Carbon dot-based room-temperature phosphorescent composite material and preparation method thereof

A room temperature phosphorescence, composite material technology, applied in luminescent materials, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problems of phosphorescence green, performance limitations, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

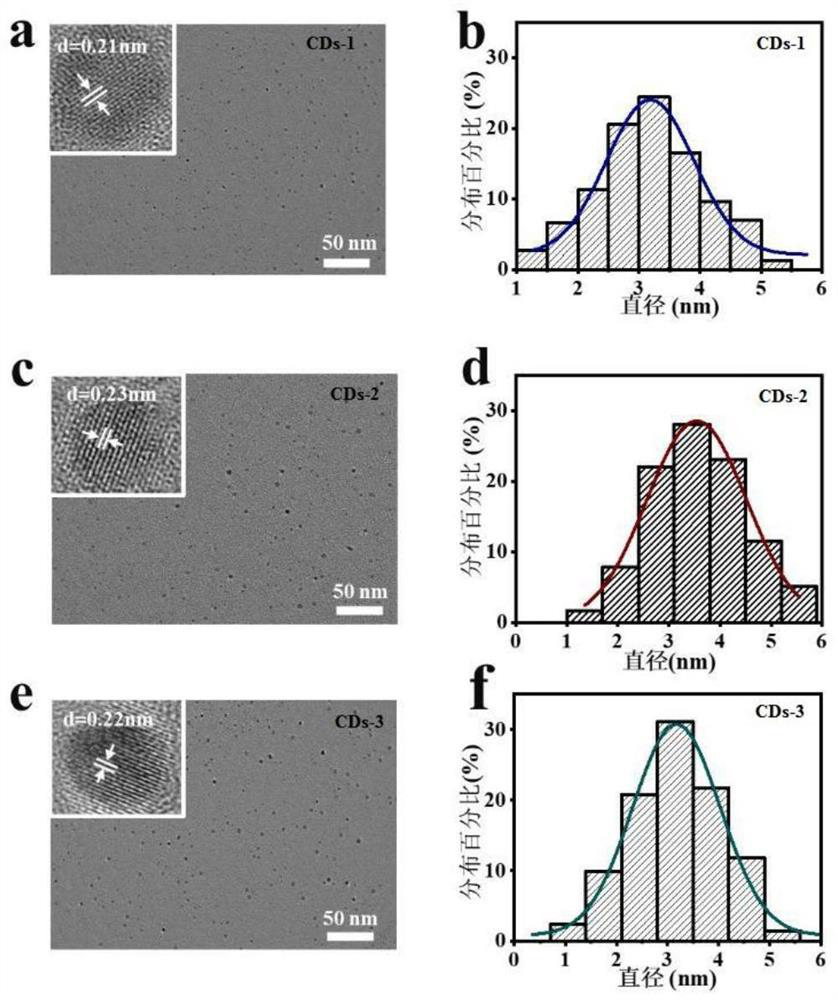

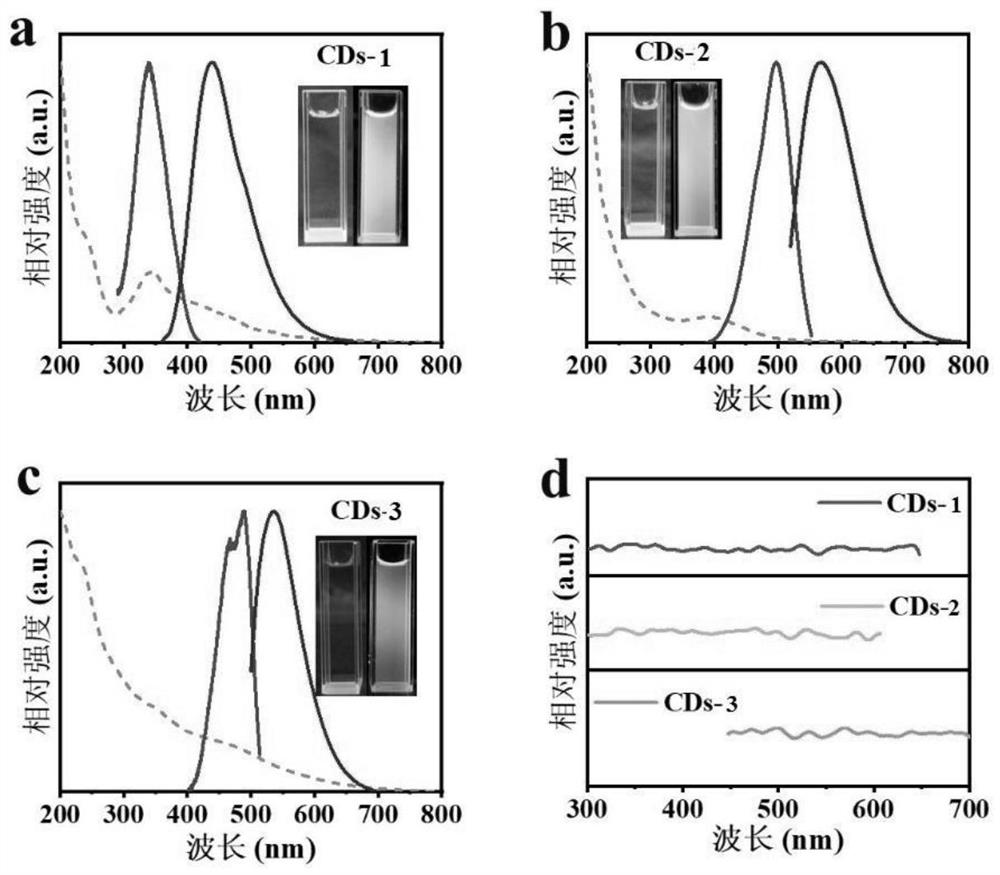

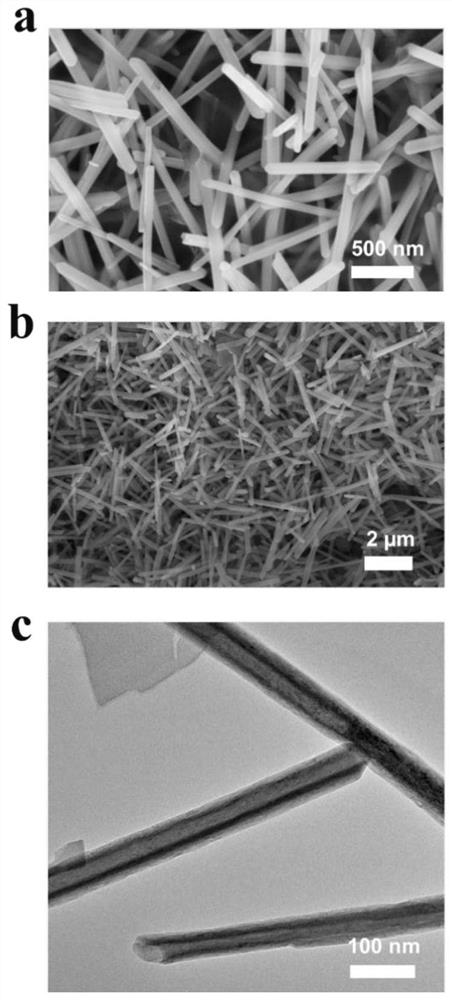

[0035] The carbon dot-based room temperature phosphorescent composite material disclosed in this embodiment is characterized in that: it is composed of Y(OH) 3 Precursor and carbon dot material composition.

[0036] In this embodiment, the carbon dot material is dispersed in the Y(OH) 3 In the precursor, the amount of carbon dot material added can be added according to actual needs, as long as the UV-excited carbon dot-based room temperature phosphorescent composite material can be guaranteed to emit light.

[0037] The preparation method of the above-mentioned carbon dot-based room temperature phosphorescent composite material comprises the following steps:

[0038] S1. Add carbon dot material to Y (NO 3 )3 In the solution, after stirring uniformly, add NaOH solution and continue stirring uniformly to obtain a mixed material solution;

[0039] S2, heating the mixed material solution prepared in S1 at 180° C. for 12 hours to obtain a white precipitate, which is centrifuged,...

Embodiment 2

[0046] The carbon dot-based room temperature phosphorescent composite material disclosed in this embodiment is characterized in that: it is composed of Y(OH) 3 Precursor and carbon dot material composition.

[0047] In this embodiment, the carbon dot material is dispersed in the Y(OH) 3 In the precursor, the amount of carbon dot material added can be added according to actual needs, as long as the UV-excited carbon dot-based room temperature phosphorescent composite material can be guaranteed to emit light.

[0048] The preparation method of the above-mentioned carbon dot-based room temperature phosphorescent composite material comprises the following steps:

[0049] S1. Add carbon dot material to Y (NO 3 ) 3 In the solution, after stirring uniformly, add NaOH solution and continue stirring uniformly to obtain a mixed material solution;

[0050] S2, heating the mixed material solution prepared in S1 at 160° C. for 15 hours to obtain a white precipitate, which is centrifuge...

Embodiment 3

[0057] The carbon dot-based room temperature phosphorescent composite material disclosed in this embodiment is characterized in that: it is composed of Y(OH) 3 Precursor and carbon dot material composition.

[0058] In this embodiment, the carbon dot material is dispersed in the Y(OH) 3 In the precursor, the amount of carbon dot material added can be added according to actual needs, as long as the UV-excited carbon dot-based room temperature phosphorescent composite material can be guaranteed to emit light.

[0059] The preparation method of the above-mentioned carbon dot-based room temperature phosphorescent composite material comprises the following steps:

[0060] S1. Add carbon dot material to Y (NO 3 ) 3 In the solution, after stirring uniformly, add NaOH solution and continue stirring uniformly to obtain a mixed material solution;

[0061] S2, heating the mixed material solution prepared in S1 at 200° C. for 10 hours to obtain a white precipitate, which is centrifuge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com