Lithium-base battery

A battery, lithium-based technology, used in dry batteries, secondary batteries, battery pack components, etc., can solve the problems of diaphragm 3 rupture, burst, battery ignition, etc., and achieve the effect of protecting the corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

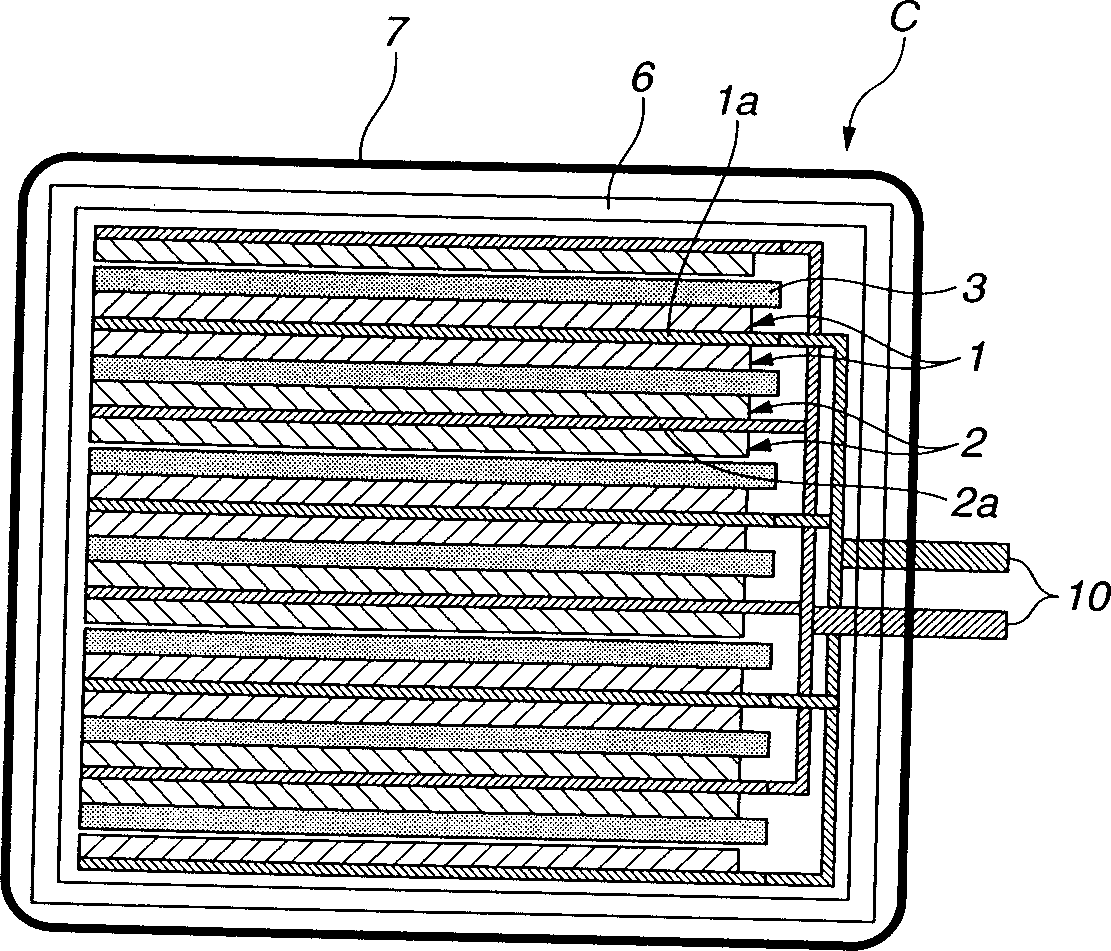

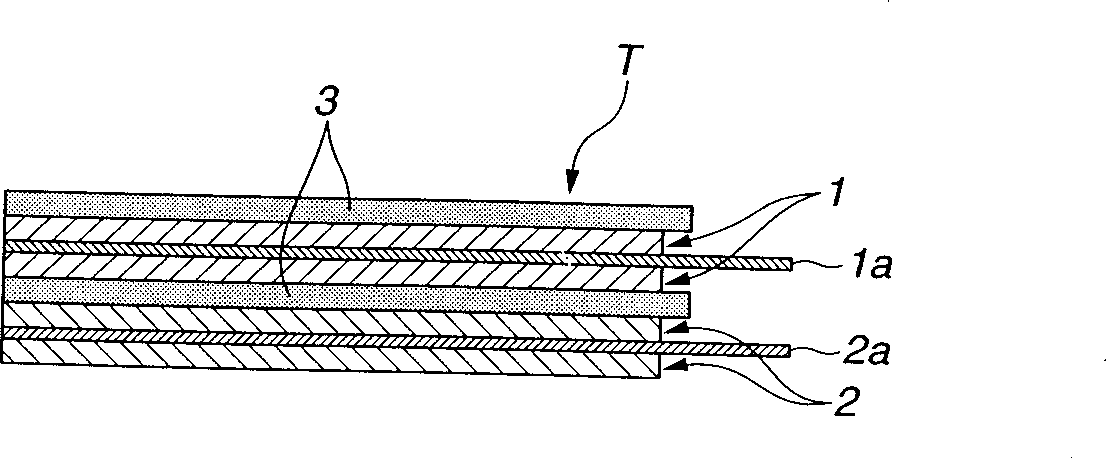

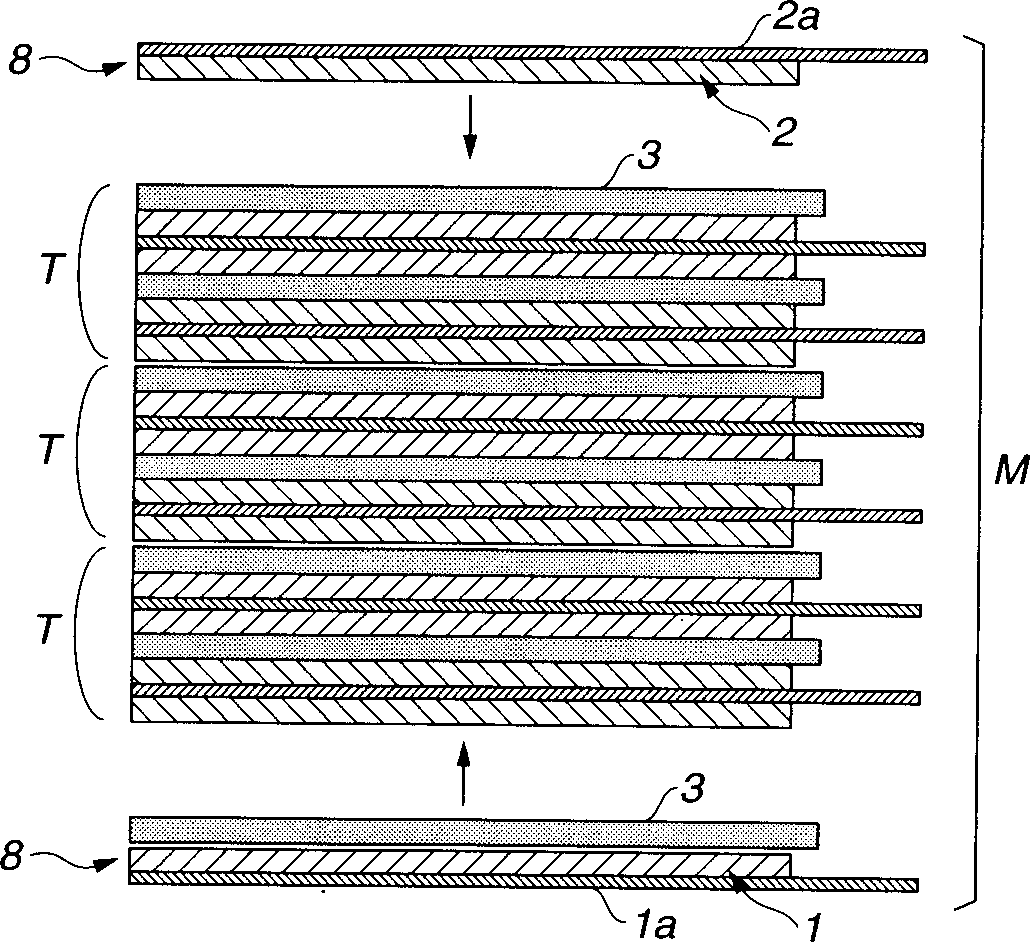

[0037] figure 1 is a schematic cross-sectional view of a lithium-based battery C according to a first embodiment of the present invention; figure 2 is a schematic cross-sectional view of the unit cell T; and image 3 is a schematic cross-sectional view illustrating the assembly of the battery structure group M of the lithium-based battery.

[0038] see figure 1 , the lithium-based battery C according to the first embodiment is obtained by stacking unit cells T one by one to form a battery structure group M, wherein each unit cell contains a positive electrode 1, a negative electrode 2, and a separator disposed therebetween 3; installing the battery structure group M in the battery container 6; filling the battery container 6 with electrolyte; and covering the battery container with an ion-impermeable and extensible polymer sheet 7 with a tensile elongation of 1% or more 6 on the peripheral surface. Such as figure 1 As shown, a positive current collector 1a is connecte...

no. 2 approach

[0129] Figure 4 is a schematic cross-sectional view of a battery structure group M of a lithium-based battery according to a second embodiment of the present invention. The lithium-based battery of this embodiment includes: a battery structure group made by stacking unit cells T, each unit cell T including a positive electrode 1, a negative electrode 2, and a separator 3 interposed therebetween, and an electrolyte, wherein the battery structure group The periphery of M is covered with an ion-impermeable and extensible high polymer sheet 7 having a tensile elongation of 1% or more.

[0130] In this case, after the outer periphery of the battery structure group M is covered with the stretchable polymer sheet, the electrolyte can be injected or poured into the battery. Alternatively, the electrolyte can be pre-infused into the battery structure, and then the outer periphery of the battery structure is covered with an extensible polymer sheet.

[0131] In the second embodiment,...

no. 3 approach

[0137] Figure 8 and 9 is a sectional view of a lithium-based battery according to a third embodiment of the present invention. The structure of this lithium-based battery is such that a battery structure group made by stacking three unit cells T including a positive electrode 1, a negative electrode 2 and a diaphragm 3 interposed therebetween.

[0138] In this case, if Figure 10 As shown, a positive electrode 1 and a negative electrode 2 of a unit cell T are respectively formed on one surface of a positive electrode current collector 1a and a negative electrode current collector 2a, and are arranged to face each other with a separator therebetween. In other words, the positive electrodes 1 of the unit cells T are arranged back to back, and the similar negative electrodes 2 are also arranged back to back. And, if Figure 8 As shown, by stacking unit cells T 1 , T 2 and T 3 The outer peripheral surface of the formed battery structure group is covered with an ion-imperm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com