Versatile tapeless drywall system

a tapeless, drywall technology, applied in the direction of covering/lining, building components, structural elements, etc., can solve the problems of silicosis and lung cancer of workers, coughing, phlegm production, and respiratory distress, and workers may also face an increased risk of silicosis and lung cancer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

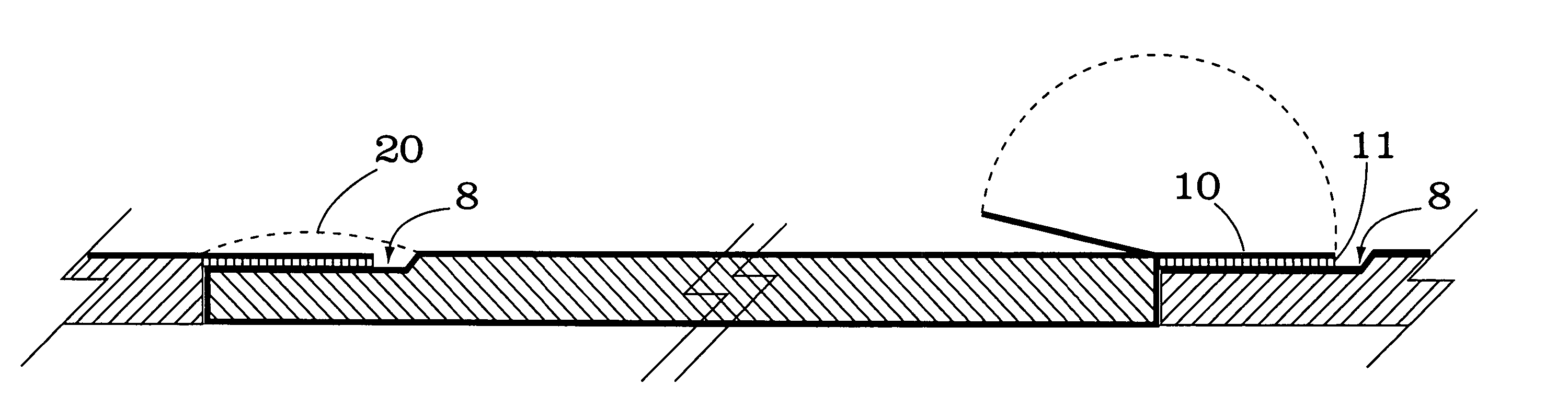

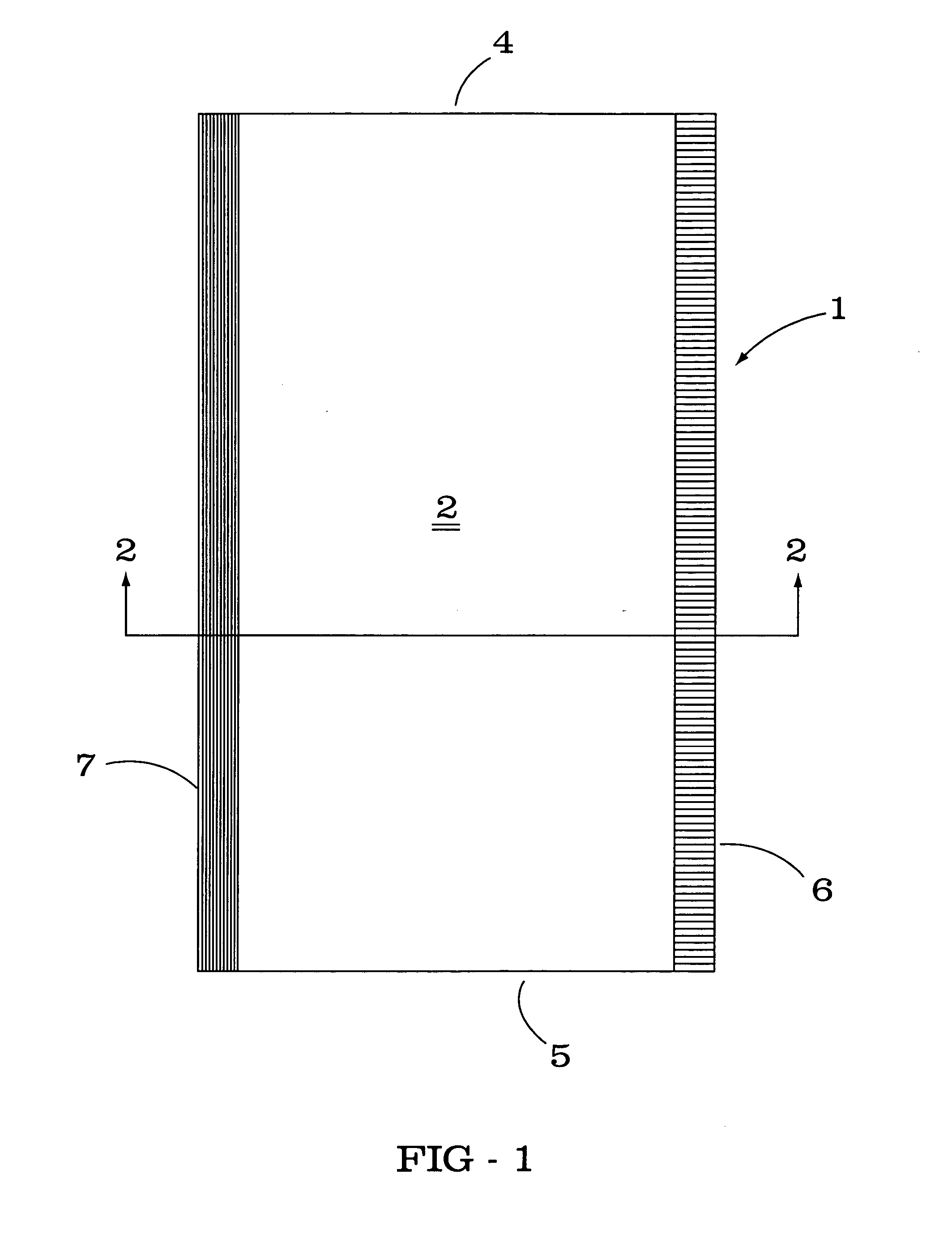

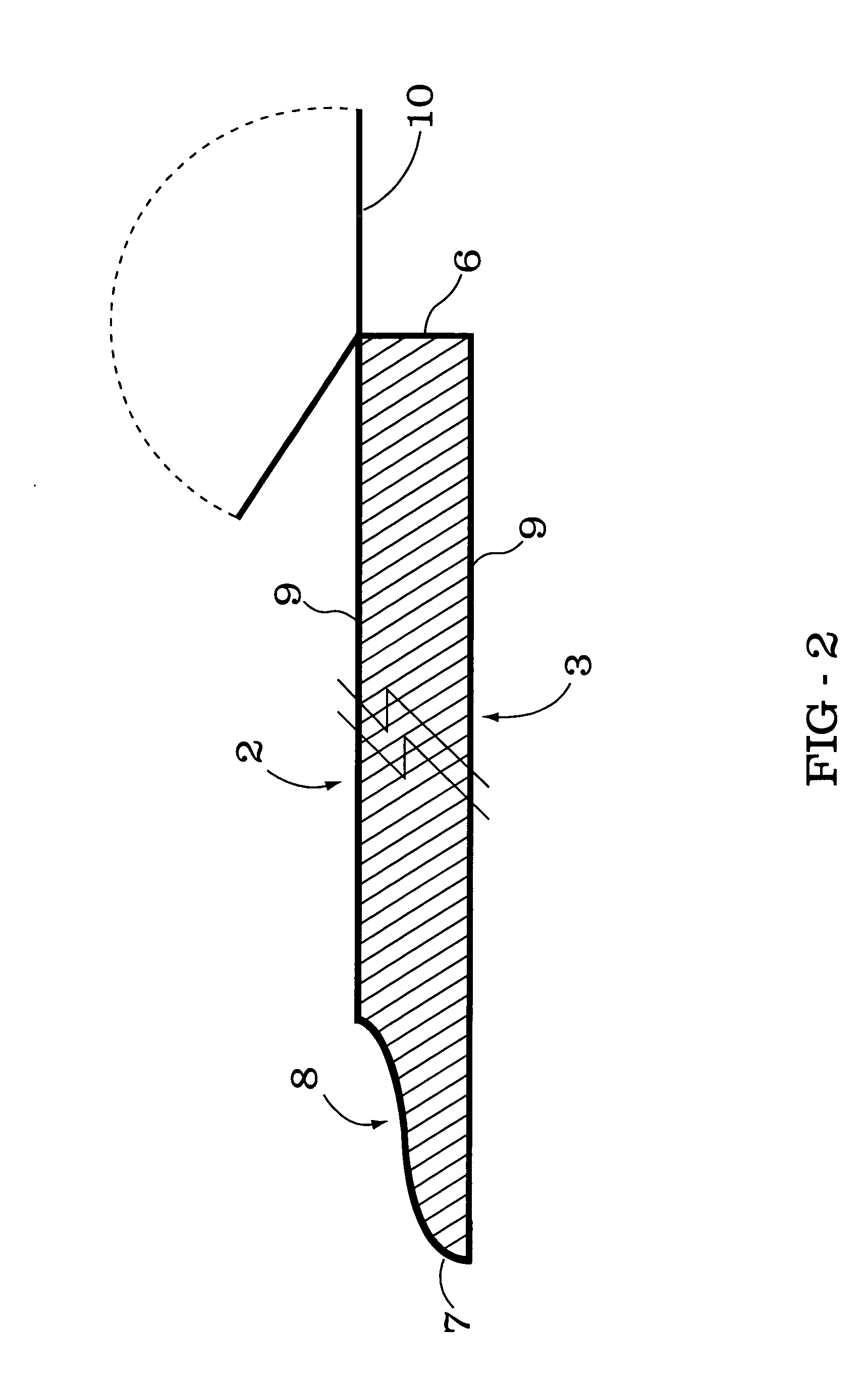

[0023] The versatile tapeless drywall system of the present invention uses a flap and taper system which eliminates the need for separately taping the drywall panels. The panels preferably would incorporate the flap into and make it an integral part of the drywall during its manufacturing. With reference to typical drywall, it would mean doing away with one of the two tapers and instead, extending the construction paper that covers the face of the drywall away from the opposing edge to form a flap. But, the flap could be placed on the drywall panels after they are formed. The flap extension would run the length of the panel and be about 1.75 inches wide on 4 foot by 8 foot panels. A person applying the drywall vertically would utilize the flap to join adjacent panels and for joining panels to for corners. For drywall panels which are hung horizontally, which can be 4 foot by 12 foot panels, a 2⅛″ flap would be employed.

[0024] The shape of the taper is not critical and so it could b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com