Grate-type waste incinerator and method for incinerating waste

A waste and incinerator technology, applied in the field of grate-type waste incinerators, can solve the problems of shortening the life of refractories, increasing the generation of CO, and increasing harmful substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

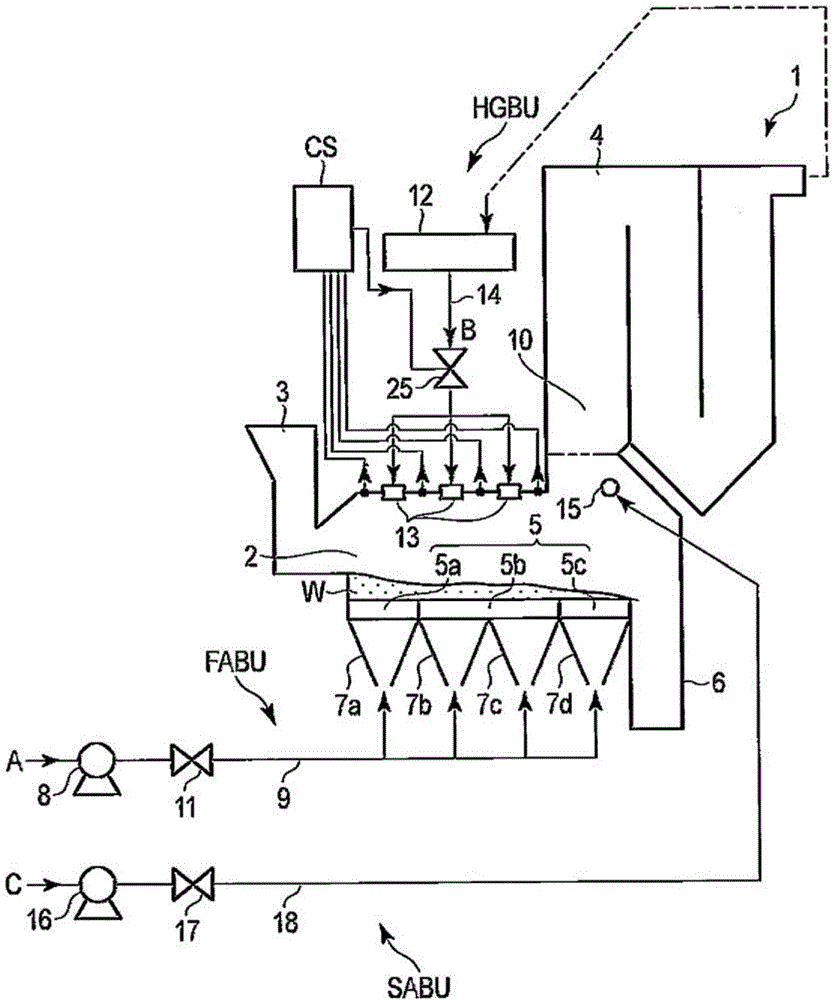

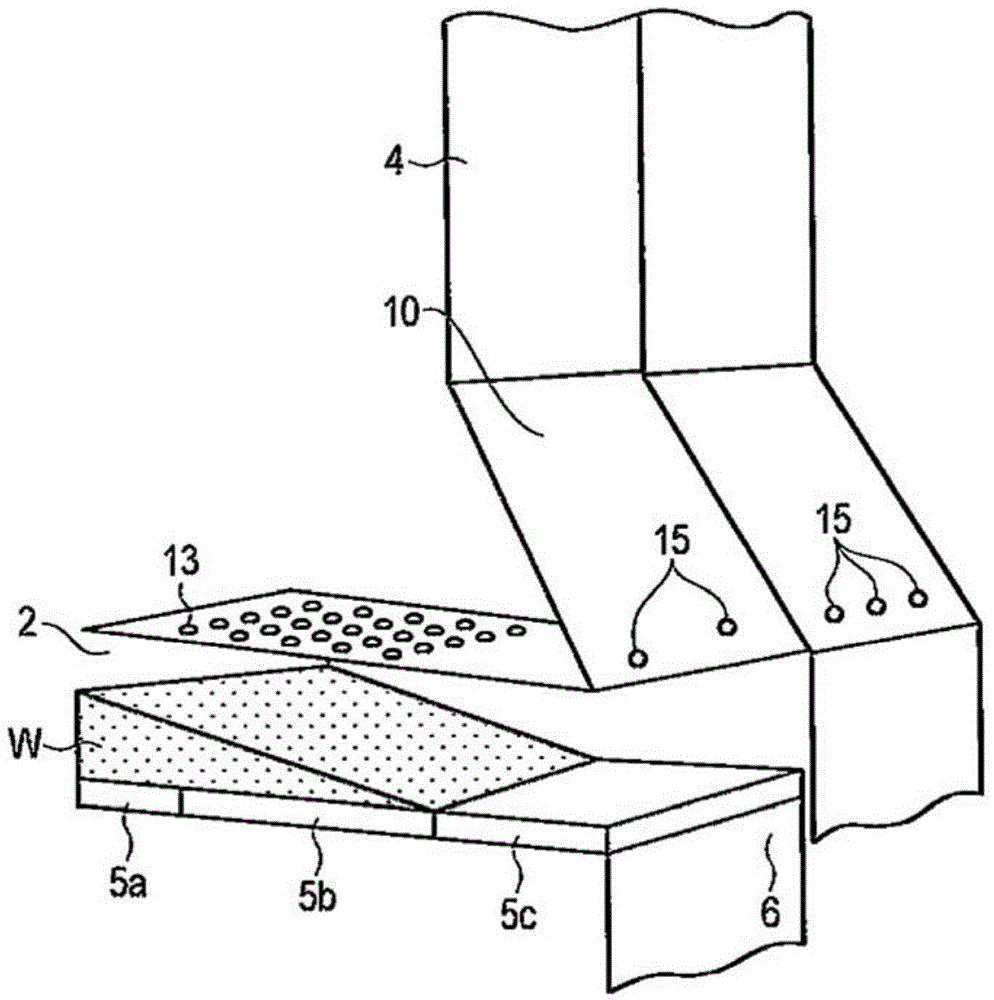

[0101] Below, refer to Figure 1 to Figure 4 The grate type waste incinerator and the waste incineration method using the grate type waste incinerator according to the first embodiment of the present invention will be described.

[0102]

[0103] figure 1 The shown grate-type waste incinerator 1 comprises a combustion chamber 2 provided with a grate 5 onto which waste W is fed, during the movement of the fed waste W Burn this waste. The height of the combustion chamber 2 from the grate 5 to the top of the combustion chamber is in the range of 1 to 3 m, which is equivalent to the height of the combustion chamber of an existing grate-type waste incinerator with a waste incineration capacity of about 100 tons / day. Compared with about 5m~6m, it is less than or equal to 1 / 2 of its height. In addition, the volume of the combustion chamber 2 of the grate type waste incinerator 1 of this embodiment is 90 m 3 , 190m with the volume of the combustion chamber of the conventional gr...

Embodiment

[0231] Using the conventional grate type waste incinerator (comparative example) disclosed in Japanese Patent Laid-Open No. 2004-84981 (Patent Document 1) and the grate type waste incinerator (example) of this embodiment, The experiment of incinerating waste was carried out on the scale of 120 tons / day of incineration, compared the NO in the exhaust gas discharged respectively from the comparative example and the embodiment X concentration and CO concentration.

[0232] The results are shown in Table 1 below.

[0233] [Table 1]

[0234] Table 1

[0235]

[0236] As can be seen from Table 1, compared with the comparative example, in the embodiment, the furnace volume (the volume of the combustion chamber 2) can be changed to about 1 / 2, even if the air ratio is further reduced, the waste can be fully burned, and , can reduce CO, NO X and other harmful gas production.

no. 2 Embodiment approach

[0238] Next, a grate type waste incinerator according to a second embodiment of the present invention will be described.

[0239] The outline of the grate type waste incinerator according to the second embodiment is as follows.

[0240] In the grate-type waste incinerator according to the second embodiment, the appropriateness of the injection flow rate of the high-temperature gas blown downward from the top of the combustion chamber corresponding to the height of the combustion chamber from the grate to the top is clarified. The upper and lower limits of the range determine the preferred range.

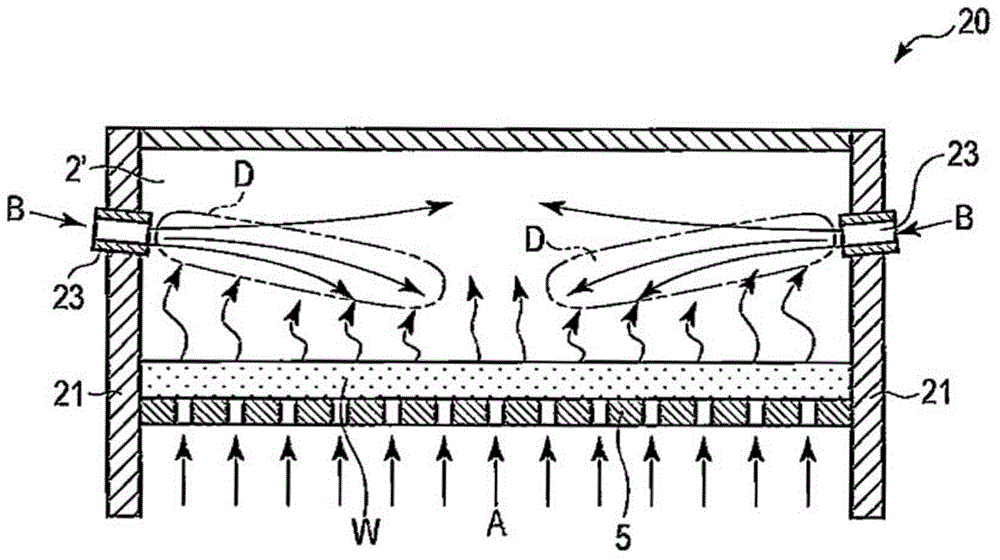

[0241] Combustion gas including combustible gas is formed above the waste on the grate by blowing hot gas downward from the top of the combustion chamber against the updraft of combustible gas containing combustible gas generated from the waste The planar combustion area can be stably formed by proper stagnation or circulation of the high-temperature gas. For this reason, it is nece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com