Method for evaluating crystallinity of polycrystalline silicon

An evaluation method, polycrystalline silicon technology, applied in the direction of crystal growth, polycrystalline material growth, chemical instruments and methods, etc., can solve problems such as non-uniform melting, melting dependence on size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

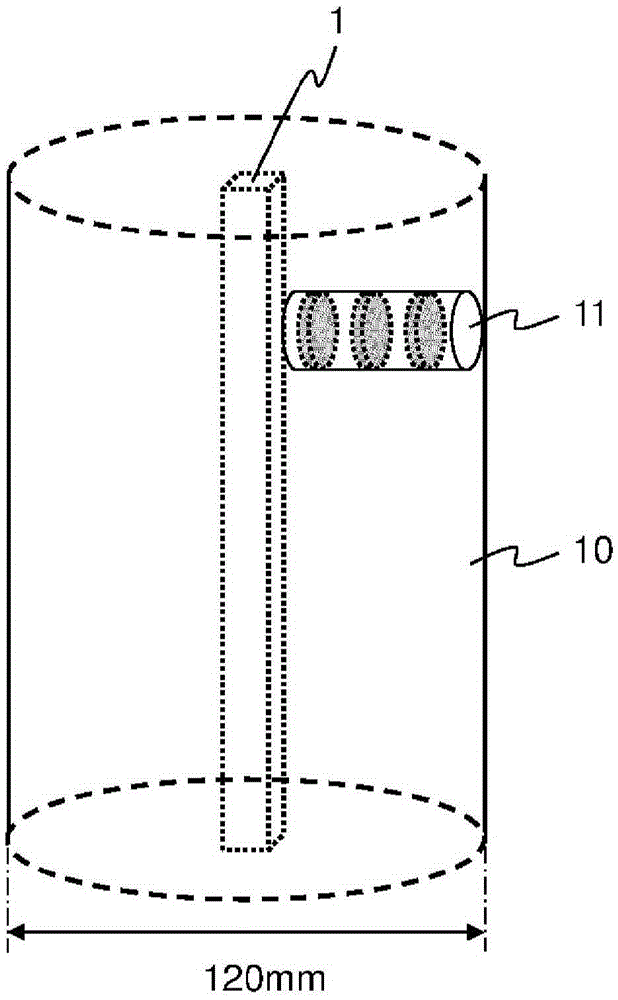

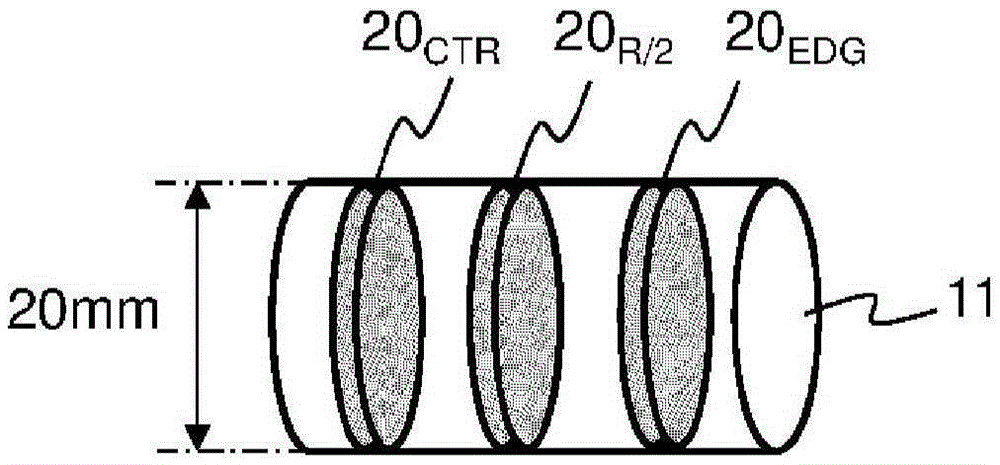

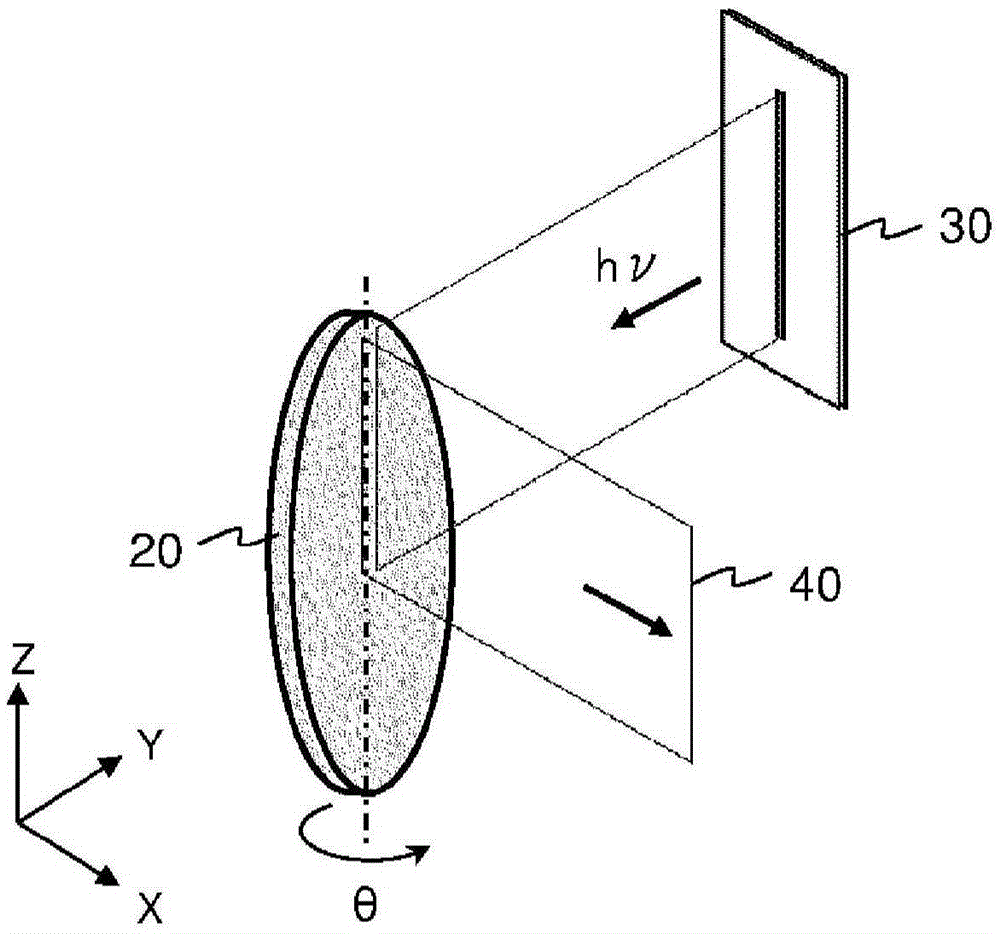

[0081] Prepare 13 polysilicon rods grown under different precipitation conditions. For these polysilicon rods (silicon rods 1 to 13), each from Figure 1A with 1B For the three positions shown, select disc-shaped samples (20 mm) with a thickness of about 2 mm. CTR 、20 EDG 、20 R / 2 ),pass Image 6 With the measurement system shown, the φ scanning diagrams of the Miller index surfaces and are obtained. In addition, the diameter of the disk-shaped sample 20 was about 20 mm.

[0082] It should be noted that the selection position of the plate sample is not limited to Figure 1A with 1B The three positions shown are, for example, positions within R / 3 from the center of the polysilicon rod of radius R, positions within 1R / 3 to 2R / 3, positions greater than 2R / 3 and within 3R / 3. three places.

[0083] Table 1 (Example) and Table 2 summarize the diffraction intensities of the baselines of each disk-shaped sample obtained from these polycrystalline silicon rods, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com