Method for preparing step standard sample of nano-scale oxide crystalloid with high precision

A nano-scale oxide, standard sample technology, applied in the preparation of test samples, measuring devices, instruments, etc., can solve the problems of poor stability of crystal plane steps, easy to be oxidized, etc., and achieve high stability, variety, and shape. rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Tungstate crystal KLu(WO 4 ) 2 It is an excellent laser crystal with stable physical and chemical properties and mature growth technology. This embodiment uses tungstate crystal KLu (WO 4 ) 2 (110) Surface natural steps make nanoscale step height standard samples, the steps are as follows:

[0024] 1) Use an X-ray orientation instrument to orient each naturally exposed surface of the tungstate crystal, determine the crystal plane Miller index of each naturally exposed surface, and select a naturally exposed surface (110) of the tungstate crystal as Naturally exposed base surface;

[0025] 2) Cut the tungstate crystal in a direction parallel to the base surface of the natural exposure surface to obtain three square oxide crystals with a thickness of 1mm and a base surface of the natural exposure surface and a cutting exposure surface; the square tungsten The crystal sizes of acid salts are 3mm×3mm, 5mm×5mm and 10mm×10mm;

[0026] 3) Grinding and polishing the cuttin...

Embodiment 2

[0029] Using tungstate crystal KLu(WO 4 ) 2 (310) surface natural steps to make standard samples of nanoscale step heights.

[0030] The oxide crystals used and the sample preparation process were the same as in Example 1, except that the selected natural exposed surface was the (310) surface, the thickness of the cut sample was 2mm, and the size was 2mm×2mm.

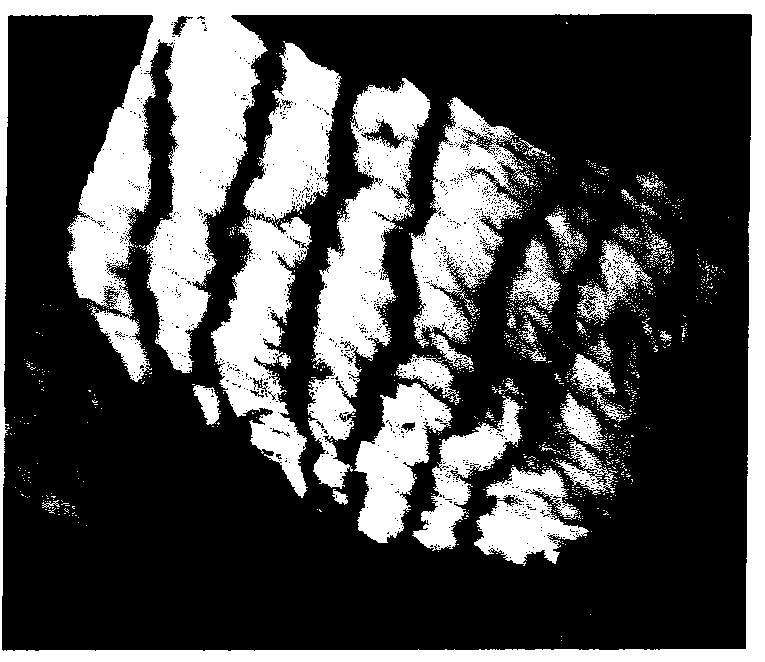

[0031] Fig. 2 is the straight step row on the surface of the standard sample (310), the step height is 0.2800nm.

[0032] According to this procedure and method, we can prepare standard samples with a step height of 0.2800nm on a large scale.

Embodiment 3

[0034] Using borate crystal La 2 CaB 10 o 19 (001) surface natural steps to make standard samples of nanoscale step heights. La 2 CaB 10 o 19 It is an excellent nonlinear optical crystal invented by the Chinese Academy of Sciences. It has stable physical and chemical properties, no deliquescence, and easy storage.

[0035] The sample preparation process is the same as in Example 1, the difference is that the oxide crystals used are borate crystals La 2 CaB 10 o 19 , the selected natural plane is the (001) plane of the crystal, the thickness of the cut sample is 0.5mm, and the size is 5mm×5mm.

[0036] Fig. 3 is the monomolecular layer step on the surface of the standard sample (001), and the step height is 0.9126nm.

[0037] According to this procedure and method, standard samples with a step height of 0.9126nm can be prepared on a large scale.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com