Supporting method of permeable soft broken rock stratum roadway

A technology for roadway support and rock formation, which is used in tunnels, tunnel linings, earthwork drilling, etc., can solve problems such as high cost and poor support effect, and achieve the effects of reasonable parameters, excellent support effect and strong adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

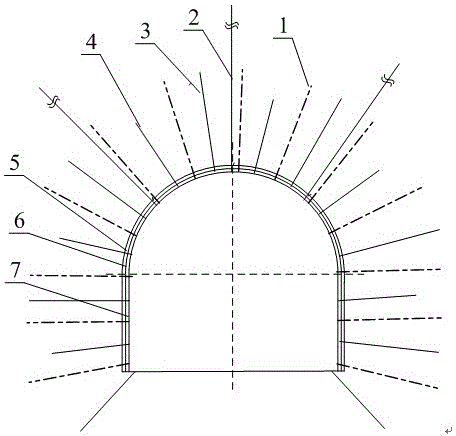

[0022] The roadway supporting method of water seepage soft broken rock layer of the present invention comprises the following steps:

[0023] A. After the blasting of the roadway, knock on the roof to prevent the loose rock from falling and hurt the construction workers. The initial spraying concrete operation is carried out. The thickness of the initial spraying layer 5 is 20-30mm.

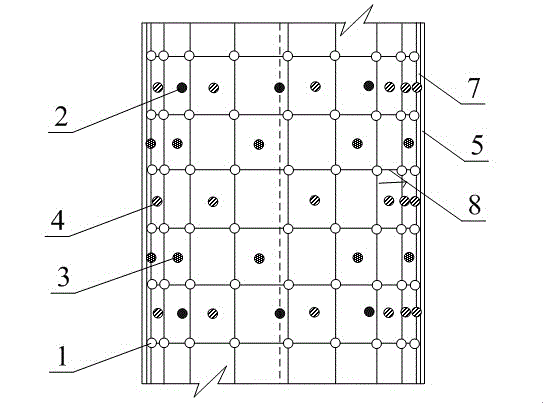

[0024] B. Use high-strength threaded steel anchor rod 1 and diamond-shaped metal mesh 6 joint support, the diameter of the anchor rod is 20mm, the length is 2500mm, the resin anchoring agent is used to anchor, the anchor length is 1400mm, and the row spacing between high-strength threaded steel anchor rods is average The axial deviation of the high-strength rebar anchor 1 located on the section of the roadway (that is, the angle between the axis of the high-strength rebar anchor 1 and the normal line of the tangent plane at the end of the anchor 1) does not exceed 10°, and each row and column A w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com