Polycrystalline silicon crystal orientation degree evaluation method, polycrystalline silicon rod selection method, polycrystalline silicon rod, polycrystalline silicon ingot, and polycrystalline silicon fabrication method

A technology of crystal orientation and polysilicon rods, which is applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problem that microcrystals cannot be melted, and achieve the effect of suppressing melting residue and stabilizing manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

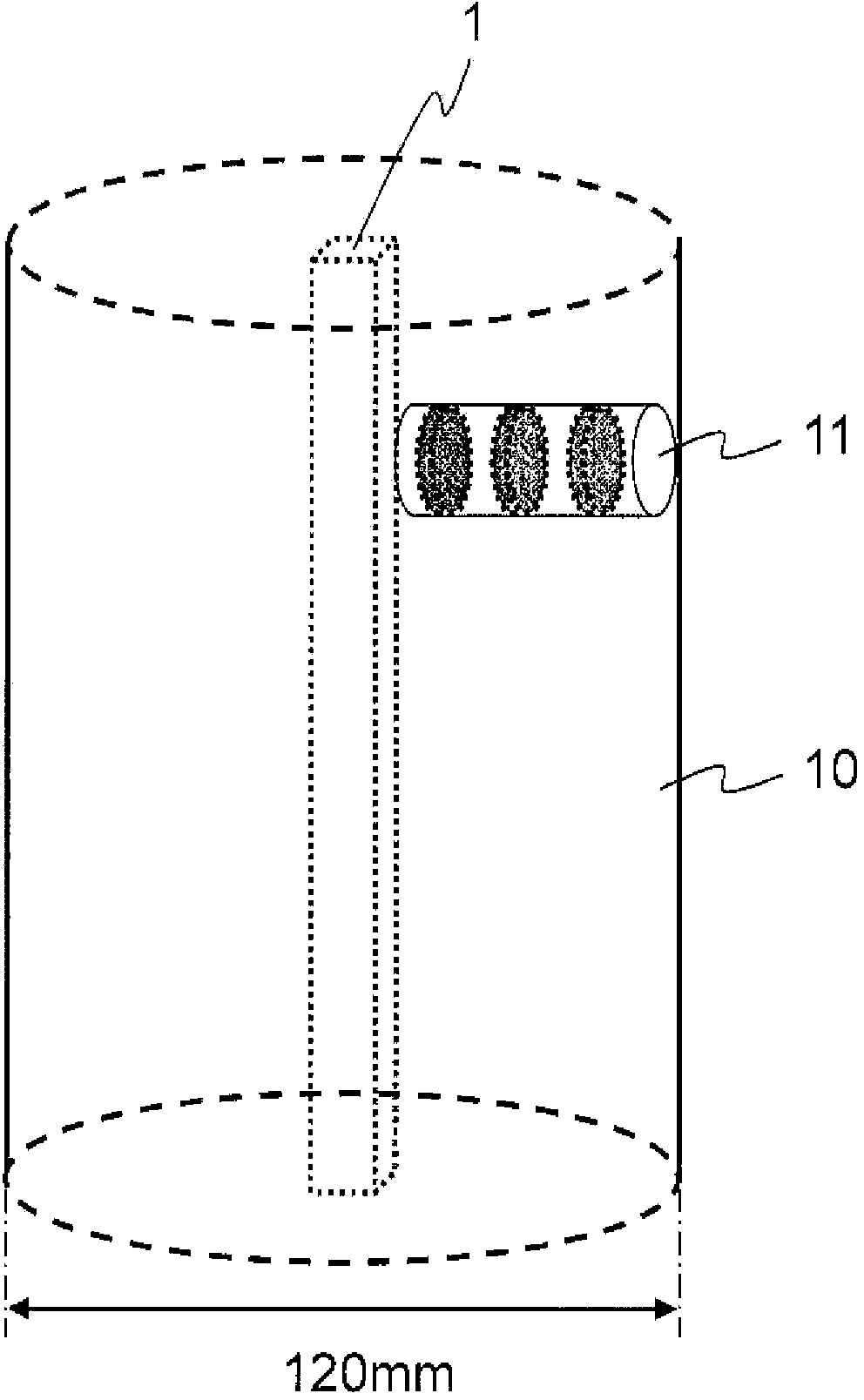

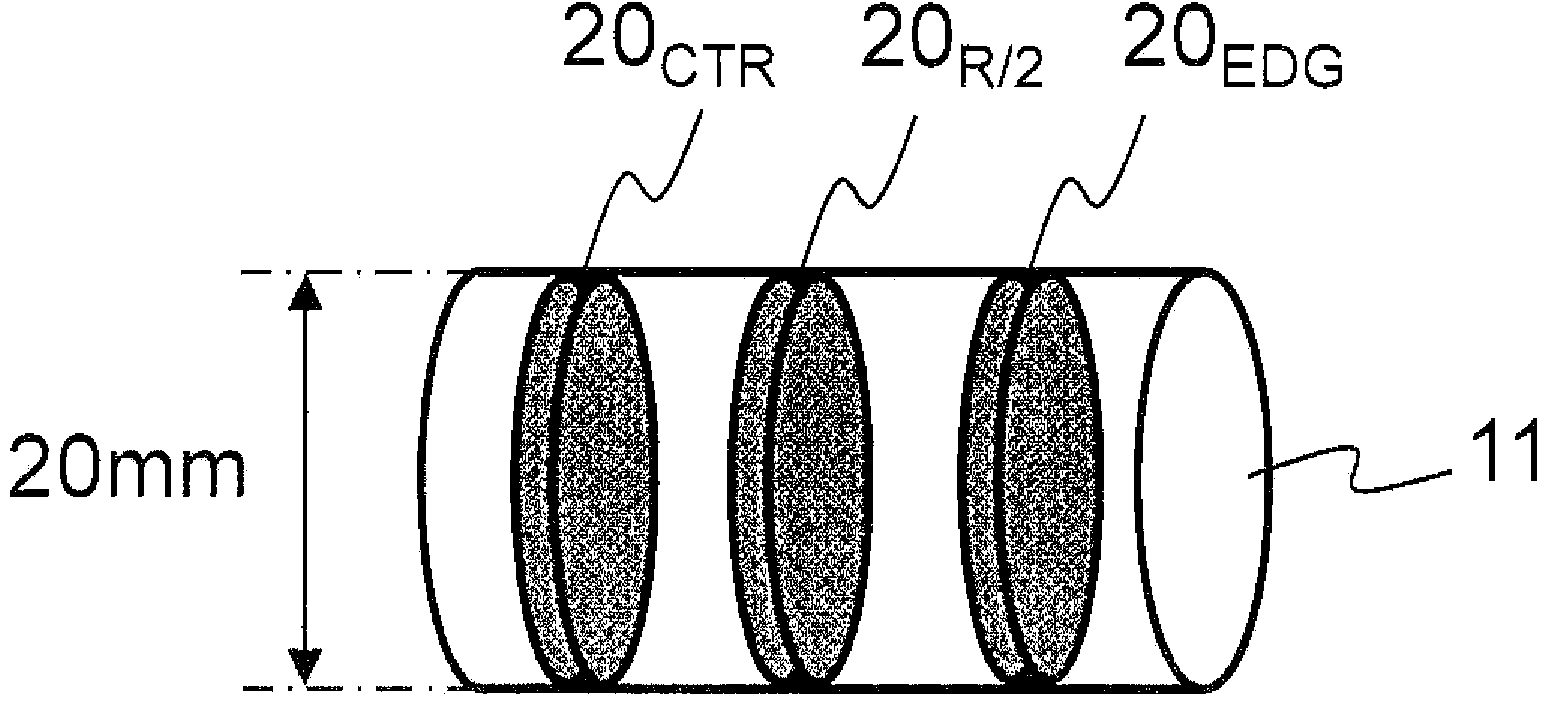

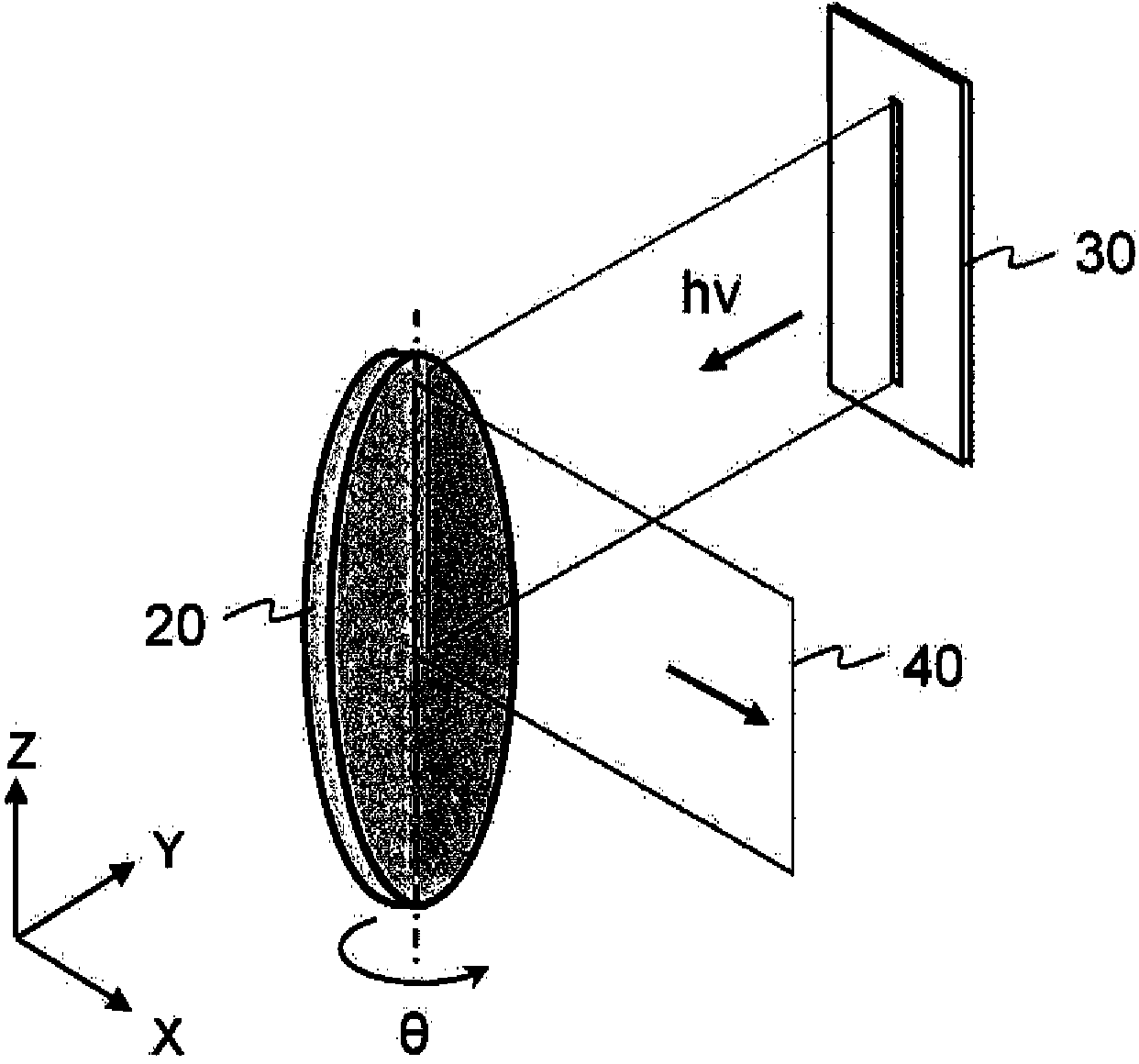

[0071] Prepare six polysilicon rods grown under different precipitation conditions. For these polycrystalline silicon rods (silicon rods A ~ F), respectively, from Figure 1A and 1B Select a circular plate-shaped sample with a thickness of about 2 mm (20 CTR 、20 EDG 、20 R / 2 ),pass Figure 6 With the measurement system shown, the φ scan charts of the Miller index surfaces and are obtained. In addition, the diameter of the disk-shaped sample 20 was about 20 mm.

[0072] Table 1 summarizes the diffraction intensity of the baseline (BL) obtained from these polycrystalline silicon rods for each disk-shaped sample, and whether or not crystal lines disappeared when the polycrystalline silicon rods were grown by the FZ method for single crystal silicon rods.

[0073] [Table 1]

[0074]

[0075] For silicon rod A, the value obtained by dividing the maximum value of the multiple baseline diffraction intensity values for the Miller index surface by the mini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com