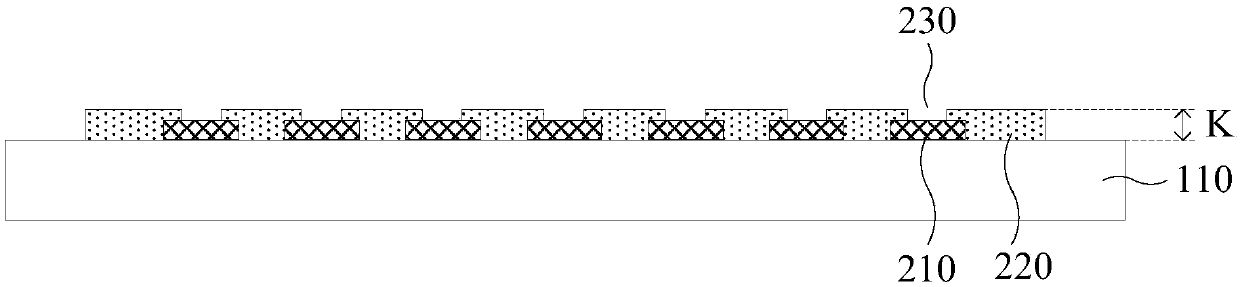

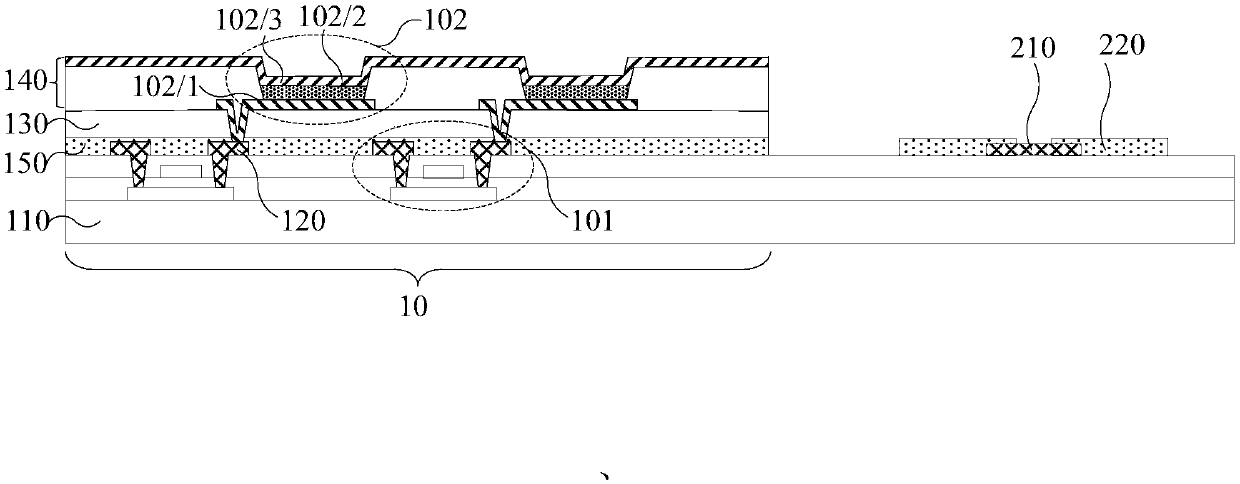

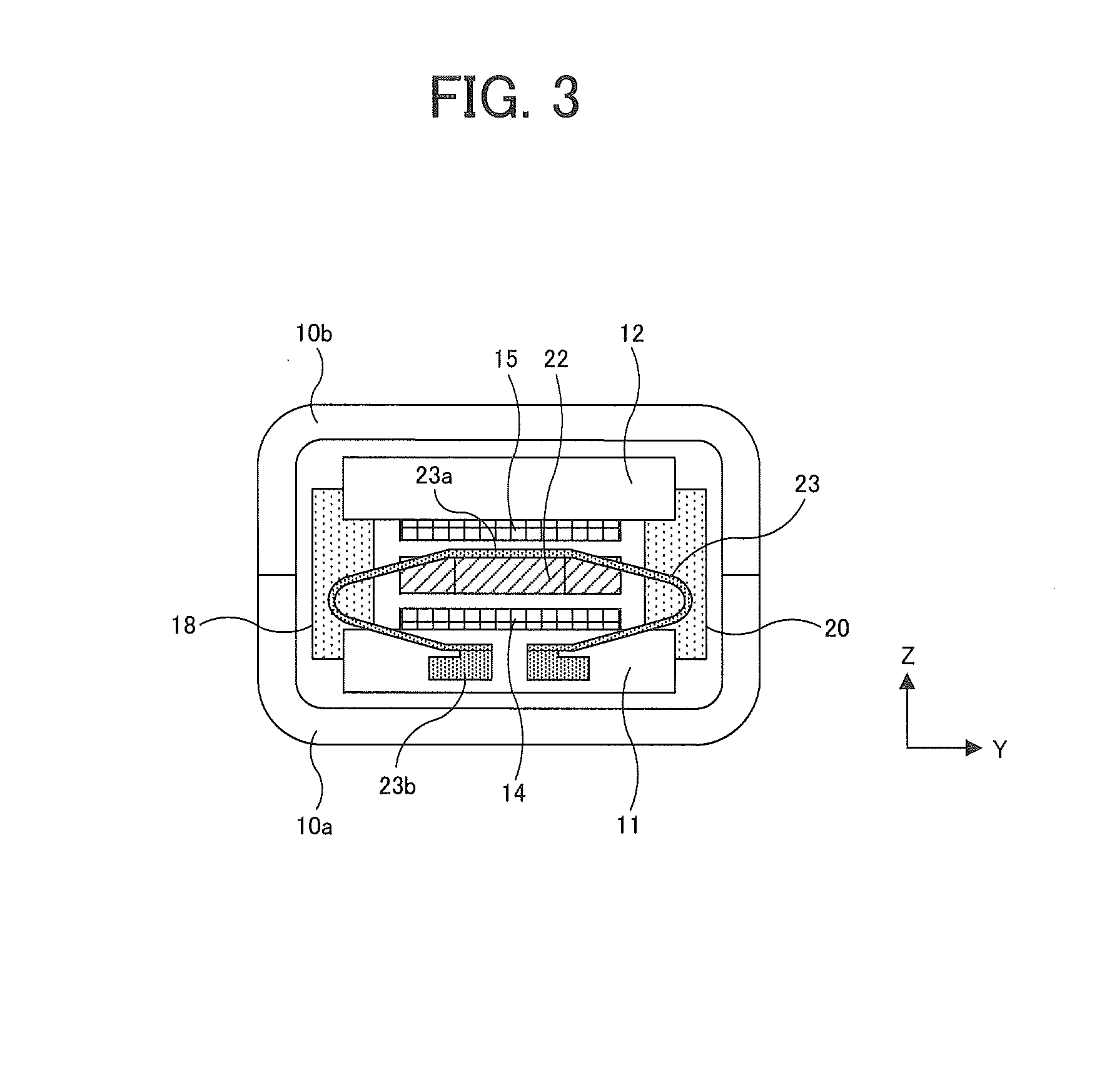

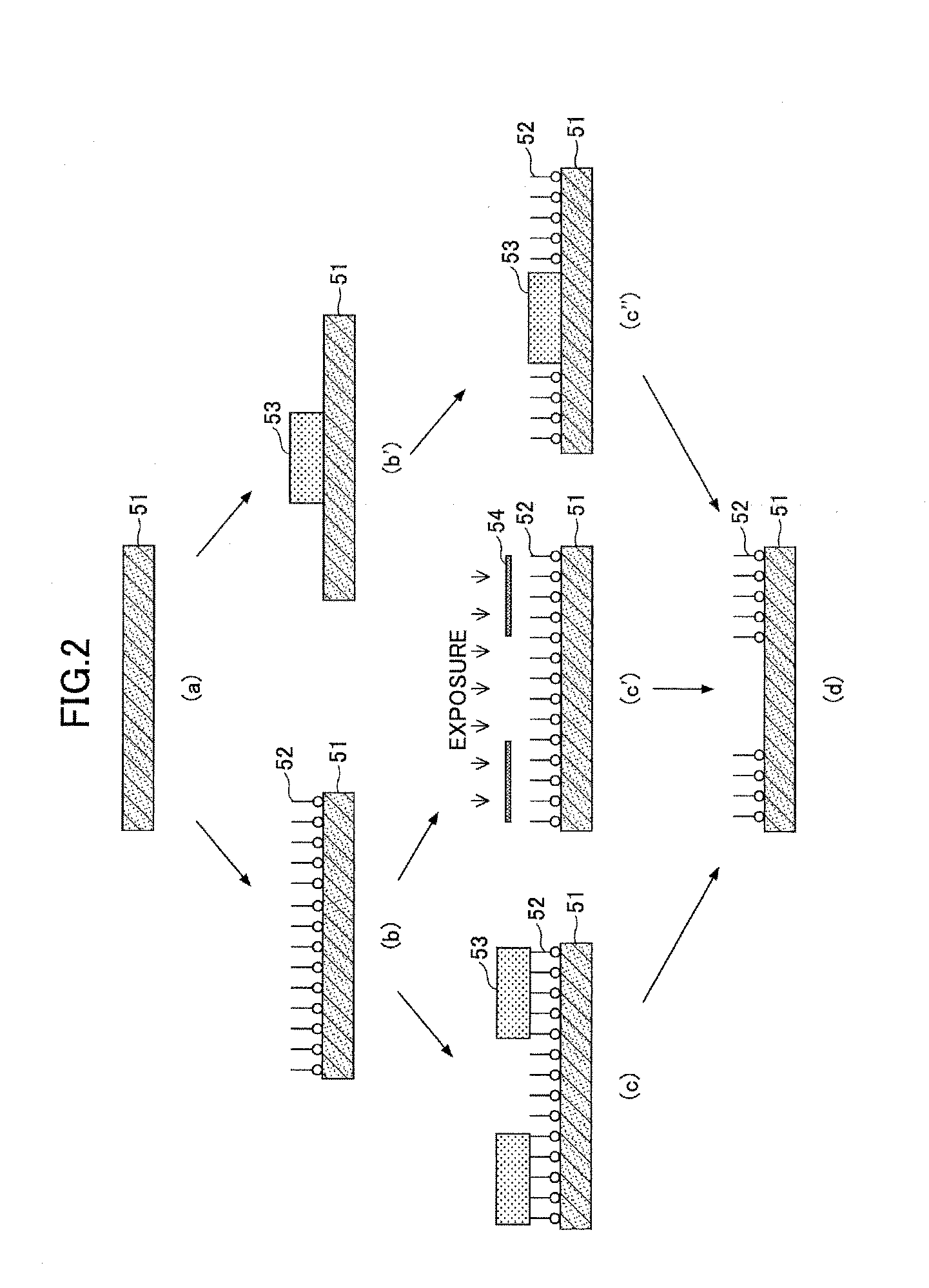

Electro-mechanical transducer element, liquid droplet ejecting head, image forming apparatus, and electro-mechanical transducer element manufacturing method

ActiveUS20140049582A1Efficient deformation and displacementEffective deformationPiezoelectric/electrostrictive device manufacture/assemblyPrintingEngineeringElectron

An electro-mechanical transducer element is disclosed. The electro-mechanical transducer element includes a first electrode formed on a substrate; an electro-mechanical transducer film formed on at least a part of the first electrode; and a second electrode formed on at least a part of the electro-mechanical transducer film. In at least one cross section of the electro-mechanical transducer film, a film thickness distribution shape is convex to the second electrode side.

Owner:RICOH KK

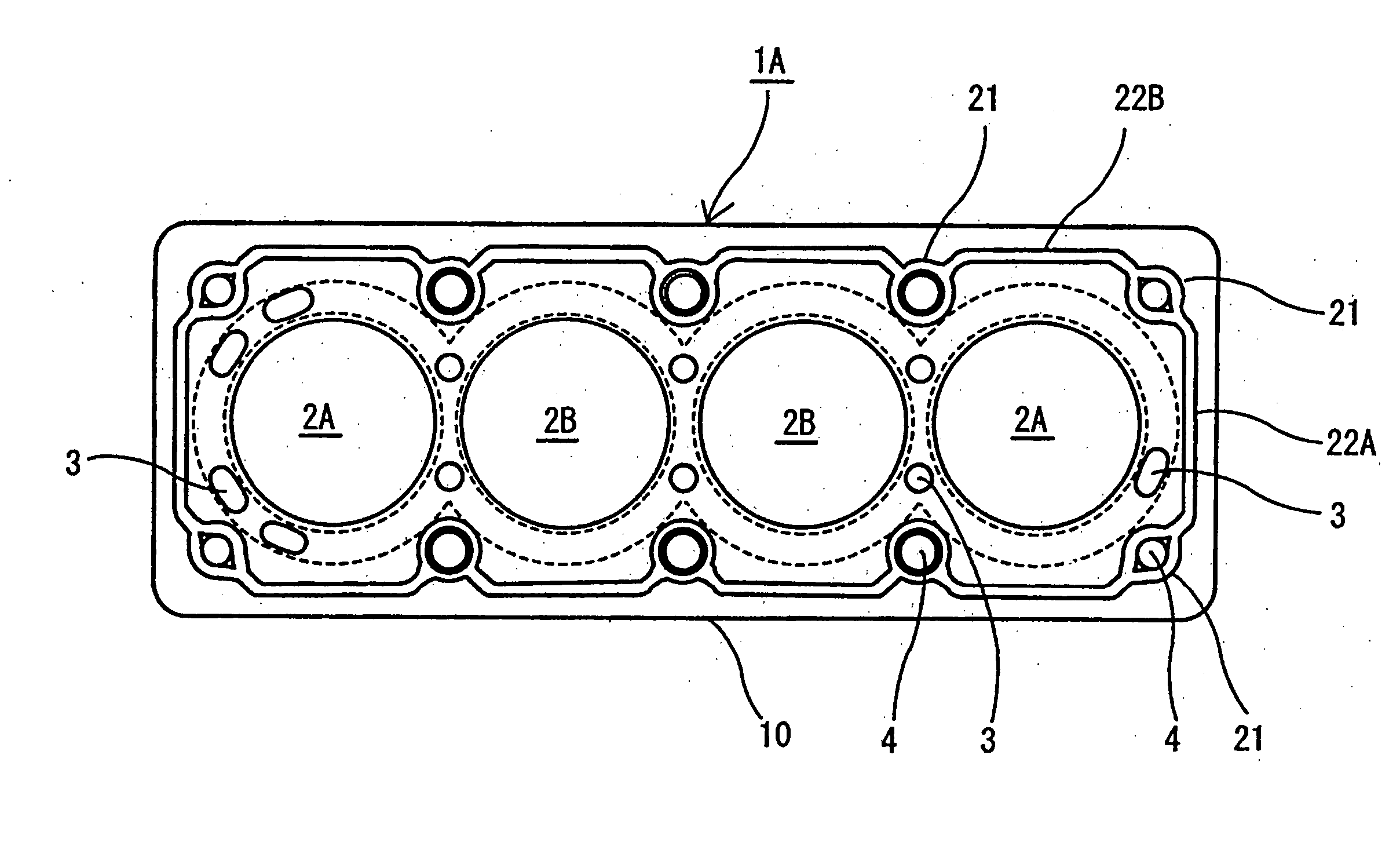

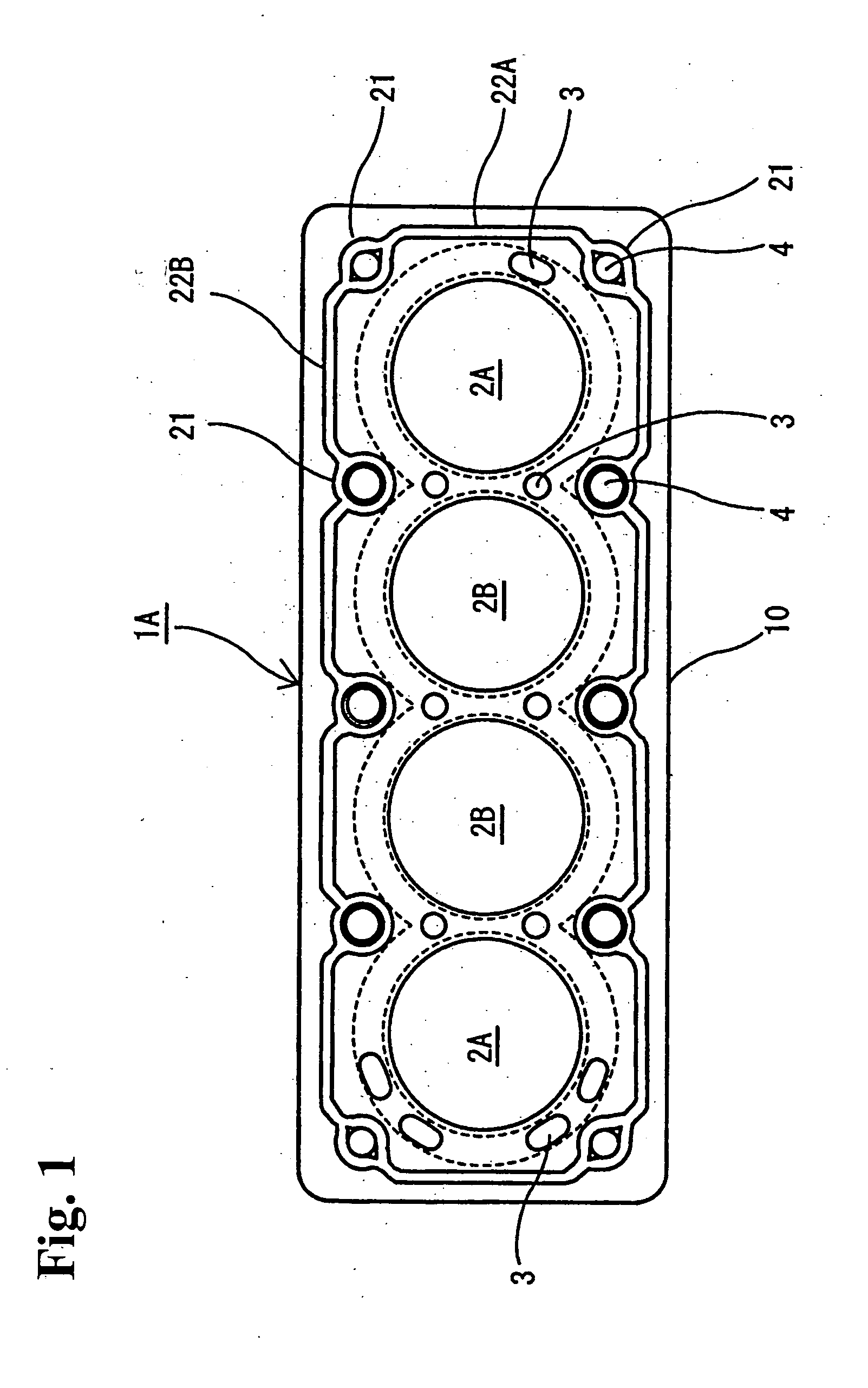

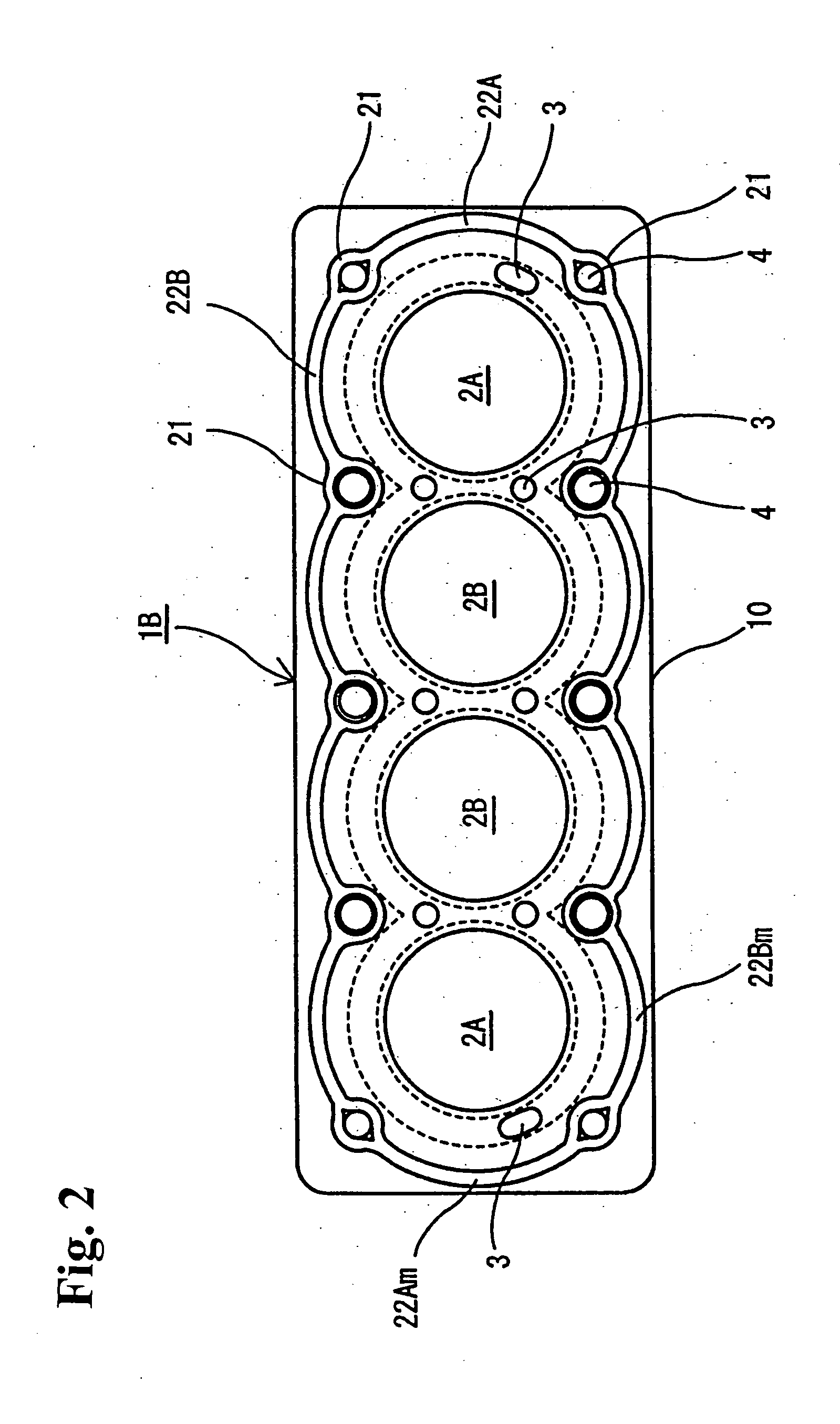

Cylinder head gasket

A cylinder head gasket is formed by a metal plate, for constituting the gasket, having at least one cylinder hole and a plurality of bolt holes arranged to surround the at least one cylinder hole. Bolt-hole beads are formed in the metal plate to surround the respective bolt holes. Also, suppress adjusting beads are formed in the metal plate to be situated between adjacent bolt-hole beads.

Owner:ISHIKAWA GASKET CO LTD

Optical window for an intracorporeal device

InactiveUS20060106287A1Softening the window preformSoften the window preformSurgeryEndoscopesEngineeringEndoscope

Optical windows for intracorporeal devices, intracorporeal devices comprising a window and a method for forming a window for an intracorporeal device are provided. The method comprises placing within a mold an assembly comprising a mandrel located within a pair of parts separated by a collar of window material, heating the window preform effective to cause the window material to soften, and applying force to urge together the pair of parts to deform the window material so as to form a window. The intracorporeal devices, such as imaging devices, include guidewires, catheters, endoscopes. In addition, the method is suitable for joining plastic parts to other parts, such as metal and ceramic parts.

Owner:WEBLER WILLIAM E +5

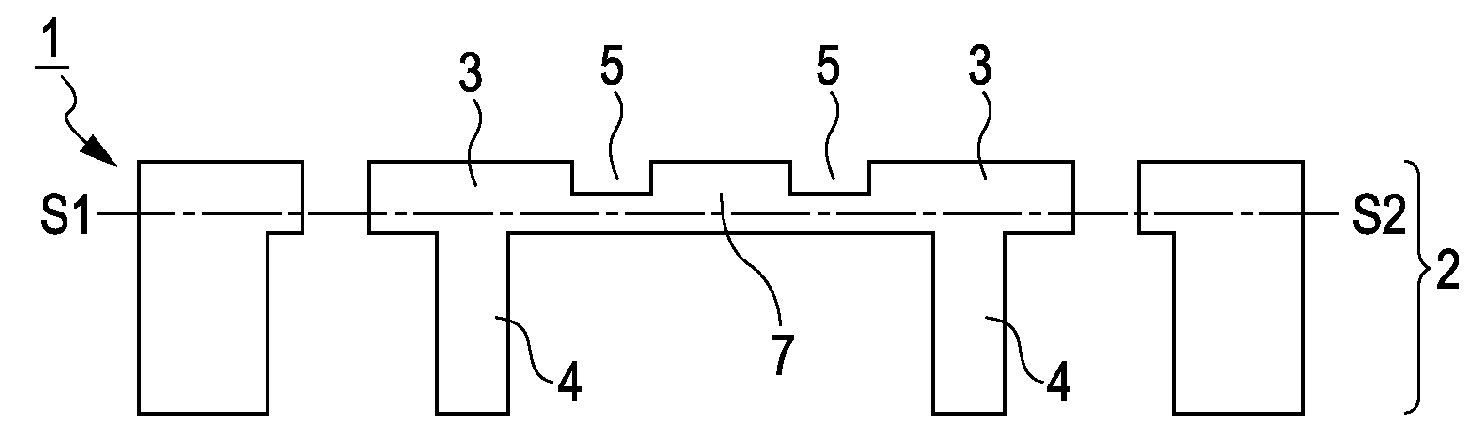

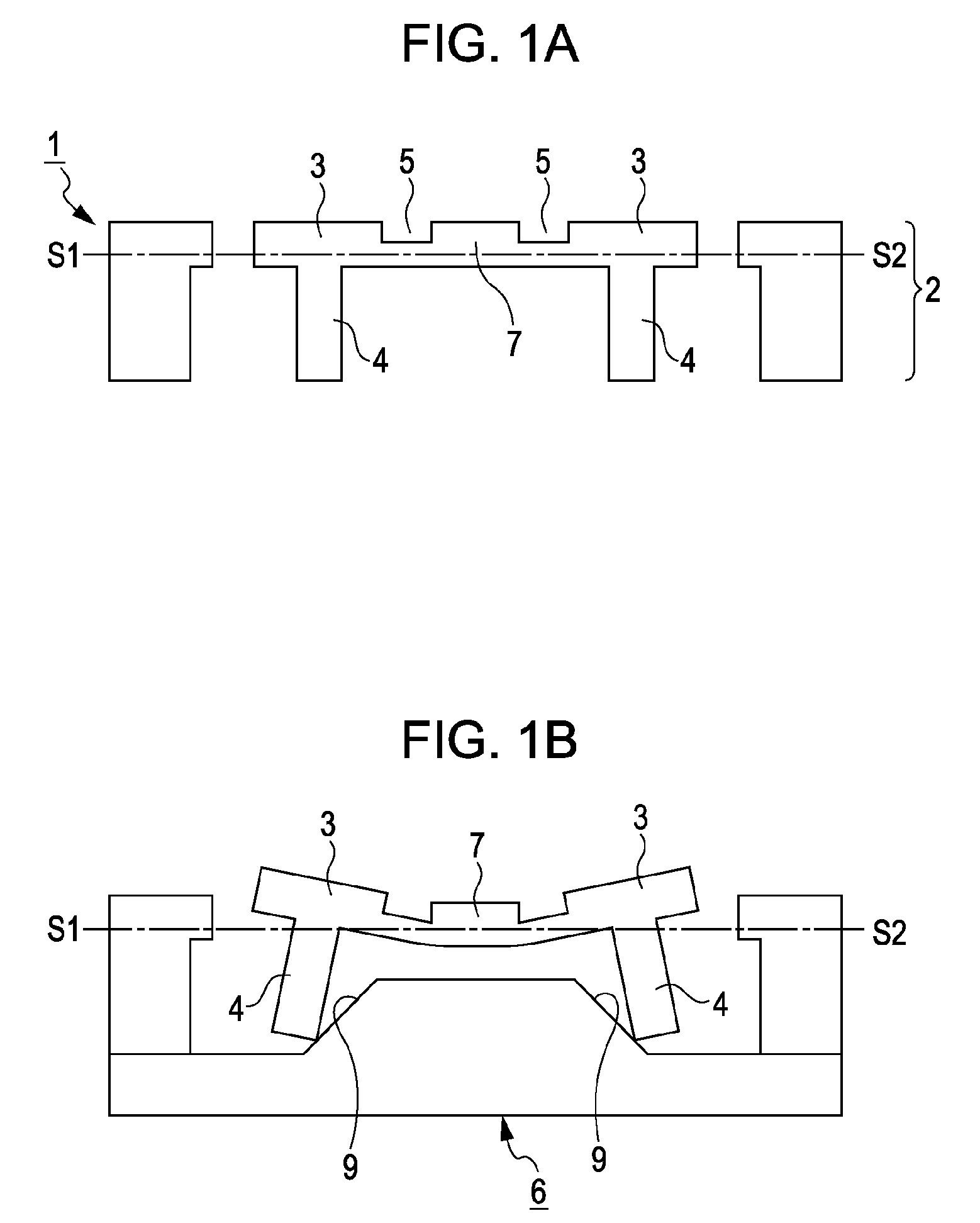

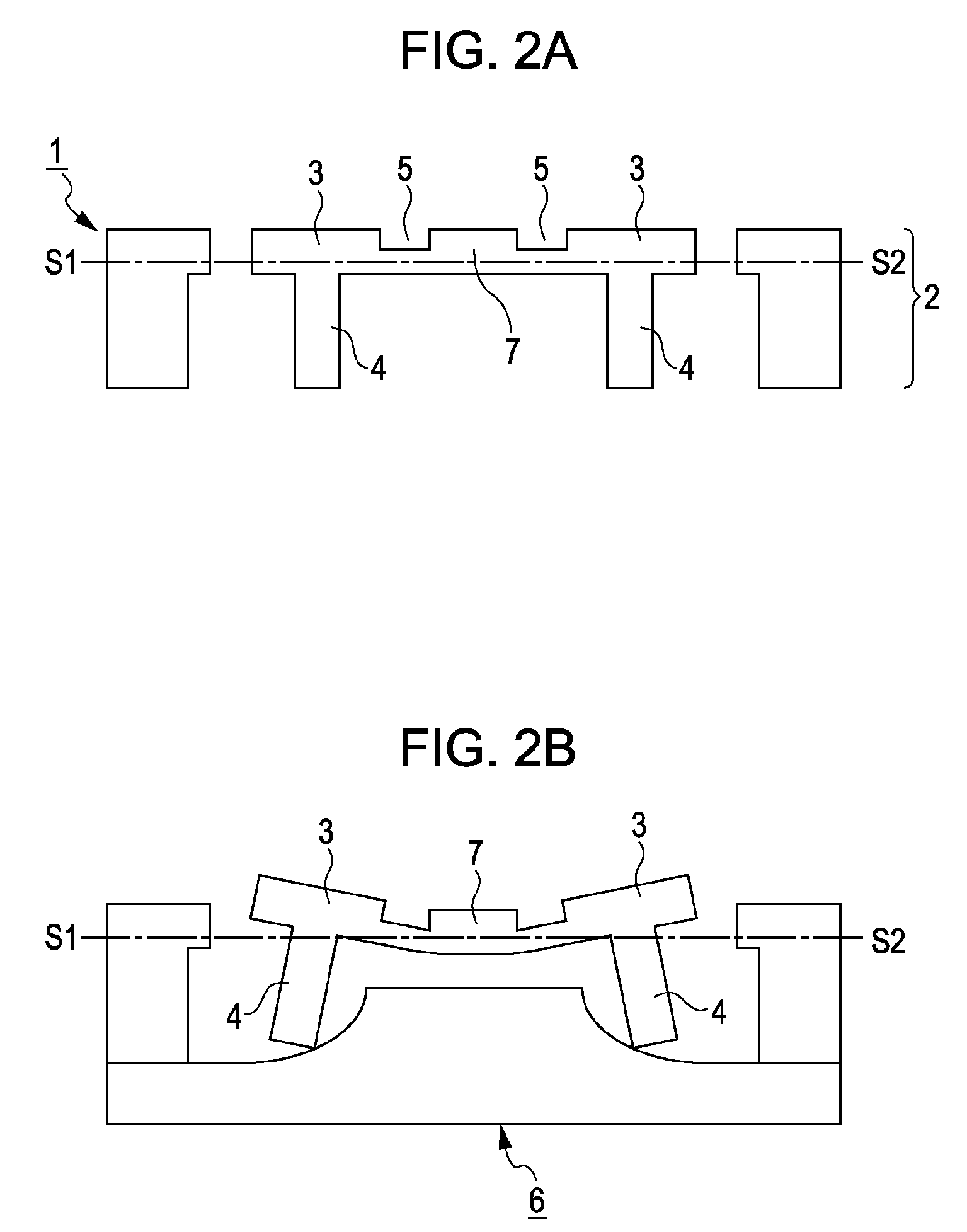

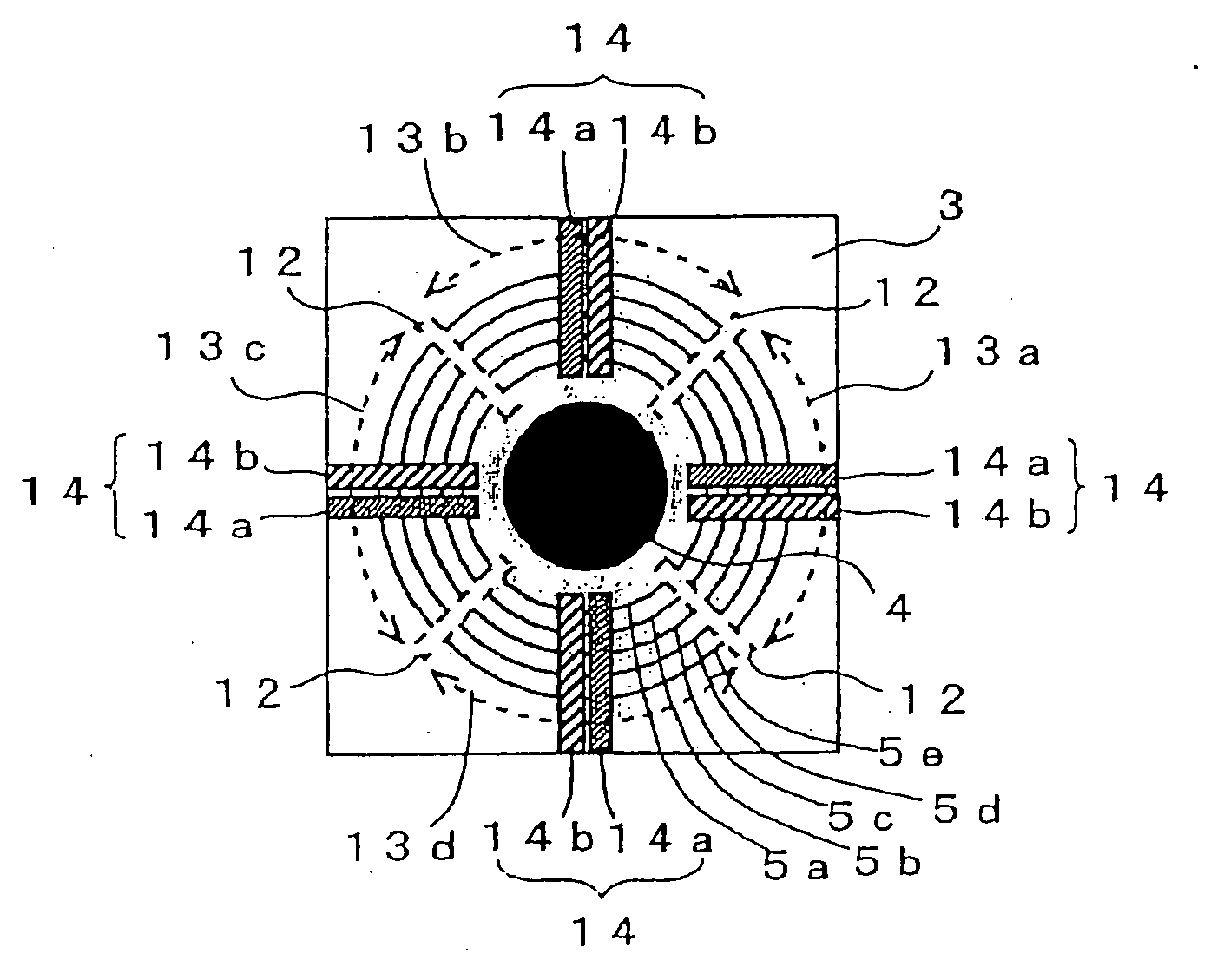

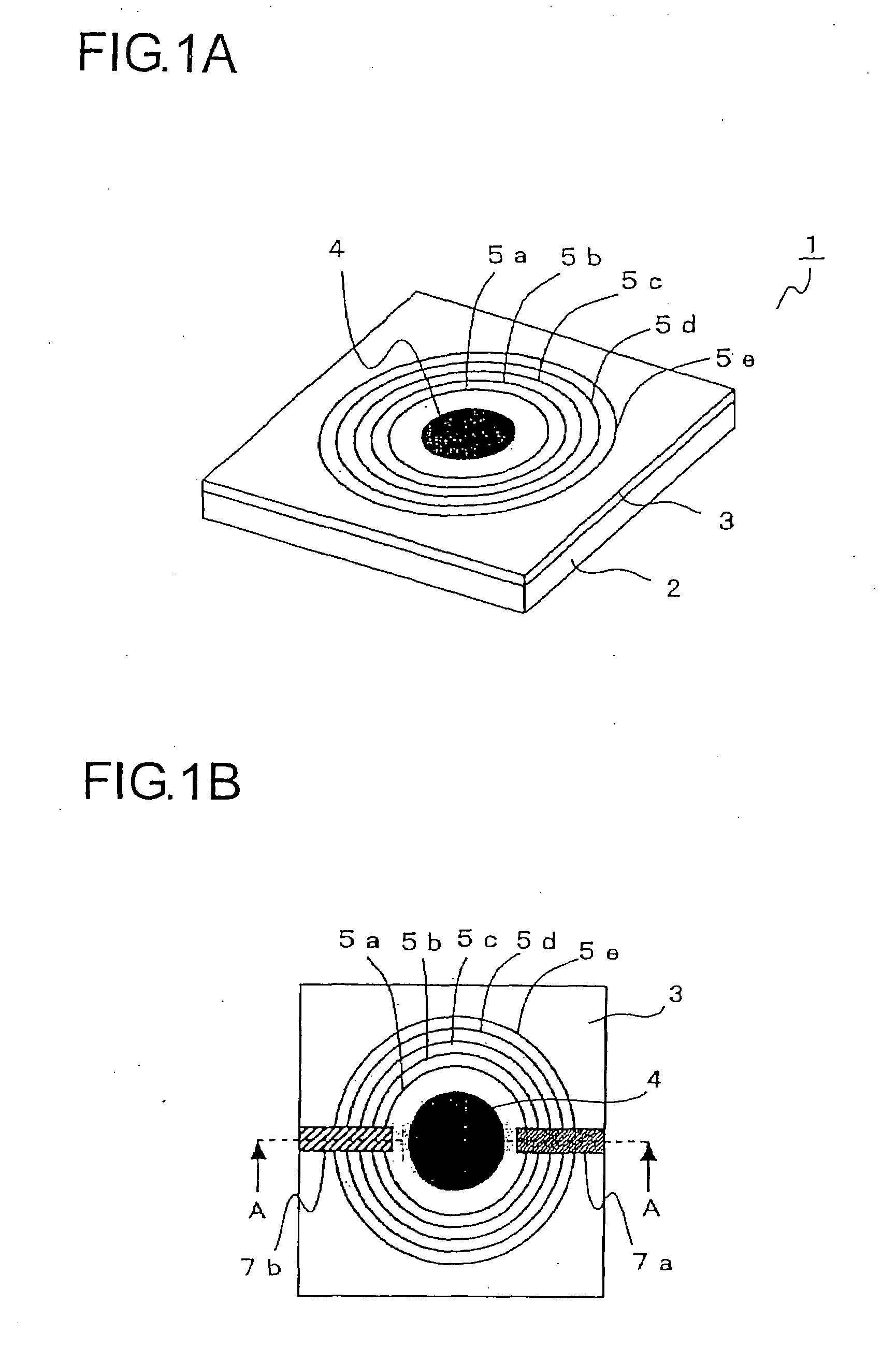

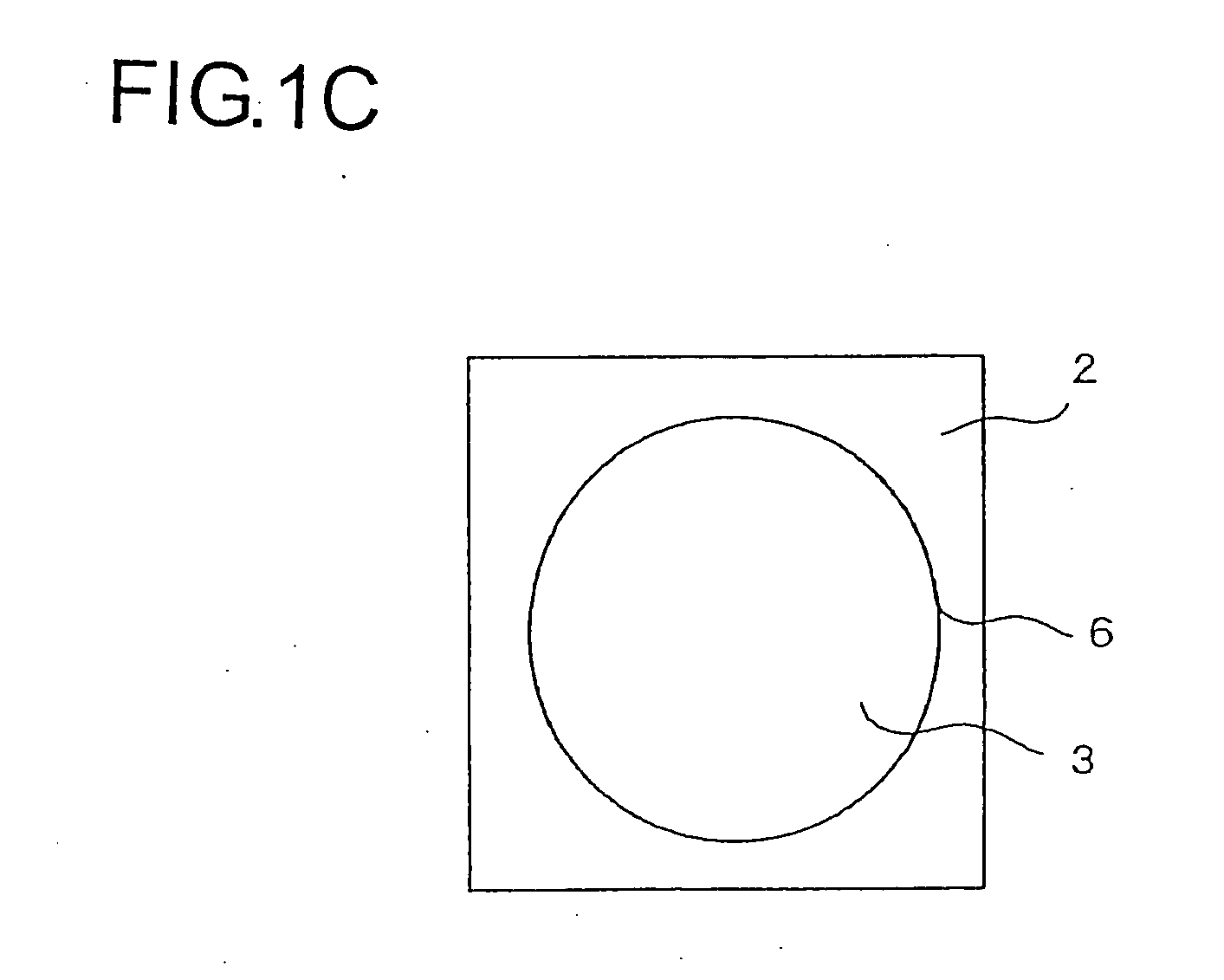

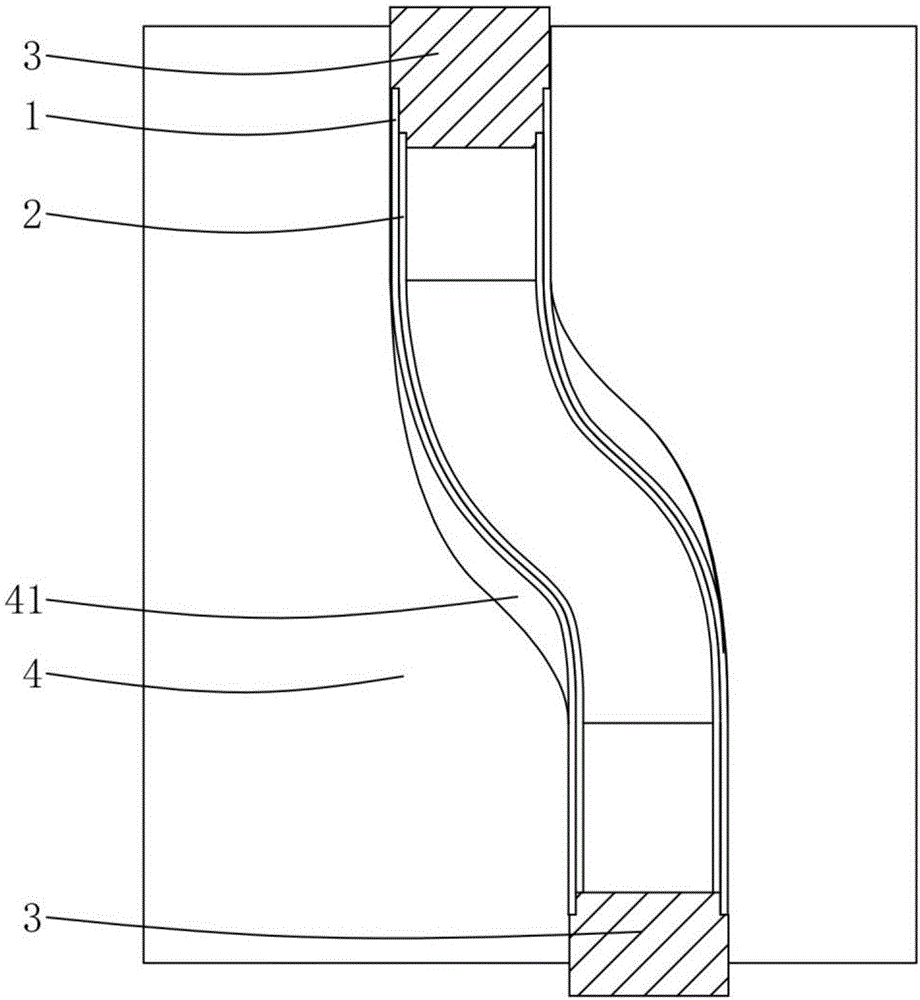

Variable shape mirror and optical pickup device having the same

InactiveUS20070206300A1Low costSurface deformationMirrorsRecord information storageOptical pickupEngineering

The variable shape mirror (1) includes a substrate (2) and a bulk piezoelectric body (3). On the piezoelectric body (3), a specular surface (4) is formed, and further a plurality of grooves (5a-5e) are formed at a predetermined interval. The grooves (5a-5e) are arranged so as to surround the specular surface (4) and filled with the conductive members. The conductive members embedded in the grooves (5a-5e) are connected electrically to one of a pair of common electrodes (7a and 7b) that is disposed to cross the grooves (5a-5e) and are formed to be electrodes having different polarities in alternating manner in the direction from the inner side to the outer side of the grooves (5a-5e).

Owner:FUNAI ELECTRIC CO LTD

Liquid ejecting head, liquid ejecting apparatus and actuator apparatus

InactiveUS20140267478A1Improve distortionImprove reliabilityInking apparatusPiezoelectric/electrostriction/magnetostriction machinesPressure generationEngineering

A liquid ejecting head includes a flow path formation substrate provided with a pressure generation chamber communicated with at least one nozzle opening through which liquid is ejected; and an actuator apparatus including a vibration plate provided at one face side of the flow path formation substrate and a plurality of piezoelectric elements being formed on the vibration plate. The actuator apparatus includes two first piezoelectric elements arranged at positions facing edge portions in at least one direction of the pressure generation chamber and a second piezoelectric element arranged between the two first piezoelectric elements.

Owner:SEIKO EPSON CORP

Lithium-base battery

InactiveCN1343023APrevent burstImprove securityPrimary cell to battery groupingPrimary cell maintainance/servicingLithiumEngineering

A lithium based battery includes a cell structure group formed by stacking unit cells each including a positive electrode, a negative electrode, and a separator interposed therebetween, or formed by repeatedly folding or winding an integral body of the unit cells; a battery container for containing the cell structure group; and an electrolyte, which is poured in the battery container after the cell structure group is contained in the battery container. The outer peripheral surface of the battery container is covered with an ion impermeable and extensible high polymer sheet having a tensile elongation percentage of 1% or more. With this configuration, even if there happens such a severe accident that nail pieces the battery or the battery is crashed, it is possible to prevent a large short-circuit current from flowing between the positive and negative electrodes, and hence to ensure a higher safety of the battery.

Owner:ITOCHU CO LTD

High rigid tilt device in a steering column for a vehicle

InactiveUS7252019B2Stable supportReliably locking samePipe supportsCandle holdersSteering wheelDriver/operator

A tilt device is provided to allow a steering column to be tilted so that a driver can adjust the position of a steering wheel to conform to his / her figure in order to more comfortably drive a vehicle. Further, the tilt device is configured to impart a high supporting strength to the steering column while reliably locking the same.

Owner:HYUNDAI MOBIS CO LTD

Machining process for double-layer composite metallic tube

The invention discloses a machining process for a double-layer composite metallic tube. The process sequentially comprises the following steps that an outer metallic tube body and an inner metallic tube body are placed into an inner tube model cavity; high-pressure water is led into the inner metallic tube body so as to finish inner high-pressure forming of the inner metallic tube body, and a primary semi-finished double-layer composite metallic tube is prepared; the primary semi-finished double-layer composite metallic tube is placed into an outer tube model cavity; high-pressure water is led into the outer metallic tube body so as to finish inner high-pressure forming of the outer metallic tube body, and a secondary semi-finished double-layer composite metallic tube is prepared; and end post-treatment is conducted on the secondary semi-finished double-layer composite metallic tube, so that the finished double-layer composite metallic tube is prepared. Two passes of inner high-pressure forming are adopted, the forming effects of the inner metallic tube body and the outer metallic tube body are guaranteed, the machining procedures are optimized, and the machining process is more concise, so that the machining efficiency is improved, the profit rate is increased, and the product rejection rate is decreased.

Owner:山东辛丁管理咨询有限公司

Uniform-speed cooling medium and application thereof in cooling control process after forging

ActiveCN103789520AImprove uniformityEffective deformationQuenching agentsDeformation controlMechanical property

The invention relates to a method for controlling cooling after a forging steel part is forged, and belongs to the field of steel forging and heat treatment. The method is characterized in that a forged workpiece is immerged into a uniform-speed cooling medium for cooling; a cooling process takes the fact that a non-equilibrium state structure is not generated on a surface as a principle and can adopt a cooling mode of cooling to proper temperature and then equalizing the temperature or other cooling modes according to the size of a material and a workpiece. The method for controlling cooling after forging, which is disclosed by the invention, can solve the problems of rough and large structure, hereditary structures, such as a banded structure, and structure nonuniformity of the traditional forging stock, ensure the rigidity uniformity of the forging stock, impulse the popularization of a dry cutting technology, improve the mechanical properties, namely anisotropy, impact ductility and the like of a product which is subjected to heat treatment, improve the uniformity of a structure which is not subjected to the heat treatment and effectively cooperate with the heat treatment deformation control.

Owner:NANJING KERUN LUBRICANTS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com