Simple method for manufacturing ceramic-metal composite wear-resistant part

A technology of composite wear-resistant parts and ceramic metal, which is applied in the field of wear-resistant composite materials, can solve the problems of unhealthy workers, easily broken prefabricated parts, and high production cost, and achieves the effects of simple operation, simple method and low mass production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

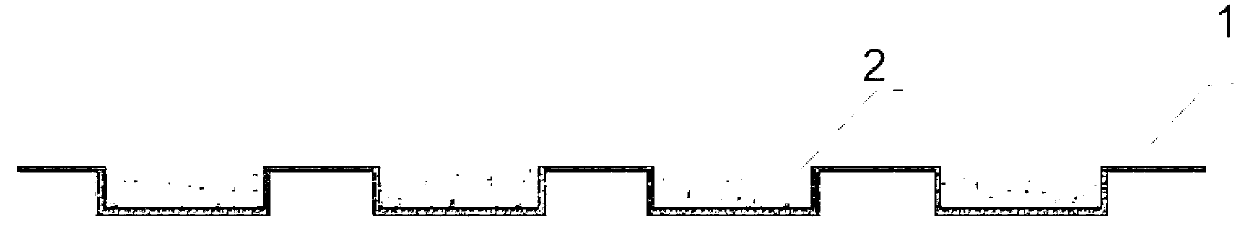

Image

Examples

Embodiment 1

[0021] The silicon carbide ceramic particles with a particle size of 1.0-2.0mm and 2.0-4.0mm are subjected to wettability treatment, that is, the surface of the ceramic particle is nickel-plated, and the silicon carbide ceramics with a particle size of 1.0-2.0mm and 2.0-4.0mm The mass ratio of the particles is 5:5. The process of nickel plating includes the processes of surface treatment and plating.

[0022] Surface preparation consists of the following 5 steps:

[0023] (1) Degreasing: soak in anhydrous alcohol solution for 10-35 minutes, wash with deionized water under the action of ultrasonic waves, completely degrease the surface of ceramic particles, and then dry naturally.

[0024] (2) Roughening: Under the action of ultrasonic waves, soak in hydrofluoric acid at room temperature to roughen the surface of ceramic particles.

[0025] (3), sensitization: soak for 4-6min at room temperature with a sensitization solution containing stannous chloride dihydrate and hydrochl...

Embodiment 2

[0034] Embodiment 2, the preparation of wear-resistant liner of ball mill

[0035] 1. The titanium carbide and silicon carbide ceramic particles with particle diameters of 1.0-2.0 mm and 2.0-4.0 mm are subjected to wettability treatment, and the mass ratio of titanium carbide and silicon carbide ceramic particles is 1:1. Wherein, and the mass ratio of the mass of ceramic particles with a particle size of 1.0-2.0 mm to the mass of ceramic particles with a particle size of 2.0-4.0 is 7:3. The process of nickel plating includes the processes of surface treatment and plating.

[0036] Surface preparation consists of the following 5 steps:

[0037] (1) Degreasing: soak in anhydrous alcohol solution for 10-35 minutes, wash with deionized water under the action of ultrasonic waves, completely degrease the surface of ceramic particles, and then dry naturally.

[0038] (2) Roughening: Under the action of ultrasonic waves, soak in hydrofluoric acid at room temperature to roughen the s...

Embodiment 3

[0049] The silicon carbide ceramic particles with a particle size of 0.5-4 mm are subjected to wetting treatment, that is, the surface of the ceramic particles is subjected to nickel plating treatment, and the nickel plating process includes surface treatment and plating processes.

[0050] Surface preparation consists of the following 5 steps:

[0051] (1) Degreasing: soak in anhydrous alcohol solution for 10-35 minutes, wash with deionized water under the action of ultrasonic waves, completely degrease the surface of ceramic particles, and then dry naturally.

[0052] (2) Roughening: Under the action of ultrasonic waves, soak in hydrofluoric acid at room temperature to roughen the surface of ceramic particles.

[0053] (3), sensitization: soak for 4-6min at room temperature with a sensitization solution containing stannous chloride dihydrate and hydrochloric acid under ultrasonic waves.

[0054] (4) Activation: Under ultrasonic waves, a solution containing palladium chlorid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com