Patents

Literature

85 results about "Face space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Face space is a theoretical idea in psychology such that it is a multidimensional space in which recognizable faces are stored. The representation of faces within this space are according to invariant features of the face itself. However, recently was theoretically demonstrated that faces can be stored in the face space according to their dynamic features as well, and that in this case the resulting space exhibits a twofold structure.

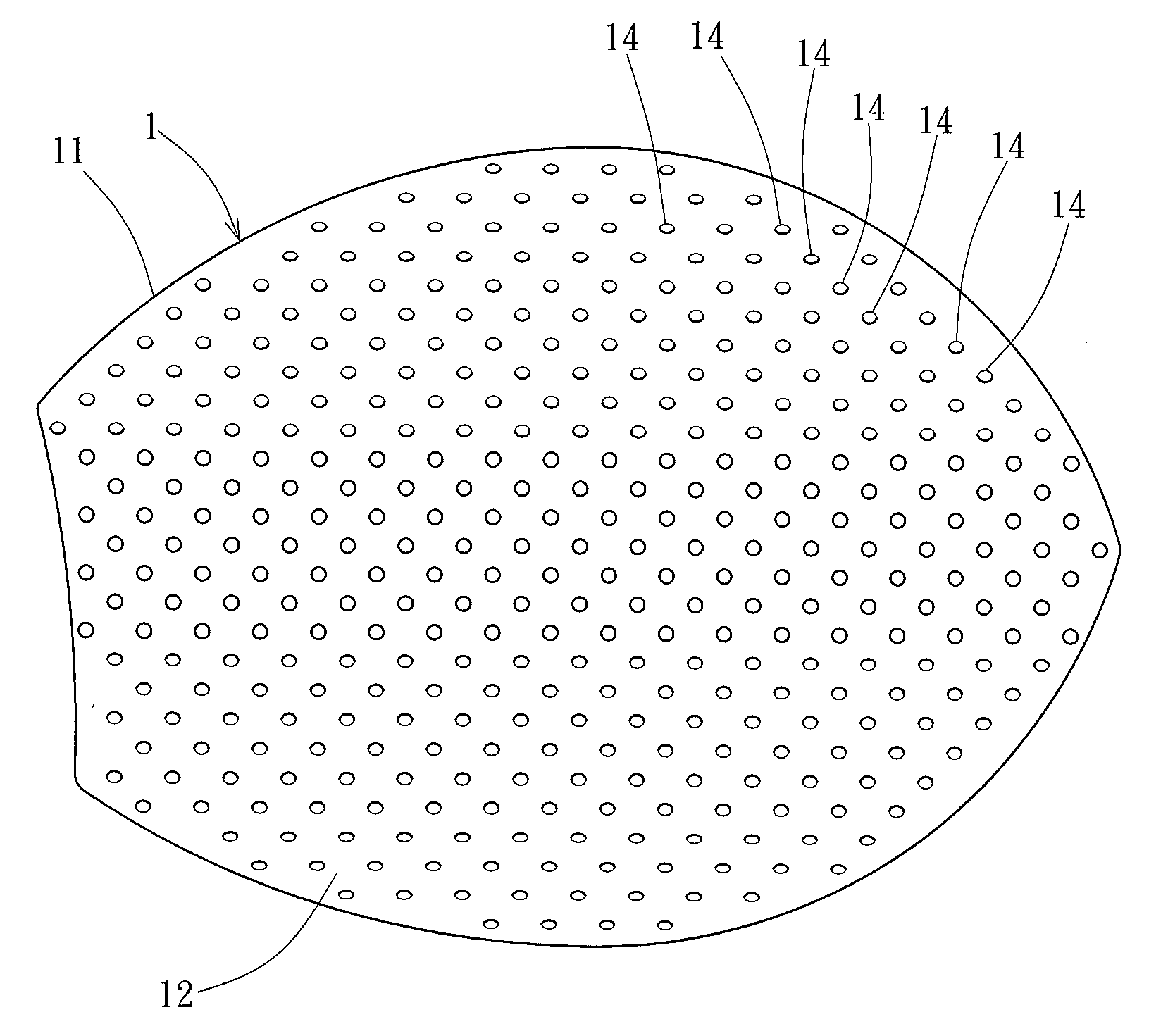

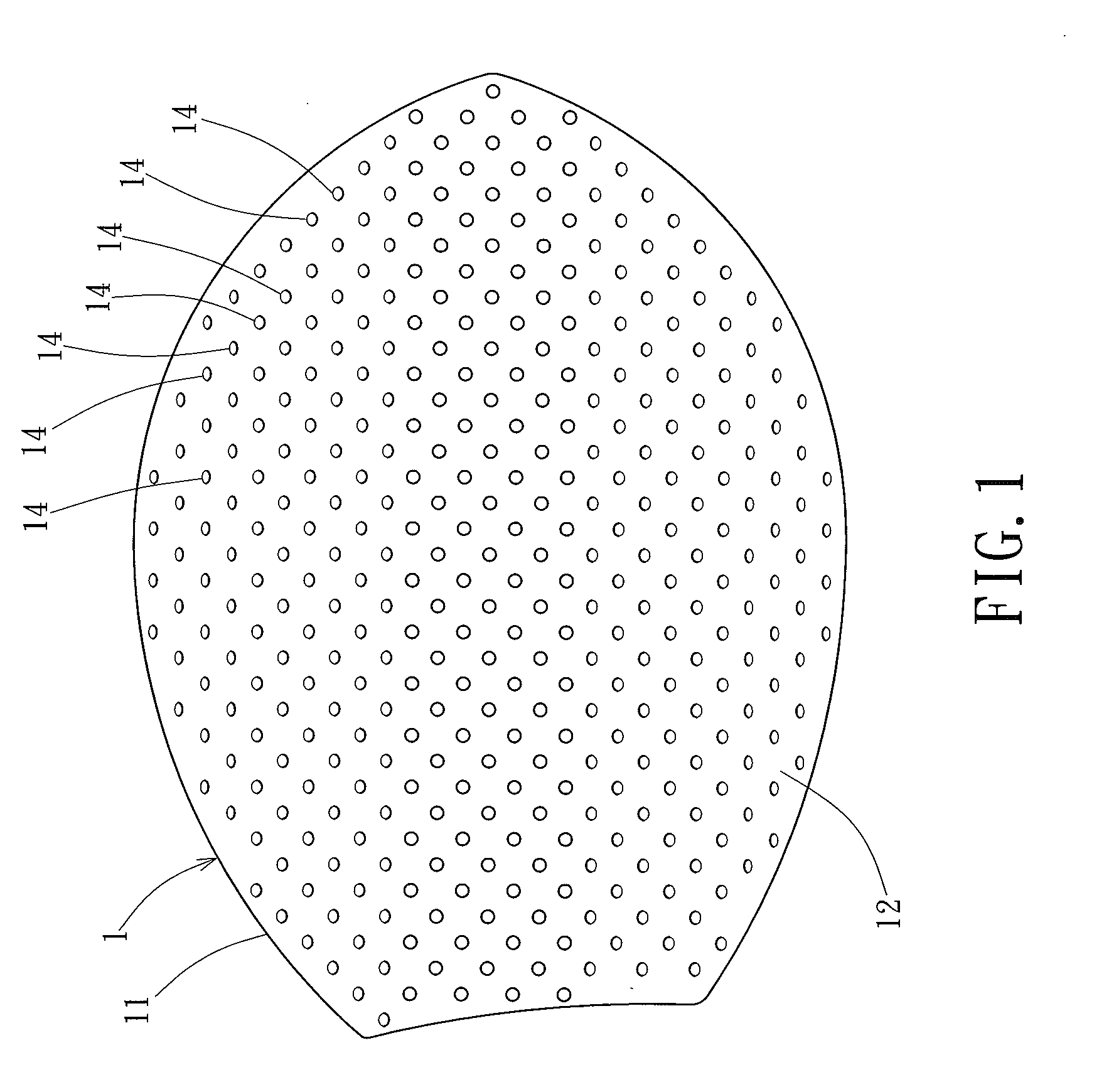

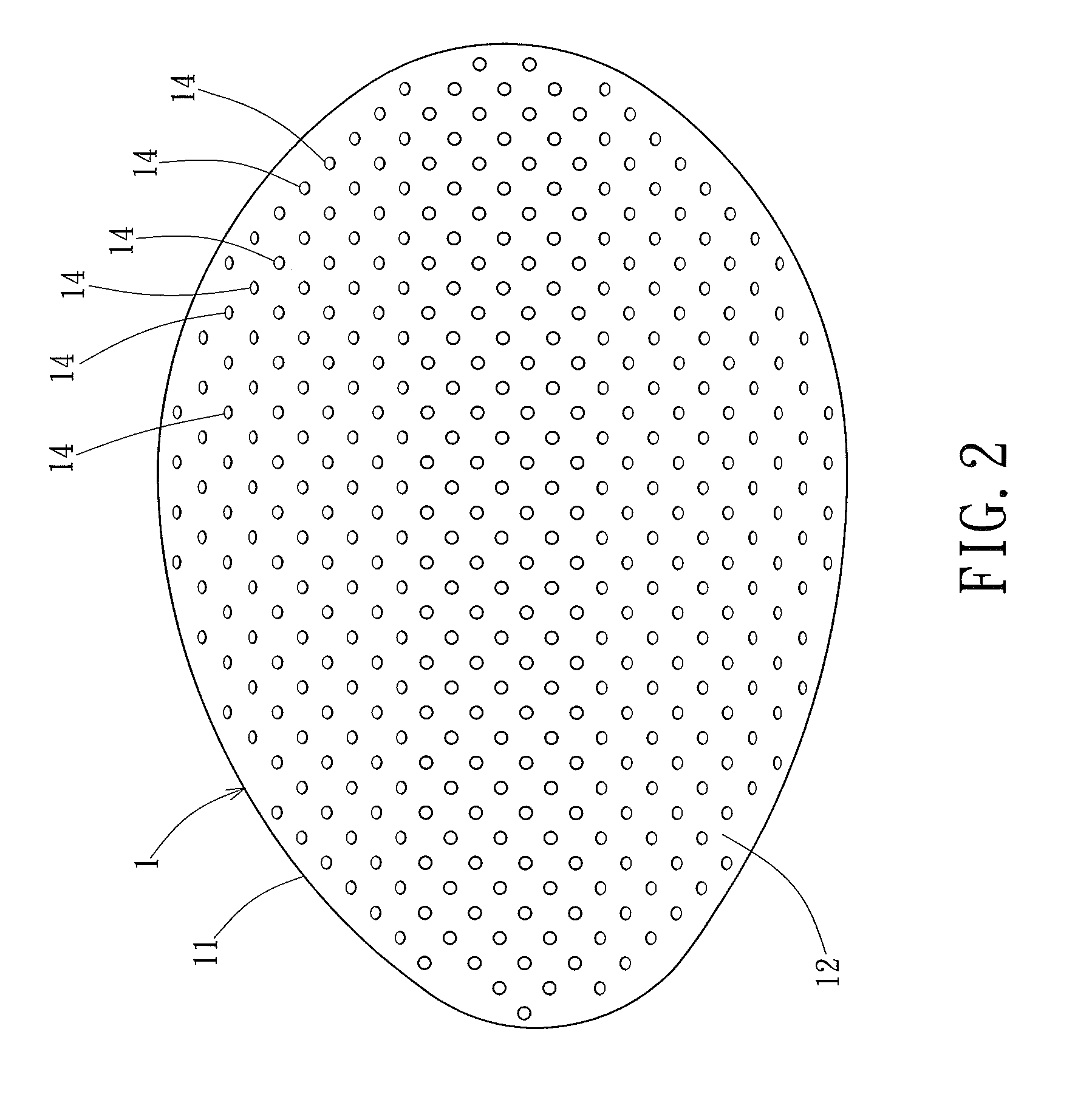

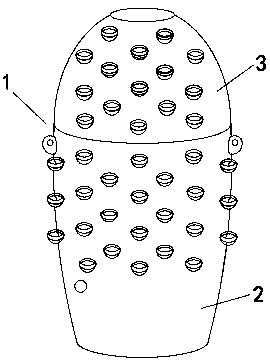

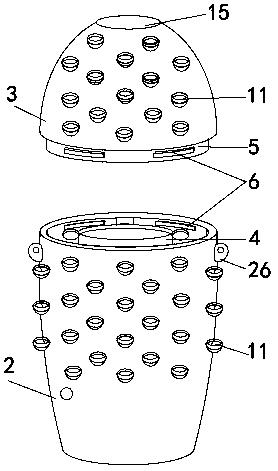

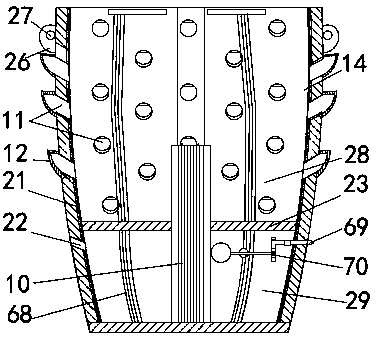

Elastic, Air-Permeable Breast Enhancer

An elastic, air-permeable breast enhancer includes an elastic body having a front, convex face and a rear, concave face spaced from the front, convex face along an axis. The body includes a plurality of air channels each extending from the front, convex face through the rear, concave face along the axis and each having a front opening in the front, convex face and a rear opening in the rear, concave face. Each of at least a portion of the air channels includes at least one enlarged section intermediate the front and rear openings and having a diameter in a radial direction perpendicular to the axis larger than a remaining section of the air channel.

Owner:CHIEN TZU HSUAN

Heavy metal pierce nut

Owner:PENN AUTOMOTIVE INC

Method for manufacturing metal composite plate

ActiveCN103658175ALow costEasy to operateMetal rolling arrangementsManufacturing technologyComposite plate

The invention discloses a method for manufacturing a metal composite plate, and belongs to the technical field of metal composite plate manufacturing technology. The method comprises the following steps that firstly, the rusty layer and the oxide layer of multiple layer metal and parent metal are removed, the corners at the two ends and the middle of the metal layer placed on the upper face in the process of heating are respectively drilled, and each position of the corners at the two ends and the middle of the metal layer is provided with a vent hole with the diameter ranging from 4mm to 8mm; secondly, the multiple layer metal and the parent metal are stacked, and the periphery of the contact face is welded and sealed; thirdly, the air inside the contact face space is completely exhausted by injecting argon through the vent hole in one end, and the vent holes in the two ends are sealed; fourthly, the metal composite plate is placed inside a heating furnace to be heated according to the production requirements for the composite layer metal; fifthly, the metal composite plate is rolled on a rolling mill; sixthly, if the multiple layer metal needs to be later processed in a heat mode, the composite plate is processed in the heat mode according to the demands. By means of the method, the oxidation of the contact face of the metal composite plate can be reduced, the shearing strength of the contact face of the metal composite plate is improved, vacuumizing is not needed, operation is easy, and cost is low.

Owner:HEBEI IRON AND STEEL

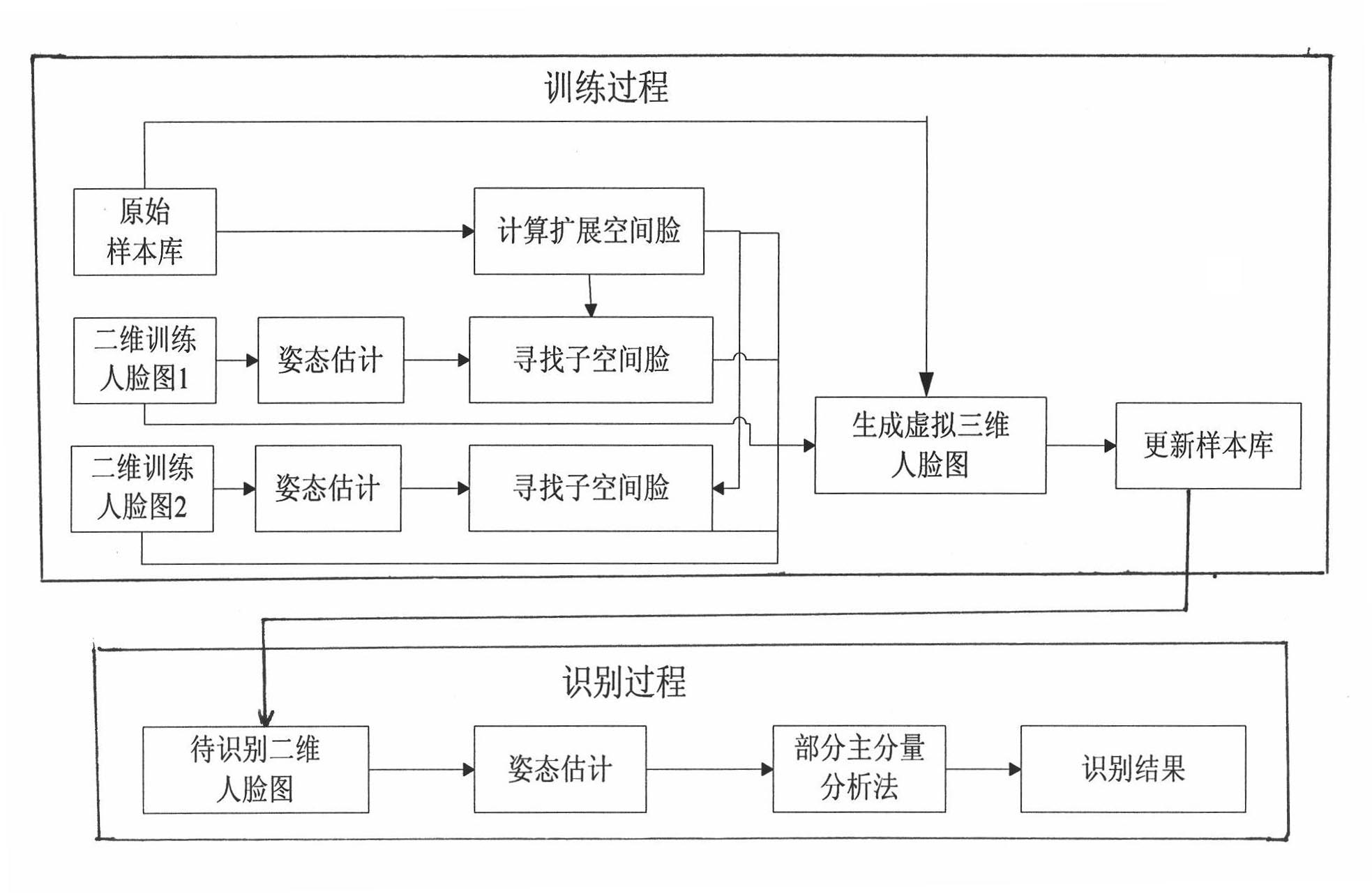

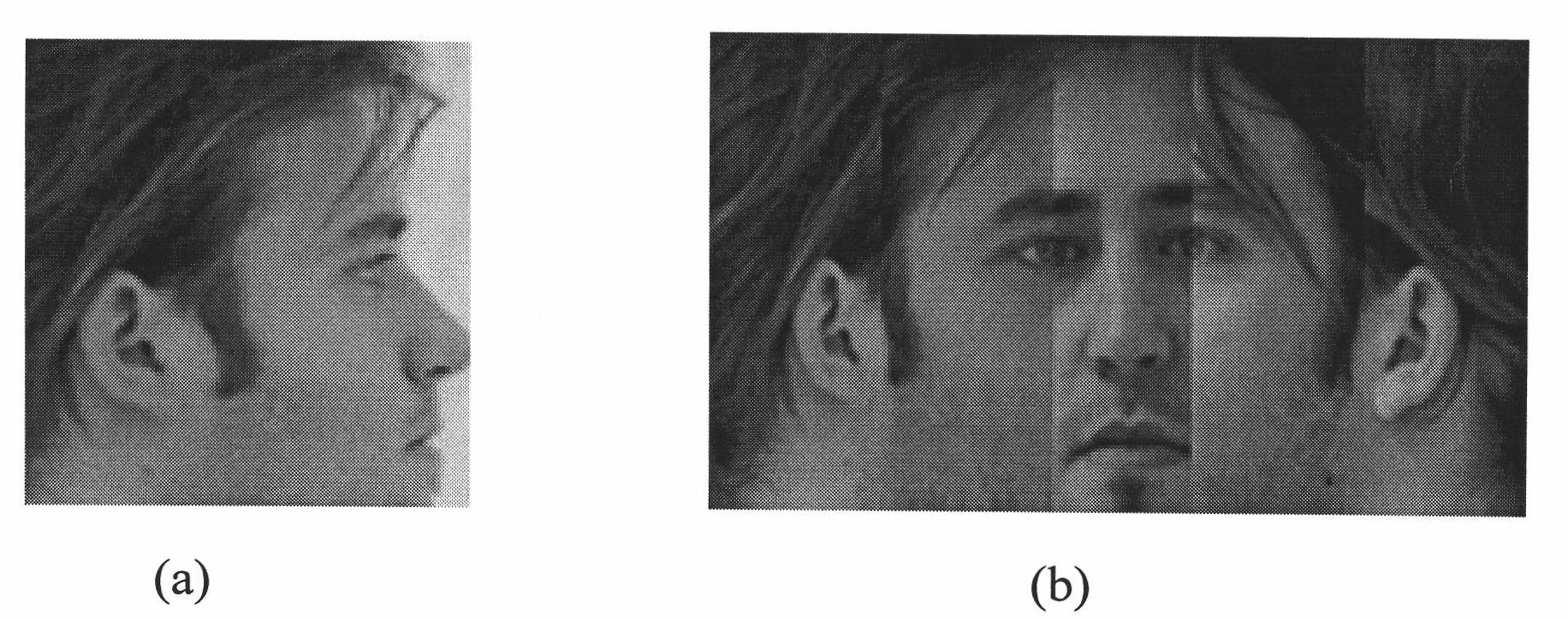

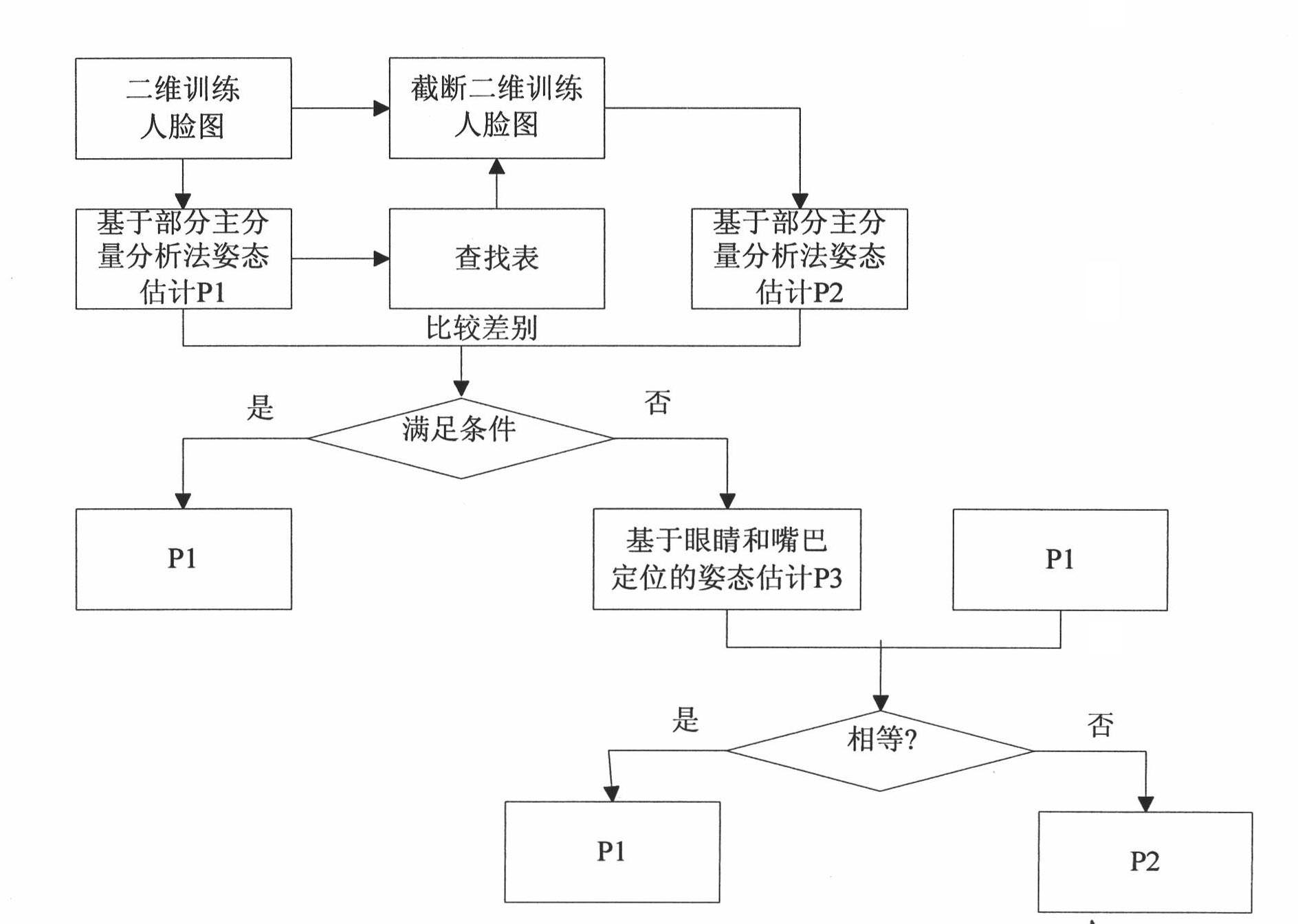

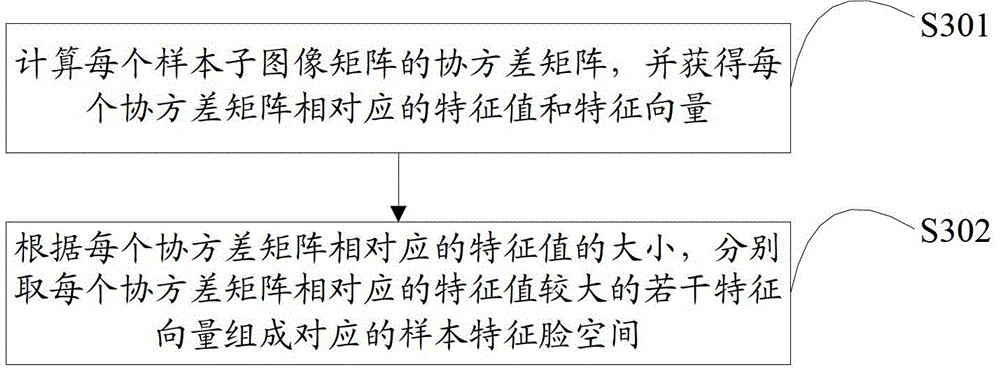

Face recognition method based on combination of partial principal component analysis (PCA) and attitude estimation

InactiveCN102043966AWithout loss of accuracyImprove accuracyCharacter and pattern recognitionKernel principal component analysisPrincipal component analysis

The invention discloses a face recognition method based on the combination of partial principal component analysis (PCA) and attitude estimation, comprising the following steps of: (1) previously storing a virtual three-dimensional face image in an original sample library, using a PCA method to compute a face-expanding space in the original sample library, and using a partial PCA method to combine with an eyes-mouth automatic positioning algorithm to perform attitude estimation to two two-dimensional training face images in different attitudes; (2) searching corresponding sub-face space in the face-expanding space according to the attitude estimation result; (3) generating a new virtual three-dimensional face image according to two two-dimensional training face images in different attitudes, the face-expanding space and the sub-face space; (4) using the new three-dimensional face image to update the original sample library; (5) using the partial PCA method to combine with the eyes-mouth automatic positioning algorithm to perform the attitude estimation to the to-be-recognized two-dimensional face image; (6) using the partial PCA method to recognize the to-be-recognized two-dimensional face image.

Owner:ZHEJIANG UNIV

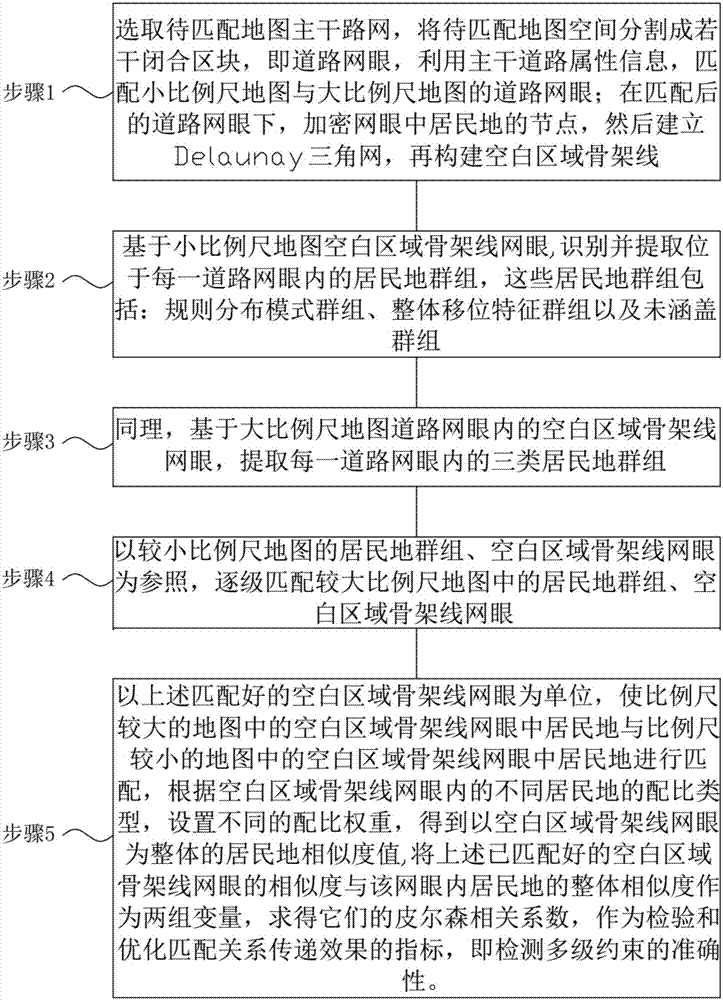

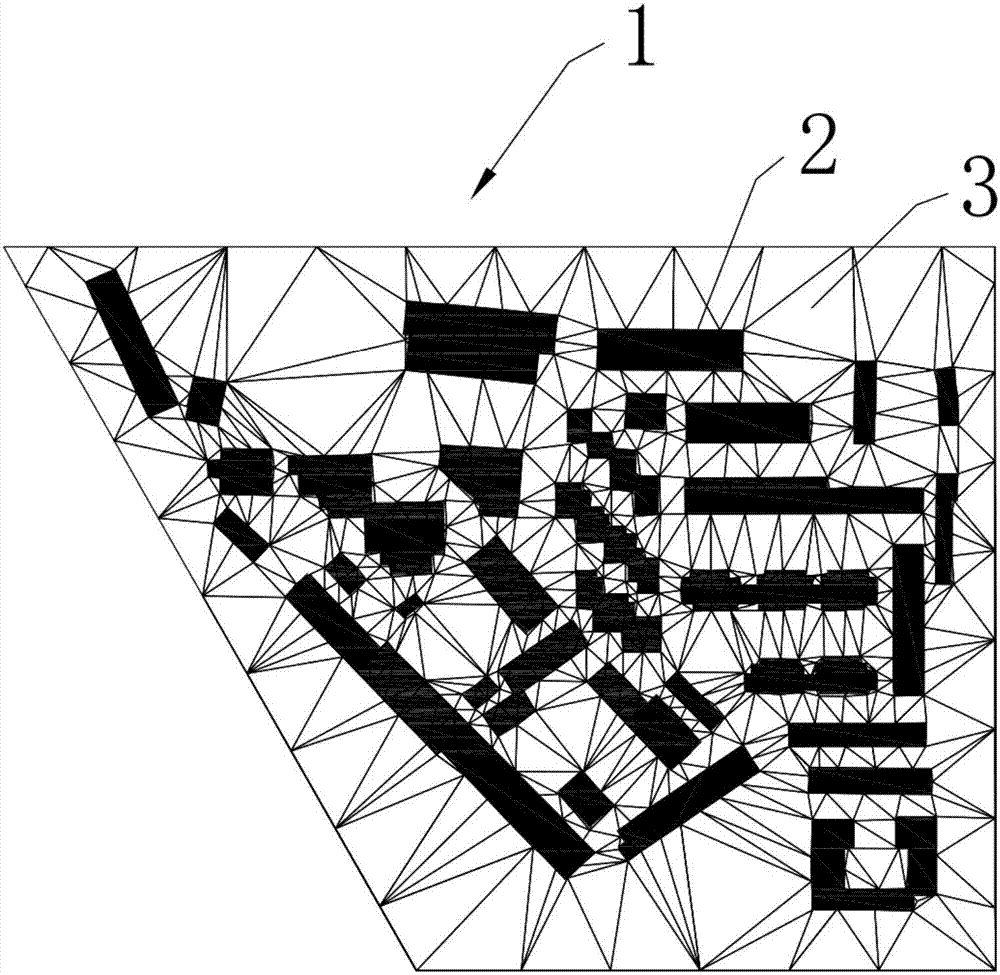

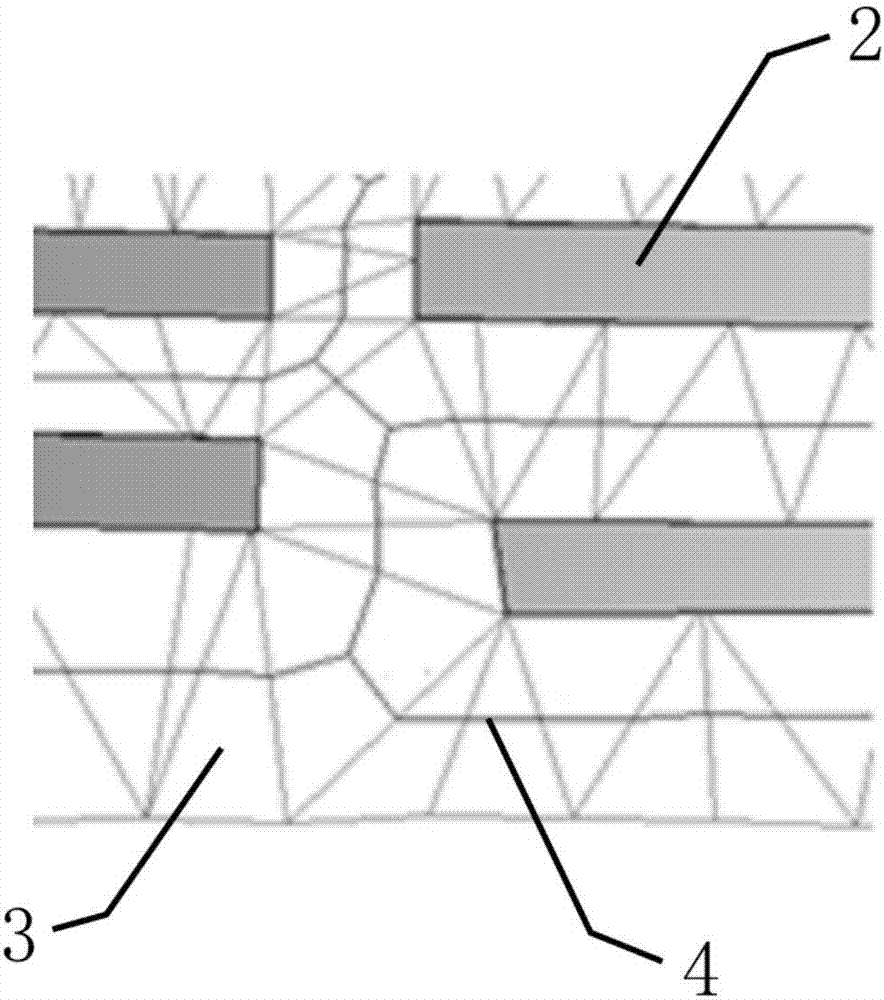

Multiple dimensioned residential area matching method facing space division

ActiveCN107292919AGet rid of blindnessNarrow down the candidate matchesImage analysisRoad networksTrunk road

The invention provides a multiple dimensioned residential area matching method facing space division; the method comprises the following steps: selecting a to-be matched map trunk road network, segmenting the to-be matched map space into a plurality of road network meshes, and matching the road network meshes between different scales; building blank area frame lines under the matched road network meshes, and dividing the road network meshes into groups and blank area frame line network meshes; dividing space of each road network mesh of the small scale map according to same steps; building blank area frame line network meshes of the large scale map, and extracting residential area groups in each road network mesh; matching the residential area groups, blank area frame line meshes and residential area entities in different scale maps grade by grade, thus finally obtaining the mapping system using the blank area frame line network meshes as units between different scale maps; the multi-grade space division and progressive matching method can enhance the entity matching accuracy and credibility between residential areas of different scales.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

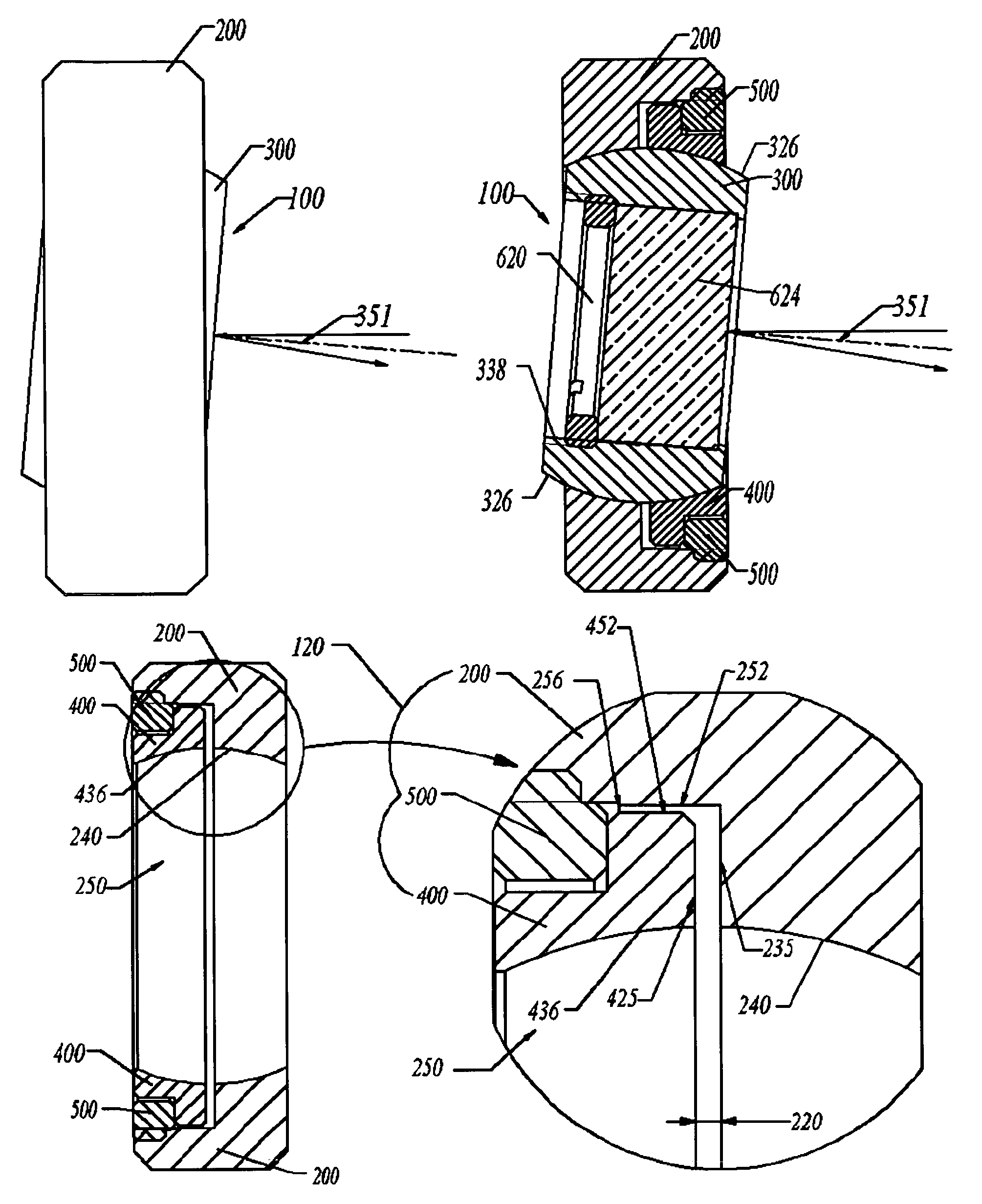

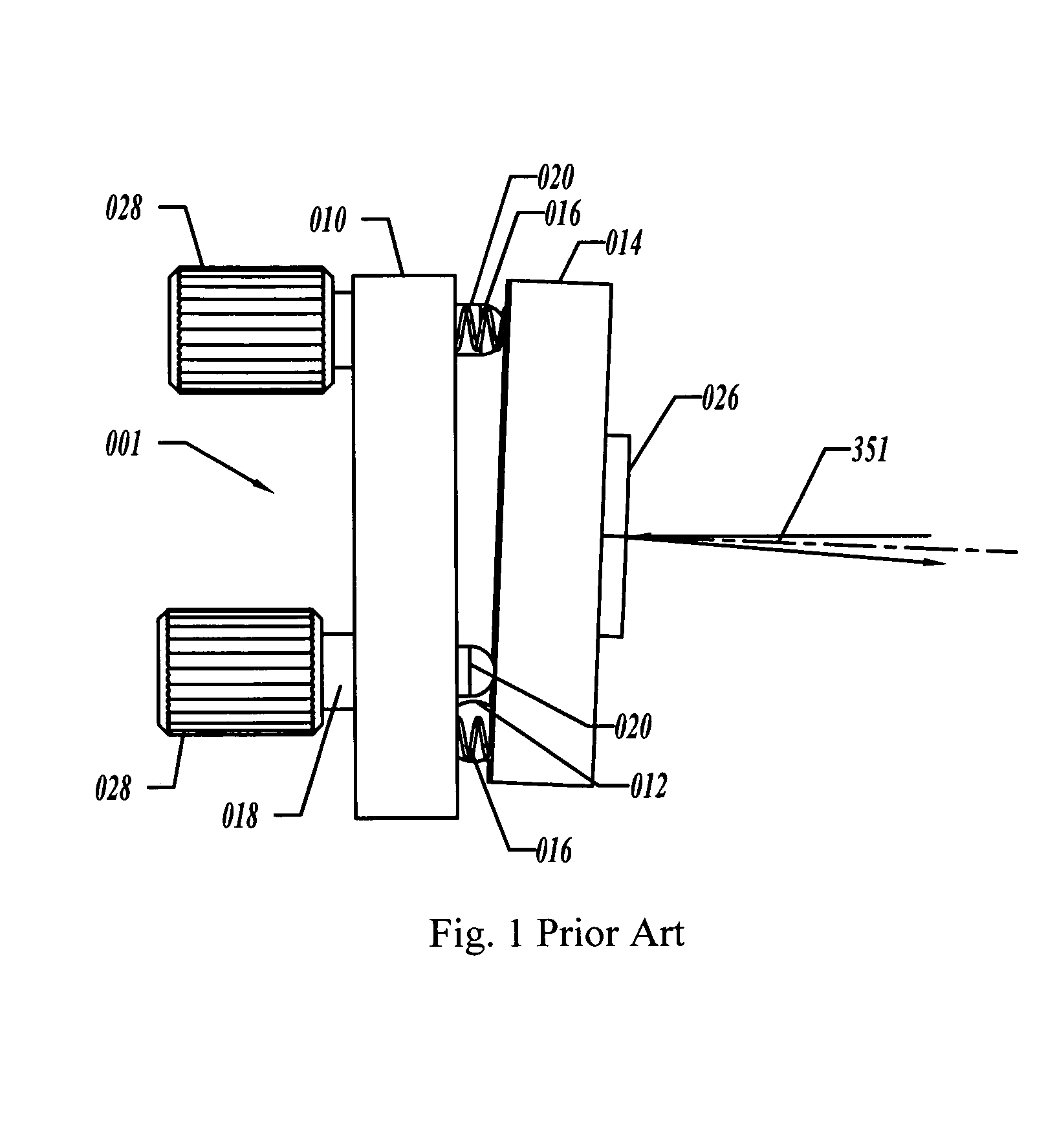

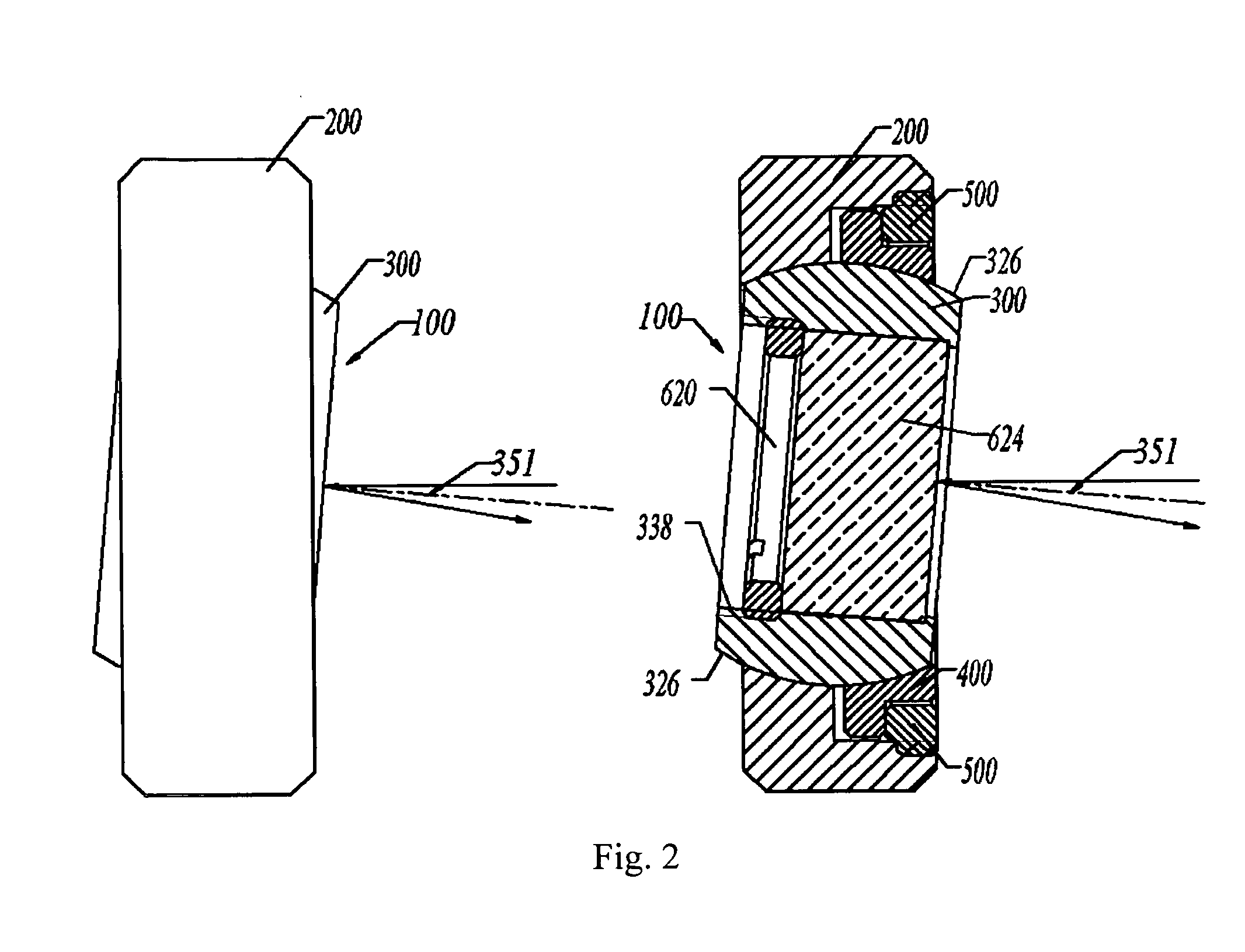

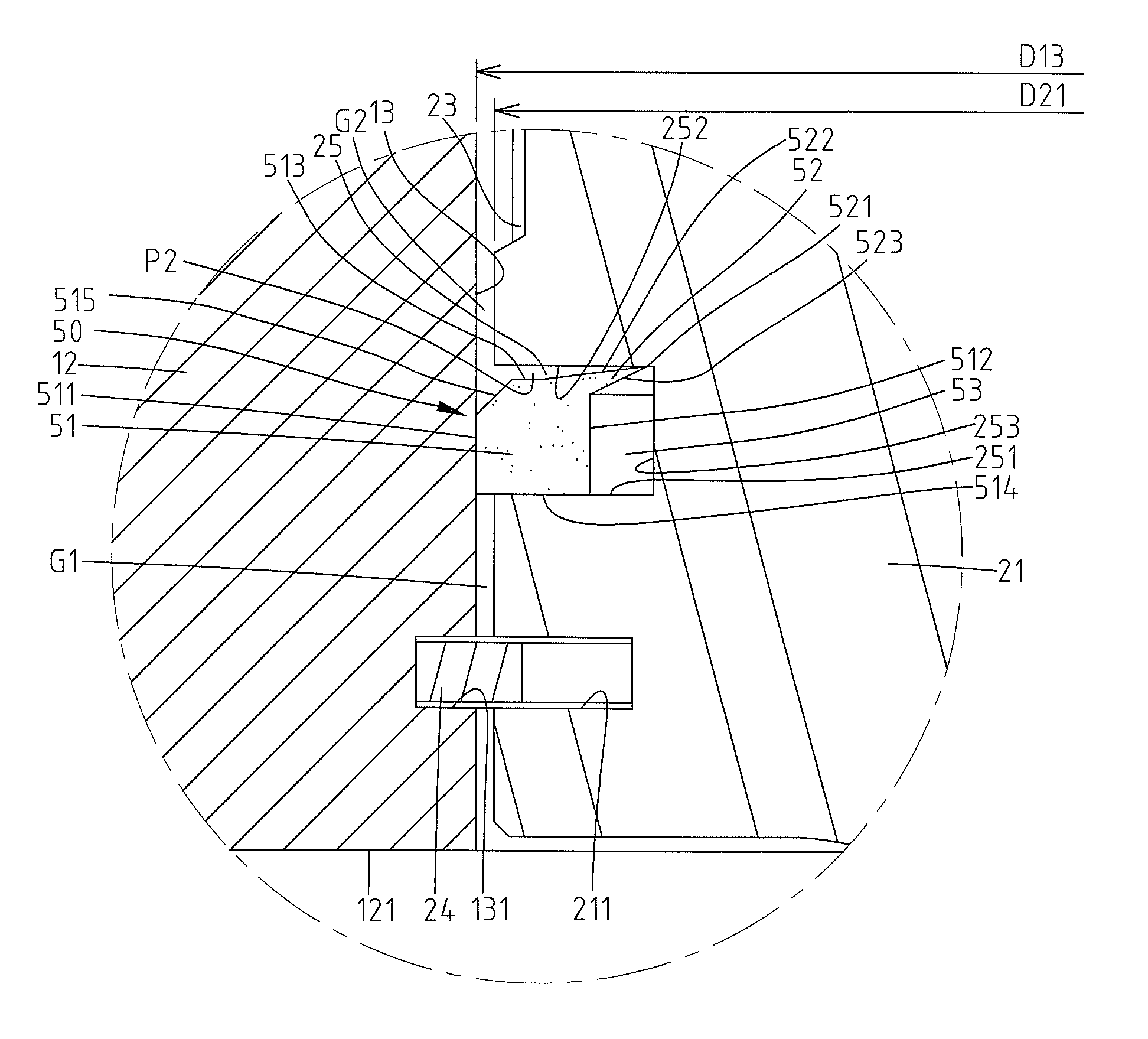

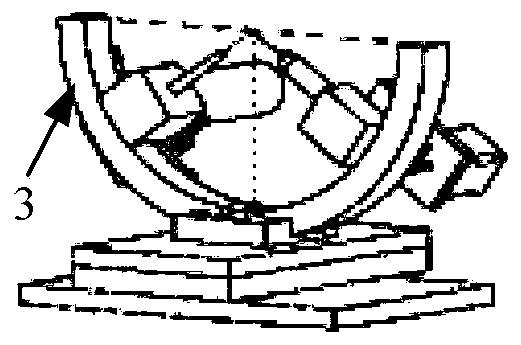

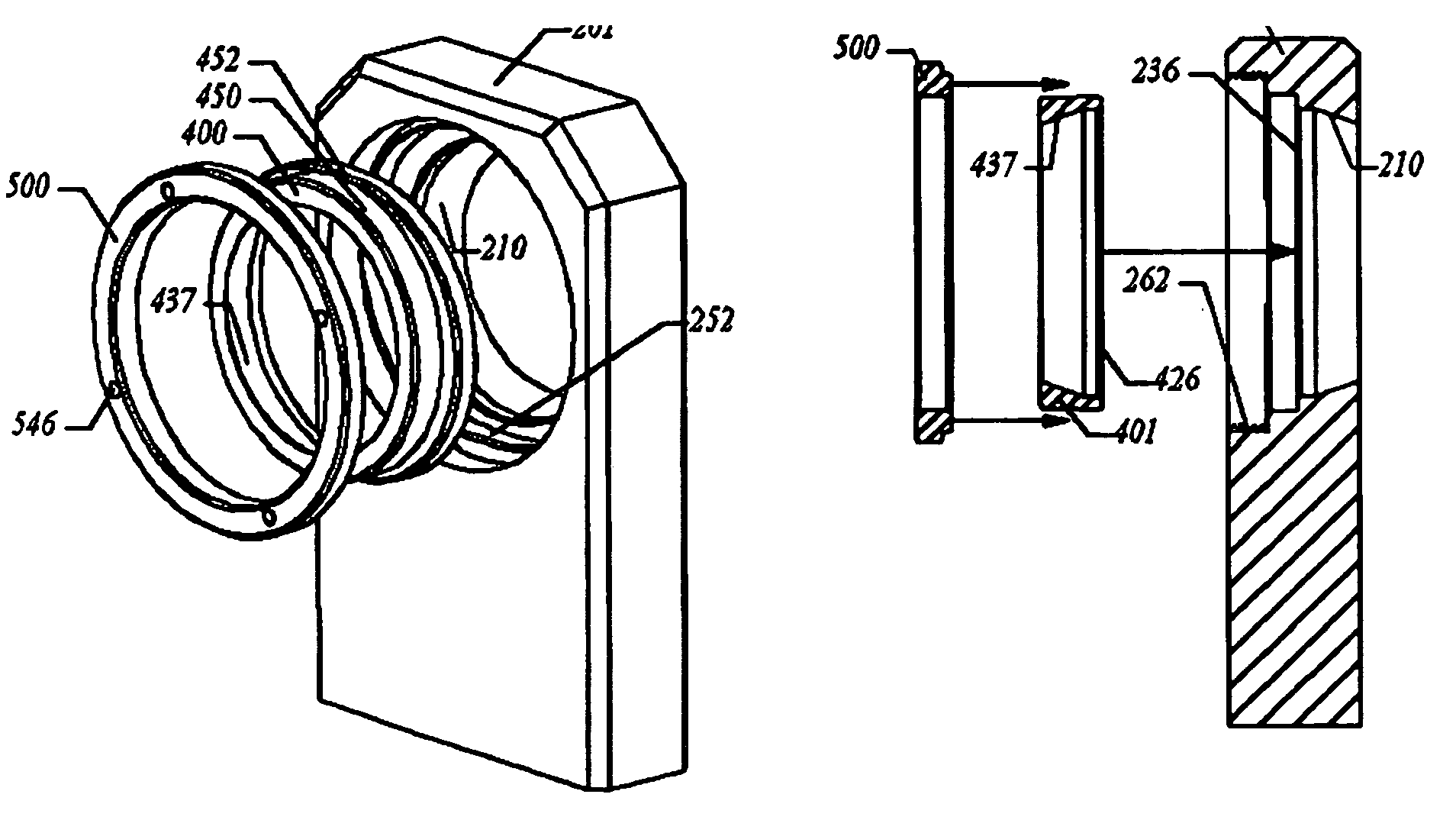

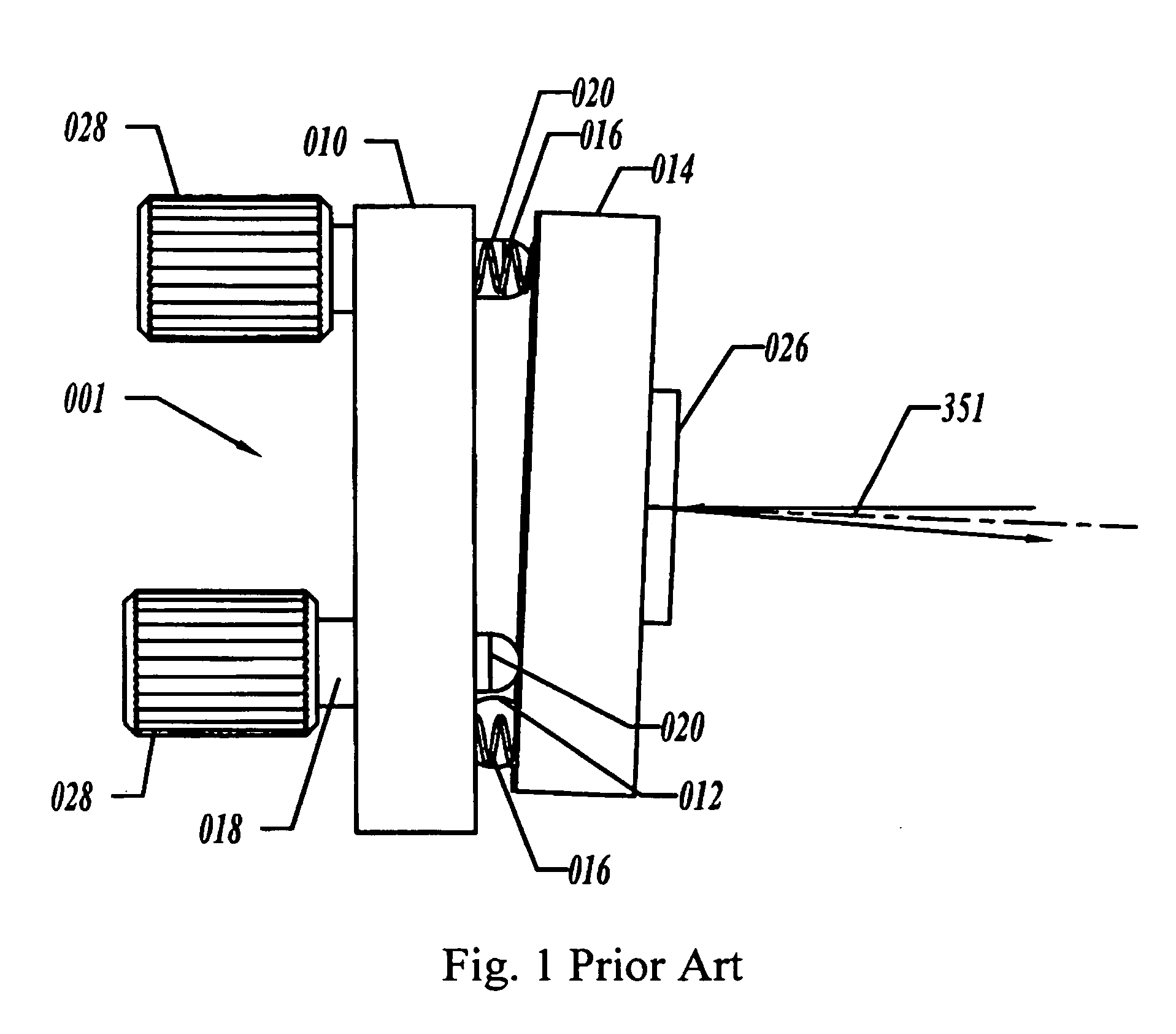

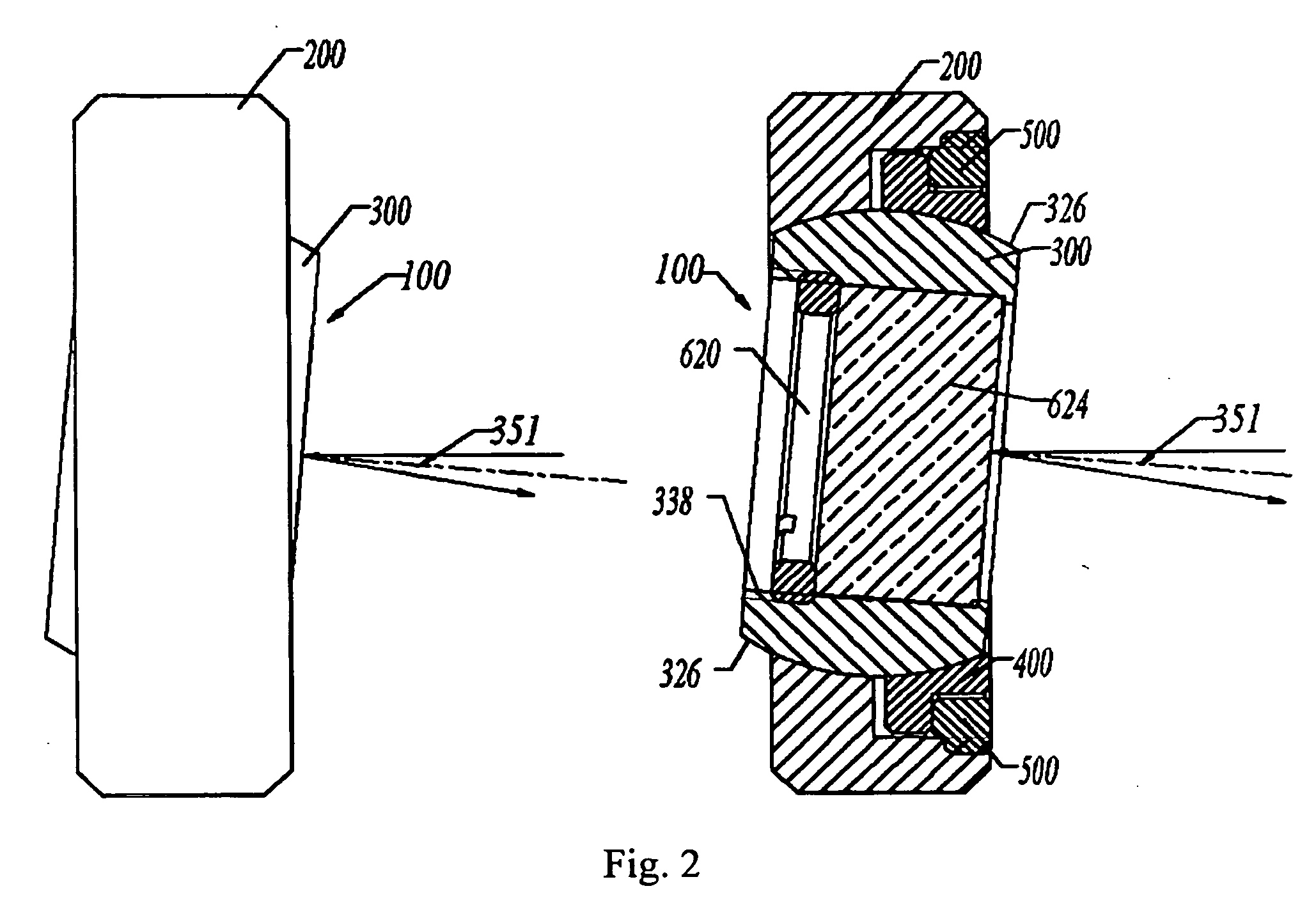

Adjustable/non-adjustable precision optical mounts

InactiveUS7679845B2Easy maintenanceSimple structureBeam/ray focussing/reflecting arrangementsProjector focusing arrangementOptical mountEngineering

A highly precision, super stable, structure compact and fully lockable ball joint mechanism optical mounts are presented. Both stationary plate and movable plate have a partial-spherical hole or conical hole. Facing spacing aligns the bases of the partial-spherical holes or conical holes; a space adjustable cavity is formed. An external-spherical circumference shape optical element carrier plate fits and mates in the space adjustable combined cavity forms a ball joint mechanism, or an external-column circumference and edges chamfered optical element carrier plate fits and mates in the space adjustable combined internal-spherical shaped cavity forms an angle tilt-able and around axis swivel-able joint pair mechanism. A removable tooling for exporting a tilting and rotating movement to the optical element carrier plate are presented. Locking ring pushes the movable plate to adjust the combined cavity and locking the optical element carrier plate and to lock optical element that is carried thereby.

Owner:NEWPORT CORP

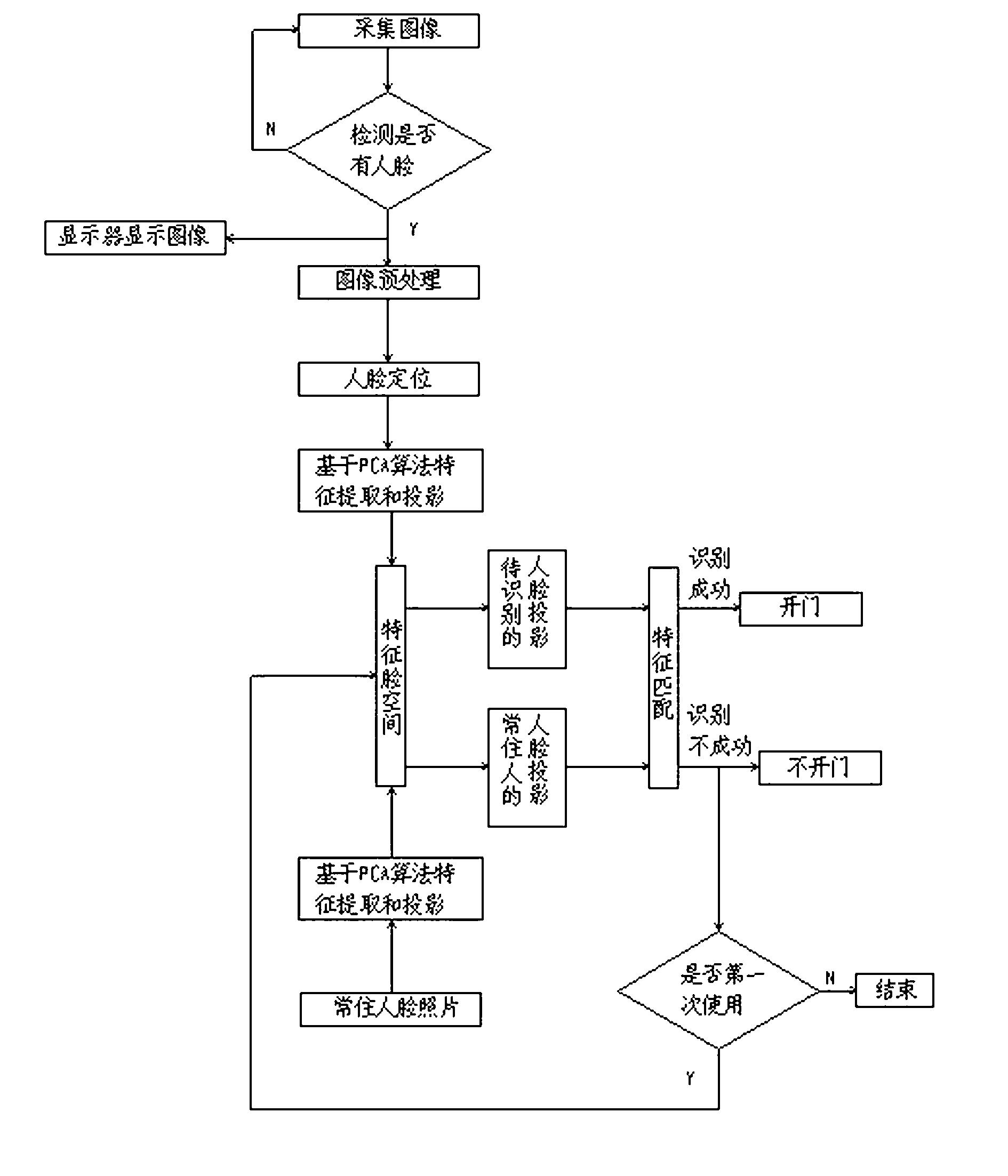

Face identification method for access control system

InactiveCN103268653AReduce visual noiseEasy to identifyIndividual entry/exit registersSkin colorImage detection

The invention relates to a face identification method for an access control system. The face identification method sequentially comprises image acquisition, image detection, image preprocessing, feature training, feature extraction, comparison identification, and control of opening of a gate by outputting a comparison result, and also comprises the following steps of: inquiring whether a user uses the system for the first time, and if the user uses the system for the first time, adding an acquired sample into a sample feature face space. By the face identification method, a face image to be identified is preprocessed, so that the vision noise of the image is reduced, and high-frequency parts are filtered out; therefore, those non-obvious low-frequency components are easier to identify; pictures are subjected to light ray compensation by a color space YCrCb skin color partitioning method and then are normalized, so that the face pictures are reduced to the same size; the standard face pictures are obtained by rotating and converting gray values; the whole system can overcome the influence of an acquisition environment; and the identification success rate of the system is further improved.

Owner:SUZHOU FUFENG TECH

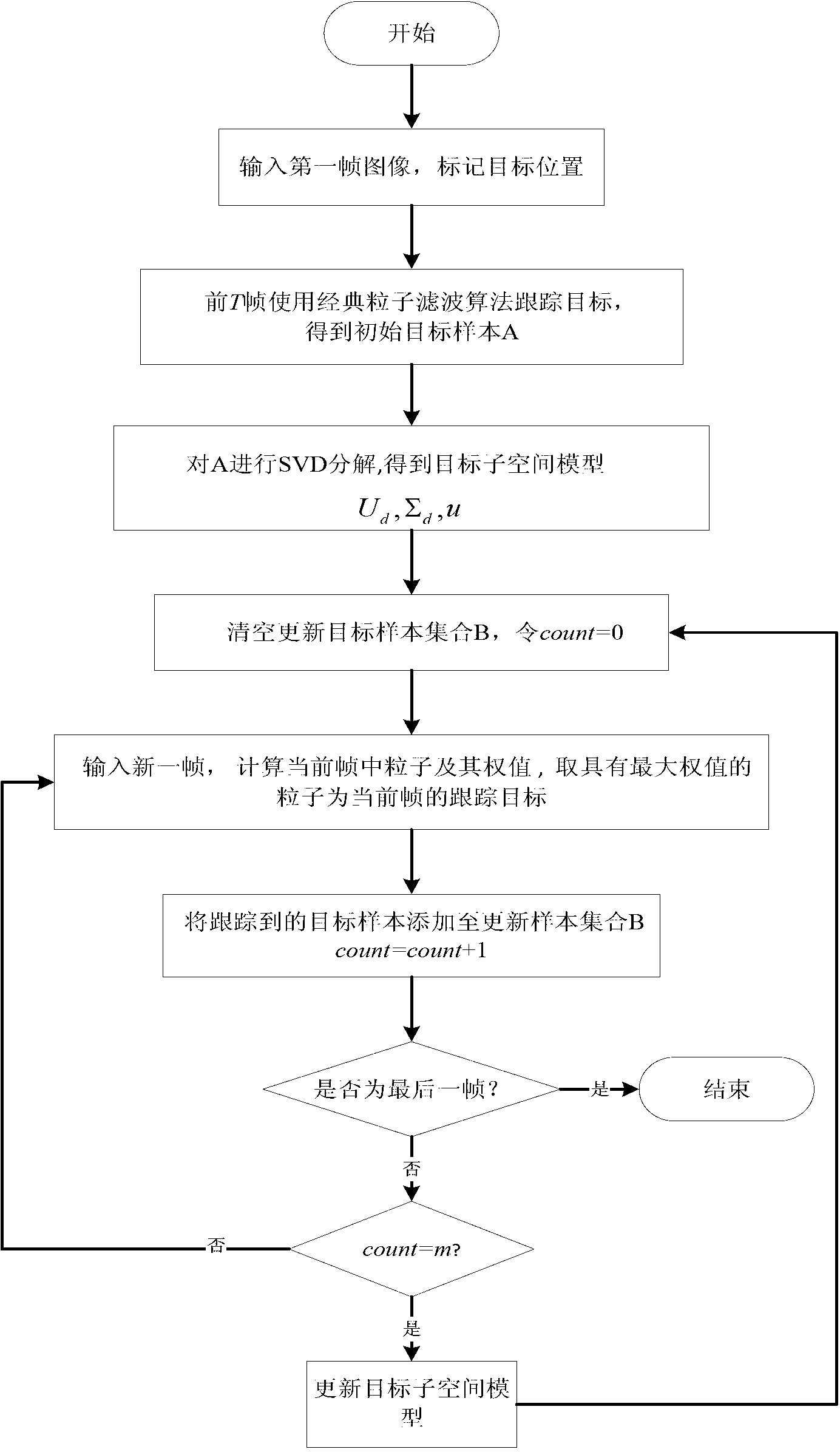

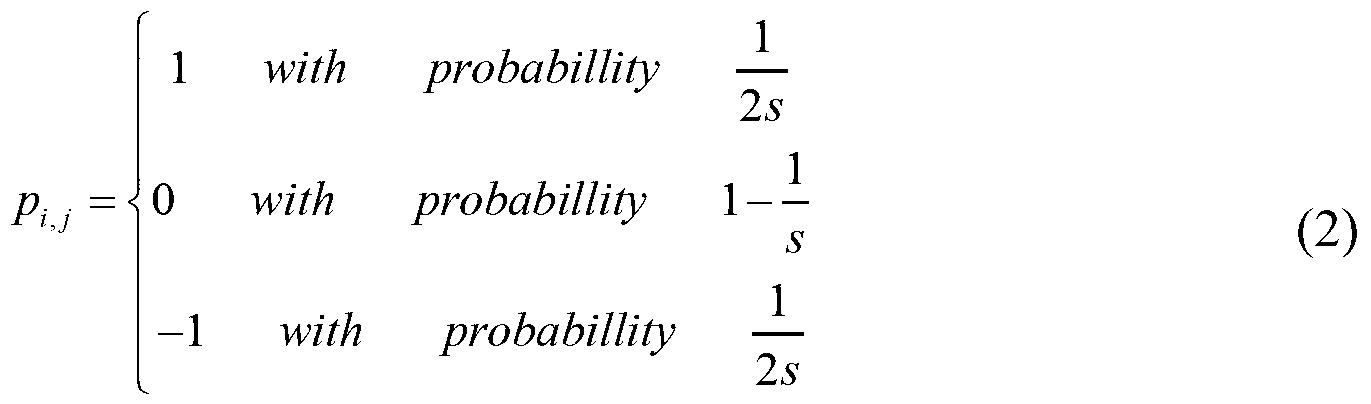

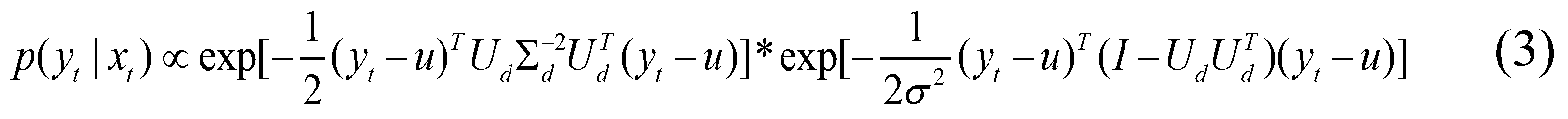

On-line target tracking method based on probabilistic principal component analysis and compressed sensing

InactiveCN103310463AImprove real-time performanceAccurate calculationImage analysisKernel principal component analysisTrack algorithm

The invention relates to an on-line target tracking method based on probabilistic principal component analysis and compressed sensing. A compressed sensing theory is combined with a PPCA (probabilistic principal component analysis) theory to obtain a quite simple target characteristic subspace representation model, and the target subspace representation model is updated on line by the aid of an incremental PCA (principal component analysis) algorithm to enable a tracking algorithm to achieve good real-time performance. Meanwhile, the PPCA theory is applied to computation of visual similarity of a candidate target and the target subspace representation model to obtain a DFFS (distance from face space) and a DIFS (distributed inter-frame space) not just reconstruction errors in PCA, so that visual similarity is computed more accurately, and further accuracy of the tracking algorithm is guaranteed.

Owner:江苏星地通通信科技有限公司

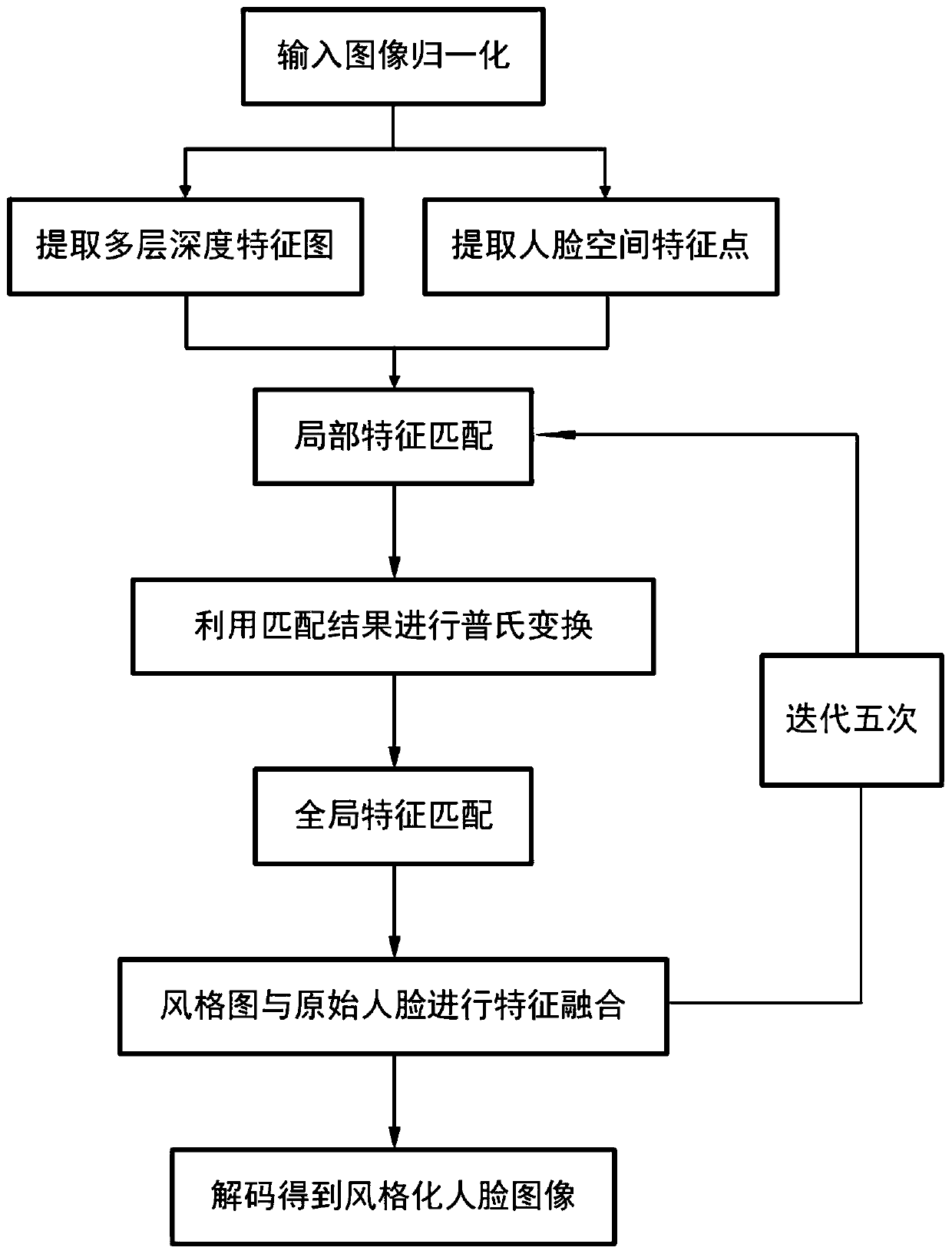

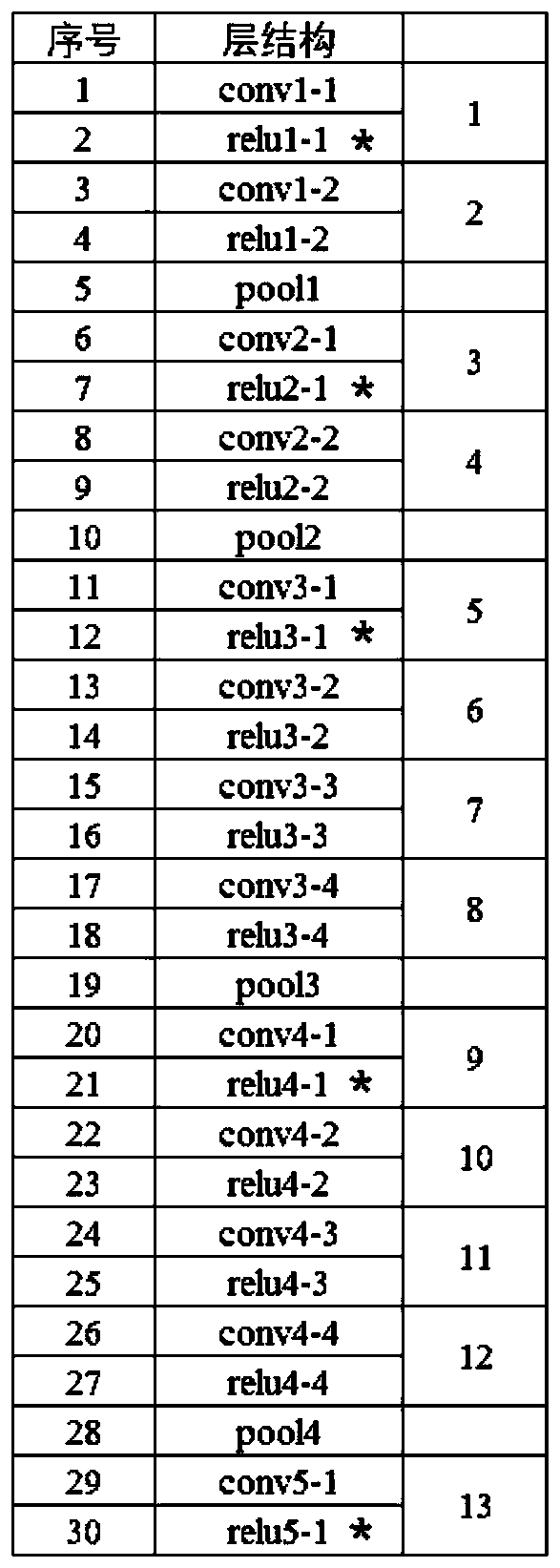

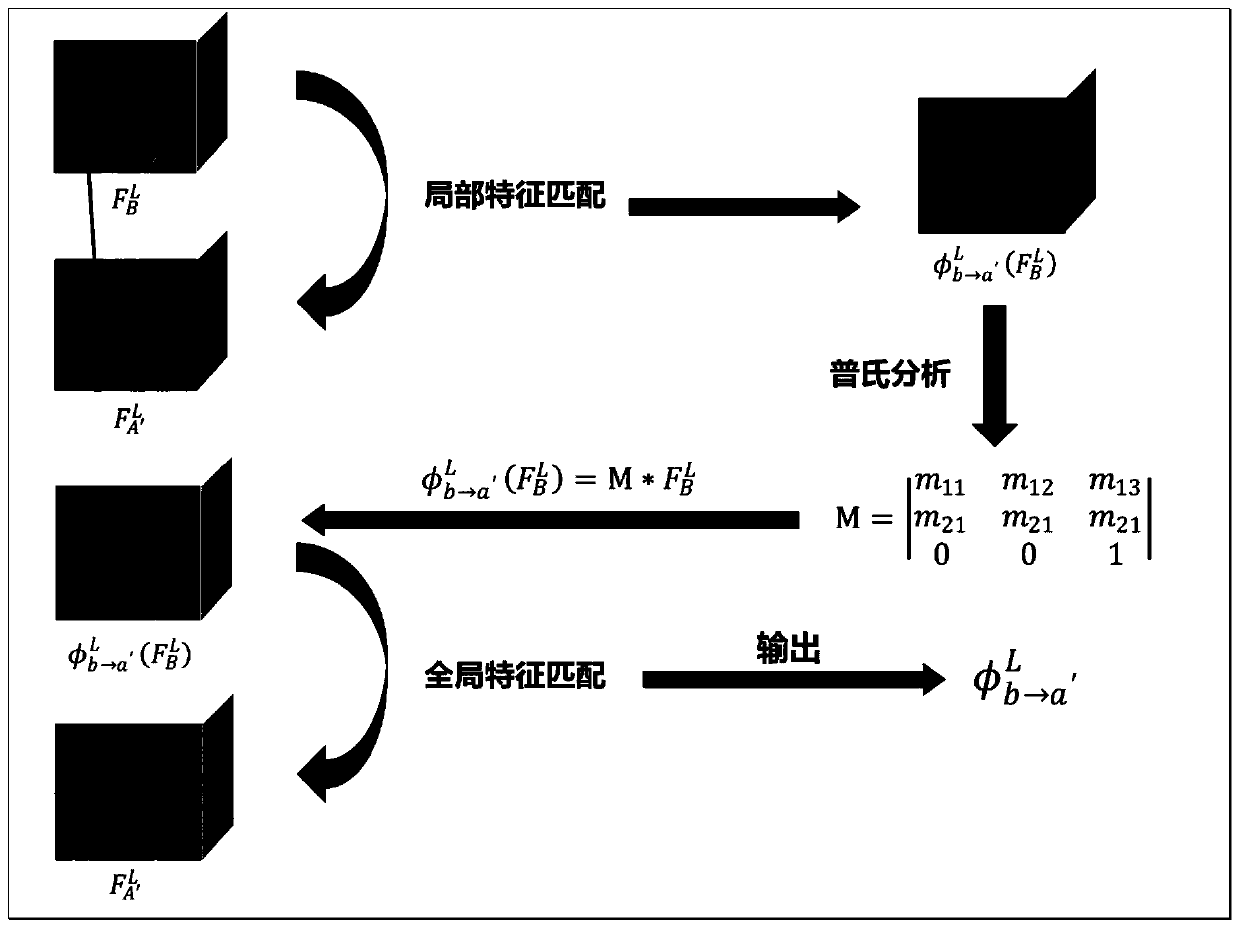

A human face image stylization method based on spatial constraint

ActiveCN109829353AImprove visual effectsGuaranteed accuracyImage analysisGeometric image transformationPattern recognitionMatching methods

The invention discloses a human face image stylization method based on spatial constraint, and the method comprises the following steps: firstly, carrying out the normalization of an input style imageand an original image, extracting a multi-layer depth feature map of a human face through a feature encoder, and extracting human face spatial feature points through a human face modeling network; Then, at each layer of the depth feature map, executing a feature block matching method by utilizing spatial constraint and Platts transform of face spatial feature points to obtain mapping from the style image to the original image; And carrying out feature fusion on the mapped style image and the original image to obtain a new depth feature map, and finally obtaining a stylized original image through a pre-trained feature decoder. The invention belongs to the field of computer vision, fully utilizes the space corresponding relation of a human face, designs a rapid feature block matching method, and can effectively improve the speed and accuracy of human face image stylization.

Owner:SOUTHEAST UNIV

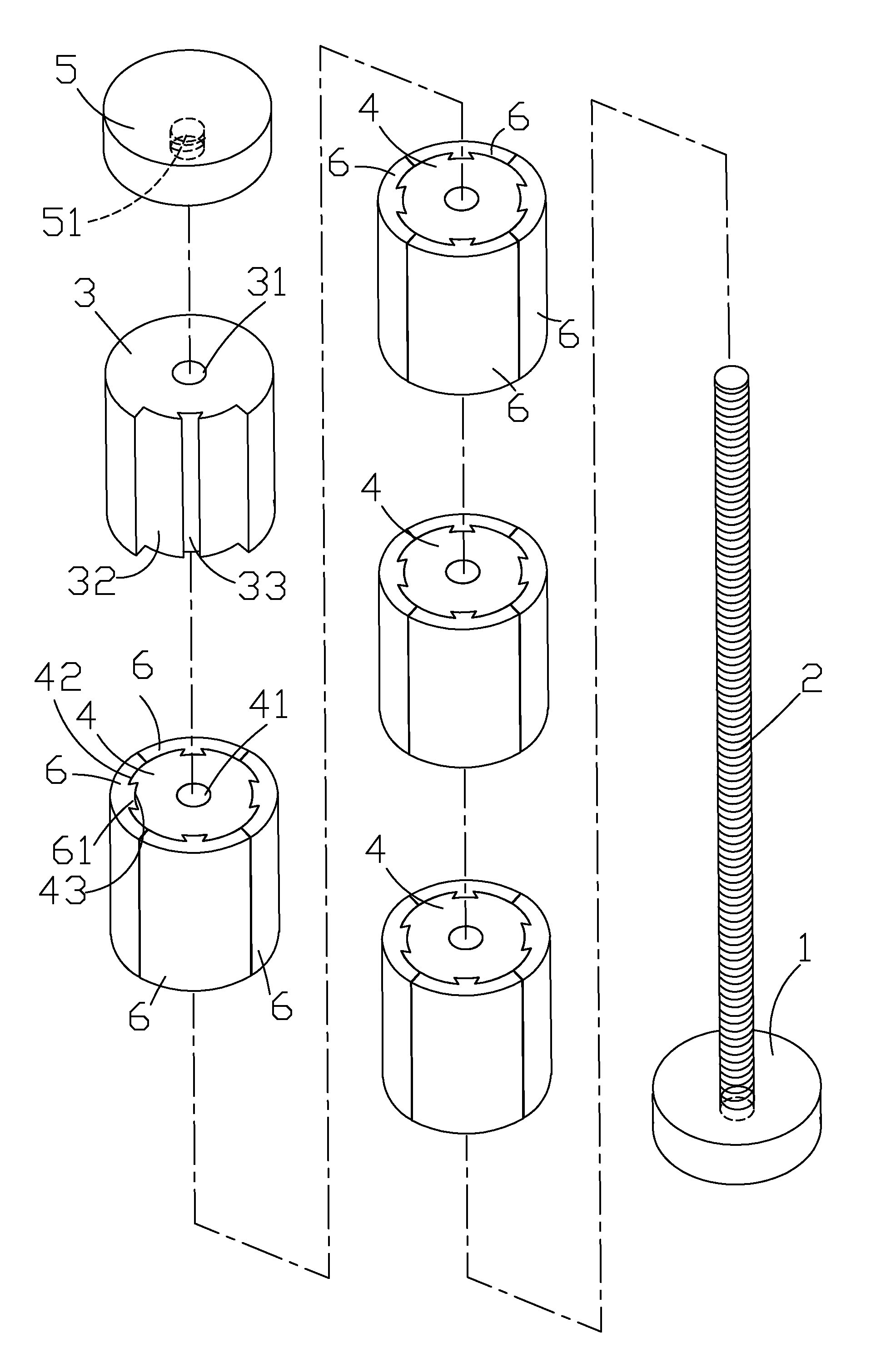

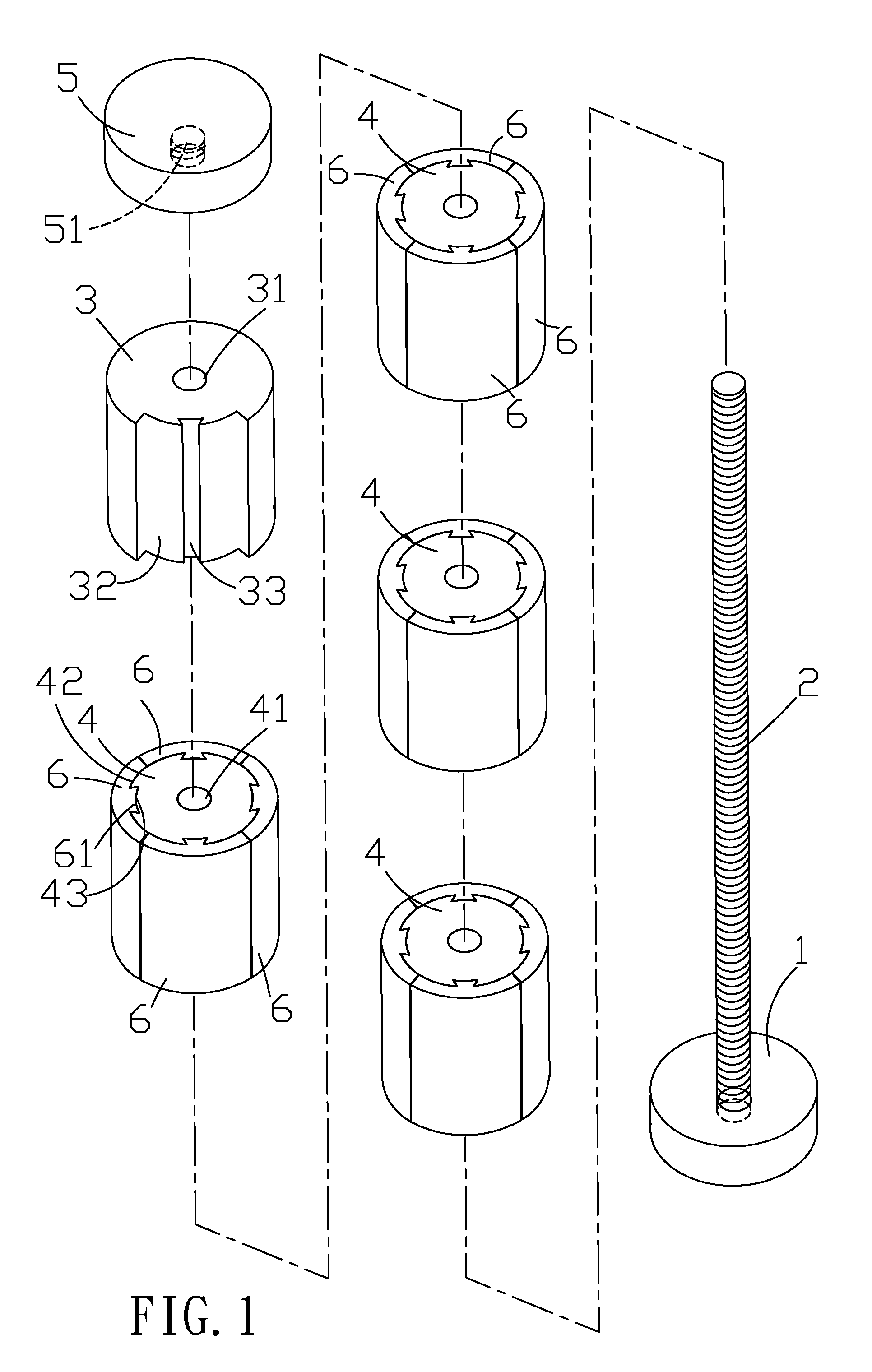

Cylinder cube

Owner:YANG CHIN HUANG

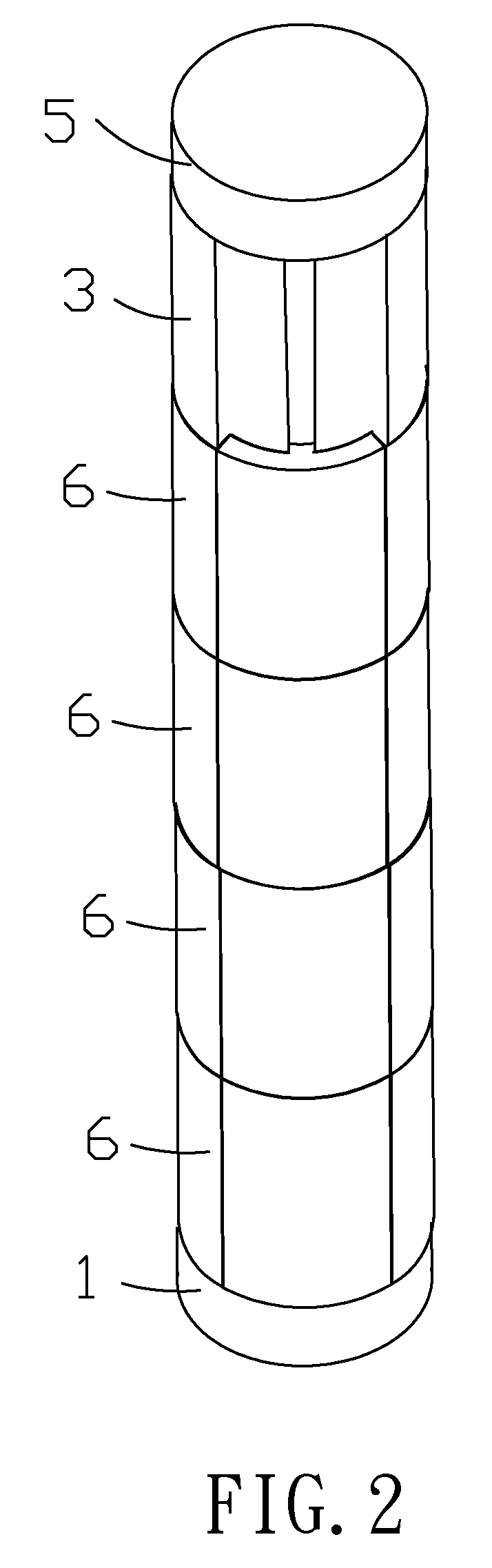

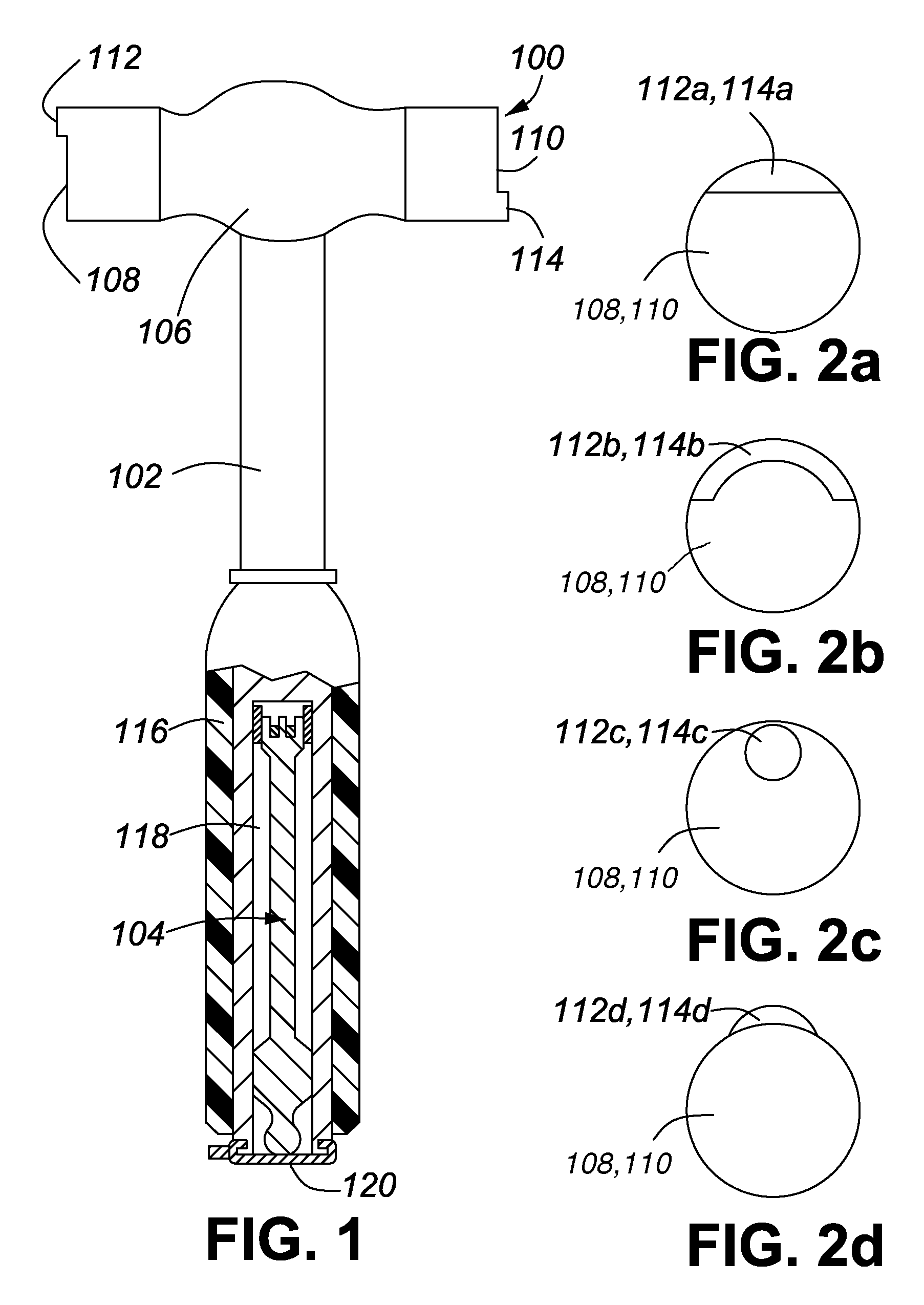

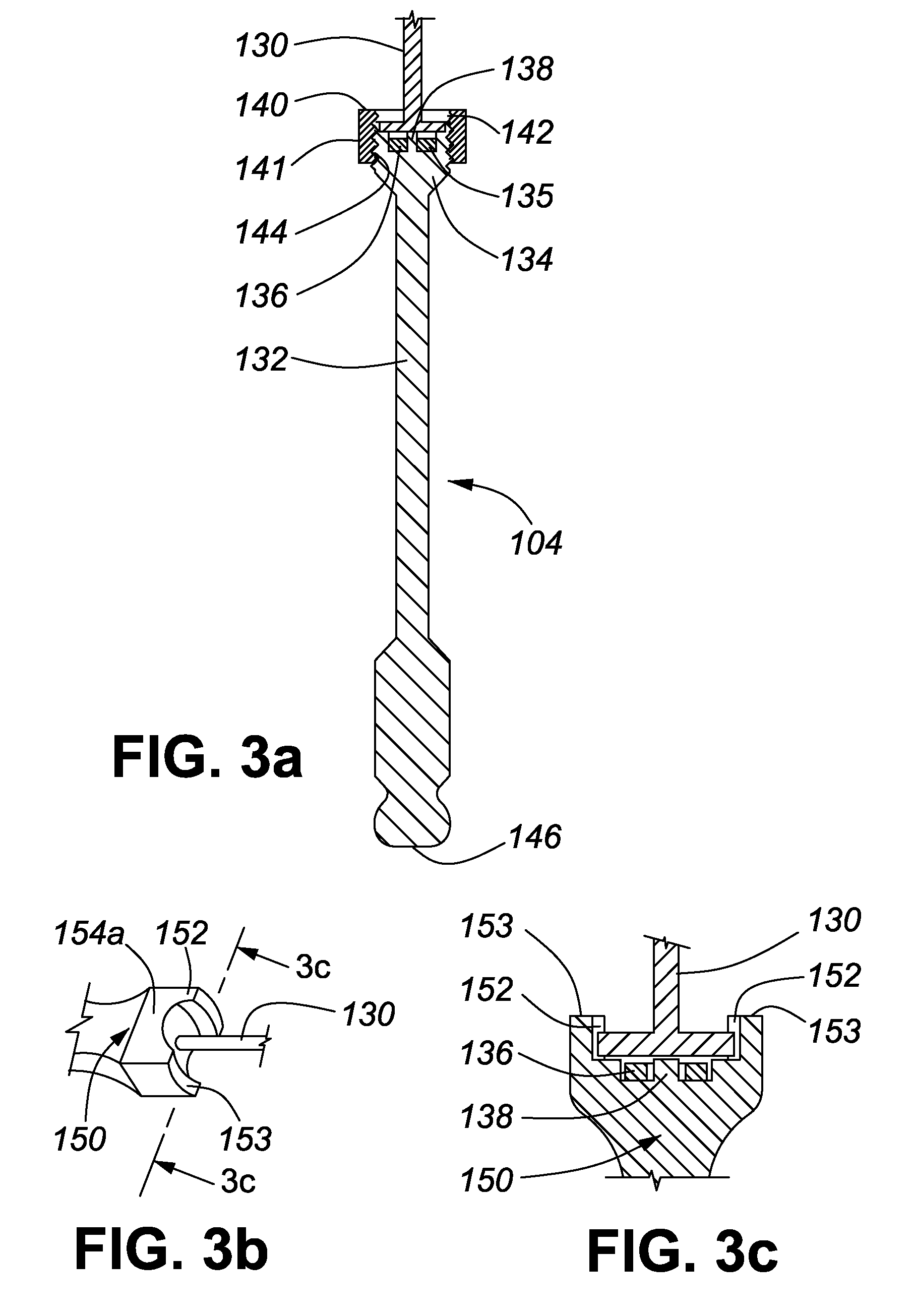

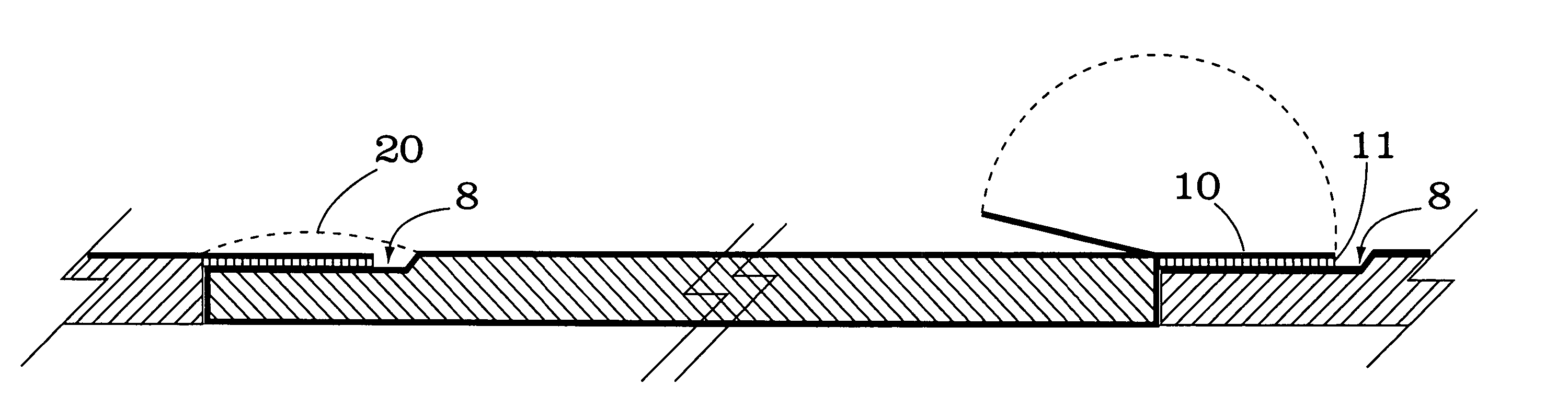

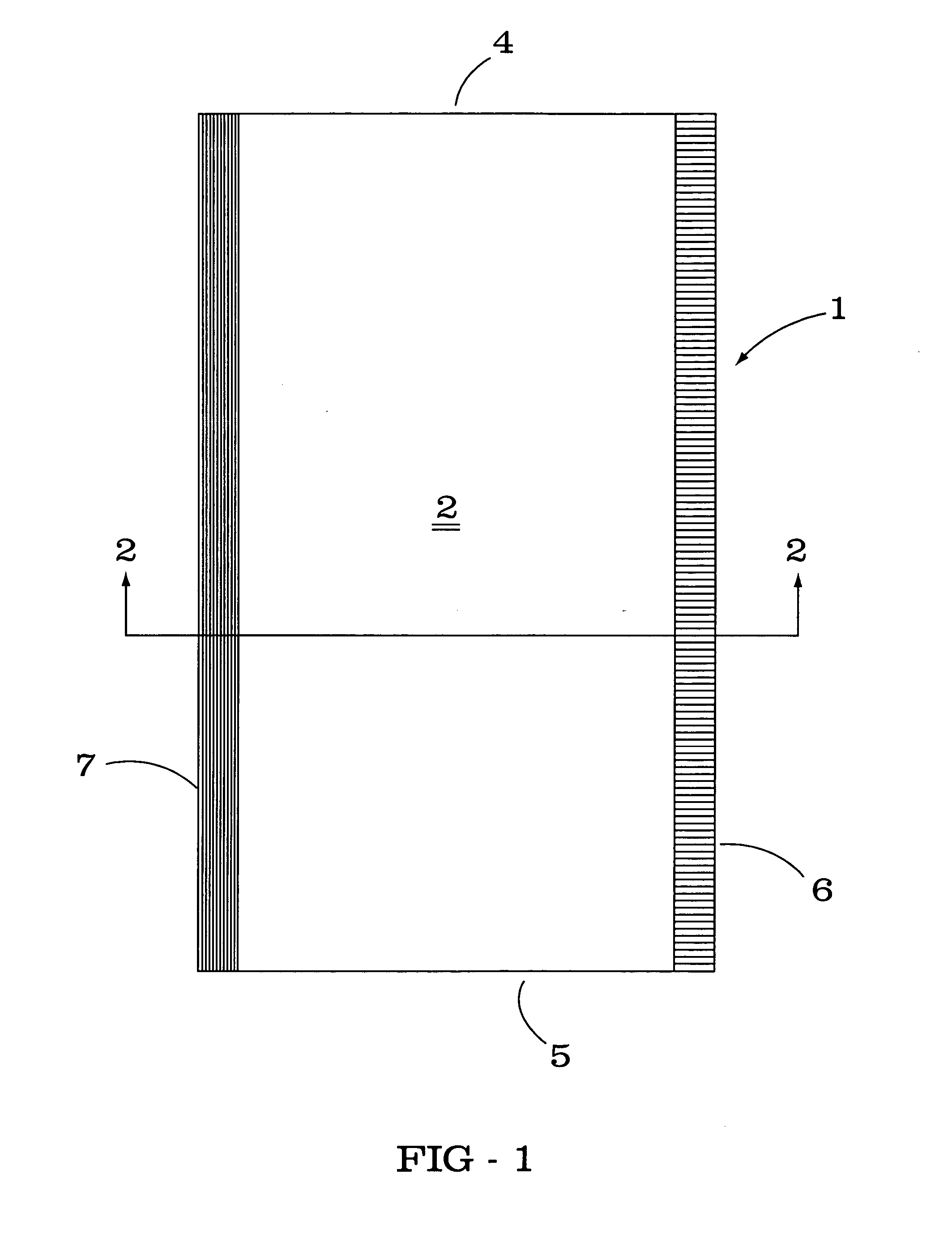

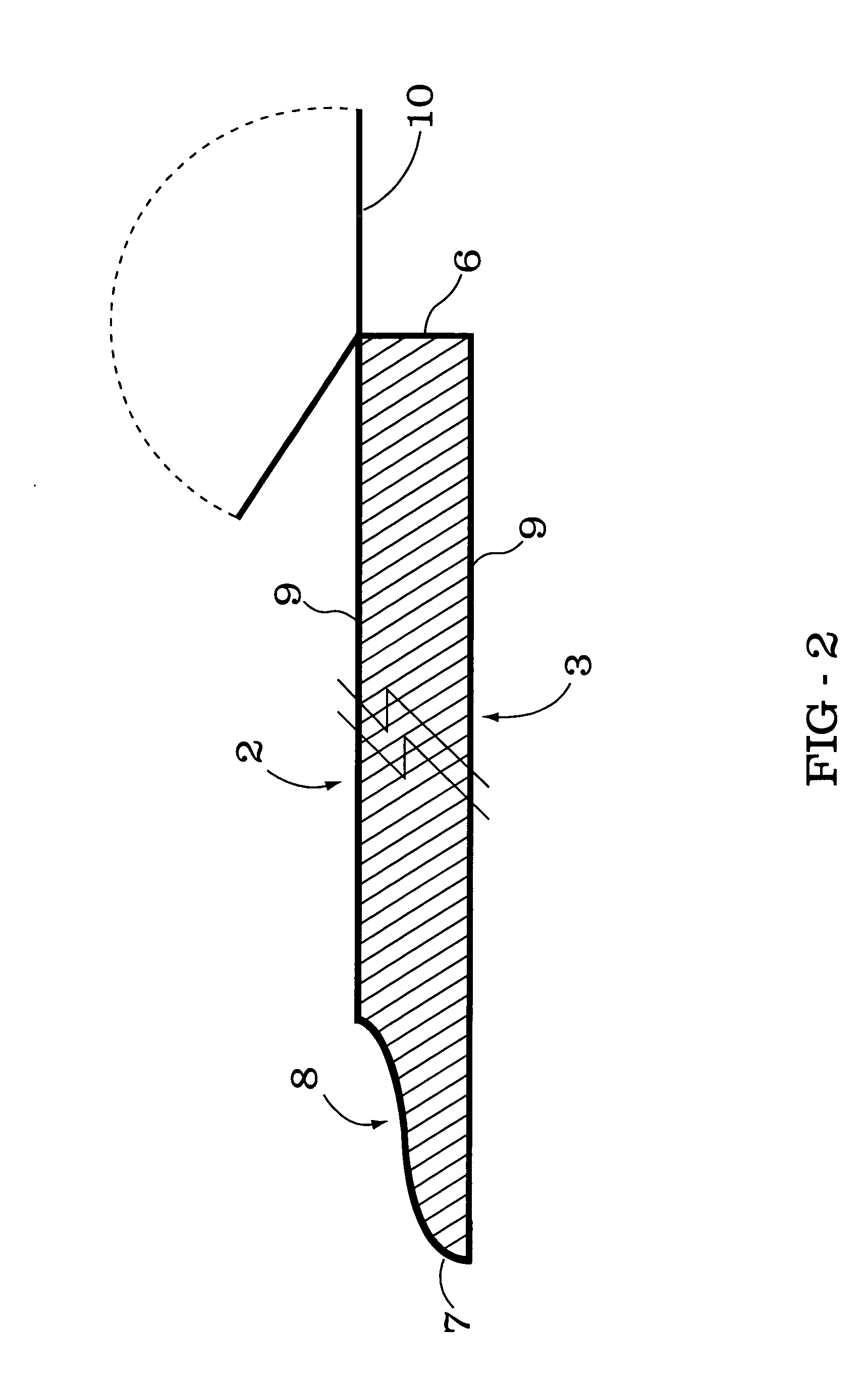

Siding hammer and attachments for converting a hammer to a siding hammer

A siding hammer having a depth control face spaced in front of a striking face of a hammer head of the hammer. The depth control face strikes a substrate into which a fastener is being driven when the fastener has been driven to a predetermined depth of penetration in the substrate to inhibit the fastener from being driven further into the substrate. In certain embodiments, the depth control face is removable to permit the hammer to be used without depth of penetration control. In certain embodiments, the depth control face is adjustable to adjustably control fastener depth penetration. Attachments are also provided for temporarily converting a hammer into a siding hammer.

Owner:KELLAND ROBERT E

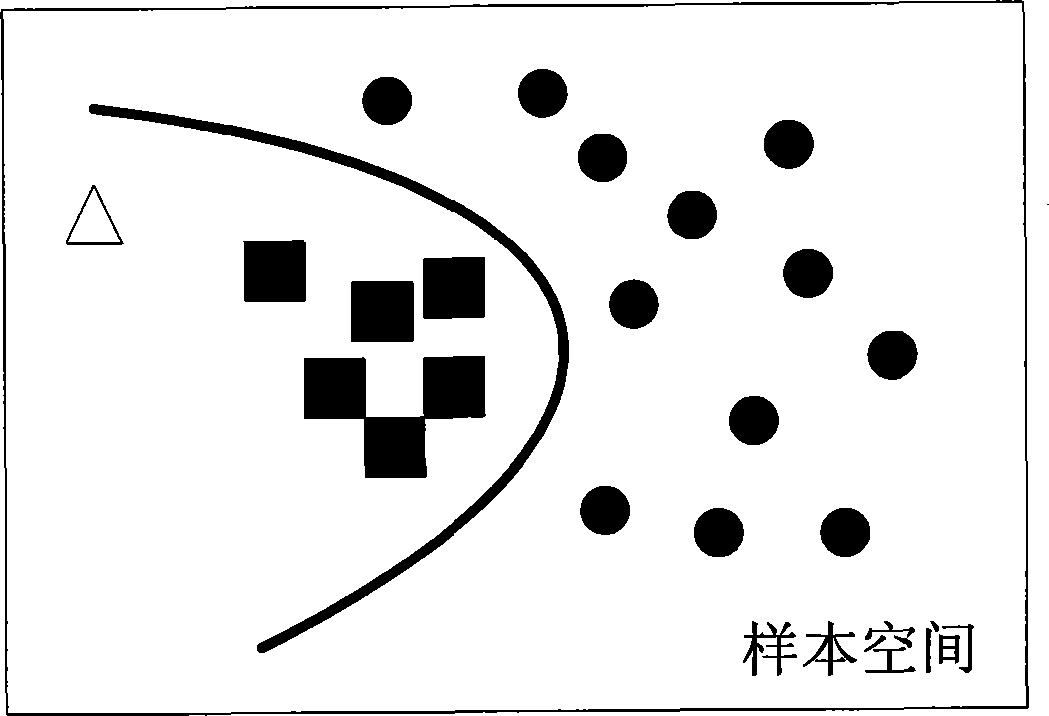

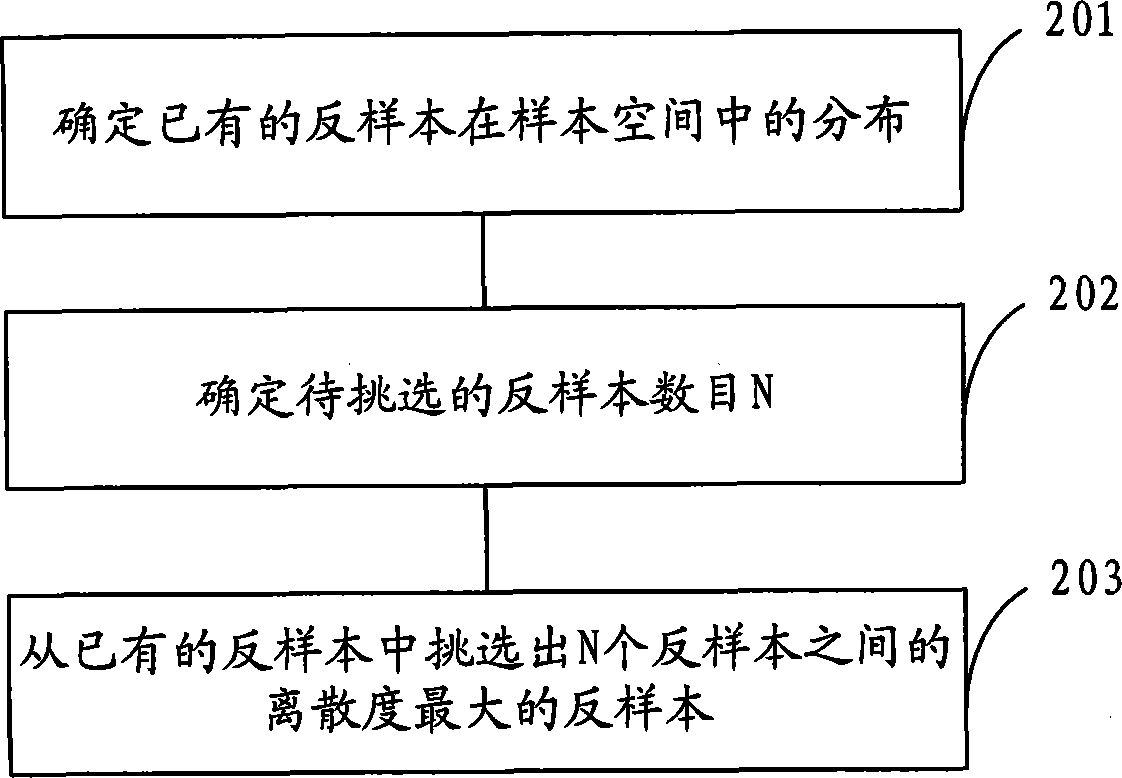

Negative sample selection method in biometrics identification and apparatus thereof

ActiveCN102385704AReduce false recognition rateImprove performanceCharacter and pattern recognitionBiometricsAuthentication system

The invention provides a negative sample selection method in biometrics identification and an apparatus thereof so as to solve a misrecognition problem in the biometrics identification. The method comprises the following steps: determining distribution of existing negative samples in a sample space; determining a negative sample number N to be selected; selecting the negative sample with the largest dispersion between the N negative samples in the existing negative samples. By using the negative sample selection method based on space dispersion analysis, under the condition of the certain negative sample number, the negative sample which can cover the face space most and most effectively reduce a misrecognition rate can be selected from the existing negative samples. Face authentication system performance can be raised. In addition, the method and the apparatus of the invention are also suitable for other bioinformation identity authentication systems, wherein the other bioinformation comprises: fingerprints, irises and the like.

Owner:GUANGDONG VIMICRO

Dustproof seal for ratchet wrench

Owner:HU BOBBY

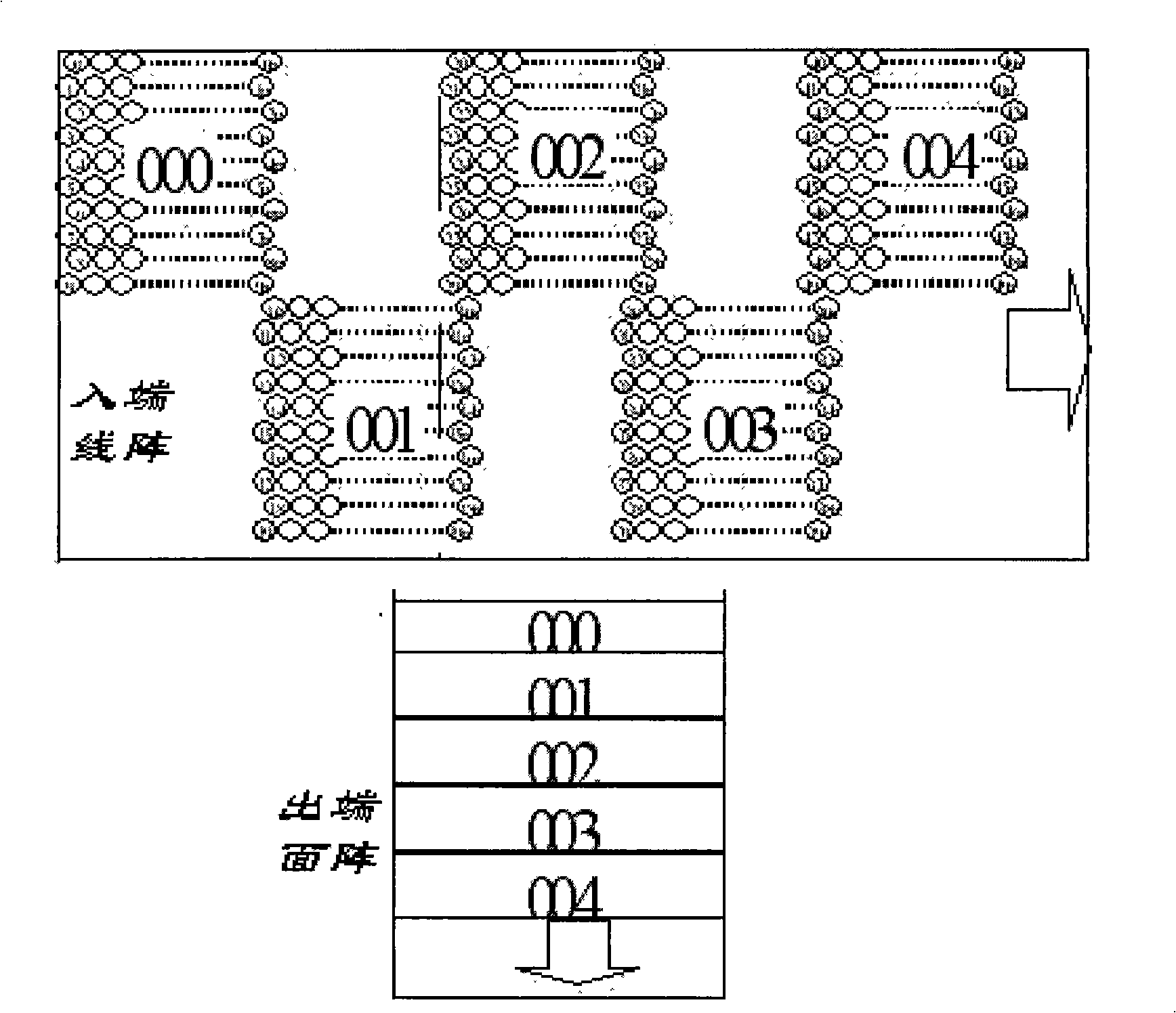

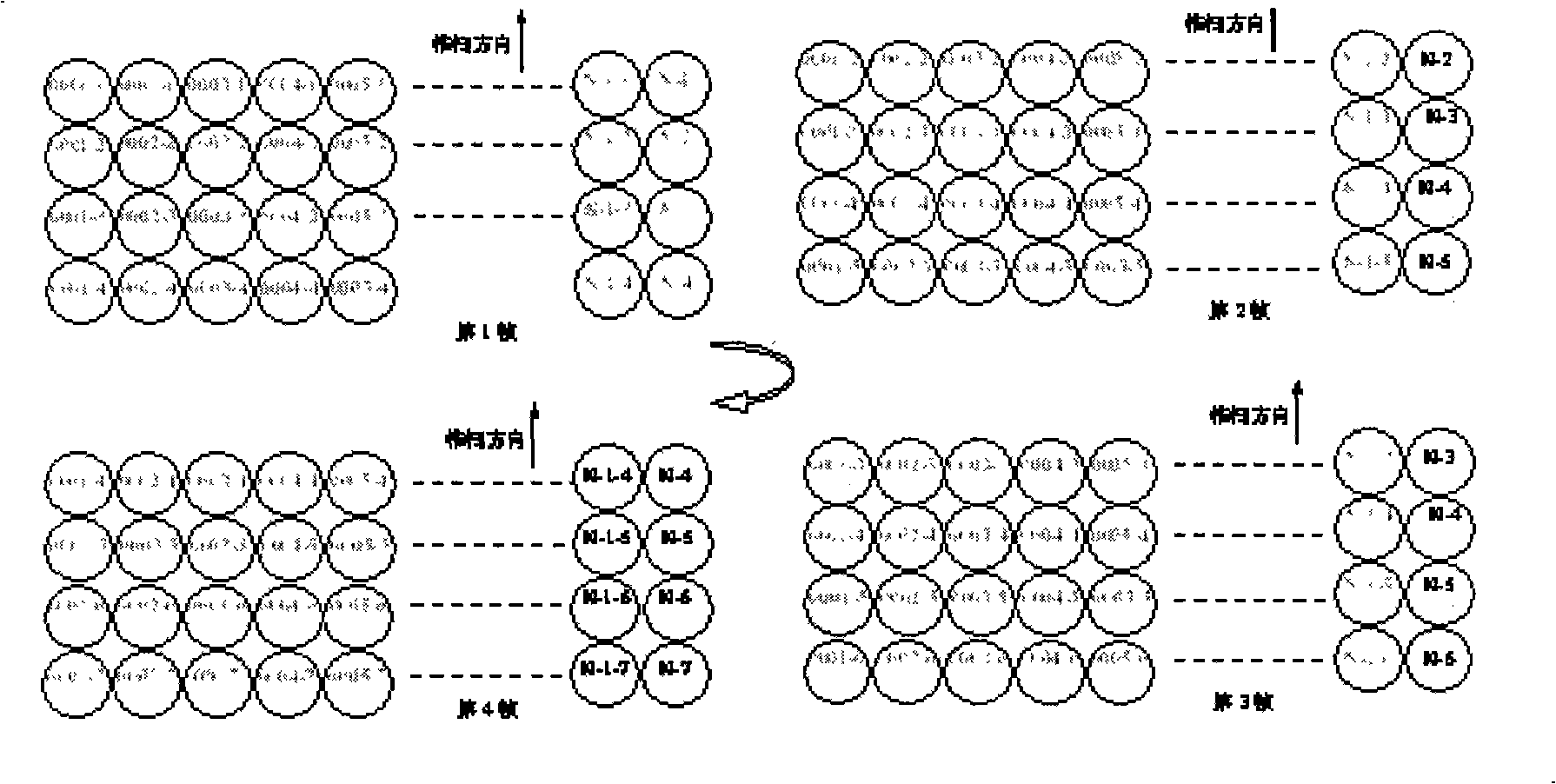

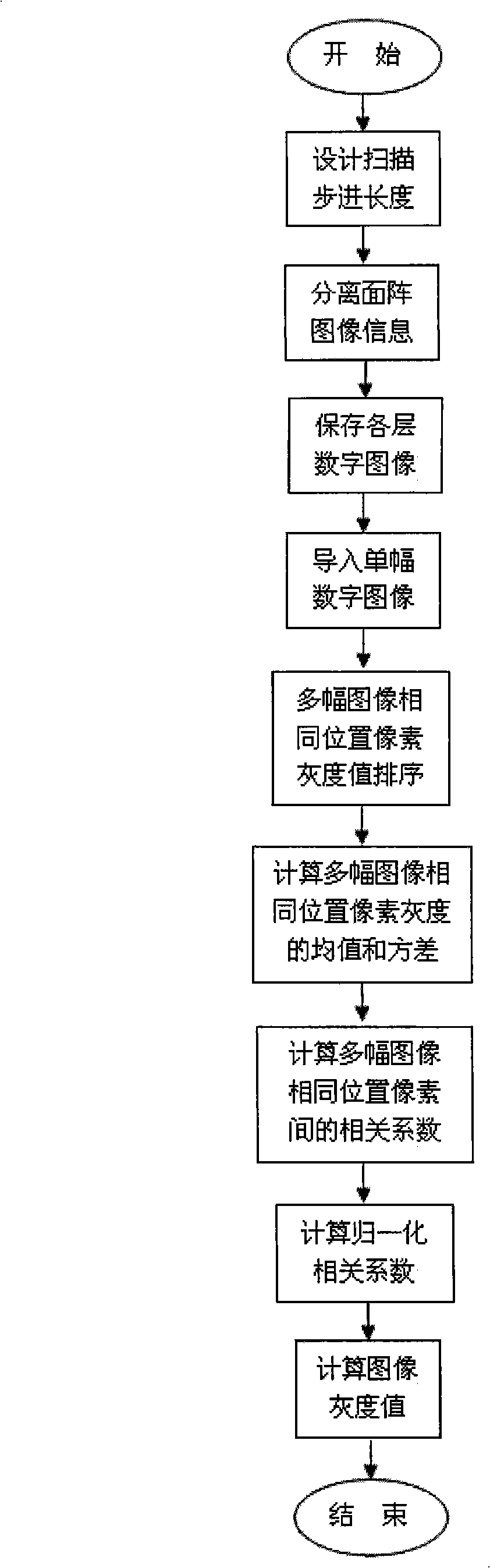

High-definition picture imaging method

InactiveCN101344646AGuaranteed clarityImprove signal-to-noise ratioBundled fibre light guideHigh resolution imagingSignal-to-noise ratio (imaging)

The invention discloses a high resolution imaging method which makes use of specially arranged optical fiber beams to realize the line / face space conversion and adopts an area array detector to realize the detection function of a linear array detector; an input end linear array of the optical beam of the invention is not a regular linear array but is a layer-superposed linear array in the shape of 'Pin' of a Chinese character; when in image scanning, the image information received by the area array detector is separated when an object image sequentially passes each optical fiber so as to obtain a plurality of digital images. The invention not only fully utilizes the information contained by a plurality of digital images but also enhances the SNR of the object image.

Owner:SHANGHAI MARITIME UNIVERSITY

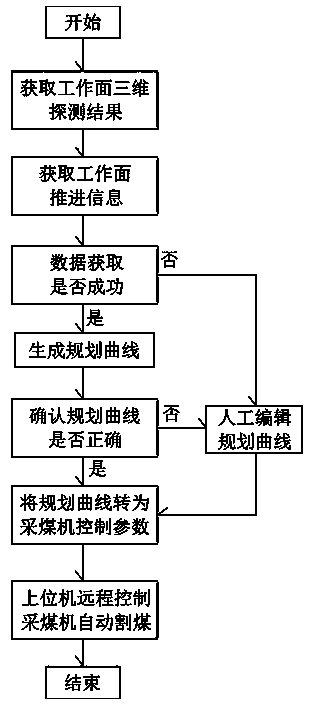

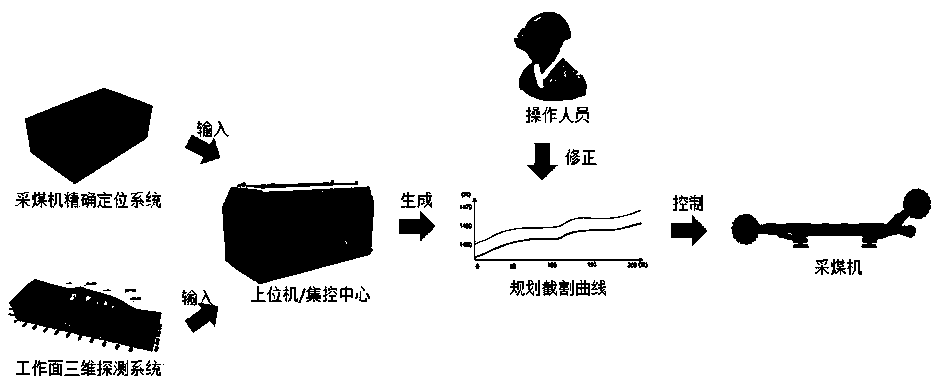

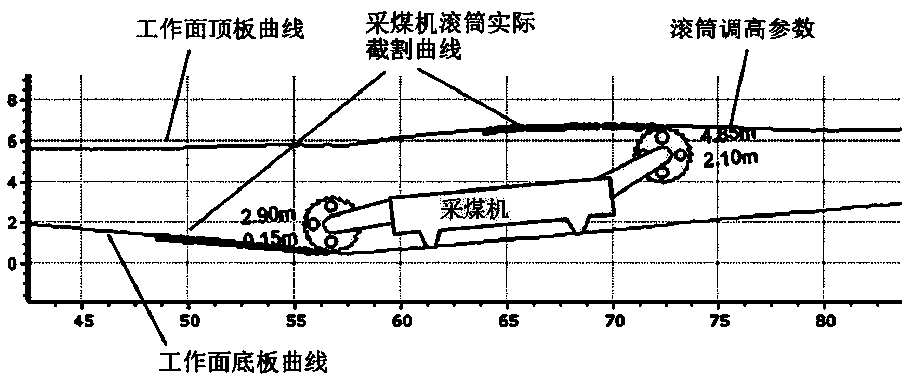

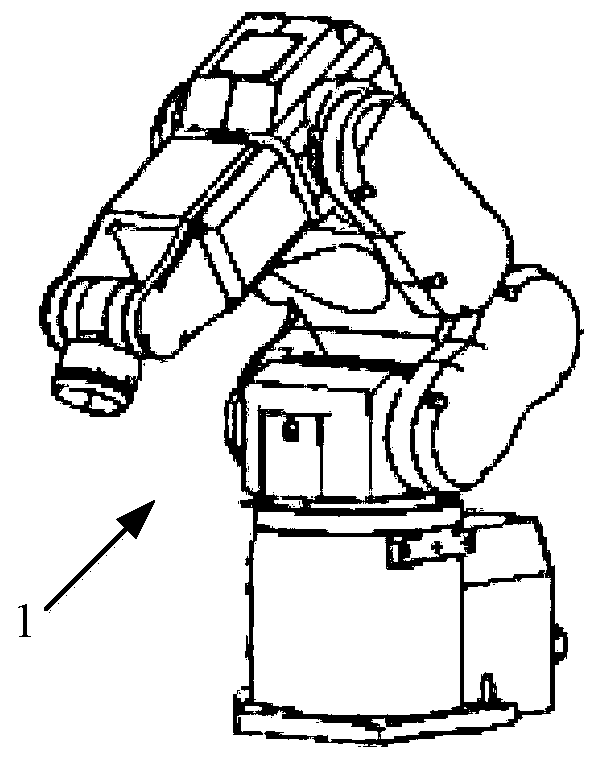

Automated coal mining method based on upper computer planning

ActiveCN109469484ASolve immutable problemsAdaptableSlitting machinesCutting machinesFace detectionRemote control

The invention discloses an automated coal mining method based on upper computer planning. The method comprises the following steps: acquiring working face roof and floor conditions by an upper computer by virtue of a three-dimensional working face detection system; 2, acquiring coordinates of a coal cutter in a three-dimensional working face space by an accurate coal cutter positioning system so as to accurately position the current working profile; 3, generating current and next working face roof and floor changing curves according to the three-dimensional working face detection results and the working face profile; 4, planning curve correction and confirmation; 5, generating heights of upper and lower drums of the coal cutter and speed parameters of the coal cutter according to the planning curve; 6, remotely regulating the heights of upper and lower drums of the coal cutter and the speed of the coal cutter by a remote control interface; 7, executing a detection instruction, performing dynamic regulation on the next instruction according to the execution results, and realizing closed-loop control. The automated coal mining method disclosed by the invention has the advantages thatthe planning curve is modified by an operator in a graphical mode, the modified effect immediately presents on a display interface, and visualization of the whole automation process is realized.

Owner:郑州恒达智控科技股份有限公司

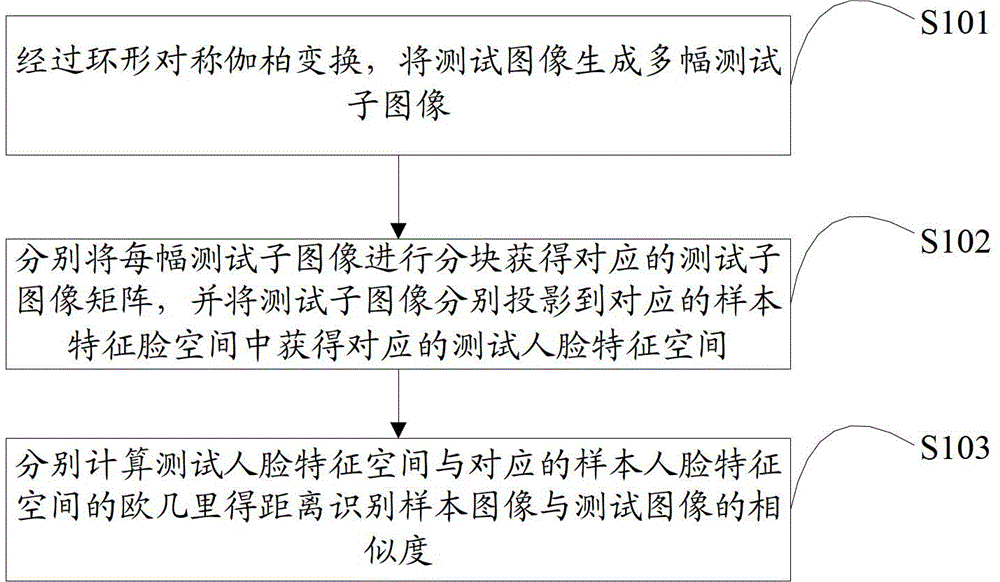

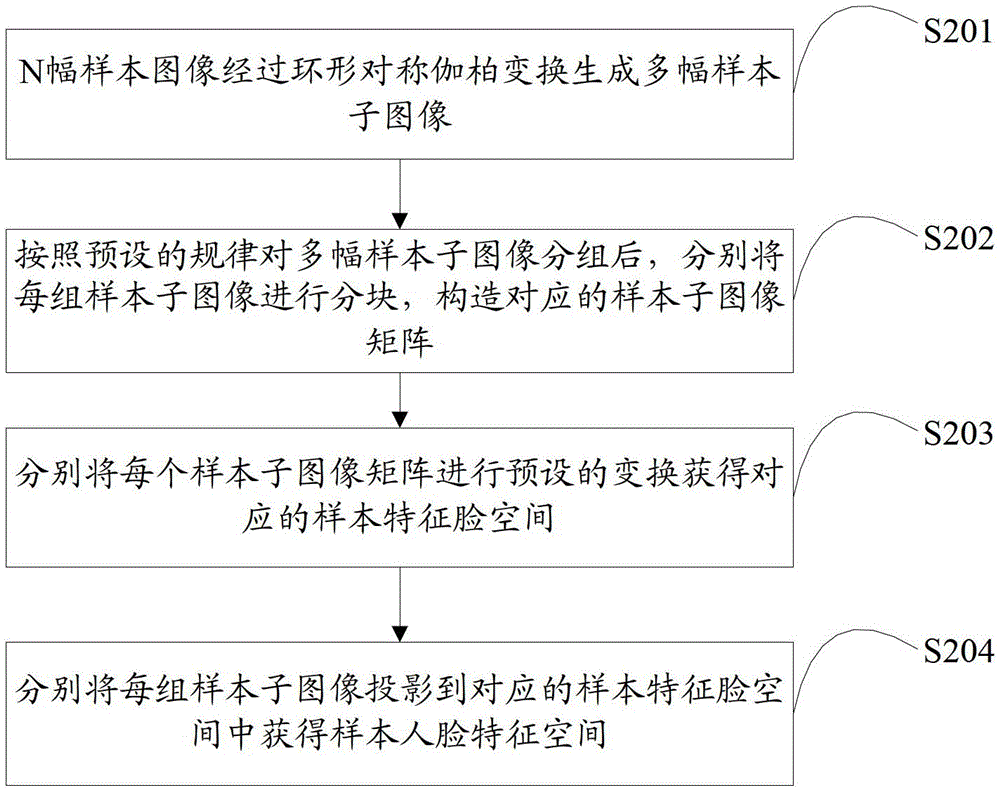

Face recognition method and device

ActiveCN102750523AAvoid the problem of discrete directionsReduce redundancyCharacter and pattern recognitionImaging processingGabor wavelet transform

The invention is applicable to the field of image processing, and provides face recognition method and device. The method comprises the steps: generating a plurality of test subimages from a test image by circularly symmetrical gabor transformation; blocking each test subimage to obtain a corresponding test subimage matrix, and respectively projecting each test subimage to a corresponding sample feature face space to obtain a corresponding test face feature space; respectively calculating Euclid distances of the test face feature spaces and those of the sample face feature spaces to recognize the similarity of a sample image and the test image. The circularly symmetrical gabor transformation has rotation without deformation, thus avoiding the direction discretion problem caused by adopting traditional gabor wavelet transformation, and obviously reducing redundancy. In addition, the high-dimensional test image is projected to the low-dimensional sample feature face space for recognition, thus greatly reducing the calculation complexity and improving the recognition property.

Owner:TCL CORPORATION

Versatile tapeless drywall system

A versatile tapeless drywall system comprising a drywall board panel having a generally rectangular shape formed of paper-wrapped core material and having front and back faces spaced apart to define a thickness of the panel and having long and short edges, said edges being characterized by one of the long edges being tapered on the front face marginal portions thereof enabling pairs of boards of such construction to be secured with the front faces exposed and with one long edge of each being abutted together to form a recess along the joint line of the abutted edges suitable for receiving finishing material therein and with the opposite long edge having a flap extending from the front face and beyond the edge and along the length of the long edge whereby the flap can be rotated about the axis of the front edge of the panel from a position against the face of the panel, for stacking and shipping the panel, through an arc of about 270° so that when the panels are in abutting relationship, the flap can be rotated into contact with and affixed to an abutting panel to thereby join adjacent panels.

Owner:YAKOBICS JEFF A

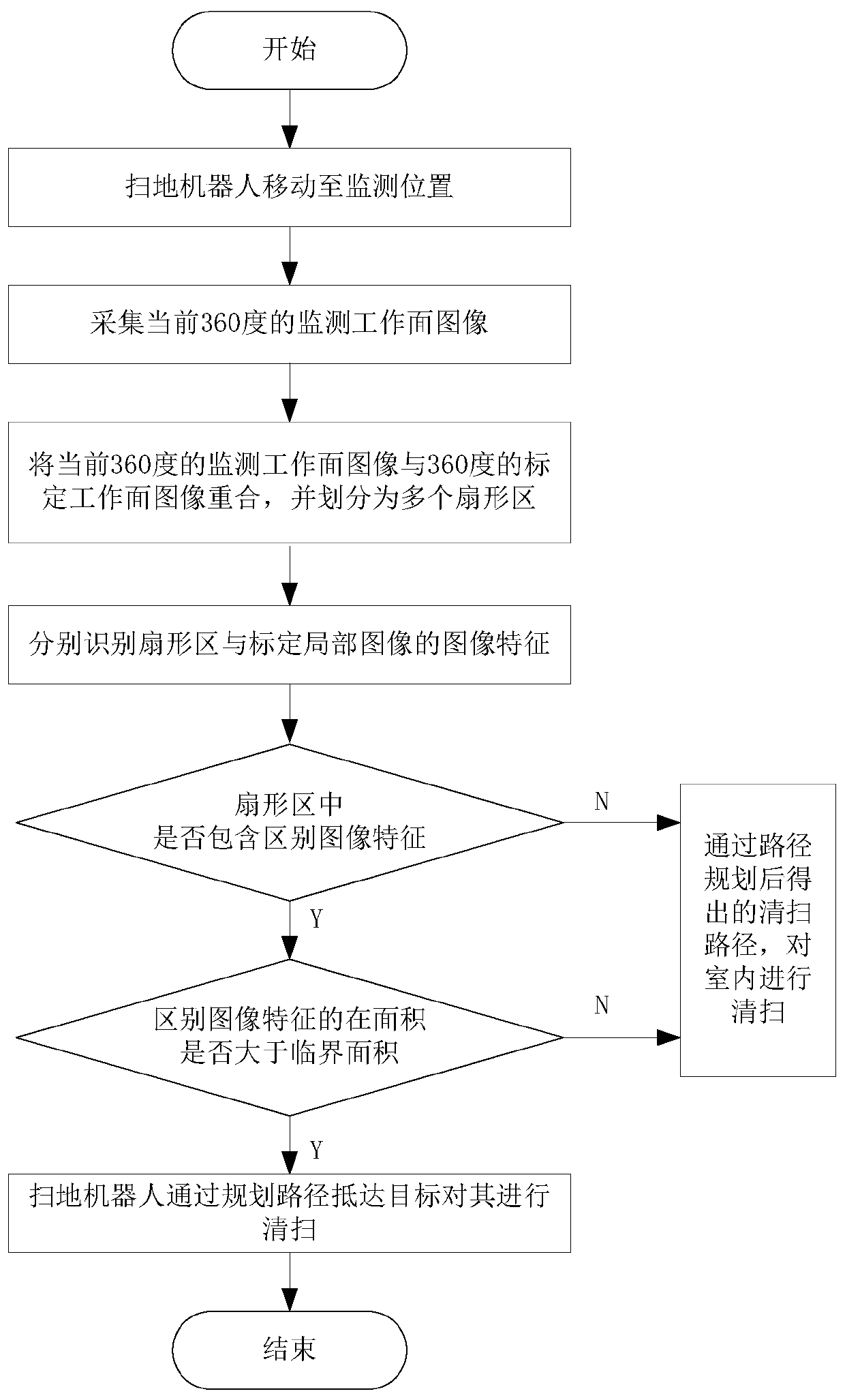

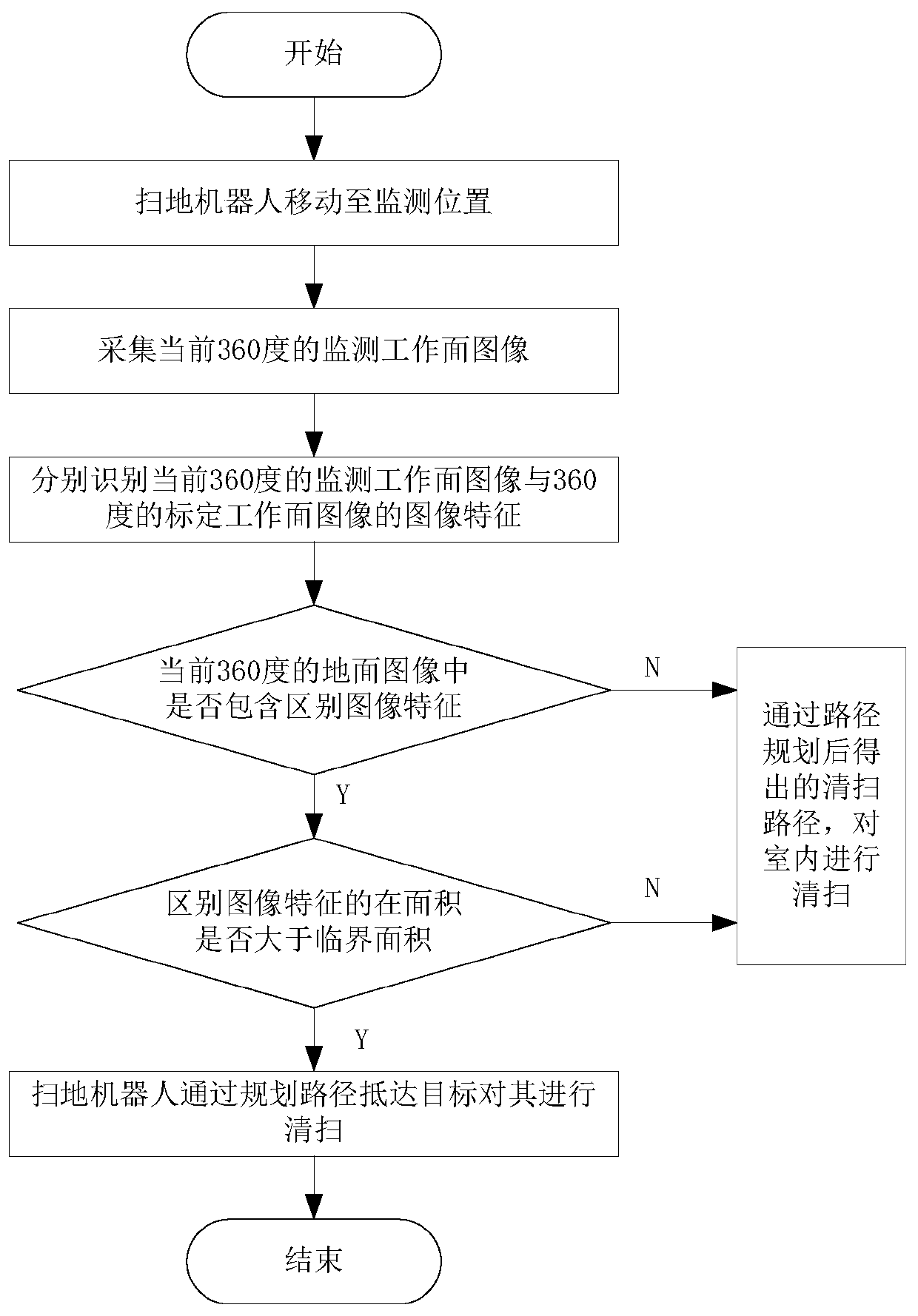

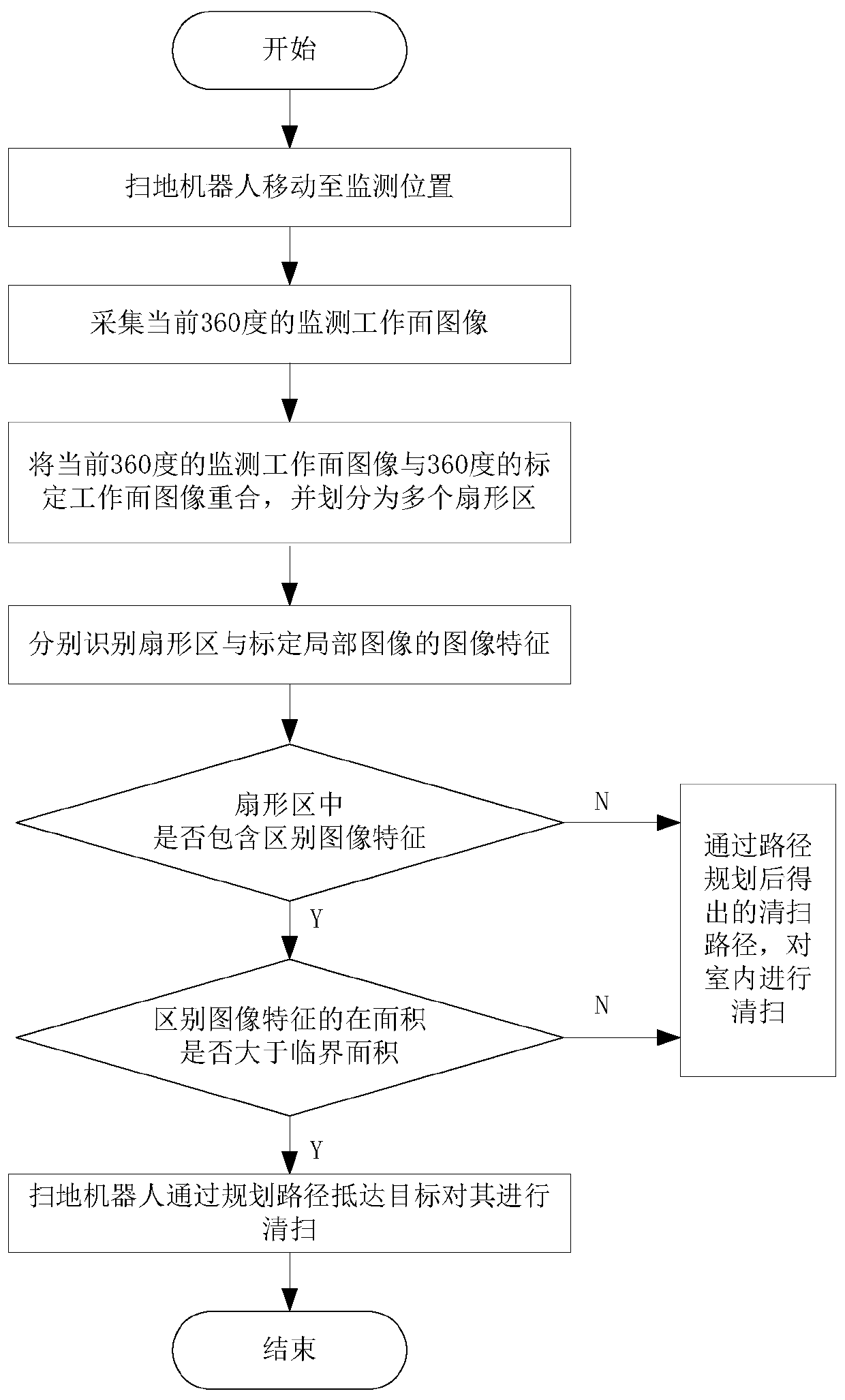

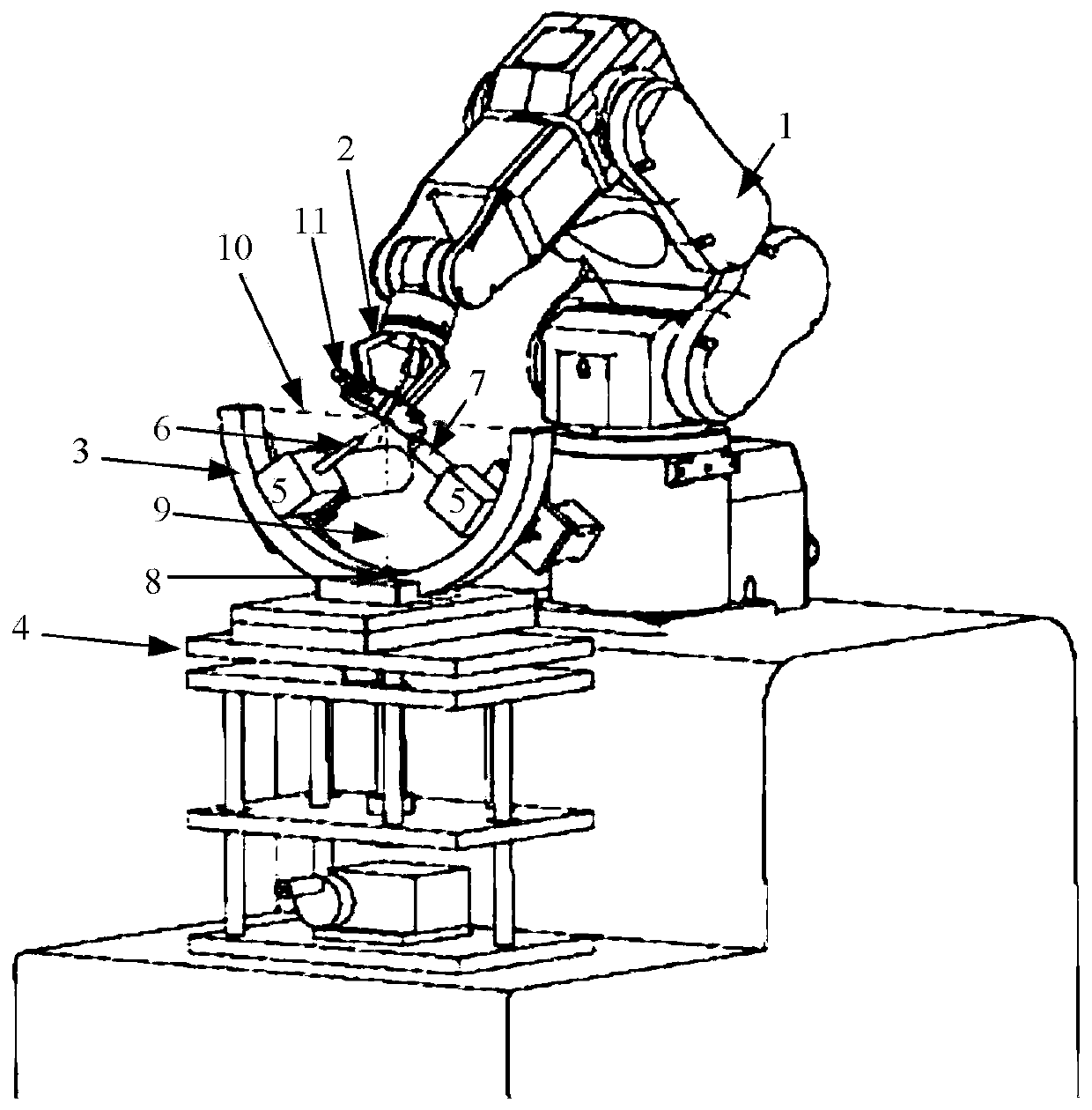

Sweeping robot working face cleaning method

ActiveCN111110117AImprove visual cleanlinessImprove cleaning purposeCarpet cleanersCleaning action controlForeign matterComputer vision

The invention relates to a sweeping robot working face cleaning method, belongs to the field of automatic cleaning equipment, and solves the problem that an existing sweeping robot is low in cleaningefficiency. The cleaning method comprises the following steps: moving the sweeping robot to a monitoring position under the guidance of a working surface space diagram; a 360-degree monitoring workingface image with the monitoring position as the center is shot through the sweeping robot; comparing the shot monitoring working surface image with the calibration image of the monitoring position, obtaining a distinguishing image feature in the image, If the area of the working surface corresponding to the distinguishing image feature is greater than the critical area, determining that the distinguishing image feature is a target feature; determining the corresponding target position of the target feature on the working face space diagram through the shot monitored working face image; and thesweeping robot is moved to the target position to clean the working face. By means of the method, large-area foreign matter can be removed preferentially, the overall cleanness of the ground is guaranteed, and the cleaning efficiency is improved.

Owner:XIAOGOU ELECTRIC INTERNET TECH BEIJING CO LTD

Method for rapidly measuring internal stress of nickel-based single crystal superalloy

ActiveCN110044527AAccurate Stress MeasurementWide range of usabilityForce measurementStress measurementSingle crystal superalloy

The invention discloses a method for rapidly measuring the internal stress of a nickel-based single crystal superalloy, and belongs to the technical field of material performance testing. The method comprises the following steps: firstly, selecting a crystal face family, rotating a sample to be tested, and recording all diffraction positions of the crystal face family and the Miller index of the corresponding crystal face; performing theta-2 theta scanning on the periphery of each diffraction position on the polar diagram, recording the position corresponding to the strongest peak of the diffraction intensity of each diffraction position and calibrating the Miller index of the corresponding crystal face and the corresponding theta-2 theta diffraction peak; obtaining the crystal face spacing at the moment by applying Bragg law; and processing data to obtain the magnitude and direction of the internal stress of the nickel-based single crystal superalloy. The method for rapidly measuringthe internal stress of the nickel-based single crystal superalloy is suitable for samples with any orientation, and realizes the integration of crystal orientation measurement and stress measurement of the monocrystal; and the automated operation process and the programmed data processing process improve the work efficiency.

Owner:成都航大新材料有限公司

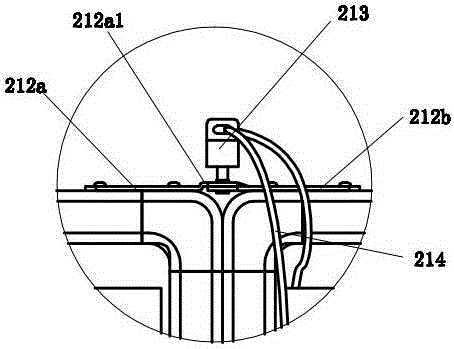

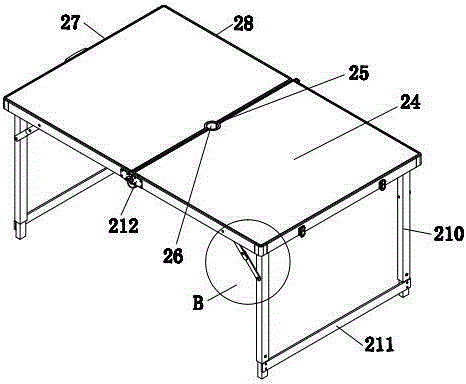

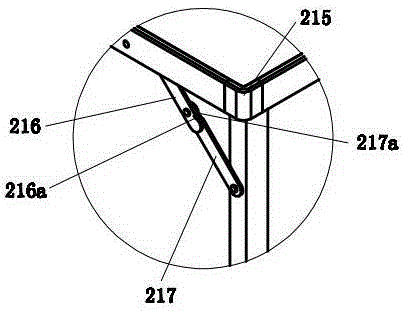

Combined outdoor box-type foldable table

InactiveCN105193084AAvoid damageImprove compactnessDismountable chairsFoldable chairsEngineeringFace space

The invention relates to a combined outdoor box-type foldable table, and belongs to the technical field of leisure equipment. The combined outdoor box-type foldable table comprises a foldable table body and foldable chairs, wherein the foldable table body is formed by symmetrically and movably connecting two half table bodies; a reinforcing baffle bar is arranged in the middle of the bottom face of each half table body to divide the bottom face space of each half table body into two inner cavities; each inner cavity is used for accommodating the corresponding foldable chair; a buckle is arranged on one side of each inner cavity; each foldable chair is fixed by the corresponding buckle and folded table legs, and the two half table bodies are folded to form a portable box. According to the combined outdoor box-type foldable table, the foldable table body and the foldable chairs form a whole set; the inner cavities for accommodating the foldable chairs are formed in the table body, so that when the foldable table is not in use, the foldable chairs are folded to be placed in the inner cavities and the two half table bodies are folded to form a box, the box is fixed by lock catches and lock pieces, and a user only needs to put one hand on a handle to lift the table; therefore, the occupied space is small, the carrying and use are convenient, and the foldable table is popular among vast consumers.

Owner:LINHAI JINYATE LEISURE PROD CO LTD

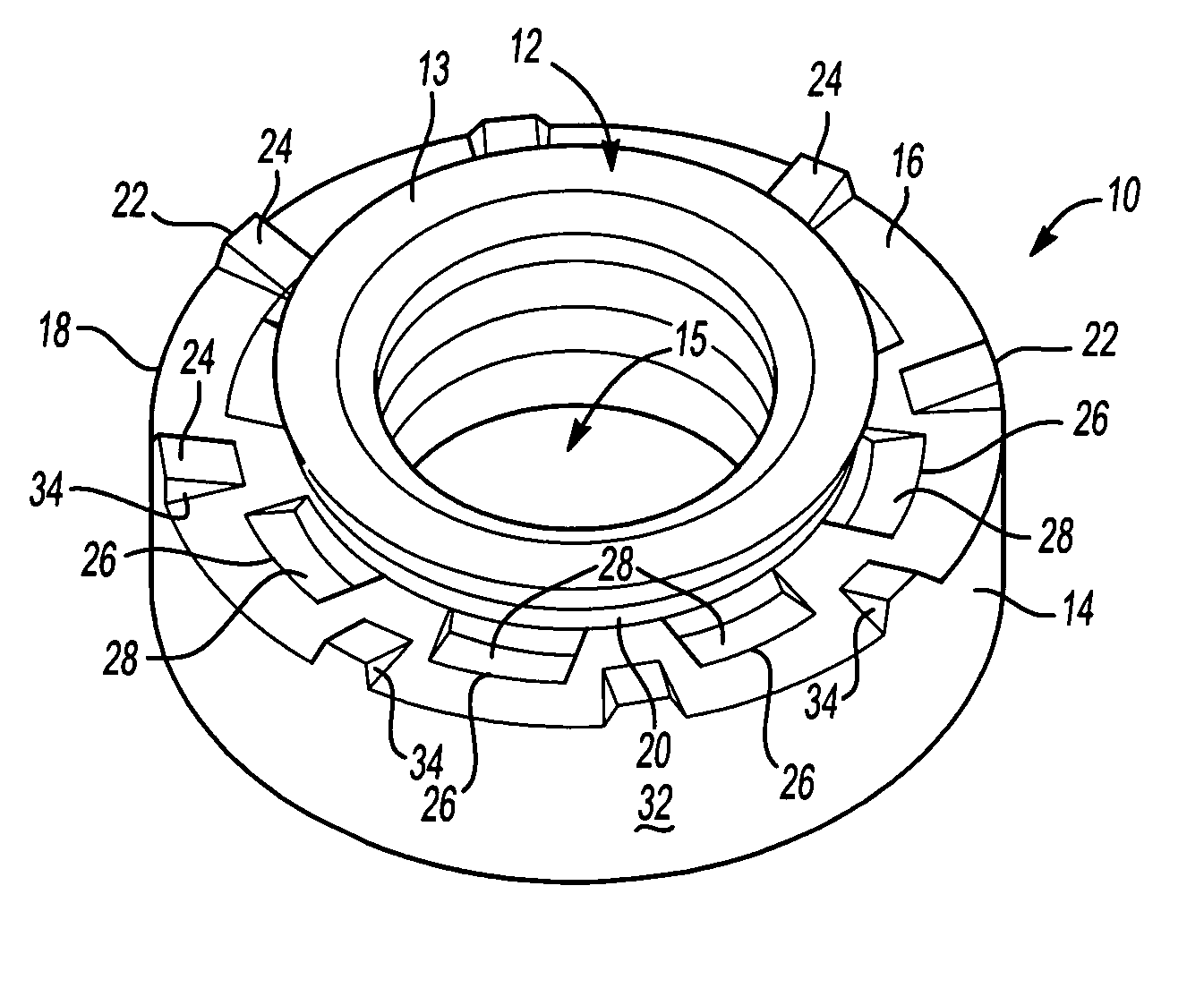

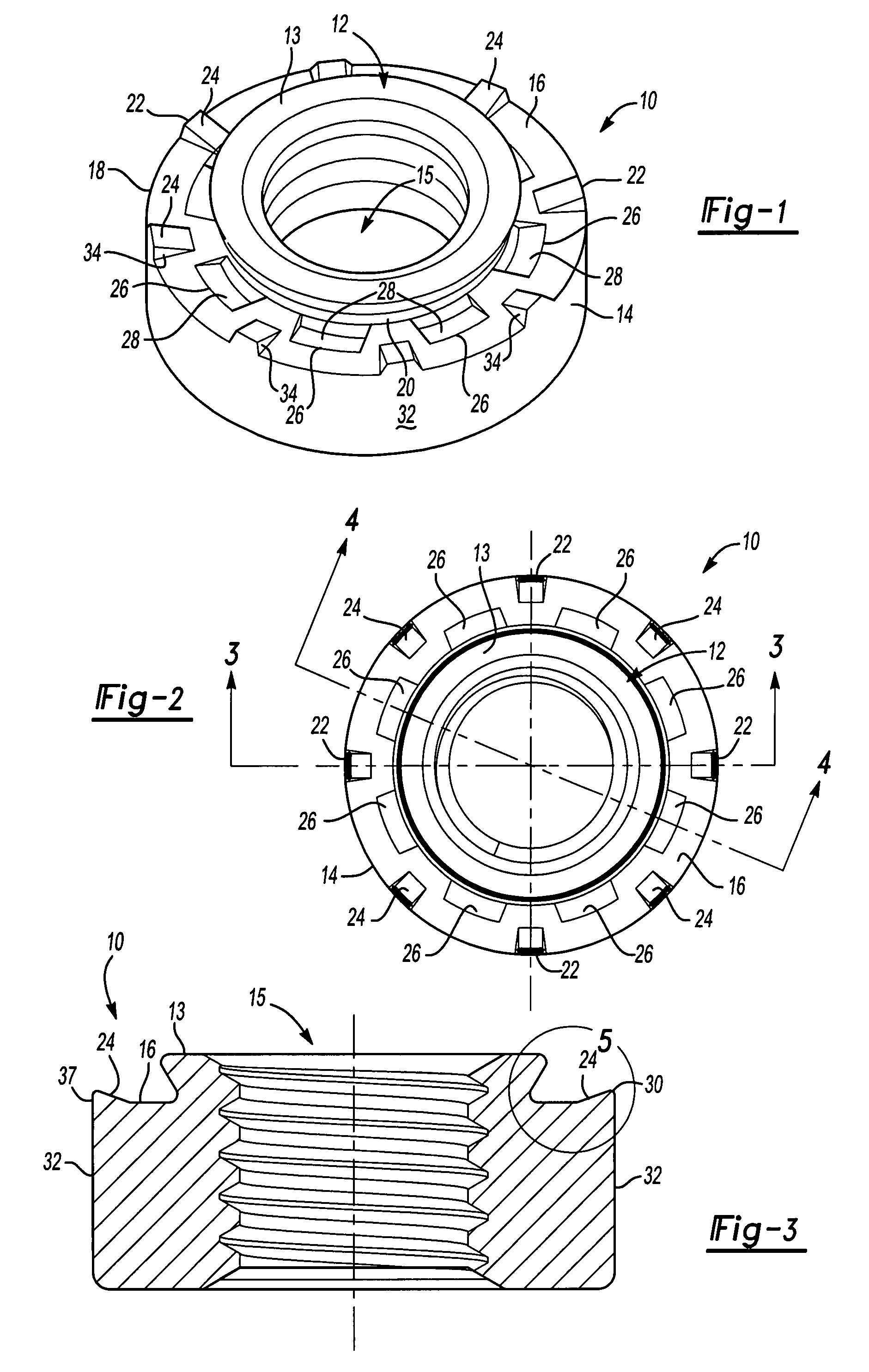

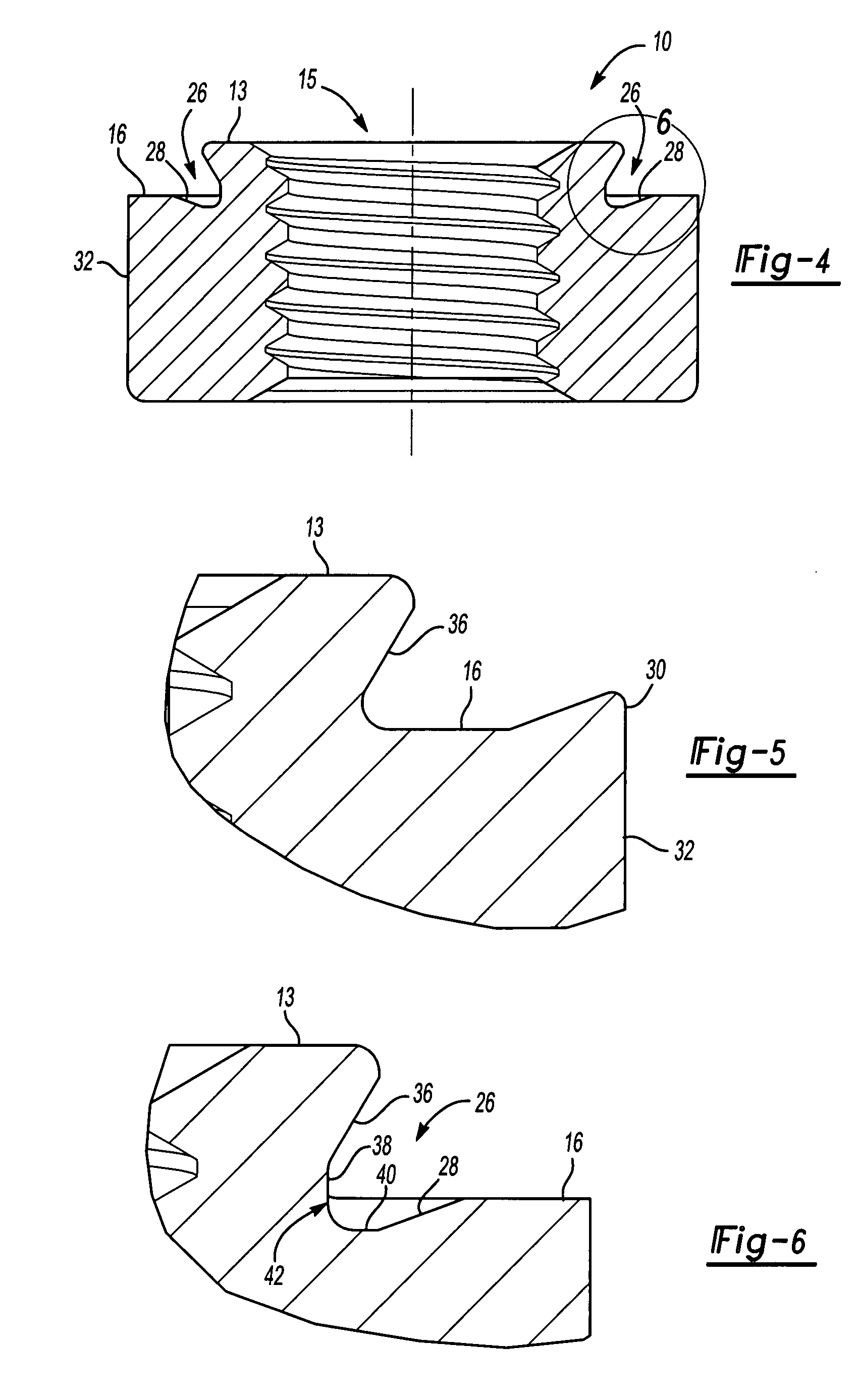

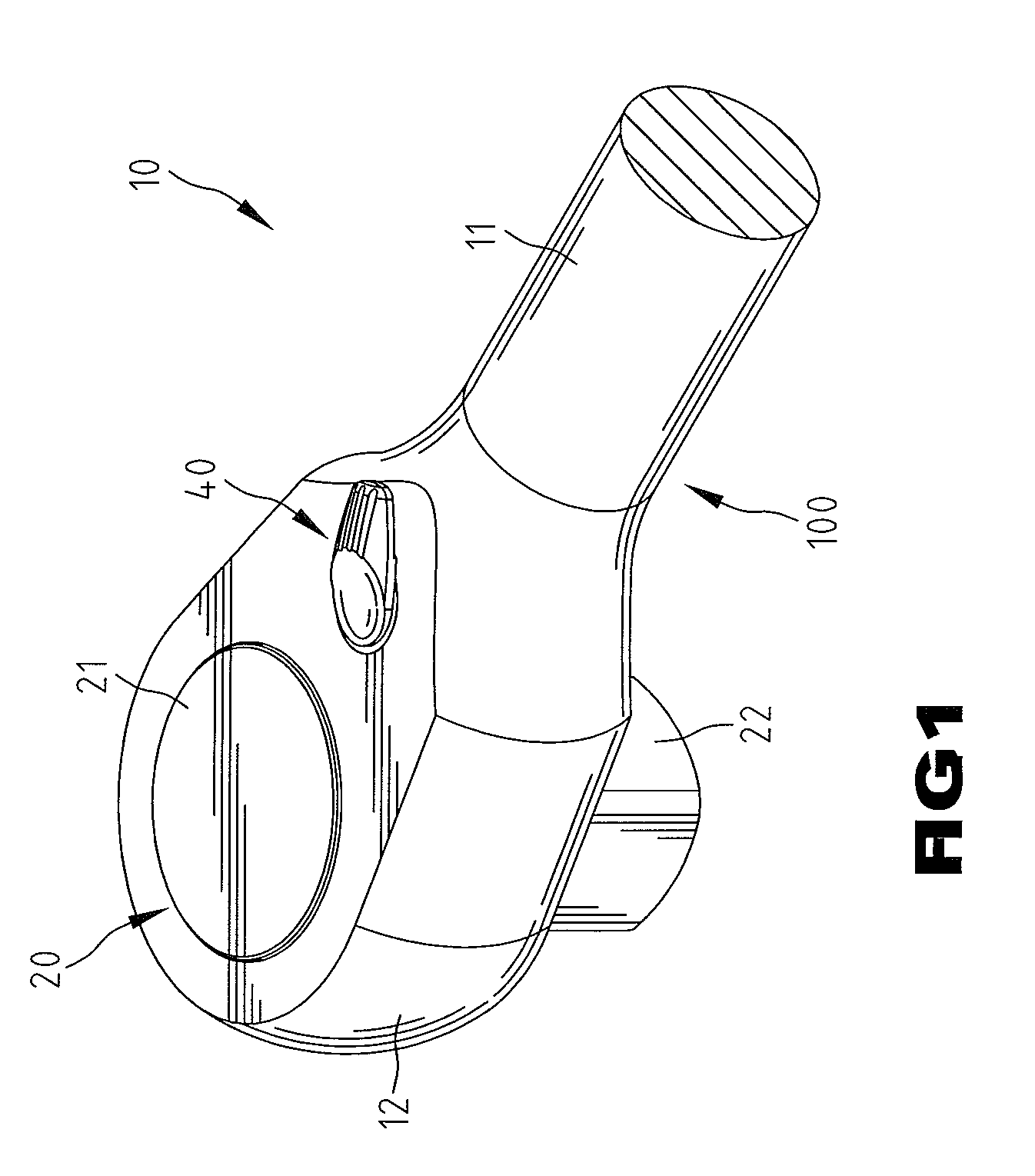

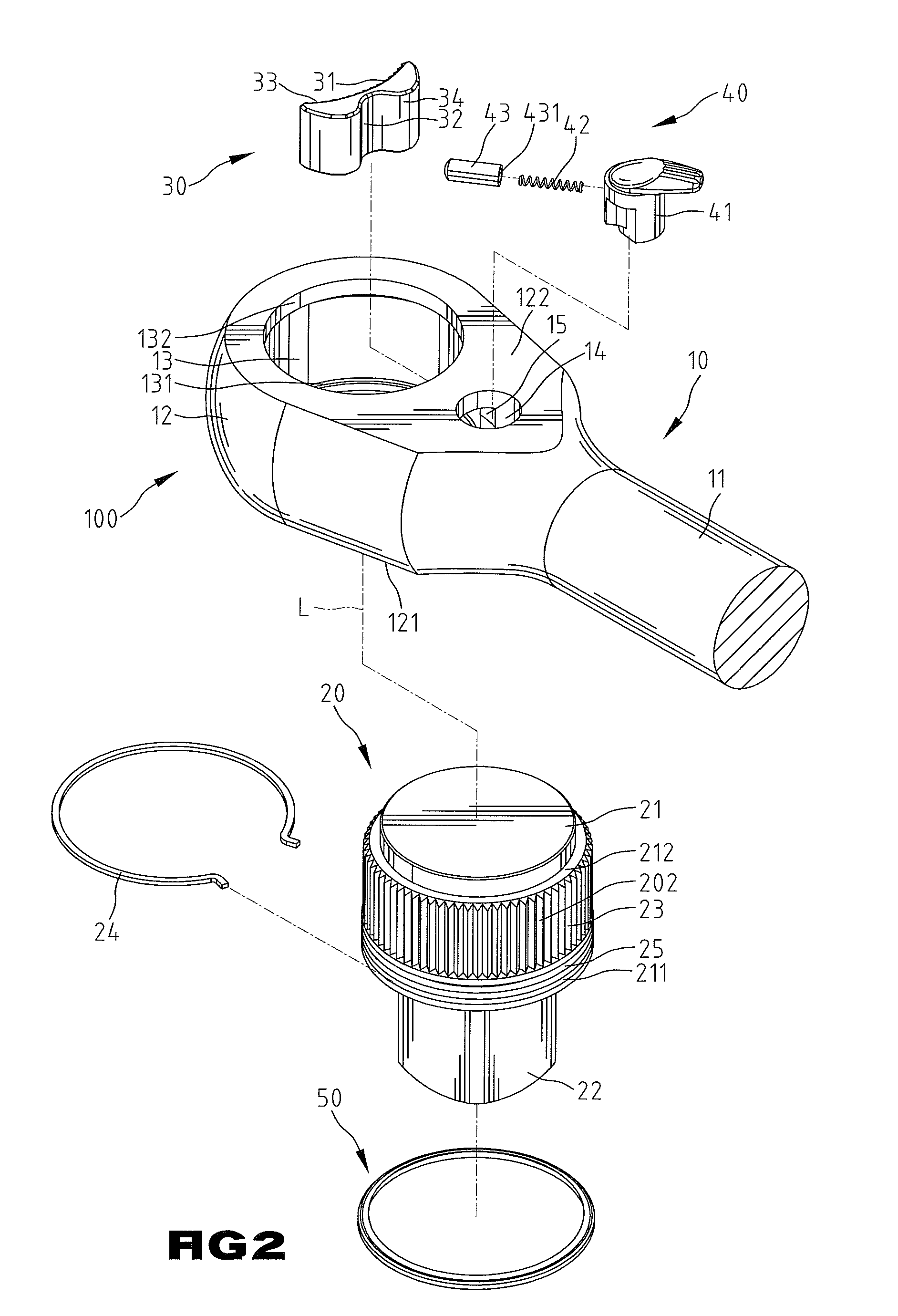

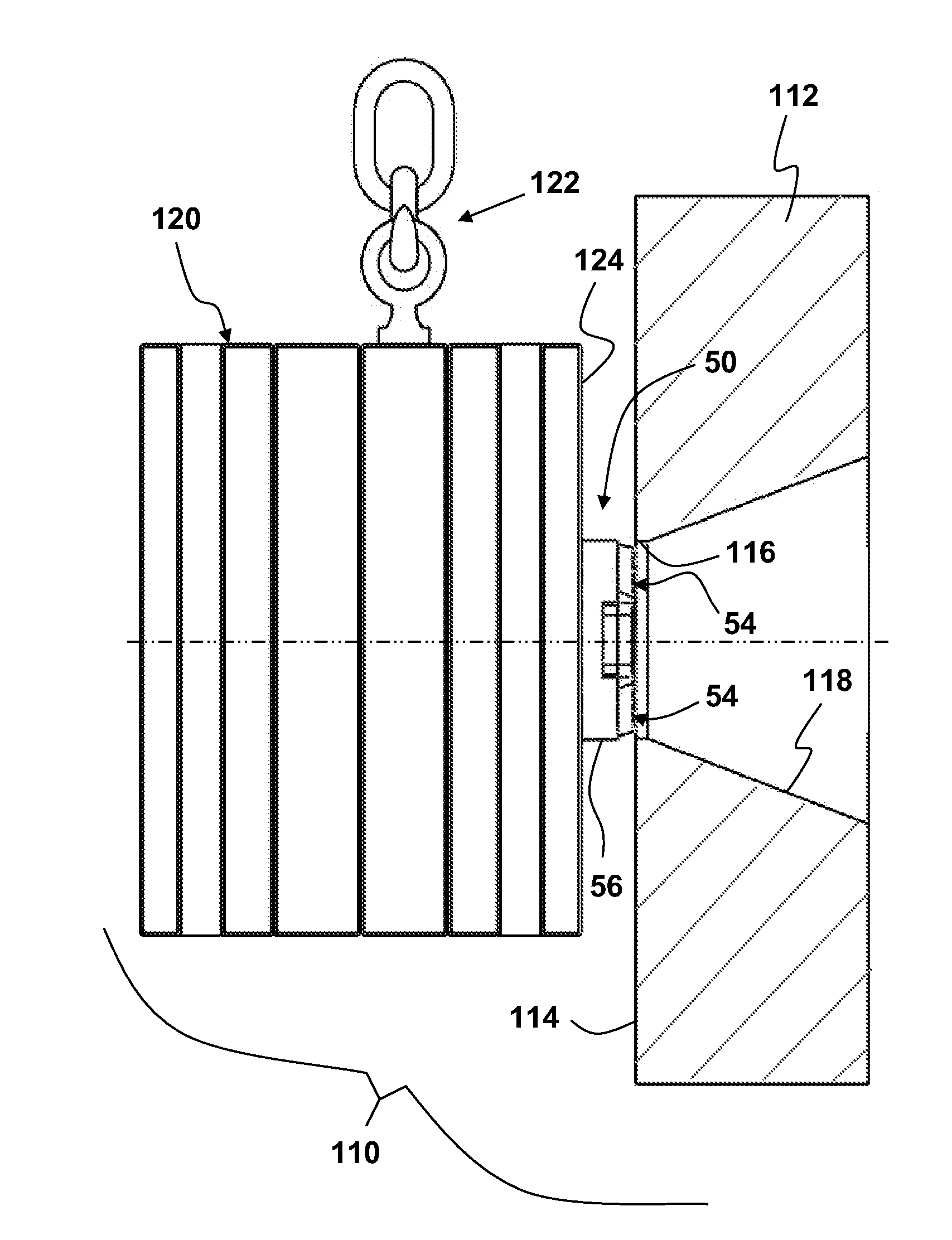

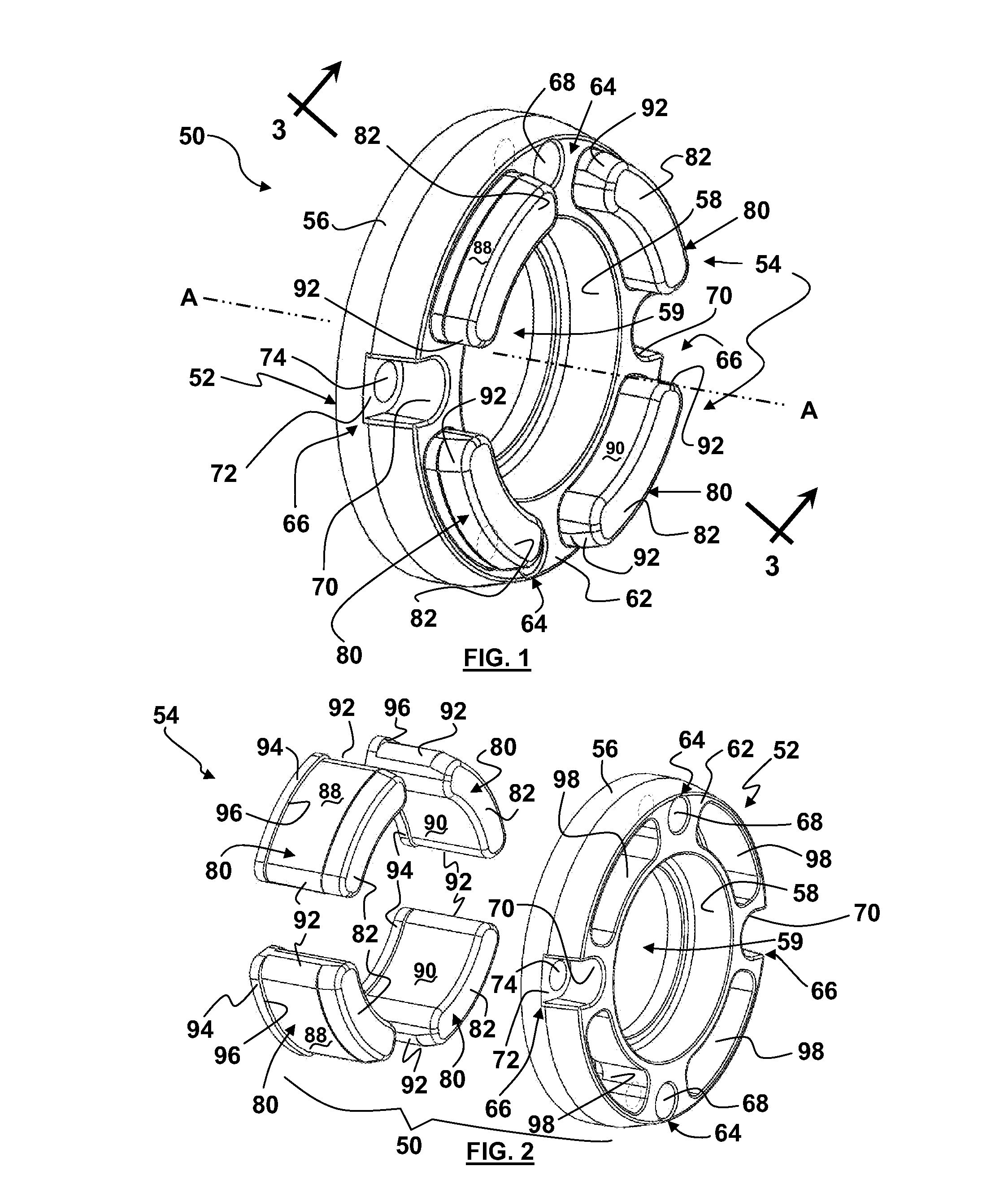

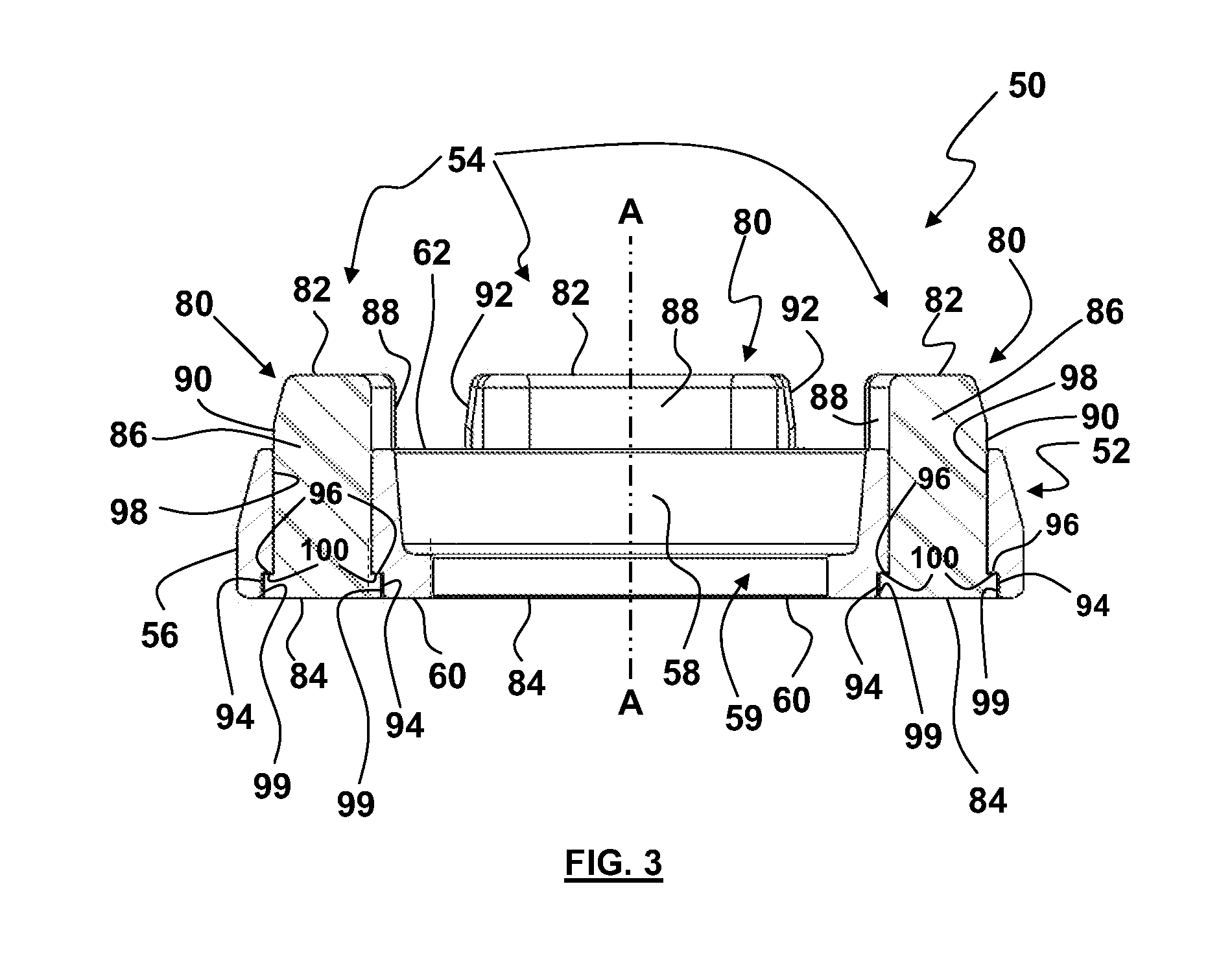

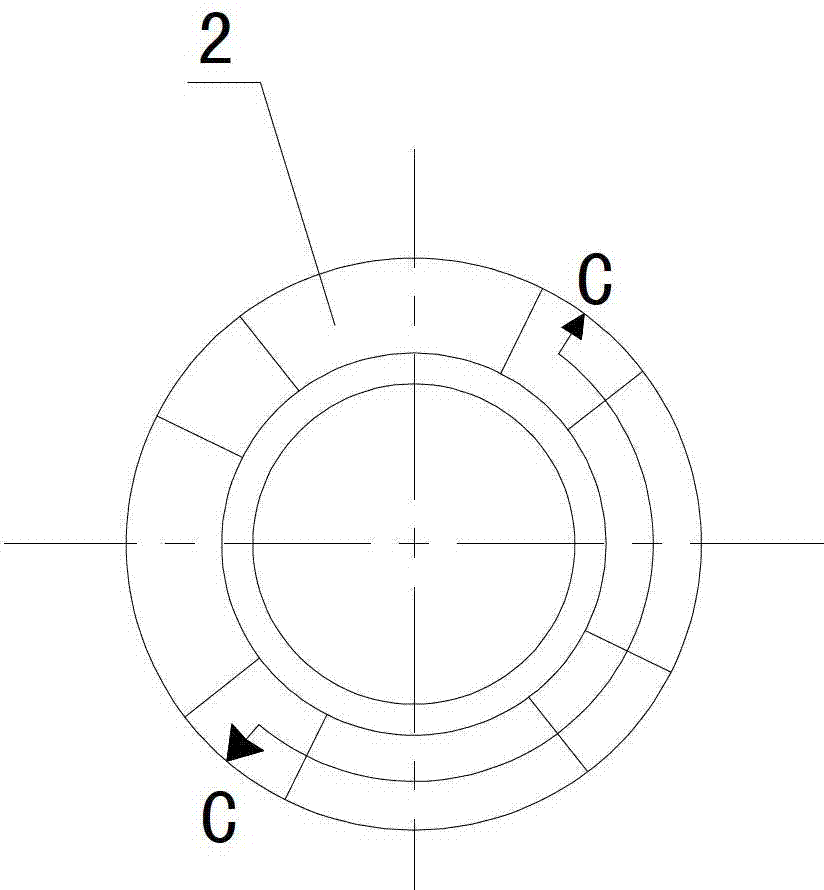

Locating Ring and Method for Positioning Parts

A locating ring has a metal body with a ring shape and having a perimeter surface facing radially outward, a center axis defined by the body, a mounting face, and a locating face spaced from and facing opposite the mounting face along the axis. The locating ring has a guard connected to the body and made of a material that is softer than the metal body. The guard is sized to be radially within the perimeter wall and to project axially beyond the locating face.

Owner:CERNILIA ANTHONY

Adjustable/non-adjustable precision optical mounts

A highly precision, super stable, structure compact and fully lockable ball joint mechanism optical mounts are presented. Both stationary plate and movable plate have a partial-spherical hole or conical hole. Facing spacing aligns the bases of the partial-spherical holes or conical holes; a space adjustable cavity is formed. An external-spherical shape optical element carrier plate fits and mates in the space adjustable combined cavity forms a ball joint mechanism, or an external-column circumference and edges chamfered optical element carrier plate fits and mates in the space adjustable combined internal-spherical shaped cavity forms an angle tilt-able and around axis swivel-able joint pair mechanism. A removable tooling for exporting a tilting and rotating movement to the optical element carrier plate are presented. Locking ring pushes the movable plate to adjust the combined cavity and locking the optical element carrier plate and to lock optical element that is carried thereby.

Owner:WANG XIWEN

Self-watering type household miniature spring onion and garlic garden

InactiveCN109089625AAvoid wastingLight in massSelf-acting watering devicesReceptacle cultivationWater storageEngineering

The invention discloses a self-watering type household miniature spring onion and garlic garden which comprises a bottle-shaped jar. An upper bottle jar for planting spring onion sprouts and a lower bottle jar for planting garlic sprouts are fastened with each other to form the bottle-shaped jar; a ventilation orifice is formed in the top of the upper bottle jar, an outer through hole is formed inan upper jar bottom, and the upper jar bottom is provided with an isolation hollow column and a connecting flat ring connected with the lower bottle jar; the lower bottle jar is divided into a cultivation region and a water storage region by a drainage partition plate, and a capillary pore water penetration layer is arranged on the inner wall of the lower bottle jar; a water feed device with an automatic water feed function is arranged in the water storage region; planting holes are formed in the wall of the bottle-shaped jar. The self-watering type household miniature spring onion and garlicgarden has the advantages that multi-dimensional structures can be formed by double-layer stereoscopic spaces and an inner leakage isolation jar arranged inside the lower bottle jar, and accordinglythe self-watering type household miniature spring onion and garlic garden is scientific, compact and novel in integral structure and ingenious in conception; a water adding valve of the water feed device can be opened and closed under the control of the water level, and accordingly technical effects of automatically watering the spring onion sprouts and the garlic sprouts and feeding and supplementing water for the water storage region can be realized; good effects of preserving moisture in soil can be realized; vertical-face spaces can be ingeniously utilized for planting the spring onion sprouts and the garlic sprouts which are easy to grow, accordingly, the planting areas can be greatly increased, and the self-watering type household miniature spring onion and garlic garden is applicable to home use.

Owner:FOSHAN MIAOTU TECH CO LTD

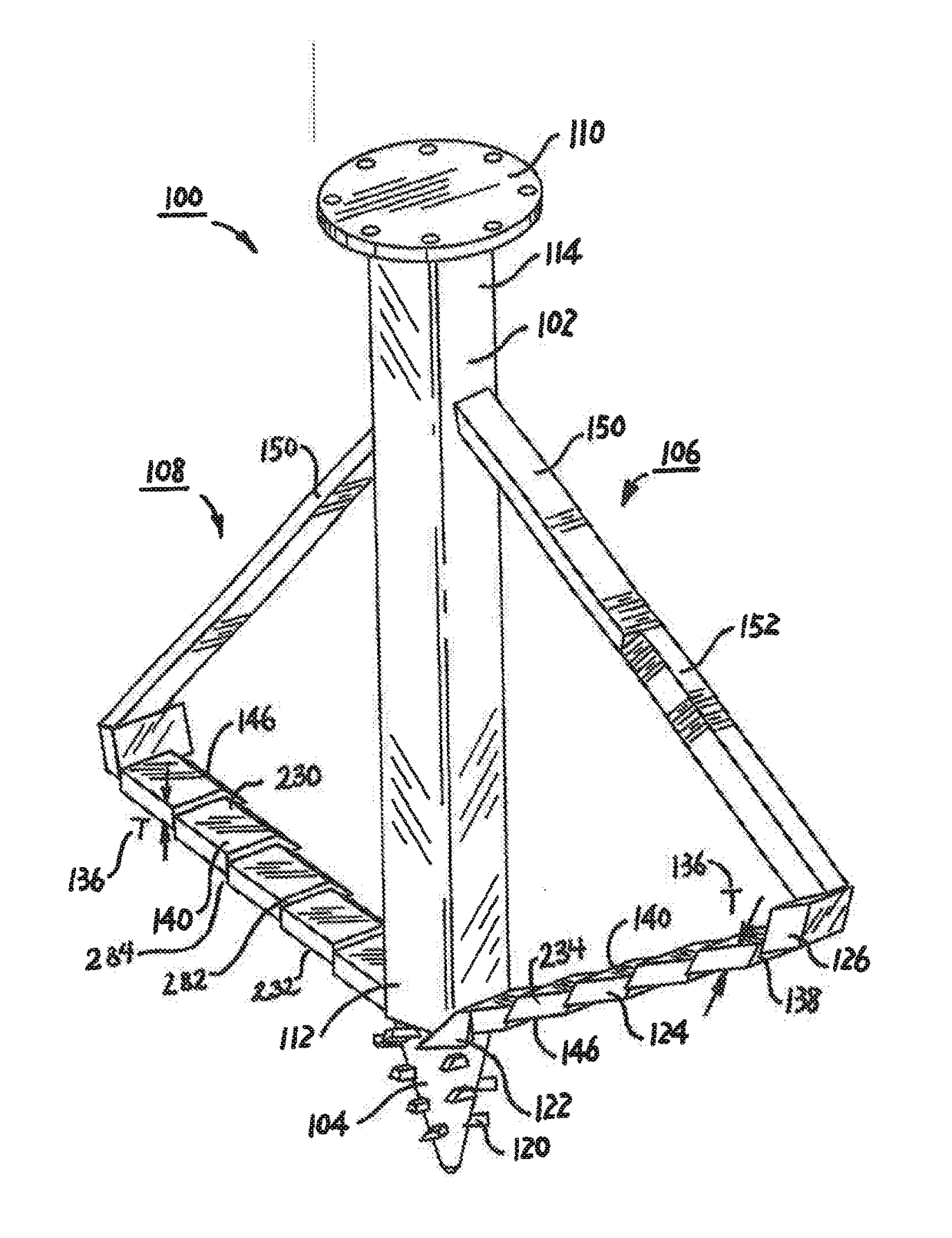

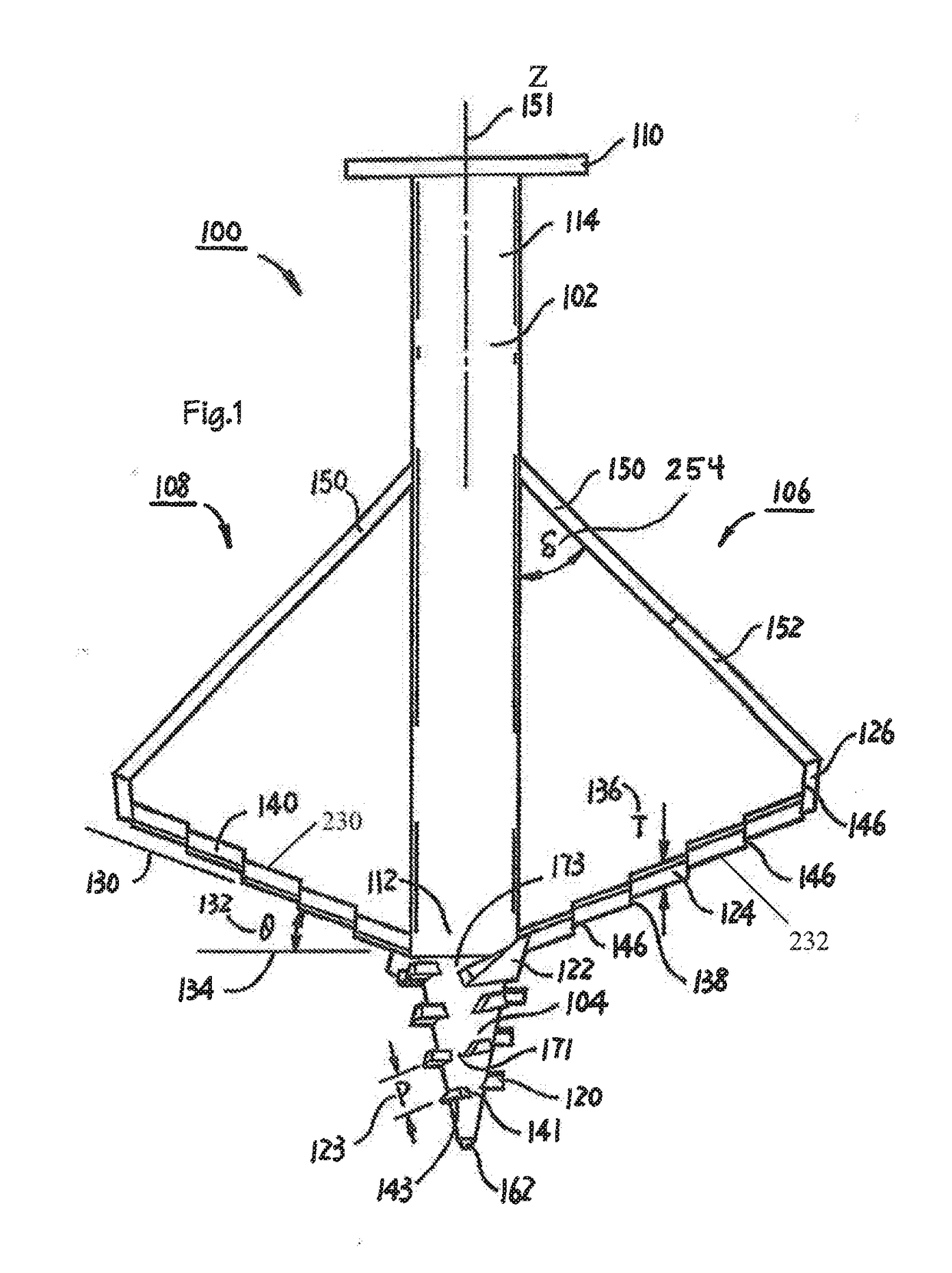

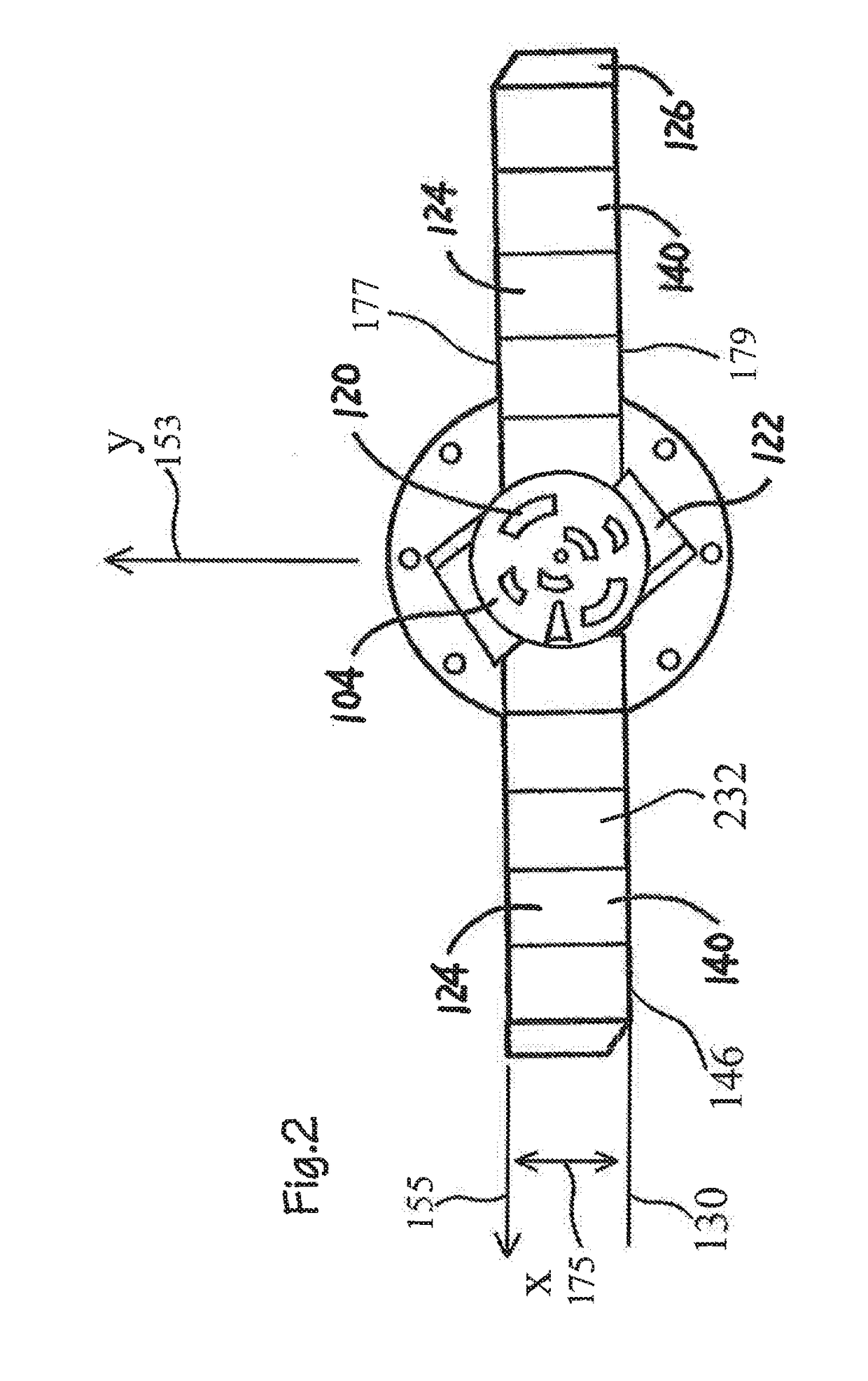

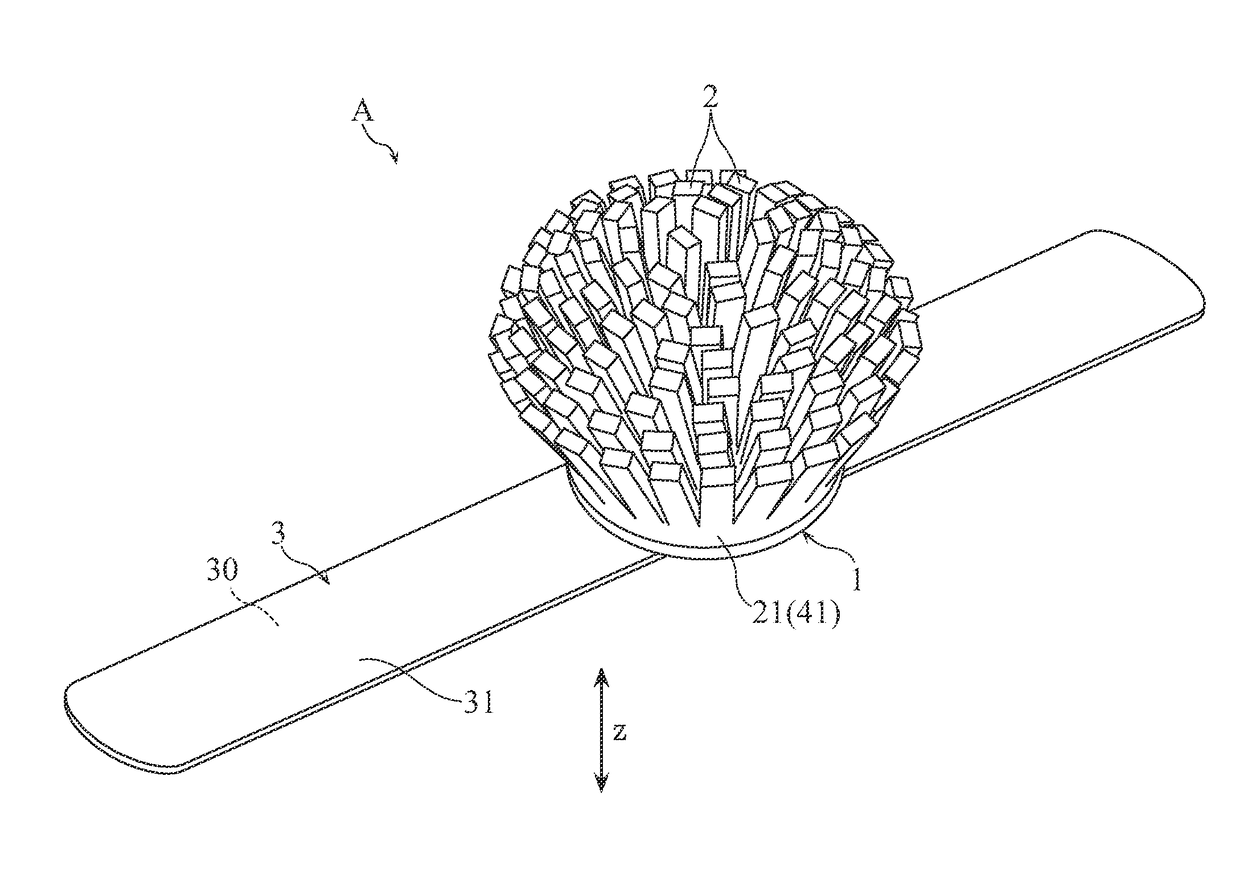

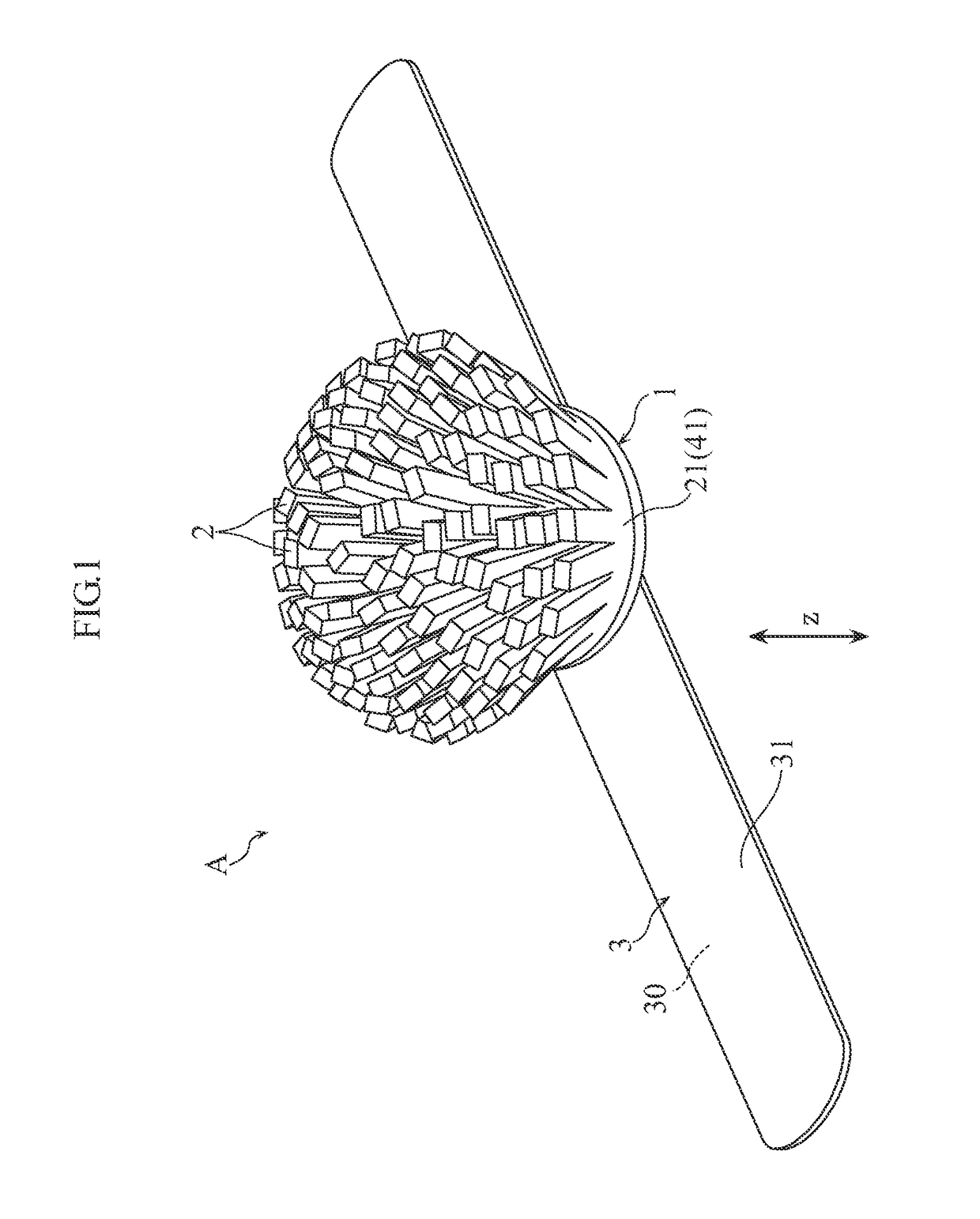

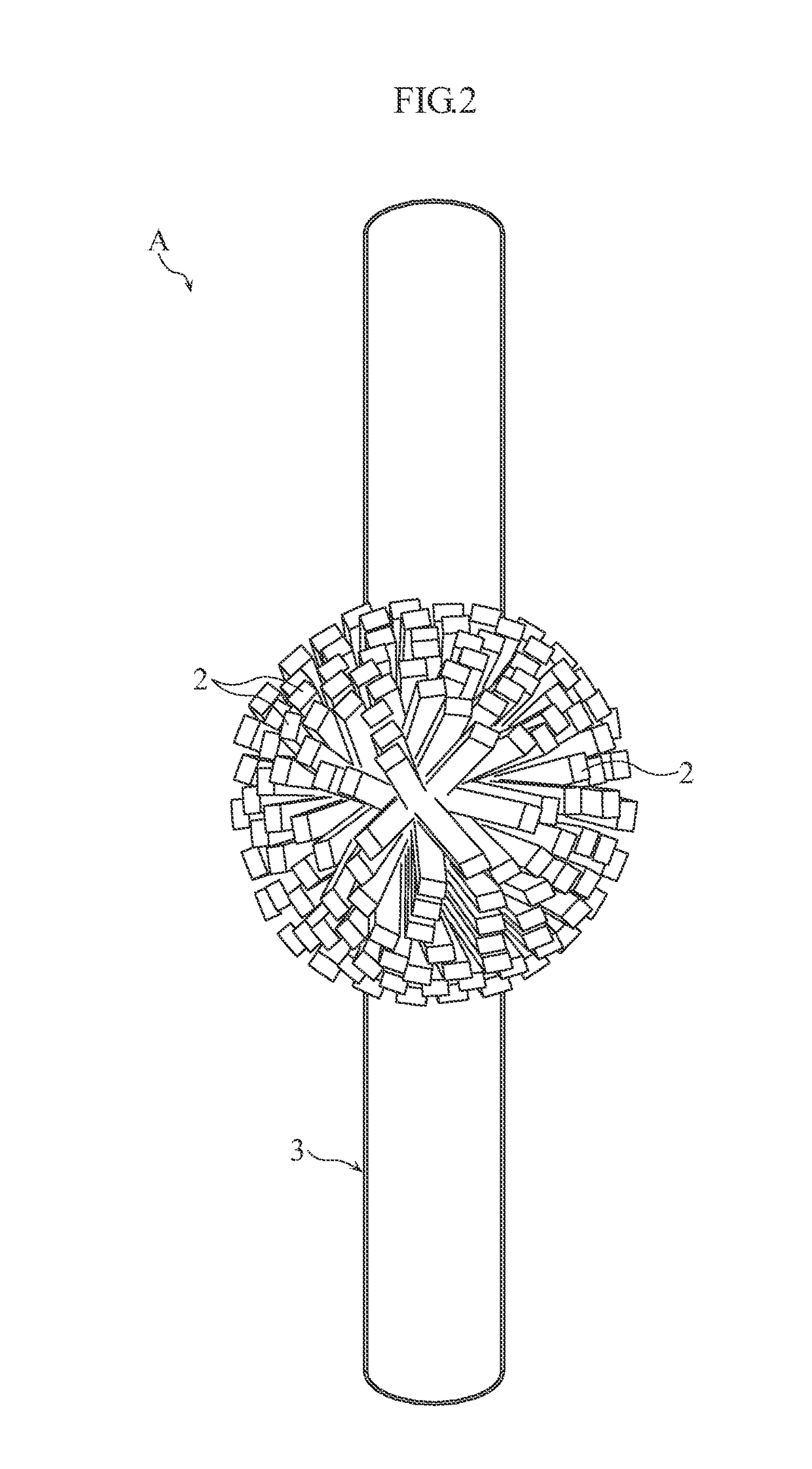

Stump auger

The present concept is a stump auger used for cutting and destroying a tree stumps, the stump auger includes a main shaft connected at a top end to a drive mechanism for turning the shaft about a vertical axis, wherein the main shaft is connected at a bottom end to a cone top such that the cone is part of the main shaft. The stump auger cone includes a spiral thread extending about the outer surface of the cone from the cone top to the cone bottom. The stump auger further includes at least two boring bars connected to the main shaft, each boring bar includes at least two third blades which include a blade edge on a front face for shaving, cutting and chipping the tree stump as the stump auger is rotated about the vertical axis and penetrates the tree stump. Each third blade includes a planar bottom surface spaced from a planar top surface, an inner face spaced from an outer face, the front face spaced from a back face, and wherein the outer face of the first third blade abuts at least partially with the inner face of the second third blade such that the bottom surface of the first third blade lies along a first plane A and the bottom surface of the second third blade lies along a second plane B such that plane B is a distance D vertically higher along the vertical z-axis, and wherein successive third blades lie along successive planes each higher along the vertical z-axis. The outer face and inner face of each third blade are rigidly connected together.

Owner:LOWE GARETH

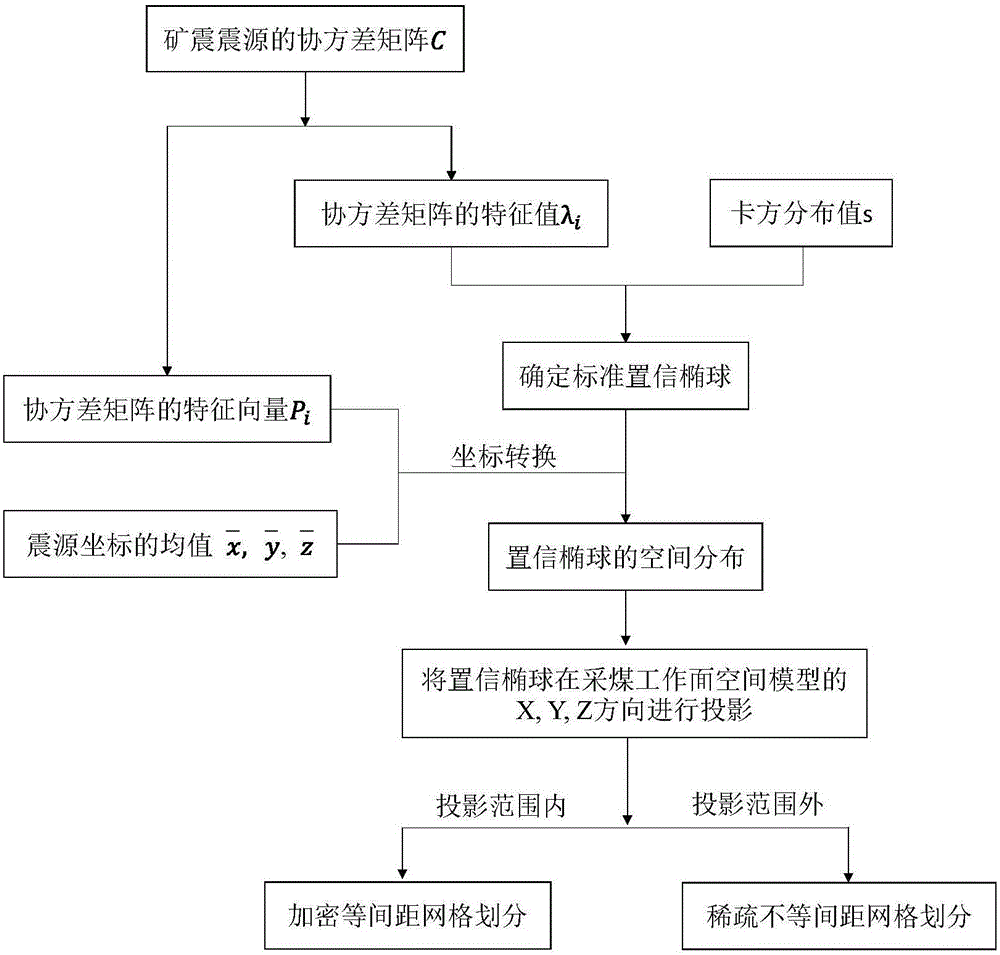

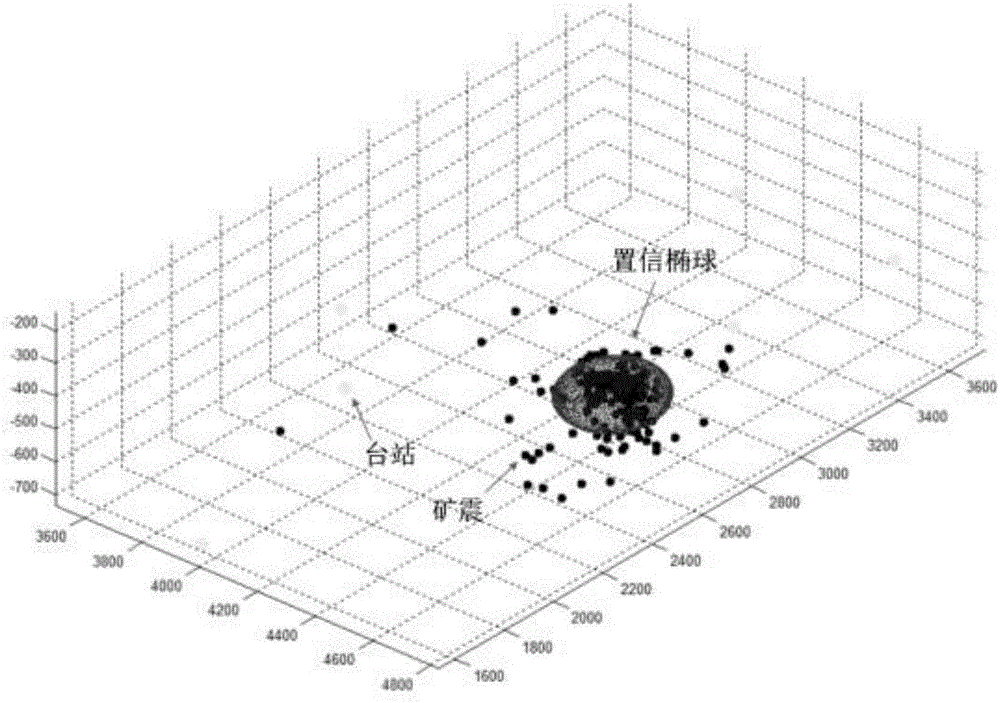

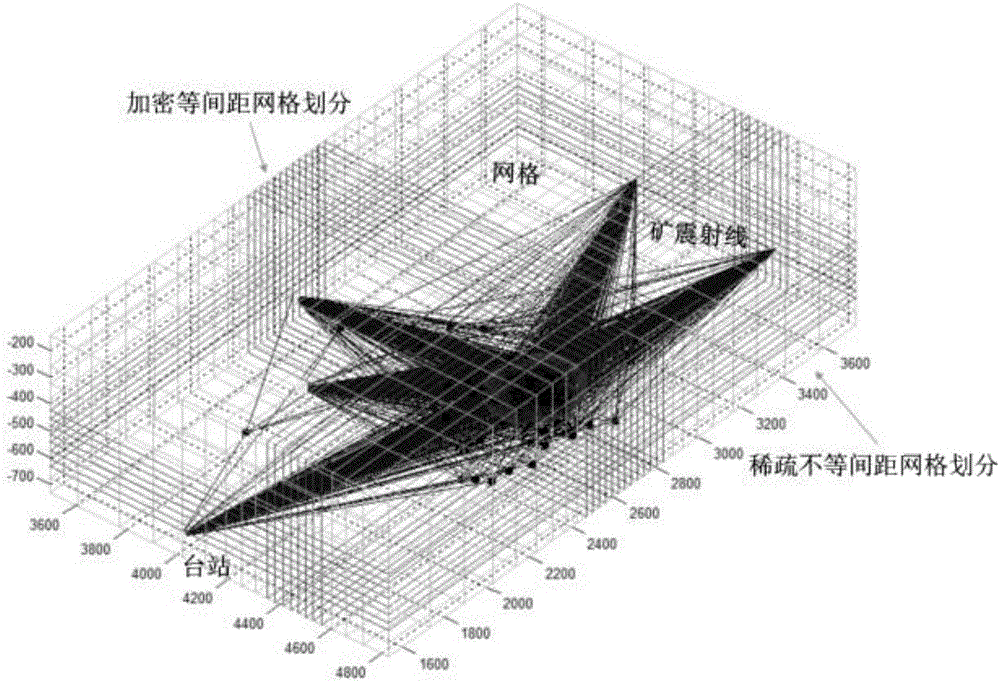

Adaptive unequal spacing grid division method capable of improving CT inversion resolution and efficiency

ActiveCN106646607AReduce in quantityGuaranteed inversion resolutionSeismic signal processingGeomorphologyImage resolution

The invention discloses an adaptive unequal spacing grid division method capable of improving CT inversion resolution and efficiency, and belongs to the coal mining and coal mine safety technical field; the method comprises the following steps: firstly using a passive CT inversion station to collect mine quake signals, using the mine quake signal to calculate a covariance matrix C of mine quake seismic source distribution in a calculated area, and determining a standard confidence ellipsoid according to the covariance matrix C; converting coordinates of the standard confidence ellipsoid so as to obtain real space distribution of the confidence ellipsoid; using the real space distribution of the confidence ellipsoid to carry out model imaging, and projecting a confidence ellipsoid image in a coal face space model, wherein encrypted equal spacing grid division is employed on the coal face space model within the projection scope, and sparse unequal spacing grid division is employed outside the projection scope. The method can ensure the inversion resolution in a key monitoring area, and can greatly reduce the grid number; the method is simple, can improve the inversion precision in the area, can reduce the calculation complexity, and can improve the calculation efficiency.

Owner:CHINA UNIV OF MINING & TECH

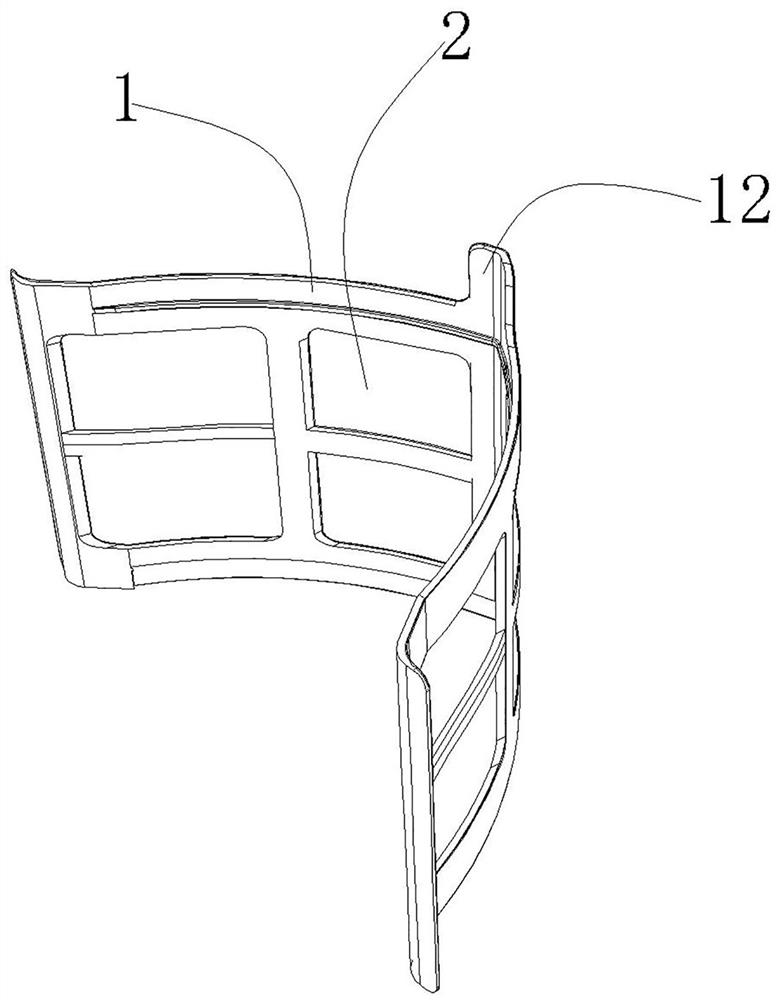

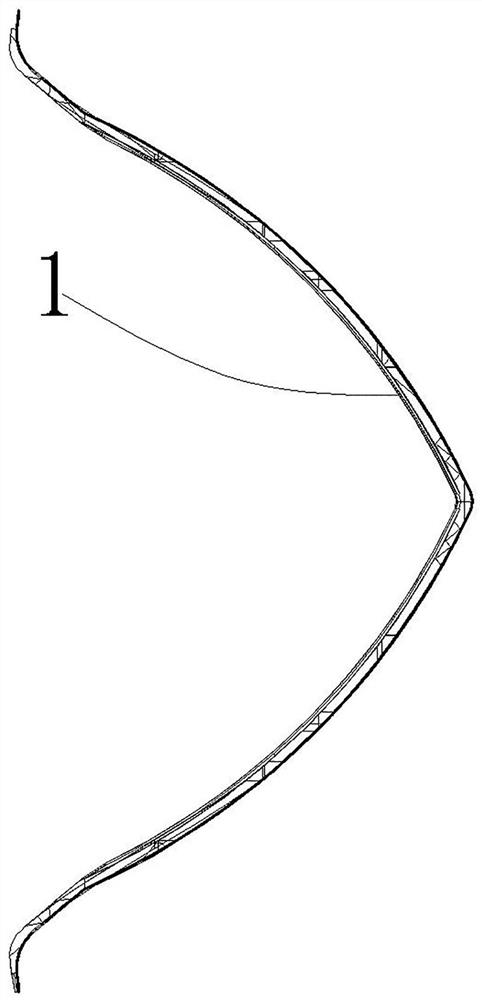

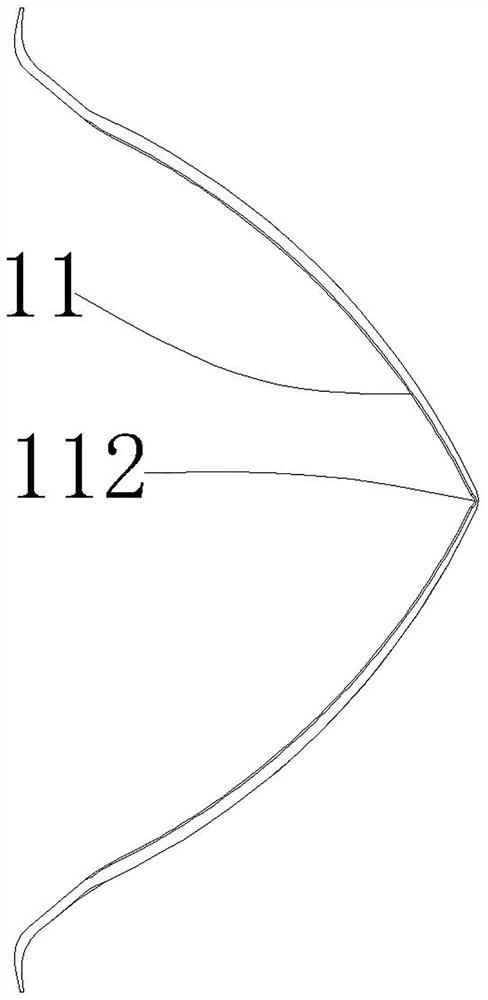

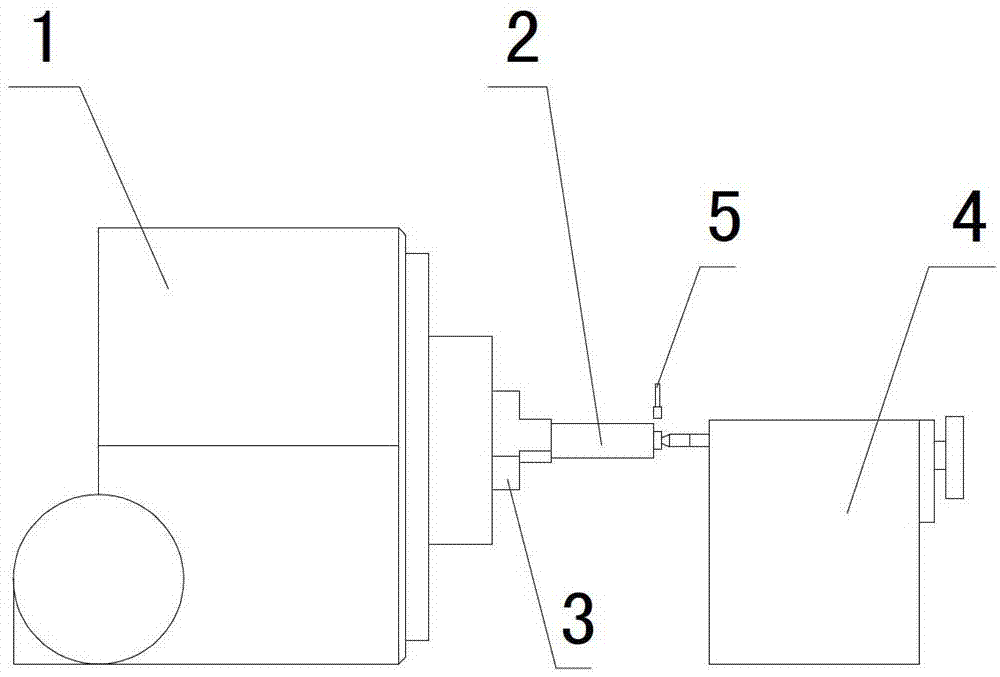

Support and comfortable non-surface-adhering mask

InactiveCN111904060ASolve the real problemProtective garmentStructural engineeringMechanical engineering

The utility model relates to a support and a comfortable non-surface-adhering mask adopting the support, a through hole is formed in the middle of the support, the support is composed of one bent or two folded support bodies, and the middle of the support supports a face space. The mask further comprises a mask face, hanging lugs are arranged on the two sides of the mask face, and the support is fixed to the inner side of the mask face. The problem of surface adhering of a traditional mask is solved; the problems that a support type mask is large in size, inconvenient to transport and high incost and wastes are solved.

Owner:NINGBO HEPINGGE ORAL MEDICAL EQUIP

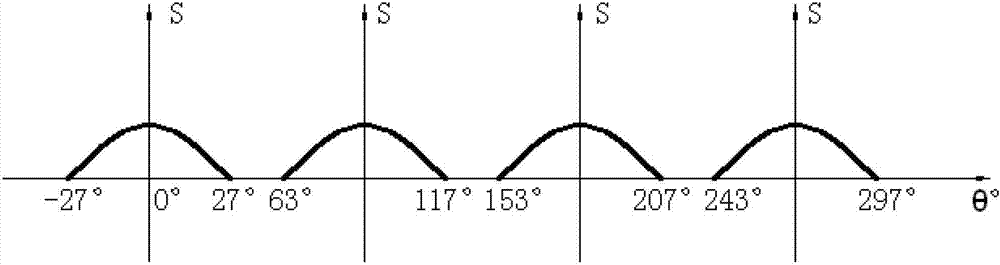

Grinding method of numerical control coordinate of cam

InactiveCN103111928AImprove product qualityHigh dimensional accuracyBelt grinding machinesNumerical controlCam

The invention discloses a grinding method of a numerical control coordinate of a cam. The grinding method of the numerical control coordinate of the cam comprises the following steps: projecting a space curve of the cam on a horizontal coordinate, defining a new XA machine coordinate system, building the relationship of a Y-coordinate and an A-coordinate, confirming a new processing point coordinate (S, theta), and utilizing the linkage of an X-axis and an A-axis of the new XA machine coordinate system to achieve the processing of the space curved face of the cam. The grinding method of the numerical control coordinate of the cam has the advantages of using a double-axis semi-numerical control machine tool to project the space curve on the horizontal coordinate, finding out the relationship between a Y-coordinate value and an A-coordinate value, utilizing the method that the linkage of the X-axis and the A-axis achieves the processing of an end face space curved face, acquiring a good size and shape precision, improving producing efficiency and reducing labor intensity and producing cost, the quality of part products is stable, sizes and shapes meet the design requirements of products, and the grinding method of the numerical control coordinate of the cam can be widely applied to the processing of faces of part series.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

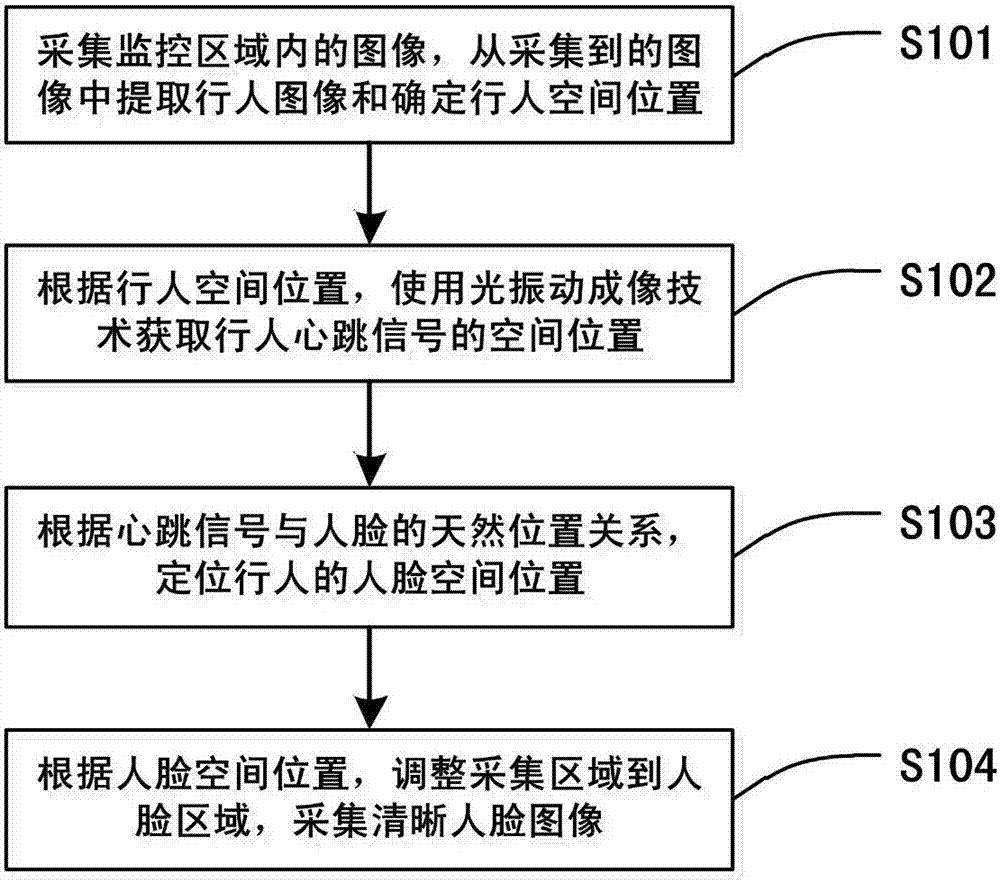

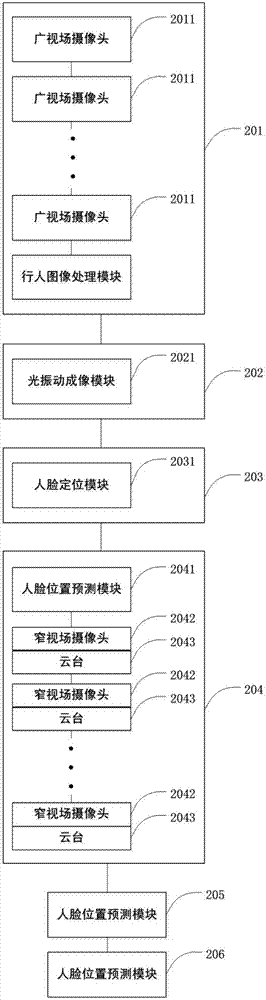

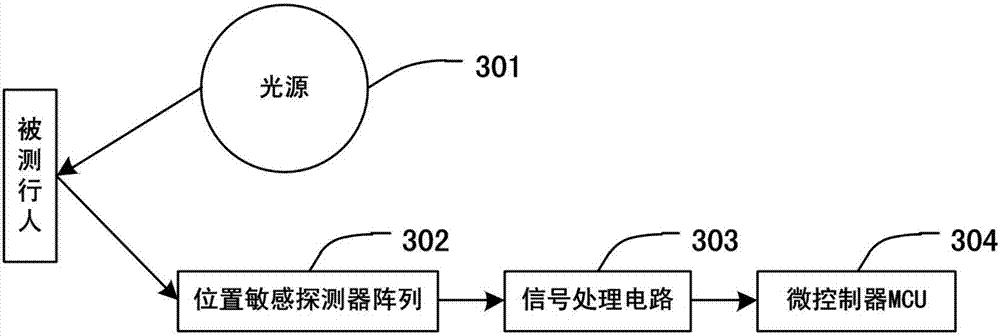

Heartbeat signal-based remote face recognition method, apparatus and system

ActiveCN106897678ASimple calculationShort timeCharacter and pattern recognitionComputer graphics (images)Natural position

The present invention provides a heartbeat signal-based remote face recognition method, a heartbeat signal-based remote face recognition apparatus and a system. The method includes the following steps that: an image in a monitoring area is acquired, a pedestrian image is extracted from the acquired image, and a pedestrian space position is determined from the acquired image; an optical vibration imaging technology is utilized to obtain the space position of pedestrian heartbeat signals according to the pedestrian space position; the face space position of a pedestrian is positioned according to the natural position relation of heartbeat signals and a face; and an acquired area is adjusted to a face area according to the face space position, and a clear face image can be acquired. According to the heartbeat signal-based remote face recognition method of the invention, the space position of the heartbeat signals is utilized, so that the space position of the face can be calculated fast, the face area can be positioned fast, and the high-resolution face image can be obtained, and the recognition rate and practicability of a remote face recognition system can be improved.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

Sewing tool holder

A sewing tool holder includes a base and a plurality of of projections. The base has an obverse face and a reverse face spaced from each other in a thickness direction of the base. The plurality of projections are supported on the obverse face of the base via a common connecting portion attached to the base. Each of the plurality of projections has an upper or front end and a root or lower end that is connected to the common connecting portion.

Owner:CLOVER MFG CO LTD

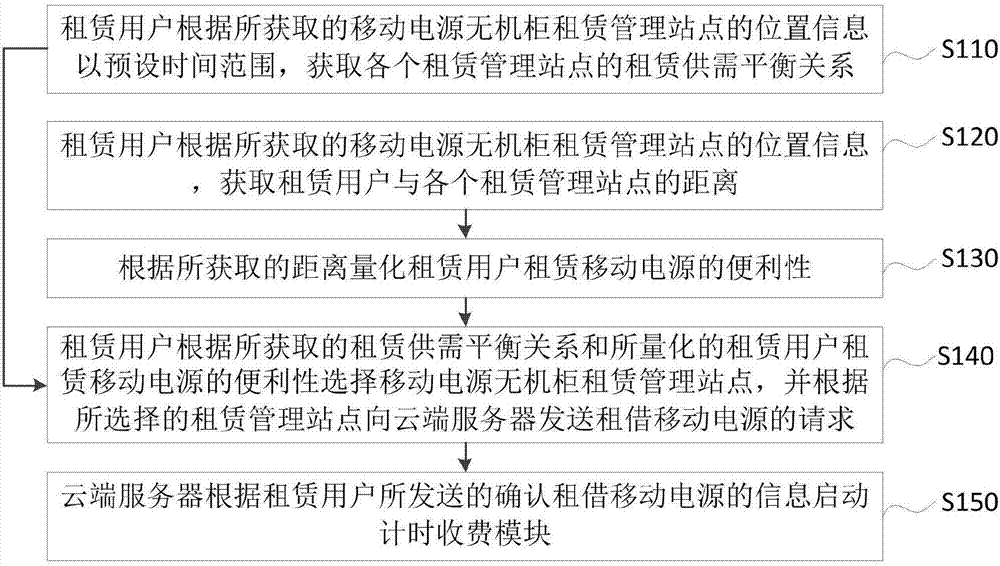

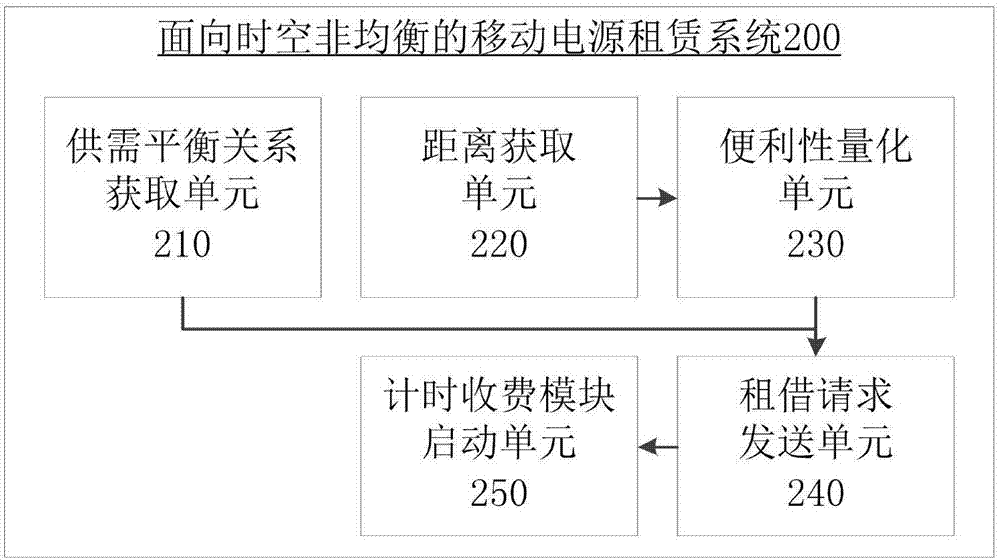

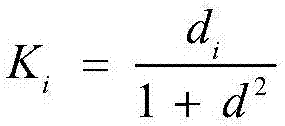

Mobile power supply leasing method and system facing space-time non-equalization

ActiveCN107045756AImprove convenienceOptimize layoutForecastingApparatus for meter-controlled dispensingEqualizationTime space

The invention provides a mobile power supply leasing method and system facing space-time non-equalization; the method comprises the following steps: obtaining mobile power supply cabinet-free lease management station positional information; obtaining a lease supply and demand balance relation and distances between a lease client and each lease management station according to the obtained position information; quantifying the convenience of the lease client renting a mobile power supply according to obtained distances; selecting a mobile power supply cabinet-free lease management station according to the lease supply and demand balance relation and the quantified convenience; sending a mobile power supply renting request to a cloud server according to the selected lease management station; allowing the cloud server to start a time-based billing module according to mobile power supply renting confirm information sent by the lease client. The method and system can improve the lease experiences of users renting mobile power supply, can take corresponding encourage measures for lease management stations with sparse layout and poor convenience, thus optimizing the lease management station layout, and further improving conveniences of users renting mobile power supply.

Owner:重庆壹元电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com