High-ammonia-content sulfur-content tail gas treatment process

A technology for treating process and tail gas, applied in air quality improvement, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as increased operating costs, high operating costs, increased operating costs, etc., and achieve good economic and social benefits, Low fuel consumption, safe and fast driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

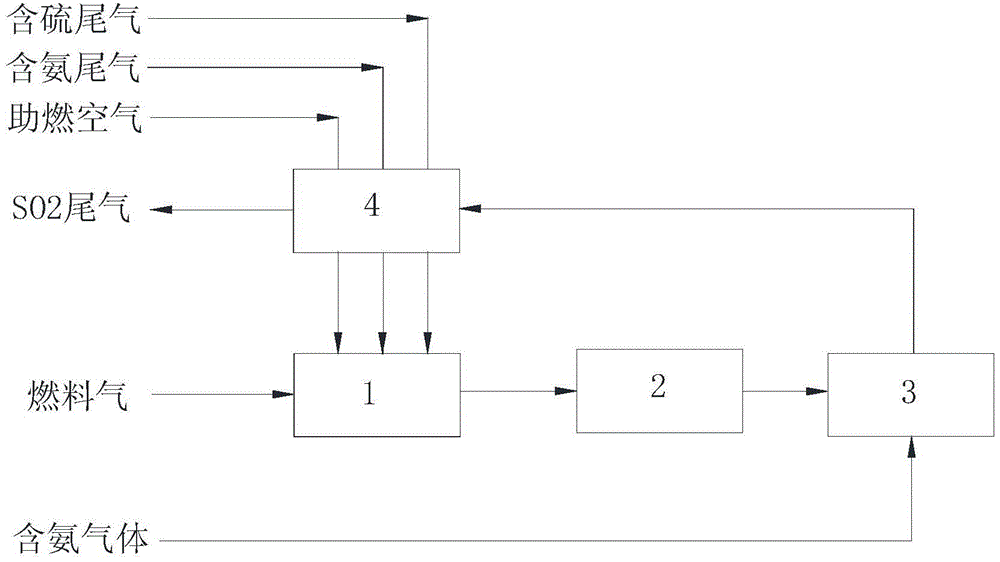

[0038] Such as figure 1 As shown, high ammonia and sulfur-containing tail gas enters the thermal oxidation furnace, the inlet material temperature is controlled at 200°C, the reaction temperature is controlled at 650°C, and the operating pressure is controlled at 2.5Kpa. The inlet temperature of the SCO reactor is controlled at 260°C, the reaction temperature is controlled at 380°C, and the operating pressure is controlled at 3Kpa. Purified tail gas is sent to follow-up SO 2 Absorption unit or sulfur recovery unit.

[0039] It has been determined that the content of other components in the purified tail gas is: non-methane total hydrocarbons ≤ 103mg / Nm 3 , NO x ≤189mg / Nm 3 , HCN≤1.8mg / Nm 3 , NH 3 ≤5mg / Nm 3 .

Embodiment 2

[0041] Such as figure 1 As shown, high ammonia and sulfur-containing tail gas enters the thermal oxidation furnace, the inlet material temperature is controlled at 250°C, the reaction temperature is controlled at 820°C, and the operating pressure is controlled at 6.1Kpa. The inlet temperature of the SCO reactor is controlled at 308°C, the reaction temperature is controlled at 420°C, and the operating pressure is controlled at 6.6Kpa. Purified tail gas is sent to follow-up SO 2 Absorption unit or sulfur recovery unit.

[0042] It has been determined that the content of other components in the purified tail gas is: non-methane total hydrocarbons ≤ 82mg / Nm 3 , NO x ≤163mg / Nm 3 , HCN≤1.6mg / Nm 3 , NH 3 ≤4mg / Nm 3 .

Embodiment 3

[0044] Such as figure 1 As shown, high ammonia and sulfur-containing tail gas enters the thermal oxidation furnace, the inlet material temperature is controlled at 300°C, the reaction temperature is controlled at 1035°C, and the operating pressure is controlled at 12.5Kpa. The inlet temperature of the SCO reactor is controlled at 395°C, the reaction temperature is controlled at 530°C, and the operating pressure is controlled at 8.5Kpa. Purified tail gas is sent to follow-up SO 2 Absorption unit or sulfur recovery unit.

[0045] It has been determined that the content of other components in the purified tail gas is: non-methane total hydrocarbons ≤ 54mg / Nm 3 , NO x ≤140mg / Nm 3 , HCN≤1.9mg / Nm 3 , NH 3 ≤4mg / Nm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com