Patents

Literature

59 results about "Miller index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Miller indices form a notation system in crystallography for planes in crystal (Bravais) lattices. In particular, a family of lattice planes is determined by three integers h, k, and ℓ, the Miller indices. They are written (hkℓ), and denote the family of planes orthogonal to h𝐛₁+k𝐛₂+ℓ𝐛₃, where 𝐛ᵢ are the basis of the reciprocal lattice vectors. (Note that the plane is not always orthogonal to the linear combination of direct lattice vectors h𝐚₁+k𝐚₂+ℓ𝐚₃ because the reciprocal lattice vectors need not be mutually orthogonal.) By convention, negative integers are written with a bar, as in 3 for −3.

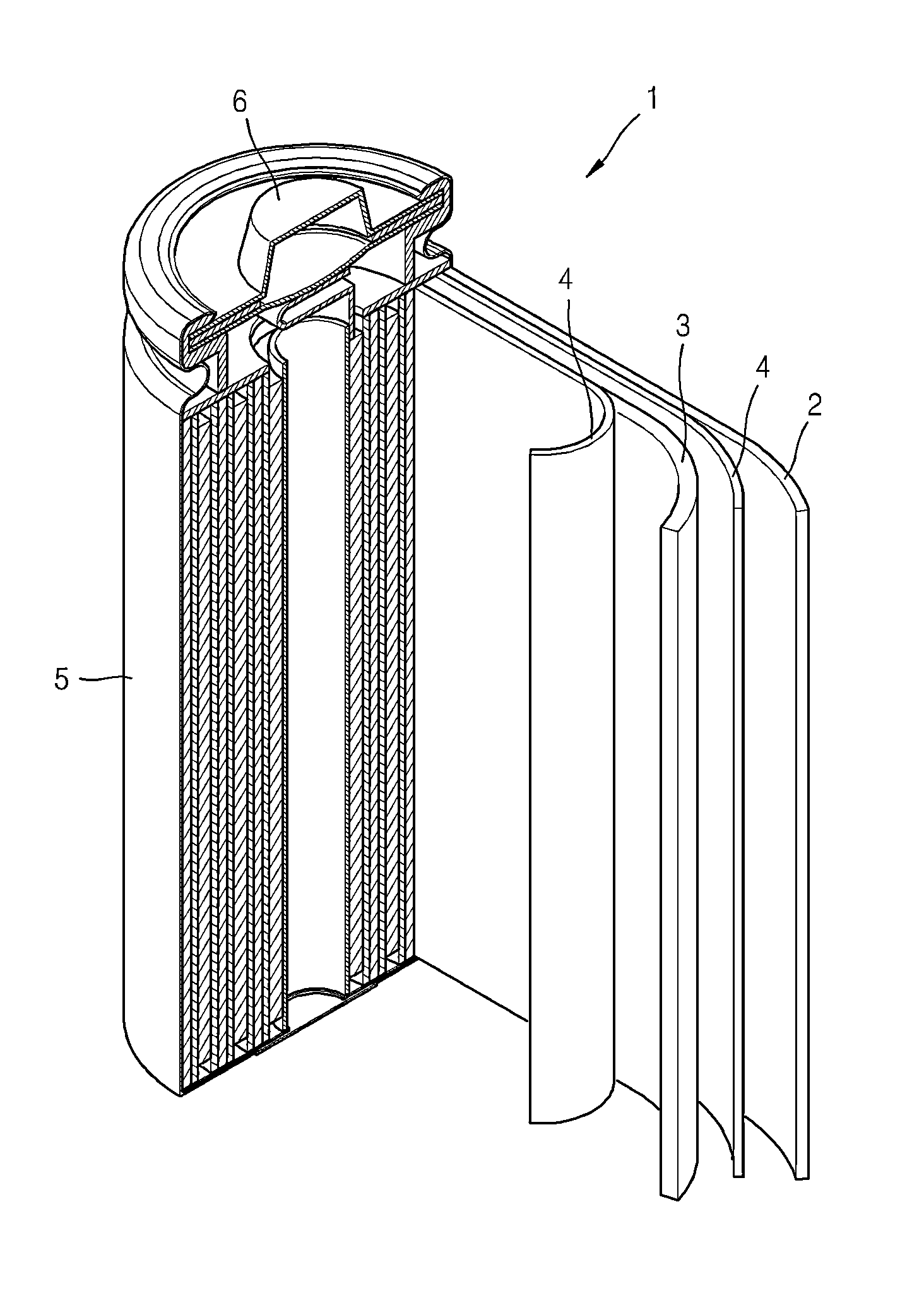

Active material for lithium secondary battery, electrode for lithium secondary battery, and lithium secondary battery

ActiveUS20130146808A1Improve discharge capacityCobalt compoundsNon-aqueous electrolyte accumulator electrodesMiller indexX-ray

[Object]There is provided an active material for a lithium secondary battery, which has a high initial efficiency and a high discharge capacity, and particularly has a high discharge capacity at a low temperature (excellent low-temperature characteristic), and a lithium secondary battery using the active material.[Solution]An active material for a lithium secondary battery, which contains a solid solution of a lithium transition metal composite oxide having an α-NaFeO2 crystal structure, wherein the composition ratio of metal elements contained in the solid solution satisfies, Li1+x−yNayCoaNibMncO2+d (0<y≦0.1, 0.4≦c≦0.7, x+a+b+c=1, 0.1≦x≦0.25, −0.2≦d≦0.2), the active material has an X-ray diffraction pattern attributable to a space group R3-m (P3112), and in the Miller index hkl, the half width of the diffraction peak of the (003) is 0.30° or less and the half width of the diffraction peak of the (114) plane is 0.50° or less. Further, the average of three oxygen position parameters determined from crystal structure analysis by the Rietveld method on the basis of the X-ray diffraction pattern is preferably 0.264 or less.

Owner:GS YUASA INT LTD

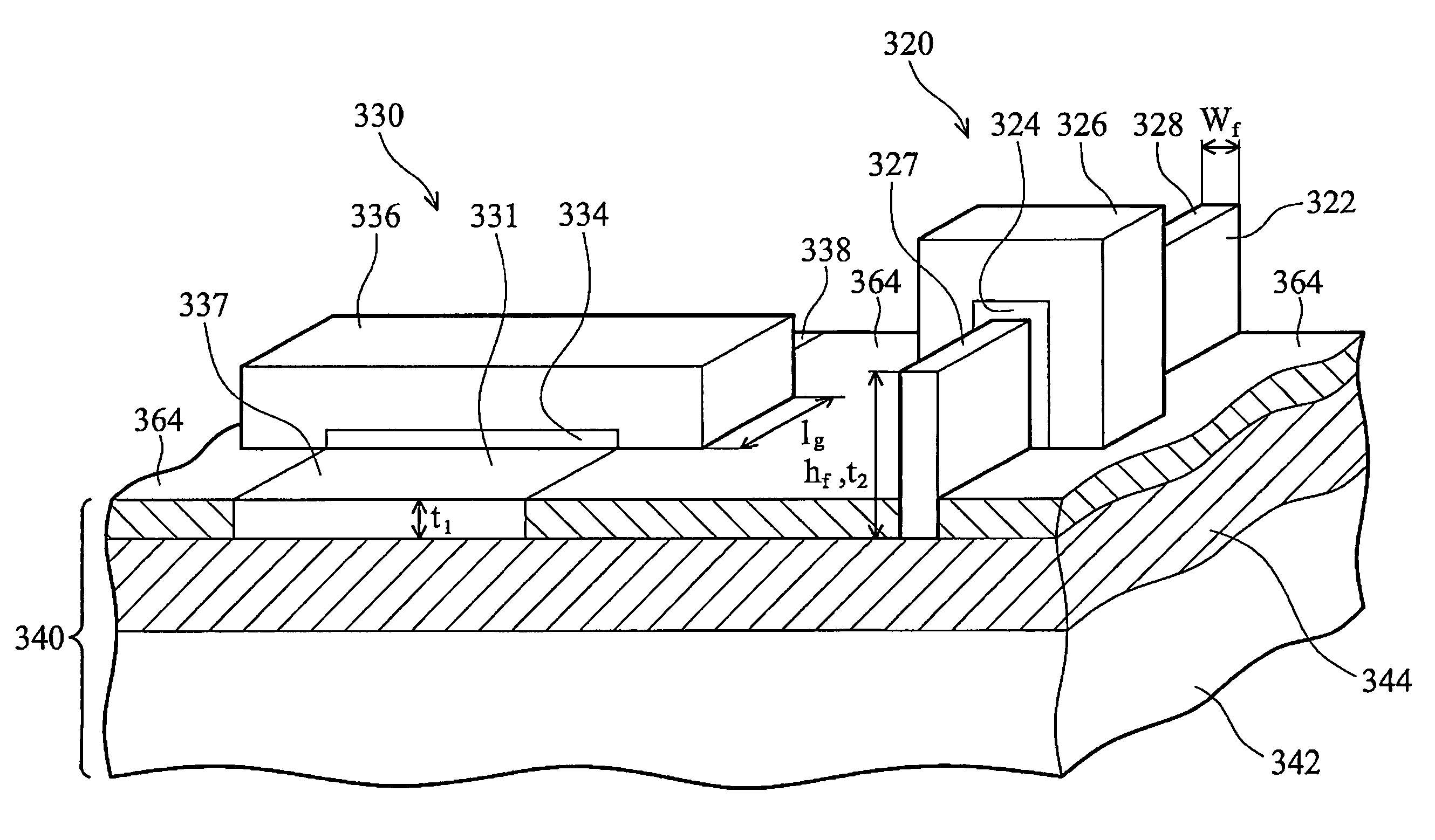

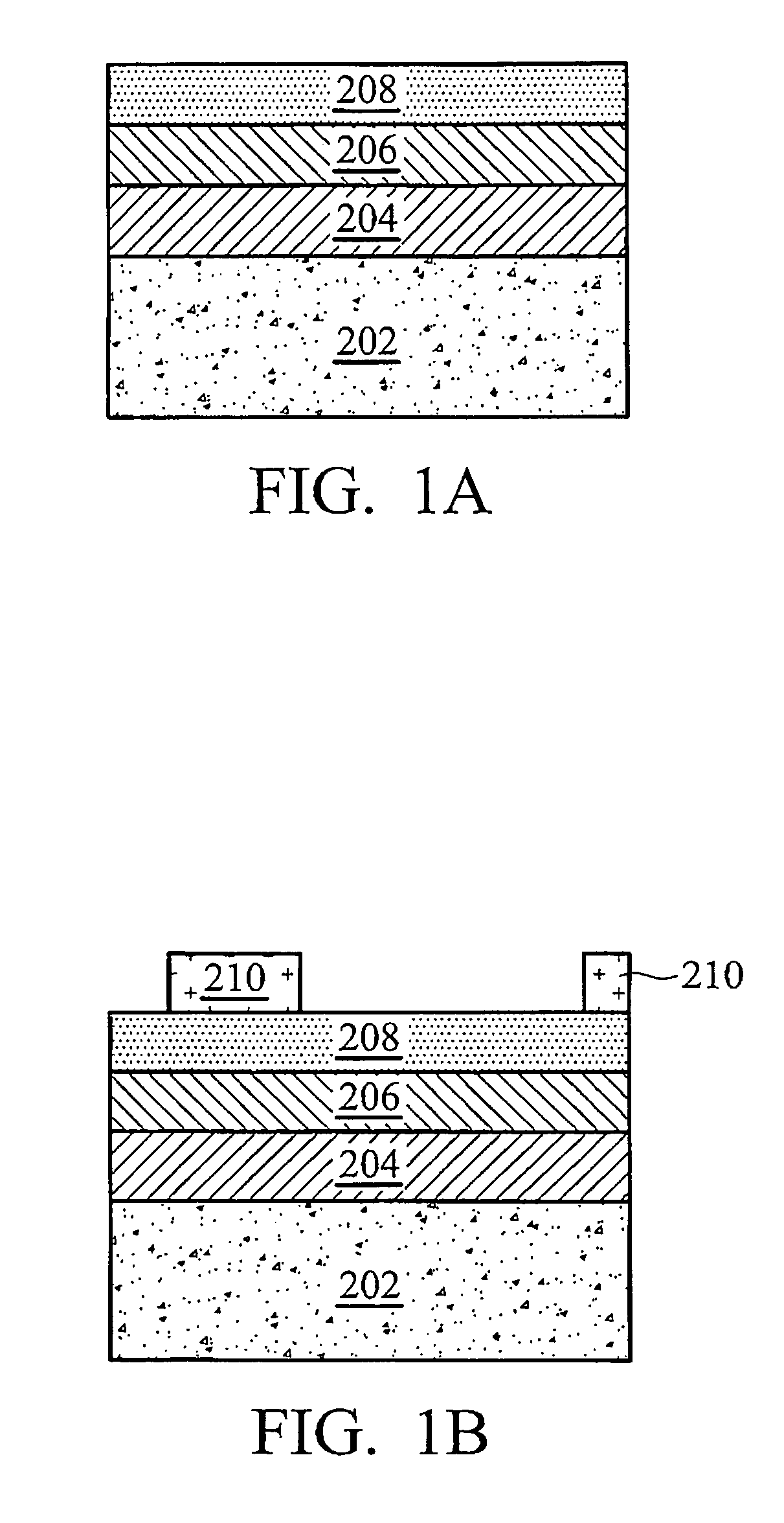

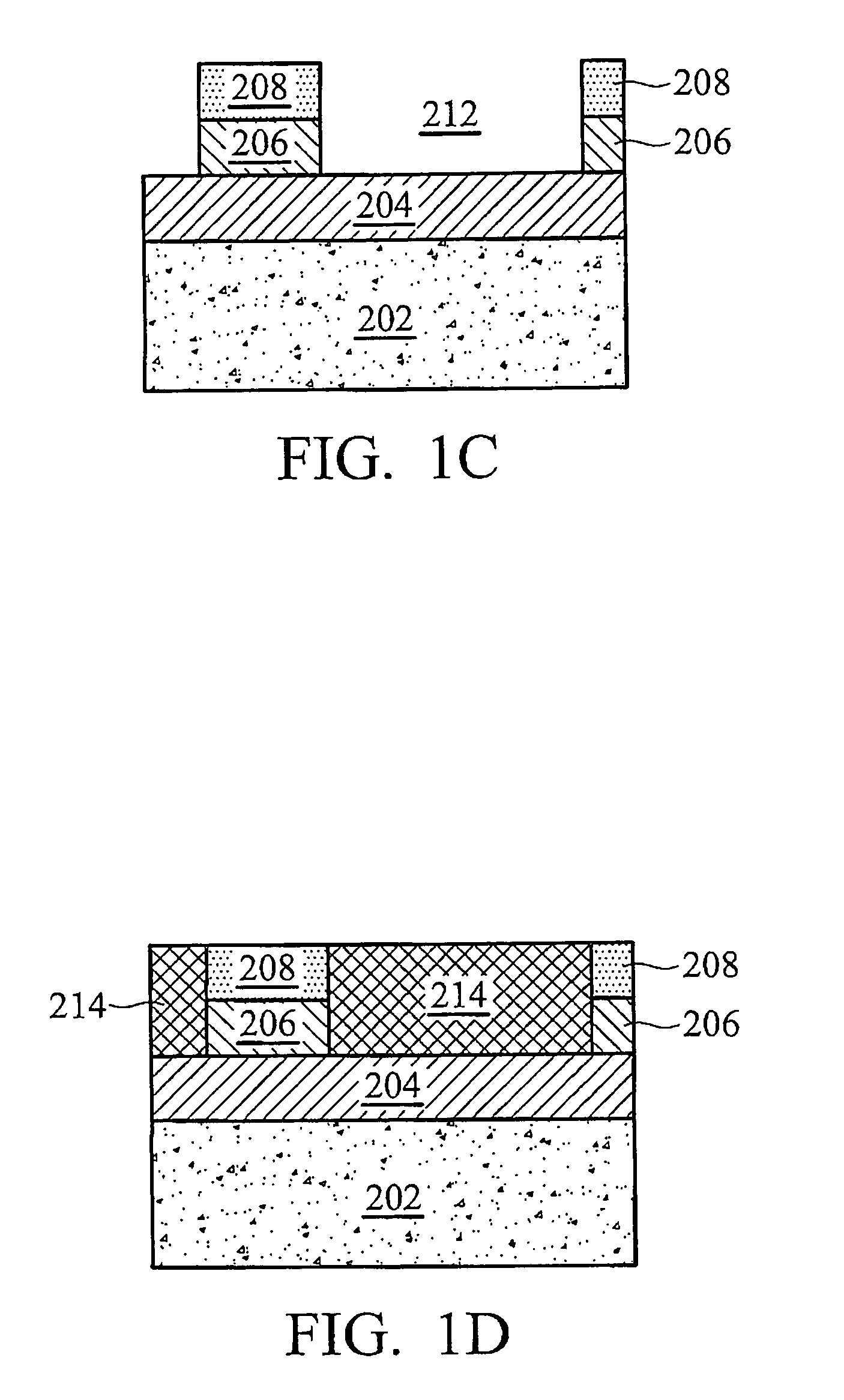

Hybrid Schottky source-drain CMOS for high mobility and low barrier

ActiveUS20070052027A1Reduce decreaseSolid-state devicesSemiconductor/solid-state device manufacturingCMOSMiller index

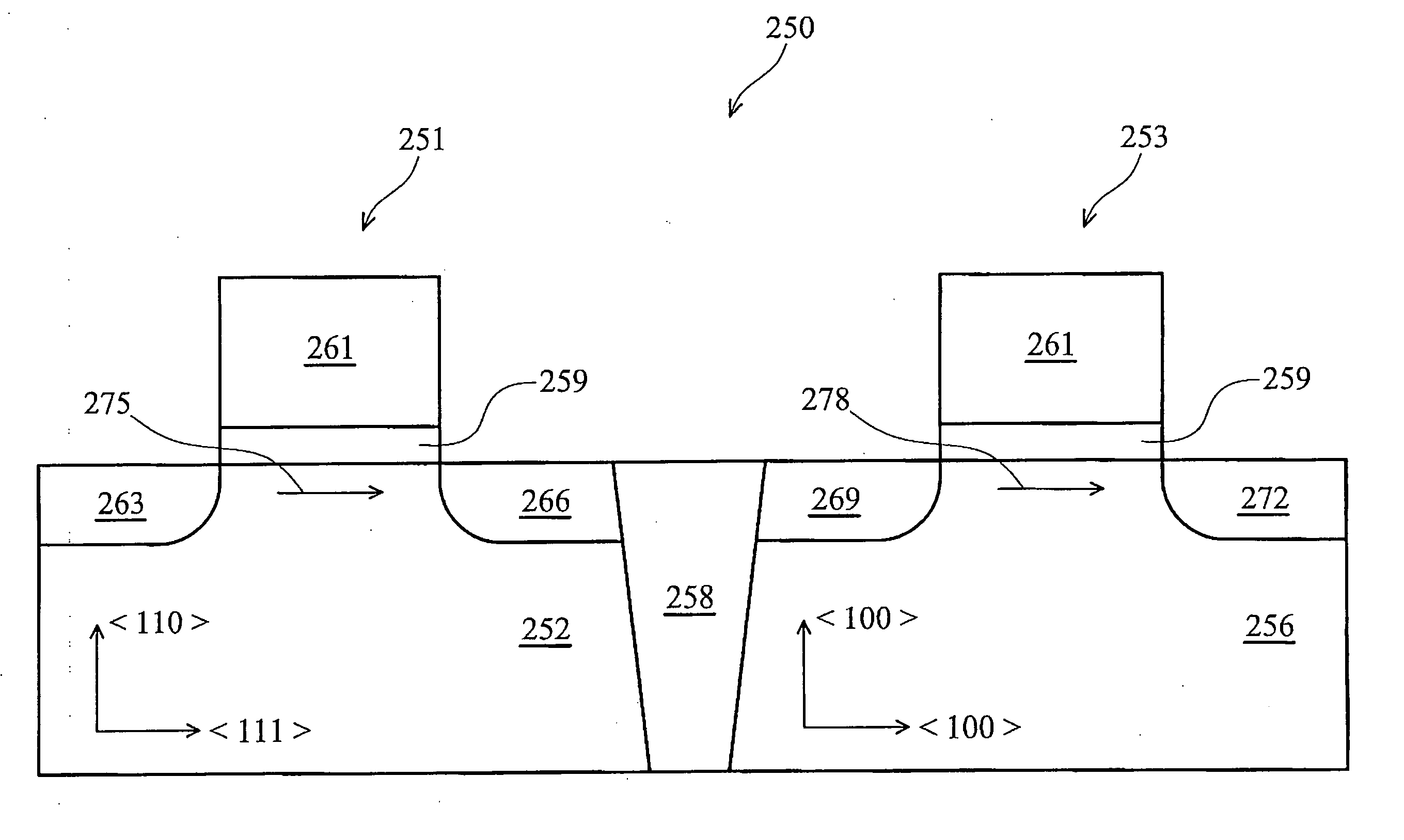

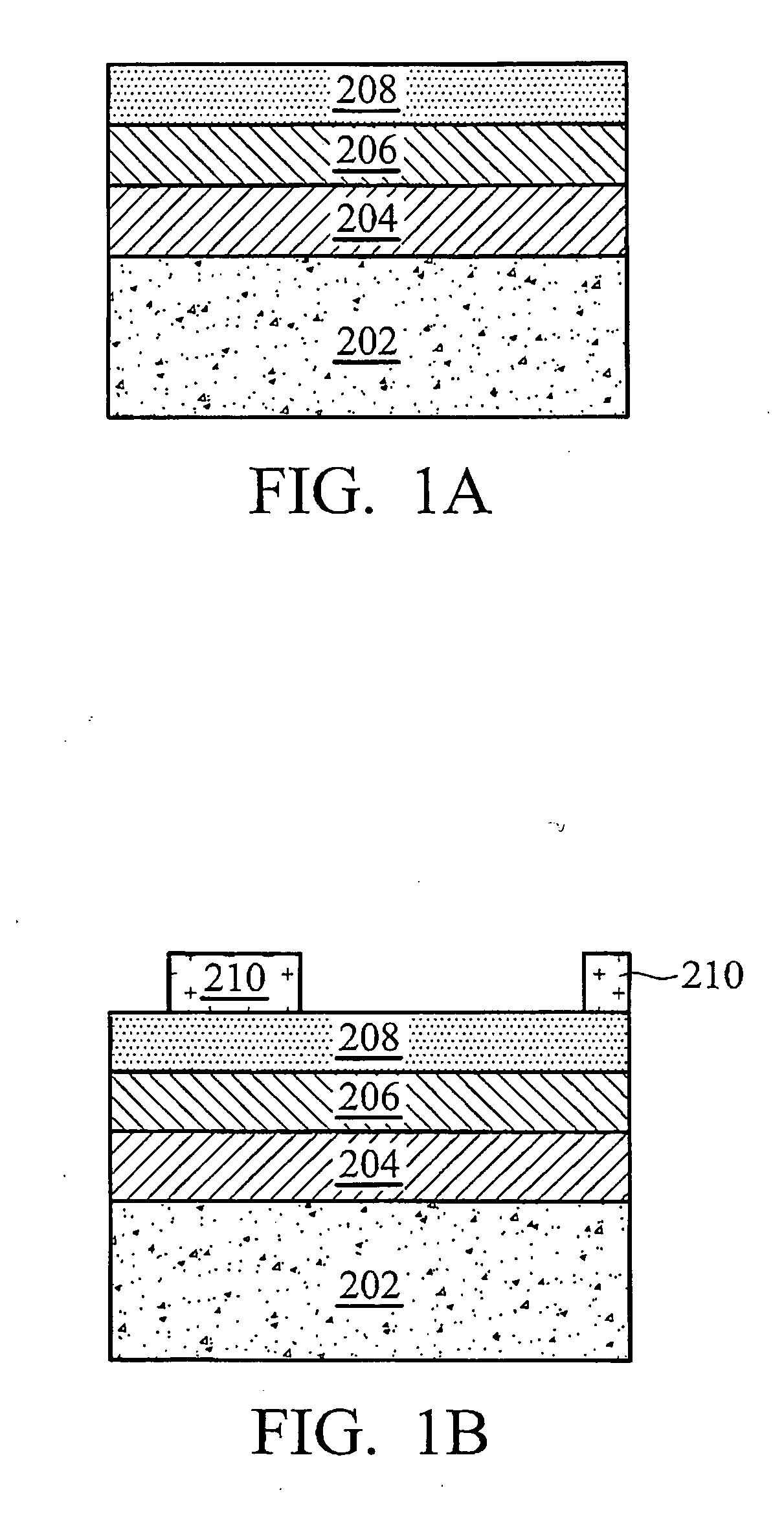

A CMOS device is provided. A semiconductor device comprises a substrate, the substrate having a first region and a second region, the first region having a first crystal orientation represented by a family of Miller indices comprising {i,j,k}, the second region having a second crystal orientation represented a family of Miller indices comprising {l,m,n}, wherein l2+m2+n2>i2+j2+k2. Alternative embodiments further comprise an NMOSFET formed on the first region, and a PMOSFET formed on the second region. Embodiments further comprise a Schottky contact formed with at least one of a the NMOSFET or PMOSFET.

Owner:TAIWAN SEMICON MFG CO LTD

Polyester fiber and process for preparing the same

InactiveUS6623681B1Outstanding resilienceHigh crystallinityMonocomponent polyesters artificial filamentPolyesterYarn

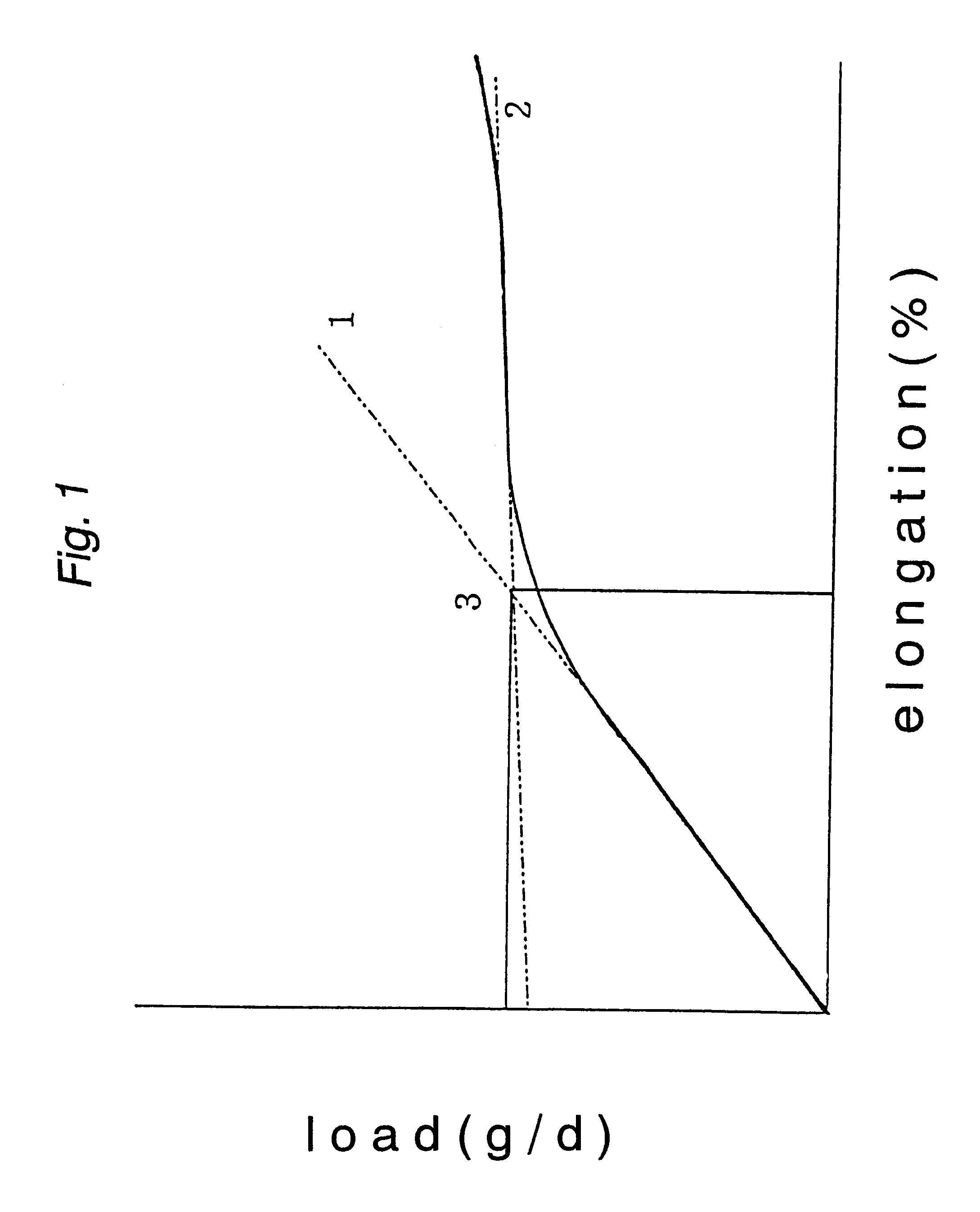

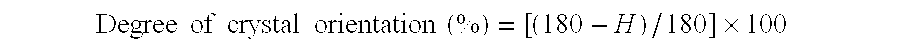

Intermediate polyester fibre and method for the production thereof, characterized in that highly oriented undrawn polyester yarn with a degree of crystallinity in a specified range is passed under a tension of 0.3x10<-2 >g / d to 5.0x10<-2 >g / d through a non-contact heater of heater temperature at least 250° C., and 5-40% shrinkage effected, giving the following properties (A):(1) Specific gravity 1.335-1.360 (g / cm<3>),(2) Degree of crystallinity 21-26%,(3) Crystal size in terms of Miller index (010) 1.4-2.2 nm, in terms of Miller index (100) 1.4-2.5 nm and in terms of Miller index (105) 1.6-3.5,(4) Degree of crystal orientation no more than 75% in the 010 plane and no more than 85% in the 105 plane, and(5) Degree of amorphous orientation 0.15-0.4, hot water shrinkage 0 to 35% and dry heat shrinkage 0-35%, anda method for the production of fabric or spatial fabric of outstanding resilience, which exhibits resistance to permanent yielding (resistance to pile damage or resistance to pile slanting, etc), together with bulkiness and cushioning properties.

Owner:TORAY IND INC

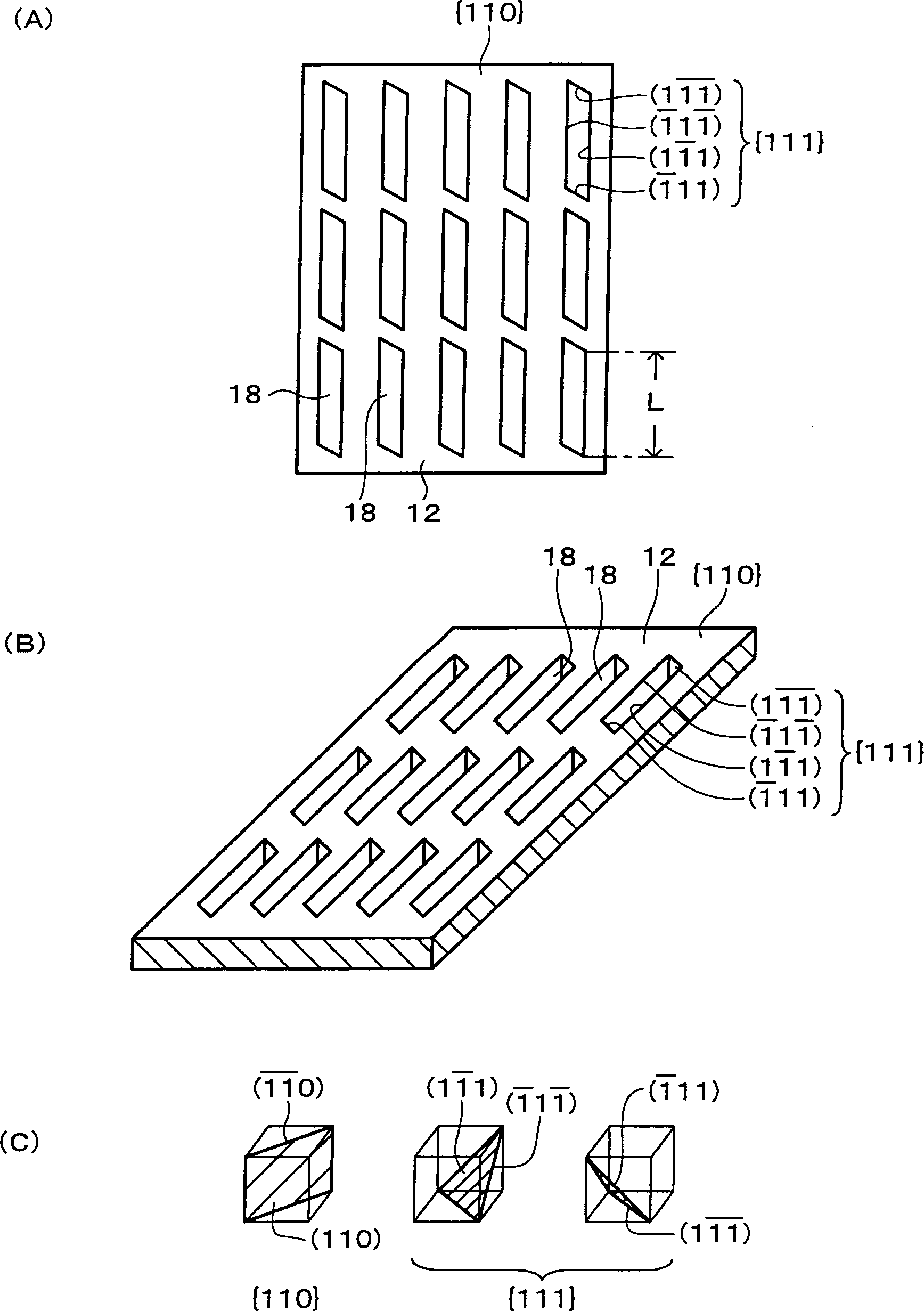

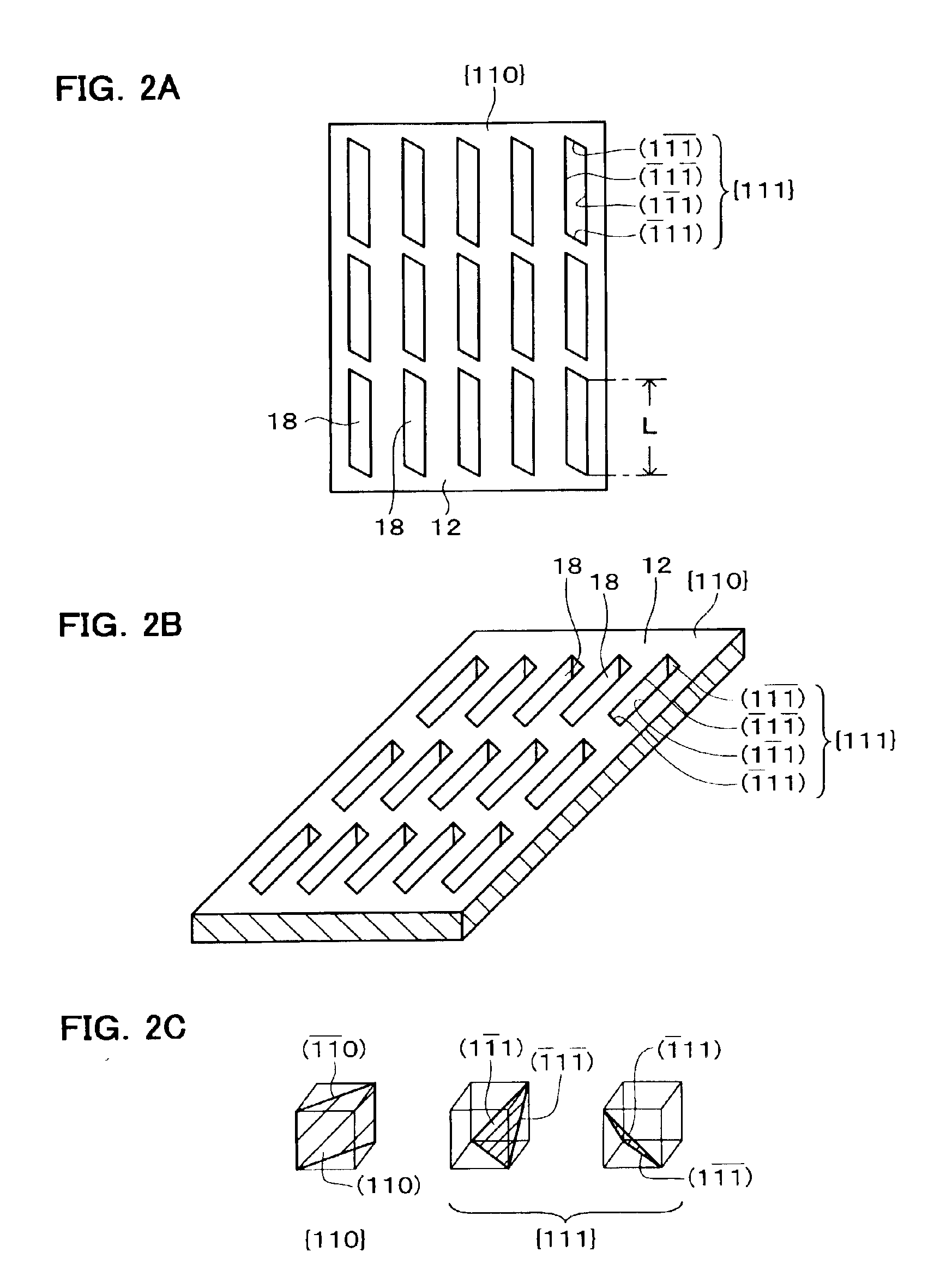

Mask and its mfg. method, electroluminance device and its mfg. method and electronic machine

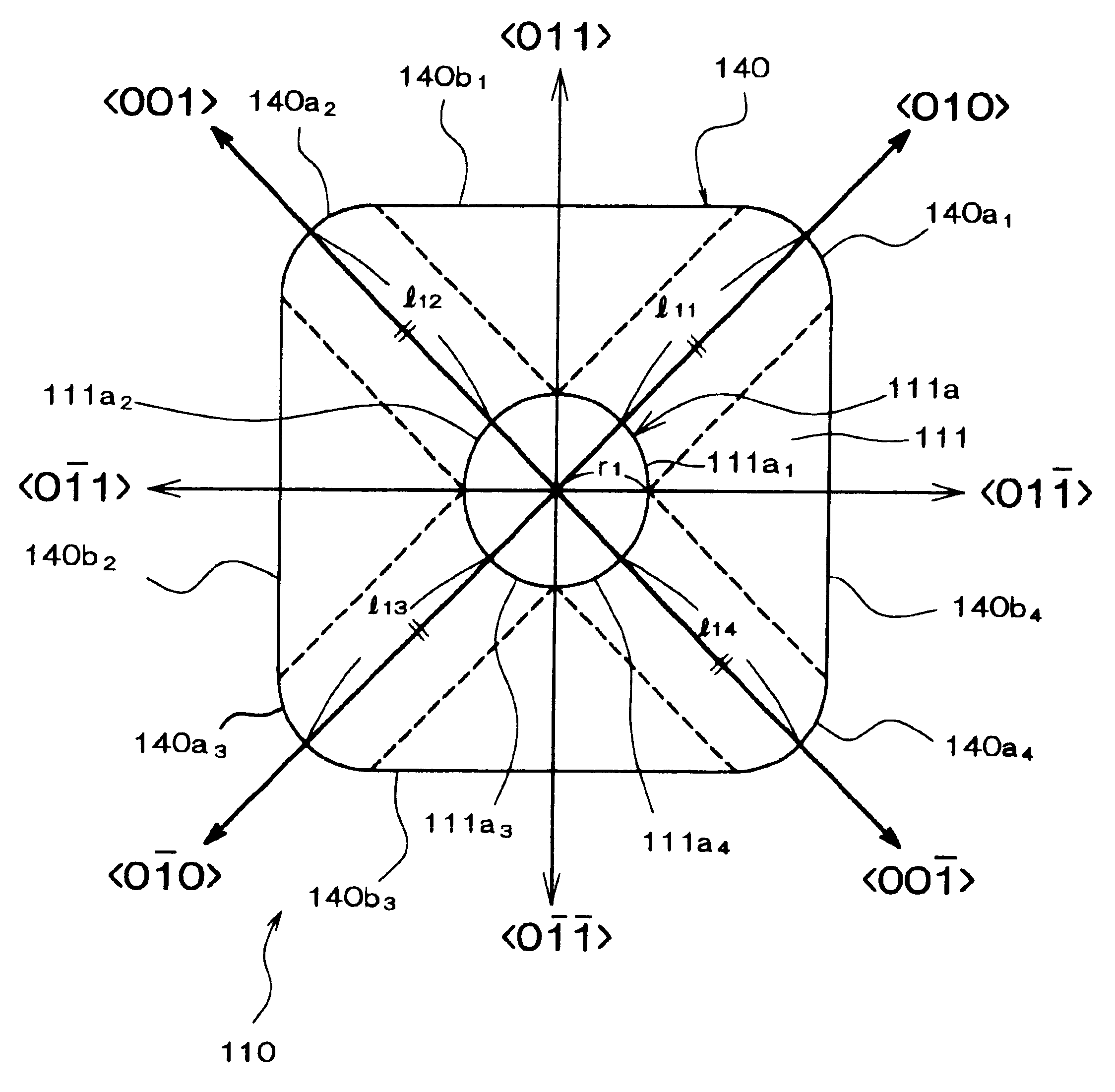

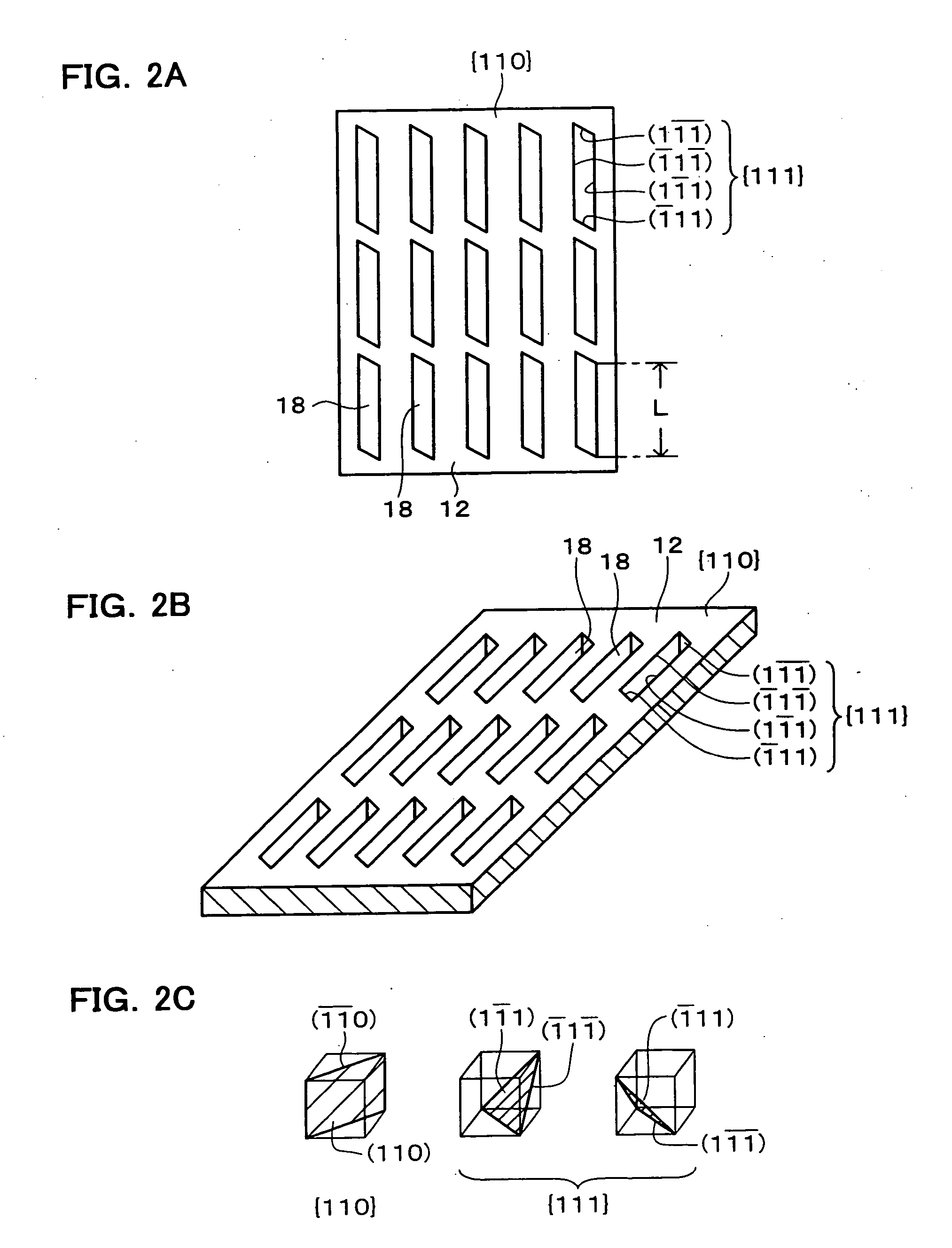

A mask has a monocrystal substrate having opposite surfaces which are planes having Miller indices {110}. A plurality of penetrating holes are formed in the monocrystal substrate. An opening shape of each of the penetrating holes is a polygon and each side of the polygon is parallel with a plane in a group of the {111} planes. The wall surfaces of the penetrating holes are the {111} planes. In the method of manufacturing a mask, openings are formed in the etching resistant film corresponding to the shape of the penetrating holes and the monocrystal substrate is etched.

Owner:BOE TECH GRP CO LTD

Cathode active material, cathode including the cathode active material, and sodium secondary battery including the cathode

ActiveUS20150111097A1Improve conductivityImprove structural stabilityFinal product manufactureSecondary cellsMiller indexX-ray

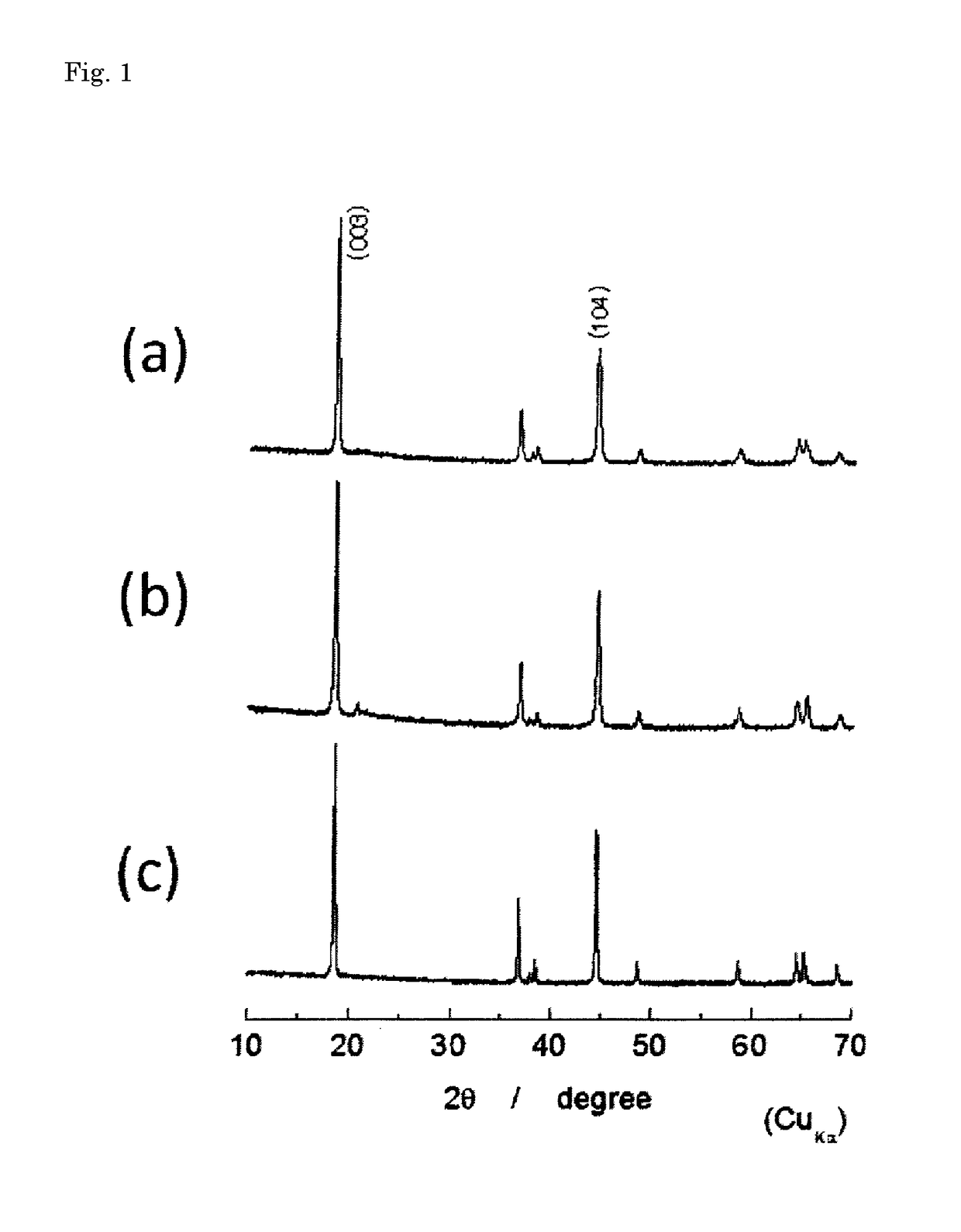

A cathode active material including a composite transition metal oxide including: sodium; a first transition metal; and a second transition metal, wherein the composite transition metal oxide has a first diffraction peak corresponding to a Miller index of (003) and derived from a layered rock salt structure, and a second diffraction peak corresponding to a Miller index of (104) and derived from a cubic rock salt structure in an X-ray powder diffraction (XRD) pattern, wherein an intensity ratio (I1 / I2) of the first diffraction peak to the second diffraction peak is about 7 or greater.

Owner:SAMSUNG ELECTRONICS CO LTD

Alloy catalyst for redox reaction

InactiveUS20100316937A1Good effectHigh catalytic activityActive material electrodesFuel cellsMiller indexOxidation-Reduction Agent

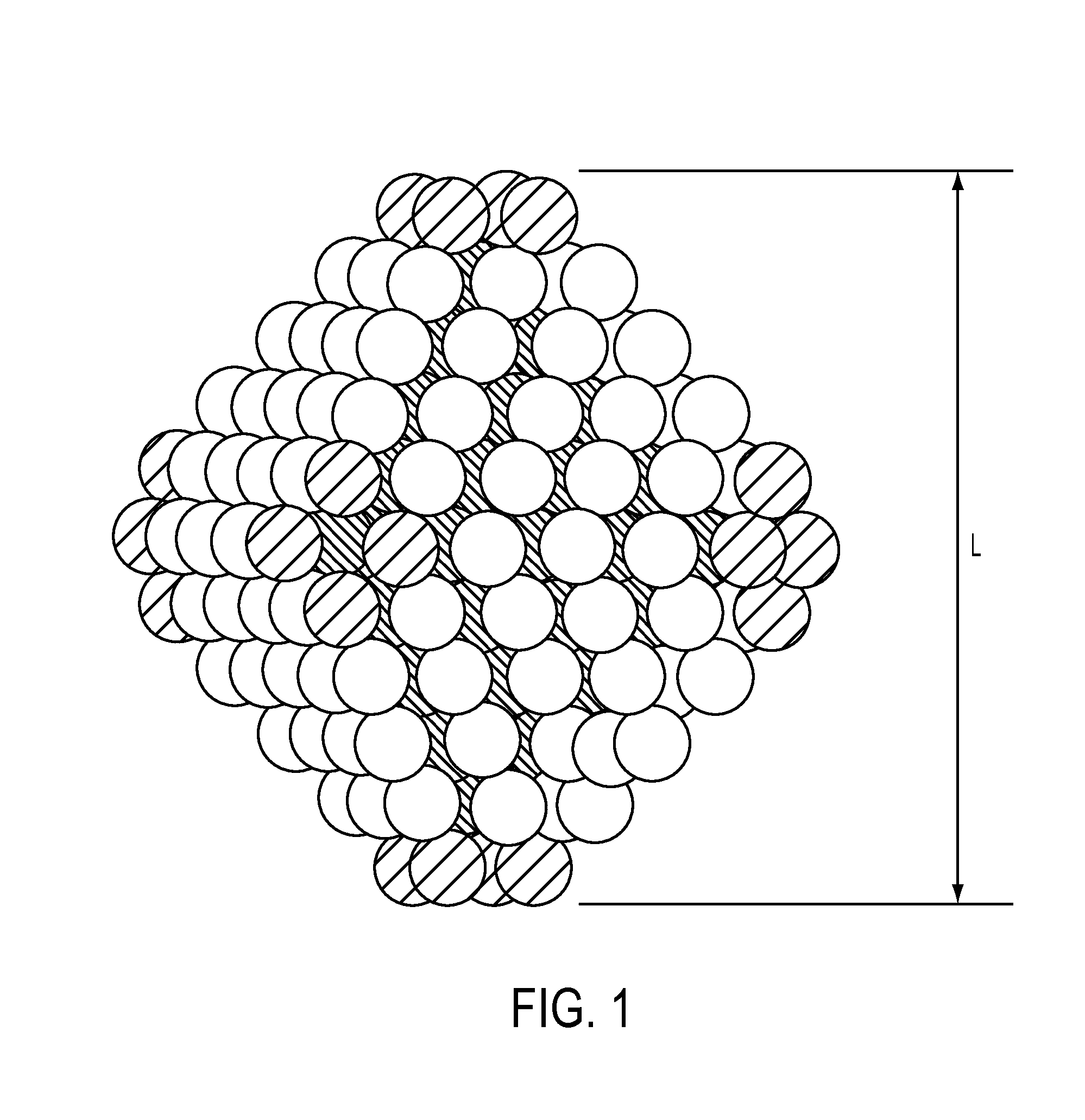

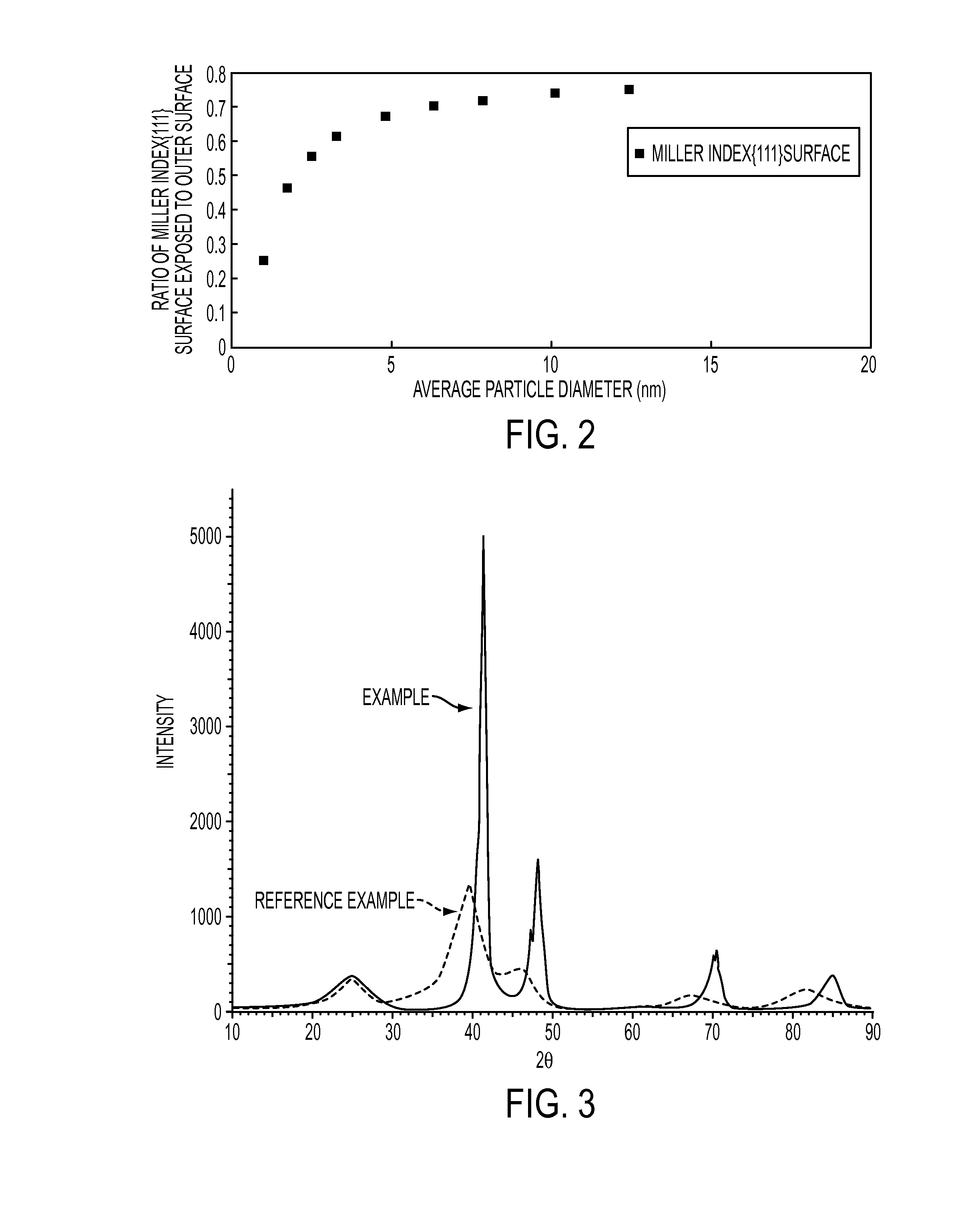

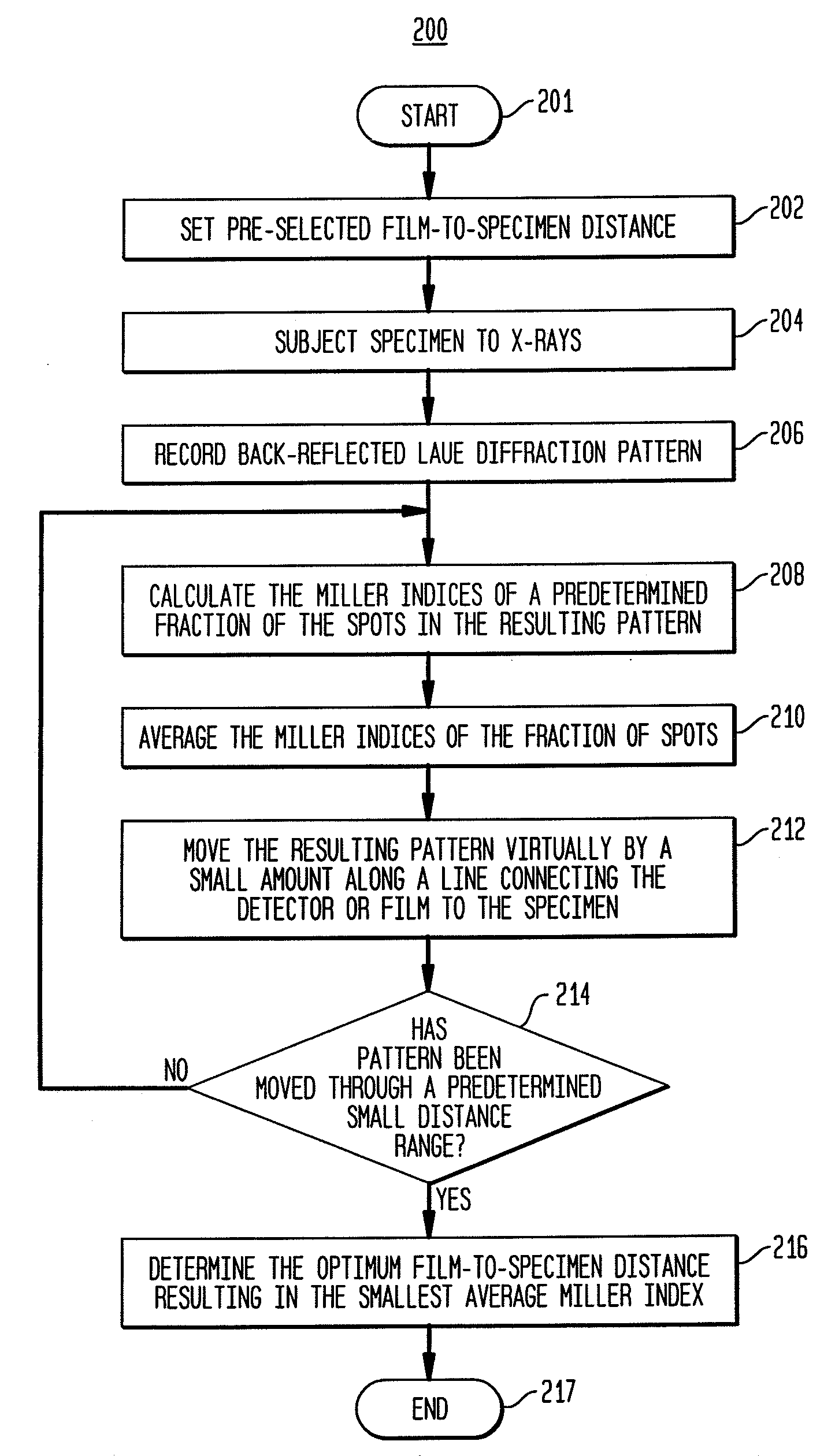

An alloy catalyst for redox reaction which is capable of obtaining even superior catalytic activity comprises alloy particles of platinum and nickel, wherein the alloy particle is equipped at an outer surface with a crystal lattice plane represented by a Miller index {111}, and has an average particle diameter in a range of from 6 to 20 nm. The alloy particle preferably takes a shape selected from a regular octahedron, a truncated octahedron, a regular tetrahedron, and a truncated tetrahedron.

Owner:HONDA MOTOR CO LTD

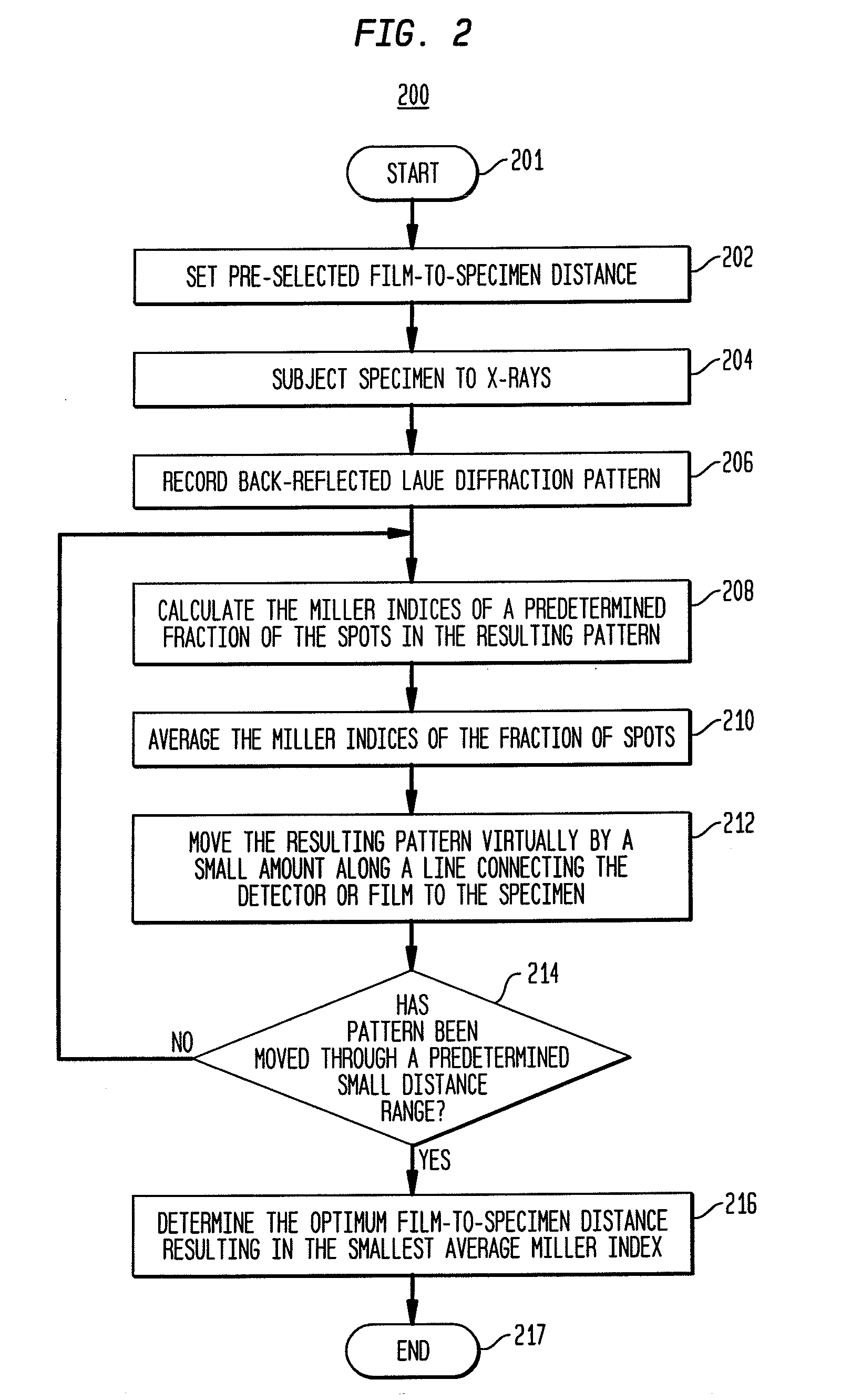

Back-reflection x-ray crystallography method and system

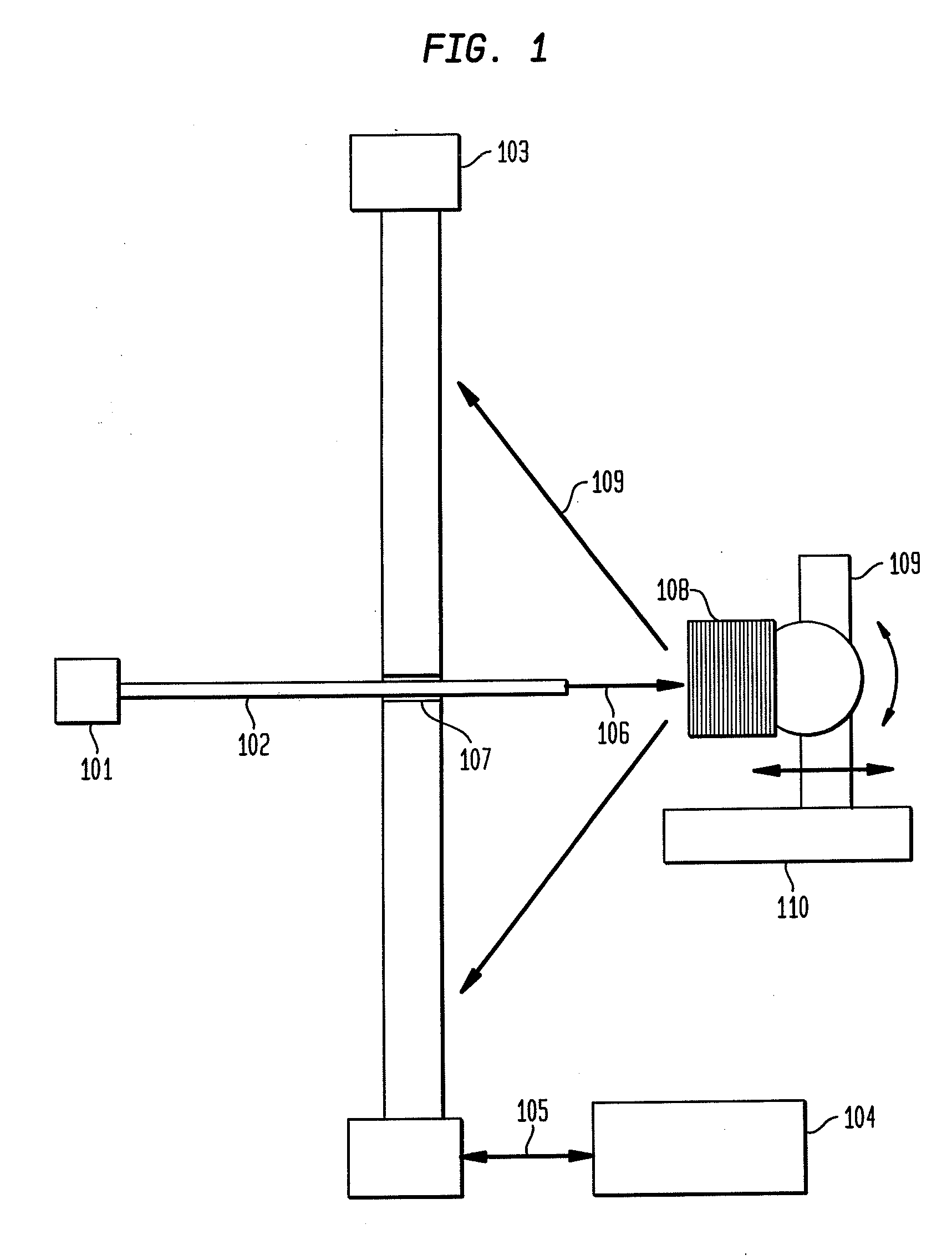

Provided is a method and system for back-reflection X-ray diffraction of a specimen that yields the orientation of a crystalline sample in a quick and an automated way. The method includes setting an approximate pre-selected X-ray detector to specimen distance, subjecting the specimen to X-rays, recording the Laue diffraction pattern, calculating the Miller indices of a fraction of the spots in the resulting pattern, averaging the Miller indices, moving a virtual representation of the specimen by a small amount along a line connecting the film to the specimen, changing the film-to-specimen distance, repeating the calculation, averaging and moving in small angular steps until the virtual representation of the specimen has been moved through a small distance range and best fits to the observed data, and determining the optimum film-to-specimen distance resulting in the smallest average Miller index.

Owner:MULTIWIRE LAB

Hybrid Schottky source-drain CMOS for high mobility and low barrier

A CMOS device is provided. A semiconductor device comprises a substrate, the substrate having a first region and a second region, the first region having a first crystal orientation represented by a family of Miller indices comprising {i,j,k}, the second region having a second crystal orientation represented a family of Miller indices comprising {l,m,n}, wherein l2+m2+n2>i2+j2+k2. Alternative embodiments further comprise an NMOSFET formed on the first region, and a PMOSFET formed on the second region. Embodiments further comprise a Schottky contact formed with at least one of a the NMOSFET or PMOSFET.

Owner:TAIWAN SEMICON MFG CO LTD

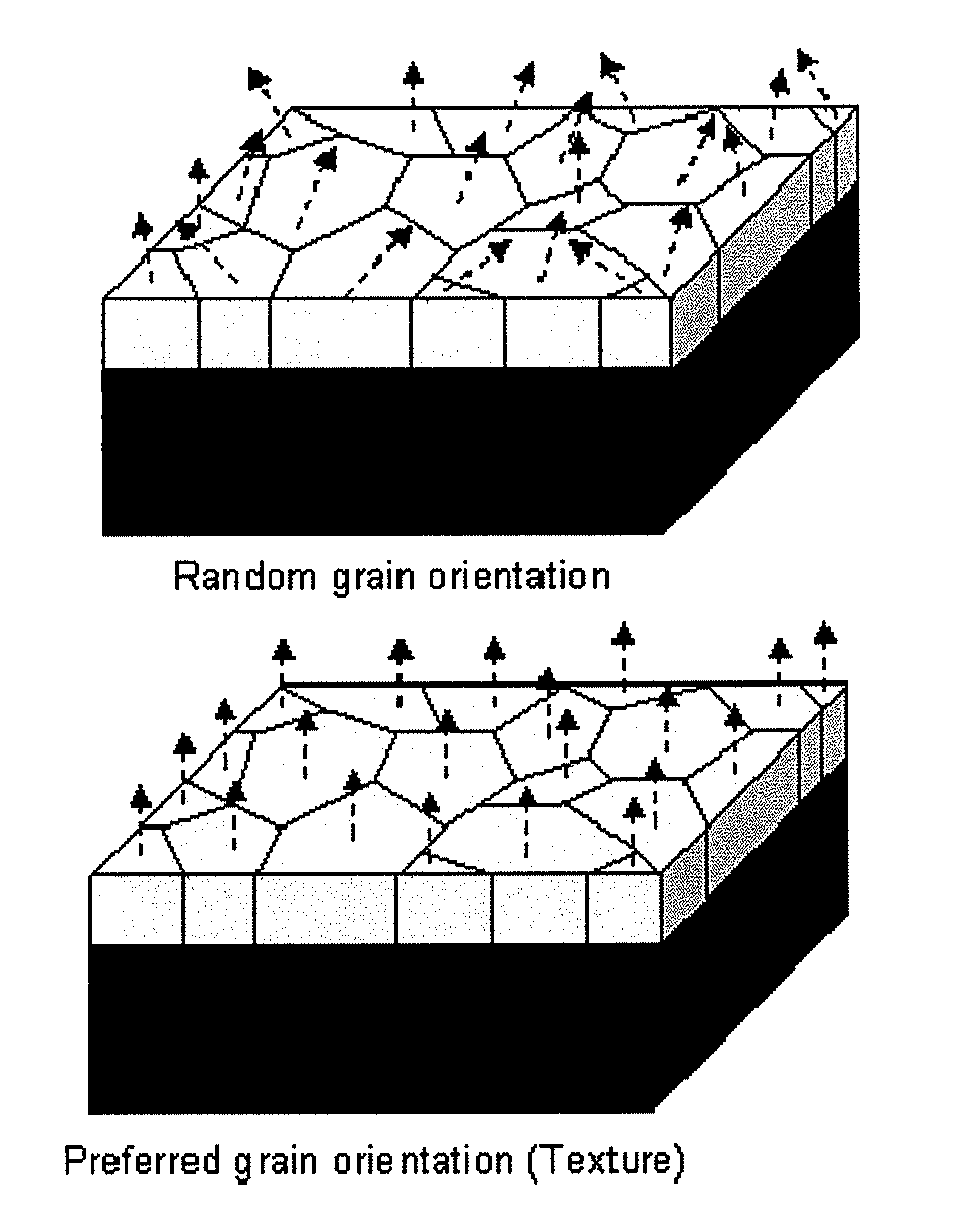

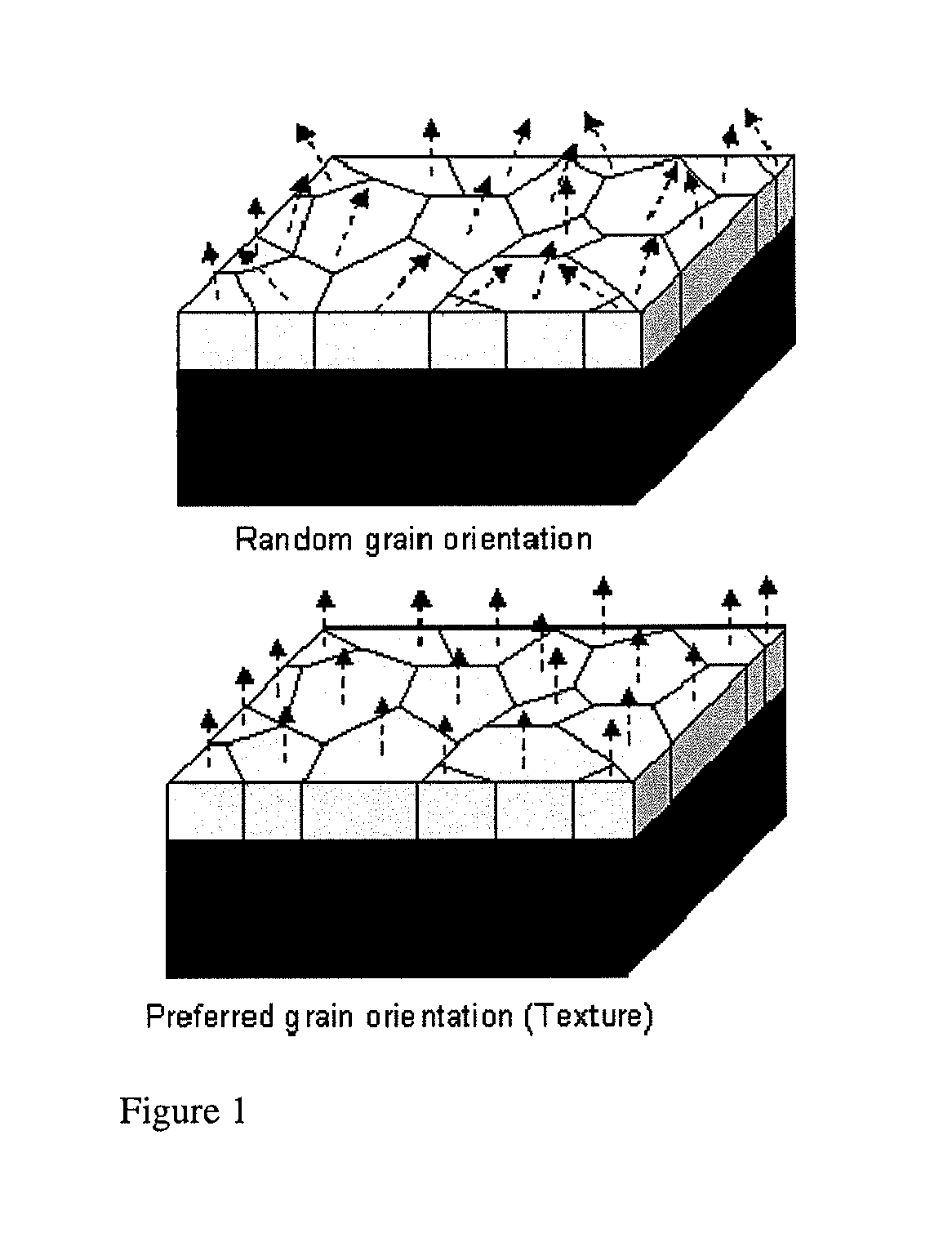

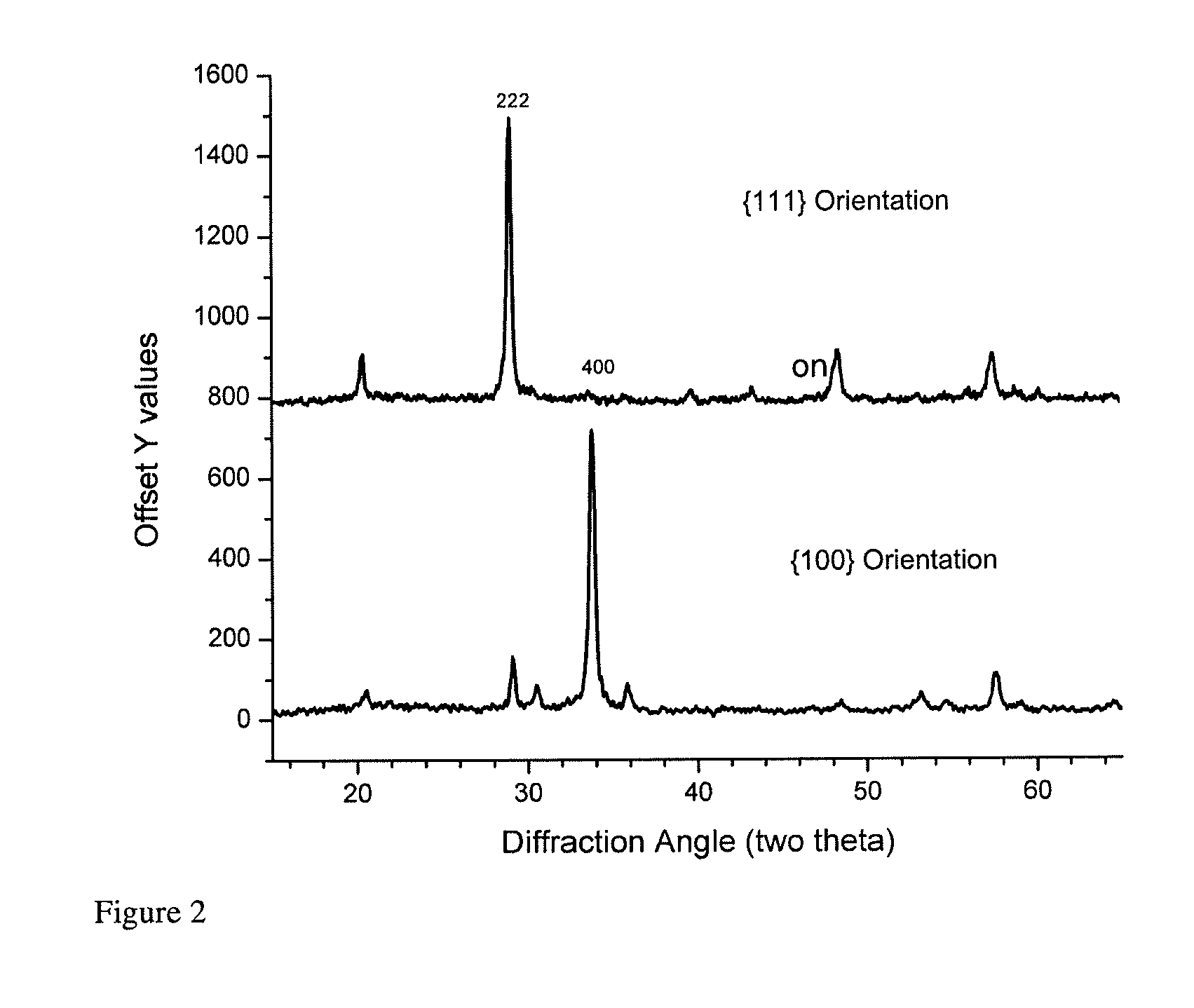

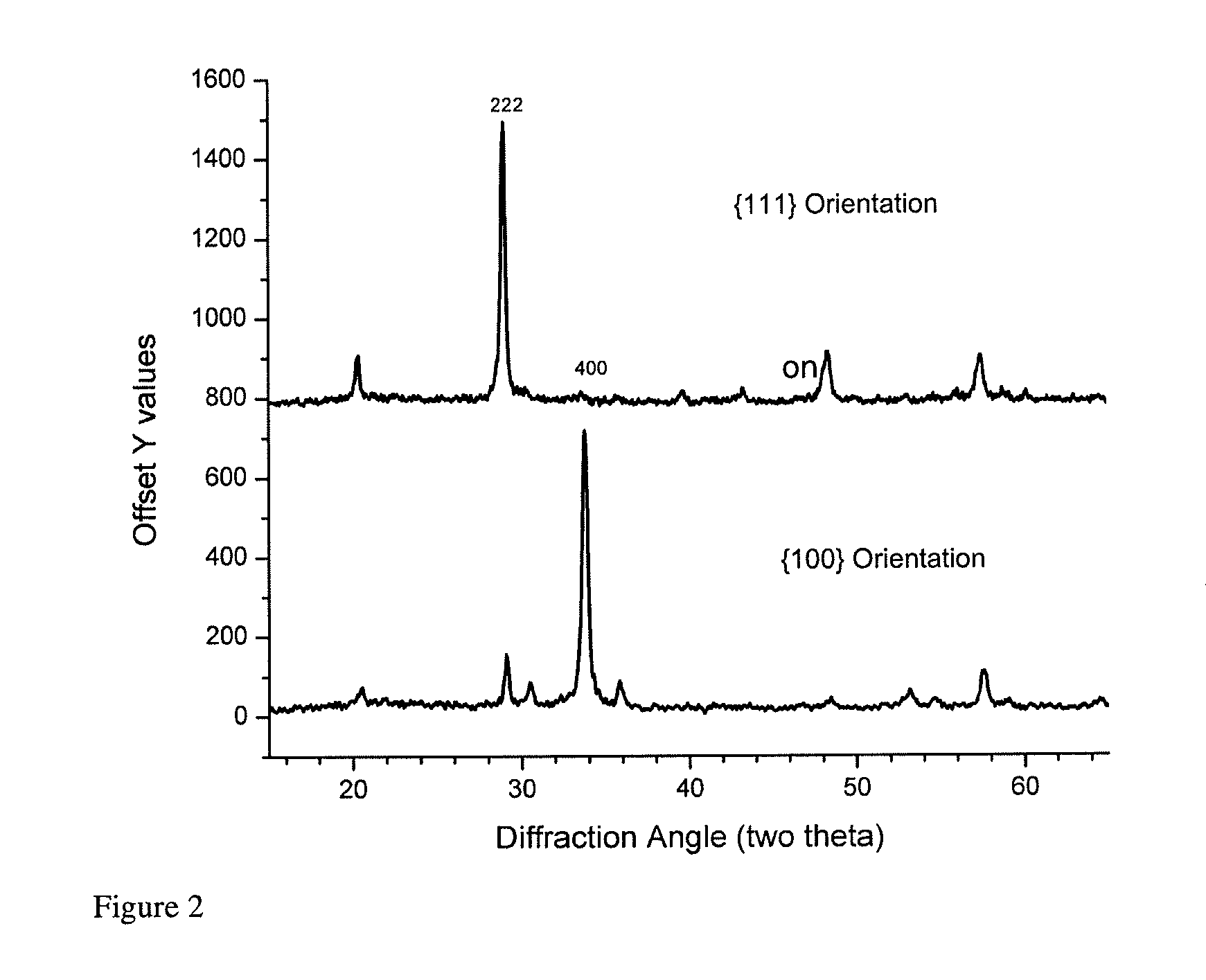

Plasma Etch Resistant, Highly Oriented Yttria Films, Coated Substrates and Related Methods

InactiveUS20120103519A1Improve plasma resistanceImprove the immunityMolten spray coatingElectric discharge heatingMiller indexMaterials science

Included within the scope of the invention are plasma etch-resistant films for substrates. The films include a yttria material and a at least a portion of the yttria material is in a crystal phase having an orientation defined by a Miller Index notation {111}. Also included are methods of manufacturing plasma etch-resistant films on a substrate. Such methods include applying a yttria material-containing composition onto at least a portion of a surface of a substrate to form a film. The film includes a yttria material and at least a portion of the yttria material is in a crystal phase having an orientation defined by a Miller Index notation {111}.

Owner:GREENE TWEED TECH

Mask and method of manufacturing the same, electro-luminescence device and method of manufacturing the same, and electronic instrument

InactiveUS6893575B2After-treatment detailsDecorative surface effectsMiller indexElectronic instrument

Owner:BOE TECH GRP CO LTD

Plasma Etch Resistant, Highly Oriented Yttria Films, Coated Substrates and Related Methods

InactiveUS20130277332A1Improve plasma resistanceImprove the immunityMolten spray coatingDecorative surface effectsMiller indexSubstrate surface

Included within the scope of the invention are plasma etch-resistant films for substrates. The films include a yttria material and a at least a portion of the yttria material is in a crystal phase having an orientation defined by a Miller Index notation {111}. Also included are methods of manufacturing plasma etch-resistant films on a substrate. Such methods include applying a yttria material-containing composition onto at least a portion of a surface of a substrate to form a film. The film includes a yttria material and at least a portion of the yttria material is in a crystal phase having an orientation defined by a Miller Index notation {111}.

Owner:GREENE TWEED TECH

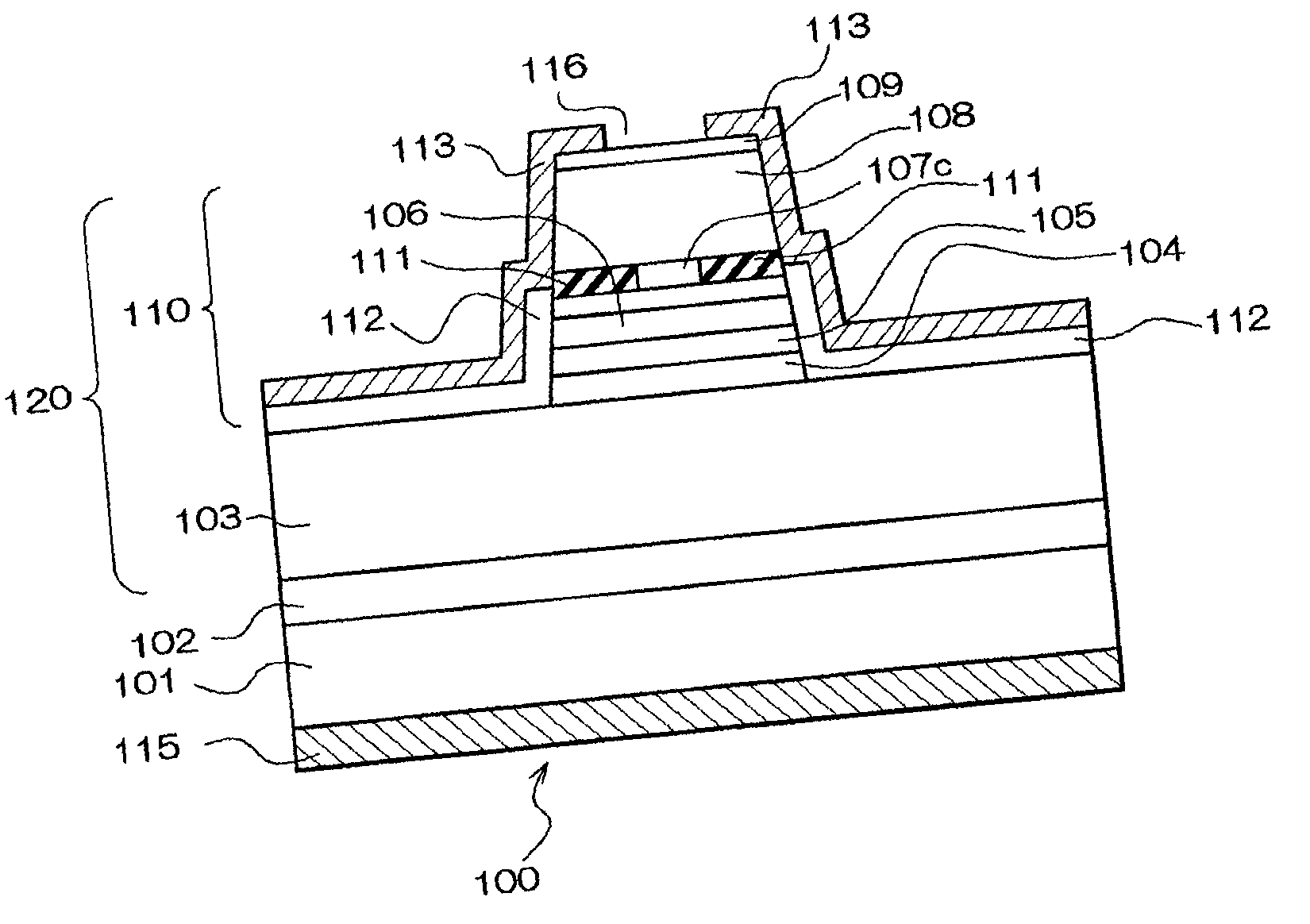

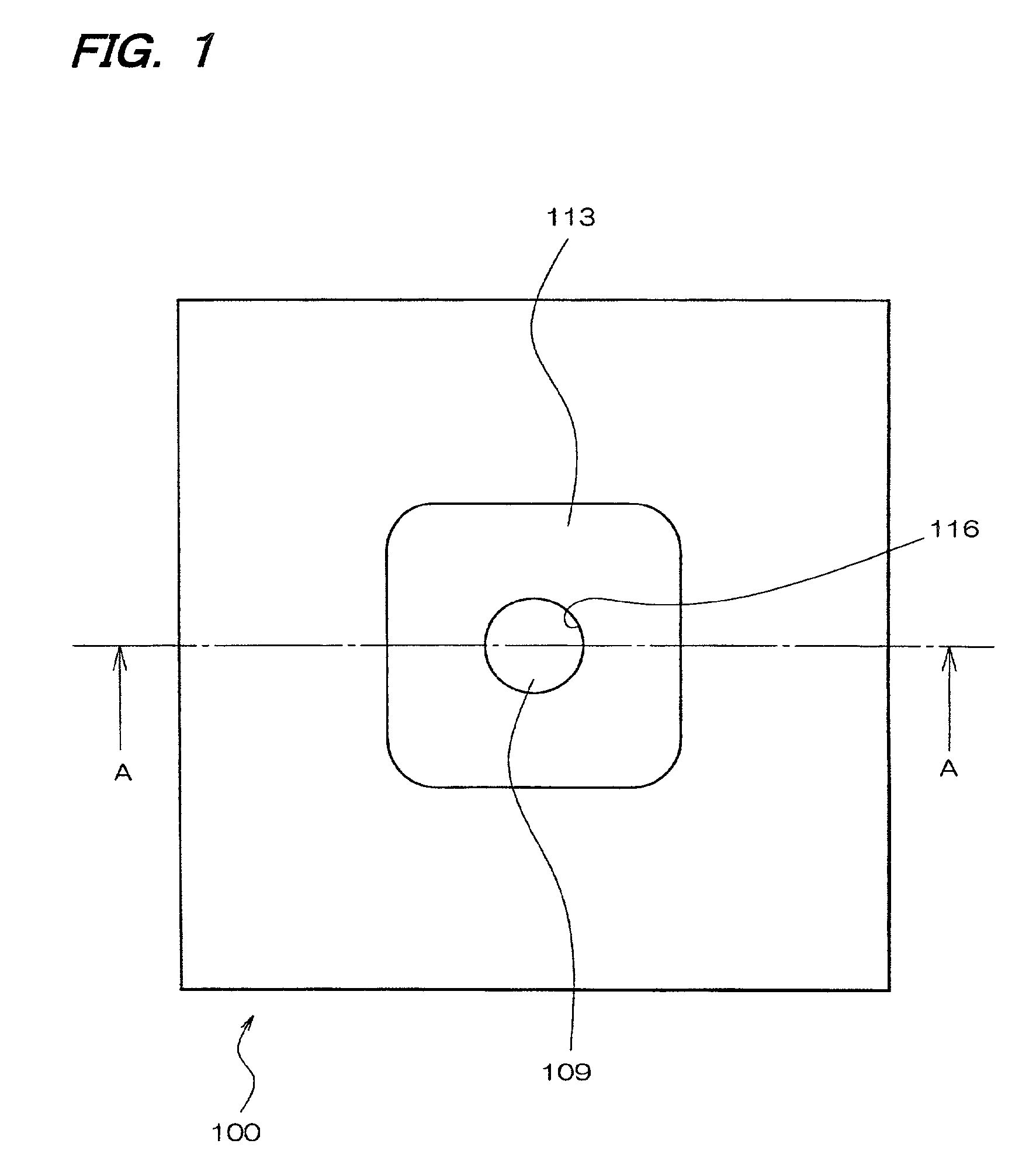

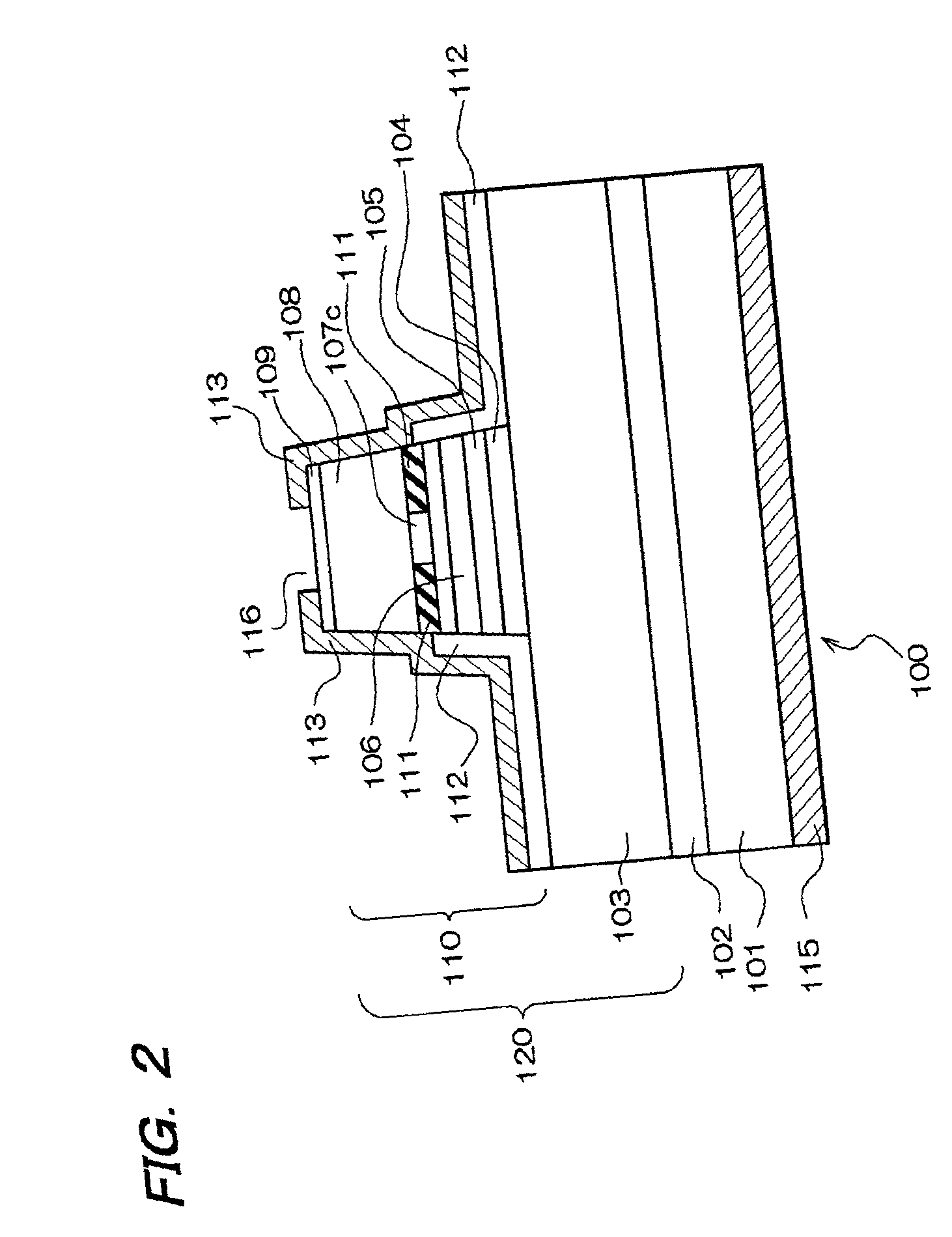

Surface emitting semiconductor laser and method of manufacturing the same

InactiveUS20020044581A1Optical wave guidanceOptical resonator shape and constructionMiller indexSemiconductor package

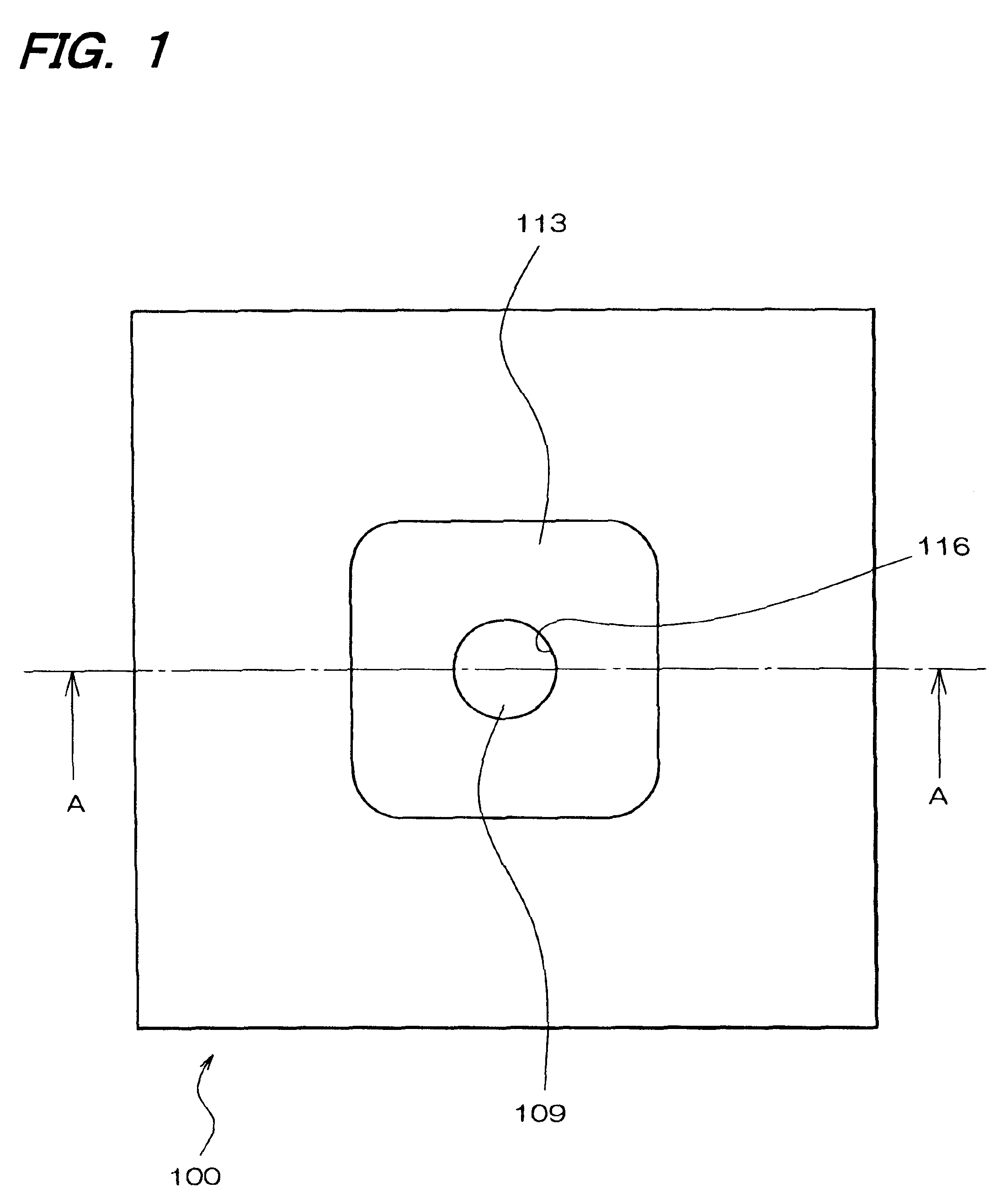

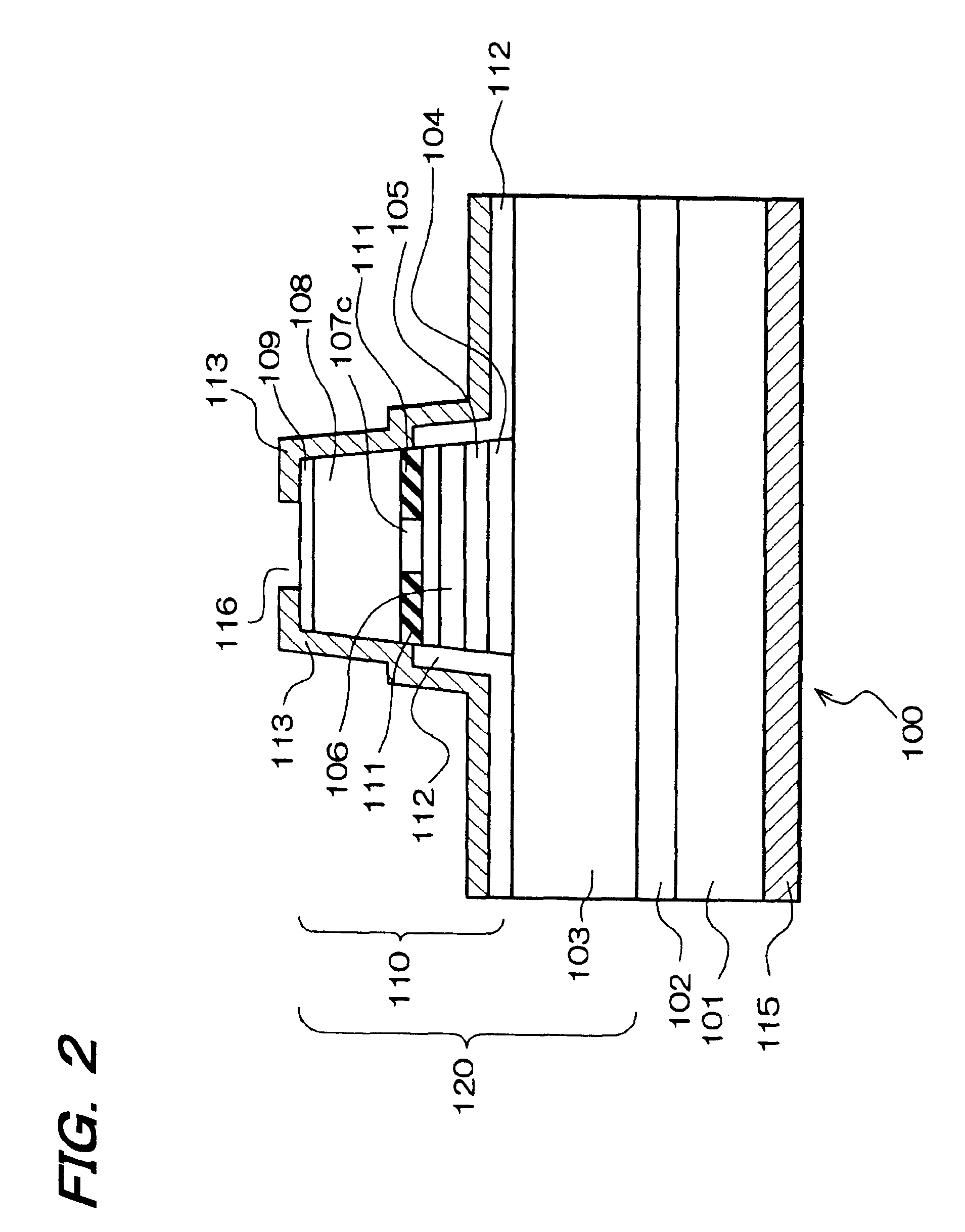

A surface emitting semiconductor laser of the present invention comprises a resonator formed on a semiconductor substrate having Miller indices (100). The resonator includes a pillar portion, and a current constriction layer is formed in this pillar portion. In the plane including the current constriction layer, the periphery of the pillar portion includes arc-shaped portions approximating parts of an inner edge of the current constriction layer. The arc-shaped portions are formed in the <010> direction, <001> direction, <0-10> direction, and <00-1> direction from the center of the inner edge of the current constriction layer, and are formed substantially in concentric circles with the part of the inner edge shape.

Owner:SEIKO EPSON CORP

Surface emitting semiconductor laser and method of manufacturing the same

InactiveUS6631152B2Optical wave guidanceOptical resonator shape and constructionMiller indexSemiconductor package

A surface emitting semiconductor laser of the present invention comprises a resonator formed on a semiconductor substrate having Miller indices (100). The resonator includes a pillar portion, and a current constriction layer is formed in this pillar portion. In the plane including the current constriction layer, the periphery of the pillar portion includes arc-shaped portions approximating parts of an inner edge of the current constriction layer. The arc-shaped portions are formed in the <010> direction, <001> direction, <0-10> direction, and <00-1> direction from the center of the inner edge of the current constriction layer, and are formed substantially in concentric circles with the part of the inner edge shape.

Owner:SEIKO EPSON CORP

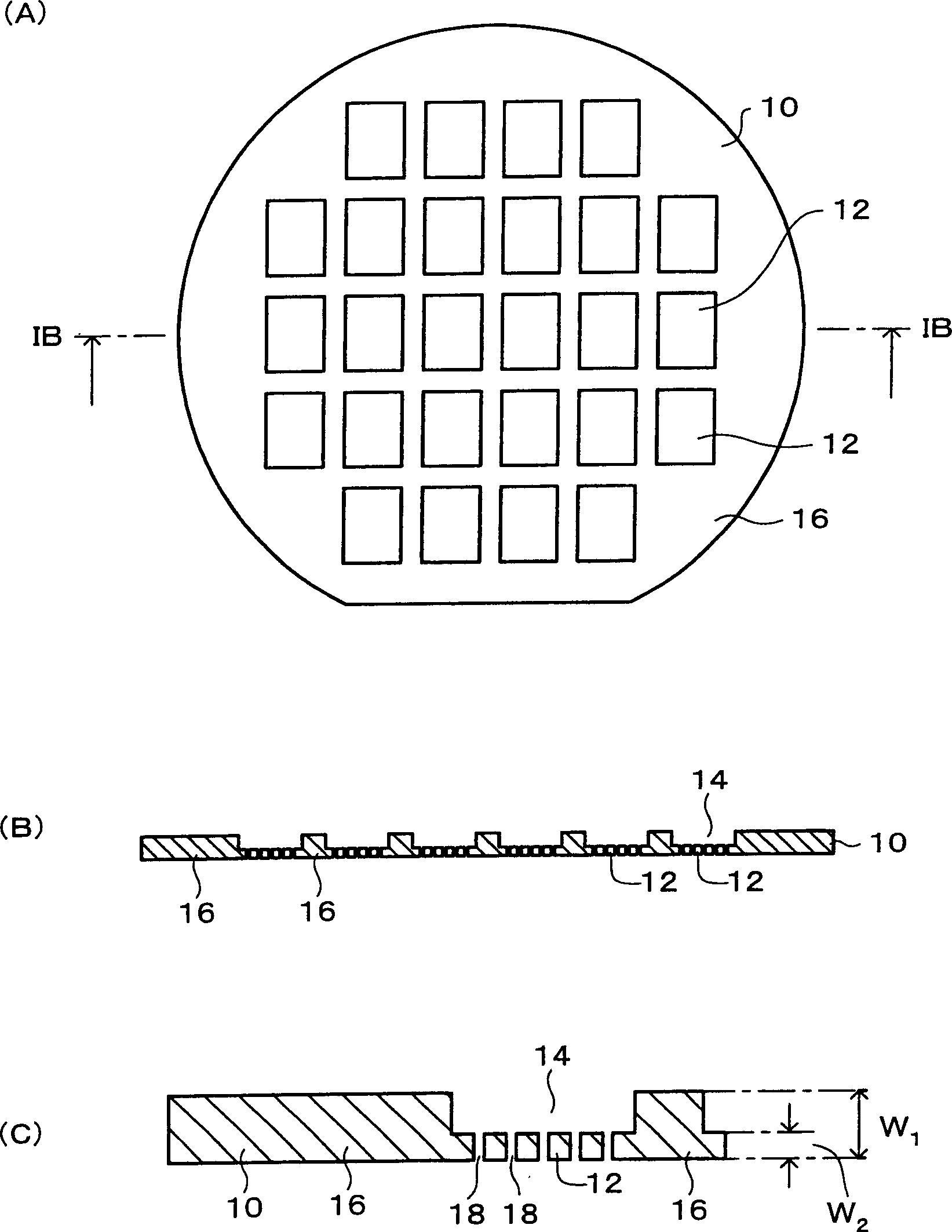

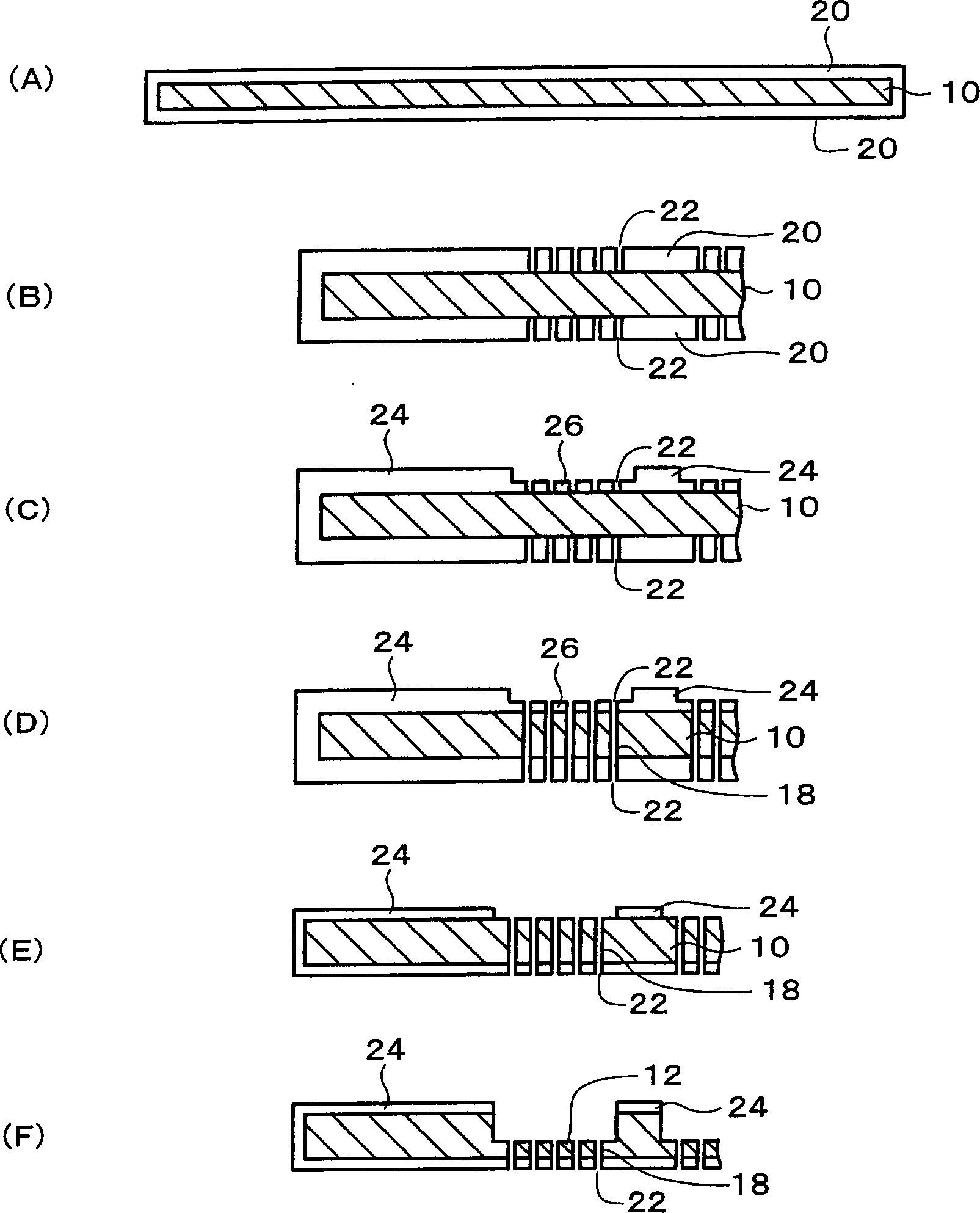

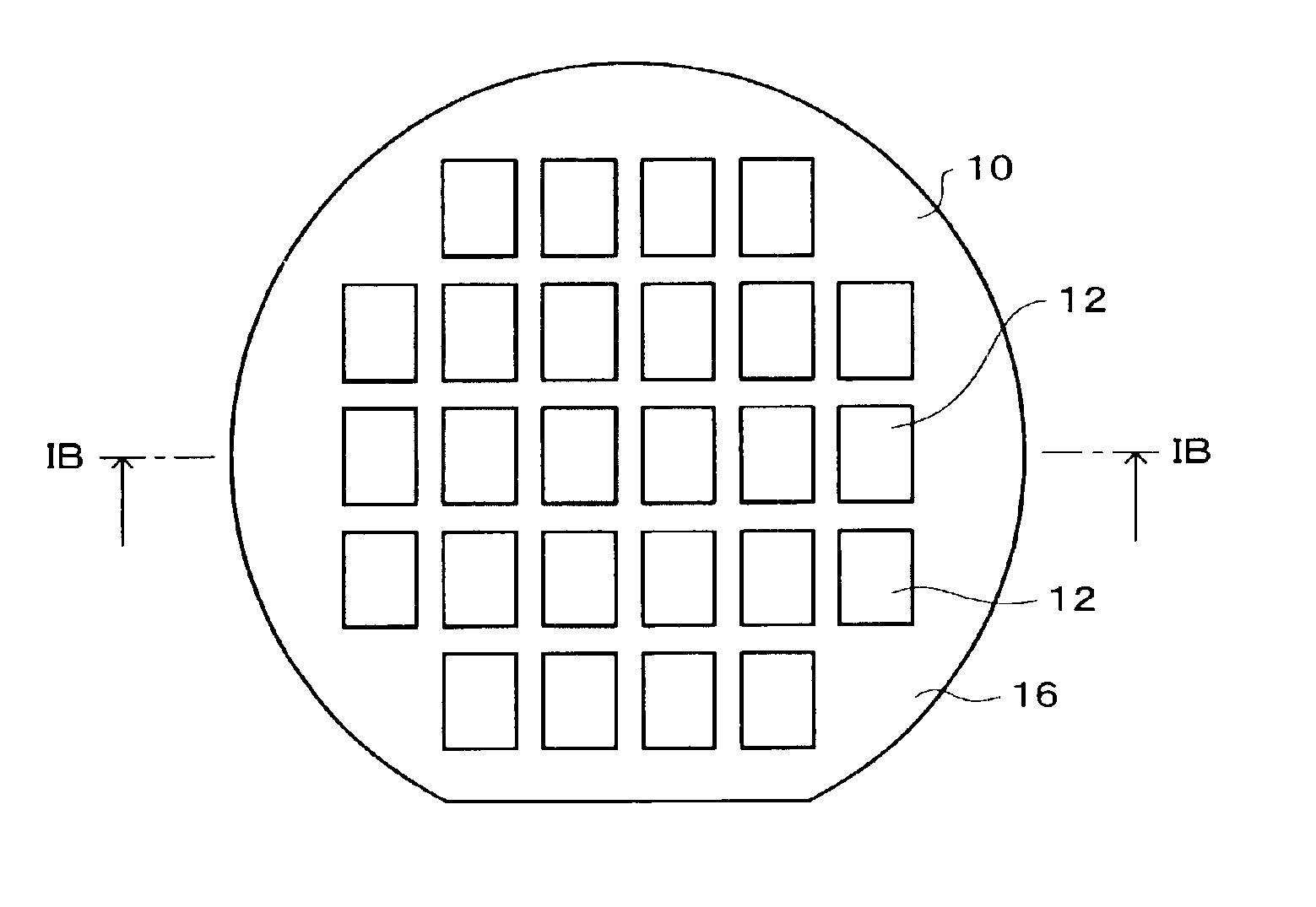

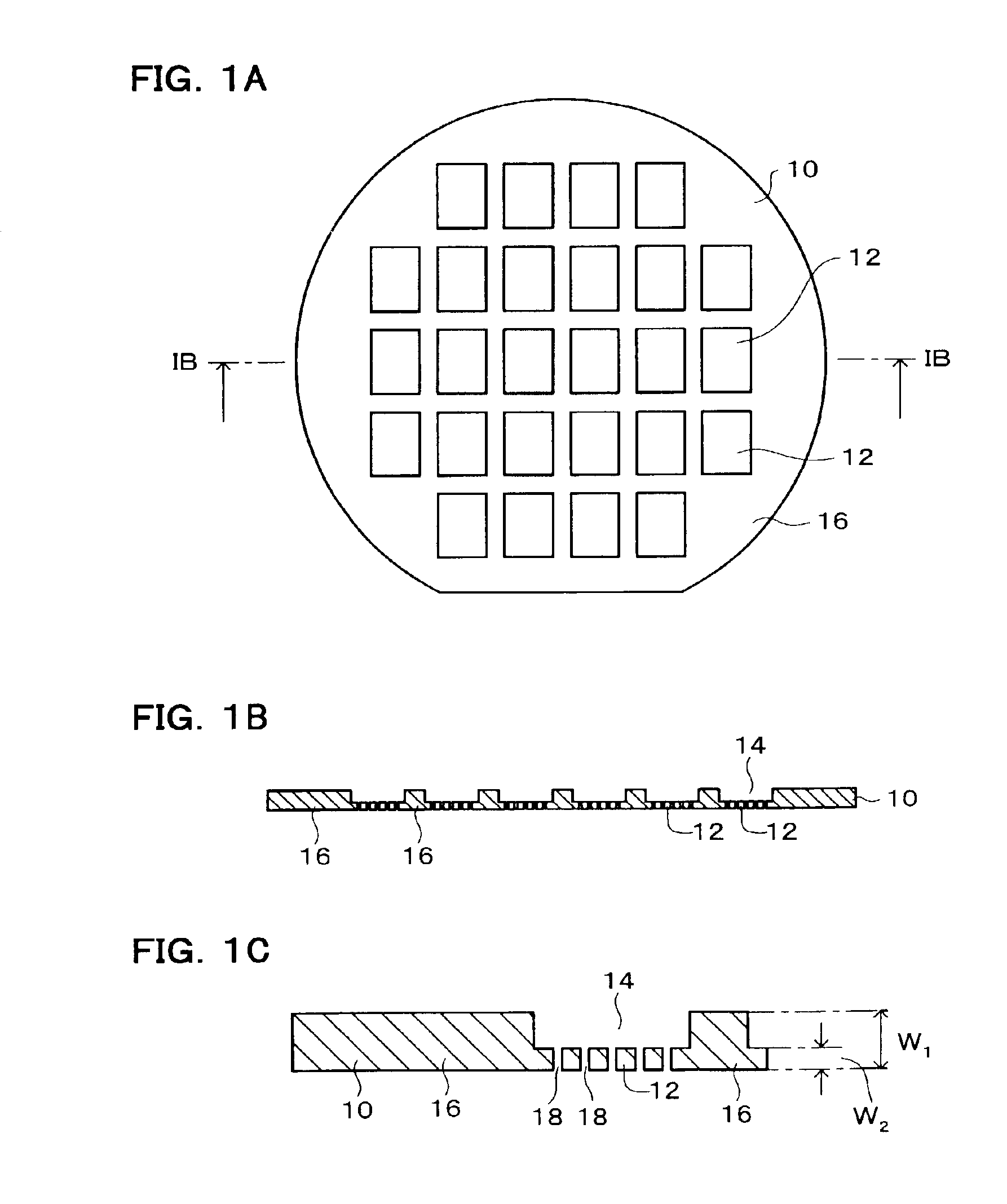

Method for evaluating crystallinity of polycrystalline silicon

InactiveCN105393112AThe production is stableAfter-treatment apparatusPolycrystalline material growthIn planeMiller index

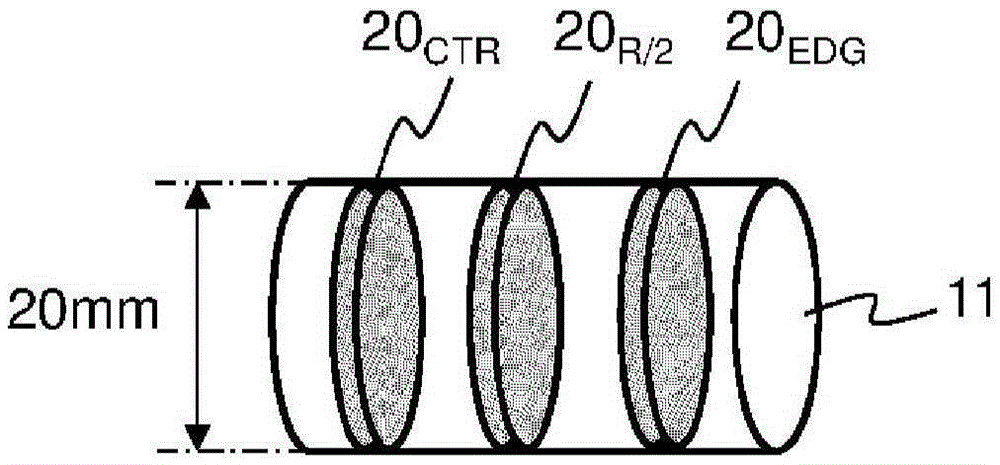

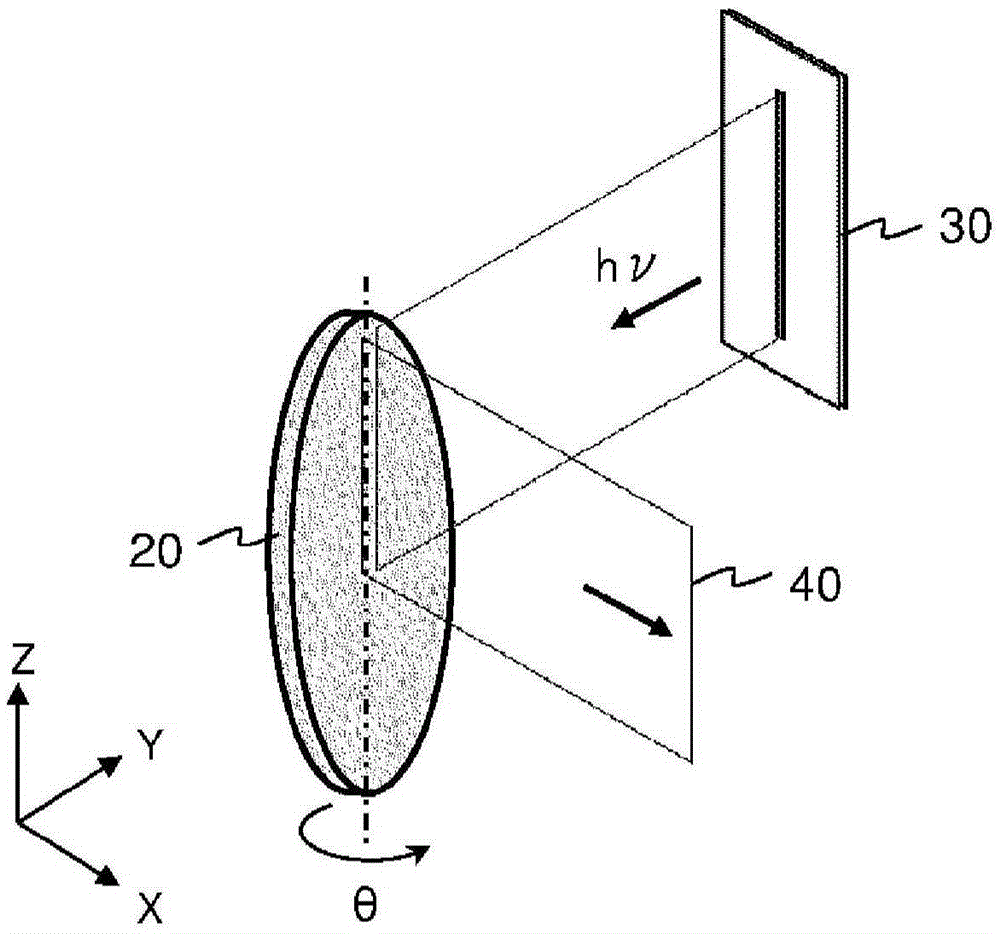

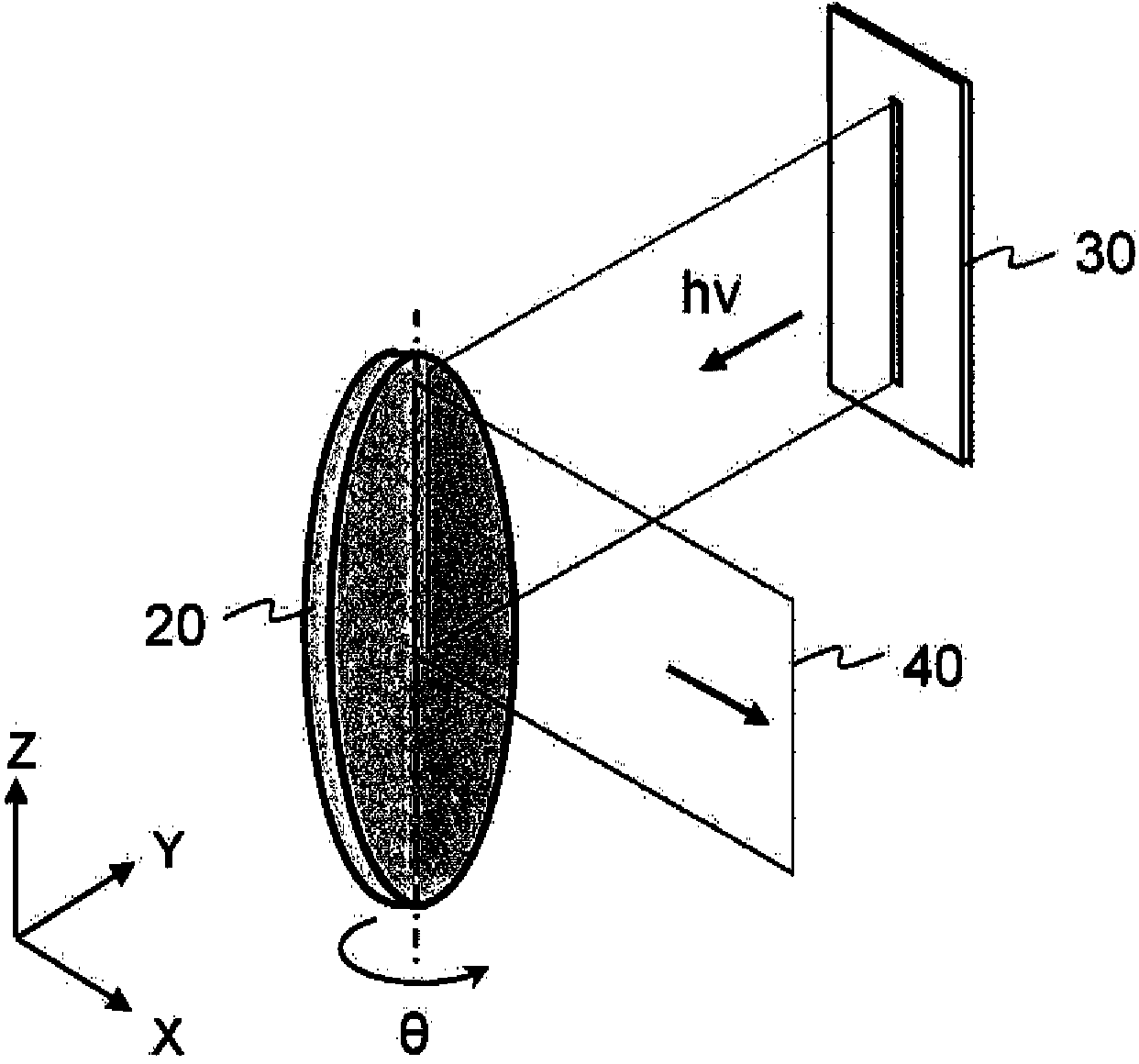

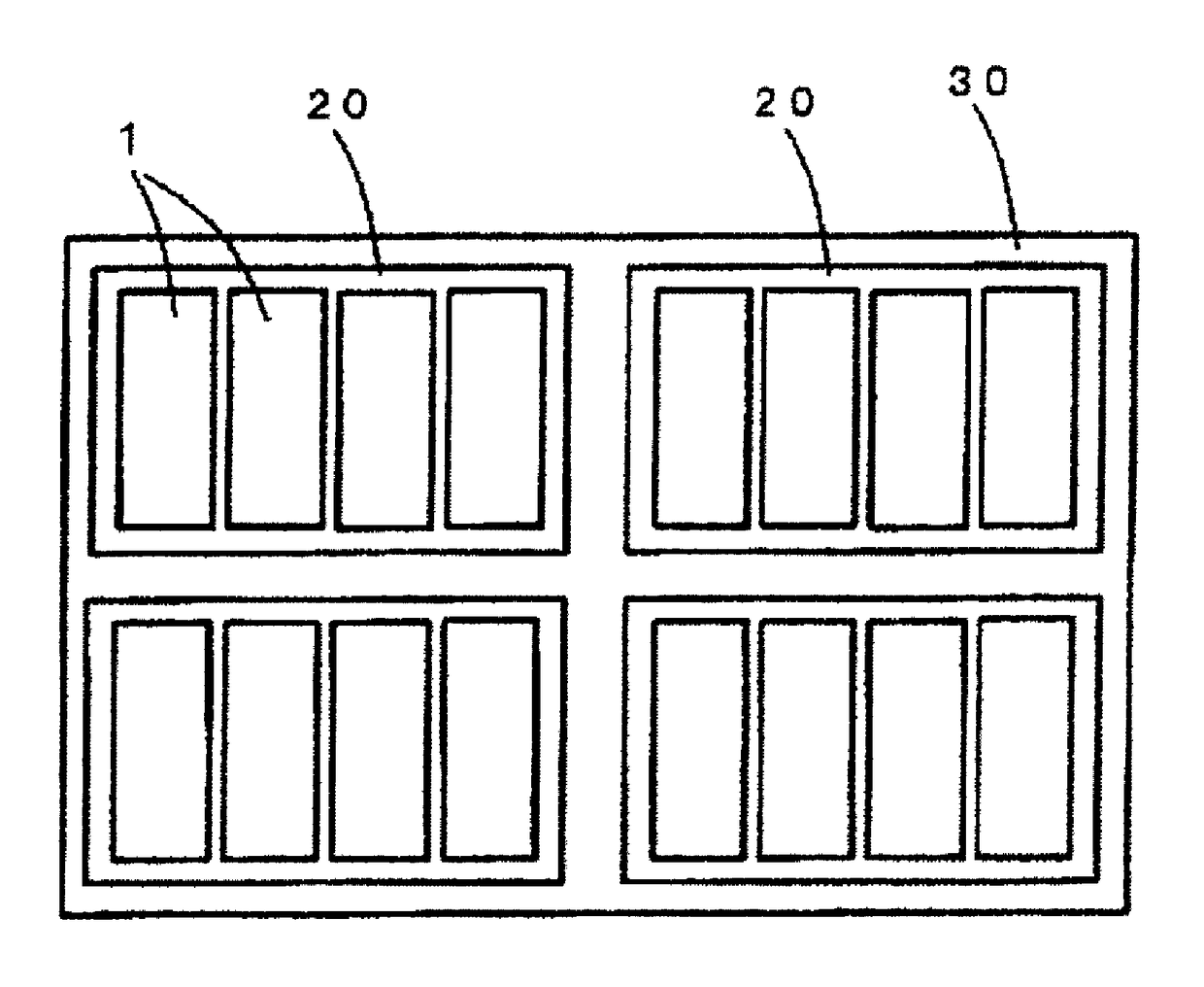

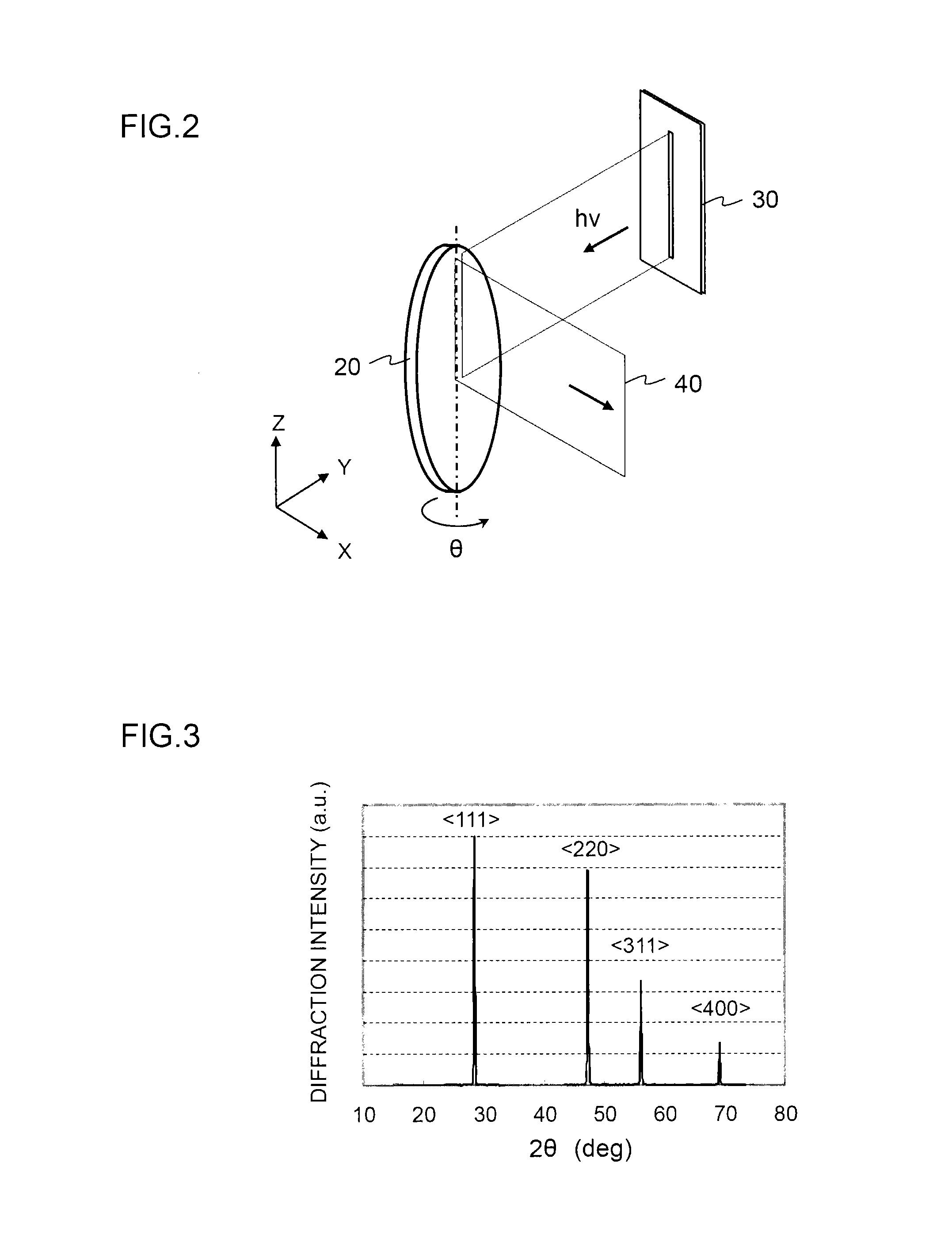

The present invention involves: positioning a collected plate-shaped specimen (20) in a position where a Bragg reflection from a first Miller index surface <h1k1l1> is detected; in-plane rotating the plate-shaped specimen (20) at a rotation angle (phi) with the center of the plate-shaped specimen (20) as the center of rotation in a manner such that the x-ray-irradiation region delimited by a slit phi-scans the principal surface of the plate-shaped specimen (20); obtaining a chart expressing the rotation-angle (phi) dependency of the plate-shaped specimen (20) of the Bragg reflection intensity from the Miller index surface <hkl>; obtaining a baseline diffraction intensity value (IB) from the chart; similarly obtaining a baseline diffraction intensity value (IB 2) from a phi-scan chart obtained from a second Miller index surface <h2k2l2>; and using the magnitude correlation between the IB 1 value and the IB 2 value as the evaluation indicator of the crystallinity of polycrystalline silicon.

Owner:SHIN ETSU CHEM IND CO LTD

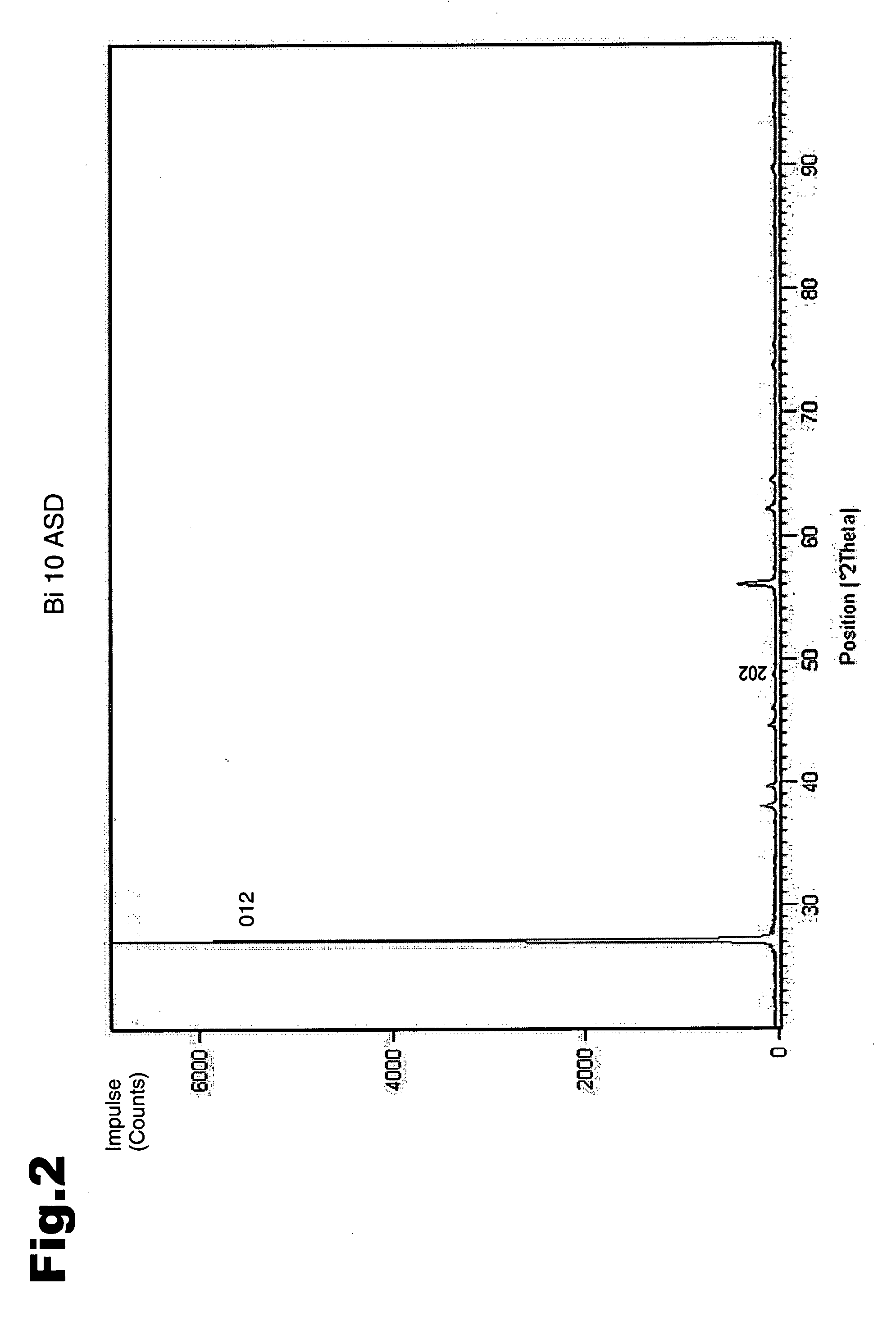

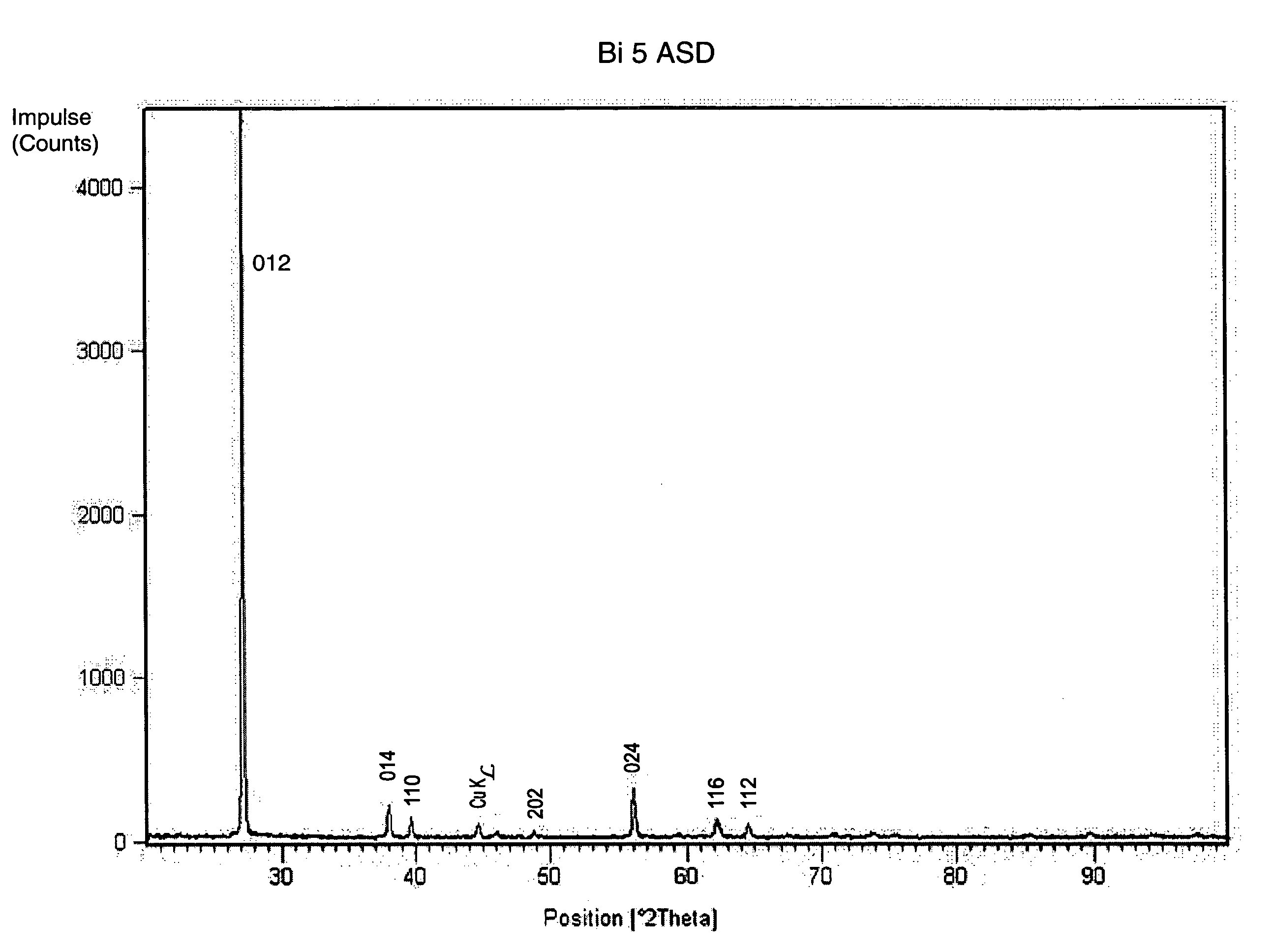

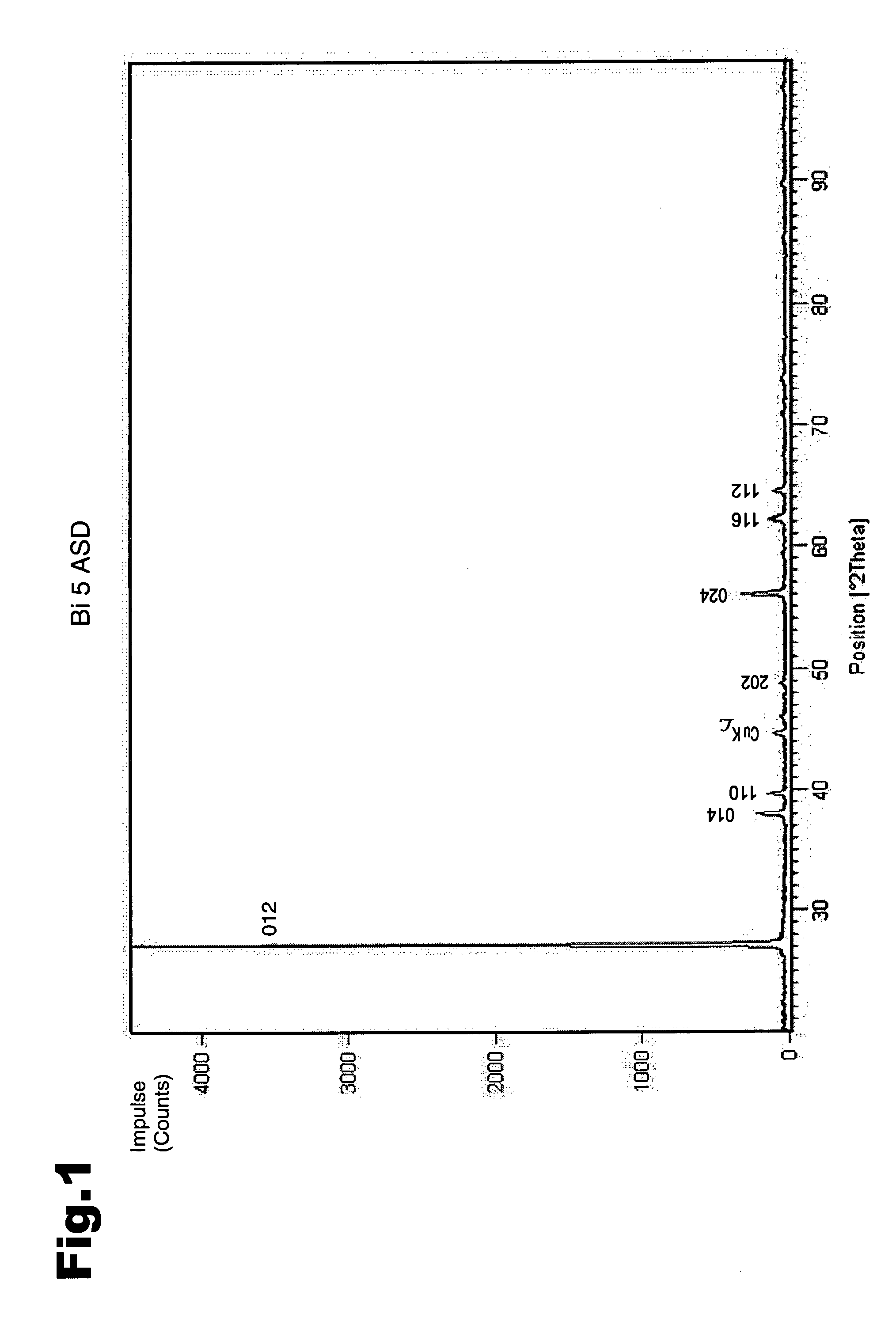

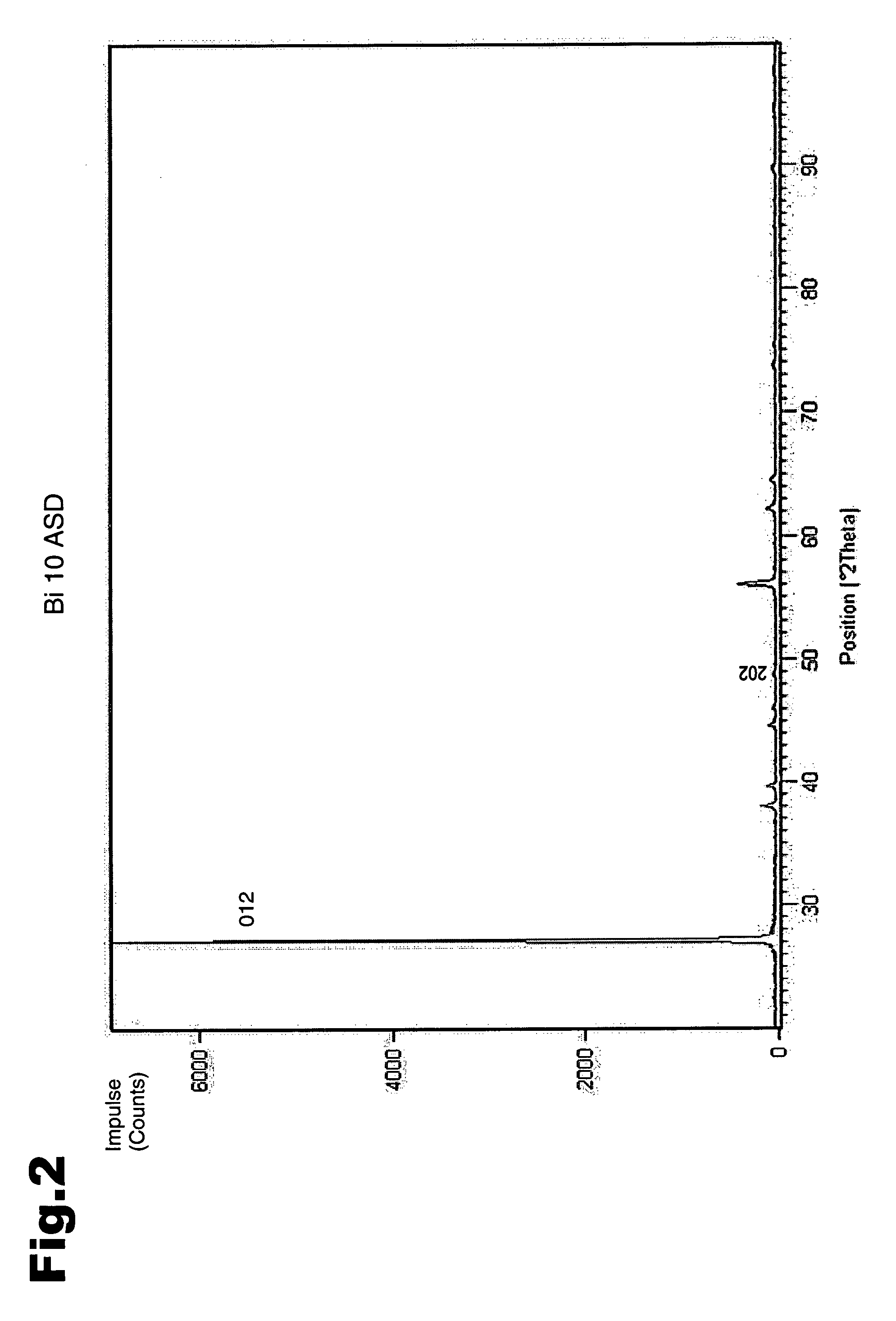

Sliding element

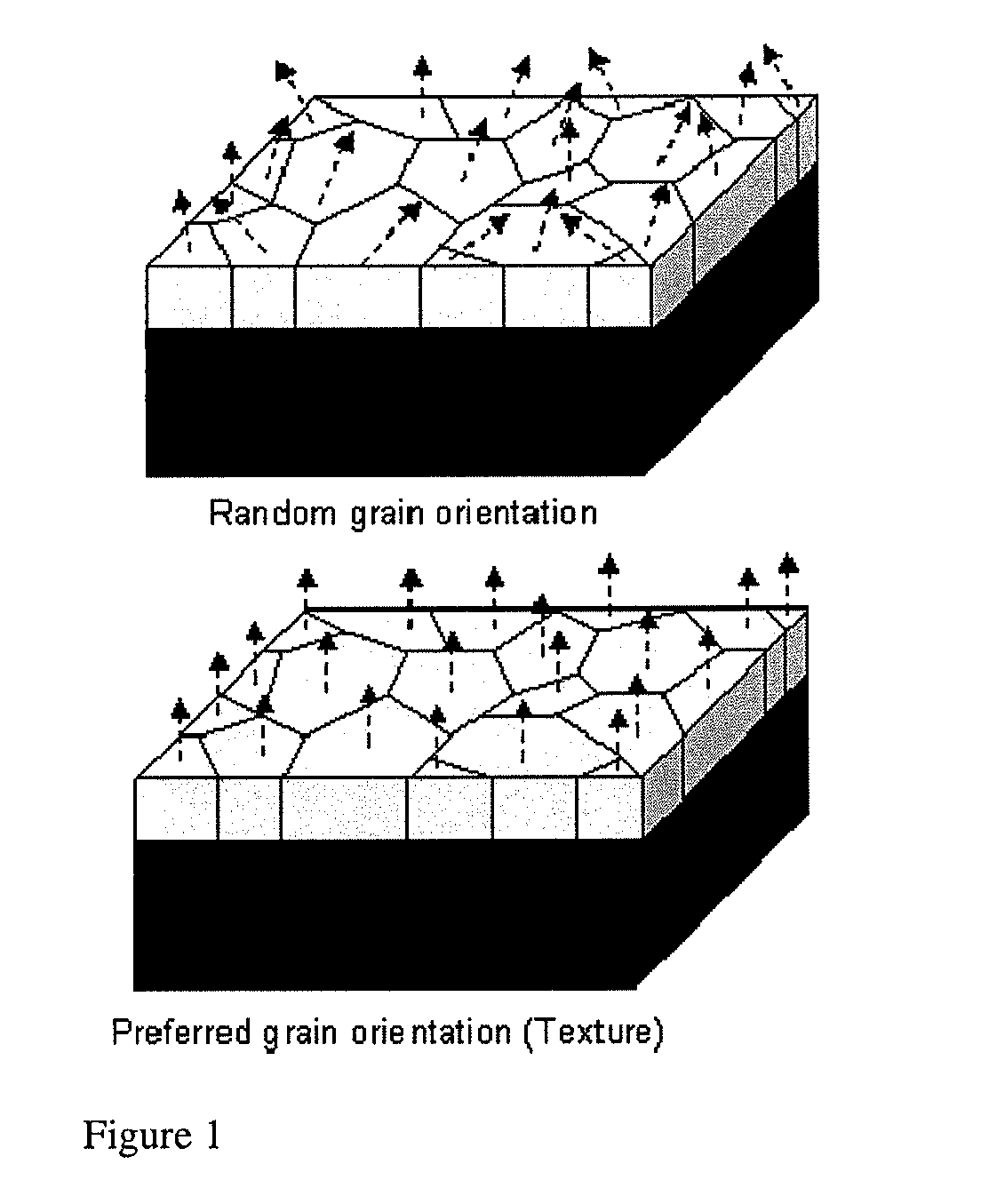

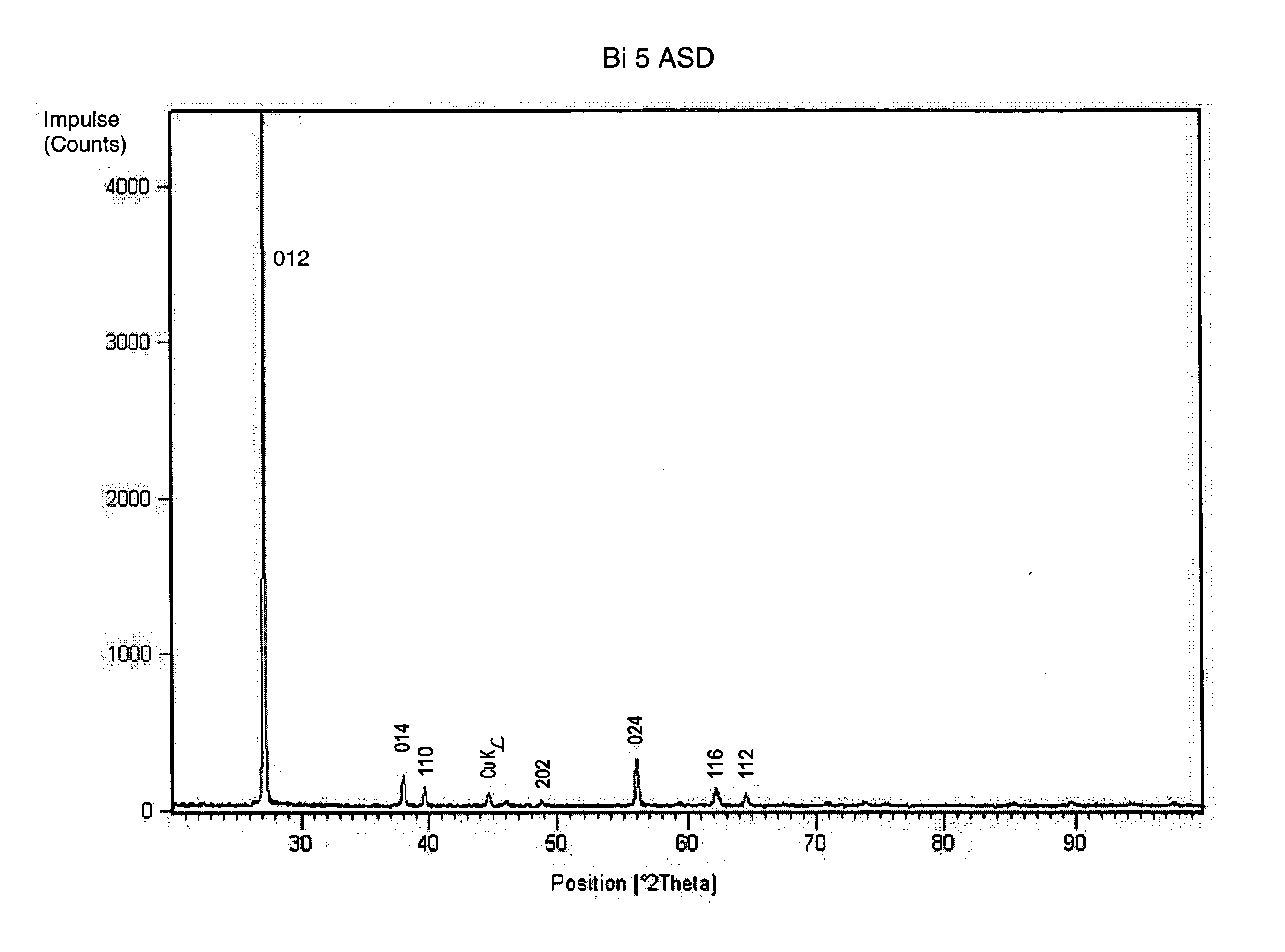

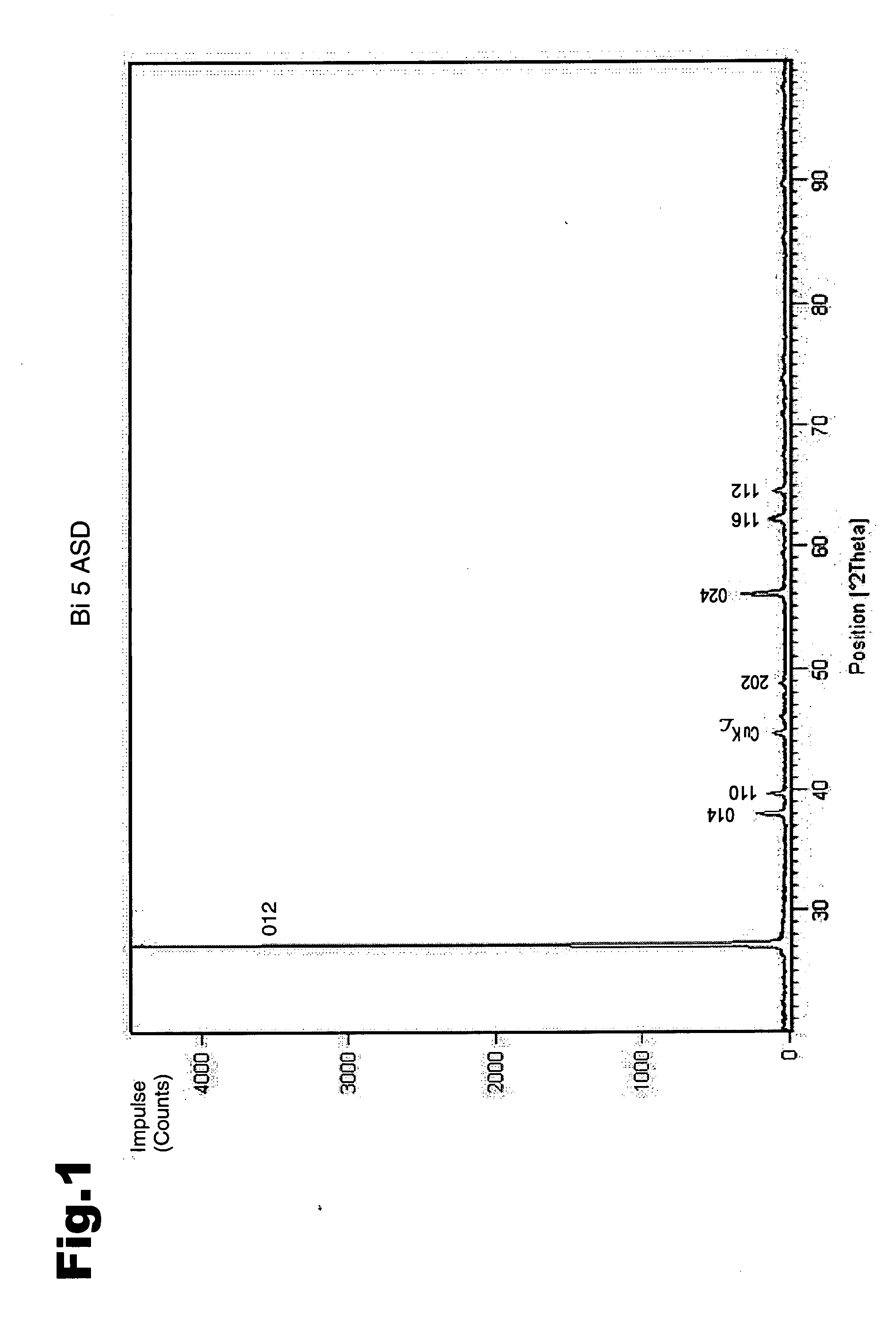

InactiveUS20070269147A1Easy to produceImprove wear resistanceLinear bearingsBearing componentsMiller indexX-ray

The invention describes a sliding element, in particular a sliding bearing, with a support element and a sliding layer, between which a bearing metal layer is arranged, wherein the sliding layer is made from bismuth or a bismuth alloy, and wherein the crystallites of the bismuth or the bismuth alloy in the sliding layer adopt a preferred direction with respect to their orientation, expressed by the Miller index of the lattice plane (012), wherein the X-ray diffraction intensity of the lattice plane (012) is the greatest compared to the X-ray diffraction intensities of other lattice planes. The X-ray diffraction intensity of the lattice plane with the second-largest X-ray diffraction intensity is a maximum of 10% of the X-ray diffraction intensity of the lattice plane (012).

Owner:MIBA SINTER AUSTRIA

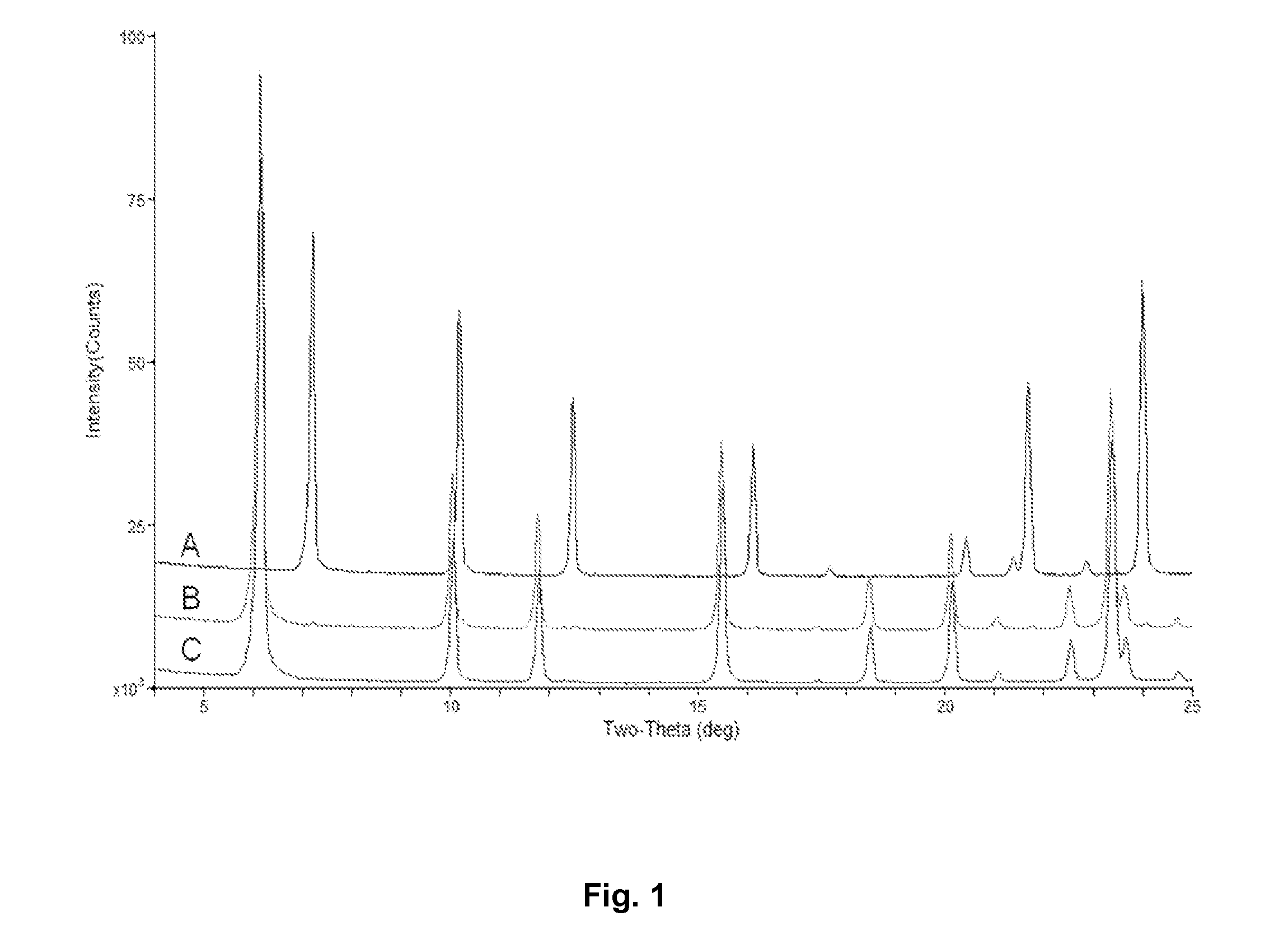

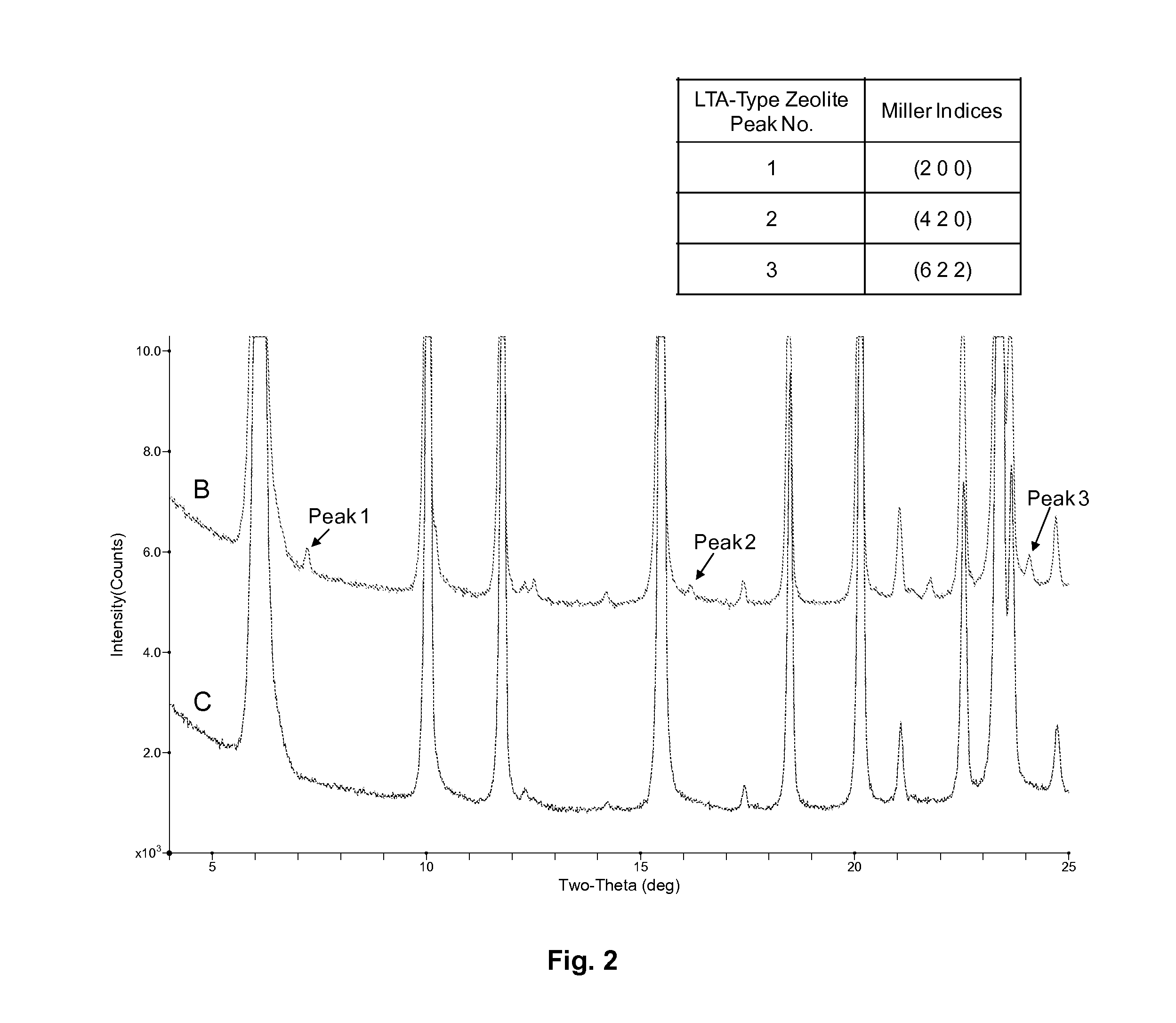

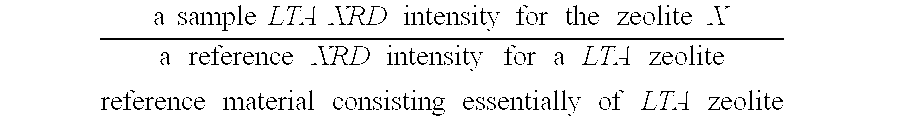

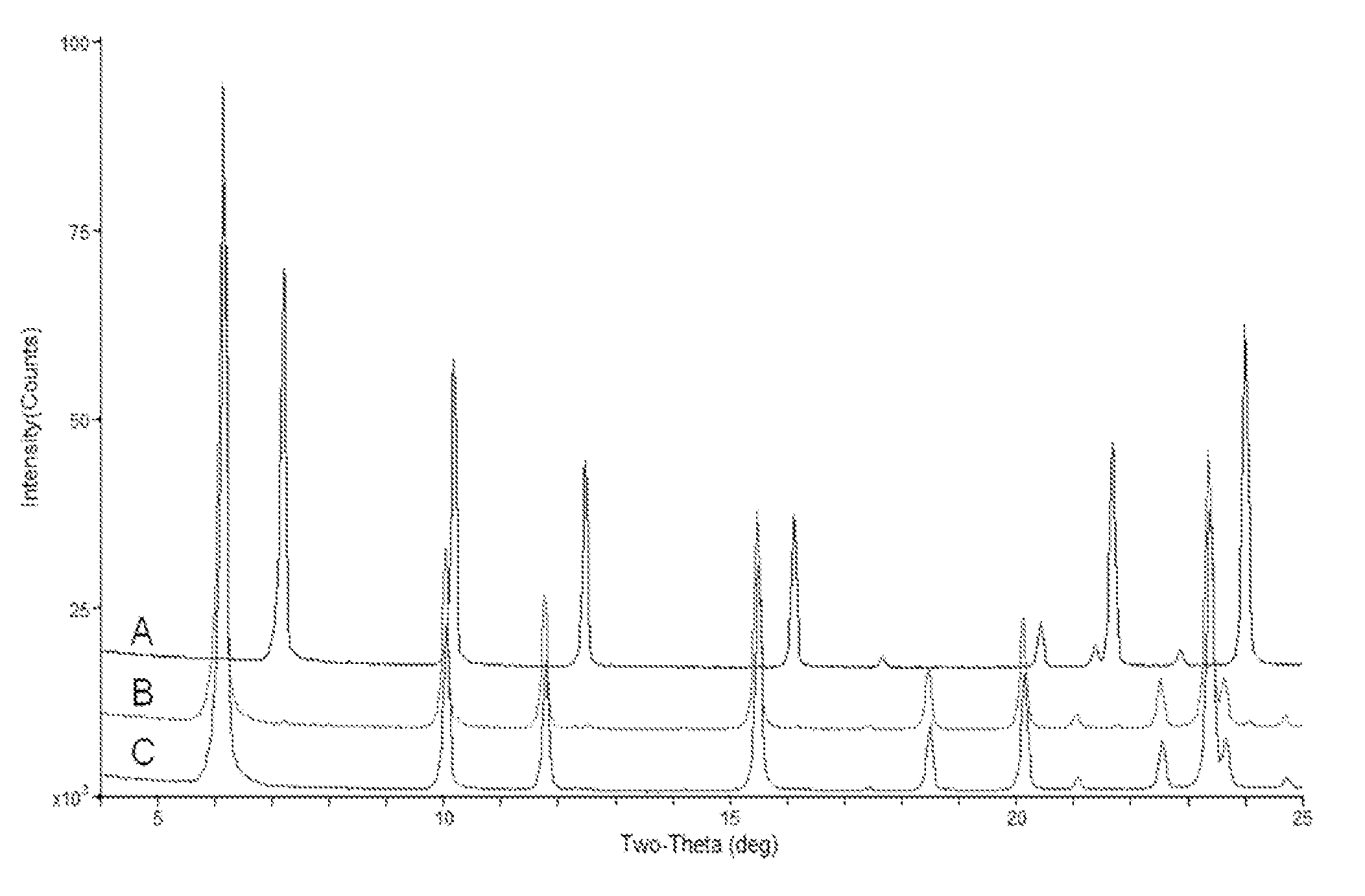

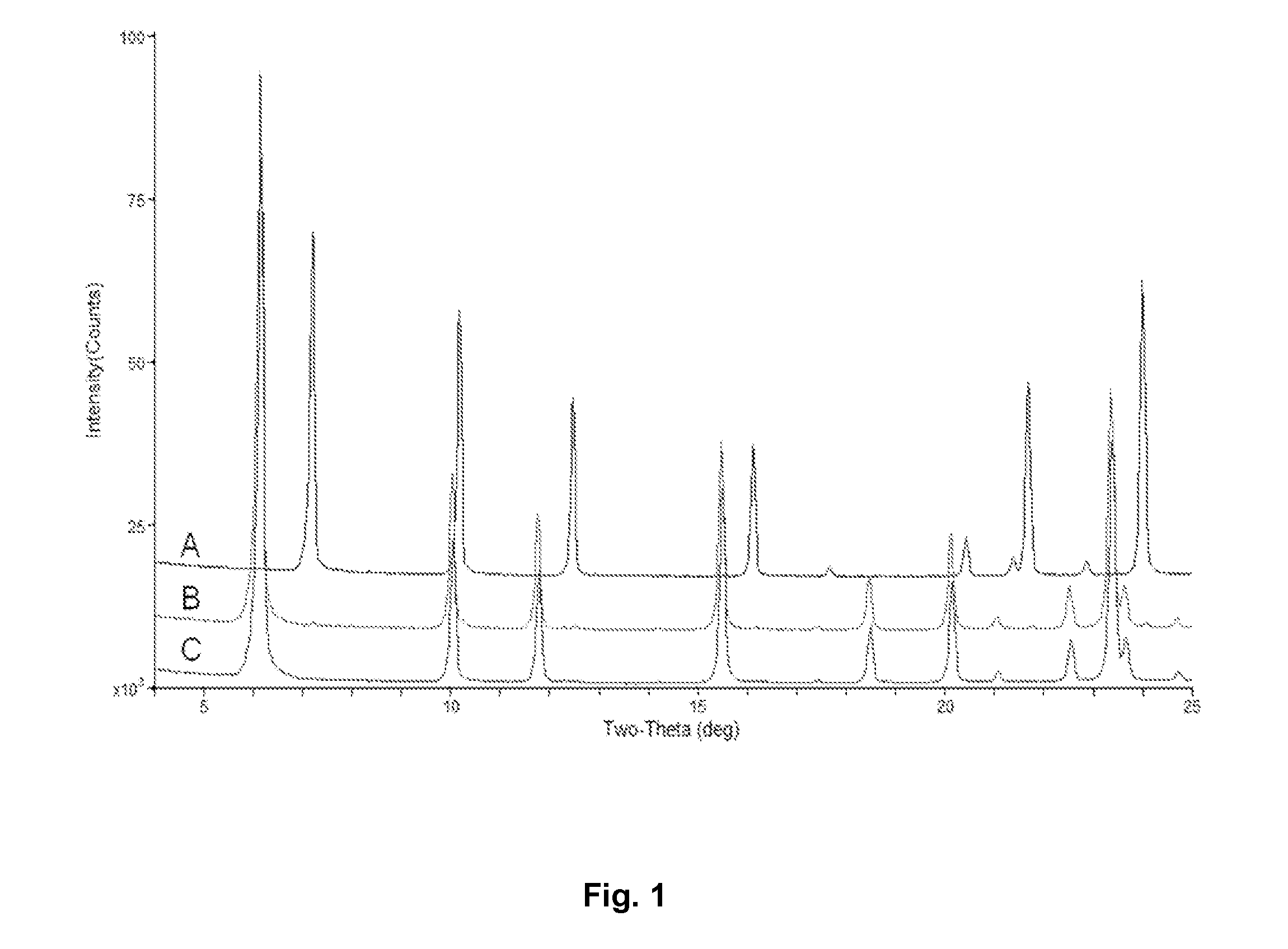

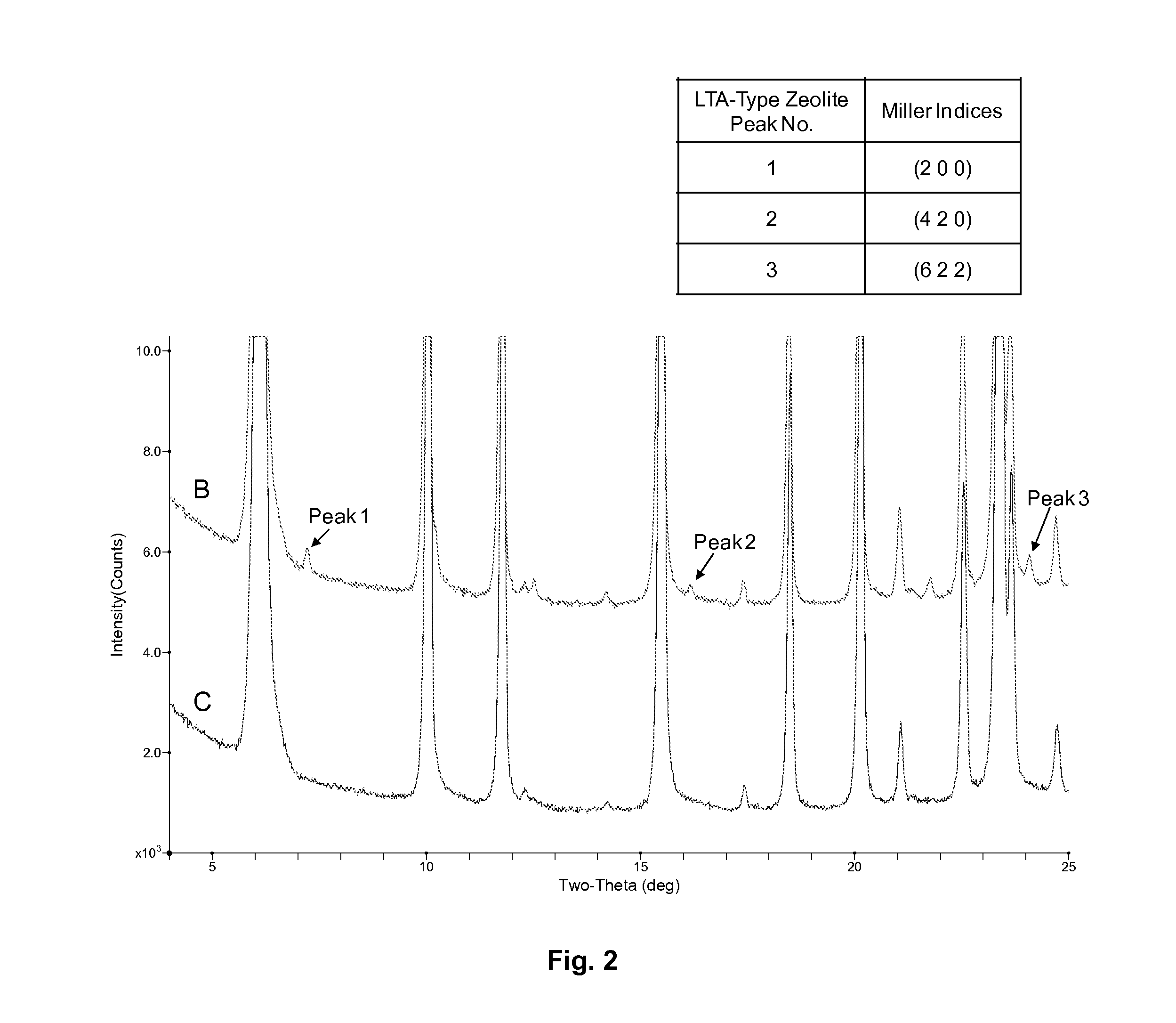

Aluminosilicate X-Type Zeolite Compositions with Low LTA-Type Zeolite

A zeolite X having (a) a Si / Al framework mole ratio in a range from 1.0 to 1.5; (b) a mean diameter not greater than 2.7 microns; and (c) a relative LTA intensity not greater than 0.35, as determined by x-ray diffraction (XRD). The relative LTA intensity is calculated as 100 times the quotient of a sample LTA XRD intensity divided by a reference XRD intensity of an LTA-type zeolite material. The intensities are summed for each LTA peak with Miller indices of (2 0 0), (4 2 0), and (6 2 2) at 7.27±0.16°, 16.29±0.34° and 24.27±0.50° 2θ.

Owner:UOP LLC

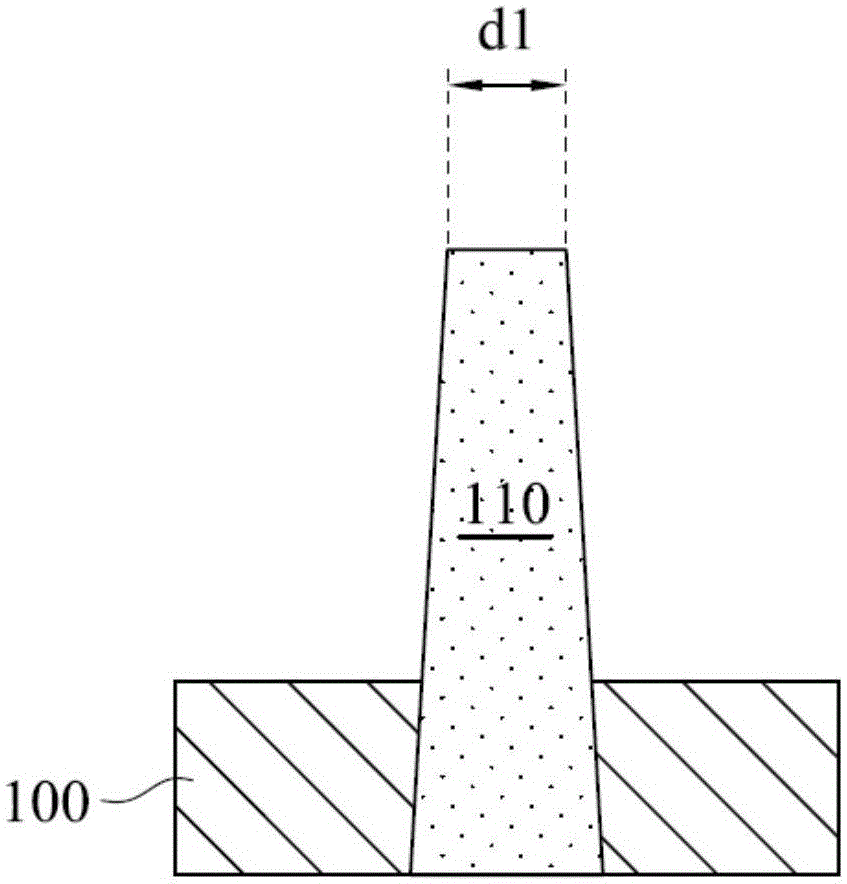

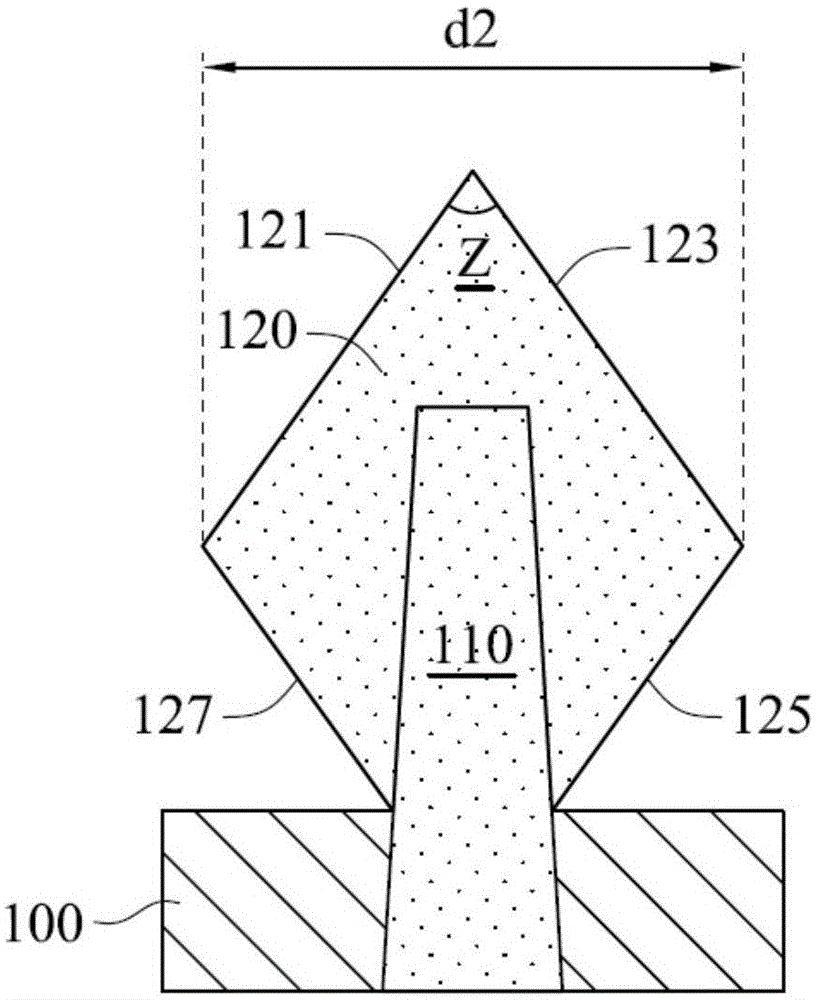

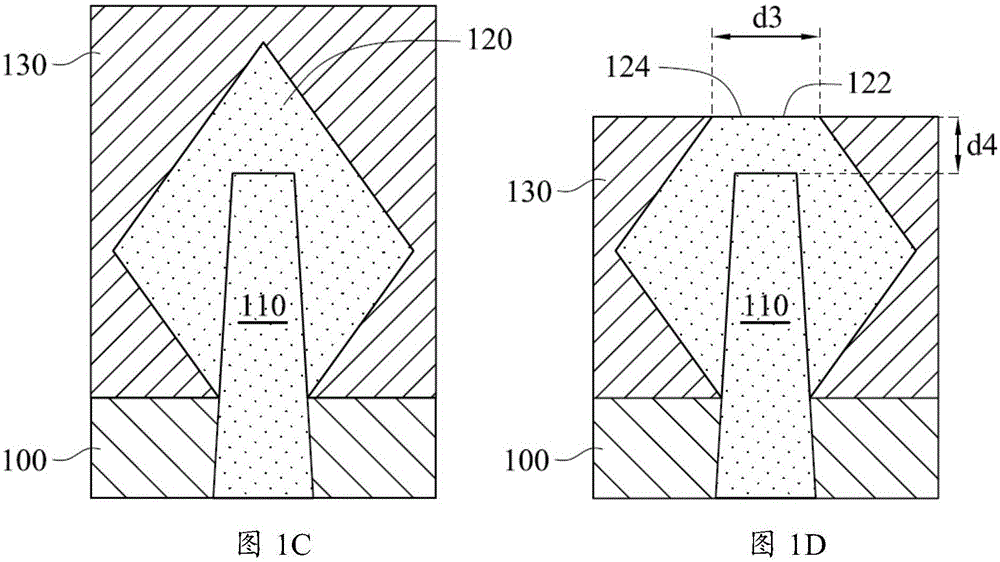

Method of trimming fin structure

ActiveCN106206314ASemiconductor/solid-state device manufacturingSemiconductor devicesMiller indexEpitaxy

A method of trimming a fin structure includes the following operations: (i) forming a fin structure on a substrate; (ii) epitaxially growing an epitaxy structure cladding the fin structure, in which the epitaxy structure has a first lattice plane with Miller index (111), a second lattice plane with Miller index (100) and a third lattice plane with Miller index (110); and (iii) removing the epitaxy structure and a portion of the fin structure to obtain a trimmed fin structure.

Owner:TAIWAN SEMICON MFG CO LTD

Sliding element

InactiveUS7651784B2Easy to produceImprove wear resistanceLinear bearingsBearing componentsMiller indexX-ray

The invention describes a sliding element, in particular a sliding bearing, with a support element and a sliding layer, between which a bearing metal layer is arranged, wherein the sliding layer is made from bismuth or a bismuth alloy, and wherein the crystallites of the bismuth or the bismuth alloy in the sliding layer adopt a preferred direction with respect to their orientation, expressed by the Miller index of the lattice plane (012), wherein the X-ray diffraction intensity of the lattice plane (012) is the greatest compared to the X-ray diffraction intensities of other lattice planes. The X-ray diffraction intensity of the lattice plane with the second-largest X-ray diffraction intensity is a maximum of 10% of the X-ray diffraction intensity of the lattice plane (012).

Owner:MIBA SINTER AUSTRIA

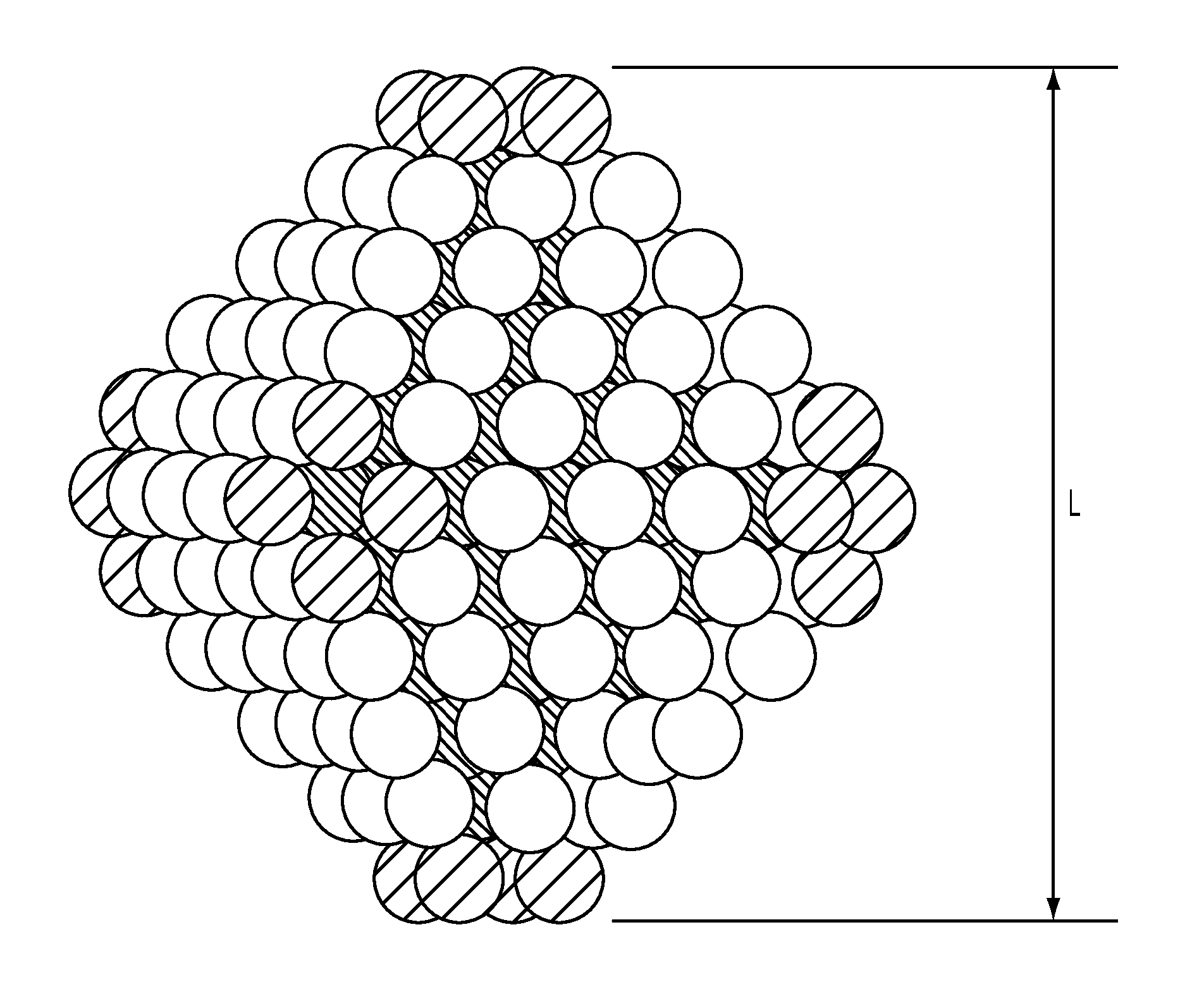

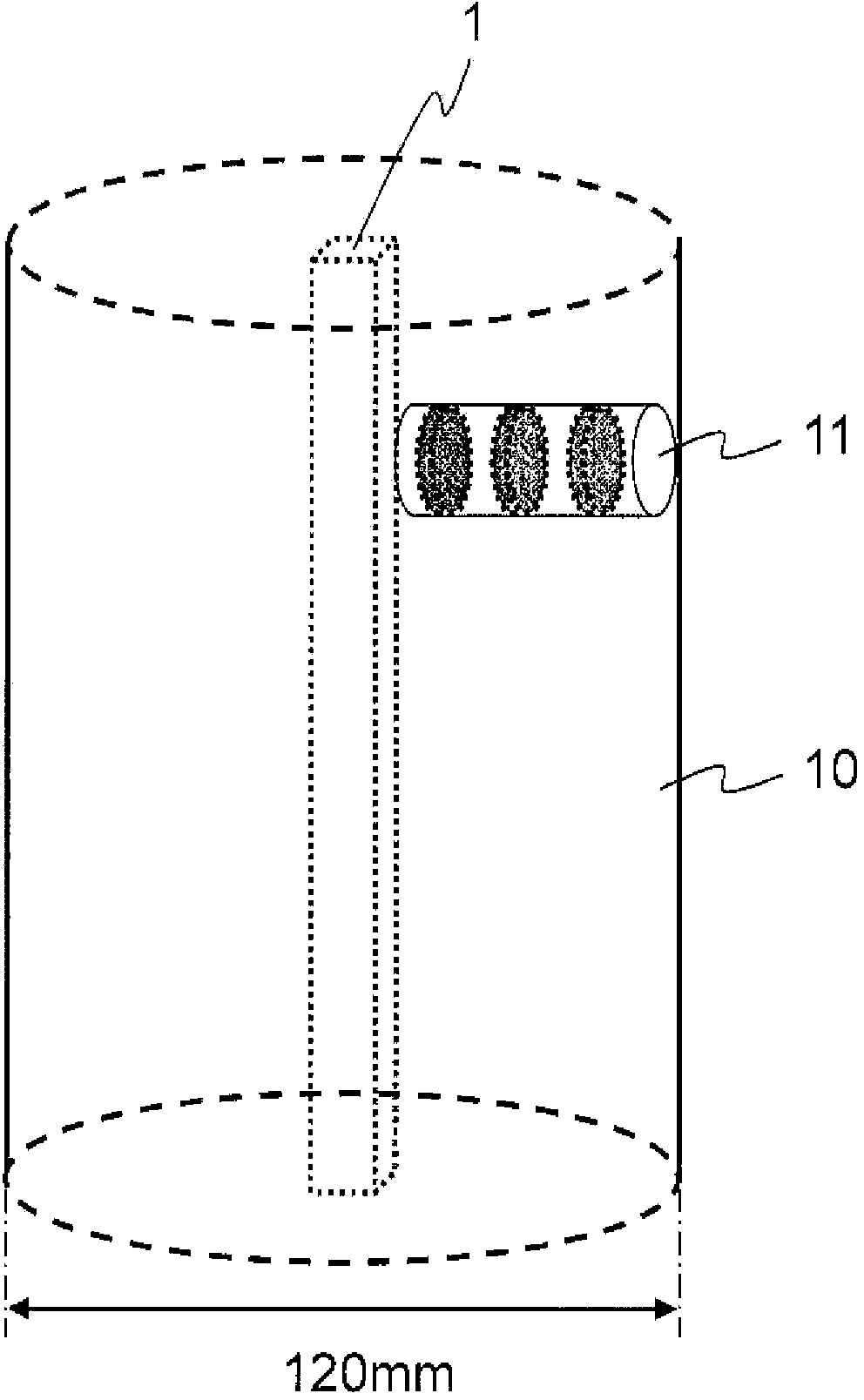

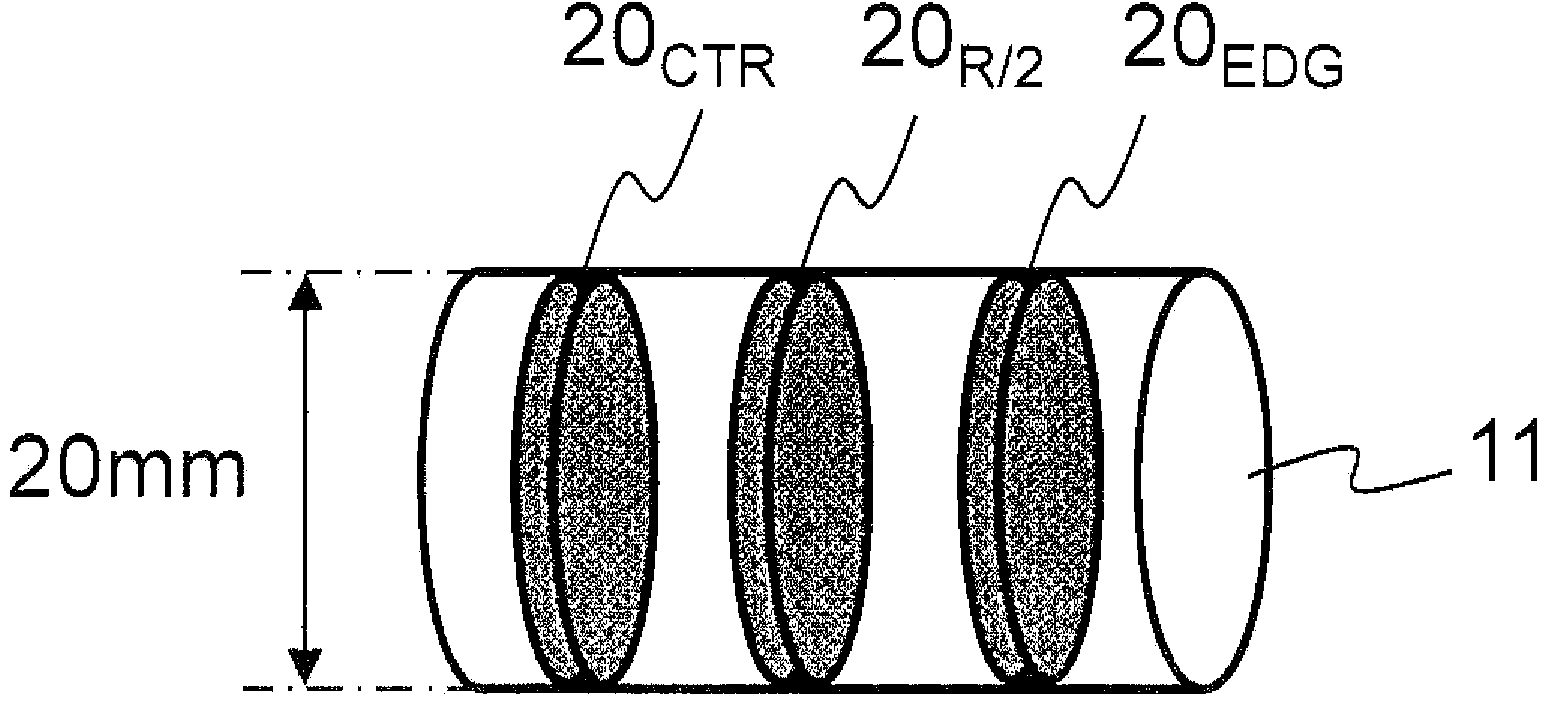

Polycrystalline silicon crystal orientation degree evaluation method, polycrystalline silicon rod selection method, polycrystalline silicon rod, polycrystalline silicon ingot, and polycrystalline silicon fabrication method

ActiveCN104395740AInhibitionStable manufacturingPolycrystalline material growthSiliconIn planeMiller index

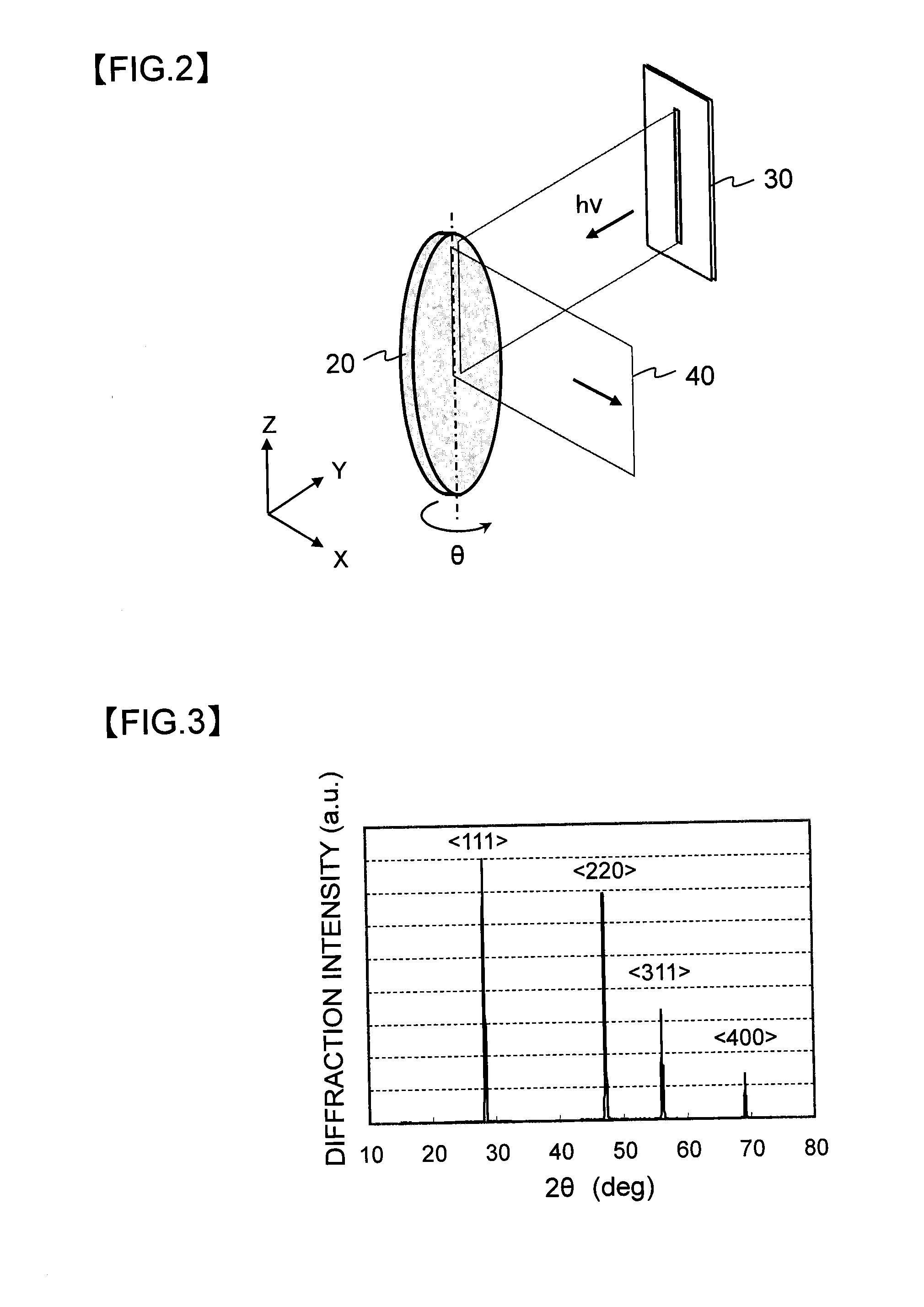

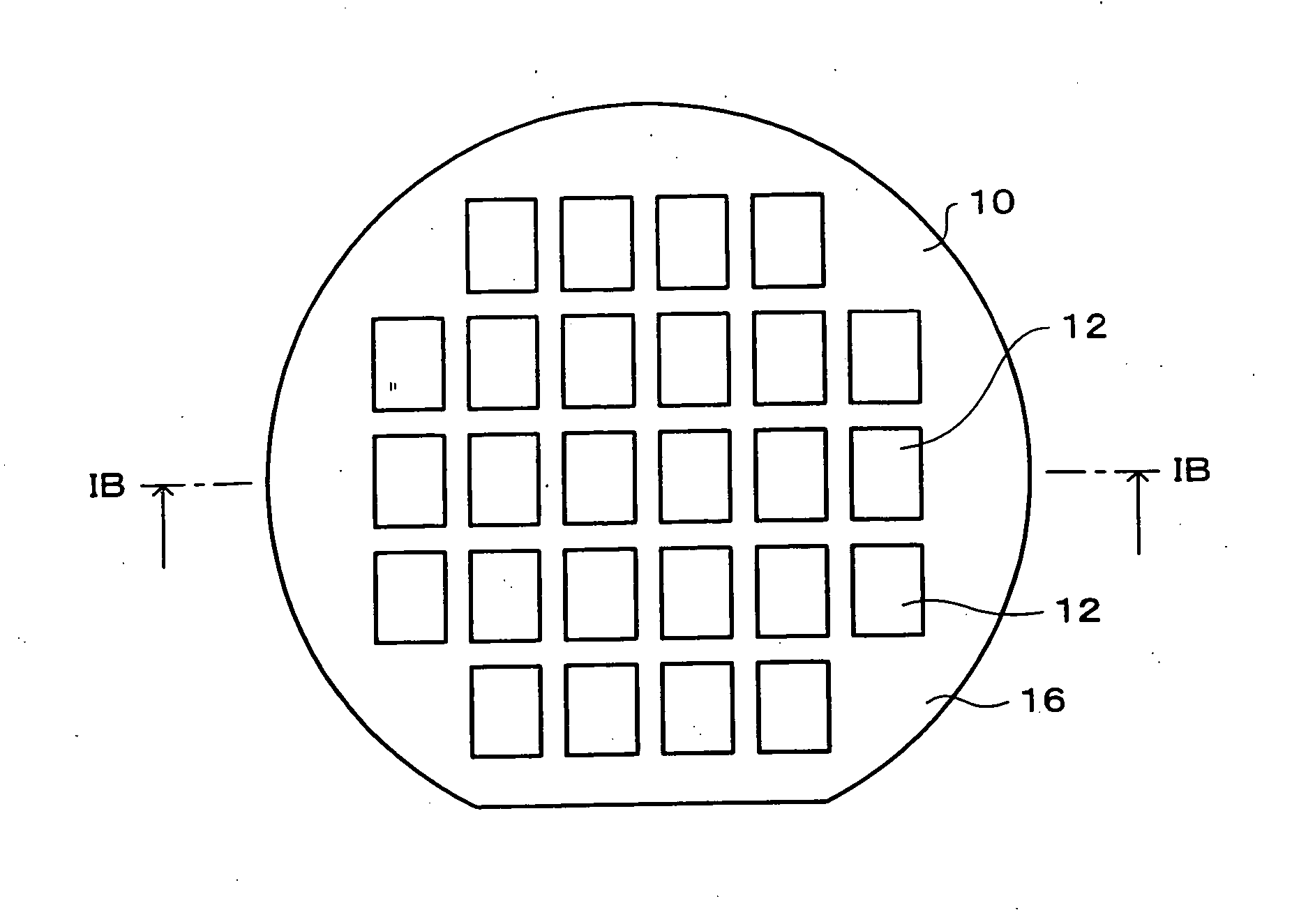

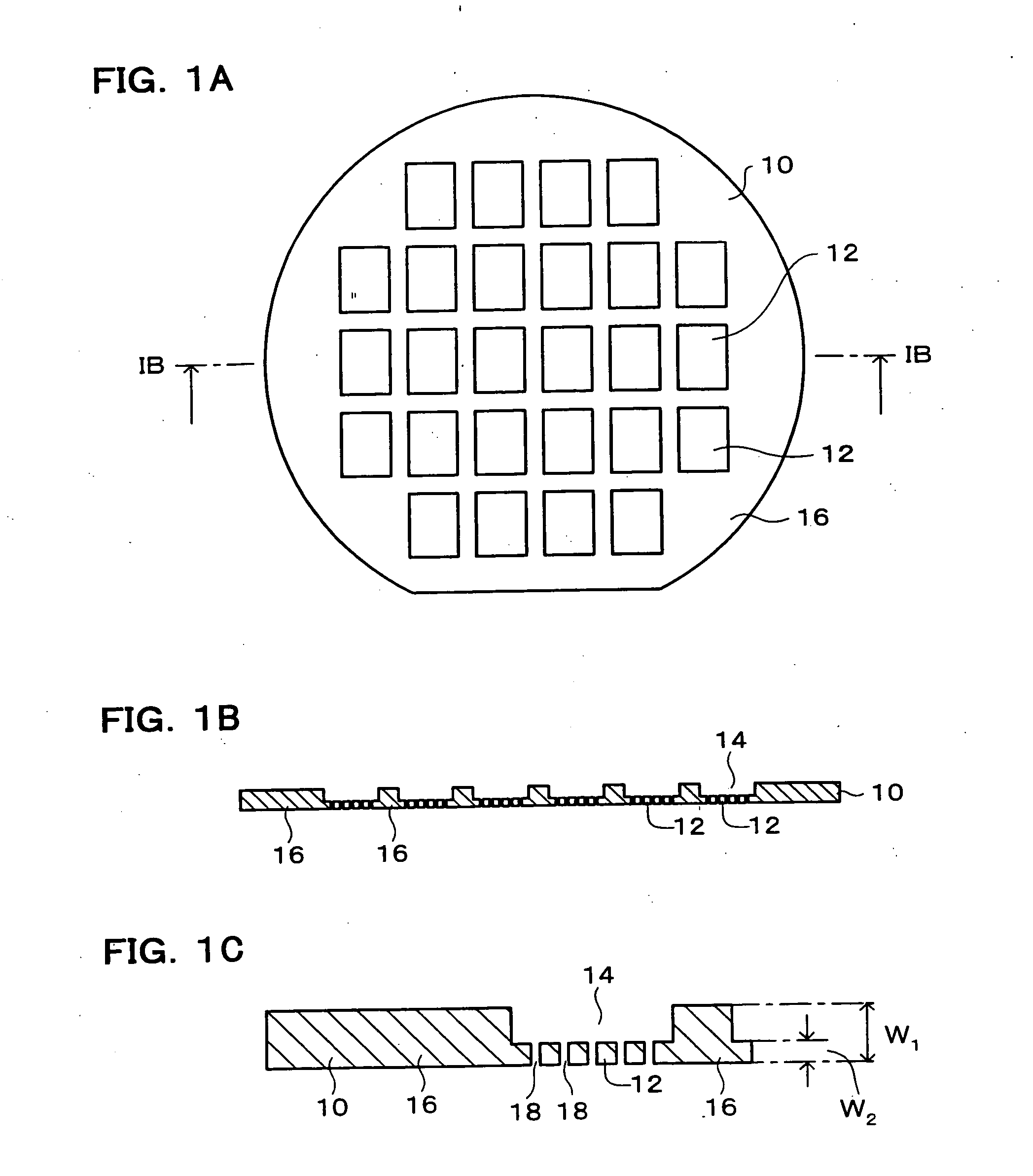

The present invention provides a technology which selects, with high levels of quantitativity and reproducibility, a desirable polycrystalline silicon as a raw material for single crystal silicon fabrication, and contributes to stable fabrication of the single crystal silicon. When evaluating a degree of orientation of a crystal of a polycrystalline silicon by x-ray diffraction: an adopted disc-shaped sample (20) is positioned in a location in which Bragg reflection from a mirror index face <hkl> is detected; an in-plane rotation is carried out at a rotation angle (Phi) with the center of the disc-shaped sample (20) as the center of rotation thereof, such that an x-ray projection region which is defined by a slit Phi scans a primary surface of the disc-shaped sample (20); a chart is derived which denotes a rotation angle (Phi) dependency of the disc-shaped sample (20) of the Bragg reflection intensity from the Miller index face <hkl>; a baseline is derived from the chart; and a value of an intensity of diffraction of the baseline is employed as an evaluation index of the degree of orientation of the crystal.

Owner:SHIN ETSU CHEM CO LTD

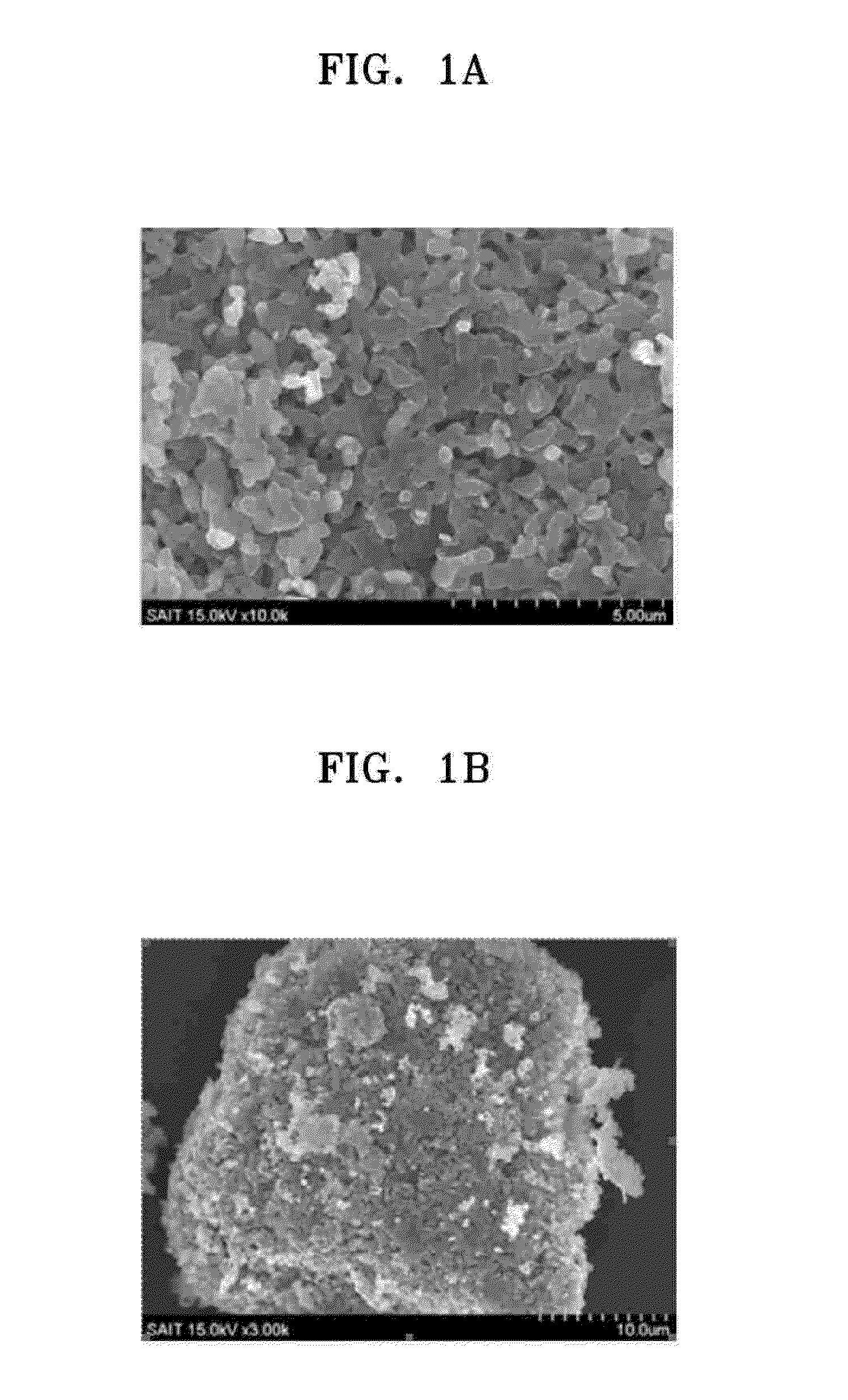

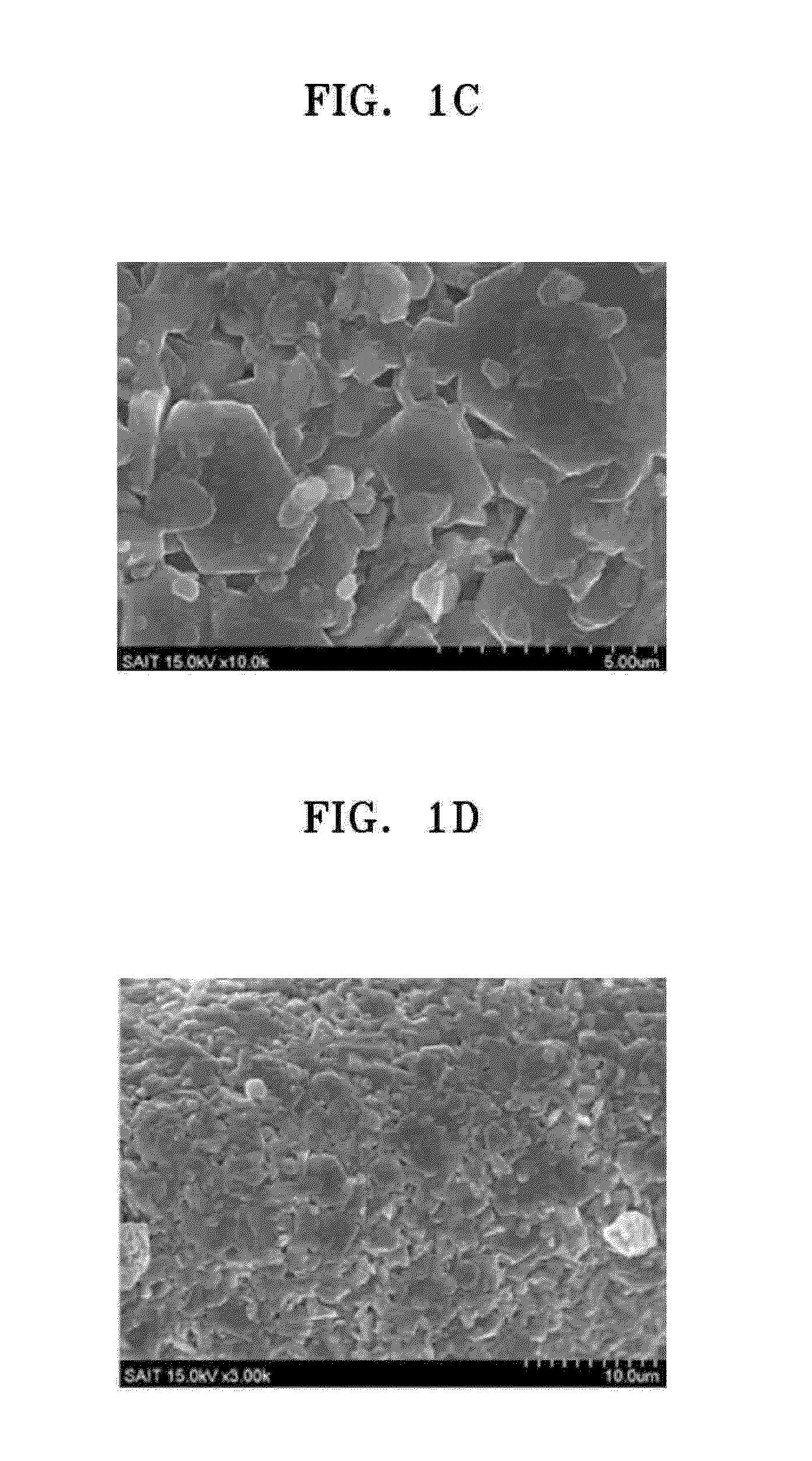

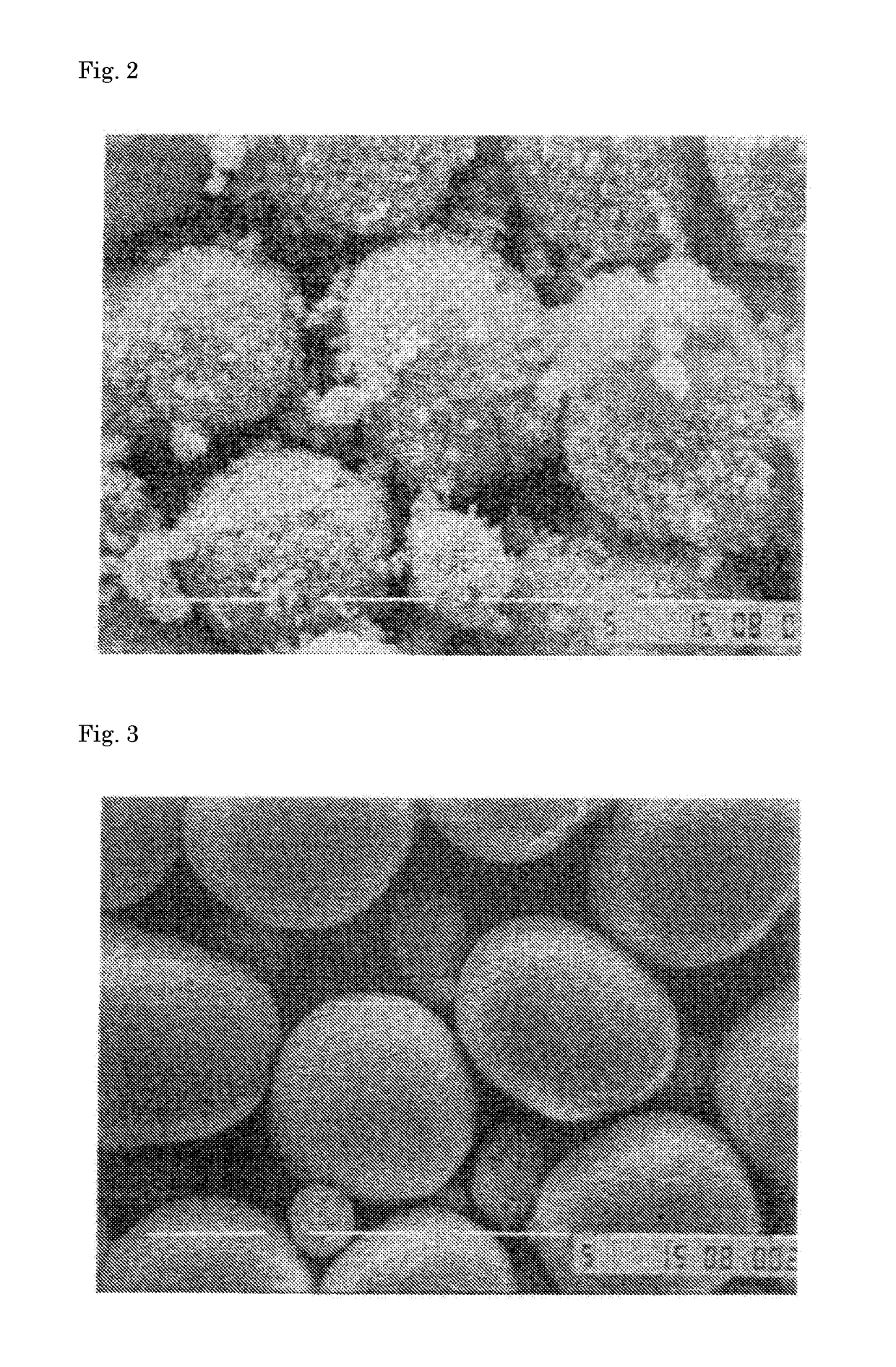

Positive active material for nonaqueous electrolyte secondary battery, method for producing same, electrode for nonaqueous electrolyte secondary battery, and nonaqueous electrolyte secondary battery

ActiveUS20180145318A1Large discharge capacityPositive electrodesLi-accumulatorsSpace groupMiller index

Provided is a positive active material for a nonaqueous electrolyte secondary battery which includes a lithium transition metal composite oxide. A molar ratio (Li / Me) of Li and a transition metal (Me) that form the lithium transition metal composite oxide is more than 1. The transition metal (Me) includes Mn, Ni and Co. The lithium transition metal composite oxide has an α-NaFeO2-type crystal structure, an X-ray diffraction pattern attributable to a space group R3-m, and a full width at half maximum (FWHM (104)) for the diffraction peak of the (104) plane at a Miller index hkl in X-ray diffraction measurement using a CuKα ray of 0.21° or more and 0.55° or less. A ratio (FWHM (003) / FWHM (104)) of a full width at half maximum for the diffraction peak of the (003) plane and the full width at half maximum for the diffraction peak of the (104) plane at the Miller index hkl is 0.72 or less. Particles of the lithium transition metal composite oxide have a peak differential pore volume of 0.33 mm3 / (g·nm) or less.

Owner:GS YUASA INT LTD

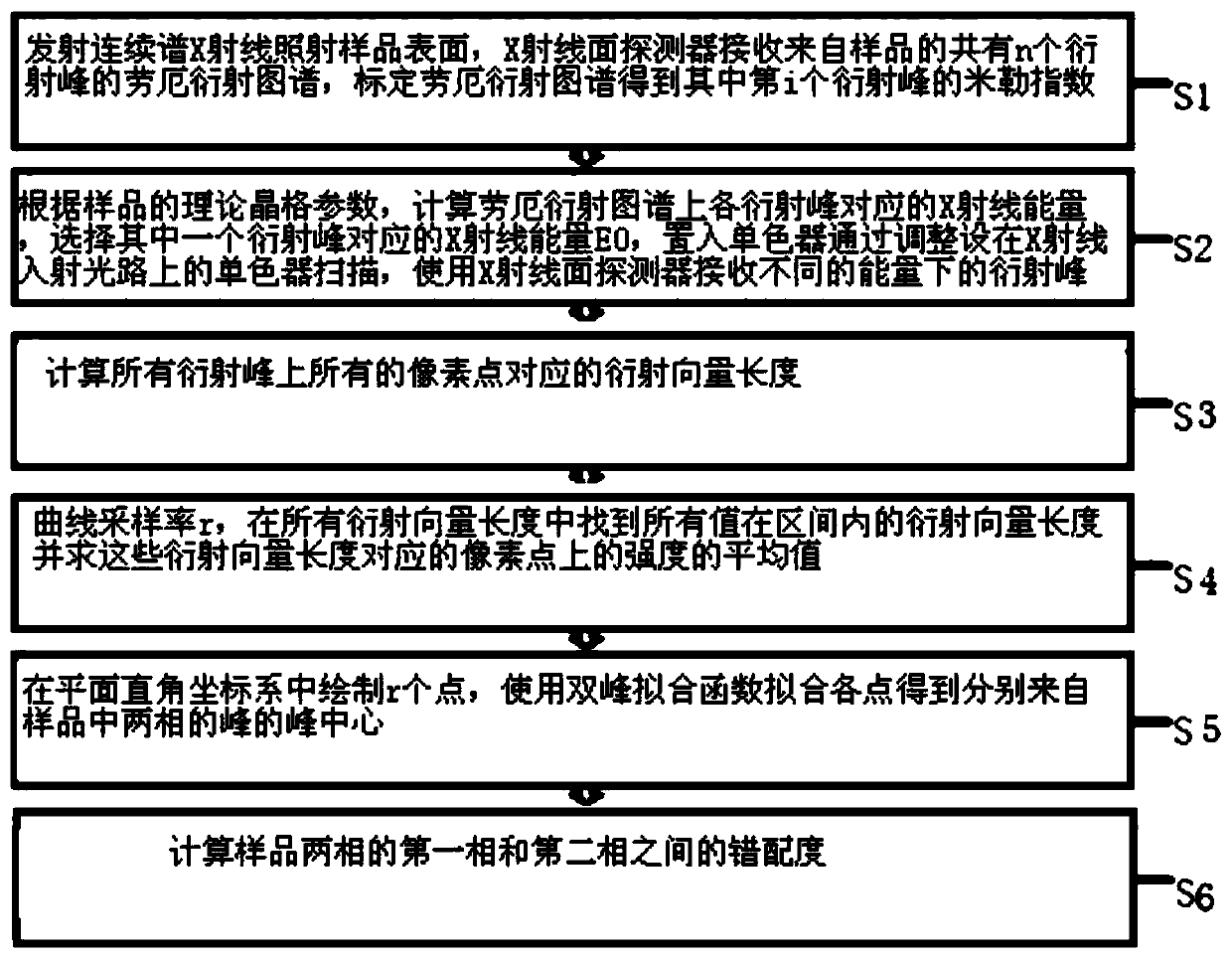

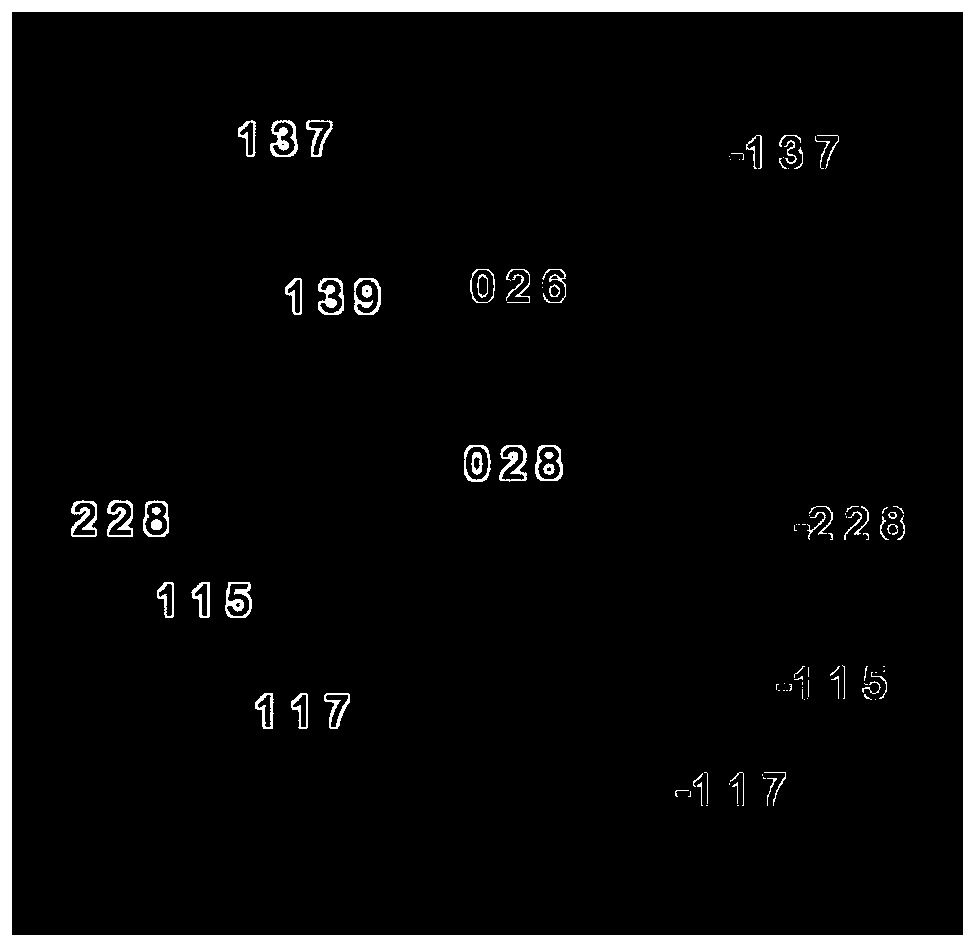

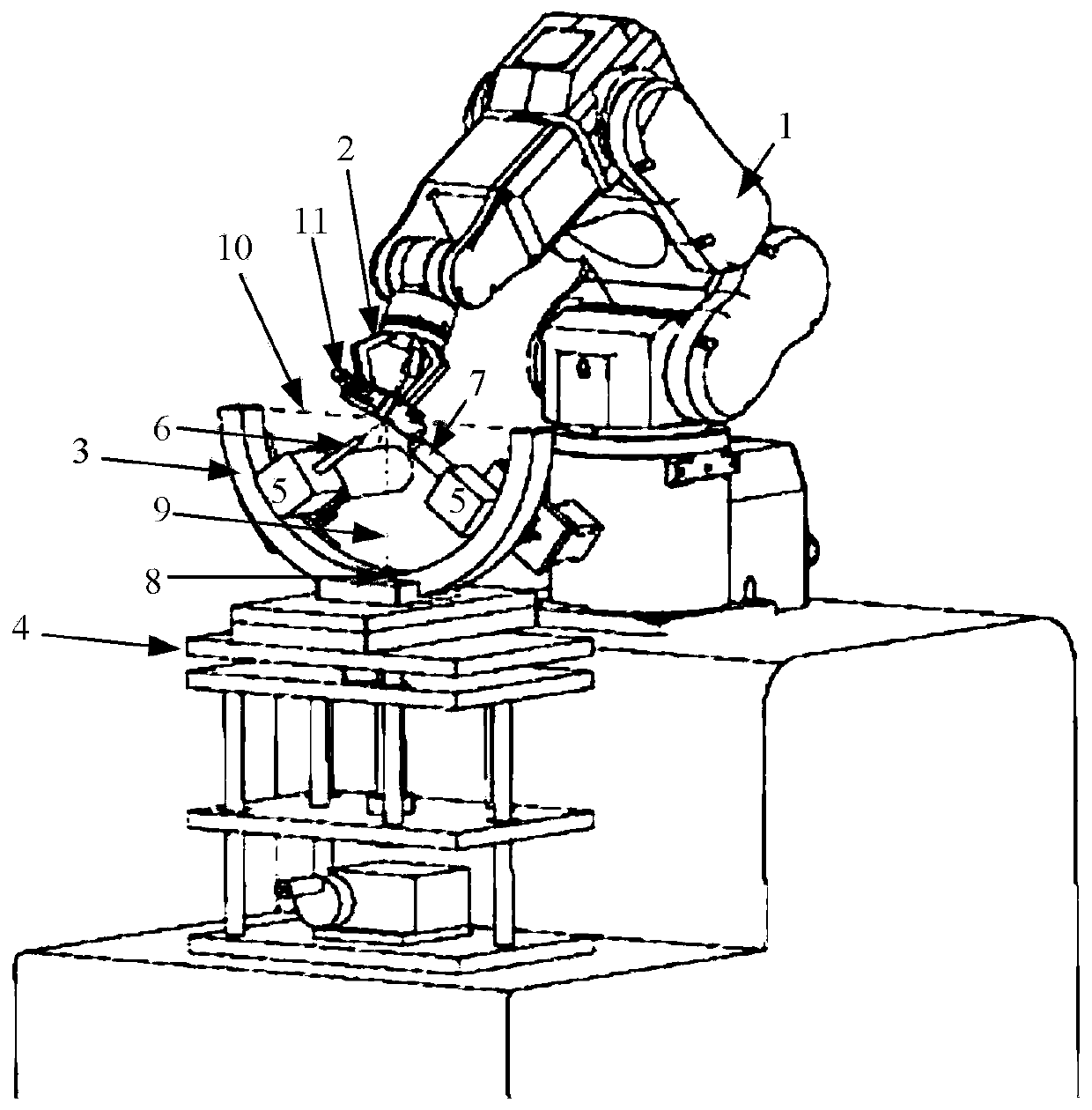

Method for measuring two-phase mismatch degree based on X-ray energy scanning

ActiveCN110658221AProcessing calculation is smallSimplify your measurement needsMaterial analysis using radiation diffractionRectangular coordinatesMiller index

The invention discloses a method for measuring a two-phase mismatch degree based on X-ray energy scanning, and the method comprises the steps of irradiating the surface of a sample with an emission continuous spectrum X-ray, receiving a Laue diffraction pattern with total n diffraction peaks from the surface of the sample by an X-ray surface detector, calibrating the Laue diffraction pattern to obtain the Miller index of the ith diffraction peak, calculating the X-ray energy corresponding to each diffraction peak on the Laue diffraction pattern, scanning with the step size deltaE0 within the energy range E0-Et to E0+Et, measuring m different energies Ej, finding out the diffraction vector lengths with all values in the interval [dl, dl+deltad) in all the diffraction vector lengths |kj, j'|, obtaining the average value Iaver, l of intensity on the pixel points corresponding to these diffraction vector lengths, drawing r points in the plane rectangular coordinate system, fitting each ofthe points by using a bimodal fitting function to obtain the peak centers d1 and d2 from the peaks of the two phases in the sample, respectively, and calculating the amount theta of mismatch degree between the first and second phases of the sample.

Owner:XI AN JIAOTONG UNIV

Method for rapidly measuring internal stress of nickel-based single crystal superalloy

ActiveCN110044527AAccurate Stress MeasurementWide range of usabilityForce measurementStress measurementSingle crystal superalloy

The invention discloses a method for rapidly measuring the internal stress of a nickel-based single crystal superalloy, and belongs to the technical field of material performance testing. The method comprises the following steps: firstly, selecting a crystal face family, rotating a sample to be tested, and recording all diffraction positions of the crystal face family and the Miller index of the corresponding crystal face; performing theta-2 theta scanning on the periphery of each diffraction position on the polar diagram, recording the position corresponding to the strongest peak of the diffraction intensity of each diffraction position and calibrating the Miller index of the corresponding crystal face and the corresponding theta-2 theta diffraction peak; obtaining the crystal face spacing at the moment by applying Bragg law; and processing data to obtain the magnitude and direction of the internal stress of the nickel-based single crystal superalloy. The method for rapidly measuringthe internal stress of the nickel-based single crystal superalloy is suitable for samples with any orientation, and realizes the integration of crystal orientation measurement and stress measurement of the monocrystal; and the automated operation process and the programmed data processing process improve the work efficiency.

Owner:成都航大新材料有限公司

Rare earth silicate single crystal and process for production of rare earth silicate single crystals

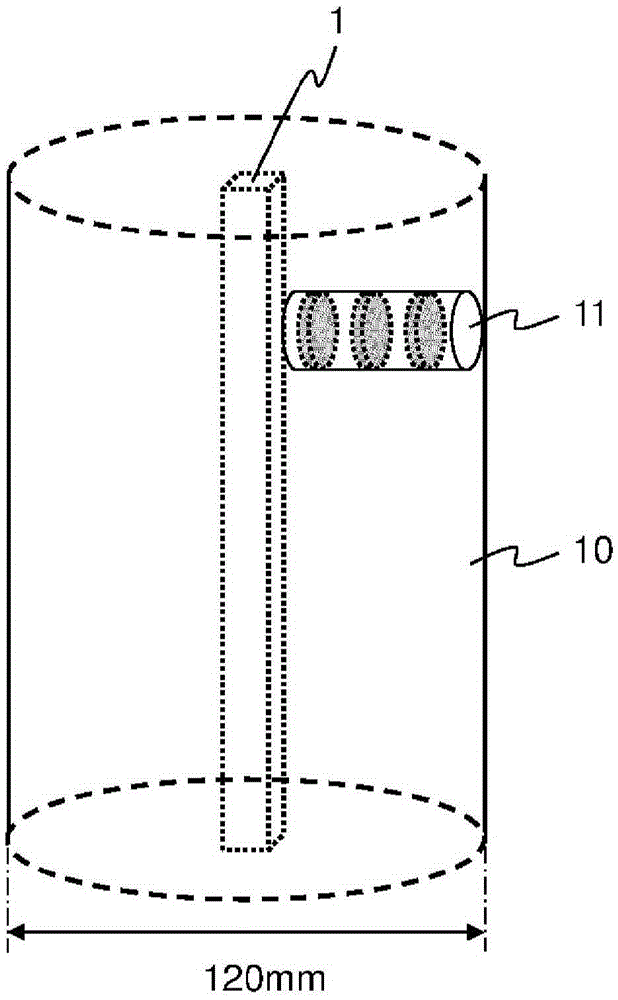

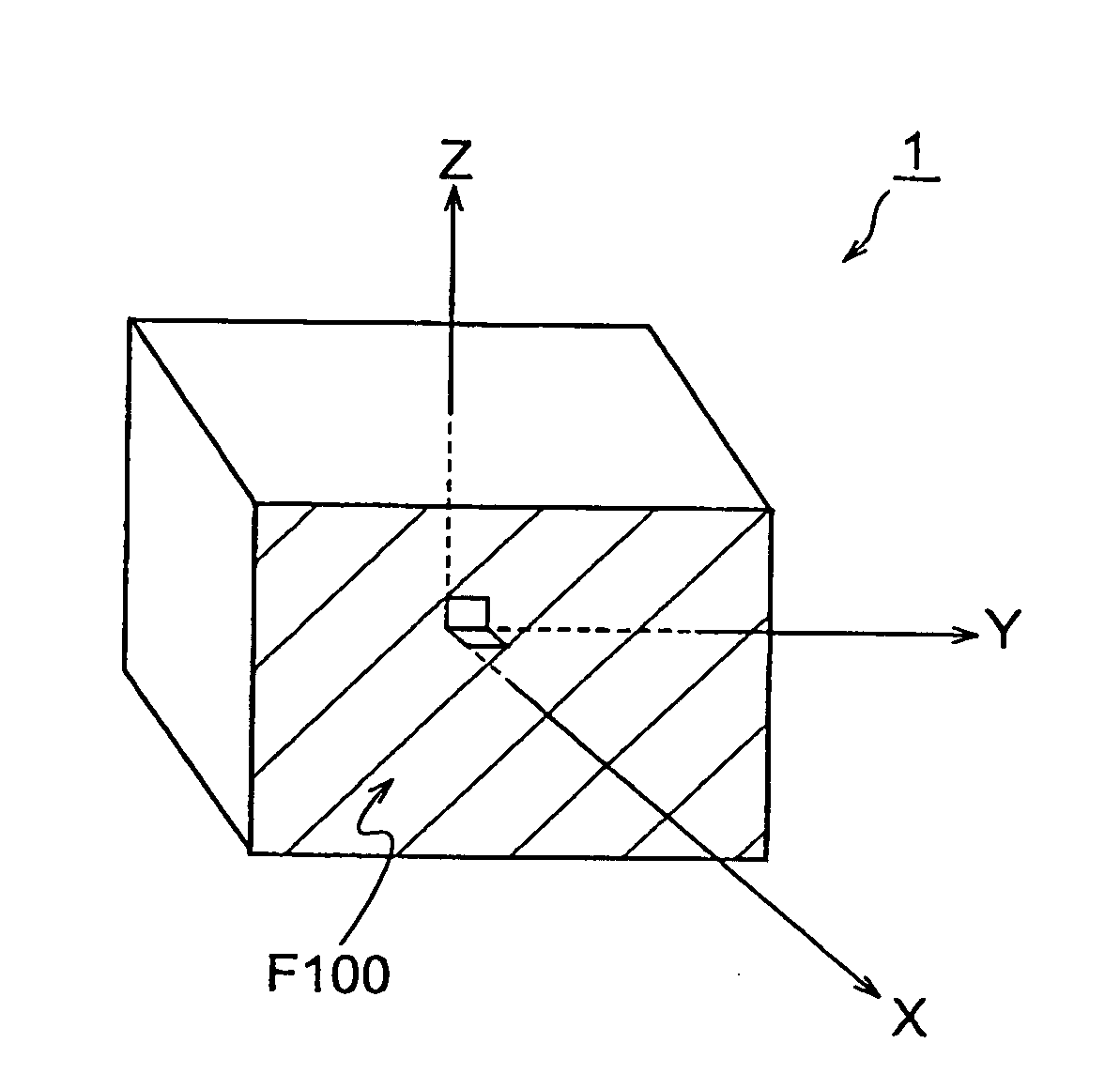

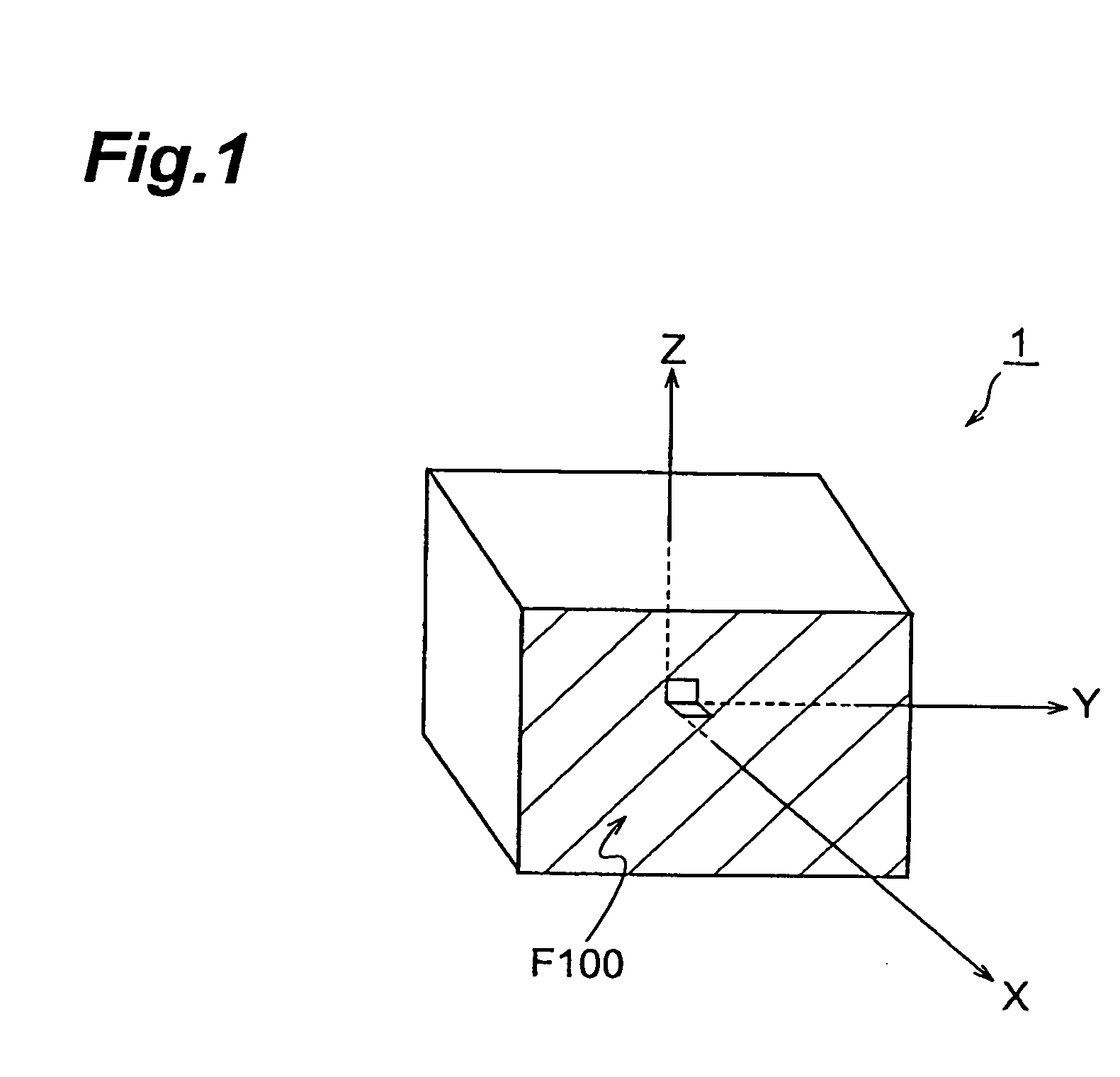

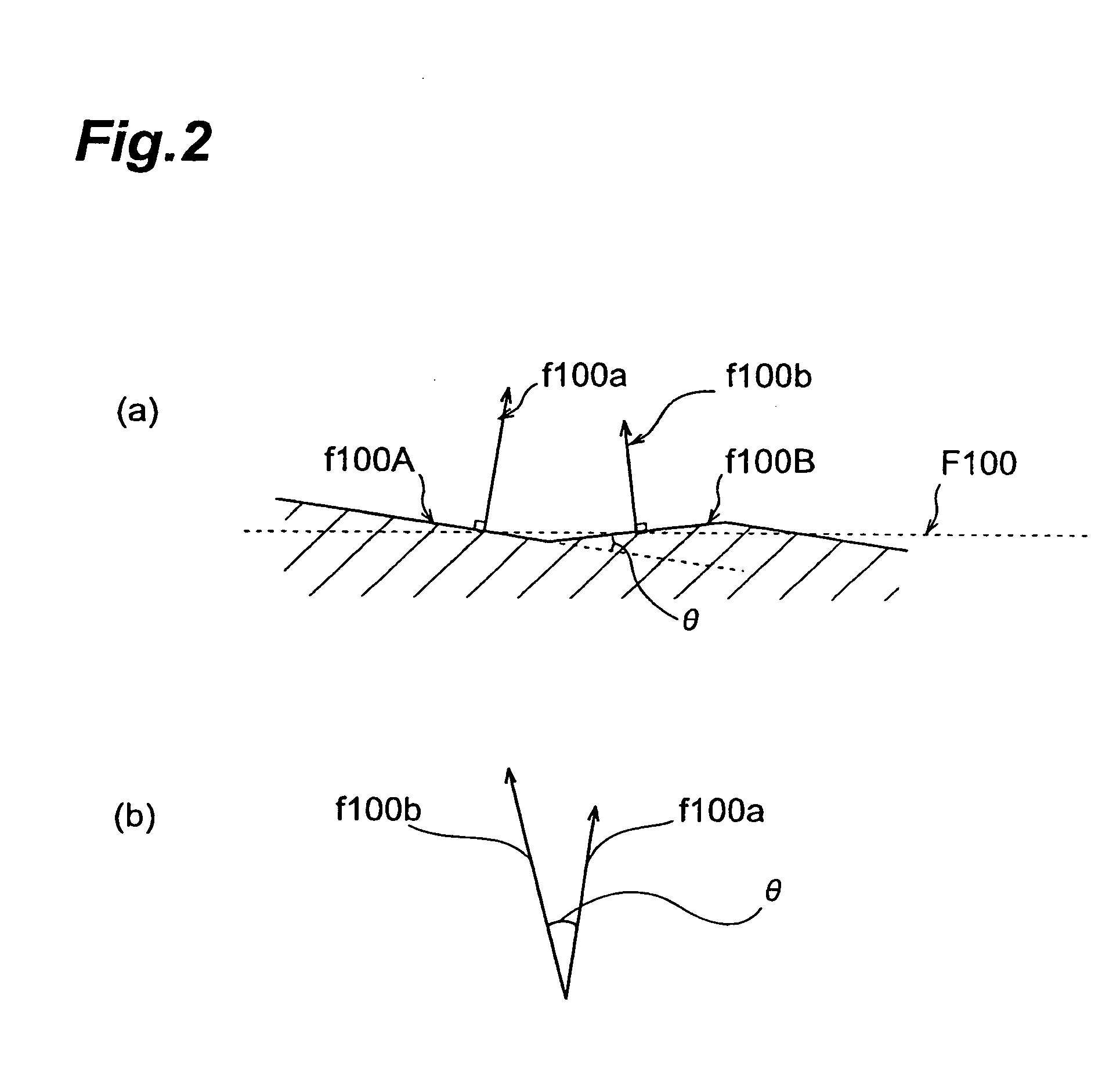

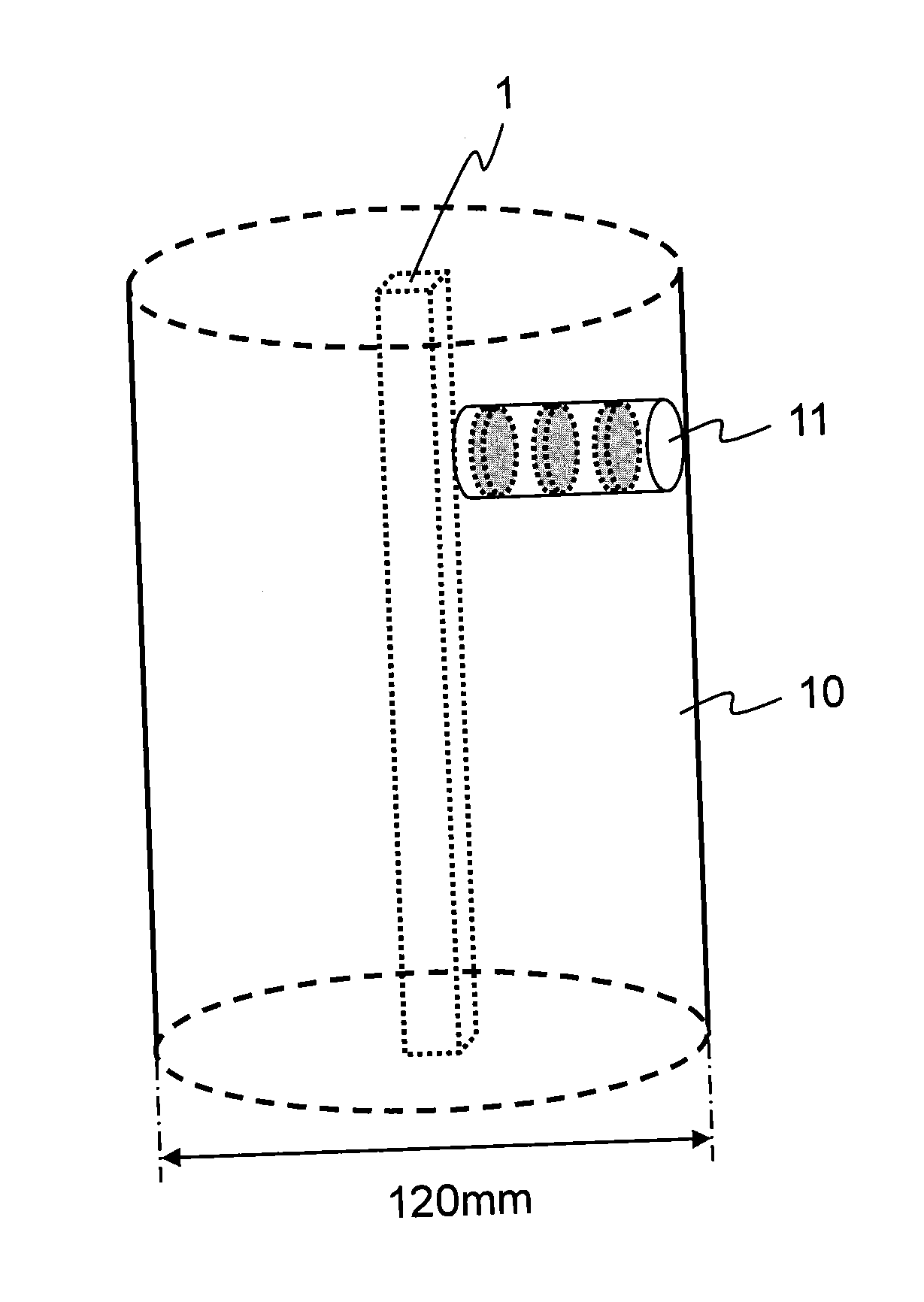

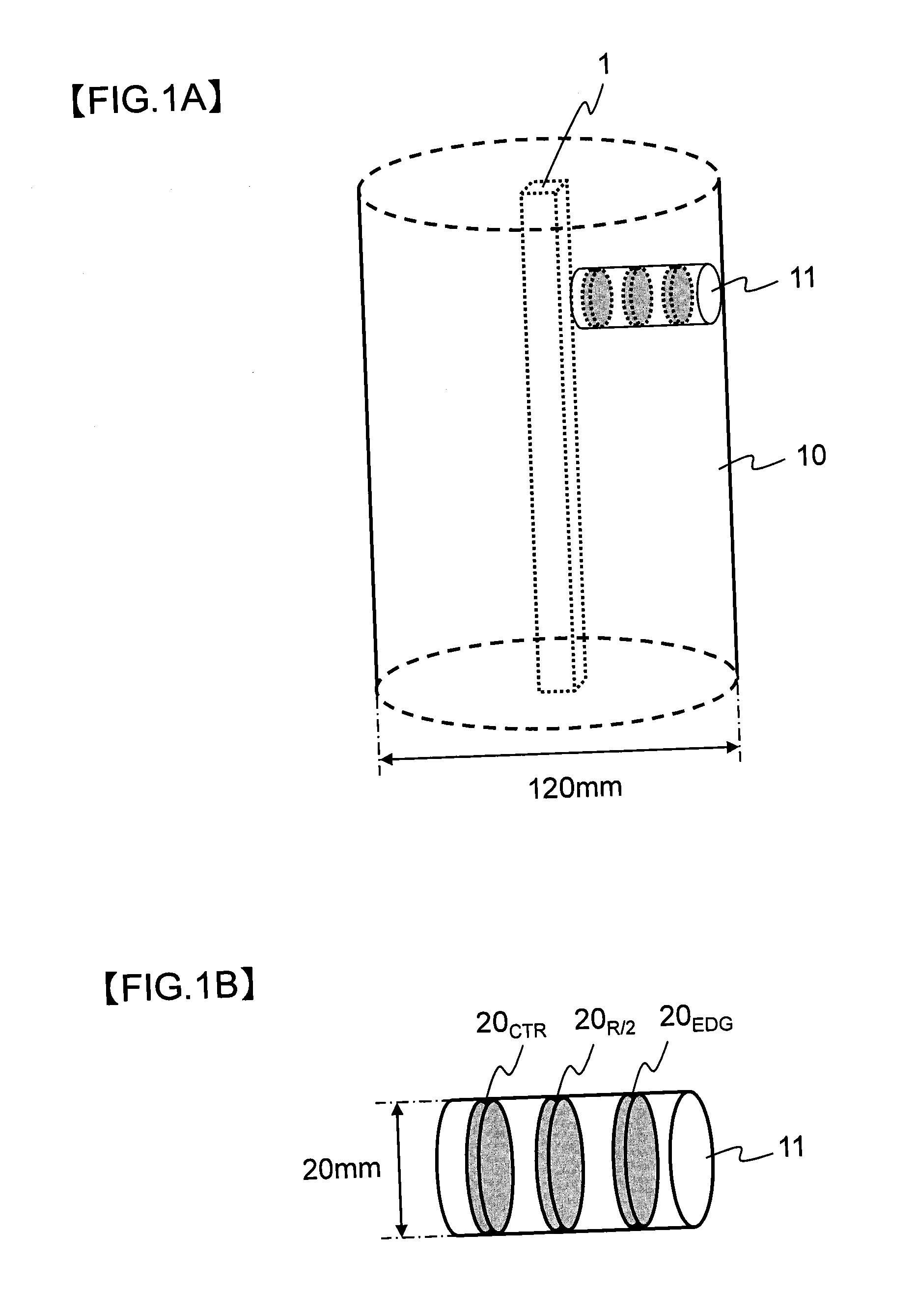

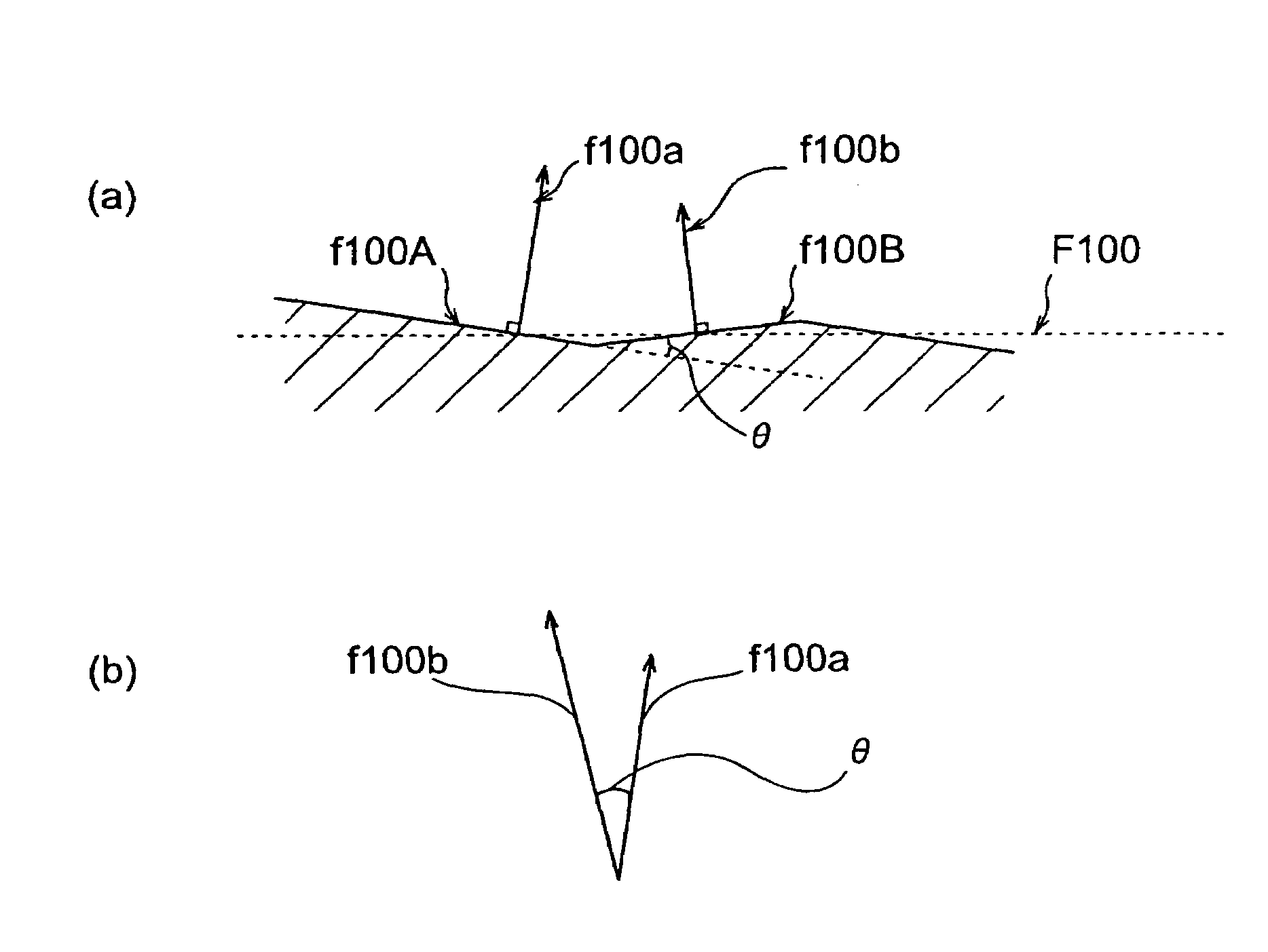

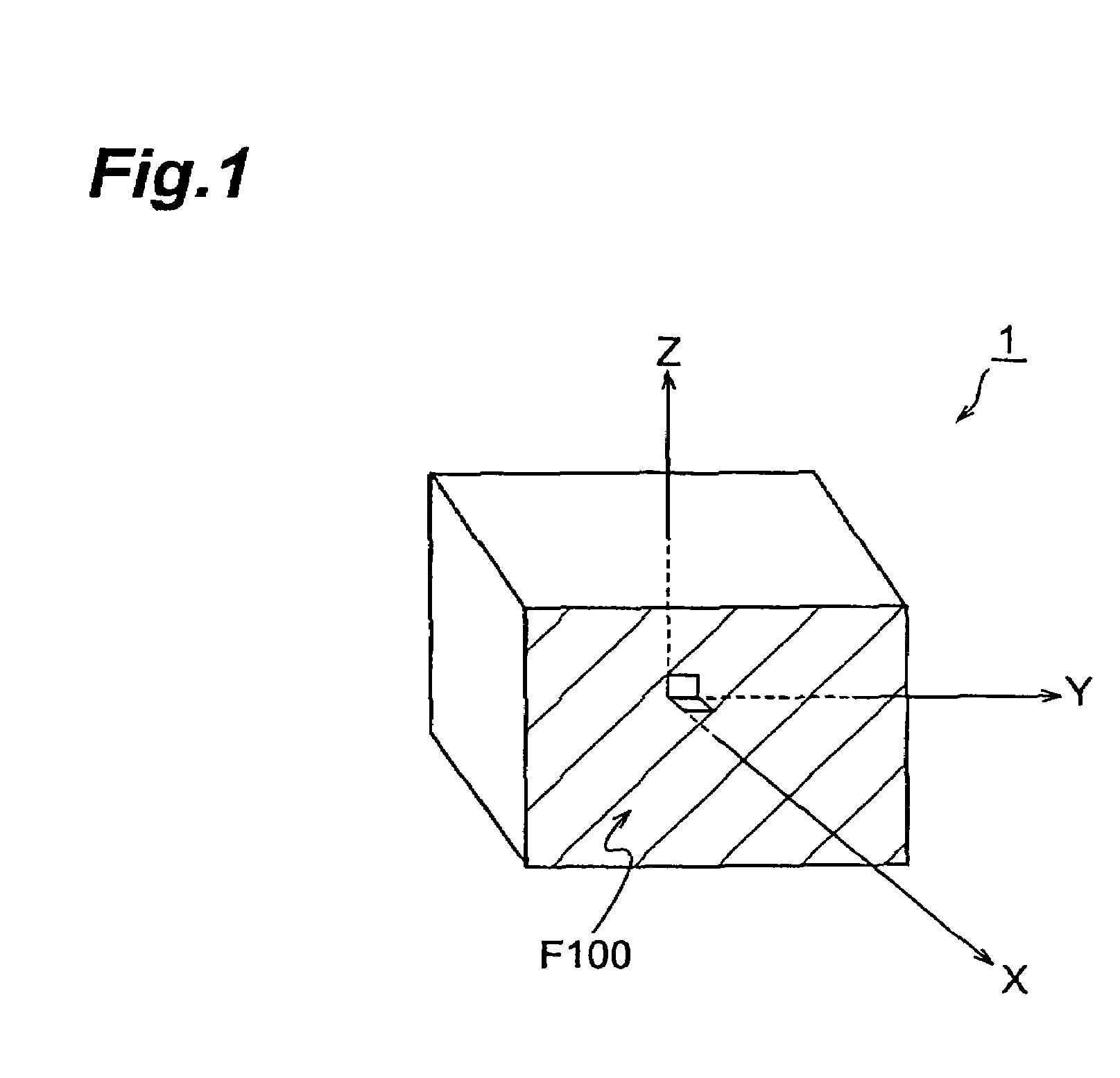

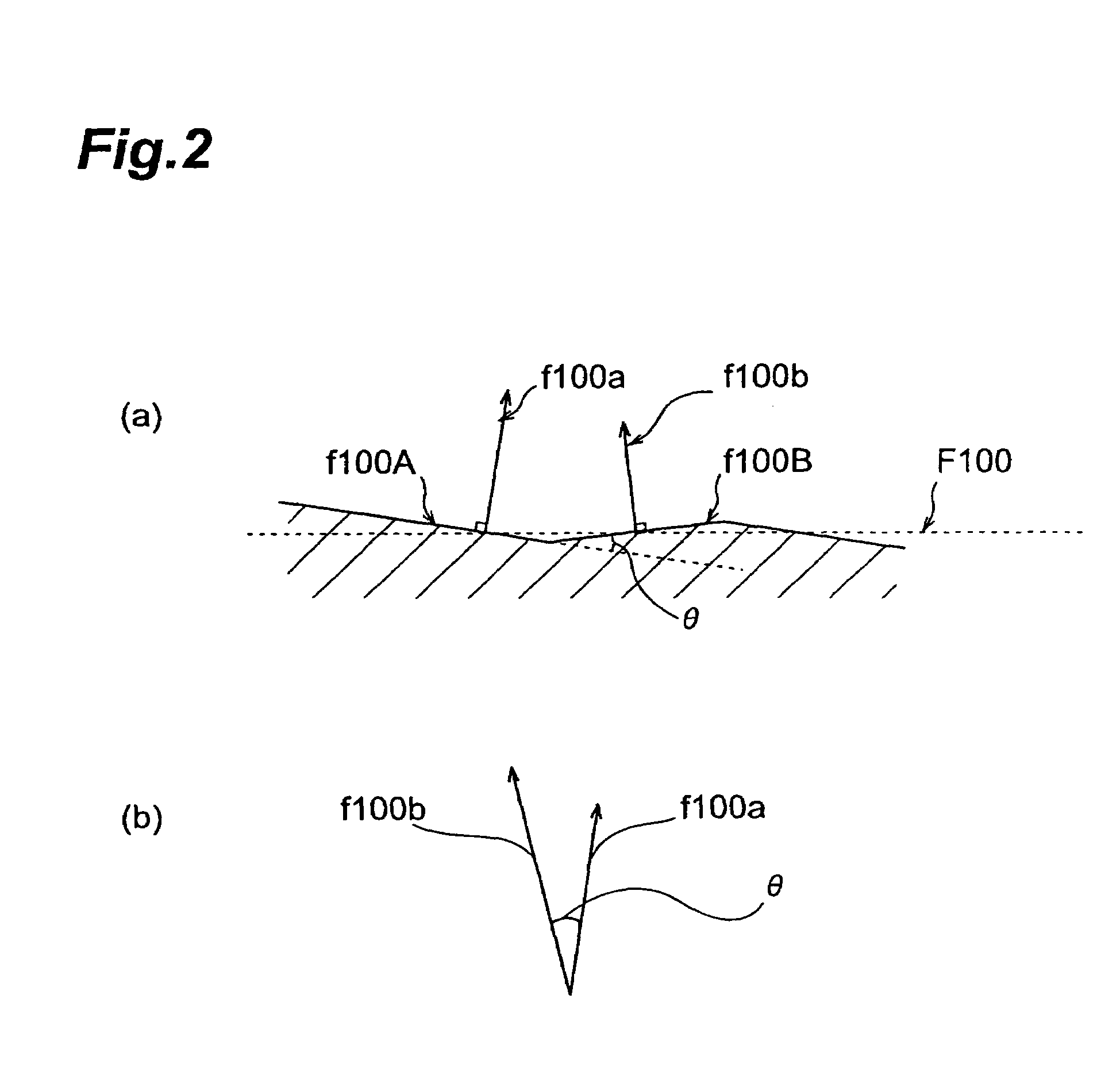

When produced as a single crystal ingot, a rare earth silicate single crystal 1 can be formed by cutting out from the single crystal ingot. The single crystal 1 has a crystal face F100 whose Miller indices can be determined by X-ray diffraction. The crystal face F100 is composed of a plurality of smooth partial region surfaces (for example, the partial region surface f100A and partial region surface f100B), the plurality of partial region surfaces each have an area detectable by X-ray diffraction, and the angles θ formed between the normal vectors of the plurality of partial region surfaces satisfy the following inequality: 0.1°≦θ≦2.0° (1).

Owner:OXIDE

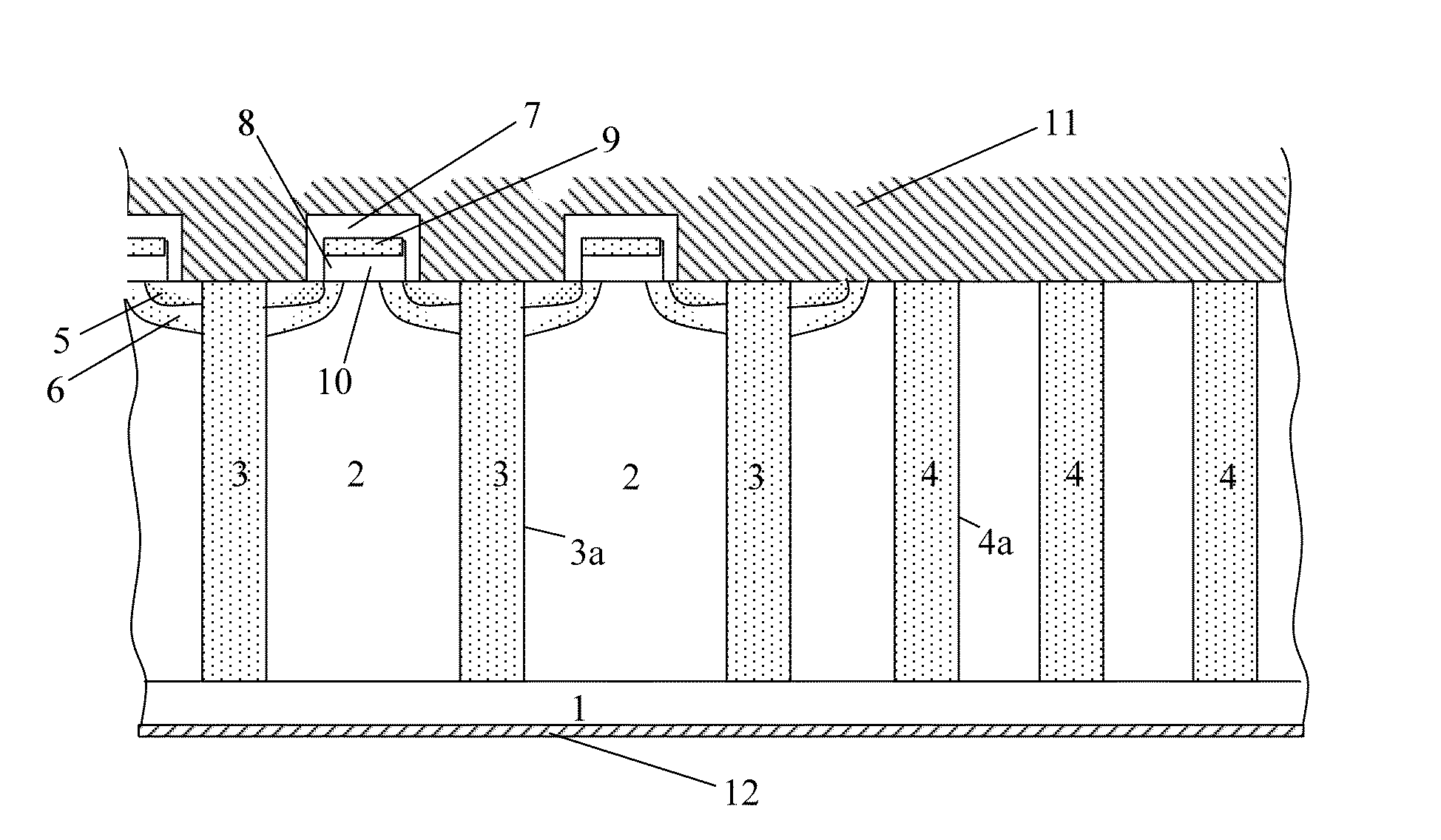

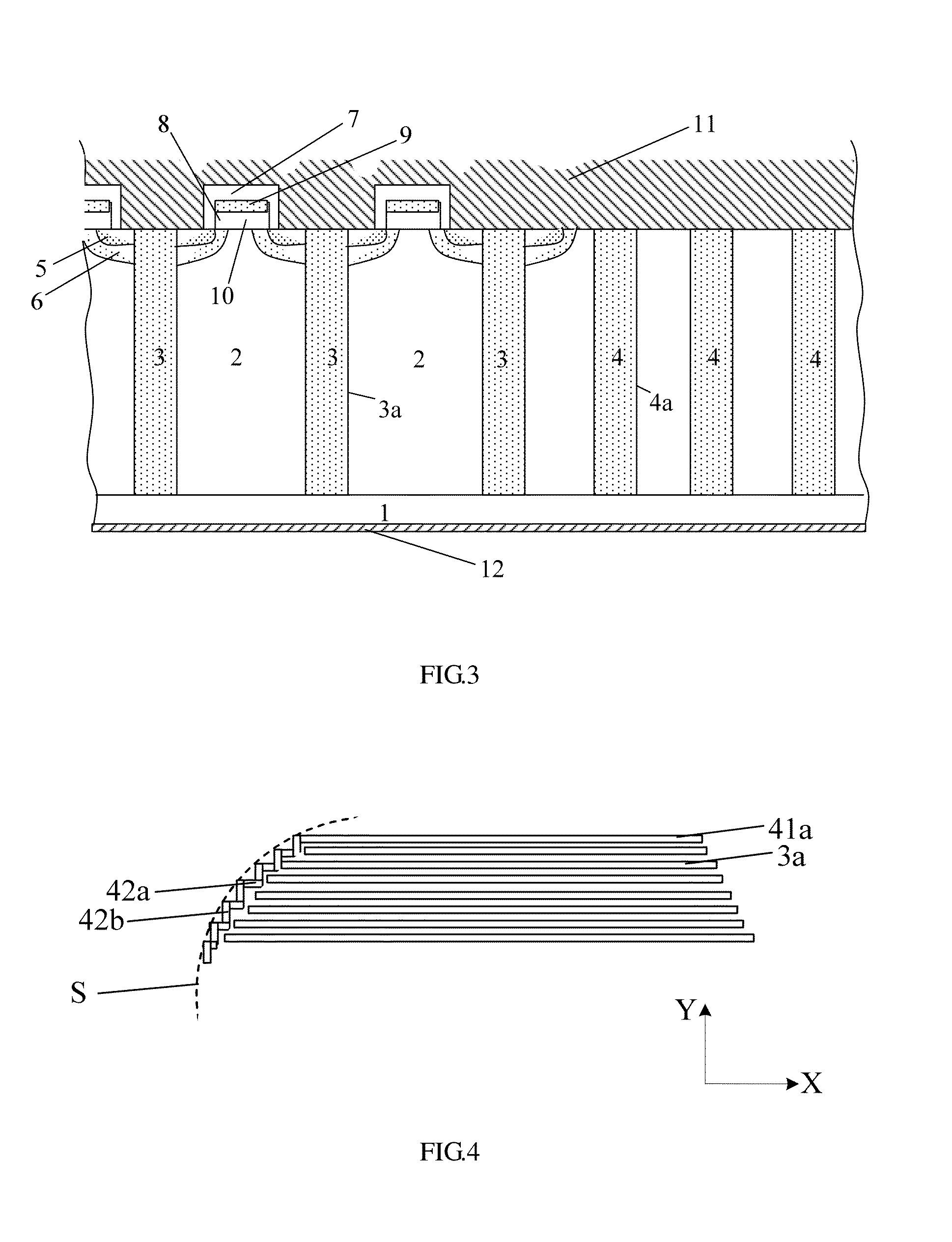

Superjunction device

ActiveUS20130299896A1Avoid it happening againImprove performanceSemiconductor devicesPower flowMiller index

A superjunction device in which corner portions of each annular-shaped second trench are composed of a plurality of alternately arranged first sides and second sides. The first sides are parallel to a plurality of parallel arranged first trenches in a current-flowing area, while the second sides are perpendicular to the first sides and the first trenches. Such design ensures that Miller indices of sidewalls and bottom face of any portion of each second trench belong to the same family of crystal planes. Moreover, with this design, the corner portions of the second trenches can be filled with a silicon epitaxial material at the same rate with the rest portions thereof, which ensures for the second trenches to be uniformly and completely filled without any defects in the corner portions and hence improve the performance of the superjunction device.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Method for evaluating degree of crystal orientation in polycrystalline silicon, selection method for polycrystalline silicon rods, and production method for single-crystal silicon

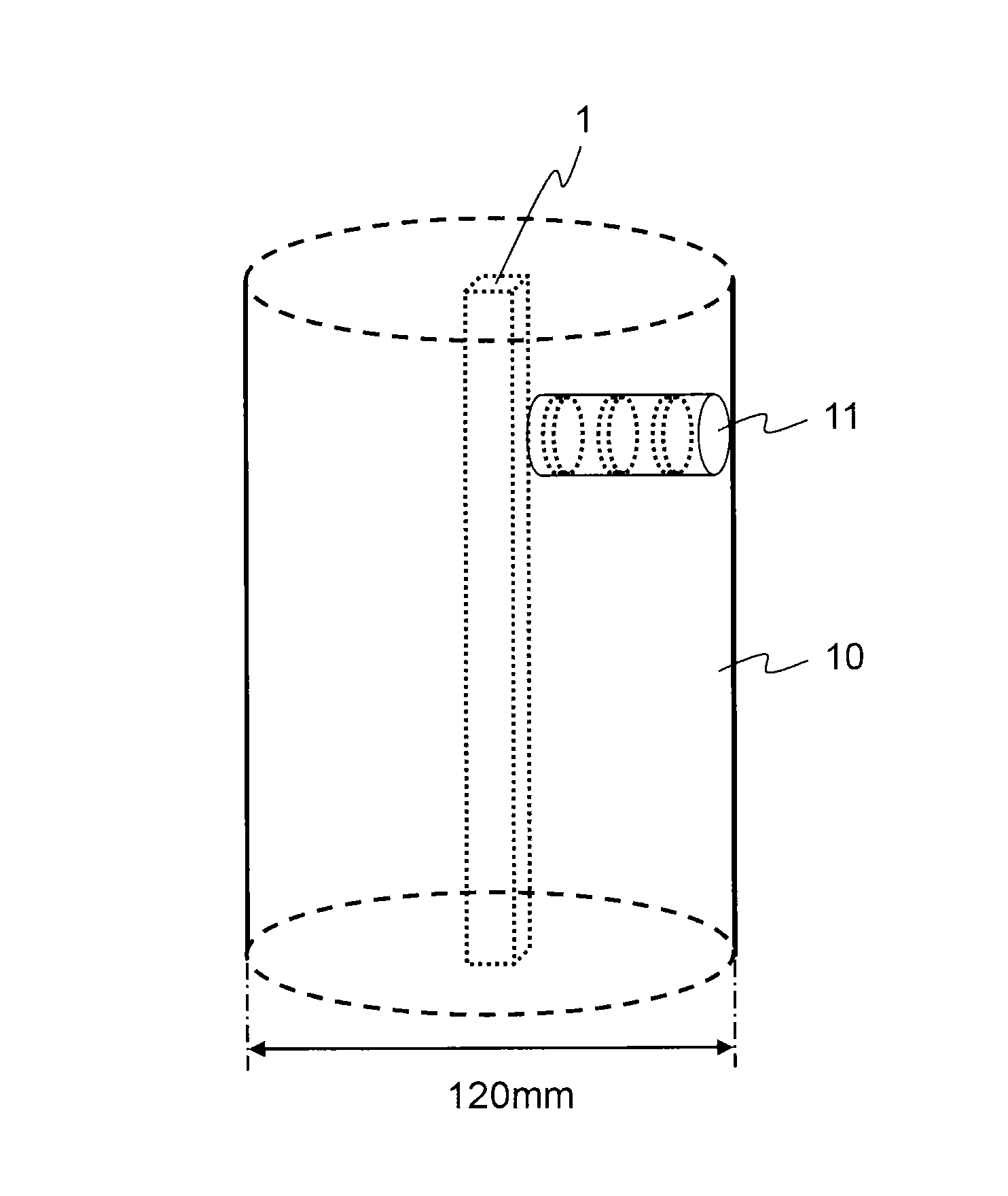

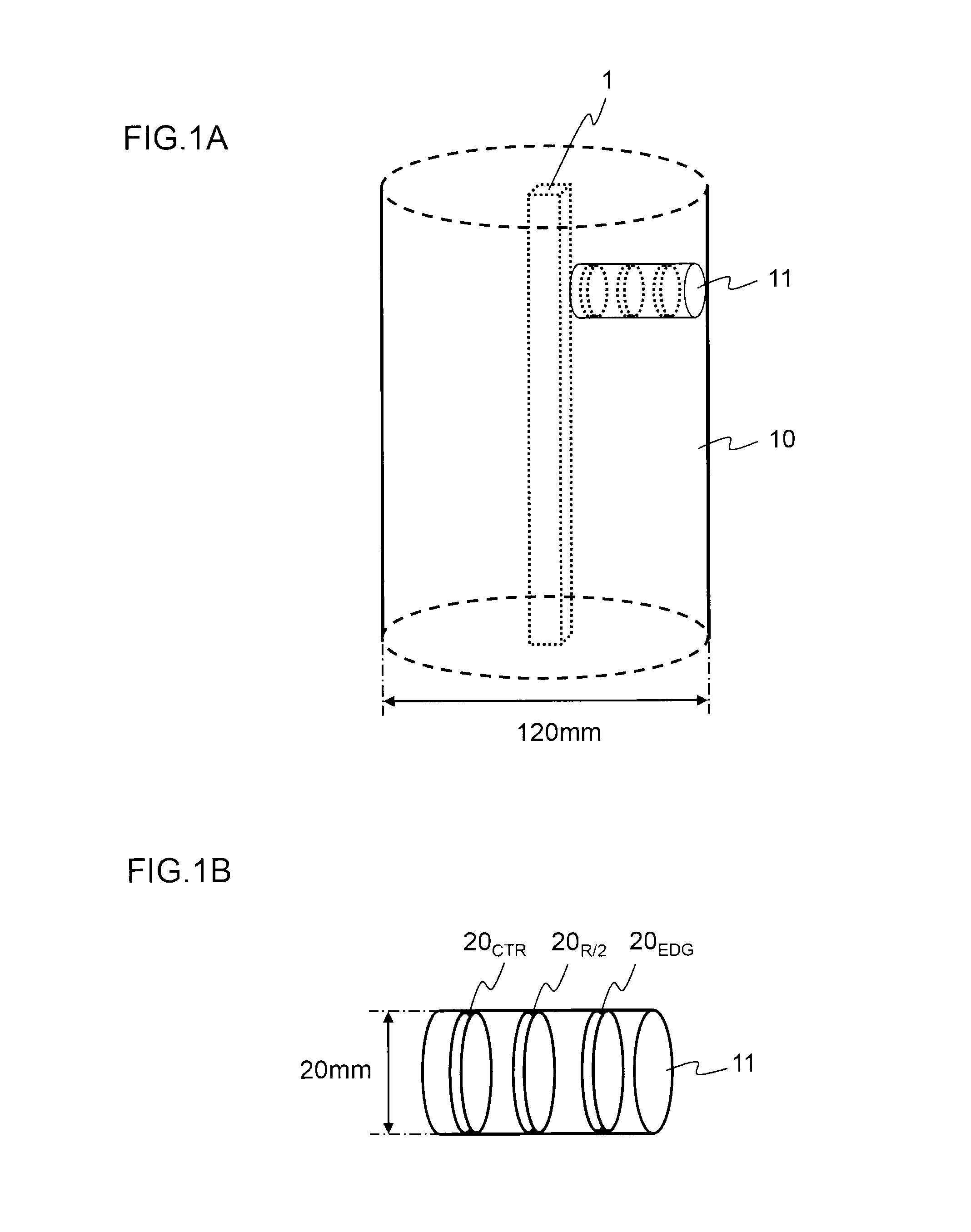

InactiveUS20150047554A1Suppress local generationStable productionAfter-treatment apparatusPolycrystalline material growthMiller indexCrystal orientation

When a plate-like sample 20 extracted from a polycrystalline rod is evaluated, peaks can appear in a φ-scanning chart. The smaller the number of such peaks, and the narrower the half-value width of the peak, the more suitable the polycrystalline silicon rod is as a raw material for producing single-crystal silicon. It is preferable that the number of peaks in the φ-scanning chart is, for both the Miller index planes <111> and <220>, equal to or smaller than 24 / cm2 when converted into unit per area of the plate-like sample. It is also preferable that the value obtained by multiplying the peak half-value width by δL=21 / 2πR0 / 360, where R0 is the radius of the sample, is defined as an inhomogeneous crystal grain size, and that a polycrystalline silicon rod of which all the inhomogeneous crystal grain sizes are smaller than 0.5 mm is selected as a raw material for producing single-crystal silicon.

Owner:SHIN ETSU CHEM IND CO LTD

Rare earth silicate single crystal and process for production of rare earth silicate single crystals

ActiveUS7264750B2Avoid it happening againFrom solid stateMaterial analysis by optical meansMiller indexRare earth

When produced as a single crystal ingot, a rare earth silicate single crystal 1 can be formed by cutting out from the single crystal ingot. The single crystal 1 has a crystal face F100 whose Miller indices can be determined by X-ray diffraction. The crystal face F100 is composed of a plurality of smooth partial region surfaces (for example, the partial region surface f100A and partial region surface f100B), the plurality of partial region surfaces each have an area detectable by X-ray diffraction, and the angles θ formed between the normal vectors of the plurality of partial region surfaces satisfy the following inequality:0.1°≦θ≦2.0°. (1)

Owner:OXIDE

Mask and method of manufacturing the same, electro-luminescence device and method of manufacturing the same, and electronic instrument

InactiveUS20050051516A1After-treatment detailsDecorative surface effectsMiller indexElectronic instrument

A mask has a monocrystal substrate having opposite surfaces which are planes having Miller indices {110}. A plurality of penetrating holes are formed in the monocrystal substrate. An opening shape of each of the penetrating holes is a polygon and each side of the polygon is parallel with a plane in a group of the {111} planes. The wall surfaces of the penetrating holes are the {111} planes. In the method of manufacturing a mask, openings are formed in the etching resistant film corresponding to the shape of the penetrating holes and the monocrystal substrate is etched.

Owner:SEIKO EPSON CORP

Aluminosilicate X-type zeolite compositions with low LTA-type zeolite

A zeolite X having (a) a Si / Al framework mole ratio in a range from 1.0 to 1.5; (b) a mean diameter not greater than 2.7 microns; and (c) a relative LTA intensity not greater than 0.35, as determined by x-ray diffraction (XRD). The relative LTA intensity is calculated as 100 times the quotient of a sample LTA XRD intensity divided by a reference XRD intensity of an LTA-type zeolite material. The intensities are summed for each LTA peak with Miller indices of (2 0 0), (4 2 0), and (6 2 2) at 7.27±0.16°, 16.29±0.34° and 24.27±0.50° 2θ.

Owner:UOP LLC

Method for preparing step standard sample of nano-scale oxide crystalloid with high precision

InactiveCN101813580ARich varietyVarious shapesSurface/boundary effectPreparing sample for investigationMiller indexPhysical chemistry

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method for evaluating degree of crystalline orientation of polycrystalline silicon, method for selecting polycrystalline silicon rod, polycrystalline silicon rod, polycrystalline silicon ingot, and method for manufacturing monocrystalline silicon

When the degree of crystalline orientation of polycrystalline silicon is evaluated by an X-ray diffraction method, each obtained disc-like sample 20 is disposed in a position where Bragg reflection from a Miller index face <hkl> is detected and in-plane rotated at a rotational angle &phgr; with the center of the disc-like sample 20 as the center of rotation, so that an X-ray-radiated region defined by a slit &phgr;-scans over the principal surface of the disc-like sample 20, to determine a chart representing the dependence of the intensity of Bragg reflection from the Miller index face <hkl> on the rotational angle (&phgr;) of the disc-like sample 20, a baseline is determined from the chart, and the diffraction intensity value of the baseline is used as an estimative index of the degree of crystalline orientation.

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com