Grinding method of numerical control coordinate of cam

A grinding and cam technology, applied in the field of CNC coordinate grinding of cams, can solve the problems of poor curve smoothness and precision, high labor intensity and high processing cost, achieve good size and shape accuracy, improve production efficiency, The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

[0018] A numerically controlled coordinate grinding method for a cam, comprising the following steps:

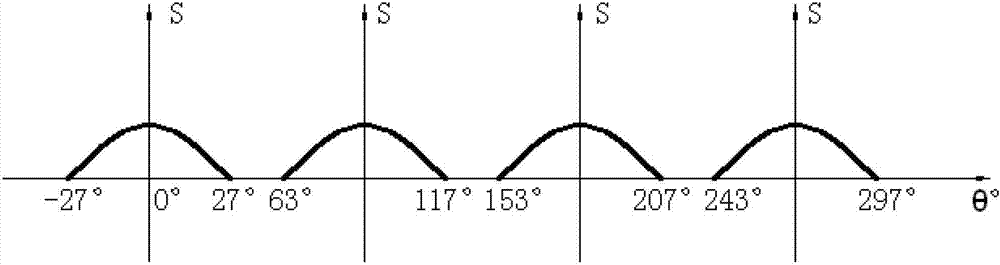

[0019] (1) Project the cam space curve to plane coordinates: Simplify the space profile curve of the cam into a plane curve, calculate the data of the plane coordinate system, obtain the plane coordinates (X, Y) of the cam processing point, and record the cam angle θ Relationship with displacement S;

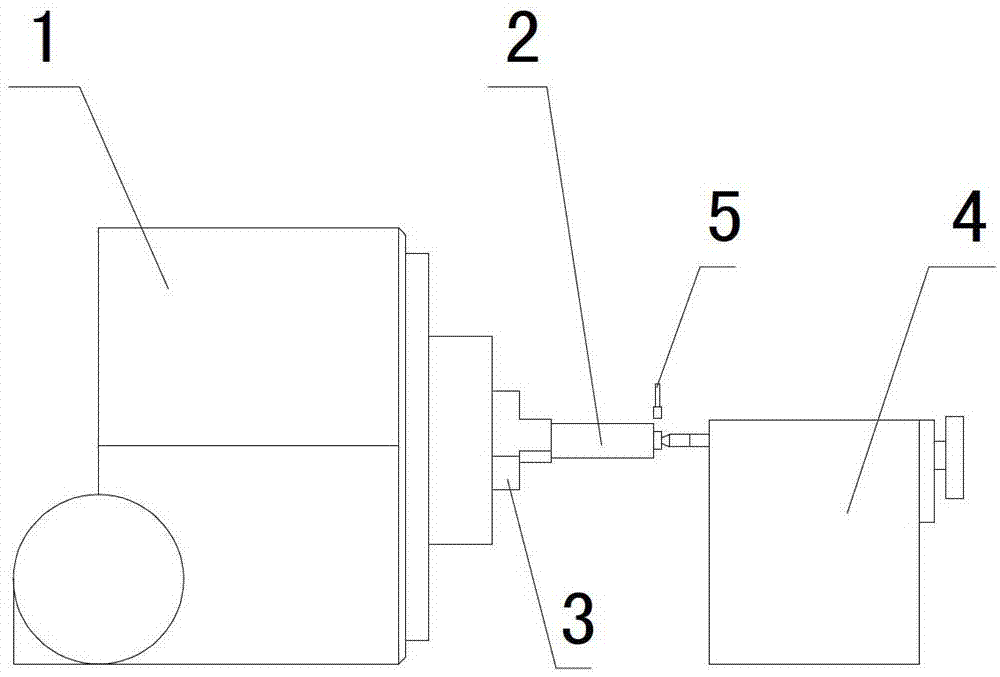

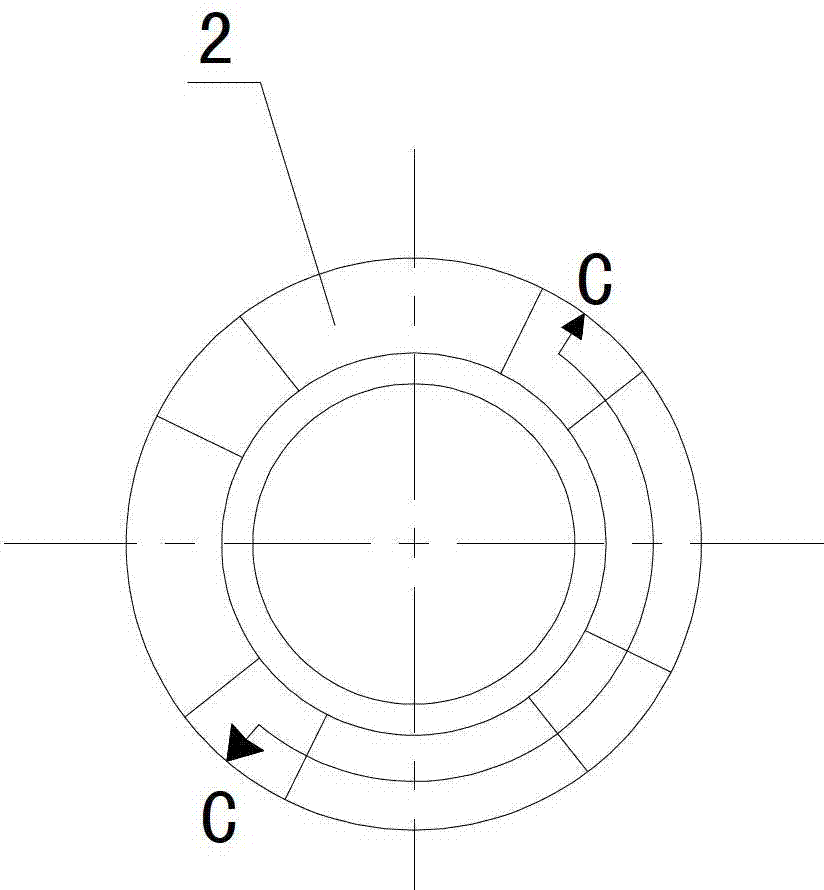

[0020] like figure 1 , clamp the cam 2 on the three-jaw disc 3 of the CNC turntable 1 of the CNC coordinate mill, and use the three-dimensional adjustable high-precision top tailstock top 4 at the other end. When adjusting the starting point, move X, Y, Z, A coordinates, move the grinding head 5 to the initial point, complete the cam track movement through the rotation of the CNC turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com