Mask and its mfg. method, electroluminance device and its mfg. method and electronic machine

一种制造方法、掩模的技术,应用在电致发光光源、照明装置、光机械设备等方向,能够解决很难制造高精密的掩模等问题,达到掩模图形高精密的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

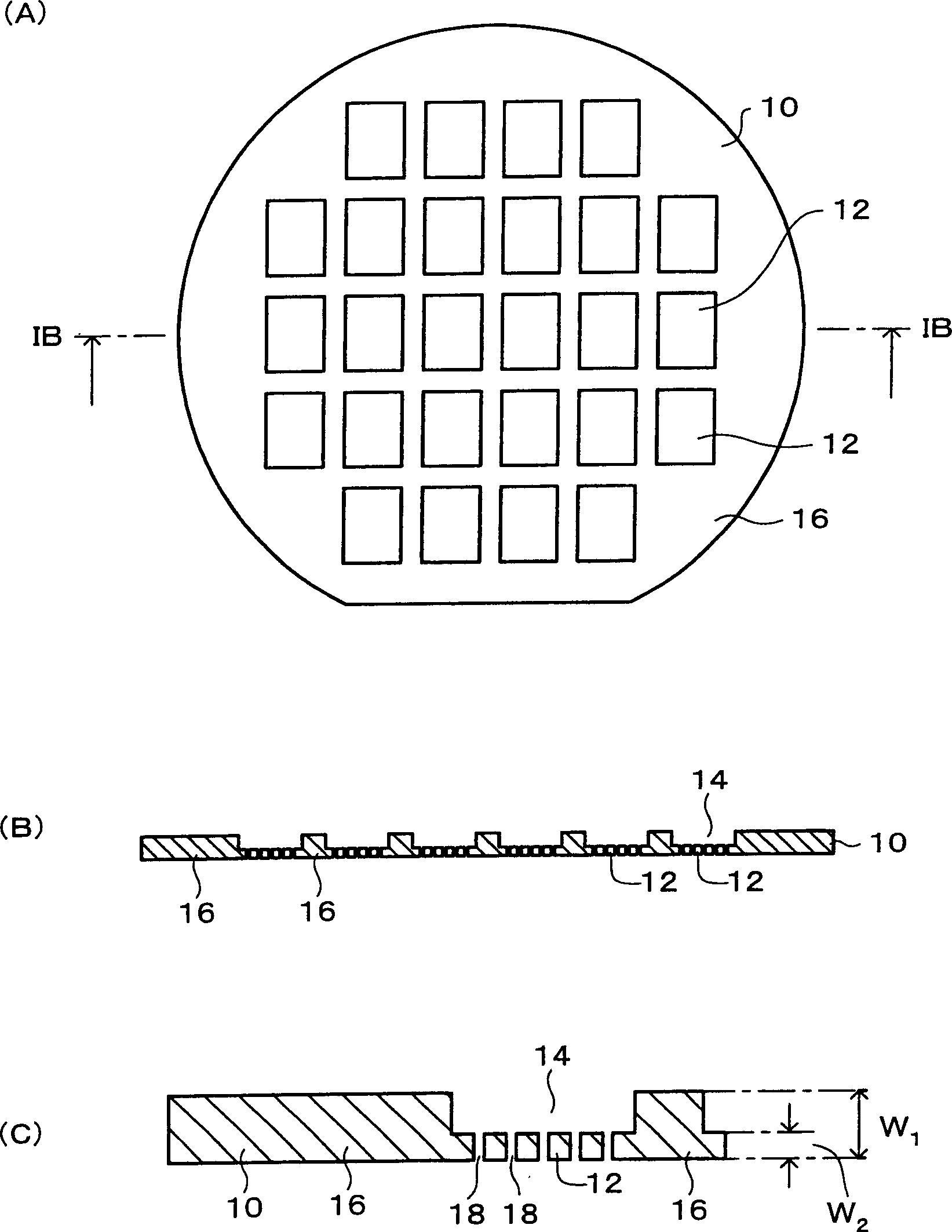

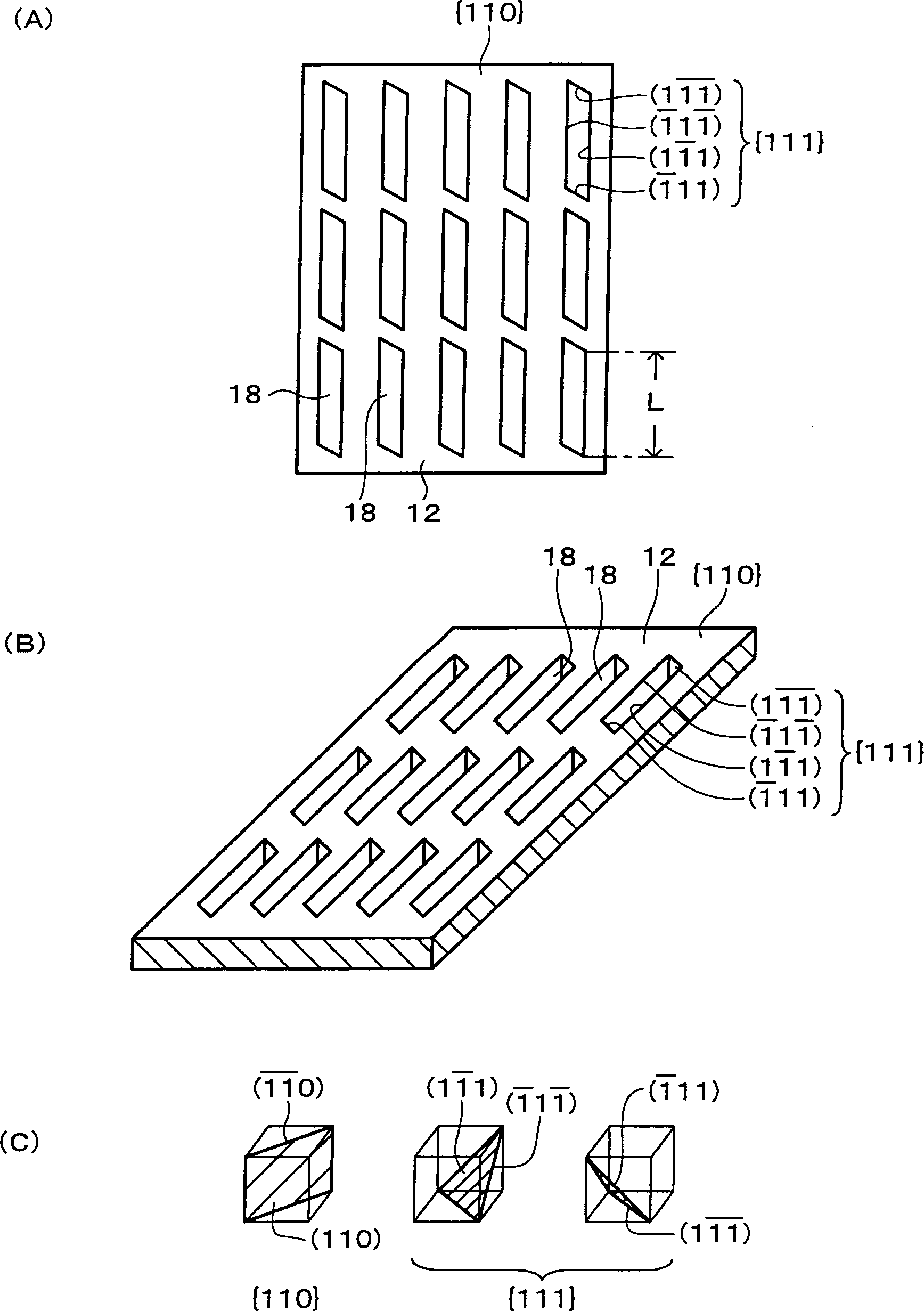

[0070] figure 1 A to 1C are diagrams illustrating masks according to examples of the present invention. figure 1 B is figure 1 The cross-sectional view of line IB-IB shown in A, figure 1 C is figure 1 Partial enlarged view of B. The mask has a single crystal substrate 10 (or consists of only the single crystal substrate 10). The single crystal substrate 10 is, for example, a single crystal silicon substrate, but may also be a silicon wafer. Single crystal substrate 10 has a surface represented by a specular index {110}. For example, the surface and the back surface of the single crystal substrate 10 are {110} planes. It should be noted that the {110} plane includes multiple planes equivalent to the (110) plane. In a cubic lattice, the direction perpendicular to the {110} planes is the orientation.

[0071] At least one (for example, a plurality of) thin-walled portion 12 is formed on single crystal substrate 10 . The plurality of thin portions 12 may be arranged in a...

Embodiment 2

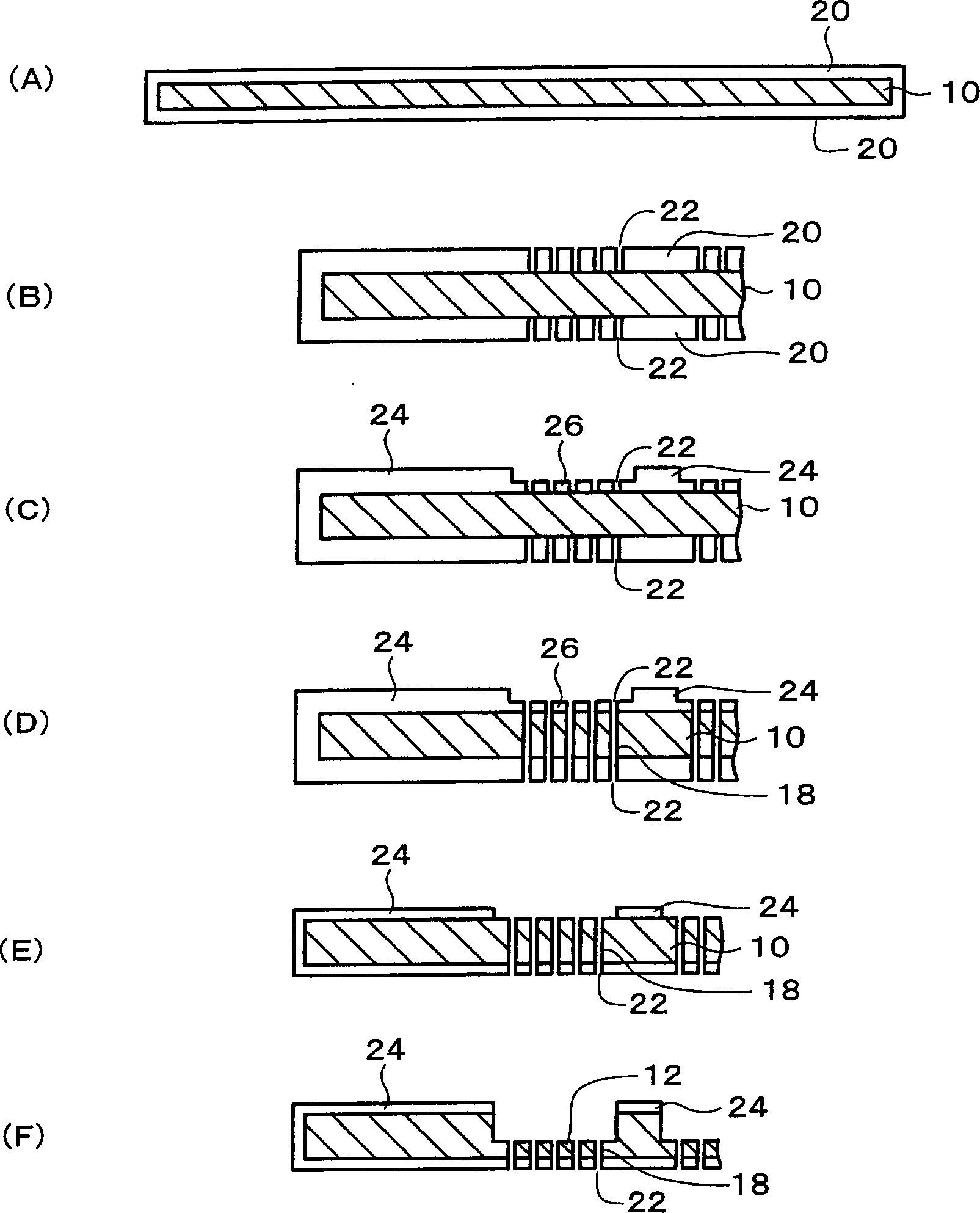

[0092] Figure 4 A to 4C are diagrams illustrating a method of manufacturing the mask of Example 2. In Example 1, openings 22 are formed in etching-resistant film 20 on both surfaces of single crystal substrate 10 . At this time, since the alignment of the openings 22 on both sides is difficult, the following description will focus on a method for easily performing the alignment.

[0093] Such as Figure 4 As shown in A, a first opening 34 is formed in the etch-resistant film 30 formed on one surface of the single crystal substrate 10, and a second opening 36 is formed in the etch-resistant film 32 formed on the other surface. Here, the widths of the first and second openings 34, 36 have the following relationship:

[0094] B Figure 4 As shown in B, etching is carried out as Figure 4 As shown in C, a through hole 38 is formed. Such as Figure 4 As shown in C, the end of the etch-resistant film 32 where the small-sized second opening 36 is formed protrudes toward the ins...

Embodiment 3

[0096] Figure 5 It is a figure explaining the manufacturing method of the mask of Example 3. In Example 1, the thickness W of the single crystal substrate 10 1 (refer to figure 1 C) and the length L of the long side of the parallelogram of the opening 22 of the etch-resistant film 20 (with figure 2The length L of the long side of the parallelogram of the through hole 18 shown in A is the same) has the following relationship:

[0097] √3×W 1 <L If it is such a relatively thin single crystal substrate, a through hole can be formed, but for a thicker single crystal substrate, etching stops halfway, and a through hole cannot be formed.

[0098] A method of forming a through-hole when the following relationship holds true in this embodiment (when the single crystal substrate is thick) will be described.

[0099] √3×W 1 ≥ L

[0100] Such as Figure 5 As shown, small through holes (holes smaller than the through holes) 42 are formed before etching in the region where the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com